Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions

Abstract

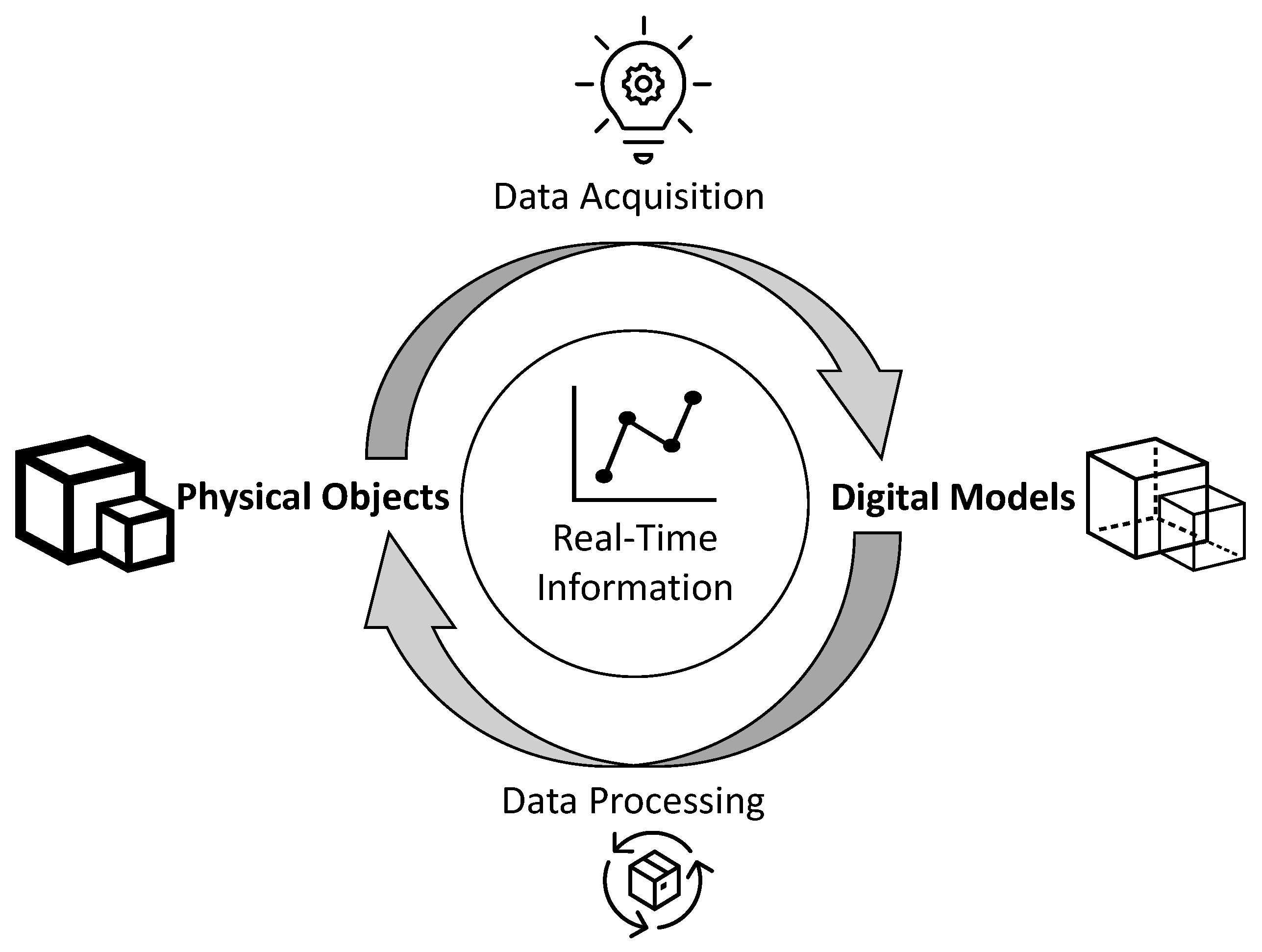

1. Introduction

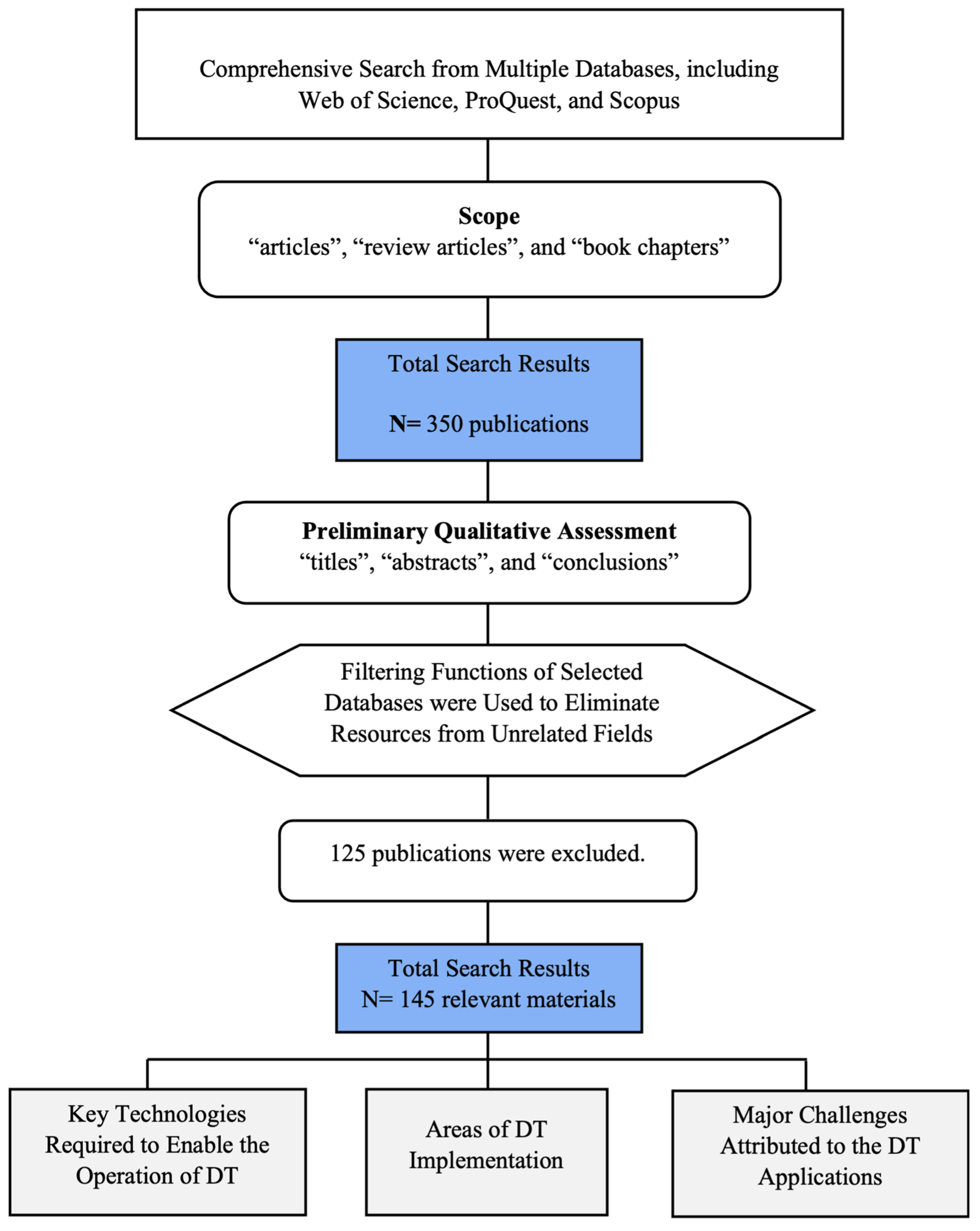

2. Research Methodology

3. Results and Analysis

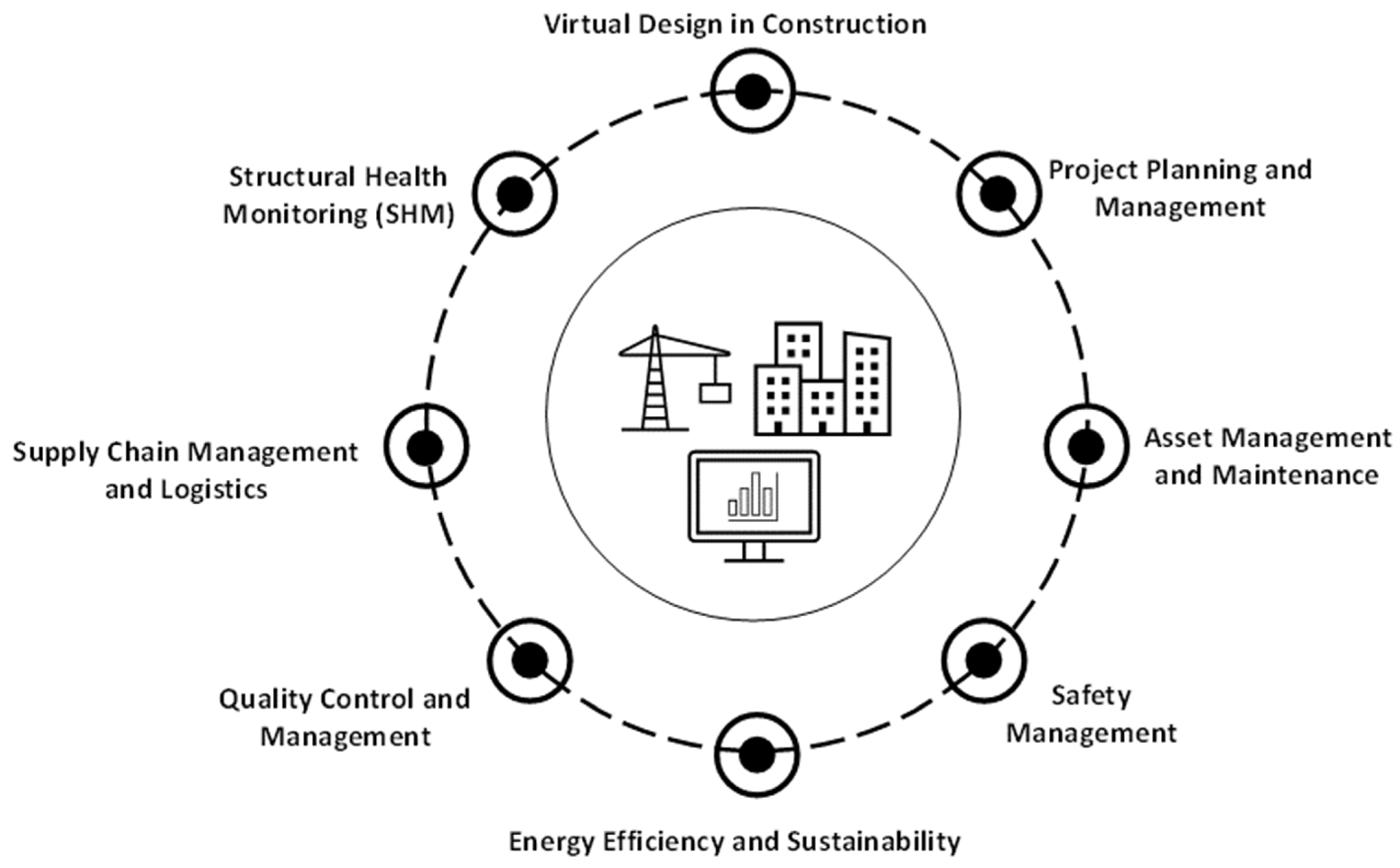

3.1. Current Implementations of Digital Twins in the Construction Industry

3.1.1. Virtual Design in Construction

3.1.2. Project Planning and Management

3.1.3. Asset Management and Maintenance

3.1.4. Safety Management

3.1.5. Energy Efficiency and Sustainability

3.1.6. Quality Control and Management

3.1.7. Supply Chain Management and Logistics

3.1.8. Structural Health Monitoring (SHM)

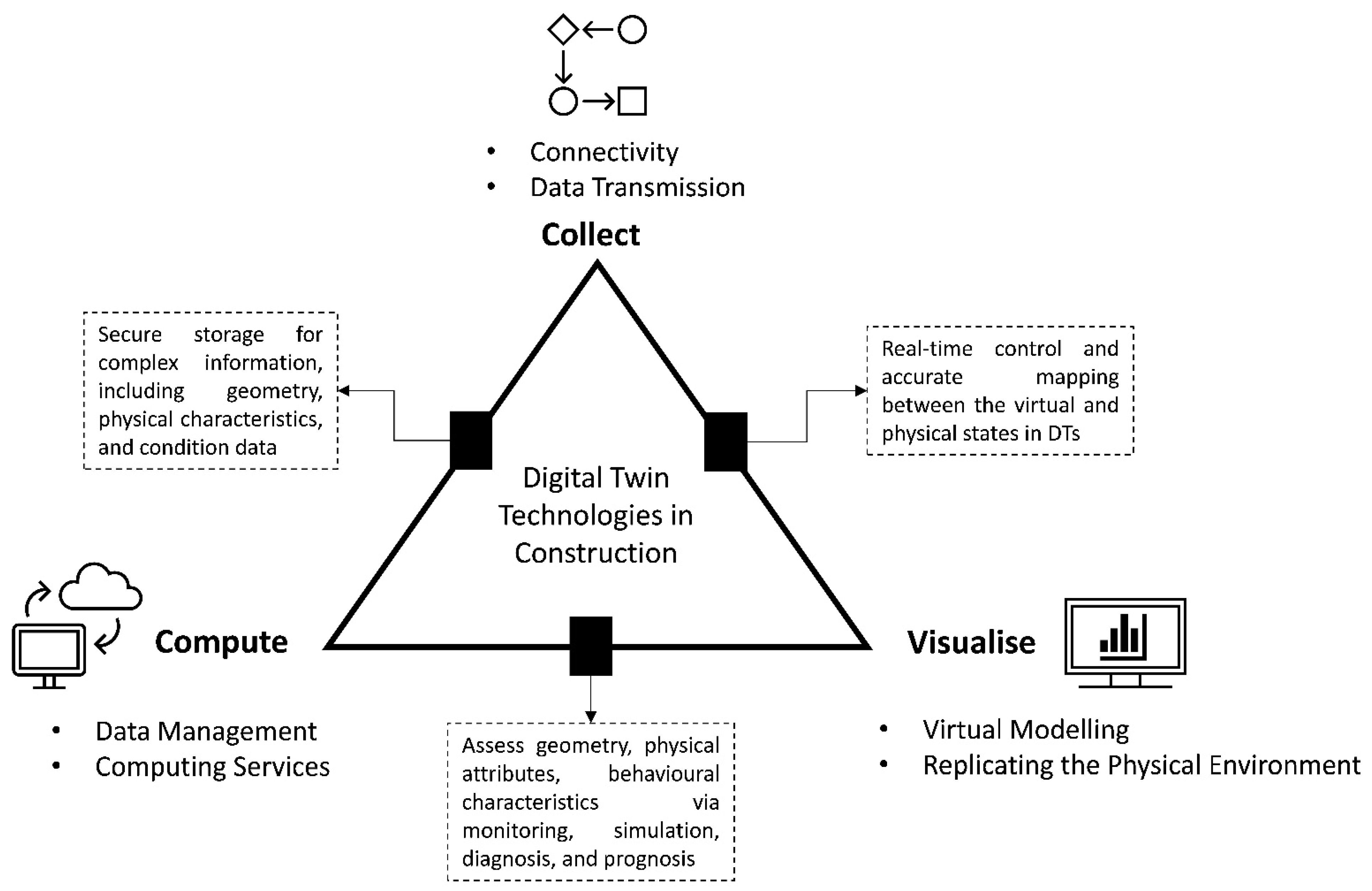

3.2. Enabling Technologies for Digital Twin Implementation in Construction

- Technologies enabling perception and control of the physical environment. The initial stage of developing DTs involves replicating the physical environment. This entails constructing a virtual environment that accurately represents the entities in the physical world, including their constituents, internal interaction logic, and external relationships [27,97,100]. The complexity of this process can vary depending on the desired level of detail for the DTs. Therefore, establishing and improving DTs is a time-intensive process. On one hand, the virtual models corresponding to physical entities are not flawless, requiring a certain degree of adaptability to improve over time in response to changes in the physical environment and its constituent elements [27,101]. This adaptability necessitates a comprehensive perception of the physical world. On the other hand, the digitalisation of physical entities often uncovers implicit associations that can support the evolution and control of the physical world [27]. One of the important steps in reflecting the physical world involves measuring various parameters (e.g., size, shape, etc.) [27,97,99]. Measurement technologies such as laser measurement, image recognition measurement, conversion measurement, and micro/nano-level precision measurement can be used for this purpose [27]. IoT can also play a crucial role in enhancing the data collection capabilities of DTs by connecting physical objects and devices to the Internet. It enables real-time data collection from various sources within the physical environment, serving as data sensors that capture and transmit information about asset or system state, behaviour, and performance [102,103]. This continuous data monitoring and integration with DTs enhances the accuracy and fidelity of the virtual representation. IoT facilitates the bidirectional flow of data between the physical world and DTs, enabling updates and calibrations based on real-time insights [102,104]. This integration empowers DTs to provide accurate and up-to-date insights, supporting asset management, optimisation, and decision-making across multiple domains in the construction industry.

