Abstract

Hunger (811 million people, 2020) and food waste (931 million tonnes annually, 2020) are long-standing interconnected challenges that have plagued humankind for centuries. Food waste originates from various sources, including consumption habits and failures within the food supply chain. Given the growing concerns regarding food insecurity, malnutrition, and hunger, there is a pressing need to recover and repurpose as much food waste as possible. A growing body of knowledge identifies the valorisation (including upcycling) of food waste as one of the strategies to fight hunger by positively impacting food availability and food security. This paper evaluates the potential role of food waste valorisation, including upcycling, in reducing global hunger. A literature search was conducted to examine how converting food waste into value-added products, such as food formulations and farming inputs, can contribute to increasing food availability. The benefits of waste-to-food operations in improving food availability through producing food ingredients and products from materials that would have been wasted or discarded otherwise were discussed.

1. Introduction

The issue of food waste and its impact on global food security has gained significant attention [1]. While the terms “food loss” and “food waste” are sometimes used interchangeably, they refer to different aspects of the same problem. Food loss encompasses the unintentional decline in food quality and quantity during production, harvest, and throughout the supply chain, often due to aesthetic concerns, rendering it unsellable but still safe for consumption. On the other hand, food waste specifically refers to the deliberate disposal of food fit for human consumption [2,3]. End users may discard food for a number of reasons, such as excessive food purchases, delayed consumption/utilisation, and incorrect usage of food date labels [4]. Nevertheless, waste is an inevitable and logical aftereffect of eating or food utilisation, as stated by Evans et al. [5]. Food is known to be prone to spoilage and decay, and can undergo various transformations. Therefore, a variety of contributors, including microorganisms, preservation/processing techniques, packaging, and kitchen appliances, as well as methods of waste treatment, disposal, and management, are involved in the generation of food-derived waste [5].

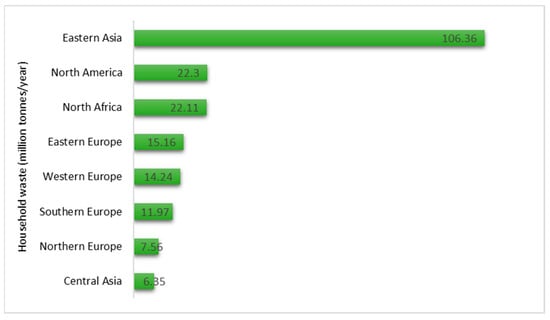

Food waste and losses occur at all stages of the agri-food chain [6], with primary production, post-harvest, and processing accounting for the main losses, while the biggest portion of wasted food originates from retail and consumption [7]. Food waste is primarily generated at the post-harvest and processing stages in underdeveloped nations. Poor practices, limited technology, financial constraints, as well as a lack of adequate infrastructure for storage and transport are the root causes of these losses in low-income countries. In industrialised nations, waste generally arises during the food-consumption stage, with the biggest portion of wasted food attributed to the household (i.e., final consumers). Consumers’ behaviour, values, and attitudes primarily influence waste generation in the developed world. A significant amount of food waste happens during preparation and cooking, as well as when people misinterpret the “use by” and “best before” dates [8,9]. However, the quantification of food loss and waste suffers from significant gaps because unequal attention is paid to different parts of the world and the food supply chain stages. For instance, numerous publications quantify food loss and waste in industrialised countries, while few studies are conducted in low-income nations, and a larger number of studies have focused mainly on food waste generation at retailing and consumer levels [10]. Additionally, the causes of food losses and waste vary along the supply chain, which affects how much waste is produced at each stage [11]. Rao et al. [12] stated that there is no concrete data on the volume of food waste at each stage of the food supply chain due to the widespread distribution of food waste and the existence of numerous methods for quantification [12]. The household sector’s food waste volume was reported in the United Nations Environment Programme’s (UNEP) Food Waste Index Report 2021 (Figure 1).

Figure 1.

Estimated household food waste (in million tonnes per year) in selected regions. Data were obtained from the database of the UNEP Food Waste Index Report 2021 [13].

According to the UNEP Food Waste Index Report 2021, more than 931 million tonnes of food go to waste annually [14]. This is particularly alarming because there are only seven years left to meet the Sustainable Development Goals (SDG), specifically SDG 12.3, aiming for a 50% reduction in food wastage at the retail and consumer stage and a decline in food losses throughout the supply and production chains [15,16]. On the other side of the coin, hunger is on the rise, with millions of people enduring undernourishment and malnutrition in their day-to-day lives [17]. In 2020, 3 billion people could not afford a healthy diet, and up to 811 million individuals faced hunger [18]. Moreover, the demand for food will rise continuously as the global population grows [19]. Reynolds et al. [19] stated that all the avoidable food waste disposed of in Australia (estimated to be 1/3 of all food waste or 2.5 million tonnes) could be rescued to yield 1.8 trillion calories (worth US$ 190 billion), which would be enough to feed 921 thousand individuals for one year [20].

Food loss and waste represent a social and environmental concern that negatively impacts food security. Additionally, economic losses are experienced by all actors along the agri-food supply chain, including consumers. Food loss and waste could negatively impact food availability in markets, raising food prices and significantly reducing the ability of low-income households to purchase food. Furthermore, suppose food quality deteriorates to the point where it must be sold at lower prices or even disposed of. In that case, reduced profitability will jeopardise farmers’ and producers’ livelihoods. Food production constitutes resource-intensive activities, as a consequence, food waste and loss equally lead to waste in water, land, energy, and other natural resources used in the production process [21,22]. Therefore, overcoming food loss and waste has been cited as a sustainable strategy for achieving zero hunger (SDG 2) [17]. According to Ardra and Barua [14], a synergistic relationship exists between the SDGs since lowering food loss may also assist in finding solutions to issues that contribute to achieving other targets (for example, target 2.4, which aims to end hunger and improve food security, and target 3.9 whose objective is healthy lives for every age group) [15]. Hence, reducing food squandering while feeding a growing human population is an ongoing global challenge [23]. The difference between food loss and waste has been established in this article. In the next sections, the term “food waste” will predominantly refer to food loss and waste.

There is no universal method for the treatment of food waste due to the complexity of its physical and chemical composition, differing local government rules, and budgetary restrictions [24]. Popular approaches to reducing food waste are converting it into animal feed [25] and redistributing edible food waste or surplus food to underprivileged communities by charity associations [26]. A more recent strategy that is being investigated involves extracting components and ingredients from food waste to produce new food items. This valorisation of food waste can be defined as turning waste, by-products, or underutilised/undervalued food material into valued products or using those products effectively. The decreasing abundance of renewable resources, the declining availability of arable land, the ongoing increase in global population, and the excessive accumulation of waste justify the use of food waste and by-products in the food industry [27].

Food waste valorisation is an instrument for reducing the negative consequences of food wastage as well as achieving zero hunger. Bhatia et al. [27] stated that utilising or valorising food wastes aids in the resolution of environmental pollution challenges associated with food wastage reduces the socioeconomic consequences of food waste and contributes to meeting the ‘zero waste’ target [28]. Zero waste describes a visionary objective and a remedy to eradicate waste generation. The valorisation/reutilisation of these wastes using various techniques offers an avenue of possibilities allowing them to be no longer considered waste [29]. Since the rate of food consumption is higher than the rate of food waste recycling, high quantities of food waste are dumped into landfills where they are incinerated or allowed to decompose, leading to the emission of greenhouse gases that exacerbate climate change and the release of harmful gaseous substances (e.g., methane) that increase the risk of human health issues caused by air pollution and soil leaching [28,30]. For instance, bananas are recognised as one of the world’s most valuable foods and the second most produced fruit. The edible portion of the fruit accounts for only 12% of the tree’s overall weight, resulting in a significant quantity of agro-industrial waste like banana peels, which account for 30–40% of the entire fruit weight. After bananas are processed, a significant quantity of peels is collected and discarded as garbage because it is viewed as waste. Given that they are spread throughout the cultivation area or burned, these leftovers pose a severe pollution hazard [31,32].

Food-derived waste and by-products can be utilised as raw materials to produce food additives, fertilizers for crops, and animal feed given to livestock raised for human consumption, contributing to food production and supply [33,34]. In addition, agri-food wastes and by-products are among the most promising raw materials for producing biodegradable food packaging [35]. As such, the farming, food processing and packaging businesses can profit from creating value-added products. This has major financial advantages while also helping to reduce the accumulation of waste. By valorising by-products, the food chain activities are diversified, generating job opportunities and new income streams for the population that can benefit underprivileged communities. This is essential because addressing poverty is necessary to fulfill the Millennium Development Goals that deal with hunger and malnutrition [33].

The purpose of this article is to assess the potential role of food waste valorisation in alleviating world hunger. It offers a dedicated analysis of the contributions of food waste valorisation in supporting progress towards zero hunger in the world. Different methods employed for valorising food waste are presented. Besides, discussions of the benefits, drawbacks, and obstacles associated with food valorisation technologies are also included. While there are existing reviews on related topics, this manuscript offers a unique perspective and contributes to the field in several ways:

Unique Focus: The manuscript addresses food waste valorisation and its impact on achieving zero hunger. It explores converting food waste into value-added products, such as food formulations and farming inputs, to increase food availability. This focused approach sets it apart from broader reviews that may not delve into the specific role of valorisation in addressing hunger.

