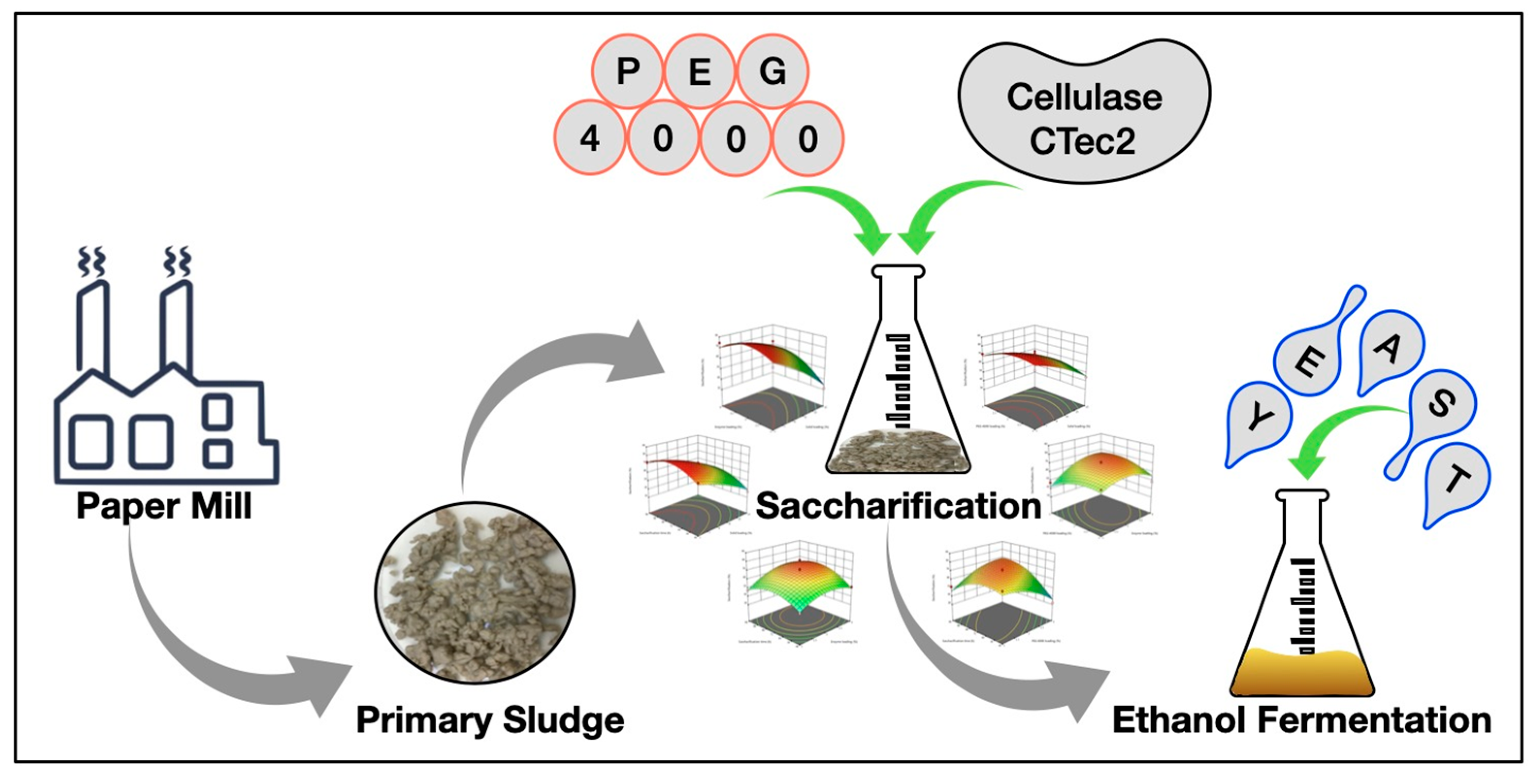

Box–Behnken Design-Based Optimization of the Saccharification of Primary Paper-Mill Sludge as a Renewable Raw Material for Bioethanol Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate, Enzymes, and Chemicals

