3D Printing of Hybrid Cements Based on High Contents of Powders from Concrete, Ceramic and Brick Waste Chemically Activated with Sodium Sulphate (Na2SO4)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Production of Mixes and Characterization

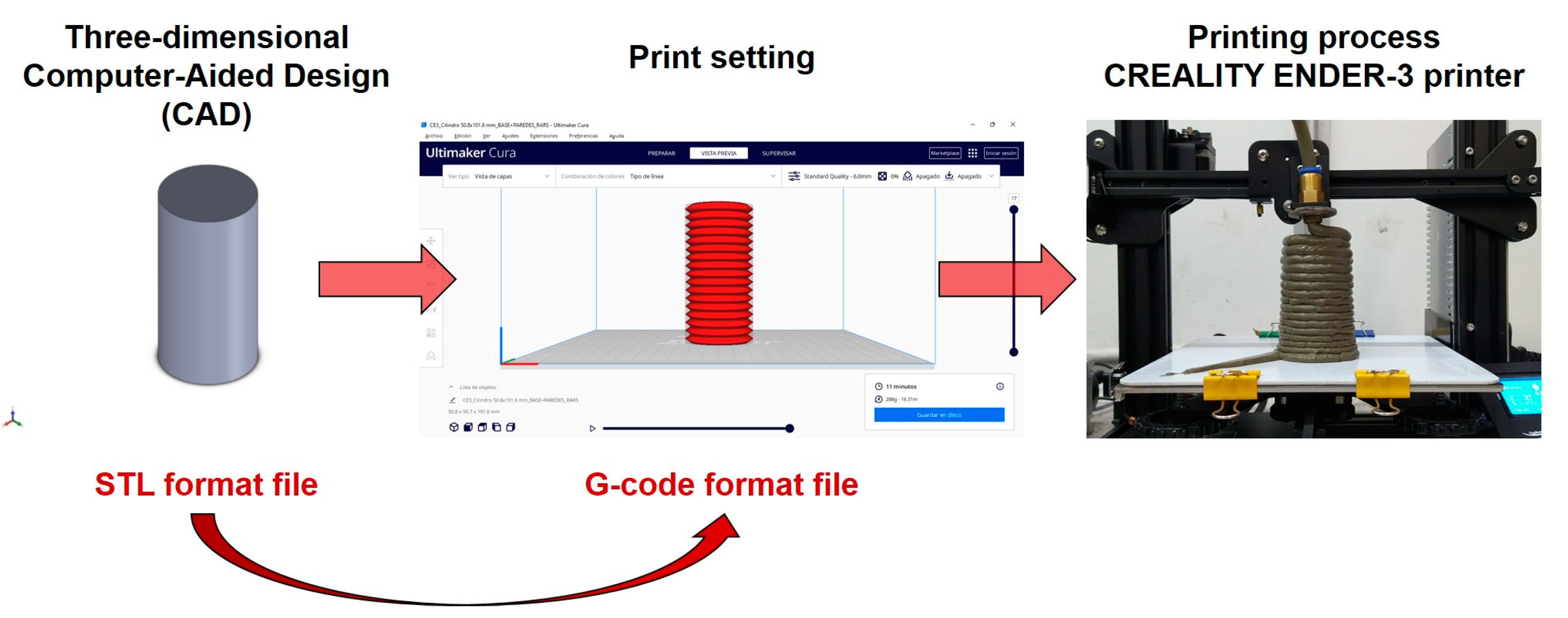

2.3. Additive Manufacturing (3D Printing) and Tests

3. Results and Discussion

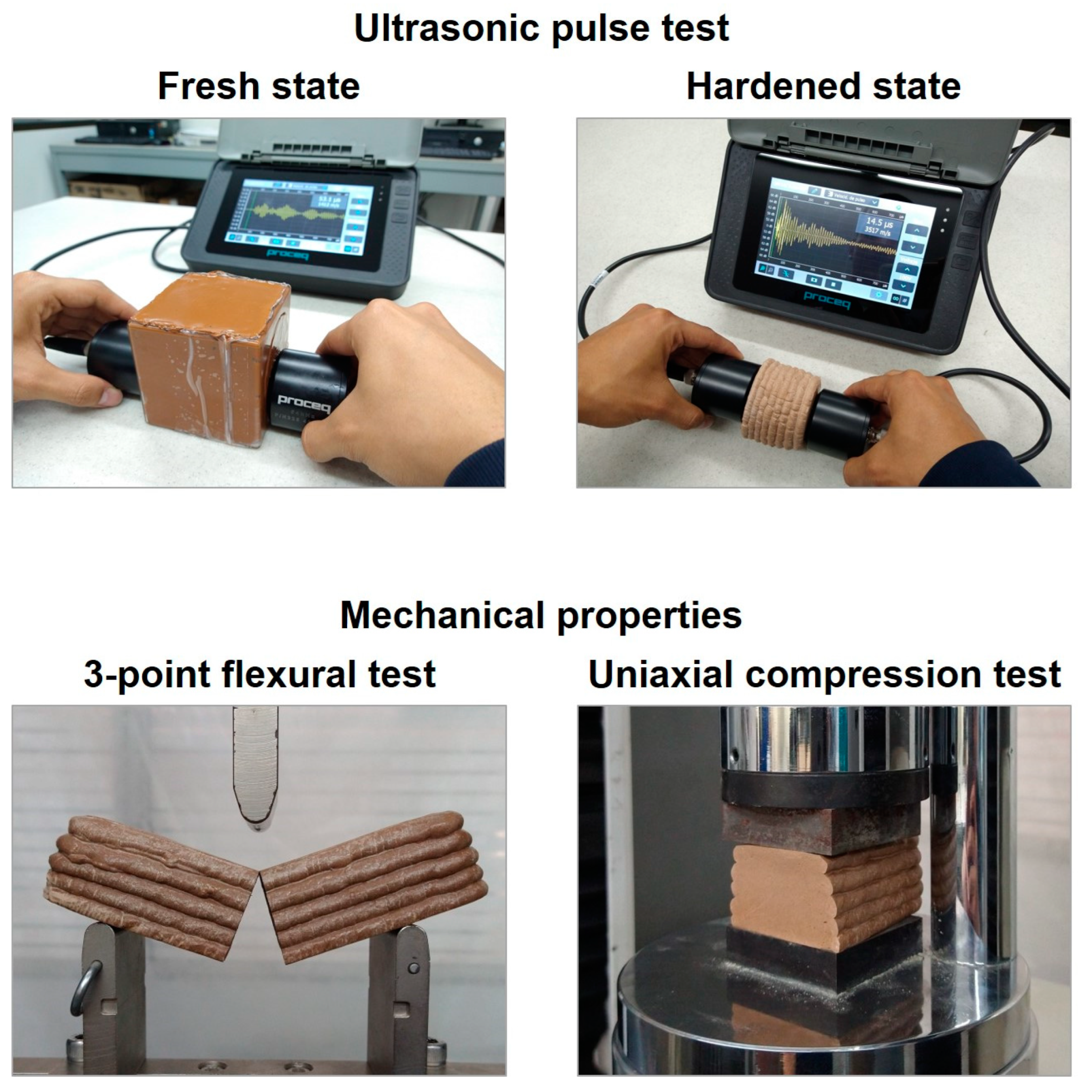

3.1. Materials Characterization

3.2. Fresh Properties

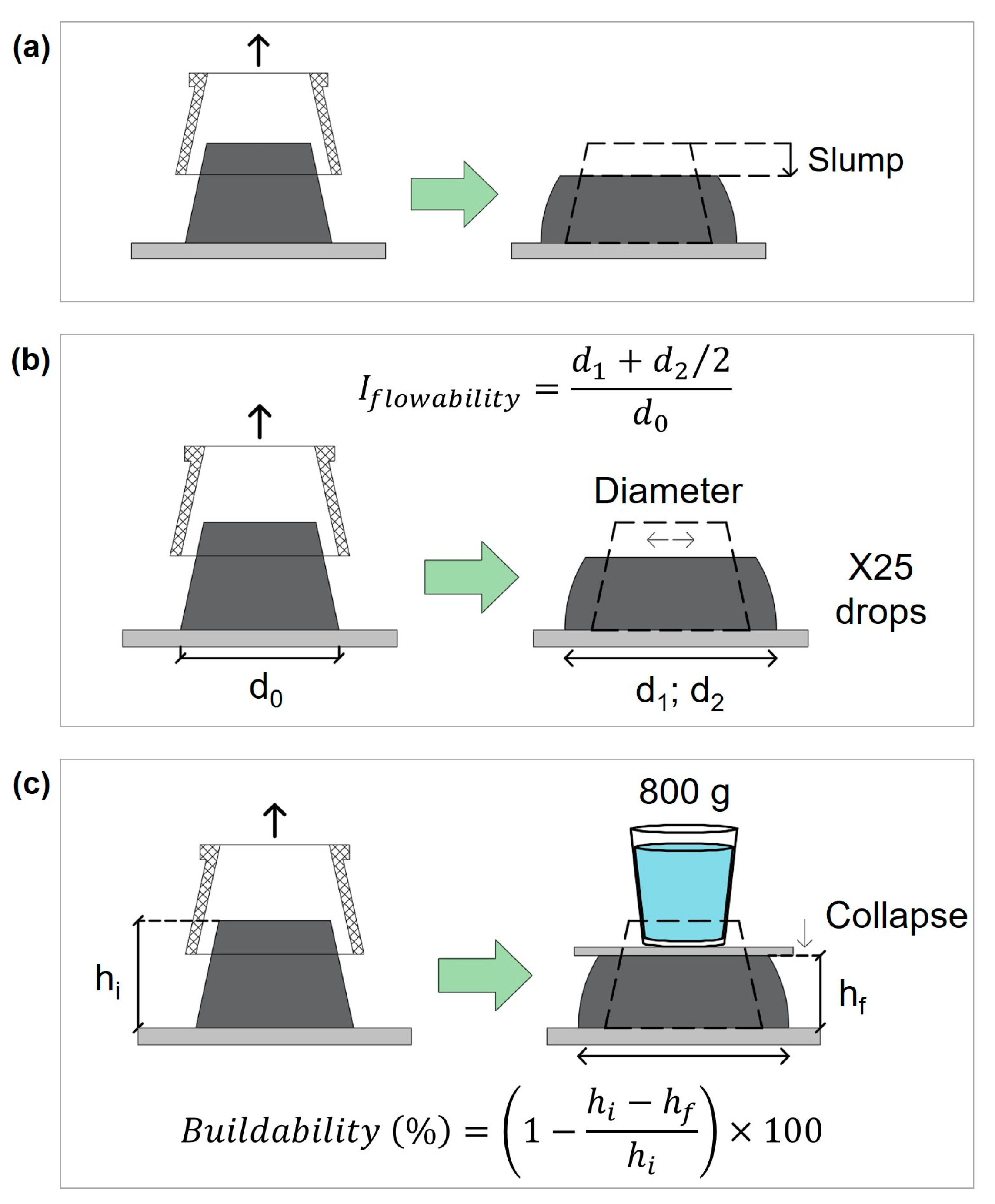