- Technologies enabling data management. A high-fidelity DT model necessitates secure storage for complex information, including geometry, physical characteristics, and condition data [27,98,99]. Technologies such as bar codes, quick response codes, and radio frequency identification (RFID) can be utilised for the safe storage of data generated using DT systems [98]. Big data storage frameworks like MySQL, HBase, and NoSQL databases are used to effectively manage and utilise large volumes of data. In MySQL, data are organised in tables, with rows representing records and columns containing specific data values [98]. HBase relies on the Hadoop Distributed File System (HDFS) for storage and harnesses Hadoop MapReduce for high-performance computing, whereas NoSQL databases excel in handling extensive data volumes, offering exceptional read-write performance [98].

- 3.

- Technologies enabling virtual modelling. Previous research indicated that a rigorous robust model should incorporate key components such as geometry, physical attributes, behavioural characteristics, and rule-based associations [27,98,101]. The geometry aspect involves visualising shape and position utilising well-established computer-aided design (CAD) software [27,98]. Physical information encompasses crucial details like tolerances and material properties that contribute to an accurate representation of the virtual model [27,98,101]. Behavioural models play a significant role in capturing how the virtual model interacts and responds to external stimuli and environmental changes [27]. Rule models are essential for defining associations and constraints that enable performance analysis and optimisation [27,98,101]. Extracting rule information relies on a variety of techniques, including data mining and semantic data analytics, which facilitate the identification and extraction of relevant rules. To ensure the fidelity and reliability of a virtual model, verification, validation, and accreditation technology should be used, which helps evaluate and validate the accuracy of the virtual model against real-world scenarios and data [27,98,101].

- 4.

- Technologies enabling services. DT technology combines multiple disciplines to achieve advanced monitoring, simulation, diagnosis, and prognosis [27,97,98]. Monitoring involves technologies such as computer graphics, image processing, virtual reality synchronisation, and 3D rendering [27,98]. Simulation encompasses various areas such as structural, mechanical, electronic, control, and process simulation. Diagnosis