The Impact of Digital Transformation on Supply Chain Capabilities and Supply Chain Competitive Performance

Abstract

1. Introduction

2. Theoretical Background

2.1. Supply Chain Competitive Performance

2.2. Supply Chain Capability

2.3. Digital Transformation

2.4. Contingency Theory

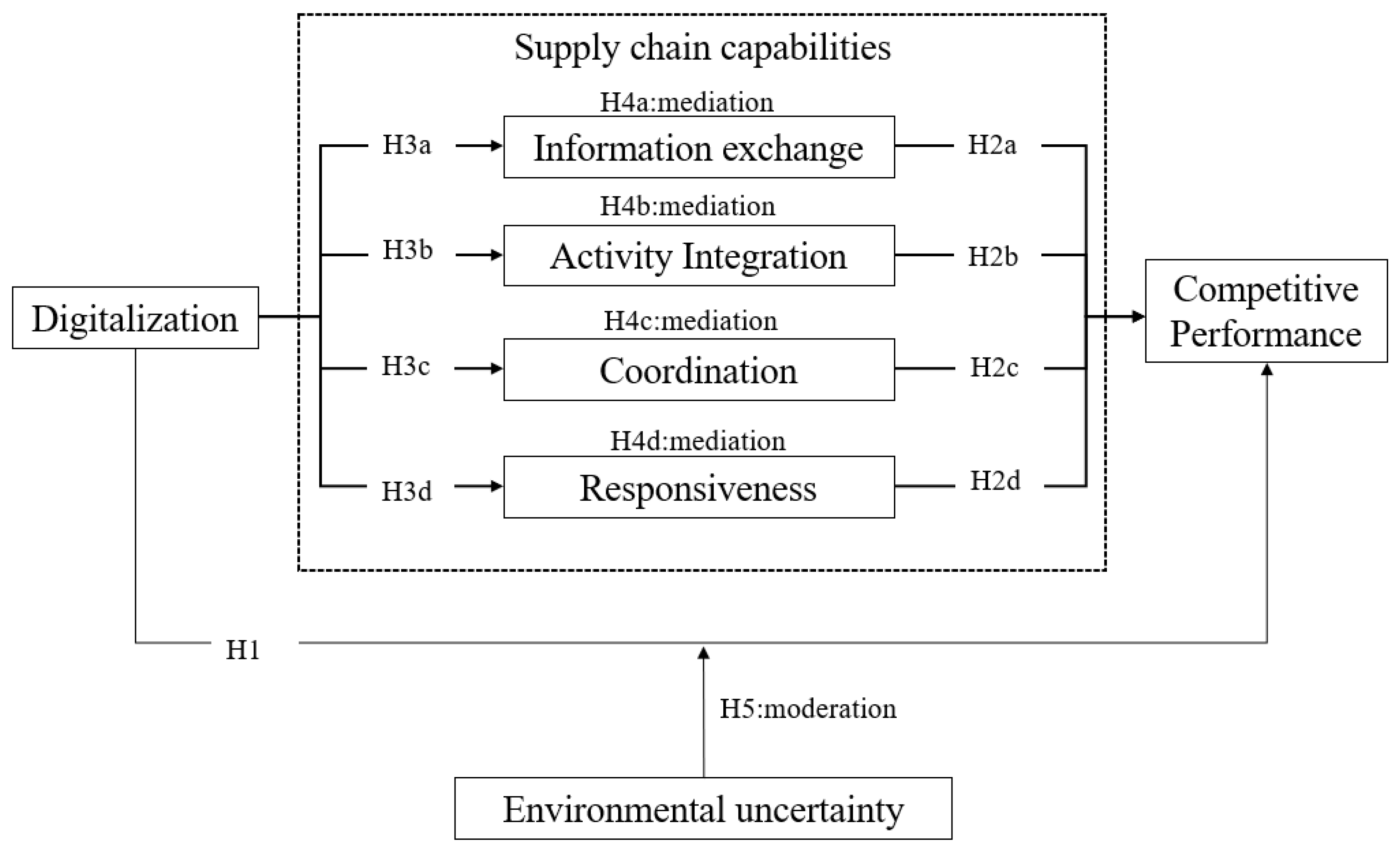

3. Hypothesis Development

3.1. Digital Transformation and Supply Chain Competitive Performance

3.2. Supply Chain Capability and Supply Chain Competitive Performance

3.3. Digitization Transformation, Supply Chain Capabilities, and Supply Chain Competitive Performance

3.4. The Moderating Role of Environmental Uncertainty

3.5. Control Variables

4. Methodology

4.1. Measurement Scales

4.2. Sample Selection and Data Collection

5. Results

5.1. Nonresponse Bias and Common Method Bias

5.2. Reliability and Validity Testing

5.3. Hypothesis Testing

5.3.1. Proposed Structural Model and Main Effect Hypotheses Testing

5.3.2. Testing the Mediating Effect of SCF

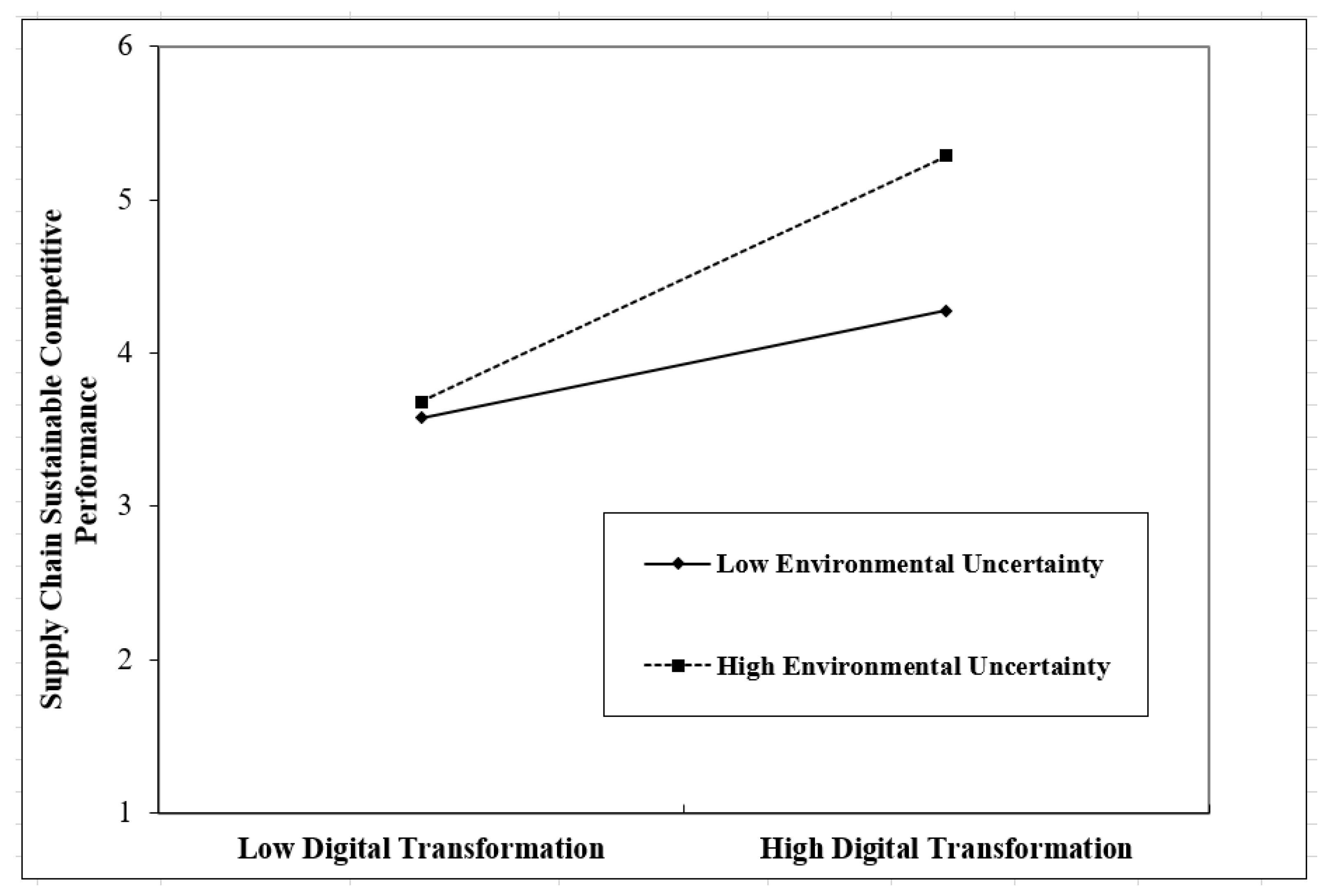

5.3.3. Testing the Moderating Effect of Environmental Uncertainty

6. Discussion

6.1. Discussion of Results

6.2. Theoretical Implications

6.3. Managerial Implications

7. Conclusions and Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, J.; Sarfraz, M.; Khawaja, K.F.; Abdullah, M.I. Sustainable Supply Chain Strategy and Sustainable Competitive Advantage: A Mediated and Moderated Model. Front. Public Health 2022, 10, 1291. [Google Scholar] [CrossRef]

