A Systemic Approach to Simulate the Construction Process of Self-Supporting Masonry Structures

Abstract

:1. Introduction

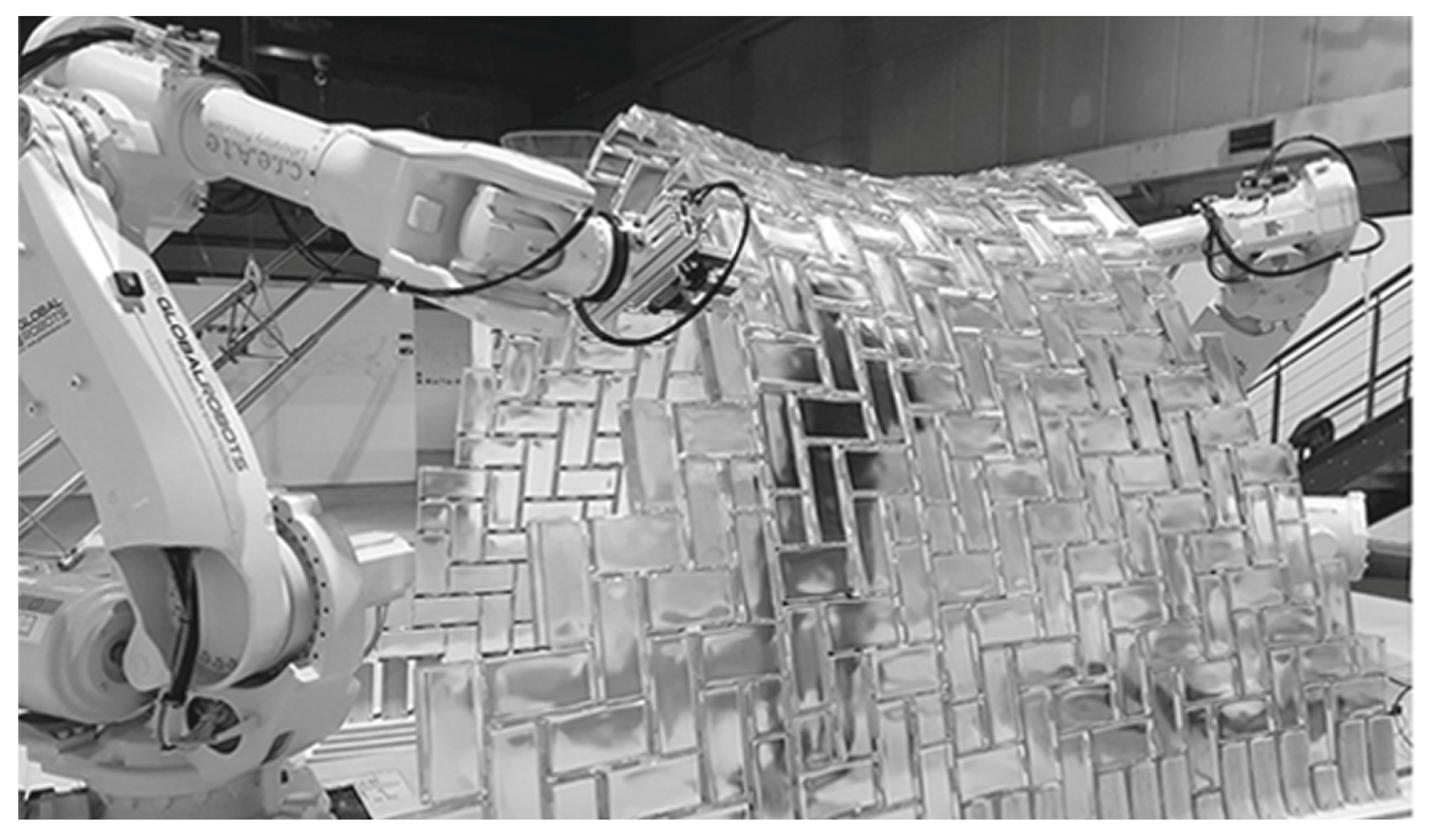

