Abstract

There is growing interest in sustainable road pavement technologies to protect the environment and provide economic benefits. Post-consumer recycled (PCR) plastics are considered for construction to address the threat of plastic waste materials (PWM) and to improve sustainability. Asphalt pavement construction is highly considered for PWM recycling due to its large daily production. The purpose of this study is to investigate the performance of asphalt mixture containing PWM, specifically high-density polyethylene (HDPE), and compare its performance with two conventional mixtures. Three asphalt mixtures were considered: (1) mixture with asphalt binder PG 76-22 (SBS-modified); (2) mixture with asphalt binder PG 70-22 (SBS-modified); and (3) mixture with binder PG 67-22 and 3% HDPE (the plastic mixture). The rheological properties of the modified asphalt binders and the performance of the modified asphalt mixtures were evaluated. The long-term field performance of the pavements was modeled using AASHTOWare software (v.1.1.6) for the three mixtures considered. The results showed that all the mixtures were able to comply with the cracking threshold specified by the Louisiana Department of Transportation and Development (LaDOTD) for high-traffic volume roads. In addition, the plastic asphalt mixture showed similar performance to the one containing PG 70-22 (SBS-modified) asphalt binder.

1. Introduction

Plastic waste materials (PWM) are being produced daily in massive tonnage quantities across the globe. In 2010, the United States Environmental Protection Agency (EPA) reported 31,400 tons of PWM, with only 8% recycled, 14.4% combusted with energy recovery, and the remaining were landfilled [1]. In 2018, the EPA reported 35,680 tons of PWM, with 8.66% recycled, 15.8% combusted, and the remaining landfilled (75.6%) [1]. These high-tonnage quantities of PWM with low recycling percentages are not only occurring in the US but worldwide. In Australia, in 2016–2017, over 3.5 million tons of PWM were produced, with 11.8% recycled [2]. In China, over 30 million tons of PWM per year are being produced recently, with 30% recycled [3,4]. In Europe, 60 million tons of PWM are produced yearly, with only 30% recycled [5,6]. In 2010, 275 million metric tons of PWM were produced in 192 coastal countries, with 12.7 million tons of PWM thrown into the oceans, which destroyed hundreds of thousands of sea creatures and animals [7]. In addition, landfilling PWM pollutes the soil due to the microplastic effects [8] and pollutes drinking water [9]. This means that landfills cannot be considered the endpoint of the PWM. In 2018–2019, China and India banned importing PWM from Western nations to tackle the PWM crisis [10].

In 2018, the EPA reported that US landfills received 27 million tons of PWM, mostly from polyethylene terephthalate (PET) and high-density polyethylene (HDPE) [1]. Recycling PET and HDPE have attracted more interest recently from asphalt researchers due to mitigating this environmental crisis and reducing life cycle costs (LCC). In 2022, Yao et al. reported a 29% reduction in greenhouse gas (GHG) emissions and 26.2% reduction in the LCC when recycled plastic was used in pavements [1,11], and a similar study reported 20% cost savings [11].

Agencies are reluctant to use recycling materials in general in asphalt binders until it is proven that they do not compromise asphalt mixture performance but enhance it [12]. Numerous studies have investigated the utilization of different waste polymers in road applications [13,14,15,16,17,18,19,20]. However, there remains a gap in comprehensively understanding the performance of asphalt pavement incorporating PWM at different dosages and types.

HDPE was introduced in asphalt mixtures utilizing the wet process by adding HDPE gradually to the virgin asphalt binder and blending them together using a high-shear mixer [21]. HDPE was reported to enhance rutting, stiffness, moisture damage, and fatigue performances when introduced into asphalt mixtures [21,22]. In addition, similar findings for enhancing stiffness, rutting performance, and moisture damage resistance were also reported [23,24]. However, different findings and concerns were reported in terms of fatigue cracking performance, creep recovery [25], and permanent deformation [12]. Moreover, issues of depolymerization when HDPE reacted with asphalt binder were found, such that HDPE absorbs the asphalt binder aromatic components of virgin asphalt binder [26].

Despite the urgent need to solve the PWM crisis, few studies have been conducted on recycling HDPE materials specifically as one of the major components of PWM [1]. As such, recycling HDPE in pavement and investigating its performance is the goal of this study. To achieve this goal, a detailed study of the asphalt binders’ and mixtures’ properties containing HDPE is needed. This study is anticipated to facilitate utilizing recycling HDPE in flexible pavement construction. In doing so, the percentage of recycling PWM would effectively increase, significant monetary and natural resources might be saved, and asphalt pavement sustainability can be developed.