and prognosis rely on data analysis methods such as statistical theory, machine learning, neural networks, and fault tree analysis. Hardware, software, and knowledge can be encapsulated into services, which go through stages like service generation, management, and on-demand utilisation [27,97,98,100]. Resource and knowledge services, along with application services, are managed with an industrial IoT platform that provides functions like service publishing, searching, communication, and evaluation. Sharing and using models and data is crucial, and services can play a vital role in encapsulating and managing DT components, enabling convenient sharing and reuse. The use of a service platform allows for uniform management of DTs, and service-oriented architecture stands out as a key enabling technology for DT services.In addition, this study recommends integrating blockchain technology into this layer to provide secure and transparent transactions, data sharing, and traceability within the DT environment. Through its decentralised and immutable nature, blockchain ensures the integrity and authenticity of data by securely recording and verifying transactions and data exchanges among stakeholders [111,112]. The use of this technology also enables secure data sharing and collaboration, eliminates the need for intermediaries, and facilitates data tracking and provenance [111,112]. Leveraging blockchain technology allows DTs to enhance data integrity, foster trust, and enable efficient and secure collaboration in construction.

- 5.

- Technologies enabling connectivity and data transmission. To achieve real-time control and accurate mapping between the virtual and physical states in DTs, establishing a reliable connection is of utmost importance. Various connection protocols exist for data exchange, both between the physical space and the DT, as well as among different software within cyberspace. Data transmission methods include wired options such as twisted pair, coaxial cable, and optical fibre, and wireless technologies such as Zig-Bee, Bluetooth, Wi-Fi, ultra-wide band (UWB), and near-field communication (NFC) [98,113]. Long-distance wireless transmission can utilise technologies such as GPRS/CDMA, digital ratio, spread spectrum microwave communication, wireless bridge, and satellite communication [97,99,101,105]. In this regard, a wide array of application program interfaces (APIs) is commonly being utilised to facilitate data exchange between different software applications, ensuring seamless data transmission at the software level [98]. The emerging 5G and 6G technologies show promise in meeting the requirements for high data rates, reliability, coverage, and low latency in DT applications [114,115].