Novelty in Research: The manuscript presents a comprehensive analysis of the contributions of food waste valorisation in supporting progress towards zero hunger. It explores various methods employed for valorising food waste and discusses their benefits, drawbacks, and associated obstacles. This comprehensive assessment adds new insights and knowledge to the existing literature.

Relevance to Sustainable Development Goals: The manuscript explicitly aligns with Sustainable Development Goal 2 (Zero Hunger) and highlights the synergistic relationship between different goals. It emphasizes the importance of reducing food loss and waste as a sustainable strategy to achieve zero hunger while considering other targets, such as improved food security and healthy lives.

By focusing specifically on food waste valorisation and its implications for achieving zero hunger, this manuscript brings a unique perspective to the existing literature. It contributes new insights and knowledge while aligning with global sustainable development goals.

2. Food Waste Valorisation Techniques

Food waste valorisation techniques aim to convert food waste into value-added products that can be integrated into various stages of the food supply chain. Some sustainable techniques for food waste valorisation include composting, anaerobic digestion, bioconversion, and upcycling.

Food waste exists in solid, semi-solid and liquid form and is rich in compounds, including proteins, carbohydrates, lignin, lipids, cellulose, and other elements. These substances usually exist in the diluted form in liquid food waste such as potato-processing wastewater, apple residue sludge and whey from the dairy industry [36,37,38]. Because of this rich composition, food waste is categorised as an inexpensive, high-potential second-generation raw material [39]. The foundation of any procedure for valorising food waste is the composition of the generated food waste [40]. Food waste has a diverse and inconsistent composition that depends on a specific population’s region, season, and dietary patterns. Typically, heterogeneous food waste could comprise above 50% of total sugars, over 40% of starch, 45% of proteins, and less than 2% of cellulose [41]. The substances in food waste can be used for the manufacture of developing biofuels, bulk chemicals, enzymes, food supplements, nutraceuticals, bio-adsorbents (e.g., activated charcoal), antimicrobial products (e.g., antibiotics), bio-based fertilisers, bioplastics, among several other applications [37,42,43]. This section discusses the resource recovery from food waste by utilising various sustainable techniques or practices that aim to convert food waste into value-added products that can be introduced into various stages of the food supply chain. Such food waste valorisation strategies regarded as sustainable in the waste management literature include composting, anaerobic digestion, bioconversion, and upcycling to value-added derivatives and new food products/ingredients such as fertilizer, animal feed and food additives [36,42,44,45,46].

2.1. Composting

Food waste composting is a controlled process in which a complex microbial community degrades food wastes into their basic constituents in the presence or absence of oxygen [47,48]. Composting is divided into four stages: mesophilic, thermophilic, cooling, and maturation. Several factors influence the duration of composting, including pH, Carbon-Nitrogen (C/N) ratio, moisture, feedstock nature (type and composition of food waste), oxygen availability (aeration), and composting technology [49,50]. Aerobic composting is the most efficient type of degradation, producing mature compost in a shorter period (4 weeks) compared to anaerobic composting, which can take up to 2 or 3 years [51]. Composting can be hastened by turning the compost pile and shredding the feedstock materials (i.e., food waste) on a regular basis, as well as using efficient microbial species, chemical nitrogen activators, worms, natural minerals, plant-based bulking agents (e.g., agricultural waste) and a variety of additives and amendments, like biochar [52].

The product of composting is a stabilised substance that is rich in organic matter known as compost. Compost finds use in agriculture because it promotes soil fertility as well as crop development and growth. It has been employed as an organic fertilizer to replace chemical fertilizers, whose excessive and uncontrolled usage has negatively affected soil quality indices and agricultural yields over time. It also serves as a natural soil conditioner [53]. Compost is packed with nutrients and humic substances. Humic compounds, which include humic acids (HAs), fulvic acids (FAs), and humin, are heterogeneous organic molecules. Humic compounds increase soil fertility by boosting soil physiochemical characteristics and enhancing soil structure and texture [54]. Furthermore, applying compost derived from bio-transformed food waste to soils enhances soil aggregation, water-retentiveness, and porosity [55]. Humic substances present in compost favourably impact plants’ physiological, metabolic, and developmental processes. Humic substances activate genes related to nitrate uptake in plants as well as plasma membrane H+-ATPase, which is involved in nutrient uptake and transport. According to research studies, humic compounds stimulate stomatal opening, which is necessary for photosynthesis and respiration. They have a significant role in land resource restoration through phytoremediation and vegetation revival in impoverished arable soils, in addition to increasing the composition of soil organic matter [54,56,57].

Besides its numerous benefits, composting still has the disadvantages of long mineralisation times, long process duration, the potential presence of thermotolerant pathogens and limited nutritional content. The release of odorous substances and chemicals (such as hydrogen sulphides released under anaerobic conditions), as well as greenhouse gases (CO2, N2O, and CH4), are additional downsides of this biological waste treatment process [48,58]. One of the key restrictions on the usage of compost as biofertilizer is the fact that the availability of nutrients to plants, particularly N and P, is uncertain due to their existence in both inorganic and organic forms, which are not all readily available for intake by crops. Yet, less compost is needed in successive applications to attain the same nutritional load as mineral fertilisers because compost keeps releasing nutrients over an extended period. In practice, it would take less than eight times as much of this compost (1% N) over four years to provide the same quantity of nitrogen as mineral-based fertilizer [59]. On the other hand, compost is made up of a mixture of nutrients, and soil health will greatly benefit from the ability to extract certain nutrients (such as N, P, K, etc.) but not all. For example, matured compost contains trace elements within permissible levels, but when applied to the soil for bioremediation, some trace elements can be added to the soil’s already present trace elements rather than being removed, thereby negatively impacting the soil quality [58].

2.2. Anaerobic Digestion

Anaerobic digestion is the degradation of organic materials by microorganisms in an environment devoid of oxygen. This procedure generates biogas, which can be utilised as a source of energy. The steps of anaerobic digestion include hydrolysis, acidogenesis, acetogenesis, and methanogenesis [60]. Anaerobic digestion of food waste offers numerous advantages, including lowering methane emissions at landfills and providing an on-site, renewable energy source. Anaerobic digestion produces a digestate as a by-product rich in nutrients (e.g., nitrogen and phosphorus) extracted from the food waste substrate [61]. A long-term release of nutrients is achievable from the decomposition of fine organic matter retained within the cultivated soil following the application of fertilizer because organic fertilizers like food waste anaerobic digestate are very rich in organic matter. However, dissolved synthetic fertilizers provide nutrients available in their formulations prone to nutrient leaching and fixation, which restricts the quantity of nutrients plants can absorb over time [62]. Chemical fertilizers provide nutrients and have no positive influence on the physical state of the soil, unlike organic fertilizers, such as anaerobic digestate, that enhance soil fertility and properties [63]. The results of Panuccio et al. [63] demonstrated the application of anaerobic digestate as soil amendment increased the contents of vitamin C, phenols, and flavonoids in tomato fruits [64]. Furthermore, some research has indicated that the proper application of digestate can prevent the spread of soil-borne illnesses and may even lessen nutrient runoff, all while preserving crop productivity [65].

This waste treatment process outperforms ordinary compost when applied as a soil biofertilizer. Anaerobic digestion is recommended over composting and landfilling to treat and dispose of high-moisture biomass, such as food waste [66], because anaerobic digestion releases fewer odours and greenhouse gases. Additionally, the production of high-value products like bio-CNG (biogas) by anaerobic digestion might be economically advantageous on a large scale [67,68]. Despite the aforementioned benefits, the food waste utilised as the substrate for anaerobic digestion is typically a source of pathogenic microbes and some pathogens, such as Listeria and spore-formers, can survive the anaerobic digestion treatment and remain in the digestate, posing potential hazards to the environment, and cause serious illnesses in both humans and animals [69,70]. The incorrect calculation of fertilizer dose and nutrient availability can result in improper biofertilizer application and imbalanced release of nutrients that could compromise soil quality and crop growth [66,71]. The high water content of the digestate poses challenges and increases transportation and storage costs. [61]. Consequently, an existing need exists to increase the suitability of anaerobic digestate as a bio-based fertilizer. Moreover, the high capital cost required for anaerobic digestion is a common challenge for the implementation of this technology [68].

2.3. Bioconversion

Biotransformation, also called bioconversion is the process of converting organic resources, for example, biomass from animal or vegetative waste, into marketable products or renewable energy sources via biological reactions or agents, such as microbial species, enzymes, etc. [72]. Bioconversion of food wastes involves converting them into value-added products which include feed and food additives, bio-based fuels, animal feeds, enzymes, food-grade pigments, fertilizers, single cell protein (SCP), and other useful biochemicals or bioproducts thereby improving food security and supporting sustainable development [73]. Bioconversion has various advantages, including high value in terms of biomaterial and energy recovery, reduction in landfill areas, lower technology costs, and increased farmer income through sales of agricultural/horticultural waste [74].