2. Objective and Scope

The objectives of this study are to: (1) evaluate the rheological properties of HDPE-modified asphalt binder in comparison with conventional styrene–butadiene–styrene (SBS)-polymer-modified asphalt binders; (2) evaluate the mechanical performance of asphalt mixtures containing HDPE-modified asphalt binder in comparison with similar mixtures containing SBS-modified asphalt binders; and (3) predict the long-term field performance of the studied mixtures.

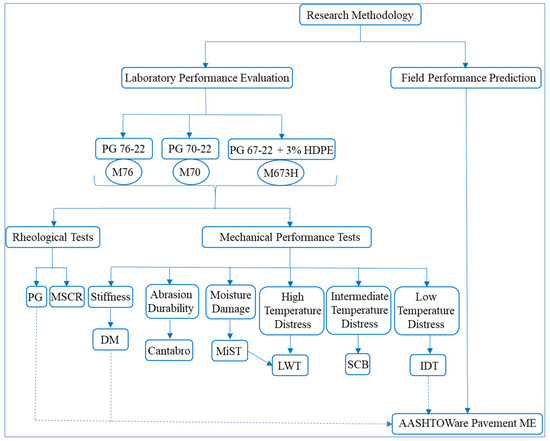

Three 12.5 mm nominal maximum aggregate size (NMAS) Superpave asphalt mixtures were designed to achieve these objectives. Mixtures 1 and 2 include SBS-modified asphalt binders, namely PG 76-22 and PG 70-22 (hereafter referred to as M76 and M70, respectively), specified by the Louisiana Department of Transportation and Development (LaDOTD), respectively [27]. The third asphalt mixture contained PG 67-22 and 3% HDPE by weight of the asphlat binder (hereafter referred to as M673H). Asphalt binders with various modifications were rheologically characterized (Figure 1). Further, a suite of laboratory asphalt mixture mechanical tests were conducted, namely dynamic modulus test for linear viscoelastic properties; semi-circular bend (SCB) test for fracture and fatigue resistance; loaded wheel tracking (LWT) test for rutting resistance; moisture-induced stress tester (MiST) conditioning method was utilized along with LWT for evaluating the moisture susceptibility; indirect tensile (IDT) creep compliance and tensile strength tests for low temperature cracking resistance; and Cantabro abrasion test for durability. AASHTOWare Pavement ME was used to predict the long-term performance of asphalt pavements containing the three mixtures evaluated. Figure 1 presents the research methodology adopted in this study.

Figure 1.

Research methodology. Note: HDPE: high-density polyethylene; PG: performance grading of asphlat binder; MSCR: multiple stress creep recovery test; DM: dynamic modulus; LWT: loaded wheel tracking; SCB: semi-circular bend; IDT: indirect tensile creep compliance and strength; MiST: moisture-induced stress tester.