2.2. Microorganisms

2.3. Substrate (DPS) Composition

2.4. Enzyme Assay

2.5. Effect of Surfactant and Enzymatic Saccharification

2.6. Saccharification

2.7. BBD-Based Statistical Analysis

2.8. Model Validation

2.9. Yeast Propagation and Ethanol Fermentation

3. Results and Discussion

3.1. Compositional Analysis

3.2. Enzymatic Saccharification

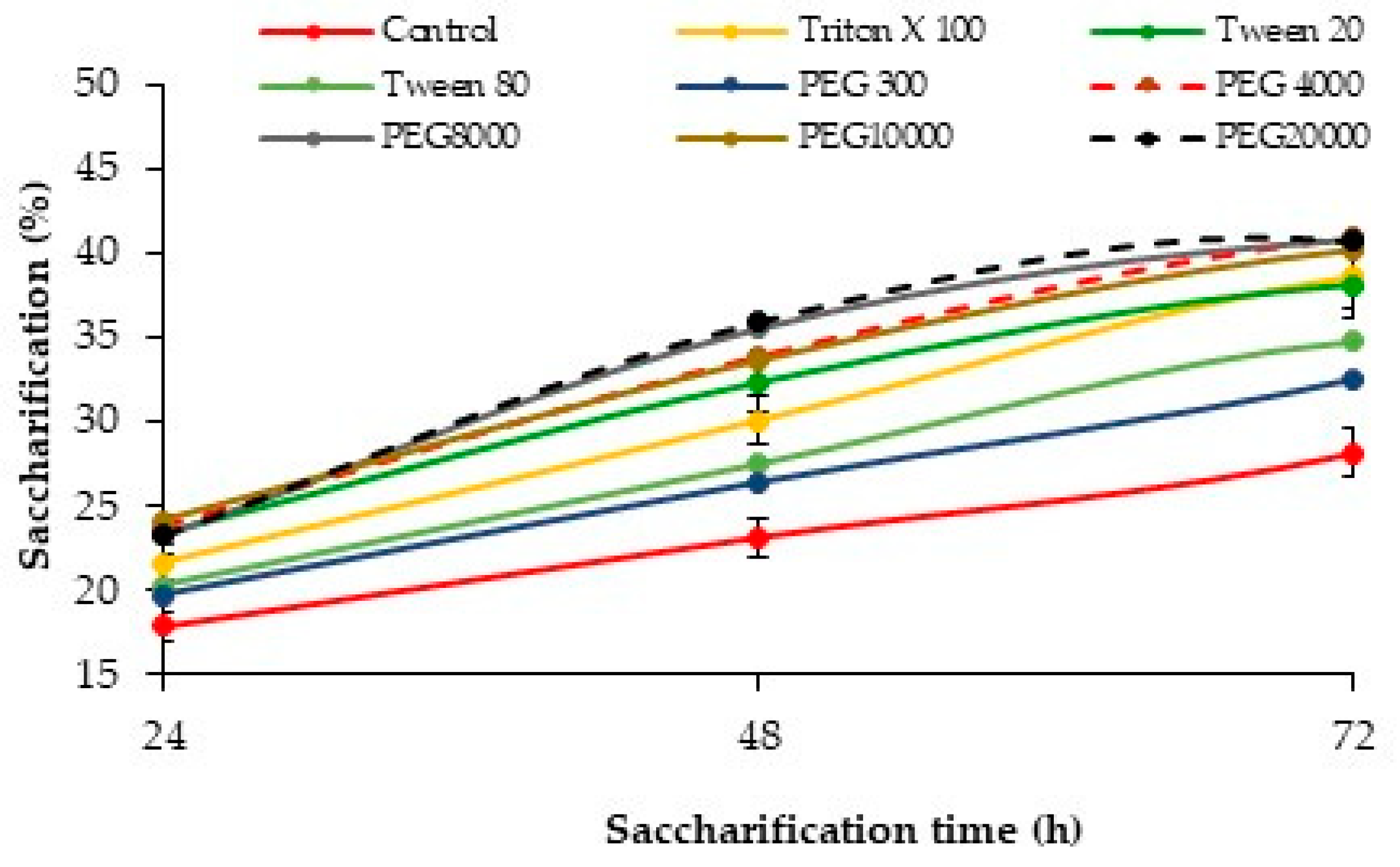

3.2.1. Effect of Non-Ionic Surfactants

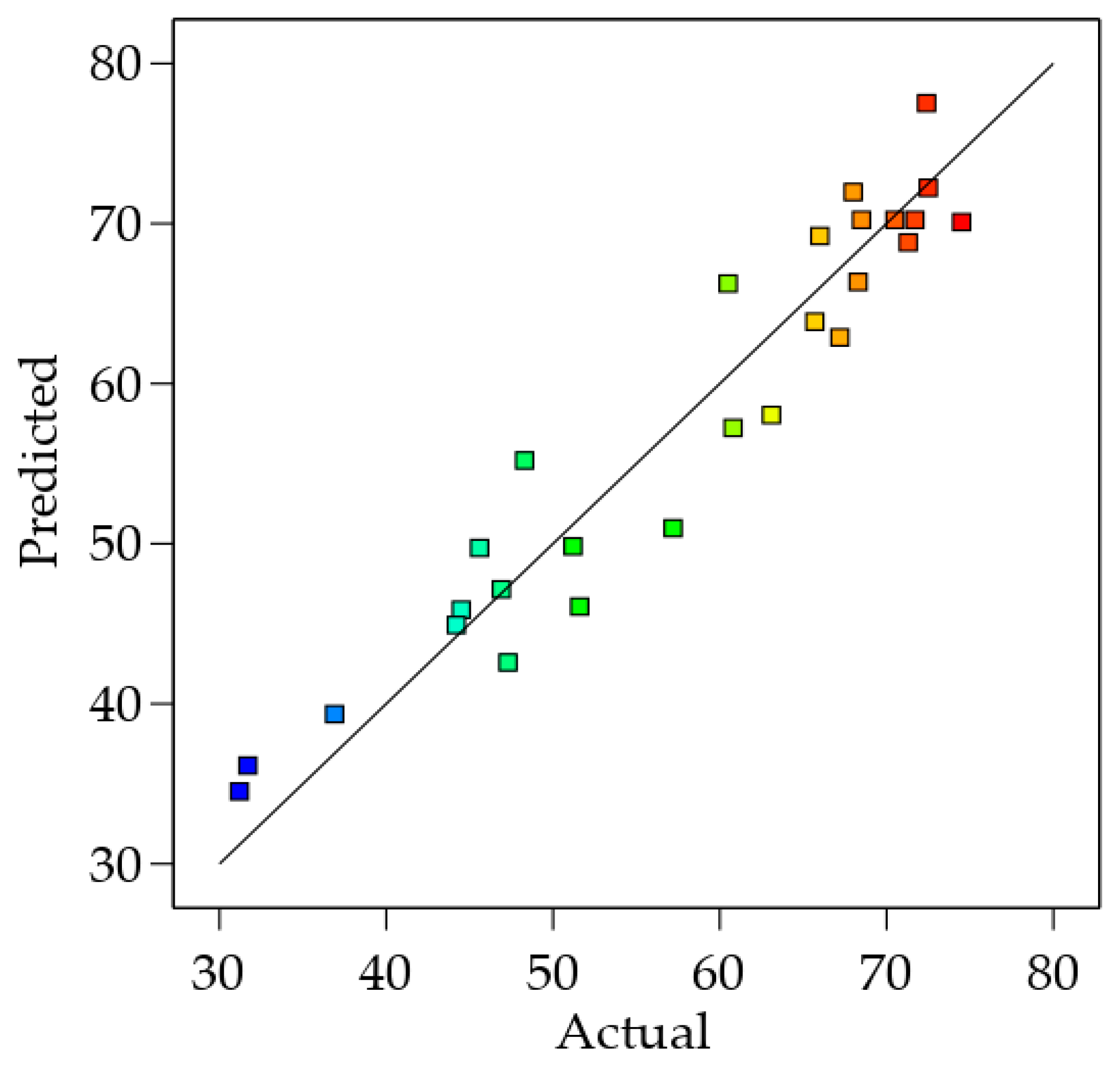

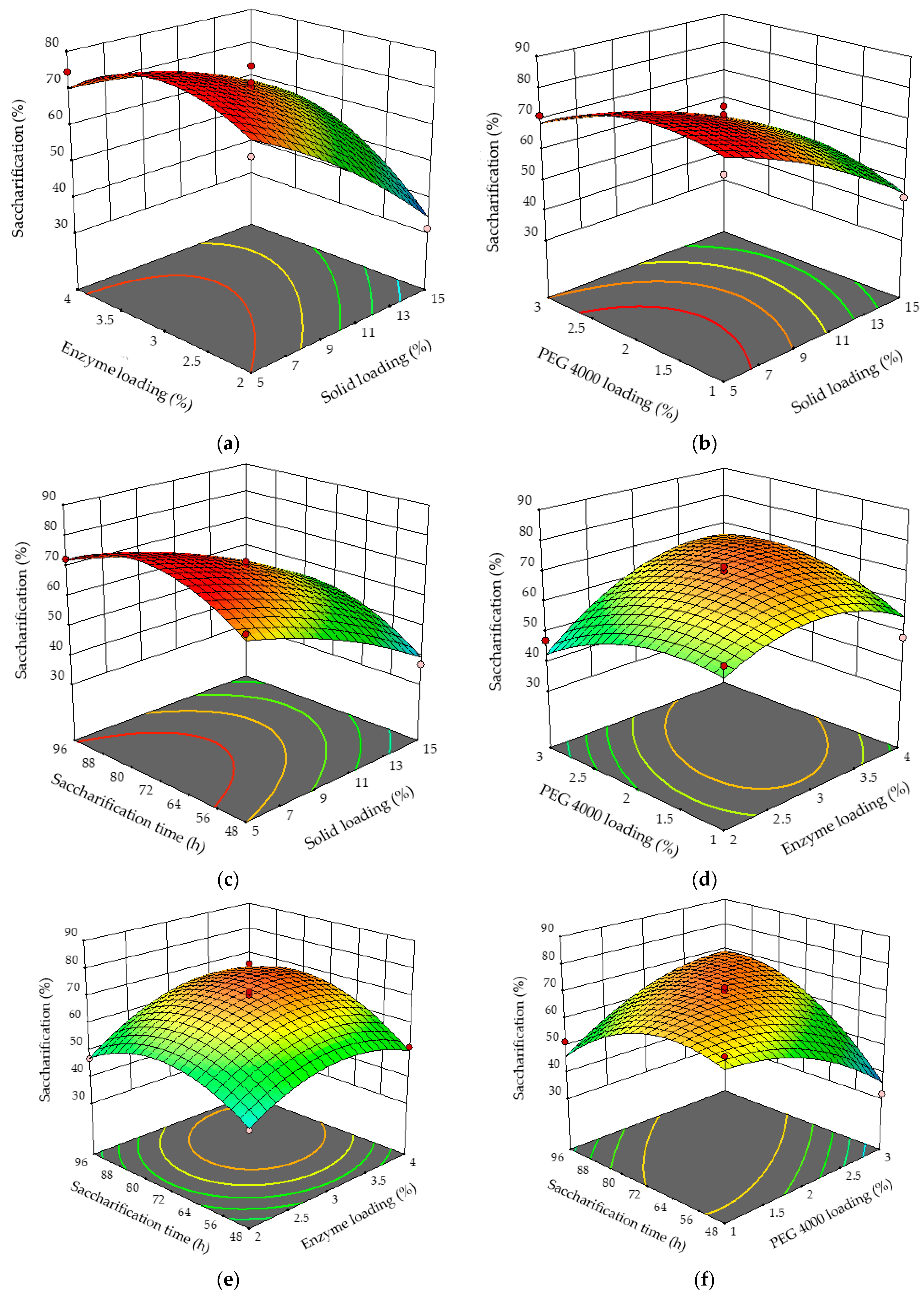

3.2.2. Box–Behnken Design

3.2.3. Model Validation

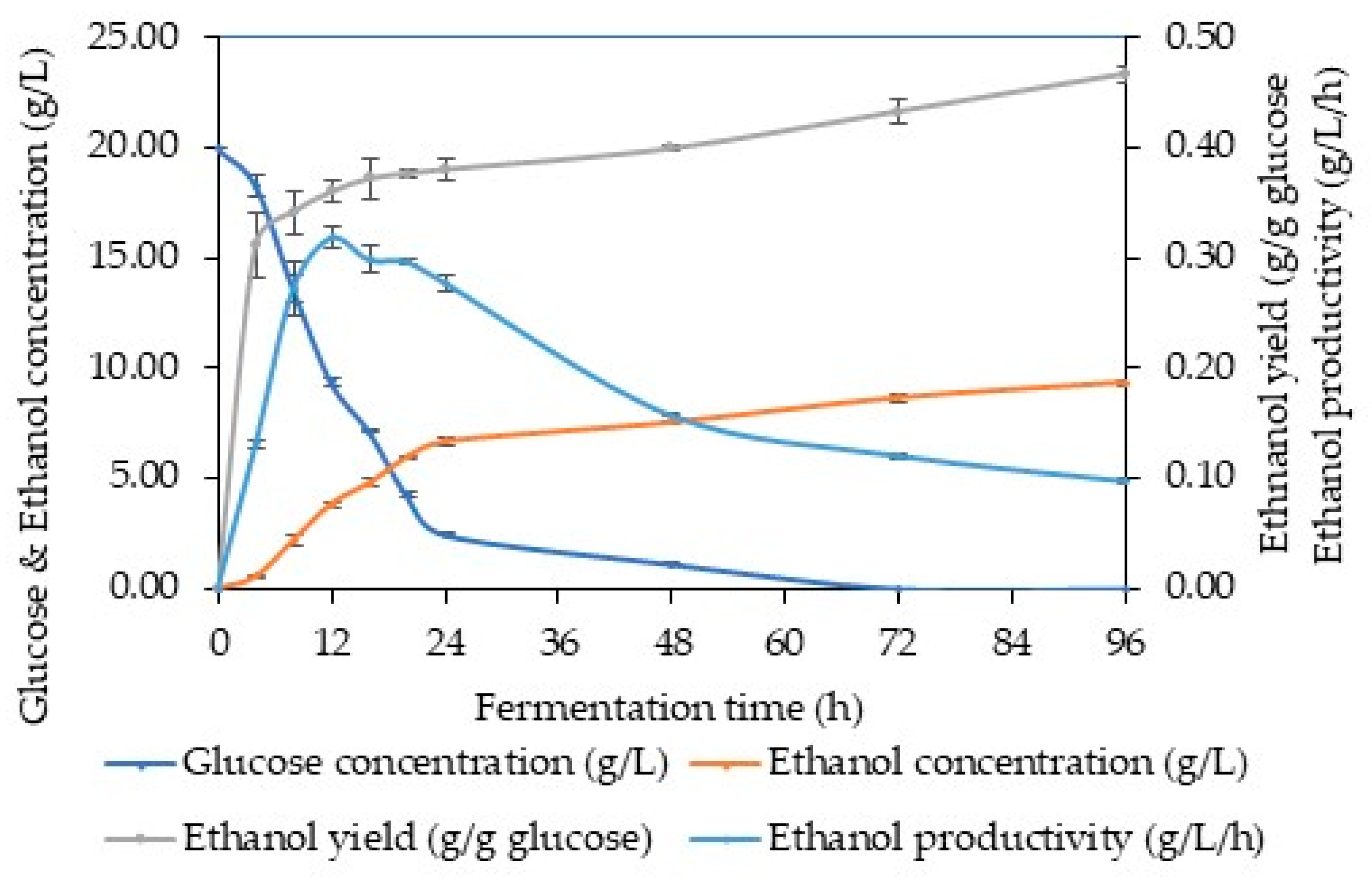

3.3. Ethanol Fermentation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anwar, Z.; Gulfraz, M.; Irshad, M. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Sassi, M.; Galarza, M.X.L. Biofuels and Food Security Future Challenges and Opportunities. Energy-Agro-Food Nexus East Africa 2016, 1, 49–65. [Google Scholar]