3.3. Current Challenges and Future Directions

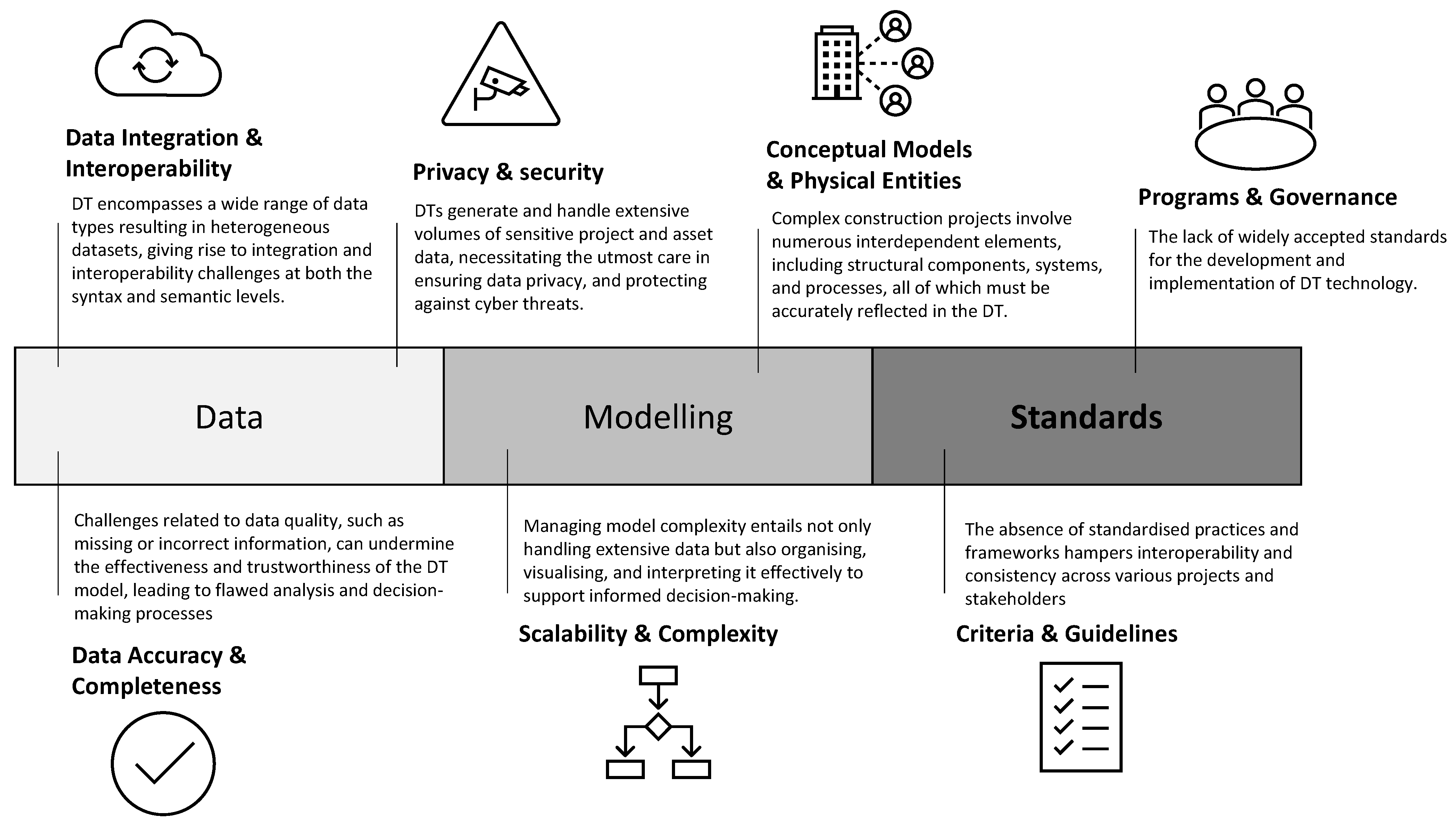

- Data integration and interoperability: The seamless consolidation and merging of a virtual model and IoT sensor data outline the fundamental basis for the functionality of a DT. As evident from various research studies, the data generated with DTs encompasses a wide range of types, collected using diverse sensors, evolving into heterogeneous datasets that encompass image data, video data, positioning data, environmental data, mechanical data, and more [27,118,119]. These datasets need to be effectively incorporated within BIM models. However, acquiring these data involves sourcing from distinct and diverse arrangements such as building management systems, each operating on different software platforms and having separate syntax and representations [27,118,119]. Consequently, the complexity of DT models increases, giving rise to incorporation and interoperability challenges at both the syntax and semantic stages.

- Data accuracy and completeness: The accuracy of data utilised in a DT is of utmost importance, as it forms the foundation for accurate analysis, simulations, and decision-making processes [4,123,124]. Challenges related to data quality, such as missing or incorrect information, can undermine the effectiveness and trustworthiness of a DT model, leading to flawed analysis and decision-making processes. Inaccurate and incomplete data can stem from various factors, including human errors during data acquisition or entry, difficulties in integrating data from diverse sources with inconsistencies in formats and structures, limitations or malfunctions of sensors used for real-time data capture, and gaps in information that may be unavailable or inadequately recorded [1,15,123]. Therefore, measures should be taken to ensure that data integrated into a DT is precise, up-to-date, and complete.

- Scalability and complexity: The successful realisation of DT technology in the construction industry encounters challenges associated with scalability and effectively managing the growing complexity of models. Scalability refers to a DT’s capacity to accommodate large-scale construction projects and intricate infrastructure while maintaining optimal performance [103,125]. As projects increase in size and complexity, accurately capturing and representing all relevant aspects within a DT becomes progressively more arduous.

- Privacy and security: The widespread use of DT technology in the construction industry faces a significant challenge related to privacy and security [97,128]. DTs generate and handle extensive volumes of sensitive project and asset data, necessitating the utmost care in ensuring data privacy, protecting against cyber threats, and complying with data governance regulations [27,97]. Hence, robust security measures should be implemented in order to safeguard DT data and prevent unauthorised access [129].