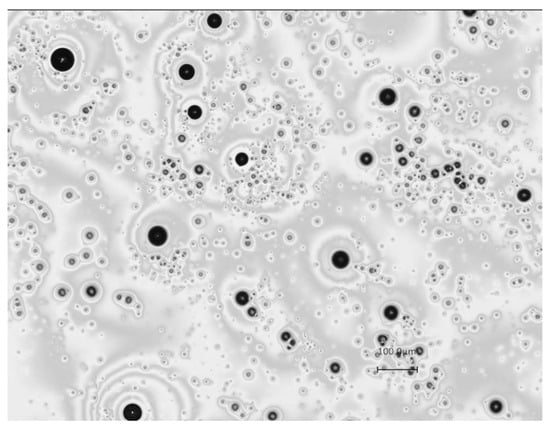

3. Materials

Limestone and coarse natural sand, commonly used in Louisiana, were utilized in this study. Three asphalt binders meeting Louisiana specifications were selected, including PG 76-22 (SBS-modified), PG 70-22 (SBS-modified), and PG 67-22 [27]. The HDPE was utilized as a plastic additive to the unmodified virgin asphalt binder, PG 67-22, and was collected from MilliporeSigma, Inc. (400 Summit Drive, Burlington, MA 01803). The melt flow index of the HDPE is 2.2 g/10 min, and it was added in pellet form to the PG 67-22 unmodified virgin binder. The storage stability test was utilized to assess the optimum dosage rate of HDPE in asphalt binder, according to ASTM D7173 [28] (Standard Practice for Determining the Separation Tendency of Polymer from Polymer-Modified Asphalt). In this test method, about 50 gm of the sample was taken in an aluminum tube and placed in a forced draft oven at 163 °C for 48 h. Then, the tube was stored in the refrigerator for at least 4 h at −18 °C temperature. The tube was then cut into three equal dimensions. The bottom and top portions were utilized for dynamic shear rheometer (DSR) shear modulus testing. It was observed that 3% HDPE produced a stable mix with insignificant changes in shear modulus between top and bottom specimens. ASTM D4124 [29] (Standard Test Method for Separation of Asphalt into Four Fractions) was conducted to determine the asphaltene content of the binder, which was found to be 15.63%. The details of the storage stability results can be found in the literature [30]. A laser scanning confocal microscope (LSCM) was also utilized to map HDPE particle distribution and size within the asphalt binder matrix. A glass vial contained 1 g polymer-modified asphalt binder and 10 mL toluene. The mixture was left for 12 h before a few drops were placed on a microscope cover glass and spin-coated at 500 rpm and 50 ramp for 90 s. The slide holding the sample was heated to 110 °C for 5 min to evaporate the solvent. Keyence (model: VK-x100 series) LSCM with 10× to 100× resolution was used to collect 3D laser and optical images of each sample. In this case, toluene was used to dilute the asphalt binder. LSCM image shows that most of the HDPE particles in binders are less than 100 μm (Figure 2).

Figure 2.

3% HDPE binder in toluene.

Preparation of HDPE-Modified Binder

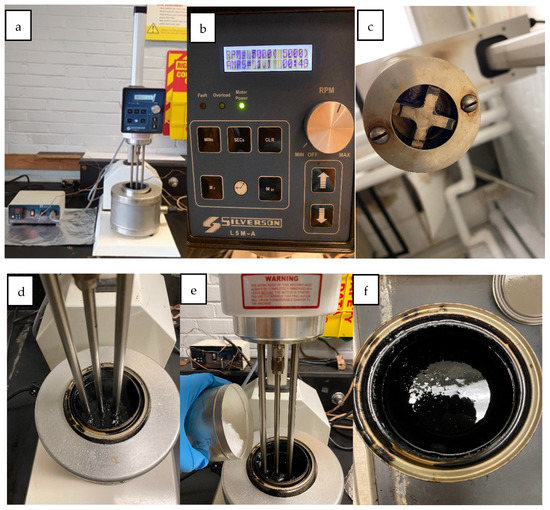

Figure 3 presents the mixing process of HDPE with the unmodified asphalt binder PG 67-22. The process adopted in this paper is based on Rahman et al. [30]. A quart can with 600 ± 20 gm of PG 67-22 asphalt binder was heated for 2 to 2.5 h at 170 °C inside a forced draft oven. The heated quart can was placed inside a melting pot. At this point, the heating of the melting pot as well as the high-shear mixer (Silverson) were turned on. The melting pot was heated for 5 min at 100 °C using a temperature controller, and, for the remaining mixing time, the melting pot was turned off. High-density polyethylene pellets were added gradually (Figure 3) into the neat asphalt binder at 5 min intervals. The addition of the HDPE pellets was completed within the first 28 min. The speed of the high-shear mixer was set at 5000 rpm for the first 28 min and then increased to 8000 rpm for the next 2 min. One third of a dial type thermometer was inserted inside the quart can to monitor the mixing temperature. After completion of 2 min of 8000 rpm mixing, the speed was reset to 5000 rpm for the next two hours. At the beginning, when the quart can was moved from the force draft oven to the melting pot, the temperature dropped but then the temperature would continue to rise and increase to 170 to 180-°C because of high-shear mixing for the first 30 min. Within the next 15 to 30 min, the temperature would go down and remain somewhere between 160 and 170 °C for the rest of the time. If the room temperature is low, or for a lower HDPE dosage, the mixing temperature can be decreased. This reduction in temperature can be resolved by increasing the temperature by turning the heating of the melting pot on for 1 to 2 min.

Figure 3.

Mixer and mixing technique: (a) high-shear mixer integrated with heating mantle; (b) parameter set for mixing; (c) mixer agitator (bottom view); (d) sample placed for mixing; (e) addition of plastic in the asphalt; (f) PMA immediately after mixing.

4. Mixture Design

Three Superpave asphalt mixtures utilizing a nominal maximum aggregate size (NMAS) of 12.5 mm were designed and evaluated in this study. A Louisiana level 2 asphalt mixture design was performed following AASHTO R 35 [31] (Standard Practice for Superpave Volumetric Design for Hot Mix Asphalt (HMA)) and Section 502 of the 2018 Louisiana Standard Specifications for Roads and Bridges [27].