Numerous scientists explored the production of useful products, through the utilisation of food wastes, as an alternative source of raw materials. For example, the production of single-cell protein via fermentative bioconversion is intended to address global protein deficits and has demonstrated huge benefits because it is not reliant on climate, soil health, and land available for cultivation [75]. For the production of single-cell protein, food waste is broken down into simpler compounds by microbial cells like algae, yeast, bacteria, and fungi during fermentation, which produces high-quality protein sources for consumption by fish, livestock, and humans [76,77]. SCP can be a good substitute for expensive conventional protein sources like soy meal as well as protein-based ingredients included in the formulation of animal feed such as fishmeal and meat meal [78]. Research has demonstrated single-cell protein production from waste derived from oranges, lemon, corn stover [76], pineapple, mango, banana, apple, cashew apple, jackfruit, cacao, pomegranate [79], cheese, coffee [80], and fish [75]. On the other hand, regulatory obstacles and uncertainties about the safety of the products in relation to harmful or antinutritional substances still exist. In addition, it is critical to assess the environmental sustainability of these waste-to-nutrition processes at an early stage when attempting to substitute traditional food ingredients such as proteins to prevent undesirable implications and burden-shifting [77].

A fed-batch fermentation process combined with in-situ separation was carried out for the bioconversion of restaurant leftovers and bakery waste by Starmerella bombicola ATCC 22214 into sophorolipids. Although this method proved to be practical with high productivity, further optimisation of the separation process could be applied at an industrial scale [81]. Sophorolipids are biodegradable molecules with great potential for use in the food and agricultural sector to compete with chemical surfactants [82]. Potential applications include increasing crop productivity by enhancing the solubility and mobility of nutrients [83], and the development of bio-preservatives and active packaging for food safety enhancement due to their effective antimicrobial properties [84,85]. Fed-batch fermentation was equally employed to produce vinegar from discarded onion juice by microbial fermentation using Acetobacter tropicalis KFCC 11476P [86]. Fermentation techniques, particularly, solid-state fermentation (SSF) is a widely researched and effective procedure for the bioconversion of agro-industrial food waste, which produces inexpensive enzymes, organic acids, vitamins, fermented feeds and aroma compounds [87,88]. SSF offers the following advantages: lower production cost, a higher output, less amount of waste generated, simpler equipment design, and organic culture media produced with solid food/agricultural waste [89]. Compared to alternative fermentation methods, SSF has many benefits, including improved end-product recovery, superior product activity and quality, the absence of extraction solvents, and greater product stability and efficiency [90]. In addition, SSF is an efficient method for degrading antinutritional factors and insoluble macromolecules, improving nutrient utilisation and uptake [91]. Li et al. [86] investigated the use of Saccharomyces cerevisiae, Candida utilis, and Yarrowia lipolytica in SSF for the bioconversion of food waste obtained from a canteen to prepare fermented feed destined for crayfish farming. The study highlighted that replacing the basal diet with 30% of the food waste-derived fermented feed is suitable for crayfish growth [87]. SSF was previously investigated for the production of the packaging material poly-3-hydroxybutyrate (PHB) using a medium containing sugarcane molasses [92]. Moreso, food and kitchen waste were also tested to produce PHB by five different microbial consortiums. Consortium A, which consisted of three Bacillus species (B. pumilus MPTDFH, B. cereus MPTDC, and B. sonorensis MPTD1), yielded the highest PHB concentration (0.91 g/L) [93]. Although SSF is an attractive technology, several challenges need to be addressed. For instance, the low moisture content of the waste substrates used in SSF inhibits enzymatic activity and restricts the transport of nutrients and metabolites, leading to a slower microbial growth rate. Additionally, SSF is limited to microorganisms that have the ability to survive in low moisture conditions [94].

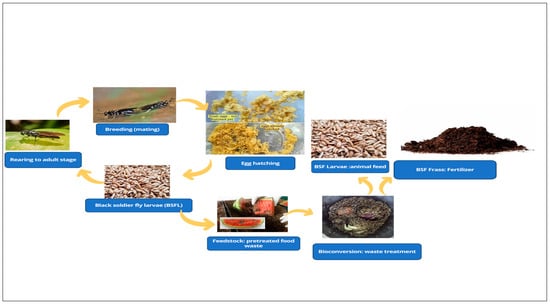

A rather novel waste valorisation approach, insect-based bioconversion, has been recently explored for the manufacture of valuable products following insects’ breakdown of food waste. During this process, value can be created at several stages, for example, the elimination of food waste enables a reduction in disposal expenses, selling insect-based biomass as protein-rich food and feed, commercialisation of fractionated secondary products (i.e., biomolecules), and selling the leftover bio-converted by-product as soil amendments for agriculture/horticulture [95]. In contrast, consumer acceptance of the produced goods is one of the challenges that insect-based food waste valorisation techniques face [96]. Using food waste as a feed source in insect farming has several environmental and economic benefits. Firstly, many insects, including grasshoppers, flies, and crickets, thrive on leftover food that humans and livestock cannot consume. Secondly, introducing insects into human diets helps to achieve a bioeconomy by utilising food that would otherwise be wasted to feed the insects, which people then eat. Moreover, this would help maintain a balance between the world’s supply and demand for animal protein [97]. Hermetia illucens (black soldier fly) is an excellent insect for bioconversion. This insect has a short reproductive cycle and the larvae have a high food conversion rate, an insatiable appetite and may eat a variety of organic waste, including food waste [98]. Black soldier fly larvae (BSFL) have received a lot of attention because they have good nutritional value. They have high quantities of lipids, proteins, minerals, vitamins and essential amino acids [99]. This makes them good edible insect candidates to be included in the human diet, particularly because they are good sources of proteins and can contribute to meeting the increasing protein demand. However, Bessa et al. [100] argued that there are several existing challenges that slow down the adoption of BSFL as a safe food source for human consumption. Consumers are willing to consume BSFL as processed food but little is known about its food safety since BSFL has been used predominantly as animal feed. Figure 2 below illustrates the bioconversion process of food waste by BSFL.

Figure 2.

Insect-based bioconversion by black soldier fly larvae, and the life cycle of black soldier fly.

Despite these advantages, insect rearing can produce huge quantities of low-value organic waste, including frass, exuviae, and uneaten feed, often disposed of by spreading on farmlands [96]. To prevent potential hazards, researchers have expressed their concerns and recommended further studies before implementing large-scale insect-based valorisation and commercial cultivation of insects. This is because some insects contain substances that are toxic to human beings, such as cyanide or thiaminases, which reduce their nutritional value. Therefore, ecological studies on selecting safe species for domestication and consumption must go hand in hand with research on the nutritional content and safety of insects for food and feed applications. Concerns have also been raised about the threat of ecosystem imbalance from insects that escape from insect farms [101].

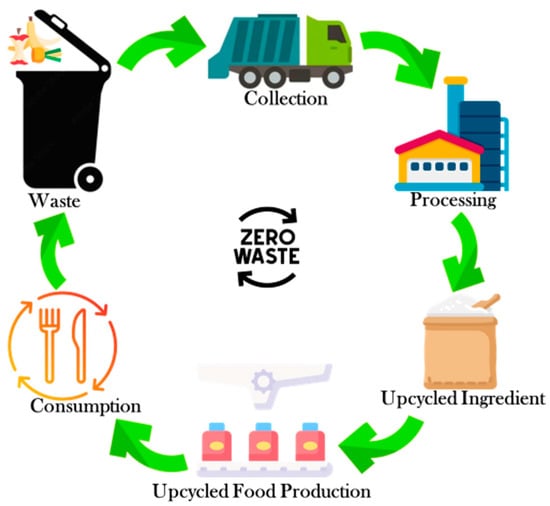

2.4. Upcycling Food Waste

Upcycled food is a novel idea in the arsenal of strategies for reducing/valorising food waste. Upcycled foods are formulated with ingredients that usually are not intended for human consumption, such as damaged (rejected) food, underutilised food parts, residues, by-products, and food processing and preparation leftovers and waste. Upcycling, therefore, results in an increase in the value of the waste material and by-products by processing them into functional and nutritive ingredients that can be reintroduced in the food supply chain as components of new food items. Upcycled ingredients/foods are sometimes referred to as waste-to-value food products or value-added surplus products. [102,103,104]. The production of upcycled foods (Figure 3) makes use of ingredients that are still usable but are generally thrown away [105]. For instance, the peel is typically removed before consuming carrots. However, the discarded carrot peels are healthy and safe to consume and can be repurposed as an ingredient in other foods, such as a powdered vegetable soup mix prepared from dried peels [106].

Figure 3.

Closing the loop with the production of upcycled foods/ingredients.

Food losses such as fruit and vegetable by-products, among others, are sources of high-value nutrients (e.g., bioactive compounds and dietary fibre) that can provide nutritional benefits to consumers. Trigo et al. [107] analysed grape pomace and pomegranate peel and found relatively high antioxidant activity and total phenolic content. The previously mentioned attributes are likely responsible for the frequent application of food processing by-products in a variety of fortified foods, including sauces, beverages, dairy products, pastry, and animal products [107].