- Future Business Insights. The Global Pulp and Paper Market Is Projected to Grow from $354.39 Billion in 2022 to $372.70 Billion by 2029, at a CAGR of 0.72% in Forecast Period 2022–2029; Future Business Insights: Pune, India, 2022. [Google Scholar]

- Statistica. Global Pulp Industry—Statistics & Facts; Statistica: Hamburg, Germany, 2023. [Google Scholar]

- Ramos, M.D.N.; Rangel, A.S.; Azevedo, K.S.; Melo, M.G.B.; Oliveira, M.C.; Watanabe, C.M.U.; Pereira, F.F.; Silva, C.M.; Aguiar, A. Characteristics and treatment of Brazilian pulp and paper mill effluents: A review. Environ. Monit. Assess. 2022, 194, 651. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, P. Generation of Waste in Pulp and Paper Mills. In Management of Pulp and Paper Mill Waste; Springer International Publishing: Cham, Switzerland, 2015; pp. 9–17. [Google Scholar]

- Kang, L.; Wang, W.; Lee, Y.Y. Bioconversion of kraft paper mill sludges to ethanol by SSF and SSCF. Appl. Biochem. Biotechnol. 2010, 161, 53–66. [Google Scholar] [CrossRef] [PubMed]

- MOEF. Tehnical EIA Guidance Manual for Pulp and Paper Industries; MOEF: Hyderabad, India, 2010. [Google Scholar]

- Salam, M.; Pondith, P.C.; Islam, A.; Khan, M.R.; Uddin, M.R.; Islam, M. Conversion of Cellulosic waste into fermentable sugar: Process optimization. J. Chem. Eng. 2014, 28, 27–31. [Google Scholar] [CrossRef]

- Palmqvist, E. Fermentation of Lignocellulosic Hydrolysates: Inhibition and Detoxification. Master’s Thesis, Lund University, Lund, Sweden, 1998. [Google Scholar]

- Biswas, R.; Uellendahl, H.; Ahring, B.K. Conversion of C6 and C5 sugars in undetoxified wet exploded bagasse hydrolysates using Scheffersomyces (Pichia) stipitis CBS6054. AMB Express 2013, 3, 42. [Google Scholar] [CrossRef]

- Zambare, V.P.; Bhalla, A.; Muthukumarappan, K.; Sani, R.K.; Christopher, L.P. Bioprocessing of agricultural residues to ethanol utilizing a cellulolytic extremophile. Extremophiles 2011, 15, 611–618. [Google Scholar] [CrossRef]