- Barney, J.B. Firm Resource and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J.A. Dynamic Capabilities: What Are They? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Haris, A.; Constantin, B.; Samuel, R.; Azhar, T.M. Dynamic supply chain capabilities: How market sensing, supply chain agility and adaptability affect supply chain ambidexterity. Int. J. Oper. Prod. Manag. 2018, 38, 2266–2285. [Google Scholar]

- Warner, K.S.R.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Miao, Z. Digital economy value chain: Concept, model structure, and mechanism. Appl. Econ. 2021, 53, 4342–4357. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Aragon-Correa, J.A.; Sharma, S. A Contingent Resource-Based View of Proactive Corporate Environmental Strategy. Acad. Manag. Rev. 2003, 28, 71–88. [Google Scholar] [CrossRef]

- Miller, D.; Friesen, P.H. Strategy-making and environment: The third link. Strateg. Manag. J. 1983, 4, 221–235. [Google Scholar] [CrossRef]

- Wang, P.; Liu, H.; Chen, P. Enterprise digitization, environmental uncertainty, and total factor productivity. Econ. Manag. 2023, 45, 43–66. [Google Scholar]

- Chen, X.; Li, Y.; Song, L.; Wang, Y. The theoretical system of digital economy and research prospects. Manag. World 2022, 38, 13–16+208–224. [Google Scholar]

- Lim, J.-S.; Vonderembse, M.A.; Tracey, M. Manufacturing technology and strategy formulation: Keys to enhancing competitiveness and improving performance. J. Oper. Manag. 1999, 17, 411–428. [Google Scholar]