Some producers of upcycled ingredients/foods are releasing their finished products on the market. Examples of companies and products include Coffee Cherry Company (US) and Kaffe Bueno (Denmark), which use coffee grounds in making baked products. Remashed (UK) and Regrained (US) are upcycling spent grains from beer production to produce granola bars, and the leftover generated from rapeseed or sunflower oil processing is converted into food-grade protein-rich powders by Planetarians (US) and NapiFeryn BioTech (Poland) [104]. The Upcycled Food Association initiated a scheme to certify upcycled ingredients and foods to make it easier for producers to manufacture these foods [102]. These foods offer an appealing economic and environmental response to partly alleviate the food waste issue. Upcycling waste to the food industry is a major circular economy concept that is consistent with policy trends favouring ‘closing the loop’ in major sectors, including food and agriculture [44], hence, simultaneously taking advantage of nutrients (e.g., protein and fibre) that are still present in the waste material and creating a circular food system [106]. Another advantage is that the upcycled food sector seeks to utilize the whole waste resources in place of extracting bioactive ingredients and nutrients from food waste, resulting in a net reduction of food waste [108].

Although upcycled foods can reduce food waste and improve food security, there is limited knowledge of the ideal marketing approach to maximize consumer acceptability for these products [105]. Regarding consumers’ perceptions, one of the greatest concerns is that they may imagine the products are less valuable than they are. This may result from one’s association with garbage, which is typically considered useless and frequently considered repugnant and harmful. This view might also lead to the fear that upcycling may give rise to foods with diminished quality and safety [103]. Moreover, neophobia might lead to the reluctance of consumers towards these novel products [106]. Creating a label that could be added to the item’s packaging formalizes the concept of “upcycled food”. Similarly to existing labels such as clean or sustainability labels, this label would aid the buyer in making a purchasing decision by emphasising the benefits of “upcycling” to promote a circular economy [109]. The upcycled food market appears to have significant growth potential, as 85% of consumers in the UK would be open to purchasing foods and beverages that contain upcycled ingredients. In another study in Italy (2020), 56% of participants claimed they would purchase a food item manufactured with waste or by-products. If the food produced using wastes or by-products additionally had a lower production-related environmental burden, this percentage increased to 69%. [104]. Also, when potential consumers are informed that upcycled foods can be helpful to reduce food waste, they are prepared to pay a higher price [110]. Therefore, upcycling could respond to a significant market desire for sustainable development [109].

Table 1 summarises some waste valorisation strategies used in the manufacture of products as well as their potential applications in the food industry.

Table 1.

Value-added products obtained from various food waste sources and their potential use in the food industry.

3. The Impact of Food Waste Valorisation on Achieving Zero Hunger

Targets 2.1–2.5 of SDG 2 are directly related to food security and the sustainability of food production with Target 2.4 focusing on the sustainable production of food. According to the World Resource Institute (WRI), in order to produce sustainable food and feed 10 billion people by 2050, food losses would have to be reduced by 25% [123]. This decrease would not only contribute to achieving “zero hunger” but would also significantly reduce the environmental impact of food production [124]. The planet produces sufficient food to feed all individuals, but it is distributed unevenly and sometimes handled improperly, resulting in losses and waste [125]. The social consequences of food waste are linked to nutritional loss and global hunger. The squandered food could theoretically provide millions of people with missing nutrients. Food waste is regarded as an important reservoir of major nutrients including proteins, complex carbohydrates, lipids, and phytochemicals due to its high quantities of polysaccharides, dietary fibres, oils, vitamins, phenolics, carotenoids, and other compounds. In case the necessary measures for lowering food waste are not adopted, and food production and consumption are inadequately planned, the estimated world population of more than nine billion people in 2050 will require about 60% more food or a minimum of 2 billion tons of food. Meanwhile, it is estimated that cutting down on global food waste by half will enable a 20% reduction in the food gap in 2050 [126].

The food system can greatly benefit from waste valorisation strategies. In a circular economy concept, anaerobic digestion and composting might serve as the mines for the manufacture of organic fertilizers. Food waste-derived compost can be used as organic fertilizers in cropping systems to improve degraded soil quality which is responsible for lowering agricultural production [127,128]. Digestate is a well-known soil enhancer that can address soil fertility issues, according to scientific research. Hence, these fertilizers produced from food waste valorisation can increase the productivity of agricultural soils, increasing food availability, contributing to food security and simultaneously reducing the environmental impact of food waste accumulation and disposal [129]. Automatic and electric composters are currently available for quick and efficient urban composting of food waste in homes, restaurants, schools, and other catering facilities. It is becoming increasingly common to manage food waste in such a manner while also producing a useful product, giving rise to a profitable business opportunity [130]. Compared to conventional inorganic fertilizers, food waste-based compost and anaerobic digestate provide a low-cost alternative to supply nutrients in agriculture. Using food-waste-derived fertilizers reduces the expenditures of agricultural producers and their dependence on industrially-produced fertilizers [55,129].

Valorising or upcycling food has been presented as a technological solution that preserves the nutritional and economic value of food waste and unwanted by-products [131]. Food security and social welfare can be enhanced by increasing availability and access to healthy diets as well as increasing the revenue of those selling the food items. However, this depends on how prices fluctuate due to waste diminutions because if prices collapse, the population will have higher access to food, but farmers’ profits might suffer. Previously, researchers found that reducing food losses by half will improve nutritional intake and positively impact chronic health conditions like heart disease and type II diabetes [132]. The results of Chen et al., (2020) indicated that a 25–50% loss of the daily nutritional requirements of several micronutrients (vitamins B6, C and K, Selenium, copper, zinc, Iron, and Manganese) is embedded in food waste [133]. A study conducted in Kenya, Cameroon, and India revealed that food loss and waste cause micronutrient losses. Hence, minimising food losses, particularly at the post-harvest level in developing countries, could improve nutritional status through higher consumption of micronutrients like iron and vitamins A and C [134]. Chitin and chitosan obtained from the waste of crustacean farming have a significant potential for use as food packaging materials, food additives, fruit preservatives, and nutritional supplements. Moreover, the US Environmental Protection Agency presented a scientific review in August 2019 recommending chitosan’s incorporation to the list of minimum-risk ingredients in pesticide formulations, promoting the safety and eco-friendliness of chitosan-based insecticides, and increasing their agricultural market prospects [135]. The addition of nutrient-rich upcycled ingredients to basic foodstuffs would improve restrictive diets like gluten-free diets, which are known to be lower in fibre and higher in saturated fats. For instance, adding plant-based food waste and by-products to gluten-free pasta raises the amount of protein, dietary fibre, and micronutrients in such items [108]. In a world with finite resources and a rising population, food and nutrition security can only be accomplished by more sustainable resource utilisation, as well as changes in human consumption and production habits, such as reducing or, ideally, eliminating food losses and waste [133]. Hence, by reducing food loss and waste along the food supply chain, zero hunger could be achieved more rapidly.

3.1. Industrial Case Studies of Food Waste Valorisation Initiatives

3.1.1. Insectipro: Production of Protein-Rich Feed for Animal Farming

In Sub-Saharan Africa (SSA), there are significant food waste issues, with nearly 50% of produced fruits and vegetables being lost or discarded. In Kenya, estimates suggest that 30% of the production is rejected at the farm stage, and 50% is rejected before it is exported. Additionally, across the nation, farms and packaging facilities reject around 44.5% of the food that is produced. In addition to decreasing farmers’ and exporters’ income, this high rejection rate ultimately results in the production of enormous amounts of food waste, whose management and disposal are expensive [136]. Africa’s population is expected to reach 2.53 billion people by 2050, increasing demand for food and protein to levels that the existing linear food system may not be able to satisfy. In East Africa, insect farming is a fast-expanding industry with the potential to contribute to economic circularity by supplying consumers with ‘climate-smart’ proteins and additional nutrients and generating an income stream for producers [137]. Black soldier fly production by Insectipro (Kenya) is renowned for being an effective approach to providing sustainably produced animal proteins. The organization also solves challenges regarding organic waste management while using insects to sustain Kenya’s food supply [138]. The black soldier fly breaks down a multitude of biological waste into high-value biomasses like proteins and oils [139]. It has been identified as one of the most effective recyclers of a variety of organic waste, including food waste, fruit and vegetable waste, slaughterhouse waste, and human excrement [140]. Black soldier fly larvae have a high affinity for avocado and mango waste. The dried larvae are abundant in protein and are ground into feed suitable for livestock, poultry and fish farming [141]. The activities of Insectipro provide numerous benefits to the Kenyan farming sector while making the country more food secure. Insectipro conducted field trials by administering their feed on a pig farm, and it was observed that the animals gained weight at a quicker rate. While following this insect-based diet, the weight gain was one month faster compared to when utilising a conventional feed. Additionally, the pork was of higher grade, and the farmer could sell it at a superior price. Furthermore, the demand for this feed increased during the pandemic while the borders were closed as the company could provide a locally-produced alternative to farmers [141].