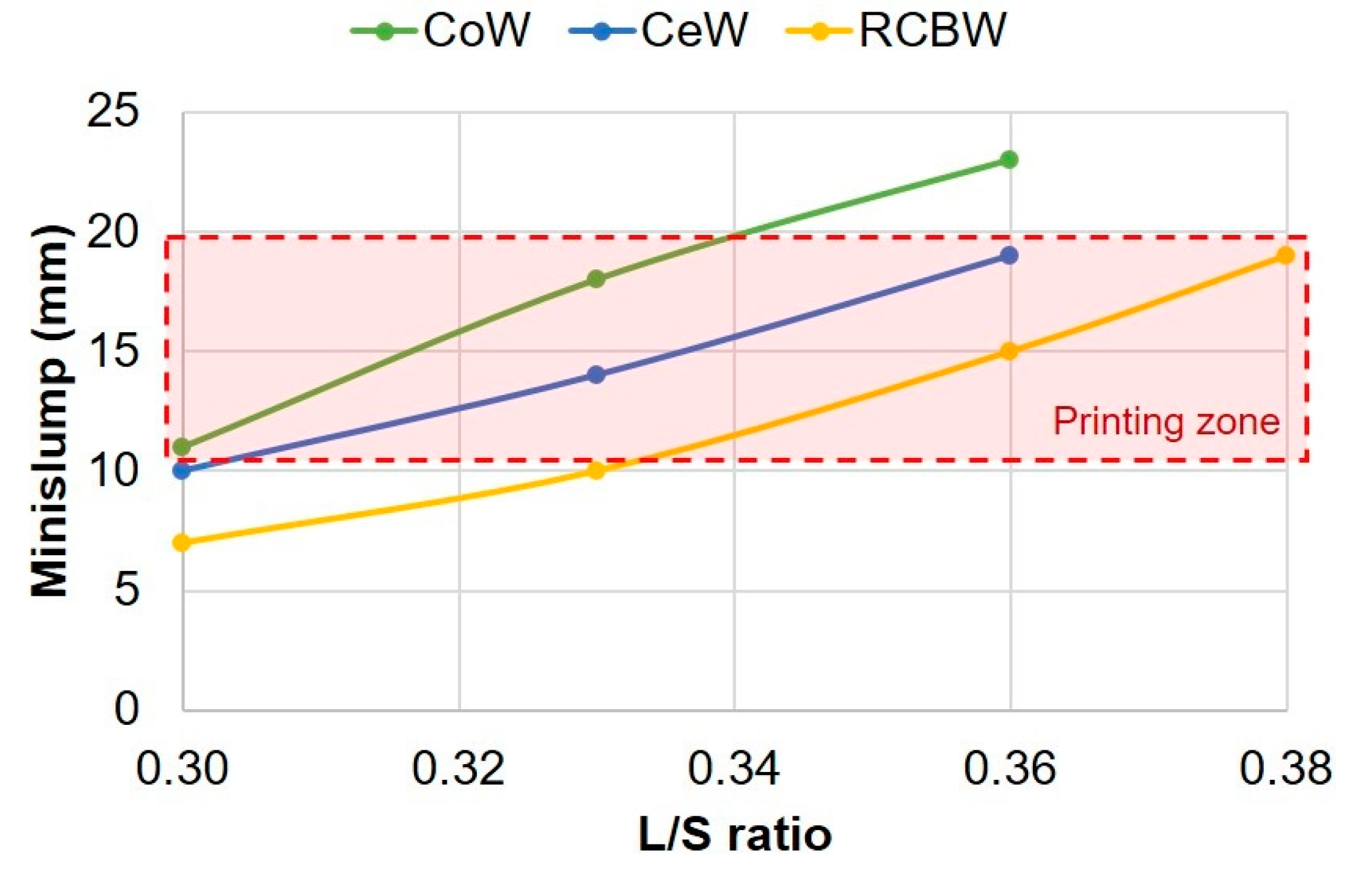

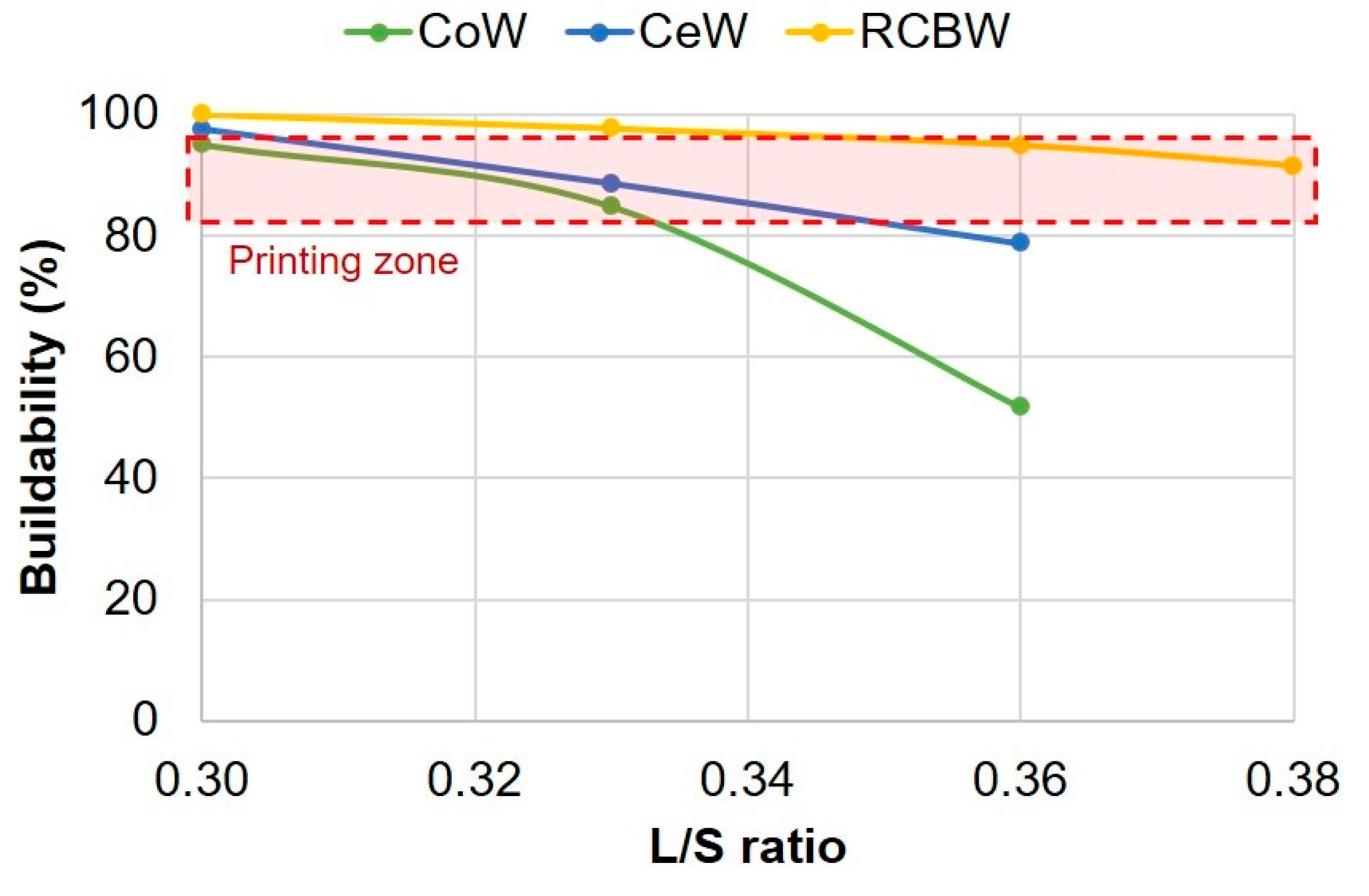

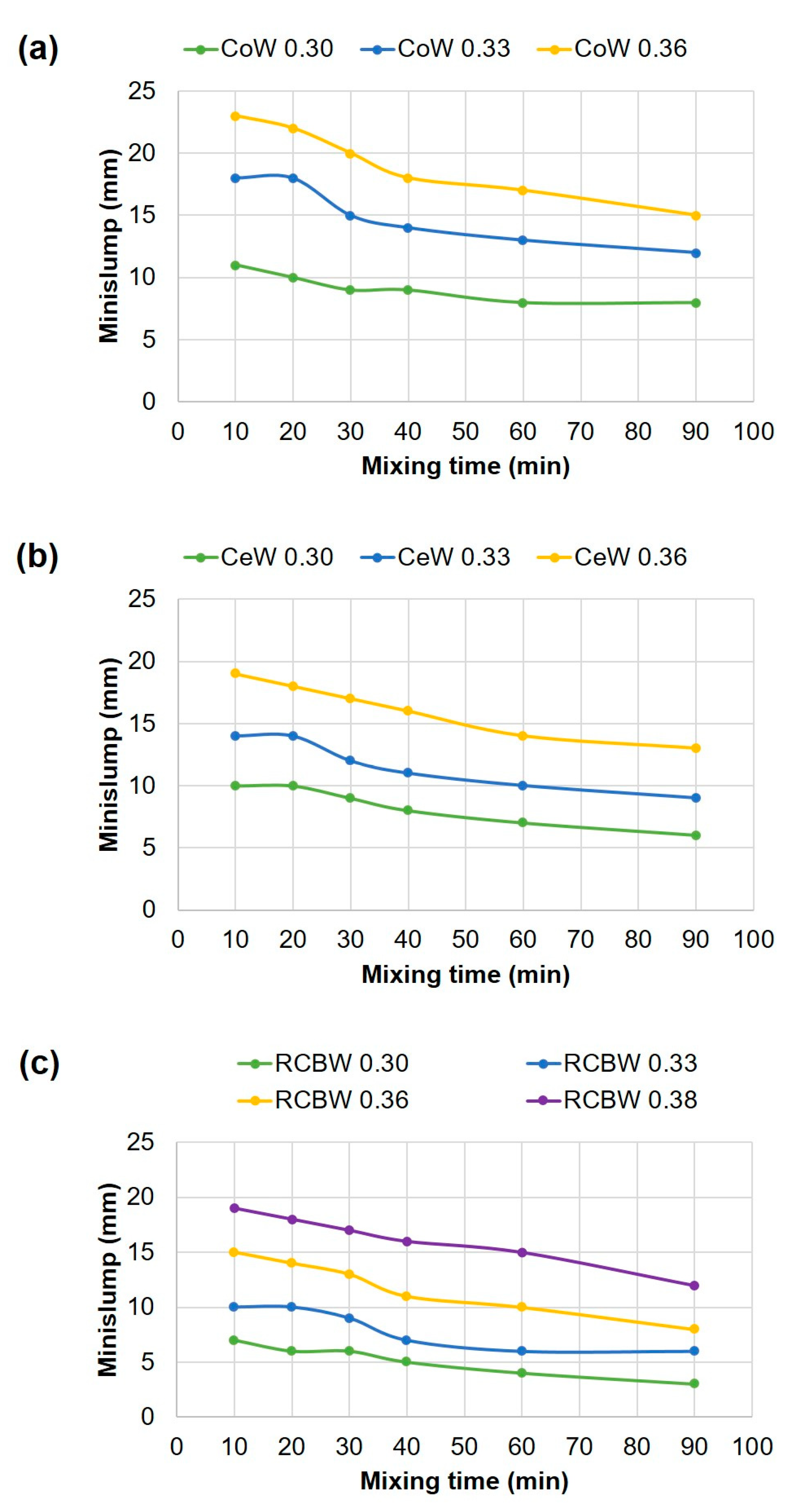

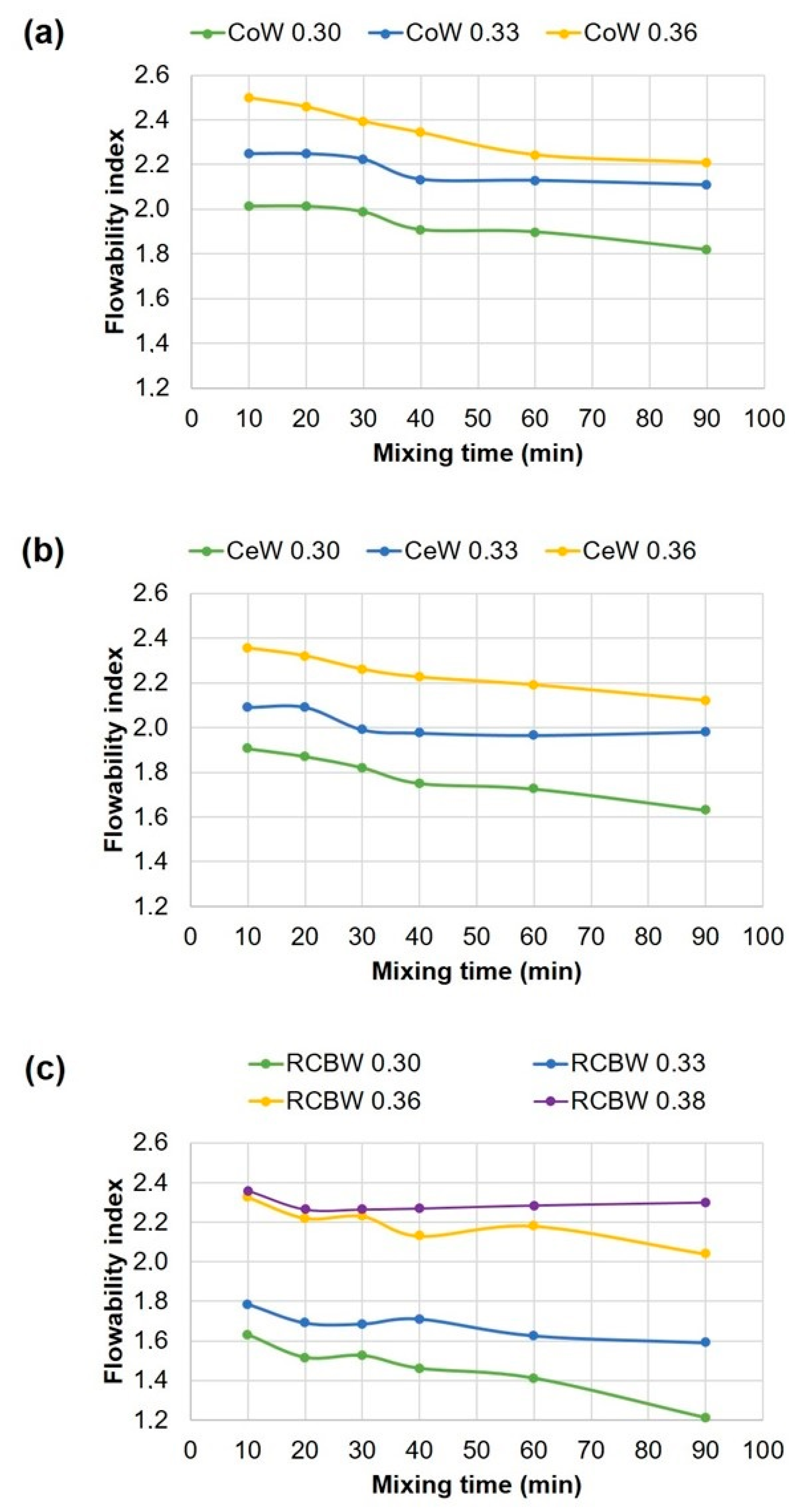

3.2.1. Minislump, Flow Rate and Buildability