- Datta, P.P. Enhancing competitive advantage by constructing supply chains to achieve superior performance. Prod. Plan. Control 2016, 28, 57–74. [Google Scholar] [CrossRef]

- Porter, M.E.; Millar, V.E. How Information Gives You Competitive Advantage: The Information Revolution Is Transforming the Nature of Competition. Knowl. Spec. Libr. 1999, 191, 85–103. [Google Scholar]

- Hoffman, N.P. An Examination of the “Sustainable Competitive Advantage” Concept: Past, Present, and Future. Acad. Mark. Sci. Rev. 2000, 2000, 1–16. [Google Scholar]

- Yang, X.; Song, H. Supply Chain Finance, Supply Chain Capability, and Competitive Performance: A Multi-case Study. Manag. Case Stud. Rev. 2017, 10, 491–507. [Google Scholar]

- Lei, X.; Chen, P. Review of Supply Chain Competitiveness Research. Bus. Econ. Manag. 2008, 3–8. [Google Scholar]

- Guan, B. Improving the Overall Competitiveness of the Supply Chain through Supply Chain Finance. Southwest Financ. 2017, 32–36. [Google Scholar]

- John, T. The Nature of Interfirm Partnering in Supply Chain Management. J. Retail. 2002, 4, 549–568. [Google Scholar]

- Porter, M.E. The Competitive Advantages of Nations; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Ma, G. Definition and Theoretical Review of the Connotation of Enterprise Competitive Advantage. Econ. Rev. 2006, 113–121. [Google Scholar]

- Wu, F.; Yeniyurt, S.; Kim, D.; Cavusgil, S.T. The impact of information technology on supply chain capabilities and firm performance: A resource-based view. Ind. Mark. Manag. 2006, 35, 493–504. [Google Scholar] [CrossRef]