3.1.2. Okara: A Waste Product Turned Valuable Food Ingredient by Renewal Mills

The supply chain for functional foods has seen a growth in the market potential of soy-based products due to rising interest and public knowledge of the health advantages of soy-based products’ consumption. Okara (also known as soybean paste) is the insoluble, pale-yellow by-product obtained during the manufacturing of soy milk, soybean curd, or tofu. The accumulation of this soybean waste presents a major challenge to the soybean processing sector since 1.2 kg of wet (fresh) okara is produced from every kilogram of soybean used to make tofu or soy milk [142]. Despite being a rich source of fibre, protein, calcium, potassium, isoflavone, polysaccharides, vitamin B, antioxidants, and lipid-soluble nutritious components, tremendous quantities of okara are discarded. Okara waste disposal is costly and has a negative impact on the environment due to putrefaction and greenhouse gas emissions [143]. Therefore, converting this highly nutritious “food waste” into a nutrient-encapsulating matrix for food applications is a viable idea for okara waste management and a cost-effective and sustainable approach to addressing micronutrient deficiencies [144]. Renewal Mill is an upcycled food company in the United States that manufactures ready-to-use flour made with okara [145]. Okara flour is a gluten-free product that mimics the taste and appearance of white flour and can be used alone or in conjunction with other types of flour. It is a delectable, easy-to-use and versatile superfood providing considerable nutrients. Okara flour has a lower net carbohydrate content compared to white flour. In the majority of recipes, replacing 25% of wheat flour with okara flour delivers a product with a protein and fibre content equivalent to that of whole grain flour. The caterers that collaborated with Renewal Mills had excellent results in developing novel recipes with okara flour, including okara dumplings, pulled noodles, and okara-stuffed puff pastries [146]. Table 2 provides examples of waste valorisation initiatives by the private sector that develop value added products that can re-enter in the agri-food supply chain.

Table 2.

Overview of innovative food waste valorisation projects and their developed products.

4. The Challenges of Implementing Food Waste Valorisation

The challenges of implementing food waste valorisation strategies are indeed complex and multifaceted. These challenges can be divided into several sections.

4.1. Financial Constraints and Resistance to Change

Financial input and resistance to change pose significant barriers to the implementation of food waste valorisation technologies [157]. Implementing these technologies often requires substantial investment, which can be a deterrent for many organisations. Furthermore, resistance to change from existing methods and practices can impede the adoption of new valorisation processes. High processing costs and overall process viability are additional challenges that need to be addressed [43,158]. The costs associated with transportation and storage of waste, as well as the expenses related to traditional extraction procedures, can hinder the cost-effectiveness of food waste valorisation. These challenges make it difficult for valorised products to compete with conventional alternatives.

4.2. Technical and Regulatory Obstacles

Technical difficulties in converting extracted substances into value-added products, especially on a large scale, pose further obstacles to effective food waste valorisation [43,158]. Scaling up the conversion of extracted substances into marketable products requires the development of efficient and scalable processes. Additionally, the lack of a robust regulatory framework for handling waste further complicates the implementation of valorisation strategies.

4.3. Heterogenous Composition of Food Waste

The composition of food waste is not uniform, exhibiting significant seasonal, geographical, and nutritional variations [159]. These variations make it challenging to determine which valorisation technology is the most suitable for scaling up. Developing smart approaches to overcome these composition inconsistencies is crucial to effectively utilize food waste in valorisation strategies [160].

4.4. Unavailability of Food Waste Generation Data and Quantification Difficulties

There is a lack of published data on food waste generation, particularly in underdeveloped regions. This knowledge gap hinders our understanding of the disparities in food waste between regions and the associated nutrient loss and ecological consequences [161]. It is essential to identify and measure food waste generation to determine suitable valorisation techniques and identify the main resources required for processing value-added products. Identifying hotspots of food losses and waste generation can help prioritize food supply chain stages and types of waste with the greatest valorisation potential, facilitating targeted reduction efforts [162]. It is important to acknowledge that the definition of food losses and waste can vary based on the policy target and the conceptual frameworks used. These variations can influence the quantification methods and measurement of food waste [163]. Therefore, it is necessary to consider regional needs and perspectives when developing waste valorisation technologies to ensure their sustainability and effectiveness [160].

4.5. Quality and Safety Challenges

Ensuring the quality and safety of valorised waste and by-products is critical. Food waste can harbor germs, organic residues, water content, and chemical contaminants that may pose health risks [158]. Legislation, regulations, and scientific studies are necessary to establish standards and protocols for the safe and high-quality valorisation of waste. Additionally, addressing consumer concerns regarding the safety and acceptability of valorised products through targeted education and awareness initiatives is crucial for large-scale implementation [66,108,164].

In summary, implementing food waste valorisation strategies involves addressing various challenges, including financial input, resistance to change, high processing costs, technical difficulties, regulatory frameworks, compositional variations, data gaps, and safety considerations. A multidisciplinary approach, collaboration between industries and public-private partnerships, and investment in research and development are crucial for overcoming these challenges and creating sustainable food waste valorisation solutions [165,166].

5. Conclusions

Food loss and waste are global challenges requiring comprehensive and targeted solutions. While various stakeholders are increasingly interested in this topic, it is concerning that food waste generation continues to rise, leading to increased hunger and malnutrition worldwide. Addressing these issues necessitates the production of more food in a safe and eco-friendly manner while effectively managing food waste.

To achieve these goals, it is crucial to implement mass-scale food waste valorisation strategies. Emphasising the circular bioeconomy as a key innovation concept can unlock additional benefits from waste valorisation strategies, creating economic value from food losses and waste. This approach capitalizes on the composition and nutritional characteristics of food waste and inedible foods, enabling their reintegration into the food and agriculture industries, thereby contributing to food security and combating hunger.

The study highlights the promising potential of food waste valorisation initiatives that focus on developing products for reuse in food and agricultural production operations. However, it is important to acknowledge that food waste composition and environmental impacts vary among different nations, necessitating tailored waste reduction strategies for each country. As public awareness increases, the market for waste-to-value goods is expected to expand, driving technological advancements in food waste valorisation and fostering positive consumer perception.

Increasing investment and support are necessary to fully realize the benefits of food waste valorisation and achieve zero waste in food production and consumption. Research efforts should focus on addressing safety concerns and the heterogeneous composition of food waste to optimize its valorisation. Without adequate research, the potential to produce high-quality food-grade products from food waste will be limited, impeding the progress toward zero hunger.

Finally, it is crucial to prioritize specific issues related to food loss and waste in the conclusions. By implementing targeted and research-driven strategies, such as mass-scale valorisation initiatives and tailored waste reduction approaches, we can significantly reduce food waste, ensure food security, and achieve zero hunger. Increased investment, technological advancements, and public awareness will be key drivers of progress in the field of food waste valorisation.

Author Contributions

Conceptualization, R.D.T. and H.O. writing—original draft preparation, R.D.T., H.O. and T.M.; writing—review and editing. H.O. and T.M.; supervision, H.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kavanaugh, M.; Quinlan, J.J. Consumer Knowledge and Behaviors Regarding Food Date Labels and Food Waste. Food Control 2020, 115, 107285. [Google Scholar] [CrossRef]

- Santeramo, F.G. Exploring the Link among Food Loss, Waste and Food Security: What the Research Should Focus On? Agric. Food Secur. 2021, 10, 26. [Google Scholar] [CrossRef]

- Castagna, A.C.; Pinto, D.C.; Mattila, A.; de Barcellos, M.D. Beauty-Is-Good, Ugly-Is-Risky: Food Aesthetics Bias and Construal Level. J. Bus. Res. 2021, 135, 633–643. [Google Scholar] [CrossRef]

- Davenport, M.L.; Qi, D.; Roe, B.E. Food-Related Routines, Product Characteristics, and Household Food Waste in the United States: A Refrigerator-Based Pilot Study. Resour. Conserv. Recycl. 2019, 150, 104440. [Google Scholar] [CrossRef]

- Evans, D.; Campbell, H.; Murcott, A. A Brief Pre-History of Food Waste and the Social Sciences. Sociol. Rev. 2012, 60, 5–26. [Google Scholar] [CrossRef]

- Block, L.G.; Keller, P.A.; Vallen, B.; Williamson, S.; Birau, M.M.; Grinstein, A.; Haws, K.L.; LaBarge, M.C.; Lamberton, C.; Moore, E.S.; et al. The Squander Sequence: Understanding Food Waste at Each Stage of the Consumer Decision-Making Process. J. Public Policy Mark. 2016, 35, 292–304. [Google Scholar] [CrossRef]

- Tan, Y.; Hai, F.; Popp, J.; Oláh, J. Minimizing Waste in the Food Supply Chain: Role of Information System, Supply Chain Strategy, and Network Design. Sustainability 2022, 14, 11515. [Google Scholar] [CrossRef]

- Pandey, A. Food wastage: Causes, impacts and solutions. Sci. Herit. J. 2021, 5, 17–20. [Google Scholar] [CrossRef]

- Żmieńka, E.; Staniszewski, J. Food Management Innovations for Reducing Food Wastage—A Systematic Literature Review. Management 2020, 24, 193–207. [Google Scholar] [CrossRef]

- Xue, L.; Liu, G.; Parfitt, J.; Liu, X.; Van Herpen, E.; Stenmarck, Å.; O’Connor, C.; Östergren, K.; Cheng, S. Missing Food, Missing Data? A Critical Review of Global Food Losses and Food Waste Data. Environ. Sci. Technol. 2017, 51, 6618–6633. [Google Scholar] [CrossRef]

- Read, Q.D.; Brown, S.; Cuéllar, A.D.; Finn, S.M.; Gephart, J.A.; Marston, L.T.; Meyer, E.; Weitz, K.A.; Muth, M.K. Assessing the Environmental Impacts of Halving Food Loss and Waste along the Food Supply Chain. Sci. Total Environ. 2020, 712, 136255. [Google Scholar] [CrossRef] [PubMed]

- Rao, M.; Bast, A.; de Boer, A. Valorized Food Processing By-Products in the EU: Finding the Balance between Safety, Nutrition, and Sustainability. Sustainability 2021, 13, 4428. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Food Waste Index Report; UNEP: Nairobi, Kenya, 2021. [Google Scholar]

- Amato, M.; Verneau, F.; Coppola, A.; La Barbera, F. Domestic Food Waste and COVID-19 Concern: An Application of the Theory of Planned Behaviour. Sustainability 2021, 13, 8366. [Google Scholar] [CrossRef]

- Ardra, S.; Barua, M.K. Halving Food Waste Generation by 2030: The Challenges and Strategies of Monitoring UN Sustainable Development Goal Target 12.3. J. Clean. Prod. 2022, 380, 135042. [Google Scholar] [CrossRef]

- Henz, G.P.; Porpino, G. Food Losses and Waste: How Brazil Is Facing This Global Challenge? Hortic. Bras. 2017, 35, 472–482. [Google Scholar] [CrossRef]

- Behera, B.K.; Rout, P.K.; Behera, S. (Eds.) Move Towards Zero Hunger; Springer: Singapore, 2019; pp. 1–35. ISBN 978-981-329-800-2. [Google Scholar]

- United Nations Food. Available online: https://www.un.org/en/global-issues/food (accessed on 7 June 2023).