- Standards and governance: The lack of widely accepted standards for the development and implementation of DT technology poses a significant challenge to its widespread use in the construction industry [27,124,130]. This absence of standardised practices and frameworks hampers interoperability and consistency across various projects and stakeholders. To address this challenge, it is imperative to establish industry-wide standards and governance frameworks that promote harmonisation and enable seamless data exchange.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Ozturk, G.B. Digital Twin Research in the AECO-FM Industry. J. Build. Eng. 2021, 40, 102730. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, J.C.P.; Chen, W.; Chen, K. Digital Twins for Construction Sites: Concepts, LoD Definition, and Applications. J. Manag. Eng. 2022, 38, 04021094. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Imran, A.; Cardenas-Cartagena, J.; Svennevig, P.R.; Svidt, K.; Nielsen, H.K. A Review of the Digital Twin Technology in the AEC-FM Industry. Adv. Civ. Eng. 2022, 2022, 2185170. [Google Scholar] [CrossRef]

- Omrany, H.; Soebarto, V.; Ghaffarianhoseini, A. Rethinking the concept of building energy rating system in Australia: A pathway to life-cycle net-zero energy building design. Arch. Sci. Rev. 2021, 65, 42–56. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; AlWaer, H.; Ghaffarianhoseini, A.; Clements-Croome, D.; Berardi, U.; Raahemifar, K.; Tookey, J. Intelligent or smart cities and buildings: A critical exposition and a way forward. Intell. Build. Int. 2017, 10, 122–129. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Berardi, U.; AlWaer, H.; Chang, S.; Halawa, E.; Ghaffarianhoseini, A.; Clements-Croome, D. What is an intelligent building? Analysis of recent interpretations from an international perspective. Arch. Sci. Rev. 2015, 59, 338–357. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Clements-Croome, D.J. The uptake of City Information Modelling (CIM): A comprehensive review of current implementations, challenges and future outlook. Smart Sustain. Built Environ. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Chang, R.; Ghaffarianhoseini, A.; Pour Rahimian, F. Applications of Building information modelling in the early design stage of high-rise buildings. Autom. Constr. 2023, 152, 104934. [Google Scholar] [CrossRef]

- Bakhshi, S.; Chenaghlou, M.R.; Pour Rahimian, F.; Edwards, D.J.; Dawood, N. Integrated BIM and DfMA parametric and algorithmic design based collaboration for supporting client engagement within offsite construction. Autom. Constr. 2021, 133, 104015. [Google Scholar] [CrossRef]

- Chang, R.; Song, X.; Omrany, H. What hinders the transition towards sustainable construction in china? Critical challenges and future directions. J. Green Build. 2022, 17, 99–127. [Google Scholar] [CrossRef]

- Omrany, H.; Soebarto, V.; Zuo, J.; Chang, R. A Comprehensive Framework for Standardising System Boundary Definition in Life Cycle Energy Assessments. Buildings 2021, 11, 230. [Google Scholar] [CrossRef]

- Goulding, J.S.; Rahimian, F.P. Offsite Production and Manufacturing for Innovative Construction: People, Process and Technology; Routledge: London, UK, 2019. [Google Scholar]

- Xie, H.; Xin, M.; Lu, C.; Xu, J. Knowledge map and forecast of digital twin in the construction industry: State-of-the-art review using scientometric analysis. J. Clean. Prod. 2023, 383, 135231. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. NASA Technology Roadmap: Modeling, Simulation. Information Technology & Processing Roadmap; National Aeronautics and Space Administration: Washington, DC, USA, 2012; pp. 1–38.

- Ghosh, A.K.; Ullah, A.S.; Kubo, A. Hidden Markov model-based digital twin construction for futuristic manufacturing systems. Artif. Intell. Eng. Des. Anal. Manuf. 2019, 33, 317–331. [Google Scholar] [CrossRef]

- Hribernik, K.A.; Rabe, L.; Thoben, K.-D.; Schumacher, J. The product avatar as a product-instance-centric information management concept. Int. J. Prod. Lifecycle Manag. 2006, 1, 367. [Google Scholar] [CrossRef]

- Almatared, M.; Liu, H.; Tang, S.; Sulaiman, M.; Lei, Z.; Li, H.X. Digital Twin in the Architecture. Engineering, and Construction Industry: A Bibliometric Review. Constr. Res. Congr. 2022, 2022, 670–678. [Google Scholar] [CrossRef]

- Airports International. Case Study: Digital Twinning in Construction 2022. Available online: https://www.airportsinternational.com/article/case-study-digital-twinning-construction (accessed on 21 June 2023).

- Bortolini, R.; Rodrigues, R.; Alavi, H.; Vecchia, L.F.D.; Forcada, N. Digital Twins’ Applications for Building Energy Efficiency: A Review. Energies 2022, 15, 7002. [Google Scholar] [CrossRef]

- Hou, L.; Wu, S.; Zhang, G.K.; Tan, Y.; Wang, X. Literature Review of Digital Twins Applications in Construction Workforce Safety. Appl. Sci. 2020, 11, 339. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M.; Bamdad, K.; Famakinwa, T. Barriers to the Adoption of Digital Twin in the Construction Industry: A Literature Review. Informatics 2023, 10, 14. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M.; Famakinwa, T.; Bamdad, K. Drivers for Digital Twin Adoption in the Construction Industry: A Systematic Literature Review. Buildings 2022, 12, 113. [Google Scholar] [CrossRef]

- Salem, T.; Dragomir, M. Options for and Challenges of Employing Digital Twins in Construction Management. Appl. Sci. 2022, 12, 2928. [Google Scholar] [CrossRef]

- Omrany, H.; Chang, R.; Soebarto, V.; Zhang, Y.; Ghaffarianhoseini, A.; Zuo, J. A bibliometric review of net zero energy building research 1995–2022. Energy Build. 2022, 262, 111996. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Kalantari, S.; Pourjabar, S.; Xu, T.B.; Kan, J. Developing and user-testing a “Digital Twins” prototyping tool for architectural design. Autom. Constr. 2022, 135, 104140. [Google Scholar] [CrossRef]

- Rafsanjani, H.N.; Nabizadeh, A.H. Towards digital architecture, engineering, and construction (AEC) industry through virtual design and construction (VDC) and digital twin. Energy Built Environ. 2023, 4, 169–178. [Google Scholar] [CrossRef]

- Callcut, M.; Agliozzo, J.-P.C.; Varga, L.; McMillan, L. Digital Twins in Civil Infrastructure Systems. Sustainability 2021, 13, 11549. [Google Scholar] [CrossRef]

- Broo, D.G.; Schooling, J. Digital twins in infrastructure: Definitions, current practices, challenges and strategies. Int. J. Constr. Manag. 2021, 23, 1254–1263. [Google Scholar] [CrossRef]

- Lu, R.; Brilakis, I. Digital twinning of existing reinforced concrete bridges from labelled point clusters. Autom. Constr. 2019, 105, 102837. [Google Scholar] [CrossRef]

- Lu, V.Q.; Parlikad, A.K.; Woodall, P.; Ranasinghe, G.D.; Heaton, J. Developing a dynamic digital twin at a building level: Using Cambridge campus as case study. In Proceedings of the International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving Data-Informed Decision-Making, Churchill College, Cambridge, UK, 8–10 July 2019; ICE Publishing: New York, NY, USA, 2019. [Google Scholar]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Ranasinghe, G.D.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a digital twin at building and city levels: Case study of West Cambridge campus. J. Manag. Eng. 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Yang, A.; Gao, J. Digital Twin-Based Ecogreen Building Design. Complexity 2021, 2021, 1391184. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Nielsen, H.K.; Kraniotis, D.; Svennevig, P.R.; Svidt, K. Digital Twin framework for automated fault source detection and prediction for comfort performance evaluation of existing non-residential Norwegian buildings. Energy Build. 2023, 281, 112732. [Google Scholar] [CrossRef]