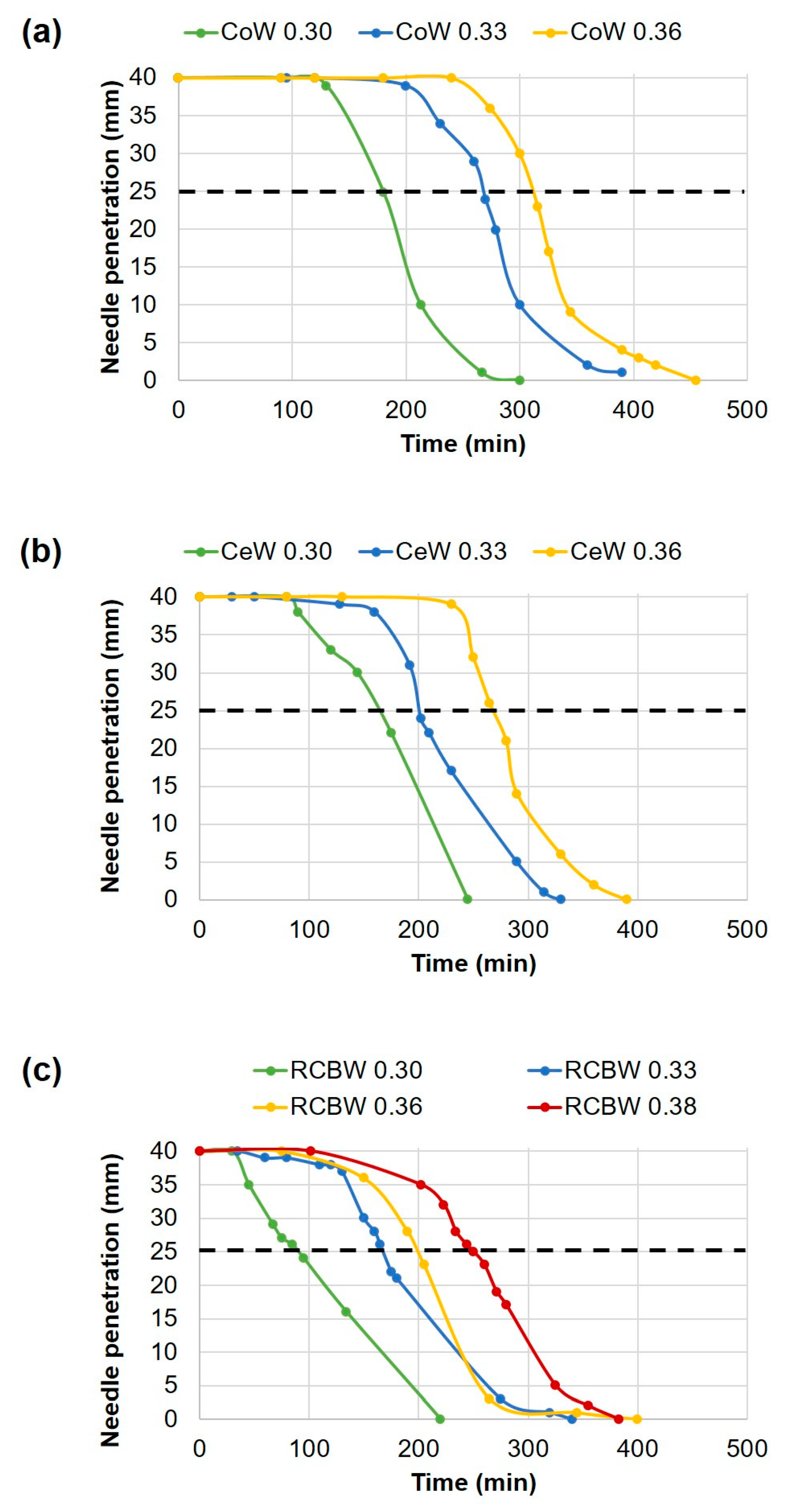

3.2.2. Open Time

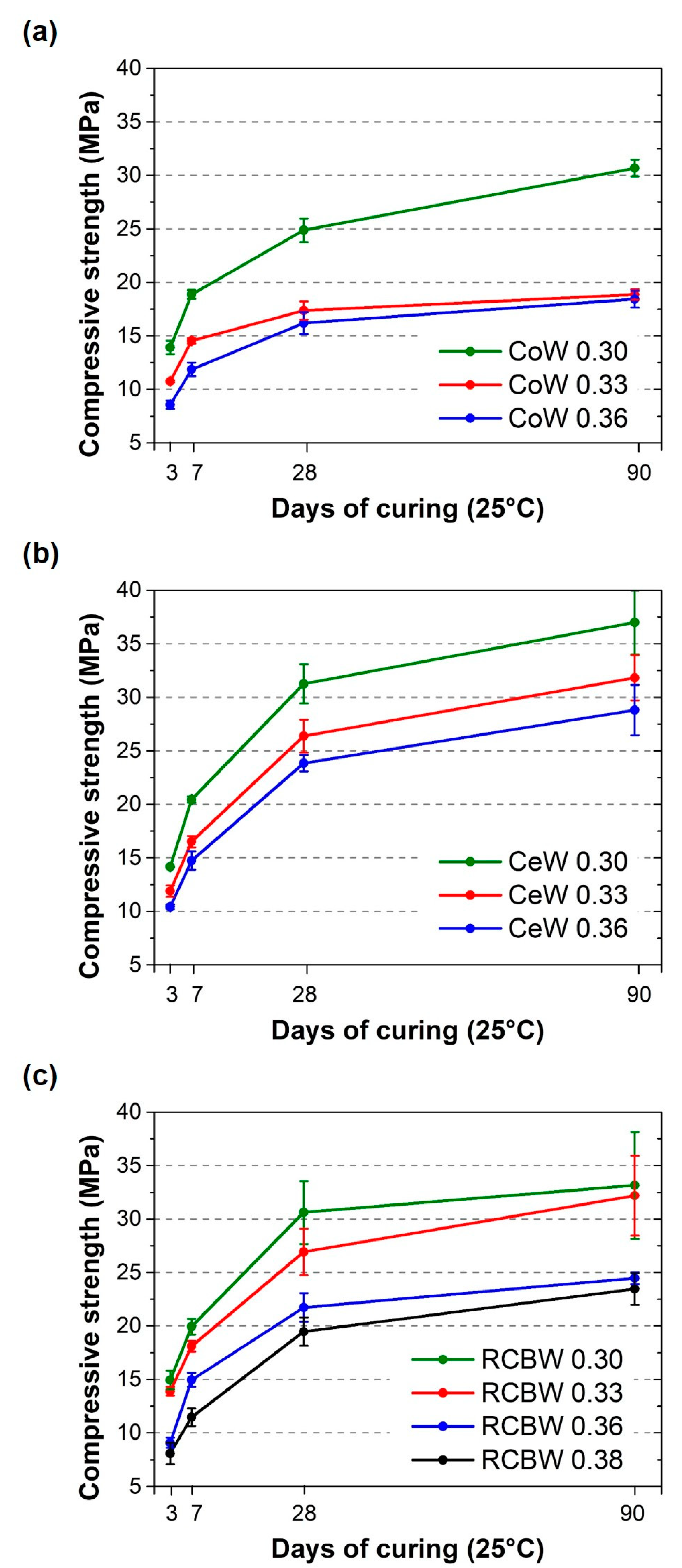

3.3. Compressive Strength of the Mixes

3.4. 3D Printing Tests

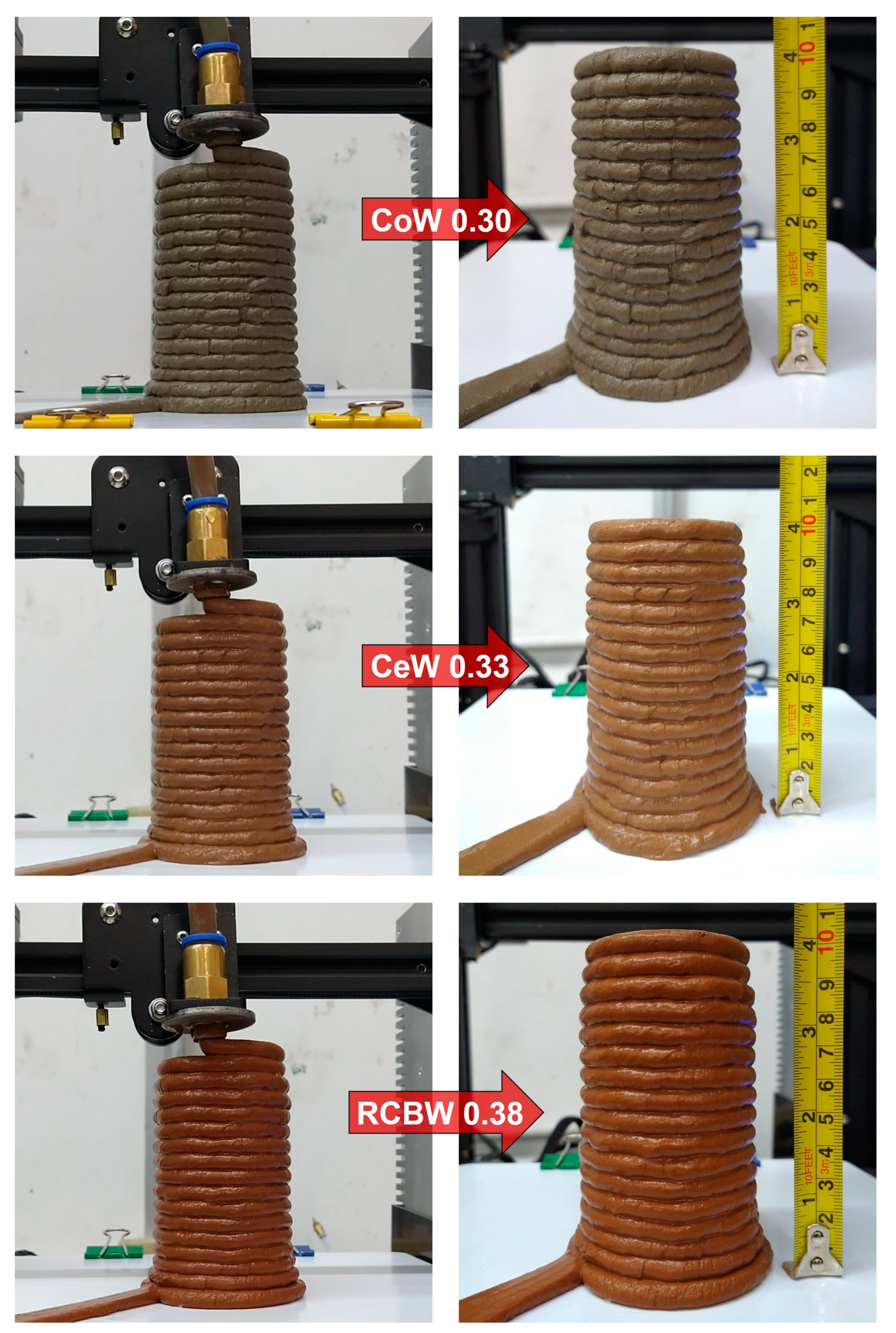

3.4.1. Printability and Buildability

3.4.2. Physical-Mechanical Behaviour

3.4.3. Microstructural Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grand View Research 3D Printing Construction Market Size, Share & Trends Analysis Report by Construction Method (Extrusion, Powder Bonding), by Material Type (Concrete, Metal), by End-User (Building, Infrastructure), and Segment Forecasts, 2022–2030. Available online: https://www.grandviewresearch.com/industry-analysis/3d-printing-constructions-market (accessed on 24 November 2022).