- Facchini, F.; Silvestri, B.; Digiesi, S.; Lucchese, A. Agri-Food Loss and Waste Management: Win-Win Strategies for Edible Discarded Fruits and Vegetables Sustainable Reuse. Innov. Food Sci. Emerg. Technol. 2023, 83, 103235. [Google Scholar] [CrossRef]

- Reynolds, C.J.; Piantadosi, J.; Boland, J. Rescuing Food from the Organics Waste Stream to Feed the Food Insecure: An Economic and Environmental Assessment of Australian Food Rescue Operations Using Environmentally Extended Waste Input-Output Analysis. Sustainability 2015, 7, 4707–4726. [Google Scholar] [CrossRef]

- Rezaei, M.; Liu, B. Food Loss and Waste in the Food Supply Chain; International Nut and Dried Fruit Council: Reus, Spain, 2017; pp. 26–27. [Google Scholar]

- Santeramo, F.G. Price Transmission in the European Tomatoes and Cauliflowers Sectors. Agribusiness 2015, 31, 399–413. [Google Scholar] [CrossRef]

- Newsome, T.M.; Van Eeden, L.M. The Effects of Food Waste on Wildlife and Humans. Sustainability 2017, 9, 1269. [Google Scholar] [CrossRef]

- Ooi, J.K.; Woon, K.S.; Hashim, H. A Multi-Objective Model to Optimize Country-Scale Municipal Solid Waste Management with Economic and Environmental Objectives: A Case Study in Malaysia. J. Clean. Prod. 2021, 316, 128366. [Google Scholar] [CrossRef]

- Nath, P.C.; Ojha, A.; Debnath, S.; Sharma, M.; Nayak, P.K.; Sridhar, K.; Inbaraj, B.S. Valorization of Food Waste as Animal Feed: A Step towards Sustainable Food Waste Management and Circular Bioeconomy. Animals 2023, 13, 1366. [Google Scholar] [CrossRef] [PubMed]

- Hecht, A.A.; Neff, R.A. Food Rescue Intervention Evaluations: A Systematic Review. Sustainability 2019, 11, 6718. [Google Scholar] [CrossRef]

- Roy, P.; Mohanty, A.K.; Dick, P.; Misra, M. A Review on the Challenges and Choices for Food Waste Valorization: Environmental and Economic Impacts. ACS Environ. Au 2023, 3, 58–75. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, L.; Jha, H.; Sarkar, T.; Sarangi, P.K. Food Waste Utilization for Reducing Carbon Footprints towards Sustainable and Cleaner Environment: A Review. Int. J. Environ. Res. Public Health 2023, 20, 2318. [Google Scholar] [CrossRef] [PubMed]

- Seberini, A. Economic, Social and Environmental World Impacts of Food Waste on Society and Zero Waste as a Global Approach to Their Elimination. SHS Web Conf. 2020, 74, 03010. [Google Scholar] [CrossRef]

- To, S.; Coughenour, C.; Pharr, J. The Environmental Impact and Formation of Meals from the Pilot Year of a Las Vegas Convention Food Rescue Program. Int. J. Env. Res. Public Health 2019, 16, 1718. [Google Scholar] [CrossRef]

- Happi Emaga, T.; Robert, C.; Ronkart, S.N.; Wathelet, B.; Paquot, M. Dietary Fibre Components and Pectin Chemical Features of Peels during Ripening in Banana and Plantain Varieties. Bioresour. Technol. 2008, 99, 4346–4354. [Google Scholar] [CrossRef]

- Memon, J.R.; Memon, S.Q.; Bhanger, M.I.; Memon, G.Z.; El-Turki, A.; Allen, G.C. Characterization of Banana Peel by Scanning Electron Microscopy and FT-IR Spectroscopy and Its Use for Cadmium Removal. Colloids Surf. B Biointerfaces 2008, 66, 260–265. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzman, N.; Londoño-Hernandez, L.; Martinez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macias, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Lopes, C.; Herva, M.; Franco-Uría, A.; Roca, E. Inventory of Heavy Metal Content in Organic Waste Applied as Fertilizer in Agriculture: Evaluating the Risk of Transfer into the Food Chain. Env. Sci. Pollut. Res. 2011, 18, 918–939. [Google Scholar] [CrossRef]

- Cristofoli, N.L.; Lima, A.R.; Tchonkouang, R.D.N.; Quintino, A.C.; Vieira, M.C. Advances in the Food Packaging Production from Agri-Food Waste and By-Products: Market Trends for a Sustainable Development. Sustainability 2023, 15, 6153. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M.N. Sustainable Bioconversion of Food Waste into High-Value Products by Immobilized Enzymes to Meet Bio-Economy Challenges and Opportunities—A Review. Food Res. Int. 2019, 123, 226–240. [Google Scholar] [CrossRef]

- Ebikade, E.O.; Sadula, S.; Gupta, Y.; Vlachos, D.G. A Review of Thermal and Thermocatalytic Valorization of Food Waste. Green Chem. 2021, 23, 2806–2833. [Google Scholar] [CrossRef]

- Lo Turco, V.; Potortì, A.G.; Tropea, A.; Dugo, G.; Di Bella, G. Element Analysis of Dried Figs (Ficus carica L.) from the Mediterranean Areas. J. Food Compos. Anal. 2020, 90, 103503. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Lozano, R.; Steinberger, J.K.; Wright, N.; bin Ujang, Z. The Food Waste Hierarchy as a Framework for the Management of Food Surplus and Food Waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; García, I.L.; Sáez-Bastante, J.; Pinzi, S.; Koutinas, A.A.; Dorado, M.P. Food Waste from Restaurant Sector—Characterization for Biorefinery Approach. Bioresour. Technol. 2020, 301, 122779. [Google Scholar] [CrossRef] [PubMed]

- Kazemi Shariat Panahi, H.; Dehhaghi, M.; Guillemin, G.J.; Gupta, V.K.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Bioethanol Production from Food Wastes Rich in Carbohydrates. Curr. Opin. Food Sci. 2022, 43, 71–81. [Google Scholar] [CrossRef]

- O’Connor, J.; Hoang, S.A.; Bradney, L.; Dutta, S.; Xiong, X.; Tsang, D.C.W.; Ramadass, K.; Vinu, A.; Kirkham, M.B.; Bolan, N.S. A Review on the Valorisation of Food Waste as a Nutrient Source and Soil Amendment. Environ. Pollut. 2021, 272, 115985. [Google Scholar] [CrossRef]

- Jõgi, K.; Bhat, R. Valorization of Food Processing Wastes and By-Products for Bioplastic Production. Sustain. Chem. Pharm. 2020, 18, 100326. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Asioli, D.; Banovic, M.; Perito, M.A.; Peschel, A.O.; Stancu, V. Defining Upcycled Food: The Dual Role of Upcycling in Reducing Food Loss and Waste. Trends Food Sci. Technol. 2023, 132, 132–137. [Google Scholar] [CrossRef]

- Otles, S.; Kartal, C. 11—Food Waste Valorization. In Sustainable Food Systems from Agriculture to Industry; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 371–399. ISBN 978-0-12-811935-8. [Google Scholar]

- Nayak, A.; Bhushan, B. An Overview of the Recent Trends on the Waste Valorization Techniques for Food Wastes. J. Environ. Manag. 2019, 233, 352–370. [Google Scholar] [CrossRef] [PubMed]

- Palaniveloo, K.; Amran, M.A.; Norhashim, N.A.; Mohamad-Fauzi, N.; Peng-Hui, F.; Hui-Wen, L.; Kai-Lin, Y.; Jiale, L.; Chian-Yee, M.G.; Jing-Yi, L.; et al. Food Waste Composting and Microbial Community Structure Profiling. Processes 2020, 8, 723. [Google Scholar] [CrossRef]

- Amuah, E.E.Y.; Fei-Baffoe, B.; Sackey, L.N.A.; Douti, N.B.; Kazapoe, R.W. A Review of the Principles of Composting: Understanding the Processes, Methods, Merits, and Demerits. Org. Agric. 2022, 12, 547–562. [Google Scholar] [CrossRef]

- Ho, T.T.K.; Tra, V.T.; Le, T.H.; Nguyen, N.-K.-Q.; Tran, C.-S.; Nguyen, P.-T.; Vo, T.-D.-H.; Thai, V.-N.; Bui, X.-T. Compost to Improve Sustainable Soil Cultivation and Crop Productivity. Case Stud. Chem. Environ. Eng. 2022, 6, 100211. [Google Scholar] [CrossRef]

- Meena, A.; Karwal, M.; Dutta, D.; Mishra, R.P. Composting: Phases and Factors Responsible for Efficient and Improved Composting. Agric. Food E Newsl. 2021, 1, 85–90. [Google Scholar]

- USEPA. Types of Composting and Understanding the Process. Available online: https://www.epa.gov/sustainable-management-food/types-composting-and-understanding-process (accessed on 12 May 2023).