- Arsiwala, A.; Elghaish, F.; Zoher, M. Digital twin with Machine learning for predictive monitoring of CO2 equivalent from existing buildings. Energy Build. 2023, 284, 112851. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Nielsen, H.K.; Kraniotis, D.; Svennevig, P.R.; Svidt, K. Improving building occupant comfort through a digital twin approach: A Bayesian network model and predictive maintenance method. Energy Build. 2023, 288, 112992. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Li, M.; Liu, X.; Zhong, R.Y.; Pan, W.; Huang, G.Q. Digital twin-enabled real-time synchronization for planning, scheduling, and execution in precast on-site assembly. Autom. Constr. 2022, 141, 104397. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, X.; Wang, Z.; Li, M.; Zhong, R.Y.; Huang, G.Q. Blockchain-enabled digital twin collaboration platform for fit-out operations in modular integrated construction. Autom. Constr. 2023, 148, 104747. [Google Scholar] [CrossRef]

- Petri, I.; Rezgui, Y.; Ghoroghi, A.; Alzahrani, A. Digital twins for performance management in the built environment. J. Ind. Inf. Integr. 2023, 33, 100445. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital twin-enabled smart modular integrated construction system for on-site assembly. Comput. Ind. 2021, 136, 103594. [Google Scholar] [CrossRef]

- Lin, J.-R.; Wu, D.-P. An approach to twinning and mining collaborative network of construction projects. Autom. Constr. 2021, 125, 103643. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Zhao, R.; Chen, Z.; Xue, F. A blockchain 3.0 paradigm for digital twins in construction project management. Autom. Constr. 2023, 145, 104645. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Arisekola, K.; Madson, K. Digital twins for asset management: Social network analysis-based review. Autom. Constr. 2023, 150, 104833. [Google Scholar] [CrossRef]

- Love, P.E.; Matthews, J. The ‘how’of benefits management for digital technology: From engineering to asset management. Autom. Constr. 2019, 107, 102930. [Google Scholar] [CrossRef]

- Pregnolato, M.; Gunner, S.; Voyagaki, E.; De Risi, R.; Carhart, N.; Gavriel, G.; Tully, P.; Tryfonas, T.; Macdonald, J.; Taylor, C. Towards Civil Engineering 4.0: Concept, workflow and application of Digital Twins for existing infrastructure. Autom. Constr. 2022, 141, 104421. [Google Scholar] [CrossRef]

- Hüthwohl, P.; Lu, R.; Brilakis, I. Multi-classifier for reinforced concrete bridge defects. Autom. Constr. 2019, 105, 102824. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Xie, X.; Lu, Q.; Parlikad, A.K.; Schooling, J.M. Digital Twin Enabled Asset Anomaly Detection for Building Facility Management. IFAC-PapersOnLine 2020, 53, 380–385. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Yu, Y.; Samali, B. Integration of TLS-derived Bridge Information Modeling (BrIM) with a Decision Support System (DSS) for digital twinning and asset management of bridge infrastructures. Comput. Ind. 2023, 147, 103881. [Google Scholar] [CrossRef]

- Consilvio, A.; Hernández, J.S.; Chen, W.; Brilakis, I.; Bartoccini, L.; Di Gennaro, F.; van Welie, M. Towards a digital twin-based intelligent decision support for road maintenance. Transp. Res. Procedia 2023, 69, 791–798. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, H.; Chen, Q.; de Soto, B.G. Developing a conceptual framework for the application of digital twin technologies to revamp building operation and maintenance processes. J. Build. Eng. 2022, 49, 104028. [Google Scholar] [CrossRef]

- Kamari, M.; Ham, Y. AI-based risk assessment for construction site disaster preparedness through deep learning-based digital twinning. Autom. Constr. 2022, 134, 104091. [Google Scholar] [CrossRef]

- Teizer, J.; Johansen, K.W.; Schultz, C. The Concept of Digital Twin for Construction Safety. Constr. Res. Congr. 2022, 2022, 1156–1165. [Google Scholar] [CrossRef]

- Liu, Z.; Bai, W.; Du, X.; Zhang, A.; Xing, Z.; Jiang, A. Digital Twin-based Safety Evaluation of Prestressed Steel Structure. Adv. Civ. Eng. 2020, 2020, 104421. [Google Scholar] [CrossRef]

- Wu, S.; Hou, L.; Zhang, G.K.; Chen, H. Real-time mixed reality-based visual warning for construction workforce safety. Autom. Constr. 2022, 139, 104252. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, C.; Liu, Z. A Framework for Prefabricated Component Hoisting Management Systems Based on Digital Twin Technology. Buildings 2022, 12, 276. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, L.; Zhou, C. Digital twin: Stability analysis for tower crane hoisting safety with a scale model. Autom. Constr. 2022, 138, 104257. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, X.; Xing, Z.; Jiang, A. Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors 2021, 21, 3583. [Google Scholar] [CrossRef]

- Liu, Z.-S.; Meng, X.-T.; Xing, Z.-Z.; Cao, C.-F.; Jiao, Y.-Y.; Li, A.-X. Digital Twin-Based Intelligent Safety Risks Prediction of Prefabricated Construction Hoisting. Sustainability 2022, 14, 5179. [Google Scholar] [CrossRef]

- Ye, Z.; Ye, Y.; Zhang, C.; Zhang, Z.; Li, W.; Wang, X.; Wang, L.; Wang, L. A digital twin approach for tunnel construction safety early warning and management. Comput. Ind. 2023, 144, 103783. [Google Scholar] [CrossRef]

- Clausen, A.; Arendt, K.; Johansen, A.; Sangogboye, F.C.; Kjærgaard, M.B.; Veje, C.T.; Jørgensen, B.N. A digital twin framework for improving energy efficiency and occupant comfort in public and commercial buildings. Energy Inform. 2021, 4, 40. [Google Scholar] [CrossRef]

- Seo, H.; Yun, W.-S. Digital Twin-Based Assessment Framework for Energy Savings in University Classroom Lighting. Buildings 2022, 12, 544. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, P.; Shou, W.; Sadick, A.-M. Digital Twin-driven approach to improving energy efficiency of indoor lighting based on computer vision and dynamic BIM. Energy Build. 2022, 270, 112271. [Google Scholar] [CrossRef]

- Tang, Y.; Gao, F.; Wang, C.; Huang, M.M.; Wu, M.; Li, H.; Li, Z. Vertical Greenery System (VGS) Renovation for Sustainable Arcade-Housing: Building Energy Efficiency Analysis Based on Digital Twin. Sustainability 2023, 15, 2310. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Xu, N. Digital Twin for Sustainability Evaluation of Railway Station Buildings. Front. Built Environ. 2018, 4, 77. [Google Scholar] [CrossRef]

- Alibrandi, U. Risk-Informed Digital Twin of Buildings and Infrastructures for Sustainable and Resilient Urban Communities. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2022, 8, 04022032. [Google Scholar] [CrossRef]