2. Robotic Assistance in Masonry Structures: Combating Tensile Stress through Compression-Focused Design

3. Aim of the Paper

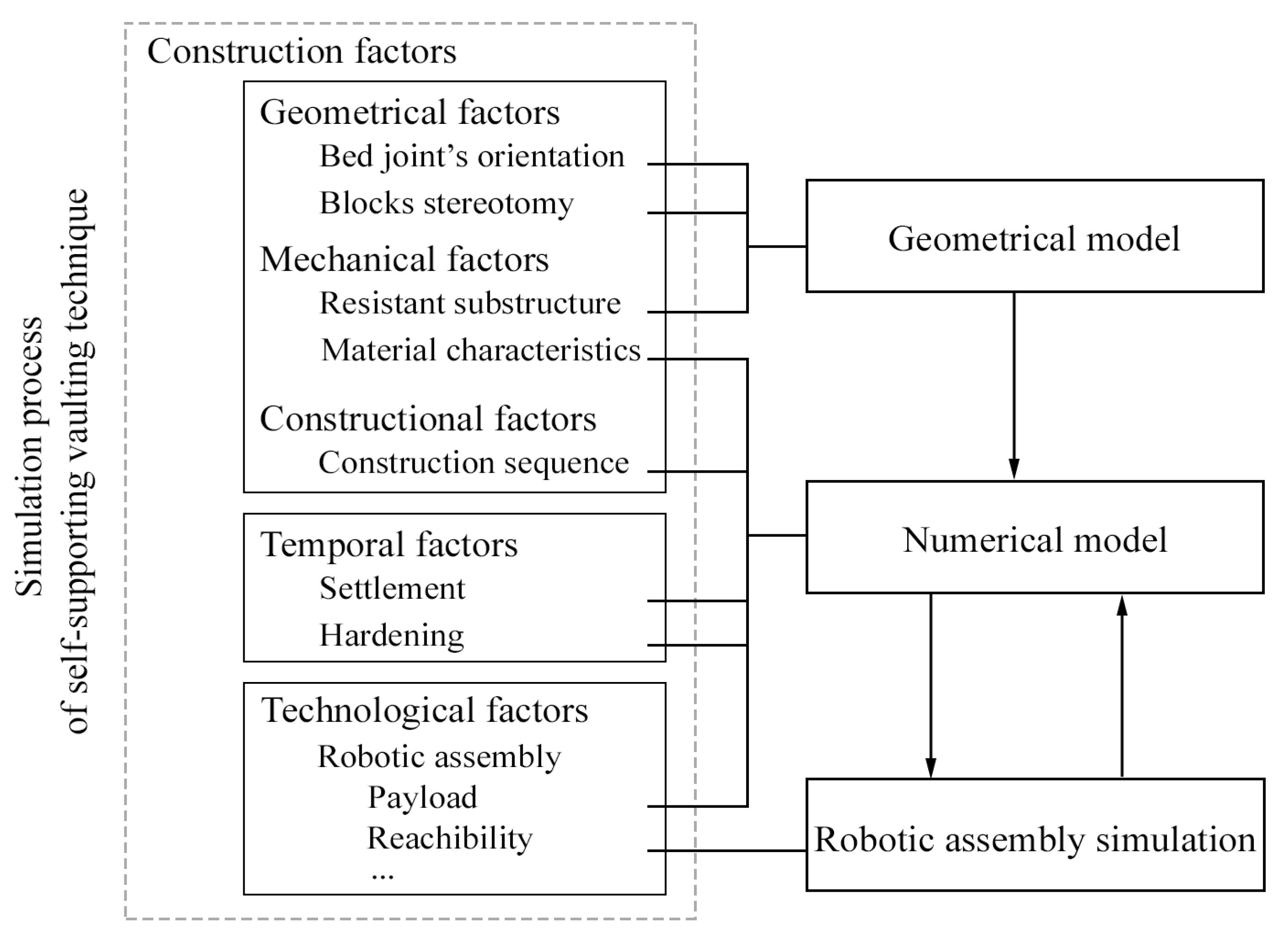

4. Construction Factors

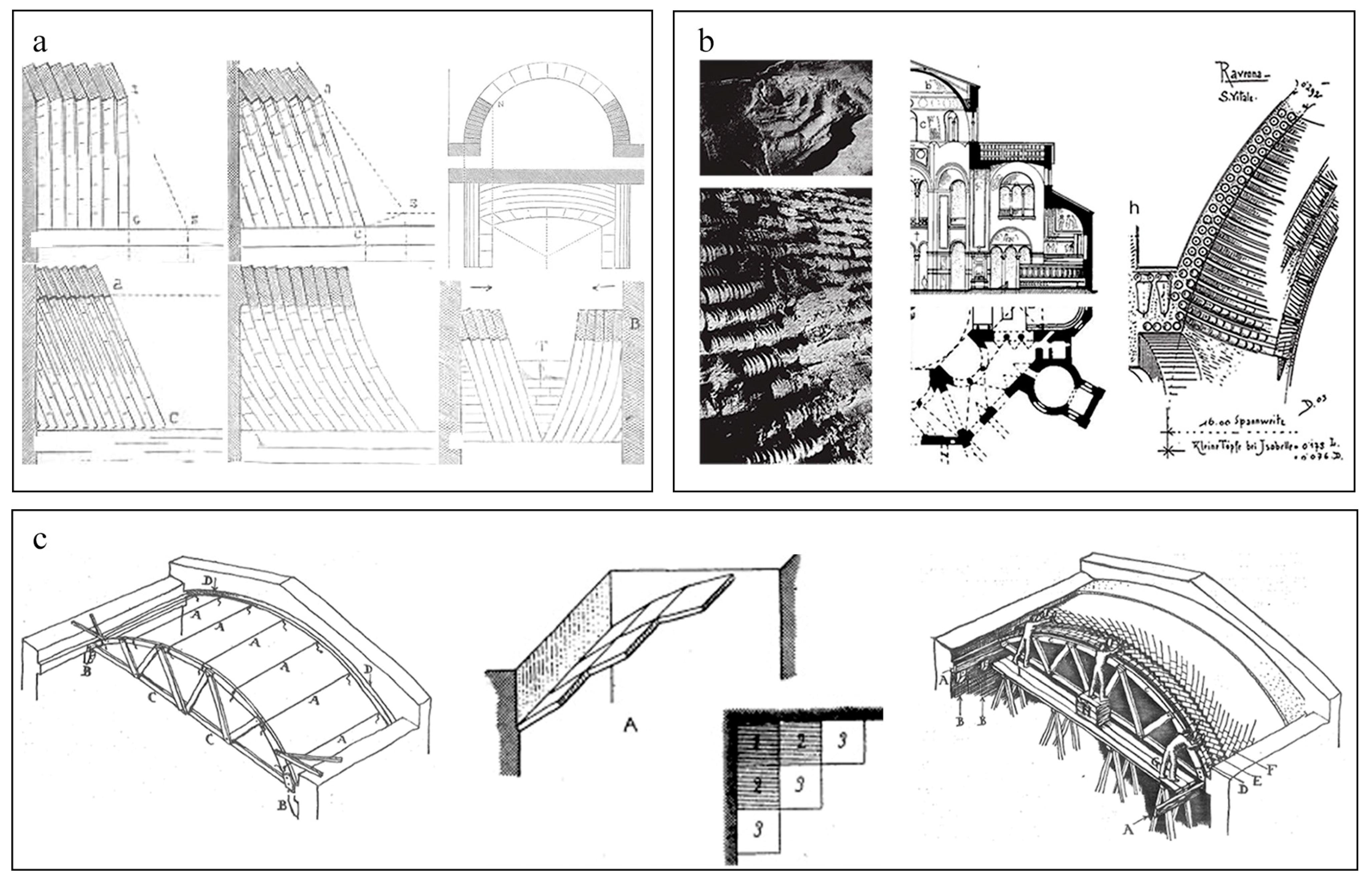

4.1. Construction Factors in Historical