- Waqas, M.; Nizami, A.S.; Aburiazaiza, A.S.; Barakat, M.A.; Ismail, I.M.I.; Rashid, M.I. Optimization of Food Waste Compost with the Use of Biochar. J. Environ. Manag. 2018, 216, 70–81. [Google Scholar] [CrossRef]

- Le Pera, A.; Sellaro, M.; Bencivenni, E. Composting Food Waste or Digestate? Characteristics, Statistical and Life Cycle Assessment Study Based on an Italian Composting Plant. J. Clean. Prod. 2022, 350, 131552. [Google Scholar] [CrossRef]

- Palanivell, P.; Susilawati, K.; Ahmed, O.H.; Majid, N.M. Compost and Crude Humic Substances Produced from Selected Wastes and Their Effects on Zea mays L. Nutrient Uptake and Growth. Sci. World J. 2013, 2013, e276235. [Google Scholar] [CrossRef]

- Das, A.; Verma, M.; Mishra, V. Food Waste to Resource Recovery: A Way of Green Advocacy. Env. Sci. Pollut. Res. 2023, 1–13. [Google Scholar] [CrossRef]

- González, Á.; García-Gonzalo, P.; Gil-Díaz, M.M.; Alonso, J.; Lobo, M.C. Compost-Assisted Phytoremediation of As-Polluted Soil. J. Soils Sediments 2019, 19, 2971–2983. [Google Scholar] [CrossRef]

- Chen, Q.; Qu, Z.; Ma, G.; Wang, W.; Dai, J.; Zhang, M.; Wei, Z.; Liu, Z. Humic Acid Modulates Growth, Photosynthesis, Hormone and Osmolytes System of Maize under Drought Conditions. Agric. Water Manag. 2022, 263, 107447. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Bernal, M.P.; Sommer, S.G.; Chadwick, D.; Qing, C.; Guoxue, L.; Michel, F.C. Chapter Three—Current Approaches and Future Trends in Compost Quality Criteria for Agronomic, Environmental, and Human Health Benefits. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2017; Volume 144, pp. 143–233. [Google Scholar]

- Uddin, M.N.; Siddiki, S.Y.A.; Mofijur, M.; Djavanroodi, F.; Hazrat, M.A.; Show, P.L.; Ahmed, S.F.; Chu, Y.-M. Prospects of Bioenergy Production from Organic Waste Using Anaerobic Digestion Technology: A Mini Review. Front. Energy Res. 2021, 9, 627093. [Google Scholar] [CrossRef]

- Song, S.; Lim, J.W.; Lee, J.T.E.; Cheong, J.C.; Hoy, S.H.; Hu, Q.; Tan, J.K.N.; Chiam, Z.; Arora, S.; Lum, T.Q.H.; et al. Food-Waste Anaerobic Digestate as a Fertilizer: The Agronomic Properties of Untreated Digestate and Biochar-Filtered Digestate Residue. Waste Manag. 2021, 136, 143–152. [Google Scholar] [CrossRef] [PubMed]

- Cheong, J.C.; Lee, J.T.E.; Lim, J.W.; Song, S.; Tan, J.K.N.; Chiam, Z.Y.; Yap, K.Y.; Lim, E.Y.; Zhang, J.; Tan, H.T.W.; et al. Closing the Food Waste Loop: Food Waste Anaerobic Digestate as Fertilizer for the Cultivation of the Leafy Vegetable, Xiao Bai Cai (Brassica rapa). Sci. Total Environ. 2020, 715, 136789. [Google Scholar] [CrossRef] [PubMed]

- Mtaita, T.A. CHAPTER 3—Food. In Field Guide to Appropriate Technology; Hazeltine, B., Bull, C., Eds.; Academic Press: San Diego, CA, USA, 2003; pp. 277–480. ISBN 978-0-12-335185-2. [Google Scholar]

- Panuccio, M.R.; Mallamaci, C.; Attinà, E.; Muscolo, A. Using Digestate as Fertilizer for a Sustainable Tomato Cultivation. Sustainability 2021, 13, 1574. [Google Scholar] [CrossRef]

- Barzee, T.J.; Edalati, A.; El-Mashad, H.; Wang, D.; Scow, K.; Zhang, R. Digestate Biofertilizers Support Similar or Higher Tomato Yields and Quality Than Mineral Fertilizer in a Subsurface Drip Fertigation System. Front. Sustain. Food Syst. 2019, 3, 58. [Google Scholar] [CrossRef]

- Dutta, S.; He, M.; Xiong, X.; Tsang, D.C.W. Sustainable Management and Recycling of Food Waste Anaerobic Digestate: A Review. Bioresour. Technol. 2021, 341, 125915. [Google Scholar] [CrossRef]

- Zhu-Barker, X.; Bailey, S.K.; Paw, U.K.T.; Burger, M.; Horwath, W.R. Greenhouse Gas Emissions from Green Waste Composting Windrow. Waste Manag. 2017, 59, 70–79. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the Sustainability of Organic Waste Management Practices in the Food-Energy-Water Nexus: A Comparative Review of Anaerobic Digestion and Composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- Jiang, Y.; Xie, S.H.; Dennehy, C.; Lawlor, P.G.; Hu, Z.H.; Wu, G.X.; Zhan, X.M.; Gardiner, G.E. Inactivation of Pathogens in Anaerobic Digestion Systems for Converting Biowastes to Bioenergy: A Review. Renew. Sustain. Energy Rev. 2020, 120, 109654. [Google Scholar] [CrossRef]

- Insam, H.; Gómez-Brandón, M.; Ascher, J. Manure-Based Biogas Fermentation Residues—Friend or Foe of Soil Fertility? Soil Biol. Biochem. 2015, 84, 1–14. [Google Scholar] [CrossRef]

- Guruchandran, S.; Muninathan, C.; Ganesan, N.D. Novel Strategy for Effective Utilization of Anaerobic Digestate as a Nutrient Medium for Crop Production in a Recirculating Deep Water Culture Hydroponics System. Biomass Conv. Bioref. 2022, 1–13. [Google Scholar] [CrossRef]

- Maurya, D.K.; Kumar, A.; Chaurasiya, U.; Hussain, T.; Singh, S.K. 11—Modern Era of Microbial Biotechnology: Opportunities and Future Prospects. In Microbiomes and Plant Health; Solanki, M.K., Kashyap, P.L., Ansari, R.A., Kumari, B., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 317–343. ISBN 978-0-12-819715-8. [Google Scholar]

- Tropea, A. Food Waste Valorization. Fermentation 2022, 8, 168. [Google Scholar] [CrossRef]

- Hashempour-Baltork, F.; Farshi, P.; Khosravi-Darani, K. Vegetable and Fruit Wastes as Substrate for Production of Single-Cell Protein and Aquafeed Meal. In Fruits and Vegetable Wastes: Valorization to Bioproducts and Platform Chemicals; Ray, R.C., Ed.; Springer Nature: Singapore, 2022; pp. 169–187. ISBN 9789811695278. [Google Scholar]

- Tropea, A.; Ferracane, A.; Albergamo, A.; Potortì, A.G.; Lo Turco, V.; Di Bella, G. Single Cell Protein Production through Multi Food-Waste Substrate Fermentation. Fermentation 2022, 8, 91. [Google Scholar] [CrossRef]

- Mahan, K.M.; Le, R.K.; Wells, T., Jr.; Anderson, S.; Yuan, J.S.; Stoklosa, R.J.; Bhalla, A.; Hodge, D.B.; Ragauskas, A.J. Production of Single Cell Protein from Agro-Waste Using Rhodococcus Opacus. J. Ind. Microbiol. Biotechnol. 2018, 45, 795–801. [Google Scholar] [CrossRef] [PubMed]

- Siegrist, A.; Green, A.; Gold, M.; Mathys, A. Recent Findings on Environmental Sustainability and Conversion Efficiency of Waste-to-Protein Pathways. Curr. Opin. Green Sustain. Chem. 2023, 41, 100833. [Google Scholar] [CrossRef]

- LaTurner, Z.W.; Bennett, G.N.; San, K.-Y.; Stadler, L.B. Single Cell Protein Production from Food Waste Using Purple Non-Sulfur Bacteria Shows Economically Viable Protein Products Have Higher Environmental Impacts. J. Clean. Prod. 2020, 276, 123114. [Google Scholar] [CrossRef]