- Francisco, A.; Asce, S.M.; Mohammadi, N.; Asce, A.M.; Taylor, J.E.; Asce, M. Smart City Digital Twin–Enabled Energy Management: Toward Real-Time Urban Building Energy Benchmarking. J. Manag. Eng. 2020, 36, 04019045. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital Twin: Vision, Benefits, Boundaries, and Creation for Buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Tagliabue, L.C.; Cecconi, F.R.; Maltese, S.; Rinaldi, S.; Ciribini, A.L.C.; Flammini, A. Leveraging Digital Twin for Sustainability Assessment of an Educational Building. Sustainability 2021, 13, 480. [Google Scholar] [CrossRef]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. Cyber-Physical Systems Improving Building Energy Management: Digital Twin and Artificial Intelligence. Energies 2021, 14, 2338. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Rungskunroch, P.; Welsh, J. A Digital-Twin Evaluation of Net Zero Energy Building for Existing Buildings. Sustainability 2018, 11, 159. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, H.; Wang, Q.; Wang, H. Digital-Twin-Based Evaluation of Nearly Zero-Energy Building for Existing Buildings Based on Scan-to-BIM. Adv. Civ. Eng. 2021, 2021, 6638897. [Google Scholar] [CrossRef]

- Kosse, S.; Vogt, O.; Wolf, M.; König, M.; Gerhard, D. Digital Twin Framework for Enabling Serial Construction. Front. Built Environ. 2022, 8, 864722. [Google Scholar] [CrossRef]

- Tran, H.; Nguyen, T.N.; Christopher, P.; Bui, D.-K.; Khoshelham, K.; Ngo, T.D. A digital twin approach for geometric quality assessment of as-built prefabricated façades. J. Build. Eng. 2021, 41, 102377. [Google Scholar] [CrossRef]

- Wolf, M.; Vogt, O.; Huxoll, J.; Gerhard, D.; Kosse, S.; König, M. Lifecycle oriented digital twin approach for prefabricated concrete modules. In ECPPM 2021–eWork and eBusiness in Architecture, Engineering and Construction; CRC Press: Boca Raton, FL, USA, 2021; pp. 305–312. [Google Scholar]

- Xie, M.; Pan, W. Opportunities and challenges of digital twin applications in modular integrated construction. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction (ISARC 2020), Kitakyushu, Japan, 26–30 October 2020; IAARC Publications: Chennai, India, 2020. [Google Scholar]

- Liu, Z.; Wu, L.; Liu, Z.; Mo, Y. Quality control method of steel structure construction based on digital twin technology. Digit. Twin 2023, 3, 5. [Google Scholar] [CrossRef]

- Wang, Y.; Aslani, F.; Dyskin, A.; Pasternak, E. Digital Twin Applications in 3D Concrete Printing. Sustainability 2023, 15, 2124. [Google Scholar] [CrossRef]

- Rausch, C.; Lu, R.; Talebi, S.; Haas, C. Deploying 3D scanning based geometric digital twins during fabrication and assembly in offsite manufacturing. Int. J. Constr. Manag. 2021, 23, 565–578. [Google Scholar] [CrossRef]

- Greif, T.; Stein, N.; Flath, C.M. Peeking into the void: Digital twins for construction site logistics. Comput. Ind. 2020, 121, 103264. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control. 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital Twin for Supply Chain Coordination in Modular Construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Park, K.T.; Son, Y.H.; Noh, S.D. The architectural framework of a cyber physical logistics system for digital-twin-based supply chain control. Int. J. Prod. Res. 2020, 59, 5721–5742. [Google Scholar] [CrossRef]

- Chiachío, M.; Megía, M.; Chiachío, J.; Fernandez, J.; Jalón, M.L. Structural digital twin framework: Formulation and technology integration. Autom. Constr. 2022, 140, 104333. [Google Scholar] [CrossRef]

- Mirzaei, K.; Arashpour, M.; Asadi, E.; Masoumi, H.; Li, H. Automatic generation of structural geometric digital twins from point clouds. Sci. Rep. 2022, 12, 22321. [Google Scholar] [CrossRef]

- Rios, A.J.; Plevris, V.; Nogal, M. Bridge management through digital twin-based anomaly detection systems: A systematic review. Front. Built Environ. 2023, 9, 61. [Google Scholar] [CrossRef]

- Xu, J.; Shu, X.; Qiao, P.; Li, S.; Xu, J. Developing a digital twin model for monitoring building structural health by combining a building information model and a real-scene 3D model. Measurement 2023, 217, 112955. [Google Scholar] [CrossRef]

- Lu, R.; Rausch, C.; Bolpagni, M.; Brilakis, I.; Haas, C.T. Geometric Accuracy of Digital Twins for Structural Health Monitoring, in Structural Integrity and Failure; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar]

- Futai, M.M.; Bittencourt, T.N.; Santos, R.R.; Araújo, C.R.R.; Ribeiro, D.M.; Rocha, A.R.; Ellis, R. Utilization of Digital Twins for Bridge Inspection, Monitoring and Maintenance. In Proceedings of the 1st Conference of the European Association on Quality Control of Bridges and Structures: EUROSTRUCT, Padua, Italy, 29 August–1 September 2021; Springer International Publishing: Cham, Switzerland, 2022; pp. 166–173. [Google Scholar]

- Rojas-Mercedes, N.; Erazo, K.; Di Sarno, L. Seismic fragility curves for a concrete bridge using structural health monitoring and digital twins. Earthq. Struct. 2022, 22, 503–515. [Google Scholar]

- Smarsly, K.; Dragos, K.; Kolzer, T. Sensor-integrated digital twins for wireless structural health monitoring of civil infrastructure. Bautechnik 2022, 99, 471–476. [Google Scholar] [CrossRef]

- Ye, C.; Butler, L.; Calka, B.; Iangurazov, M.; Lu, Q.; Gregory, A.; Girolami, M.; Middleton, C. A digital twin of bridges for structural health monitoring. In Proceedings of the 12th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 10–12 September 2019; DEStech Publications, Inc.: Lancaster, PA, USA, 2019. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, T.; Deng, X.; Liu, Z.; Tan, J. Digital twin: A state-of-the-art review of its enabling technologies, applications and challenges. J. Intell. Manuf. Spéc. Equip. 2021, 2, 1–34. [Google Scholar] [CrossRef]

- Thelen, A.; Zhang, X.; Fink, O.; Lu, Y.; Ghosh, S.; Youn, B.; Todd, M.D.; Mahadevan, S.; Hu, C.; Hu, Z. A comprehensive review of digital twin—Part 1: Modeling and twinning enabling technologies. Struct. Multidiscip. Optim. 2022, 65, 354. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.D.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote. Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Saad, A.; Faddel, S.; Mohammed, O. IoT-based digital twin for energy cyber-physical systems: Design and implementation. Energies 2020, 13, 4762. [Google Scholar] [CrossRef]

- Al-Obaidi, K.M.; Hossain, M.; Alduais, N.A.M.; Al-Duais, H.S.; Omrany, H.; Ghaffarianhoseini, A. A Review of Using IoT for Energy Efficient Buildings and Cities: A Built Environment Perspective. Energies 2022, 15, 5991. [Google Scholar] [CrossRef]

- Jacoby, M.; Usländer, T. Digital Twin and Internet of Things—Current Standards Landscape. Appl. Sci. 2020, 10, 6519. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.; Qadir, J.; Munir, K.; Ajayi, S.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Kaur, M.J.; Mishra, V.P.; Maheshwari, P. The convergence of digital twin, IoT, and machine learning: Transforming data into action. Digit. Twin Technol. Smart Cities 2020, 3–17. [Google Scholar] [CrossRef]