- Bi, R.; Davidson, R.; Kam, B.; Smyrnios, K. Developing Organizational Agility through IT and Supply Chain Capability. J. Glob. Inf. Manag. 2013, 21, 1–18. [Google Scholar] [CrossRef]

- Allred, C.R.; Fawcett, S.E.; Wallin, C.; Magnan, G.M. A Dynamic Collaboration Capability as a Source of Competitive Advantage. Decis. Sci. 2011, 42, 129–161. [Google Scholar] [CrossRef]

- Zheng, X.; Ma, H.; Wu, J. Overview and Future Prospects of Capability Research from the Supply Chain Perspective. Foreign Econ. Manag. 2018, 40, 59–72. [Google Scholar]

- Annarelli, A.; Battistella, C.; Nonino, F.; Parida, V.; Pessot, E. Literature review on digitalization capabilities: Co-citation analysis of antecedents, conceptualization and consequences. Technol. Forecast. Soc. Chang. 2021, 166, 120635. [Google Scholar] [CrossRef]

- Lenka, S.; Parida, V.; Wincent, J. Digitalization Capabilities as Enablers of Value Co-Creation in Servitizing Firms. Psychol. Mark. 2016, 34, 92–100. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, X.; Li, D. The Multiple Effects and Open Research Framework of Enterprise Digital Transformation. J. Xi’an Jiaotong Univ. 2022, 42, 10–19. [Google Scholar]

- Wang, H.; Wang, S.; Liu, R. Research on the Model of Enterprise Digital Maturity. Manag. Rev. 2021, 33, 152–162. [Google Scholar]

- Chen, W.; Wang, J. Attachment-Based Upgrading: Digital Transformation Strategies of Participants in Platform Ecosystems. Manag. World 2021, 37, 195–214. [Google Scholar]

- Zhao, N.; Hong, J.; Lau, K.H. Impact of supply chain digitalization on supply chain resilience and performance: A multi-mediation model. Int. J. Prod. Econ. 2023, 259, 108817. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Patel, P.C.; Gebauer, H. The relationship between digitalization and servitization: The role of servitization in capturing the financial potential of digitalization. Technol. Forecast. Soc. Chang. 2020, 151, 119804. [Google Scholar] [CrossRef]

- Tang, H.; Zhou, W.; Wan, X.; Li, H. Impact of enterprise digitalization on green innovation performance under the perspective of production and operation. Front. Public Health 2022, 10, 971971. [Google Scholar]

- Chi, M.; Ye, D.; Wang, J.; Zhai, S. How to Improve the Performance of New Product Development in Chinese Small and Medium-sized Manufacturing Enterprises: A Perspective of Digital Empowerment. Nankai Bus. Rev. 2020, 23, 63–75. [Google Scholar]

- Yu, D.; Li, Y. Industrial Organizational Innovation in the Era of Digital Economy: A Case Study of the Digitally Driven Industrial Chain Ecosystem. Reform 2021, 24–43. [Google Scholar]

- Lu, B.; Yin, Z.; Zhang, Y. Exploratory Study on the Process and Mechanism of Digital Transformation in Traditional Enterprises. Sci. Res. Manag. 2022, 43, 83–93. [Google Scholar]

- Truant, E.; Broccardo, L.; Dana, L.-P. Digitalisation boosts company performance: An overview of Italian listed companies. Technol. Forecast. Soc. Chang. 2021, 173, 121173. [Google Scholar] [CrossRef]

- Yu, F.; Wang, L. Research on the Path of Technological Innovation in Chinese Manufacturing Enterprises Empowered by Digital Technology. Sci. Res. Manag. 2022, 43, 11–19. [Google Scholar]

- Hu, H.; Lu, H. Research on Value Co-creation in the Evolution of Enterprise Business Ecosystem: A Perspective of Digital Empowerment. Econ. Manag. 2018, 40, 55–71. [Google Scholar]

- Salvi, A.; Vitolla, F.; Rubino, M.; Giakoumelou, A.; Raimo, N. Online information on digitalisation processes and its impact on firm value. J. Bus. Res. 2021, 124, 437–444. [Google Scholar] [CrossRef]

- Daft, R.L. Organization Theory and Design; South Western College Publishing: Cincinnati, OH, USA, 1998. [Google Scholar]