Mixtures 1 (M76) and 2 (M70) included SBS-modified asphalt binders PG 76-22 and PG 70-22, respectively, as specified by LaDOTD [27]. The third asphalt mixture (M673H) contained PG 67-22 and 3% HDPE by weight of the asphalt binder.

Table 1 presents the job mix formula for the three mixtures evaluated. It is noted that the three mixtures are fine-sided, dense-graded, and of similar gradation. The design asphalt binder content was 5.3%.

Table 1.

Asphalt mixture job mix formulas.

5. Testing Methods

Asphalt binders’ high- and intermediate-temperature performance grading, bending beam rheometer (BBR) test, and multiple stress creep recovery (MSCR) test were conducted on the studied modified asphalt binders to characterize the rheological properties. For the asphalt mixtures, Table 2 presents the details of the mechanical tests conducted. All specimens were prepared at an air void level of 7.0 ± 0.5%. Prior to compacting the test specimens, loose mixtures were subjected to short-term aging (165 °C for 2 h in oven). The compacted specimens were then long-term-oven-aged at 85°C for 120 h following AASHTO R30 (Standard Practice for Mixture Conditioning of Hot Mix Asphalt (HMA)) except for LWT and MiST+LWT tests. The LWT and MiST+LWT tests were conducted on specimens with the short-term aging condition.

Table 2.

List of mechanical tests conducted on asphalt mixtures.

6. Laboratory Test Results and Discussion

Statistical analyses of the test results at a significance level of 0.05 were performed using the analysis of variance (ANOVA) procedure provided by Statistical Analysis System (SAS) 9.4 software [38]. Multiple comparison procedures ranked the mean test results and placed them in groups with letters A, B, C, and so on, representing statistically distinct groups from best to worst. Multiple-letter designations, such as A/B or A/B/C, indicate that the difference in means and performances is not statistically significant within the same letter grouping. The error bars in the figures represent statistical quantification of test results’ variability as defined by standard deviation.

6.1. Asphalt Binder Rheological Tests

6.1.1. Superpave Performance Grading (PG)

The asphalt binders considered in this study were graded according to AASHTO M320 [39] (Standard Specification for Performance-Graded Asphalt Binder), Table 3. All three asphalt binders evaluated met the rotational viscosity requirements of 3.0 Pa·s. The HDPE-modified asphalt binder possessed similar viscosity to the conventional SBS-modified asphalt binder PG 70-22. The higher temperature grade of an asphalt binder is associated with greater resistance to permanent deformation. Adding HDPE PWM to PG 67-22 base asphalt binder enhanced the permanent deformation resistance to be greater than that of PG 70-22 and comparable to that of PG 76-22.

Table 3.

Performance grading results.

The lower temperature grade of an asphalt binder is associated with greater resistance to low-temperature cracking. Adding HDPE PWM to PG 67-22 base asphalt binder enhanced the low-temperature cracking resistance to be greater than that of PG 70-22 and comparable to that of PG 76-22 (Table 3).

Differential temperature (ΔTc) represents the difference between critical temperatures calculated from asphalt binder creep stiffness and m-value. Research has shown that more negative values of ΔTc appear to be strongly correlated to fatigue cracking and other distresses related to poor relaxation properties [40]. Adding HDPE to asphalt binder PG 67-22 of M673H enhanced ΔTc as compared to asphalt binder PG 70-22. Further, this parameter is approaching the one of PG76-22, indicating improvement in low-temperature cracking.

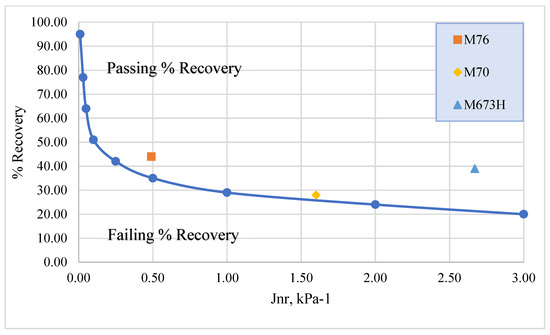

6.1.2. Multiple Stress Creep Recovery (MSCR)

The multiple stress creep recovery test was performed according to AASHTO T 350 [41] (Standard Method of Test for Multiple Stress Creep Recovery Test of Asphalt Binder Using a Dynamic Shear Rheometer). Figure 4 presents the asphalt binder percent recovery (elasticity) versus non-recoverable creep compliance (Jnr). Asphalt binders above the curves are considered to pass the required elastic recovery; asphalt binders below it are considered to fail. The percent recovery of asphalt binder PG 67-22 with 3% HDPE is comparable to that of PG 76-22. These results are consistent with the ΔTc parameters.