- Ma, G.; Wang, L.; Ju, Y. State-of-the-Art of 3D Printing Technology of Cementitious Material—An Emerging Technique for Construction. Sci. China Technol. Sci. 2018, 61, 475–495. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D Printing with Concrete—Technical, Economic and Environmental Potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental Assessment of Large-Scale 3D Printing in Construction: A Comparative Study between Cob and Concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Ow Yeong, K.L.; Qian, S. Comparative Economic, Environmental and Productivity Assessment of a Concrete Bathroom Unit Fabricated through 3D Printing and a Precast Approach. J. Clean. Prod. 2020, 261, 121245. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B. Chapter 1—3D Concrete Printing for Construction Applications. In 3D Concrete Printing Technology; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 1–11. ISBN 978-0-12-815481-6. [Google Scholar]

- Robayo-Salazar, R.; Mejía de Gutiérrez, R.; Villaquirán-Caicedo, M.A.; Delvasto Arjona, S. 3D Printing with Cementitious Materials: Challenges and Opportunities for the Construction Sector. Autom. Constr. 2023, 146, 104693. [Google Scholar] [CrossRef]

- Bhattacherjee, S.; Basavaraj, A.S.; Rahul, A.V.; Santhanam, M.; Gettu, R.; Panda, B.; Schlangen, E.; Chen, Y.; Copuroglu, O.; Ma, G.; et al. Sustainable Materials for 3D Concrete Printing. Cem. Concr. Compos. 2021, 122, 104156. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Tuyan, M.; Nehdi, M.L. Alkali-Activated and Geopolymer Materials Developed Using Innovative Manufacturing Techniques: A Critical Review. Constr. Build. Mater. 2021, 303, 124483. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D Printing Geopolymers: A Review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y.; Khan, M. Recent Advances and Productivity Analysis of 3D Printed Geopolymers. Addit. Manuf. 2022, 52, 102685. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer Additive Manufacturing: A Review. Addit. Manuf. 2022, 55, 102782. [Google Scholar] [CrossRef]

- Khan, M.A. Mix Suitable for Concrete 3D Printing: A Review. Mater. Today Proc. 2020, 32, 831–837. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J. Method of Formulating Geopolymer for 3D Printing for Construction Applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Mejía de Gutiérrez, R. Natural Volcanic Pozzolans as an Available Raw Material for Alkali-Activated Materials in the Foreseeable Future: A Review. Constr. Build. Mater. 2018, 189, 109–118. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-Friendly Geopolymer Materials: A Review of Performance Improvement, Potential Application and Sustainability Assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer Concrete as Green Building Materials: Recent Applications, Sustainable Development and Circular Economy Potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef]

- Ouellet-Plamondon, C.; Habert, G. Life Cycle Assessment (LCA) of Alkali-Activated Cements and Concretes. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Woodhead Publishing: Sawston, UK, 2015; pp. 663–686. ISBN 9781782422761. [Google Scholar]

- Valencia-Saavedra, W.; Robayo-Salazar, R.; Mejía de Gutiérrez, R. Alkali-Activated Hybrid Cements Based on Fly Ash and Construction and Demolition Wastes Using Sodium Sulfate and Sodium Carbonate. Molecules 2021, 26, 7572. [Google Scholar] [CrossRef]

- Joseph, S.; Snellings, R.; Cizer, Ö. Activation of Portland Cement Blended with High Volume of Fly Ash Using Na2SO4. Cem. Concr. Compos. 2019, 104, 103417. [Google Scholar] [CrossRef]

- Donatello, S.; Fernández-Jimenez, A.; Palomo, A. Very High Volume Fly Ash Cements. Early Age Hydration Study Using Na2SO4 as an Activator. J. Am. Ceram. Soc. 2013, 96, 900–906. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; Gutiérrez, R.M. Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units. Sustainability 2022, 14, 9685. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Recycling of Concrete, Ceramic, and Masonry Waste via Alkaline Activation: Obtaining and Characterization of Hybrid Cements. J. Build. Eng. 2022, 46, 103698. [Google Scholar] [CrossRef]

- Şahin, O.; İlcan, H.; Ateşli, A.T.; Kul, A.; Yıldırım, G.; Şahmaran, M. Construction and Demolition Waste-Based Geopolymers Suited for Use in 3-Dimensional Additive Manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological Properties and Compressive Strength of Construction and Demolition Waste-Based Geopolymer Mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Demiral, N.C.; Ozkan Ekinci, M.; Sahin, O.; Ilcan, H.; Kul, A.; Yildirim, G.; Sahmaran, M. Mechanical Anisotropy Evaluation and Bonding Properties of 3D-Printable Construction and Demolition Waste-Based Geopolymer Mortars. Cem. Concr. Compos. 2022, 134, 104814. [Google Scholar] [CrossRef]

- ASTM C230/230M-20; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2020.

- ASTM C191-21; Standard Test Methods for Setting of Hydraulic Cement by Vicat Needle. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- UNE EN 1015:2020; Methods of Test for Mortar for Masonry-Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. AENOR: Madrid, Spain, 2020.

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2013.

- ASTM C597-16; Standard Test Method for Pulse Velocity Through Concrete. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016.