- Zhu, X.; Yan, Y. Dynamic Matching: A Multi-case Study based on Structural Contingency Theory. Case Res. Rev. 2010, 3, 34–47. [Google Scholar]

- Alexander, J.W.; Randolph, A. The fit between technology and structure as a predictor of performance in nursing subunits. Acad. Manag. J. 1985, 28, 844–859. [Google Scholar] [CrossRef]

- Siggelkow, N. Change in the Presence of Fit: The Rise, the Fall, and the Renaissance of Liz Claiborne. In Strategy Process; Wiley-Blackwell: Hoboken, NJ, USA, 2017. [Google Scholar]

- Lawrence, P.R.; Lorsch, J.W. Organization and Environment: Managing Differentiation and Integration; Harvard Business Review Press: Boston, MA, USA, 2007. [Google Scholar]

- Wang, Y.; Wu, Y. Empowering the New Development Pattern with Digital Economy: Internal Mechanisms and Policy Choices. Gansu Soc. 2023, 1–10. [Google Scholar]

- Mak, H.-Y.; Shen, Z.-J.M. When Triple-A Supply Chains Meet Digitalization: The Case of JD.com’s C2M Model. Prod. Oper. Manag. 2020, 30, 656–665. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Venkatesh, M.; Jabbour, C.J.C.; Benkhati, I. Building supply chain resilience and efficiency through additive manufacturing: An ambidextrous perspective on the dynamic capability view. Int. J. Prod. Econ. 2022, 249, 108516. [Google Scholar] [CrossRef]

- Xue, L.; Xie, Q.; Wang, H. Can Digital Transformation Improve Firm’s Competitive Performance?—A Perspective Based on Supply Chain Value Management. Financ. Account. Mon. 2022, 61–70. [Google Scholar]

- Shin, N. Does information technology improve coordination? An empirical analysis. Logist. Inf. Manag. 1999, 12, 138–144. [Google Scholar] [CrossRef]

- Zeng, H.; Ran, H.; Zhou, Q.; Jin, Y.; Cheng, X. The financial effect of firm digitalization: Evidence from China. Technol. Forecast. Soc. Chang. 2022, 183, 121951. [Google Scholar] [CrossRef]

- Shore, B.; Venkatachalam, A.R. Evaluating the Information Sharing Capabilities of Supply Chain Partners: A Fuzzy Logic Model. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 804–824. [Google Scholar] [CrossRef]

- Sun, L.; Huang, J. A Resource-Based Perspective on Information Interaction Capabilities and Firm Performance: An Empirical Investigation from China. In Proceedings of the 7th International Symposium on Project Management (ISPM 2019), Chongqing, China, 6 July 2019; pp. 261–270. [Google Scholar]

- Omar, R.; Ramayah, T. Information Exchange and Supply Chain Performance. Int. J. Inf. Technol. Decis. Mak. 2010, 9, 1000365. [Google Scholar]

- Zhang, Y.; Li, J.; Hu, Y. A Review of Research on the Relationship between Supply Chain Collaboration and Performance in Foreign Countries. J. Shanxi Univ. 2014, 37, 83–90. [Google Scholar]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. Oper. Res. 2010, 50, 459–462. [Google Scholar] [CrossRef]

- Kumar, V.; Chibuzo, E.N.; Garza-Reyes, J.A.; Kumari, A.; Rocha-Lona, L.; Lopez-Torres, G.C. The impact of supply chain integration on performance: Evidence from the UK food sector. Procedia Manuf. 2017, 11, 814–821. [Google Scholar] [CrossRef]

- Cámara, S.B.; Fuentes, J.M.; Marín, J.M.M. Cloud computing, Web 2.0, and operational performance. Int. J. Logist. Manag. 2015, 26, 426–458. [Google Scholar] [CrossRef]

- Jian, Z.; Zeng, J.; Liu, Y. Analysis of the Impact Mechanism of External Integration in Service Supply Chains on Operational Performance: Moderated Mediation Effect. Manag. Rev. 2021, 33, 290–301. [Google Scholar]

- Barney, J.B. Purchasing, Supply Chain Management and Sustained Competitive Advantage The Relevance of Resource-based Theory. J. Supply Chain. Manag. 2012, 48, 3–6. [Google Scholar] [CrossRef]