- Birgen, C.; Dürre, P.; Preisig, H.A.; Wentzel, A. Butanol production from lignocellulosic biomass: Revisiting fermentation performance indicators with exploratory data analysis. Biotechnol. Biofuels 2019, 12, 167. [Google Scholar] [CrossRef]

- Torres-Mayanga, P.C.; Lachos-Perez, D.; Mudhoo, A.; Kumar, S.; Brown, A.B.; Tyufekchiev, M.; Dragone, G.; Mussatto, S.I.; Rostagno, M.A.; Timko, M.; et al. Production of biofuel precursors and value-added chemicals from hydrolysates resulting from hydrothermal processing of biomass: A review. Biomass Bioenergy 2019, 130, 105397. [Google Scholar] [CrossRef]

- Cesário, M.T.; Raposo, R.S.; de Almeida, M.C.M.D.; van Keulen, F.; Ferreira, B.S.; da Fonseca, M.M.R. Enhanced bioproduction of poly-3-hydroxybutyrate from wheat straw lignocellulosic hydrolysates. N. Biotechnol. 2014, 31, 104–113. [Google Scholar] [CrossRef]

- Leu, S.-Y.; Zhu, J.Y. Substrate-Related Factors Affecting Enzymatic Saccharification of Lignocelluloses: Our Recent Understanding. BioEnergy Res. 2013, 6, 405–415. [Google Scholar] [CrossRef]

- Bekele Bayu, A.; Abeto Amibo, T.; Beyan, S.M. Process Optimization for Acid Hydrolysis and Characterization of Bioethanol from Leftover Injera Waste by Using Response Surface Methodology: Central Composite Design. Int. J. Anal. Chem. 2022, 2022, 4809589. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.M.S.; Milan, T.M.; Tapia-Blácido, D.R. Using Response Surface Methodology (RSM) to optimize 2G bioethanol production: A review. Biomass Bioenergy 2021, 151, 106166. [Google Scholar] [CrossRef]

- Saleh, A.K.; Abdel-Fattah, Y.R.; Soliman, N.A.; Ibrahim, M.M.; El-Sayed, M.H.; Abd El-Aziz, Z.K.; El-Zawawy, W.K. Box-Behnken design for the optimization of bioethanol production from rice straw and sugarcane bagasse by newly isolated Pichia occidentalis strain AS.2. Energy Environ. 2022, 33, 1613–1635. [Google Scholar] [CrossRef]

- Pradhan, D.; Jaiswal, S.; Jaiswal, A.K. Artificial neural networks in valorization process modeling of lignocellulosic biomass. Biofuels Bioprod. Biorefining 2022, 16, 1849–1868. [Google Scholar] [CrossRef]

- Zambare, V.P.; Zambare, A.V.; Muthukumarappan, K.; Christopher, L.P. Potential of Thermostable Cellulases in the Bioprocessing of Switchgrass To Ethanol. Bioresources 2011, 6, 2004–2020. [Google Scholar] [CrossRef]

- Zambare, V.; Christopher, L. Optimization of enzymatic hydrolysis of corn stover for improved ethanol production. Energy Explor. Exploit. 2012, 30, 193–205. [Google Scholar] [CrossRef]

- Zambare, V.P.; Zambare, A.V.; Barh, D.; Christopher, L.P. Optimization of enzymatic hydrolysis of prairie cordgrass for improved ethanol production. J. Renew. Sustain. Energy 2012, 4, 33118. [Google Scholar] [CrossRef]

- Qi, B.; Chen, X.; Shen, F.; Su, Y.; Wan, Y. Optimization of enzymatic hydrolysis of wheat straw pretreated by alkaline peroxide using response surface methodology. Ind. Eng. Chem. Res. 2009, 48, 7346–7353. [Google Scholar] [CrossRef]

- Bacha, E.G. Response surface methodology modeling, experimental validation, and optimization of acid hydrolysis process parameters for nanocellulose extraction. S. Afr. J. Chem. Eng. 2022, 40, 176–185. [Google Scholar] [CrossRef]

- Sasikumar, E.; Viruthagiri, T. Optimization of process conditions using response surface methodology (RSM) for ethanol production from pretreated sugarcane bagasse: Kinetics and modeling. BioEnergy Res. 2008, 1, 239–247. [Google Scholar] [CrossRef]

- Gurram, R.N.; Al-Shannag, M.; Lecher, N.J.; Duncan, S.M.; Singsaas, E.L.; Alkasrawi, M. Bioconversion of paper mill sludge to bioethanol in the presence of accelerants or hydrogen peroxide pretreatment. Bioresour. Technol. 2015, 192, 529–539. [Google Scholar] [CrossRef] [PubMed]

- Alkasrawi, M.; Al-Othman, A.; Tawalbeh, M.; Doncan, S.; Gurram, R.; Singsaas, E.; Almomani, F.; Al-Asheh, S. A novel technique of paper mill sludge conversion to bioethanol toward sustainable energy production: Effect of fiber recovery on the saccharification hydrolysis and fermentation. Energy 2021, 223, 120018. [Google Scholar] [CrossRef]

- Duncan, S.M.; Alkasrawi, M.; Gurram, R.; Almomani, F.; Wiberley-Bradford, A.E.; Singsaas, E. Paper Mill Sludge as a Source of Sugars for Use in the Production of Bioethanol and Isoprene. Energies 2020, 13, 4662. [Google Scholar] [CrossRef]

- Alkasrawi, M.; Rajangam, A.S.; Tawalbeh, M.; Kafiah, F.; Al-Othman, A.; Al-Asheh, S.; Sun, Q. Techno-economic analysis and a novel assessment technique of paper mill sludge conversion to bioethanol toward sustainable energy production. Int. J. Energy Res. 2020, 44, 12602–12613. [Google Scholar] [CrossRef]