- Rathore, M.M.; Shah, S.A.; Shukla, D.; Bentafat, E.; Bakiras, S. The Role of AI, Machine Learning, and Big Data in Digital Twinning: A Systematic Literature Review, Challenges, and Opportunities. IEEE Access 2021, 9, 32030–32052. [Google Scholar] [CrossRef]

- Cao, K.; Liu, Y.; Meng, G.; Sun, Q. An Overview on Edge Computing Research. IEEE Access 2020, 8, 85714–85728. [Google Scholar] [CrossRef]

- Varghese, B.; Wang, N.; Barbhuiya, S.; Kilpatrick, P.; Nikolopoulos, D.S. Challenges and opportunities in edge computing. In Proceedings of the 2016 IEEE International Conference on Smart Cloud (SmartCloud), New York, NY, USA, 18–20 November 2016; IEEE: New York, NY, USA, 2016; pp. 20–26. [Google Scholar]

- Shi, W.; Cao, J.; Zhang, Q.; Li, Y.; Xu, L. Edge Computing: Vision and Challenges. IEEE Internet Things J. 2016, 3, 637–646. [Google Scholar] [CrossRef]

- Yaqoob, I.; Salah, K.; Uddin, M.; Jayaraman, R.; Omar, M.; Imran, M. Blockchain for Digital Twins: Recent Advances and Future Research Challenges. IEEE Netw. 2020, 34, 290–298. [Google Scholar] [CrossRef]

- Hasan, H.R.; Salah, K.; Jayaraman, R.; Omar, M.; Yaqoob, I.; Pesic, S.; Taylor, T.; Boscovic, D. A blockchain-based approach for the creation of digital twins. IEEE Access 2020, 8, 34113–34126. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, W.; Tao, F.; Lin, C.L. Industrial IoT in 5G environment towards smart manufacturing. J. Ind. Inf. Integr. 2018, 10, 10–19. [Google Scholar] [CrossRef]

- Kim, J.H. 6G and Internet of Things: A survey. J. Manag. Anal. 2021, 8, 316–332. [Google Scholar] [CrossRef]

- Wang, D.; Chen, D.; Song, B.; Guizani, N.; Yu, X.; Du, X. From IoT to 5G I-IoT: The Next Generation IoT-Based Intelligent Algorithms and 5G Technologies. IEEE Commun. Mag. 2018, 56, 114–120. [Google Scholar] [CrossRef]

- Mashaly, M. Connecting the Twins: A Review on Digital Twin Technology & its Networking Requirements. Procedia Comput. Sci. 2021, 184, 299–305. [Google Scholar] [CrossRef]

- Mahapatra, R.; Nijsure, Y.; Kaddoum, G.; Hassan, N.U.; Yuen, C. Energy Efficiency Tradeoff Mechanism Towards Wireless Green Communication: A Survey. IEEE Commun. Surv. Tutor. 2015, 18, 686–705. [Google Scholar] [CrossRef]

- Tuhaise, V.V.; Tah, J.H.M.; Abanda, F.H. Technologies for digital twin applications in construction. Autom. Constr. 2023, 152, 104931. [Google Scholar] [CrossRef]

- Daniotti, B.; Masera, G.; Bolognesi, C.; Spagnolo, S.L.; Pavan, A.; Iannaccone, G.; Signorini, M.; Ciuffreda, S.; Mirarchi, C.; Lucky, M.; et al. The Development of a BIM-Based Interoperable Toolkit for Efficient Renovation in Buildings: From BIM to Digital Twin. Buildings 2022, 12, 231. [Google Scholar] [CrossRef]

- Garetti, M.; Fumagalli, L.; Negri, E. Role of Ontologies for CPS Implementation in Manufacturing. Manag. Prod. Eng. Rev. 2015, 6, 26–32. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Garetti, M.; Tanca, L. Requirements and languages for the semantic representation of manufacturing systems. Comput. Ind. 2016, 81, 55–66. [Google Scholar] [CrossRef]

- Gruber, T.R. A translation approach to portable ontology specifications. Knowl. Acquis. 1993, 5, 199–220. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2020, 58, 346–361. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Jia, W.; Wang, W.; Zhang, Z. From simple digital twin to complex digital twin Part I: A novel modeling method for multi-scale and multi-scenario digital twin. Adv. Eng. Inform. 2022, 53, 101706. [Google Scholar] [CrossRef]

- Qi, Q.; Zhao, D.; Liao, T.W.; Tao, F. Modeling of cyber-physical systems and digital twin based on edge computing, fog computing and cloud computing towards smart manufacturing. In Proceedings of the International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; p. V001T05A018. [Google Scholar]

- Pushpa, J.; Kalyani, S. Using fog computing/edge computing to leverage Digital Twin. Adv. Comput. 2020, 117, 51–77. [Google Scholar] [CrossRef]

- Shahat, E.; Hyun, C.T.; Yeom, C. City Digital Twin Potentials: A Review and Research Agenda. Sustainability 2021, 13, 3386. [Google Scholar] [CrossRef]

- Alshammari, K.; Beach, T.; Rezgui, Y. Cybersecurity for digital twins in the built environment: Current research and future directions. J. Inf. Technol. Constr. 2021, 26, 159–173. [Google Scholar] [CrossRef]

- Harper, K.E.; Malakuti, S.; Ganz, C. Digital Twin Architecture and Standards. J. Innov. 2019, 1–12. [Google Scholar]

- Bitton, R.; Gluck, T.; Stan, O.; Inokuchi, M.; Ohta, Y.; Yamada, Y.; Yagyu, T.; Elovici, Y.; Shabtai, A. Deriving a cost-effective digital twin of an ICS to facilitate security evaluation. In Proceedings of the Computer Security: 23rd European Symposium on Research in Computer Security, ESORICS 2018, Barcelona, Spain, 3–7 September 2018; Springer International Publishing: Cham, Switzerland, 2018. Part I 23. pp. 533–554. [Google Scholar]

| Keywords Deployed during the Initial Search |

|---|

| Digital Twin; Digital Technology; Construction Industry; Intelligent Construction; Construction 4.0; Collaborative Platforms; Smart Construction; Industry 4.0; Digitalisation; Digital Transformation; Virtual Construction; Cognitive Technology; Virtual Twin; Digital Replica; Cyber–Physical System; Cyber Twin; Digital Shadow; Digital Clone; Intelligent Twin; Digital Doppelganger. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability 2023, 15, 10908. https://doi.org/10.3390/su151410908

Omrany H, Al-Obaidi KM, Husain A, Ghaffarianhoseini A. Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability. 2023; 15(14):10908. https://doi.org/10.3390/su151410908

Chicago/Turabian StyleOmrany, Hossein, Karam M. Al-Obaidi, Amreen Husain, and Amirhosein Ghaffarianhoseini. 2023. "Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions" Sustainability 15, no. 14: 10908. https://doi.org/10.3390/su151410908

APA StyleOmrany, H., Al-Obaidi, K. M., Husain, A., & Ghaffarianhoseini, A. (2023). Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability, 15(14), 10908. https://doi.org/10.3390/su151410908