- Lou, Z. New Industry Model: Solution to the Responsiveness Problem of Efficiency-oriented Supply Chain. Financ. Econ. Rev. 2008, 96–102. [Google Scholar]

- Wang, J. Research on the Path of Global Supply Chain Reconstruction and Digital Transformation in China’s Manufacturing Industry. China Soft Sci. 2022, 23–34. [Google Scholar]

- Vosooghidizaji, M.; Taghipour, A.; Canel-Depitre, B. Supply chain coordination under information asymmetry: A review. Int. J. Prod. Res. 2019, 58, 1805–1834. [Google Scholar] [CrossRef]

- Lutfi, A.A.; Idris, M.; Mohamad, R. AIS usage factors and impact among Jordanian SMEs: The moderating effect of environmental uncertainty. J. Adv. Res. Bus. Manag. Stud. 2017, 6, 24–38. [Google Scholar]

- Lu, Q.; Liu, B.; Song, H. How can SMEs acquire supply chain financing: The capabilities and information perspective. Ind. Manag. Data Syst. 2020, 120, 784–809. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, M.; Dhir, S. Modeling the effects of digital transformation in Indian manufacturing industry. Technol. Soc. 2021, 67, 101763. [Google Scholar] [CrossRef]

- Feng, H.; Nie, L.; Hai, F. The Interaction between Information Sharing Level and Supply Chain Capability: The Mediating Effect of Social Control. Nankai Bus. Rev. 2018, 21, 85–92. [Google Scholar]

- Wong, C.Y.; Boon-itt, S.; Wong, C.W.Y. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Yuan, Y. The effects of supply chain risk information processing capability and supply chain finance on supply chain resilience: A moderated and mediated model. J. Enterp. Inf. Manag. 2022, 35, 1–21. [Google Scholar] [CrossRef]

- Wong, C.-W.Y.; Lai, K.-H.; Ngai, E.W.T. The role of supplier operational adaptation on the performance of IT-enabled transport logistics under environmental uncertainty. Int. J. Prod. Econ. 2009, 122, 47–55. [Google Scholar] [CrossRef]

- Jiao, H. An empirical study on the relationship between dynamic capabilities, environmental dynamism, and performance. Soft Sci. 2008, 112–117. [Google Scholar]

- Zhou, S.; Wan, G. The impact of information technology capability on supply chain performance: A perspective of information integration. J. Syst. Manag. 2016, 25, 90–102. [Google Scholar]

- Xi, J. Hold High the Great Banner of Socialism with Chinese Characteristics and Strive for the Great Success of Building a Modern Socialist Country in An All-Round Way. In Proceedings of the 20th National Congress of the Communist Party of China, Beijing, China, 16 October 2022; pp. 1–21. [Google Scholar]

- Chen, M.G.; Zhang, X. The scale measurement and productivity analysis of China’s digital economy. J. Quant. Technol. Econ. 2022, 39, 3–27. [Google Scholar]

- Armstrong, J.S.; Overton, T.S. Estimating Nonresponse Bias in Mail Surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Podsakoff, P.; MacKenzie, S.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Bagozzi, R.P. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error: A Comment. J. Mark. Res. 1981, 18, 375–381. [Google Scholar] [CrossRef]

| Constructs | Indicator |

|---|---|

| Digital Transformation (DT) [34,66] | Our company is operating business processes based on digital technology. |

| Our company is integrating digital technology to transform our business processes. | |

| Our company unanimously believes that adopting digital technology and digital management is beneficial for the development of the enterprise. | |

| Supply Chain Information Exchange Capability (IE) [22] | The information exchanged between our company and partners is greater than that between competitors and their partners. |

| My company benefits more from information exchange with partners compared to our competitors. | |

| The information exchange between our company and partners is superior to that between competitors and their partners. | |

| Supply Chain Collaboration Capability (CO) [22,23,67] | Our company demonstrates more efficient coordination activities with partners compared to competitors. |

| Our company is able to carry out transactional activities with partners more efficiently compared to competitors. | |

| Our company requires less time to coordinate transactions with partners compared to competitors. | |

| Our company develops strategic plans to enhance collaboration with partners. | |

| Supply Chain Activity Integration Capability (AI) [56] | Our company actively collaborates with partners in forecasting and planning. |