Figure 4.

MSCR curve.

6.2. Asphalt Mixture Mechanical Tests

6.2.1. Stiffness

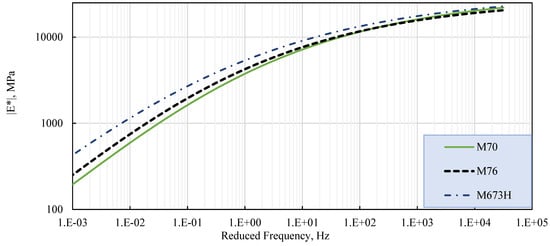

Figure 5 presents the dynamic modulus master curves of mixtures evaluated at a reference temperature of 21.1 °C using the time–temperature superposition principle. Mixture M673H, containing HDPE PWM, showed higher stiffness than conventional mixtures M70 and M76. Similar findings were reported by Wu and Montalvo [12].

Figure 5.

Dynamic modulus master curves.

6.2.2. Permanent Deformation

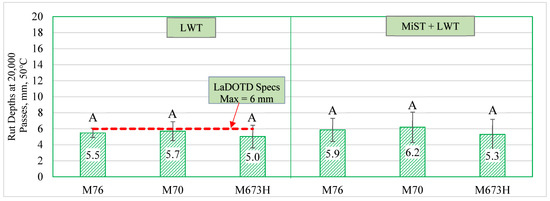

Figure 6 presents LWT rut depths at 20,000 passes for the mixtures evaluated. The coefficient of variation (CoV) of the rut depth varied between 11% and 25%, with an overall average of 16%. It can be seen that the mixture containing HDPE with binder PG 67-22 (M673H) achieved comparable rutting resistance to the conventional mixtures (M70 and M76) and passed the threshold of maximum 6 mm specified by LaDOTD for level 2 traffic (ESALs > 3 million).

Figure 6.

LWT (and MiST) rutting depths.

6.2.3. Moisture Damage

Figure 6 also illustrates the rut depths for the samples tested subsequent to conditioning using the moisture-induced stress tester (MiST). The average CoV of the rut depth is 25%. Mixture M673H exhibited lower rut depths than the other mixtures studied after MiST moisture conditioning. This suggests that the addition of HDPE PWM to M673H resulted in improved moisture resistance compared to mixtures M70 and M76.

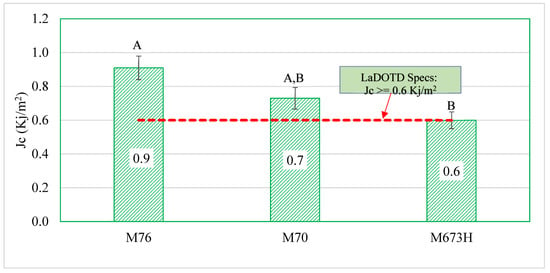

6.2.4. Fracture and Fatigue Resistance

The semi-circular bend (SCB) test was conducted according to ASTM D8044 [35] (Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance Using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures). Figure 7 presents the SCB critical strain energy release rates (Jc) results for the mixtures evaluated. The averaged CoV for the strain energy (per unit thickness) ranged from 9% to 21%, with an overall average of 15.6% for the mixtures evaluated. A higher Jc is desired for intermediate temperature crack resistance mixtures. All the mixtures met the Jc threshold specified by LaDOTD of 0.6 Kj/m2 [27]. Mixture M76 exhibited a significant crack resistance Jc parameter, followed by mixtures M70 and M673H. It is noted that mixture M673H that contains HDPE PWM possessed a comparable crack resistance Jc parameter as compared to M70 and marginal as compared to M76.

Figure 7.

SCB test results—Jc values.

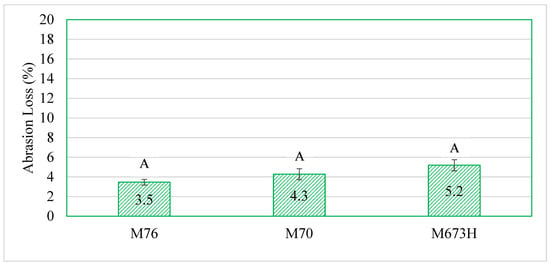

6.2.5. Durability

This test was conducted according to Tex-245-F [36] (Test Procedure for Cantabro Test). Figure 8 shows the Cantabro test results for the mixtures evaluated. This test evaluates the resistance of asphalt mixtures to abrasion by mechanical force. Compacted asphalt mixtures are subjected to 300 revolutions inside a drum of the Los Angeles abrasion device. The original compacted sample weight and final weight at the end of the test are measured and used to compute percent abrasion loss. Lower percent abrasion loss is associated with durable asphalt mixtures. A 20% abrasion loss is typically specified [42]. Overall, all the mixtures performed admirably in the test, with a maximum abrasion loss of only 5.2%. The inclusion of HDPE PWM in mixture M673H did not negatively impact its durability.