- Zambare, V.P.; Christopher, L.P. Integrated biorefinery approach to utilization of pulp and paper mill sludge for value-added products. J. Clean. Prod. 2020, 274, 122791. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Rajangam, A.S.; Salameh, T.; Al-Othman, A.; Alkasrawi, M. Characterization of paper mill sludge as a renewable feedstock for sustainable hydrogen and biofuels production. Int. J. Hydrogen Energy 2021, 46, 4761–4775. [Google Scholar] [CrossRef]

- Prasetyo, J.; Naruse, K.; Kato, T.; Boonchird, C.; Harashima, S.; Park, E.Y. Bioconversion of paper sludge to biofuel by simultaneous saccharification and fermentation using a cellulase of paper sludge origin and thermotolerant Saccharomyces cerevisiaeTJ14. Biotechnol. Biofuels 2011, 4, 35. [Google Scholar] [CrossRef]

- Yadav, S.; Mohanty, P. Utilization of paper mill sludge as a sustainable source of hydrogen production. Biofuels 2022, 13, 1113–1118. [Google Scholar] [CrossRef]

- Kaur, R.; Tyagi, R.D.; Zhang, X. Review on pulp and paper activated sludge pretreatment, inhibitory effects and detoxification strategies for biovalorization. Environ. Res. 2020, 182, 109094. [Google Scholar] [CrossRef] [PubMed]

- Statista. Leading Pulp for Paper Producing Countries Worldwide in 2021; Statistica: Hamburg, Germany, 2023. [Google Scholar]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Griffiths, S.; Bazilian, M.; Kim, J.; Foley, A.M.; Rooney, D. Decarbonizing the pulp and paper industry: A critical and systematic review of sociotechnical developments and policy options. Renew. Sustain. Energy Rev. 2022, 167, 112706. [Google Scholar] [CrossRef]

- TAPPI Test Methods. Carbohydrate composition of extractive-free wood and wood pulp by gas liquid chromatograph. Tech. Assoc. Pulp Pap. Ind. 1984, T249 cm-85, 1–8. [Google Scholar]

- Alhammad, A.; Adewale, P.; Kuttiraja, M.; Christopher, L.P. Enhancing enzyme-aided production of fermentable sugars from poplar pulp in the presence of non-ionic surfactants. Bioprocess Biosyst. Eng. 2018, 41, 1133–1142. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Kumar, R.; Wyman, C.E. Fast hemicellulose quantification via a simple one-step acid hydrolysis. Biotechnol. Bioeng. 2014, 111, 1088–1096. [Google Scholar] [CrossRef] [PubMed]

- Adney, B.; Baker, J. Measurement of Cellulase Activities Laboratory; National Renewable Energy Laboratory: Golden, CO, USA, 1996; p. 8. [Google Scholar]

- Selig, M.; Weiss, N.; Ji, Y. Enzymatic Saccharification of Lignocellulosic Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Das, S.; Bhattacharya, A.; Haldar, S.; Ganguly, A.; Gu, S.; Ting, Y.P.; Chatterjee, P.K. Optimization of enzymatic saccharification of water hyacinth biomass for bio-ethanol: Comparison between artificial neural network and response surface methodology. Sustain. Mater. Technol. 2015, 3, 17–28. [Google Scholar] [CrossRef]

- Kanno, A.; Reungsang, A.; Imai, T.; Higuchi, T.; Sekine, M.; Yamamoto, K.; Phummala, K. Optimization of enzymatic hydrolysis for pretreated wood waste by response surface methodology in fermentative hydrogen production. J. Water Environ. Technol. 2015, 13, 153–166. [Google Scholar] [CrossRef]

- Pandiyan, K.; Tiwari, R.; Singh, S.; Nain, P.K.S.; Rana, S.; Arora, A.; Singh, S.B.; Nain, L. Optimization of Enzymatic Saccharification of Alkali Pretreated Parthenium sp. Using Response Surface Methodology. Enzyme Res. 2014, 2014, 764898. [Google Scholar] [CrossRef]

- Nag, A.; Sprague, M.A.; Griggs, A.J.; Lischeske, J.J.; Stickel, J.J.; Mittal, A.; Wang, W.; Johnson, D.K. Parameter determination and validation for a mechanistic model of the enzymatic saccharification of cellulose-I β. Biotechnol. Prog. 2015, 31, 1237–1248. [Google Scholar] [CrossRef]

- Ladeira Ázar, R.I.S.; Bordignon-Junior, S.E.; Laufer, C.; Specht, J.; Ferrier, D.; Kim, D. Effect of Lignin Content on Cellulolytic Saccharification of Liquid Hot Water Pretreated Sugarcane Bagasse. Molecules 2020, 25, 623. [Google Scholar] [CrossRef]

- Ying, W.; Shi, Z.; Yang, H.; Xu, G.; Zheng, Z.; Yang, J. Effect of alkaline lignin modification on cellulase–lignin interactions and enzymatic saccharification yield. Biotechnol. Biofuels 2018, 11, 214. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Li, R.; Tang, W.; Zheng, Y.; Meng, X. Improve Enzymatic Hydrolysis of Lignocellulosic Biomass by Modifying Lignin Structure via Sulfite Pretreatment and Using Lignin Blockers. Fermentation 2022, 8, 558. [Google Scholar] [CrossRef]

- Lin, X.; Qiu, X.; Yuan, L.; Li, Z.; Lou, H.; Zhou, M.; Yang, D. Lignin-based polyoxyethylene ether enhanced enzymatic hydrolysis of lignocelluloses by dispersing cellulase aggregates. Bioresour. Technol. 2015, 185, 165–170. [Google Scholar] [CrossRef]