| Our company collaboratively engages with partners in projects and plans for future demands. | |

| Collaborative demand forecasting and planning with partners is a regular practice in our company. | |

| Our company consistently engages in collaborative forecasting and planning activities with partners. | |

| Supply Chain Responsiveness (RS) [56] | Our supply chain responds faster and more effectively to the constantly changing demands of customers and suppliers compared to our competitors. |

| Compared to our competitors, our supply chain is capable of responding more quickly and effectively to changes in their strategic plans. | |

| Our supply chain is effectively competing in most markets. | |

| Competitive Performance (CP) [16,71,72] | Lower communication costs, order management costs, inventory costs, warehouse management costs, transportation costs, logistics management costs, etc. |

| Customers are highly satisfied with our services. | |

| Our company performs well in terms of sales revenue growth compared to key competitors. | |

| Our company performs well in terms of market share compared to key competitors. | |

| Environmental Uncertainty (EU) [68,69,70,71] | Rapid changes in customer demand for products or services. |

| The performance of our suppliers is difficult to predict. | |

| Actions taken by competitors in marketing and promotion are unpredictable. | |

| Sales volumes in our industry fluctuate significantly year after year. | |

| Our company uses constantly changing core production technologies. | |

| Control Variables [65] | Operation duration of the company |

| The number of employees in the company | |

| Annual sales of the company | |

| Total assets |

| Constructs | n | % |

|---|---|---|

| Number of employees | ||

| 0–50 | 23 | 9.4% |

| 51–100 | 110 | 43.1% |

| 101–300 | 85 | 33.3% |

| 301–500 | 30 | 11.8% |

| Above 500 | 6 | 2.4% |

| Operation duration | ||

| 1–3 years | 19 | 7.5% |

| 3–8 years | 73 | 28.6% |

| 8–15 years | 122 | 47.8% |

| Above 15 years | 41 | 16.1% |

| Annual sales (million RMB) | ||

| Below 5 | 30 | 11.8% |

| 5–30 | 68 | 26.7% |

| 30–100 | 96 | 37.6% |

| 100–300 | 51 | 20.0% |

| Above 300 | 10 | 3.9% |

| Total assets (million RMB) | ||

| Below 5 | 15 | 5.9% |

| 5–50 | 29 | 11.4% |

| 50–150 | 58 | 22.7% |

| 150–50 | 89 | 34.9% |

| Above 500 | 64 | 25.1% |

| Variable | Mean | SD | DT | EU | IE | CO | AI | RS | CP |

|---|---|---|---|---|---|---|---|---|---|

| DT | 5.509 | 0.892 | 0.807 | ||||||

| EU | 4.936 | 0.789 | 0.513 ** | 0.758 | |||||

| IE | 5.273 | 0.901 | 0.604 ** | 0.123 * | 0.780 | ||||

| CO | 5.358 | 0.776 | 0.509 ** | 0.234 ** | 0.556 ** | 0.807 | |||

| AI | 5.230 | 0.886 | 0.589 ** | 0.456 ** | 0.609 ** | 0.671 ** | 0.796 | ||

| RS | 5.346 | 0.791 | 0.409 ** | 0.431 ** | 0.612 ** | 0.589 ** | 0.566 ** | 0.804 | |

| CP | 5.313 | 0.810 | 0.496 ** | 0.453 ** | 0.689 ** | 0.497 ** | 0.601 ** | 0.701 ** | 0.792 |

| Constructs | Item | Factor Loading | Cronbach’s α | CR | AVE |

|---|---|---|---|---|---|

| Environmental Uncertainty (EU) | EU1 | 0.842 | 0.796 | 0.801 | 0.574 |

| EU2 | 0.714 | ||||

| EU3 | 0.710 | ||||

| Digital Transformation (DT) | DT 1 | 0.815 | 0.881 | 0.882 | 0.652 |