Figure 8.

Cantabro test results—percent abrasion loss.

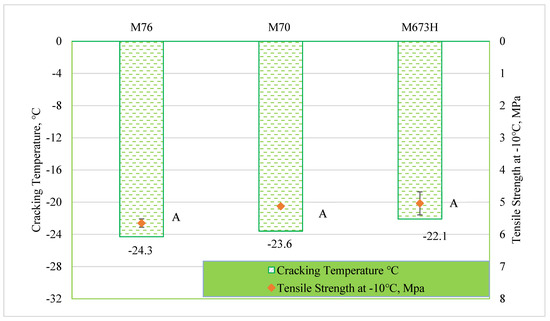

6.2.6. Low-Temperature Cracking

Indirect tensile creep compliance and strength tests (IDT) were conducted for asphalt mixtures considered to ascertain the resistance to low-temperature cracking. Creep compliances and effective cracking temperatures were analyzed using the LTSTRESS MS Excel™ spreadsheet developed under the Strategic Highway Research Program (SHRP)—NCHRP report 530 [43,44]. Figure 9 presents the IDT strength and critical cracking temperatures. Mixture M76 achieved higher numerical resistance to low-temperature cracking than M70 and M673H. However, this difference was not statistically significant. Thus, the addition of HDPE PWM in mixture M673H did not yield an adverse low-temperature cracking performance.

Figure 9.

IDT—cracking temperature and tensile strength.

7. Field Performance Prediction

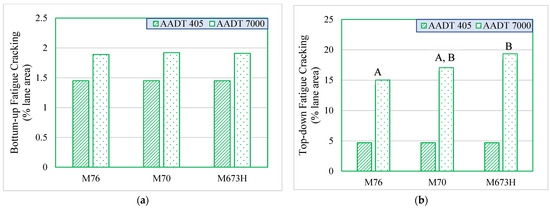

AASHTOWare Pavement Mechanistic–Empirical (ME) software (v.1.1.6) was used to predict the long-term field cracking performance of a pavement structure containing the mixtures evaluated. A pavement structure that was constructed at route LA 1077 in Louisiana was selected in the analysis to predict the field performance of the mixtures evaluated. Pertinent design information for this route can be found elsewhere [45]. The pavement structure consisted of 2 inches wearing course (12 mm NMAS with PG 76-22), 2 inches binder course (3/4 NMAS with PG 70-22), 12 inches of cement-treated base, and a subgrade [46]. This route was subjected to average annual daily truck (AADT) of 405 (equivalent to 1.48 million ESALs). The climate station was selected based on the location of the identified field project. The analysis was conducted for a 20-year design period. Two traffic levels were selected for analysis: the initial two ways AADT of 405 (equivalent to 1.48 million ESALs), which is the same as in the field, and AADT of 7000 (equivalent to 25.6 million-ESALs) [47] as a high-level of traffic loading. Both traffic levels have a growth rate of 2.1%. level 1 analysis was used for the wearing course layer, asphalt binder, and asphalt mixture, and level 2 analysis was used for the other layers. The simulations contained six runs: three wearing course mixtures (mixtures evaluated in this study) and two traffic levels. For each run, the inputs for the wearing course layer varied depending on the asphalt binder and asphalt mixture that were selected for analysis (M76, M70, or M673H), and the inputs for the other layer were kept consistent. Laboratory-measured asphalt binder complex shear modulus and mixture dynamic modulus for each mixture were used as material inputs for the wearing course. The asphalt concrete bottom-up and top-down fatigue cracking (% lane area) were predicted for each run.

Figure 10 presents the (a) bottom-up and (b) top-down fatigue cracking results obtained from the Pavement ME simulations. For each travel level, bottom-up fatigue cracking was similar for the three structures considered (Figure 10a). However, the pavement structure containing M673H in the wearing course layer showed higher predicted top-down fatigue cracking than the one containing M76 at the higher traffic level (Figure 10b). It is noteworthy that the pavement structure with the wearing course layer of M673H showed statistically comparable top-down fatigue cracking to the pavement structure containing M70.

Figure 10.

(a) Bottom-up and (b) top-down fatigue cracking under different traffic loading levels.