- Chen, Y.-A.; Zhou, Y.; Qin, Y.; Liu, D.; Zhao, X. Evaluation of the action of Tween 20 non-ionic surfactant during enzymatic hydrolysis of lignocellulose: Pretreatment, hydrolysis conditions and lignin structure. Bioresour. Technol. 2018, 269, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xu, X.; Zhang, Y.; Li, J. Effect of adding surfactant for transforming lignocellulose into fermentable sugars during biocatalysing. Biotechnol. Bioprocess Eng. 2011, 16, 930–936. [Google Scholar] [CrossRef]

- Sipos, B.; Dienes, D.; Schleicher, Á.; Perazzini, R.; Crestini, C.; Siika-aho, M.; Réczey, K. Hydrolysis efficiency and enzyme adsorption on steam-pretreated spruce in the presence of poly(ethylene glycol). Enzyme Microb. Technol. 2010, 47, 84–90. [Google Scholar] [CrossRef]

- Gunjikar, T.P.; Sawant, S.B.; Joshi, J.B. Shear deactivation of cellulase, exoglucanase, endoglucanase, and β-glucosidase in a mechanically agitated reactor. Biotechnol. Prog. 2001, 17, 1166–1168. [Google Scholar] [CrossRef]

- Wang, W.; Zhuang, X.; Tan, X.; Wang, Q.; Chen, X.; Yu, Q.; Qi, W.; Wang, Z.; Yuan, Z. Dual effect of nonionic surfactants on improving the enzymatic hydrolysis of lignocellulose. Energy Fuels 2018, 32, 5951–5959. [Google Scholar] [CrossRef]

- Rocha-Martín, J.; Martinez-Bernal, C.; Pérez-Cobas, Y.; Reyes-Sosa, F.M.; García, B.D. Additives enhancing enzymatic hydrolysis of lignocellulosic biomass. Bioresour. Technol. 2017, 244, 48–56. [Google Scholar] [CrossRef]

- Kaar, W.E.; Holtzapple, M.T. Benefits from Tween during enzymic hydrolysis of corn stover. Biotechnol. Bioeng. 1998, 59, 419–427. [Google Scholar] [CrossRef]

- Helle, S.S.; Duff, S.J.B.; Cooper, D.G. Effect of surfactants on cellulose hydrolysis. Biotechnol. Bioeng. 1993, 42, 611–617. [Google Scholar] [CrossRef] [PubMed]

- Abdul Manaf, S.F.; Indera Luthfi, A.A.; Md Jahim, J.; Harun, S.; Tan, J.P.; Mohd Shah, S.S. Sequential detoxification of oil palm fronds hydrolysate with coconut shell activated charcoal and pH controlled in bioreactor for xylitol production. Chem. Eng. Res. Des. 2022, 179, 90–106. [Google Scholar] [CrossRef]

- Gunawan, E.R.; Basri, M.; Rahman, M.B.A.; Salleh, A.B.; Rahman, R.N.Z.A. Study on response surface methodology (RSM) of lipase-catalyzed synthesis of palm-based wax ester. Enzyme Microb. Technol. 2005, 37, 739–744. [Google Scholar] [CrossRef]

- Fang, H.; Zhao, C.; Song, X.Y. Optimization of enzymatic hydrolysis of steam-exploded corn stover by two approaches: Response surface methodology or using cellulase from mixed cultures of Trichoderma reesei RUT-C30 and Aspergillus niger NL02. Bioresour. Technol. 2010, 101, 4111–4119. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; Fan, C.; Zheng, X.; Zhang, W.; Wu, D.; Wang, X.; Kong, H. Optimisation of enzymatic saccharification of wheat straw pre-treated with sodium hydroxide. Sci. Rep. 2021, 11, 23234. [Google Scholar] [CrossRef]

- Portero Barahona, P.; Bastidas Mayorga, B.; Martín-Gil, J.; Martín-Ramos, P.; Carvajal Barriga, E.J. Cellulosic Ethanol: Improving Cost Efficiency by Coupling Semi-Continuous Fermentation and Simultaneous Saccharification Strategies. Processes 2020, 8, 1459. [Google Scholar] [CrossRef]

- Nishimura, H.; Tan, L.; Sun, Z.-Y.; Tang, Y.-Q.; Kida, K.; Morimura, S. Efficient production of ethanol from waste paper and the biochemical methane potential of stillage eluted from ethanol fermentation. Waste Manag. 2016, 48, 644–651. [Google Scholar] [CrossRef]

- Branco, R.; Serafim, L.; Xavier, A. Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock. Fermentation 2018, 5, 4. [Google Scholar] [CrossRef]

| Factors | Name | Units | Low (−1) | High (+1) |

|---|---|---|---|---|

| X1 | Solid loading | % (w/w *) | 5 | 15 |

| X2 | Enzyme loading | % (w/w *) | 2 | 4 |

| X3 | PEG-4000 loading | % (w/w *) | 1 | 3 |

| X4 | Saccharification time | h | 48 | 96 |

| Components | Composition |

|---|---|

| Moisture | 70.5 ± 3.7% (w/wet w) |

| Solids | 29.5 ± 2.6% (w/wet w) |

| Cellulose (Glucan) | 51.0 ± 3.3% (w/w dry solids) |

| Hemicelluloses | 10.6 ± 1.7% (w/w dry solids) |

| Lignin | 11.0 ± 1.7% (w/w dry solids) |

| Ash | 13.9 ± 2.0% (w/w dry solids) |

| Std. Run | Point Type | Actual Factors | Observed Saccharification (%) | Predicted Saccharification (%) | |||