| DT 2 | 0.809 | ||||

| DT 3 | 0.741 | ||||

| DT 4 | 0.860 | ||||

| Information Exchange (IE) | IE 1 | 0.808 | 0.820 | 0.823 | 0.609 |

| IE 2 | 0.764 | ||||

| IE 3 | 0.768 | ||||

| Collaboration (CO) | CO1 | 0.829 | 0.881 | 0.882 | 0.651 |

| CO2 | 0.767 | ||||

| CO3 | 0.827 | ||||

| CO4 | 0.802 | ||||

| Activity Integration (AI) | AI 1 | 0.785 | 0.870 | 0.874 | 0.634 |

| AI 2 | 0.743 | ||||

| AI 3 | 0.854 | ||||

| AI 4 | 0.799 | ||||

| Responsiveness (RS) | R 1 | 0.826 | 0.845 | 0.846 | 0.647 |

| R 2 | 0.782 | ||||

| R 3 | 0.805 | ||||

| Competitive Performance (CP) | CP 1 | 0.762 | 0.868 | 0.870 | 0.627 |

| CP 2 | 0.826 | ||||

| CP 3 | 0.812 | ||||

| CP 4 | 0.765 |

| Path | Parameter Estimate | SE | p-Value | Decision |

|---|---|---|---|---|

| DT→CP | 0.241 ** | 0.046 | <0.01 | H1: Accepted |

| IE→CP | 0.181 ** | 0.063 | <0.01 | H2a: Accepted |

| CO→CP | 0.140 * | 0.067 | <0.05 | H2b: Accepted |

| AI→CP | 0.271 *** | 0.063 | <0.001 | H2c: Accepted |

| RS→CP | 0.168 ** | 0.061 | <0.01 | H2d: Accepted |

| DT→IE | 0.562 *** | 0.035 | <0.001 | H3a: Accepted |

| DT→CO | 0.438 *** | 0.038 | <0.001 | H3b: Accepted |

| DT→IAI | 0.501 *** | 0.033 | <0.001 | H3c: Accepted |

| DT→RS | 0.386 *** | 0.041 | <0.001 | H3d: Accepted |

| Path | Parameter Estimate | SE | Lower 95% CI | Upper 95% CI | Decision |

|---|---|---|---|---|---|

| DT→IE→CP | 0.157 | 0.054 | 0.046 | 0.260 | H3a: Accepted |

| DT→CO→CP | 0.135 | 0.065 | 0.011 | 0.264 | H3b: Accepted |

| DT→AI→CP | 0.245 | 0.058 | 0.138 | 0.361 | H4c: Accepted |

| DT→RS→CP | 0.159 | 0.058 | 0.046 | 0.274 | H4d: Accepted |

| Dependent Variable: Supply Chain Competitive Performance | ||||

|---|---|---|---|---|

| Constructs | Model 1 | Model 2 | Model 3 | Model 4 |

| Control variable | ||||

| Number of employees | 0.390 *** | 0.051 | 0.041 | 0.005 |

| Number of employees | 0.265 *** | 0.092 | 0.077 | 0.057 |

| Annual sales | 0.012 | 0.020 | 0.037 | 0.031 |

| Total assets | 0.369 *** | 0.082 | 0.038 | 0.020 |

| Independent variable | ||||

| DT | 0.478 *** | 0.428 *** | 0.387 *** | |

| EU | 0.279 *** | 0.219 *** | ||

| DT × EU | 0.225 *** | |||

| F-statistics | 68.237 *** | 180.786 *** | 171.772 *** | 160.765 *** |

| R2 | 0.522 | 0.784 | 0.806 | 0.820 |

| ΔR2 | 0.522 | 0.262 | 0.022 | 0.014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, L.; Yao, D. The Impact of Digital Transformation on Supply Chain Capabilities and Supply Chain Competitive Performance. Sustainability 2023, 15, 10107. https://doi.org/10.3390/su151310107

Ning L, Yao D. The Impact of Digital Transformation on Supply Chain Capabilities and Supply Chain Competitive Performance. Sustainability. 2023; 15(13):10107. https://doi.org/10.3390/su151310107

Chicago/Turabian StyleNing, Lianju, and Dan Yao. 2023. "The Impact of Digital Transformation on Supply Chain Capabilities and Supply Chain Competitive Performance" Sustainability 15, no. 13: 10107. https://doi.org/10.3390/su151310107

APA StyleNing, L., & Yao, D. (2023). The Impact of Digital Transformation on Supply Chain Capabilities and Supply Chain Competitive Performance. Sustainability, 15(13), 10107. https://doi.org/10.3390/su151310107