- Nisansala, A.; Nikagolla, D.; Kapilan, R. Fruit Waste Substrates to Produce Single-Cell Proteins as Alternative Human Food Supplements and Animal Feeds Using Baker’s Yeast (Saccharomyces cerevisiae). J. Food Qual. 2021, 2021, 9932762. [Google Scholar] [CrossRef]

- Abdullahi, N.; Dandago, M.A.; Yunusa, A.K. Review on Production of Single-Cell Protein from Food Wastes. Turk. J. Agric. Food Sci. Technol. 2021, 9, 968–974. [Google Scholar] [CrossRef]

- Wang, H.; Kaur, G.; To, M.H.; Roelants, S.L.K.W.; Patria, R.D.; Soetaert, W.; Lin, C.S.K. Efficient In-Situ Separation Design for Long-Term Sophorolipids Fermentation with High Productivity. J. Clean. Prod. 2020, 246, 118995. [Google Scholar] [CrossRef]

- Madankar, C.; Borde, P. Review on Sophorolipids—A Promising Microbial Bio-Surfactant. Tenside Surfactants Deterg. 2023, 60, 95–105. [Google Scholar] [CrossRef]

- Celligoi, M.A.P.C.; Silveira, V.A.I.; Hipólito, A.; Caretta, T.O.; Baldo, C. Sophorolipids: A Review on Production and Perspectives of Application in Agriculture. Span. J. Agric. Res. 2020, 18, e03R01. [Google Scholar] [CrossRef]

- Hipólito, A.; Alves da Silva, R.A.; de Oliveira Caretta, T.; Silveira, V.A.I.; Amador, I.R.; Panagio, L.A.; Borsato, D.; Celligoi, M.A.P.C. Evaluation of the Antifungal Activity of Sophorolipids from Starmerella Bombicola against Food Spoilage Fungi. Biocatal. Agric. Biotechnol. 2020, 29, 101797. [Google Scholar] [CrossRef]

- Silveira, V.A.I.; Marim, B.M.; Hipólito, A.; Gonçalves, M.C.; Mali, S.; Kobayashi, R.K.T.; Celligoi, M.A.P.C. Characterization and Antimicrobial Properties of Bioactive Packaging Films Based on Polylactic Acid-Sophorolipid for the Control of Foodborne Pathogens. Food Packag. Shelf Life 2020, 26, 100591. [Google Scholar] [CrossRef]

- Saha, D.; Das, P.K.; Saha, D.; Das, P.K. Bioconversion of Agricultural and Food Wastes to Vinegar; IntechOpen: Rijeka, Croatia, 2023; ISBN 978-1-80356-849-2. [Google Scholar]

- Li, Q.; Yi, P.; Zhang, J.; Shan, Y.; Lin, Y.; Wu, M.; Wang, K.; Tian, G.; Li, J.; Zhu, T. Bioconversion of Food Waste to Crayfish Feed Using Solid-State Fermentation with Yeast. Env. Sci. Pollut. Res. 2023, 30, 15325–15334. [Google Scholar] [CrossRef]

- Hadj Saadoun, J.; Bertani, G.; Levante, A.; Vezzosi, F.; Ricci, A.; Bernini, V.; Lazzi, C. Fermentation of Agri-Food Waste: A Promising Route for the Production of Aroma Compounds. Foods 2021, 10, 707. [Google Scholar] [CrossRef]

- Sharma, V.; Tsai, M.-L.; Nargotra, P.; Chen, C.-W.; Kuo, C.-H.; Sun, P.-P.; Dong, C.-D. Agro-Industrial Food Waste as a Low-Cost Substrate for Sustainable Production of Industrial Enzymes: A Critical Review. Catalysts 2022, 12, 1373. [Google Scholar] [CrossRef]

- Sakina, A.; Nazir, N.; Sultan, P.; Hassan, Q.P. Chapter 24—Bioconversion of Agricultural Residues and Waste to Value Added Products. In Value-Addition in Agri-Food Industry Waste Through Enzyme Technology; Kuddus, M., Ramteke, P., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 355–364. ISBN 978-0-323-89928-4. [Google Scholar]

- Yao, Y.; Li, H.; Li, J.; Zhu, B.; Gao, T. Anaerobic Solid-State Fermentation of Soybean Meal with Bacillus sp. to Improve Nutritional Quality. Front. Nutr. 2021, 8, 706977. [Google Scholar] [CrossRef]

- McAdam, B.; Brennan Fournet, M.; McDonald, P.; Mojicevic, M. Production of Polyhydroxybutyrate (PHB) and Factors Impacting Its Chemical and Mechanical Characteristics. Polymers 2020, 12, 2908. [Google Scholar] [CrossRef]

- Sindhu, R.; Manju, A.; Mohan, P.; Rajesh, R.O.; Madhavan, A.; Arun, K.B.; Hazeena, S.H.; Mohandas, A.; Rajamani, S.P.; Puthiyamadam, A.; et al. Valorization of Food and Kitchen Waste: An Integrated Strategy Adopted for the Production of Poly-3-Hydroxybutyrate, Bioethanol, Pectinase and 2, 3-Butanediol. Bioresour. Technol. 2020, 310, 123515. [Google Scholar] [CrossRef]

- Yang, L.; Zeng, X.; Qiao, S. Advances in Research on Solid-State Fermented Feed and Its Utilization: The Pioneer of Private Customization for Intestinal Microorganisms. Anim. Nutr. 2021, 7, 905–916. [Google Scholar] [CrossRef] [PubMed]

- Fowles, T.M.; Nansen, C. Insect-Based Bioconversion: Value from Food Waste. In Food Waste Management: Solving the Wicked Problem; Närvänen, E., Mesiranta, N., Mattila, M., Heikkinen, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 321–346. ISBN 978-3-030-20561-4. [Google Scholar]

- Ojha, S.; Bußler, S.; Schlüter, O.K. Food Waste Valorisation and Circular Economy Concepts in Insect Production and Processing. Waste Manag. 2020, 118, 600–609. [Google Scholar] [CrossRef] [PubMed]

- Skrivervik, E. Insects’ Contribution to the Bioeconomy and the Reduction of Food Waste. Heliyon 2020, 6, e03934. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Wang, W.; Lu, X.; Zhu, F.; Liu, W.; Wang, X.; Lei, C. Bioconversion Performance and Life Table of Black Soldier Fly (Hermetia illucens) on Fermented Maize Straw. J. Clean. Prod. 2019, 230, 974–980. [Google Scholar] [CrossRef]

- Lu, S.; Taethaisong, N.; Meethip, W.; Surakhunthod, J.; Sinpru, B.; Sroichak, T.; Archa, P.; Thongpea, S.; Paengkoum, S.; Purba, R.A.P.; et al. Nutritional Composition of Black Soldier Fly Larvae (Hermetia illucens L.) and Its Potential Uses as Alternative Protein Sources in Animal Diets: A Review. Insects 2022, 13, 831. [Google Scholar] [CrossRef]

- Bessa, L.W.; Pieterse, E.; Marais, J.; Dhanani, K.; Hoffman, L.C. Food Safety of Consuming Black Soldier Fly (Hermetia illucens) Larvae: Microbial, Heavy Metal and Cross-Reactive Allergen Risks. Foods 2021, 10, 1934. [Google Scholar] [CrossRef]

- Berggren, Å.; Jansson, A.; Low, M. Approaching Ecological Sustainability in the Emerging Insects-as-Food Industry. Trends Ecol. Evol. 2019, 34, 132–138. [Google Scholar] [CrossRef]

- Moshtaghian, H.; Bolton, K.; Rousta, K. Challenges for Upcycled Foods: Definition, Inclusion in the Food Waste Management Hierarchy and Public Acceptability. Foods 2021, 10, 2874. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Stangherlin, I.D.C. Upcycled By-Product Use in Agri-Food Systems from a Consumer Perspective: A Review of What We Know, and What Is Missing. Technol. Forecast. Soc. Change 2021, 168, 120749. [Google Scholar] [CrossRef]

- Grasso, S.; Asioli, D. Consumer Preferences for Upcycled Ingredients: A Case Study with Biscuits. Food Qual. Prefer. 2020, 84, 103951. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, H.; Bhatt, S.; Jeong, H.; Deutsch, J.; Ayaz, H.; Suri, R. Addressing Food Waste: How to Position Upcycled Foods to Different Generations. J. Consum. Behav. 2021, 20, 242–250. [Google Scholar] [CrossRef]

- Bhatt, S.; Ye, H.; Deutsch, J.; Jeong, H.; Zhang, J.; Suri, R. Food Waste and Upcycled Foods: Can a Logo Increase Acceptance of Upcycled Foods? J. Food Prod. Mark. 2021, 27, 188–203. [Google Scholar] [CrossRef]

- Trigo, J.P.; Alexandre, E.M.C.; Saraiva, J.A.; Pintado, M.E. High Value-Added Compounds from Fruit and Vegetable by-Products—Characterization, Bioactivities, and Application in the Development of Novel Food Products. Crit. Rev. Food Sci. Nutr. 2020, 60, 1388–1416. [Google Scholar] [CrossRef]

- Thorsen, M.; Skeaff, S.; Goodman-Smith, F.; Thong, B.; Bremer, P.; Mirosa, M. Upcycled Foods: A Nudge toward Nutrition. Front. Nutr. 2022, 9, 2881. [Google Scholar] [CrossRef]