8. Conclusions

This study compared the rheological and mechanical properties of asphalt mixtures containing HDPE PWM to similar conventional asphalt mixtures containing styrene–butadiene–styrene-modified asphalt binders PG 76-22 and PG70-22. Based on the experimental results and structural analysis, the following conclusions were drawn:

- Asphalt binder modified with HDPE PWM graded as PG 70-22 exhibited similar rheological properties as SBS-modified PG 70-22 asphalt binder.

- Asphalt mixture M673H containing HDPE PWM achieved higher stiffness than conventional mixtures M76 and M70. For permanent deformation, M673H achieved comparable rutting resistance to the conventional mixtures (M70 and M76) and complied with the threshold of maximum 6 mm specified by LaDOTD for level 2 traffic (ESALs > 3 million). Incorporating HDPE PWM to mixture M673H resulted in further moisture resistance improvement as compared to mixtures M70 and M76.

- Asphalt mixture M673H that contains HDPE PWM possessed a comparable crack resistance Jc parameter as compared to M70 and marginal as compared to M76.

- According to the predicted long-term field cracking performance results obtained from AASHTOWare Pavement ME software (v.1.1.6), the pavement structure containing the wearing course layer of M673H showed statistically similar cracking resistance as the one in pavement structure containing M70.

Author Contributions

The authors confirm their contribution to the paper as follows: study conception and design: L.N.M., I.E. and J.L.; data collection and analysis: I.E., N.W. and S.B.C.J.; results interpretation: I.E., J.L., L.N.M. and S.B.C.III; draft manuscript preparation: I.E., J.L., L.N.M. and S.B.C.III. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Louisiana DOTD and FHWA.

Acknowledgments

The authors acknowledge financial support of the Louisiana DOTD and FHWA for this study. The authors would like to express their gratitude to the Louisiana Transportation Research Center for their support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United States Environmental Protection Agency. Plastics: Material-Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/plastics-material-specific-data (accessed on 1 February 2023).

- Chin, C.; Damen, P. Viability of Using Recycled Plastics in Asphalt and Sprayed Sealing Applications; ARRB Group Limited: Victoria, Australia, 2019. [Google Scholar]

- Chen, Y.; Cui, Z.; Cui, X.; Liu, W.; Wang, X.; Li, X.; Li, S. Life cycle assessment of end-of-life treatments of waste plastics in China. Resour. Conserv. Recycl. 2019, 146, 348–357. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef] [PubMed]

- Leal Filho, W.; Saari, U.; Fedoruk, M.; Iital, A.; Moora, H.; Klöga, M.; Voronova, V. An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558. [Google Scholar] [CrossRef]

- Euronews.green. Europe Has a Plastic Problem, Only 30% of Plastic Waste Is Recycled. Available online: https://www.euronews.com/green/2019/12/12/europe-has-a-plastic-problem-only-30-of-plastic-waste-is-recycled#:~:text=Europe%20produces%2060%20million%20tons,management%20differs%20among%20European%20countries. (accessed on 1 February 2023).

- Bahl, S.; Dolma, J.; Singh, J.J.; Sehgal, S. Biodegradation of plastics: A state of the art review. Mater. Today Proc. 2021, 39, 31–34. [Google Scholar] [CrossRef]

- He, P.; Chen, L.; Shao, L.; Zhang, H.; Lü, F. Municipal solid waste (MSW) landfill: A source of microplastics?-Evidence of microplastics in landfill leachate. Water Res. 2019, 159, 38–45. [Google Scholar] [CrossRef]

- Hwang, J.; Choi, D.; Han, S.; Choi, J.; Hong, J. An assessment of the toxicity of polypropylene microplastics in human derived cells. Sci. Total Environ. 2019, 684, 657–669. [Google Scholar] [CrossRef] [PubMed]

- INDEPENDENT. India Bans Imports of Waste Plastic to Tackle Environmental Crisis. Available online: https://www.independent.co.uk/climate-change/news/india-plastic-waste-ban-recycling-uk-china-a8811696.html (accessed on 1 February 2023).