|---|---|---|---|---|---|---|---|

| X1 (%) * | X2 (%) * | X3 (%) * | X4 (h) | ||||

| 1 | Factorial | 5 | 2 | 2 | 72 | 68.0 | 72.0 |

| 2 | Factorial | 15 | 2 | 2 | 72 | 31.2 | 34.5 |

| 3 | Factorial | 5 | 4 | 2 | 72 | 74.5 | 70.1 |

| 4 | Factorial | 15 | 4 | 2 | 72 | 63.1 | 58.0 |

| 5 | Factorial | 10 | 3 | 1 | 48 | 67.2 | 62.9 |

| 6 | Factorial | 10 | 3 | 3 | 48 | 31.7 | 36.1 |

| 7 | Factorial | 10 | 3 | 1 | 96 | 51.6 | 46.1 |

| 8 | Factorial | 10 | 3 | 3 | 96 | 66.0 | 69.2 |

| 9 | Factorial | 5 | 3 | 2 | 48 | 68.3 | 66.4 |

| 10 | Factorial | 15 | 3 | 2 | 48 | 36.9 | 39.4 |

| 11 | Factorial | 5 | 3 | 2 | 96 | 72.5 | 72.2 |

| 12 | Factorial | 15 | 3 | 2 | 96 | 45.6 | 49.8 |

| 13 | Factorial | 10 | 2 | 1 | 72 | 60.8 | 57.2 |

| 14 | Factorial | 10 | 4 | 1 | 72 | 48.3 | 55.2 |

| 15 | Factorial | 10 | 2 | 3 | 72 | 47.3 | 42.6 |

| 16 | Factorial | 10 | 4 | 3 | 72 | 60.5 | 66.3 |

| 17 | Factorial | 5 | 3 | 1 | 72 | 72.4 | 77.5 |

| 18 | Factorial | 15 | 3 | 1 | 72 | 44.5 | 45.9 |

| 19 | Factorial | 5 | 3 | 3 | 72 | 71.3 | 68.9 |

| 20 | Factorial | 15 | 3 | 3 | 72 | 57.2 | 51.0 |

| 21 | Factorial | 10 | 2 | 2 | 48 | 44.2 | 44.9 |

| 22 | Factorial | 10 | 4 | 2 | 48 | 51.2 | 49.9 |

| 23 | Factorial | 10 | 2 | 2 | 96 | 46.9 | 47.2 |

| 24 | Factorial | 10 | 4 | 2 | 96 | 65.7 | 63.9 |

| 25 | Center | 10 | 3 | 2 | 72 | 70.5 | 70.2 |

| 26 | Center | 10 | 3 | 2 | 72 | 68.5 | 70.2 |

| 27 | Center | 10 | 3 | 2 | 72 | 71.7 | 70.2 |

| Source | Sum of Squares | DF | Mean Square | F Value | p-Value (Prob > F) |

|---|---|---|---|---|---|

| Model | 4195.84 | 14 | 299.70 | 9.52 | 0.0002 * |

| X1-Solid loading | 1837.69 | 1 | 1837.69 | 58.37 | <0.0001 * |

| X2-Enzyme loading | 351.00 | 1 | 351.00 | 11.15 | 0.0059 * |

| X3-PEG-4000 loading | 9.72 | 1 | 9.72 | 0.3087 | 0.5887 |

| X4-Saccharification time | 198.45 | 1 | 198.45 | 6.30 | 0.0274 * |

| X1X2 | 161.29 | 1 | 161.29 | 5.12 | 0.0430 * |

| X1X3 | 47.61 | 1 | 47.61 | 1.51 | 0.2424 |

| X1X4 | 5.06 | 1 | 5.06 | 0.1608 | 0.6955 |

| X2X3 | 165.12 | 1 | 165.12 | 5.24 | 0.0409 * |

| X2X4 | 34.81 | 1 | 34.81 | 1.11 | 0.3138 |

| X3X4 | 622.50 | 1 | 622.50 | 19.77 | 0.0008 * |

| X1X1 | 49.61 | 1 | 49.61 | 1.58 | 0.2333 |

| X2X2 | 387.60 | 1 | 387.60 | 12.31 | 0.0043 * |

| X3X3 | 217.60 | 1 | 217.60 | 6.91 | 0.0220 * |

| X4X4 | 561.70 | 1 | 561.70 | 17.84 | 0.0012 * |

| Residual | 377.83 | 12 | 31.49 | ||

| Lack of Fit | 372.60 | 10 | 37.26 | 14.26 | 0.0673 |

| Pure Error | 5.23 | 2 | 2.61 | ||

| Cor Total | 4573.67 | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zambare, V.; Jacob, S.; Din, M.F.M.; Ponraj, M. Box–Behnken Design-Based Optimization of the Saccharification of Primary Paper-Mill Sludge as a Renewable Raw Material for Bioethanol Production. Sustainability 2023, 15, 10740. https://doi.org/10.3390/su151310740

Zambare V, Jacob S, Din MFM, Ponraj M. Box–Behnken Design-Based Optimization of the Saccharification of Primary Paper-Mill Sludge as a Renewable Raw Material for Bioethanol Production. Sustainability. 2023; 15(13):10740. https://doi.org/10.3390/su151310740

Chicago/Turabian StyleZambare, Vasudeo, Samuel Jacob, Mohd Fadhil Md. Din, and Mohanadoss Ponraj. 2023. "Box–Behnken Design-Based Optimization of the Saccharification of Primary Paper-Mill Sludge as a Renewable Raw Material for Bioethanol Production" Sustainability 15, no. 13: 10740. https://doi.org/10.3390/su151310740

APA StyleZambare, V., Jacob, S., Din, M. F. M., & Ponraj, M. (2023). Box–Behnken Design-Based Optimization of the Saccharification of Primary Paper-Mill Sludge as a Renewable Raw Material for Bioethanol Production. Sustainability, 15(13), 10740. https://doi.org/10.3390/su151310740