- Souza, M.T.; Ferreira, I.M.; de Moraes, E.G.; Senff, L.; Arcaro, S.; Pessôa, J.R.C.; Ribeiro, M.J.; de Oliveira, A.P.N. Role of Chemical Admixtures on 3D Printed Portland Cement: Assessing Rheology and Buildability. Constr. Build. Mater. 2022, 314, 125666. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability Region for 3D Concrete Printing Using Slump and Slump Flow Test. Compos. Part B 2019, 174, 106968. [Google Scholar] [CrossRef]

- Kaliyavaradhan, S.K.; Ambily, P.S.; Prem, P.R.; Ghodke, S.B. Test Methods for 3D Printable Concrete. Autom. Constr. 2022, 142, 104529. [Google Scholar] [CrossRef]

- Uppalapati, S.; Vandewalle, L.; Cizer, Ö. Monitoring the Setting Process of Alkali-Activated Slag-Fly Ash Cements with Ultrasonic P-Wave Velocity. Constr. Build. Mater. 2021, 271, 121592. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Kuenzel, C.; Gundlach, C.; Pedersen, D.B.; Dolatshahi-Pirouz, A.; Spangenberg, J. Rheological Characterization of 3D Printable Geopolymers. Cem. Concr. Res. 2021, 147, 106498. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and Harden Properties of the High-Thixotropy 3D Printing Concrete. Constr. Build. Mater. 2019, 201, 278–285. [Google Scholar] [CrossRef]

- SIKA 3D CONCRETE PRINTING: Sikacrete® 3D Materials for Fast and Precisely Printed Concrete. Available online: https://www.sika.com/en/knowledge-hub/3d-concrete-printing.html#sika (accessed on 24 November 2022).

- Che, Y.; Yang, H. Hydration Products, Pore Structure, and Compressive Strength of Extrusion-Based 3D Printed Cement Pastes Containing Nano Calcium Carbonate. Case Stud. Constr. Mater. 2022, 17, e01590. [Google Scholar] [CrossRef]

- Nodehi, M.; Aguayo, F.; Nodehi, S.E.; Gholampour, A.; Ozbakkaloglu, T.; Gencel, O. Durability Properties of 3D Printed Concrete (3DPC). Autom. Constr. 2022, 142, 104479. [Google Scholar] [CrossRef]

| Mix | L/S Ratio | Proportion (g) | |||

|---|---|---|---|---|---|

| Waste | OPC | Na2SO4 | Water | ||

| CoW 0.30 | 0.30 | 70 | 30 | 4 | 30 |

| CoW 0.33 | 0.33 | 70 | 30 | 4 | 33 |

| CoW 0.36 | 0.36 | 70 | 30 | 4 | 36 |

| CeW 0.30 | 0.30 | 70 | 30 | 4 | 30 |

| CeW 0.33 | 0.33 | 70 | 30 | 4 | 33 |

| CeW 0.36 | 0.36 | 70 | 30 | 4 | 36 |

| RCBW 0.30 | 0.30 | 70 | 30 | 4 | 30 |

| RCBW 0.33 | 0.33 | 70 | 30 | 4 | 33 |

| RCBW 0.36 | 0.36 | 70 | 30 | 4 | 36 |

| RCBW 0.38 | 0.38 | 70 | 30 | 4 | 38 |

| Material | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | Na2O | K2O | Others | LOI 1 |

|---|---|---|---|---|---|---|---|---|---|

| CoW | 36.1 | 8.3 | 28.7 | 6.8 | 1.9 | 0.6 | 0.6 | 1.1 | 15.9 |

| CeW | 59.3 | 16.1 | 9.8 | 5.5 | 0.8 | 0.5 | 1.6 | 2.3 | 4.1 |

| RCBW | 59.0 | 18.4 | 5.4 | 7.8 | 2.4 | 1.1 | 1.5 | 1.5 | 2.9 |

| OPC | 19.4 | 4.1 | 55.7 | 4.7 | 1.7 | 0.3 | 0.3 | 4.6 | 9.2 |

| Mix | Absorption (%) | Bulk Density, Dry (g/cm3) | Apparent Density (g/cm3) | Permeable Pore Volume (%) |

|---|---|---|---|---|

| CoW 0.30 | 26.9 | 1.55 | 1.97 | 42.4 |

| CeW 0.33 | 28.5 | 1.52 | 1.96 | 43.9 |

| RCBW 0.38 | 32.6 | 1.44 | 1.92 | 47.6 |

| Mix | Flexural Strength (MPa) | Compressive Strength (MPa) | |

|---|---|---|---|

| 7 Days | 7 Days | 28 Days | |

| CoW 0.30 | 4.9 | 11.5 | 18.2 |

| CeW 0.33 | 4.6 | 12.7 | 27.7 |

| RCBW 0.38 | 4.4 | 10.5 | 21.7 |

| Mix | Cylinder | Ultrasonic Pulse Velocity (m/s) |

|---|---|---|

| CoW 0.30 | 3D printed | 3114 ± 12 |

| Mould-casted | 3149 ± 11 | |

| CeW 0.33 | 3D printed | 3313 ± 10 |

| Mould-casted | 3356 ± 23 | |

| RCBW 0.38 | 3D printed | 3238 ± 12 |

| Mould-casted | 3297 ± 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robayo-Salazar, R.; Martínez, F.; Vargas, A.; Mejía de Gutiérrez, R. 3D Printing of Hybrid Cements Based on High Contents of Powders from Concrete, Ceramic and Brick Waste Chemically Activated with Sodium Sulphate (Na2SO4). Sustainability 2023, 15, 9900. https://doi.org/10.3390/su15139900

Robayo-Salazar R, Martínez F, Vargas A, Mejía de Gutiérrez R. 3D Printing of Hybrid Cements Based on High Contents of Powders from Concrete, Ceramic and Brick Waste Chemically Activated with Sodium Sulphate (Na2SO4). Sustainability. 2023; 15(13):9900. https://doi.org/10.3390/su15139900

Chicago/Turabian StyleRobayo-Salazar, Rafael, Fabio Martínez, Armando Vargas, and Ruby Mejía de Gutiérrez. 2023. "3D Printing of Hybrid Cements Based on High Contents of Powders from Concrete, Ceramic and Brick Waste Chemically Activated with Sodium Sulphate (Na2SO4)" Sustainability 15, no. 13: 9900. https://doi.org/10.3390/su15139900

APA StyleRobayo-Salazar, R., Martínez, F., Vargas, A., & Mejía de Gutiérrez, R. (2023). 3D Printing of Hybrid Cements Based on High Contents of Powders from Concrete, Ceramic and Brick Waste Chemically Activated with Sodium Sulphate (Na2SO4). Sustainability, 15(13), 9900. https://doi.org/10.3390/su15139900