- El-Naga, I.A.; Ragab, M. Benefits of utilization the recycle polyethylene terephthalate waste plastic materials as a modifier to asphalt mixtures. Constr. Build. Mater. 2019, 219, 81–90. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Costa, L.M.; Silva, H.M.; Oliveira, J.R.; Fernandes, S.R. Incorporation of waste plastic in asphalt binders to improve their performance in the pavement. Int. J. Pavement Res. Technol. 2013, 6, 457–464. [Google Scholar]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Poulikakos, L.D. High and low temperature performance of polyethylene waste plastic modified low noise asphalt mixtures. Constr. Build. Mater. 2022, 348, 128633. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- Punith, V.; Veeraragavan, A. Behavior of reclaimed polyethylene modified asphalt cement for paving purposes. J. Mater. Civ. Eng. 2011, 23, 833–845. [Google Scholar] [CrossRef]

- Viscione, N.; Veropalumbo, R.; Oreto, C.; Biancardo, S.A.; Abbondati, F.; Russo, F. Additional procedures for characterizing the performance of recycled polymer modified asphalt mixtures. Measurement 2022, 187, 110238. [Google Scholar] [CrossRef]

- Hınıslıoğlu, S.; Ağar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Melbouci, B.; Sadoun, S.; Bilek, A. Study of strengthening of recycled asphalt concrete by plastic aggregates. Int. J. Pavement Res. Technol. 2014, 7, 280. [Google Scholar]

- Costa, L.M.; Silva, H.M.; Peralta, J.; Oliveira, J.R. Using waste polymers as a reliable alternative for asphalt binder modification–Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Arabani, M.; Pedram, M. Laboratory investigation of rutting and fatigue in glassphalt containing waste plastic bottles. Constr. Build. Mater. 2016, 116, 378–383. [Google Scholar] [CrossRef]

- Louisiana Department of Transportation and Development. Louisiana Standard Specifications for Roads and Bridges; Louisiana Department of Transportation and Development: Baton Rouge, LA, USA, 2016. [Google Scholar]

- ASTM D 7173; Standard Practice for Determining the Separation Tendency of Polymer from Polymer-Modified Asphalt. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM D 4124; Standard Test Method for Separation of Asphalt into Four Fractions. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- Rahman, S.; Hossain, R.; Wasiuddin, N.; Peters, A. Understanding Phase Separation, Aging Characteristics and SARA Fractions of HDPE, LDPE, and PP Modified Asphalt Binder. In Proceedings of the TRB 101st Annual Meeting, Washington, DC, USA, 9–13 January 2001. [Google Scholar]

- AASHTO R-35; Standard Practice for Superpave Volumetric Design for Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T-342; Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T-324; Standard method of test for Hamburg wheel-track testing of compacted hot mix asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- ASTM D 7870; Standard Practice for Moisture Conditioning Compacted Asphalt Mixture Specimens by Using Hydrostatic Pore Pressure. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM D 8044; Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Tex-245-F; Test Procedure for CANTABRO LOSS. 2021. Available online: https://ftp.dot.state.tx.us/pub/txdot-info/cst/TMS/200-F_series/pdfs/bit245.pdf (accessed on 12 February 2023).

- AASHTO T-322; Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA) Using the Indirect Tensile Test Device. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007.

- SAS Institute. Base SAS 9.4 Procedures Guide: Statistical Procedures; SAS Institute: Cary, NC, USA, 2017. [Google Scholar]

- AASHTO M320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Baumgardner, G. Delta Tc Binder Specification Parameter; Federal Highway Administration: Washington, DC, USA, 2021. [Google Scholar]

- AASHTO T 350; Standard Method of Test for Multiple Stress Creep Recovery Test of Asphalt Binder Using a Dynamic Shear Rheometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Doyle, J.D.; Howard, I.L. Characterization of dense-graded asphalt with the Cantabro test. J. Test. Eval. 2016, 44, 77–88. [Google Scholar] [CrossRef]

- Bennert, T.; Maher, A. Forensic study on the cracking of New Jersey’s long-term pavement performance specific pavement study sections. Transp. Res. Rec. 2013, 2371, 74–86. [Google Scholar] [CrossRef]

- Christensen, D. Analysis of creep data from indirect tension test on asphalt concrete. J. Assoc. Asph. Paving Technol. 1998, 67, 458–492. [Google Scholar]

- Elnaml, I.; Mousa, M.; Hassan, M.M.; Idris, I.; Mohammad, L. Development of Cost-Effective High-Modulus Asphalt Concrete Mixtures Using Crumb Rubber and Local Construction Materials in Louisiana. Transp. Res. Rec. 2022, 2676, 274–286. [Google Scholar] [CrossRef]

- Wu, Z.; Xiao, D.X. Development of DARWin-ME Design Guideline for Louisiana Pavement Design; Final Report No. FHWA/LA. 11/551; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2016. [Google Scholar]

- Elnaml, I.; Liu, J.; Mohammad, L.N.; Cooper, S.B., III; Cooper, S.B., Jr. Use of the Iron Chloride Type of Lewis Acid Catalyst in High Reclaimed Asphalt Pavement Content Asphalt Mixtures. Transp. Res. Rec. 2023. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).