Self-Supporting Vaulting Technologies

4.1.1. Geometrical Factors

4.1.2. Mechanical Factors

4.1.3. Construction Factors

4.2. Technological Factors

4.3. Temporal Factors

5. Simulation of the Construction Process

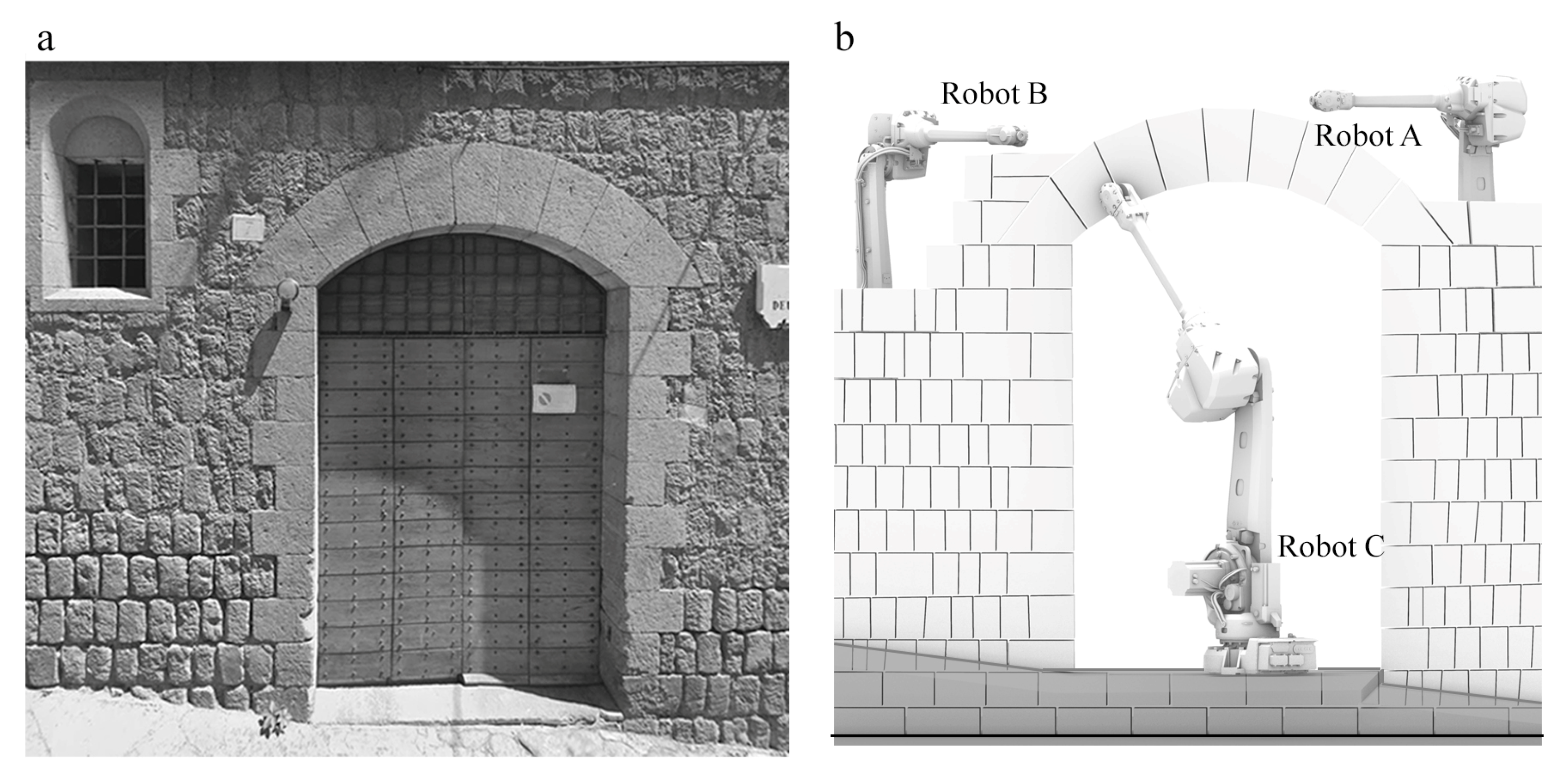

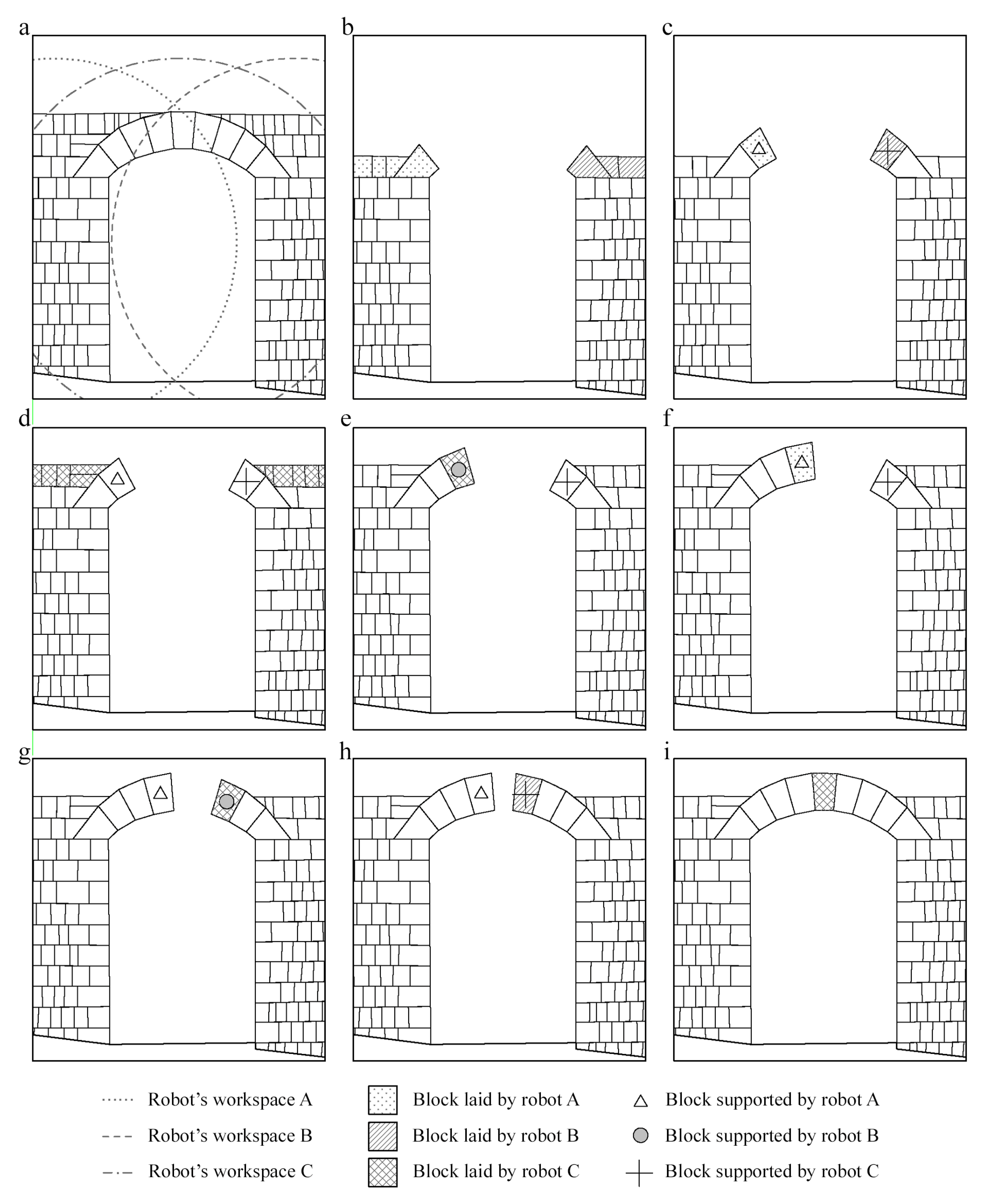

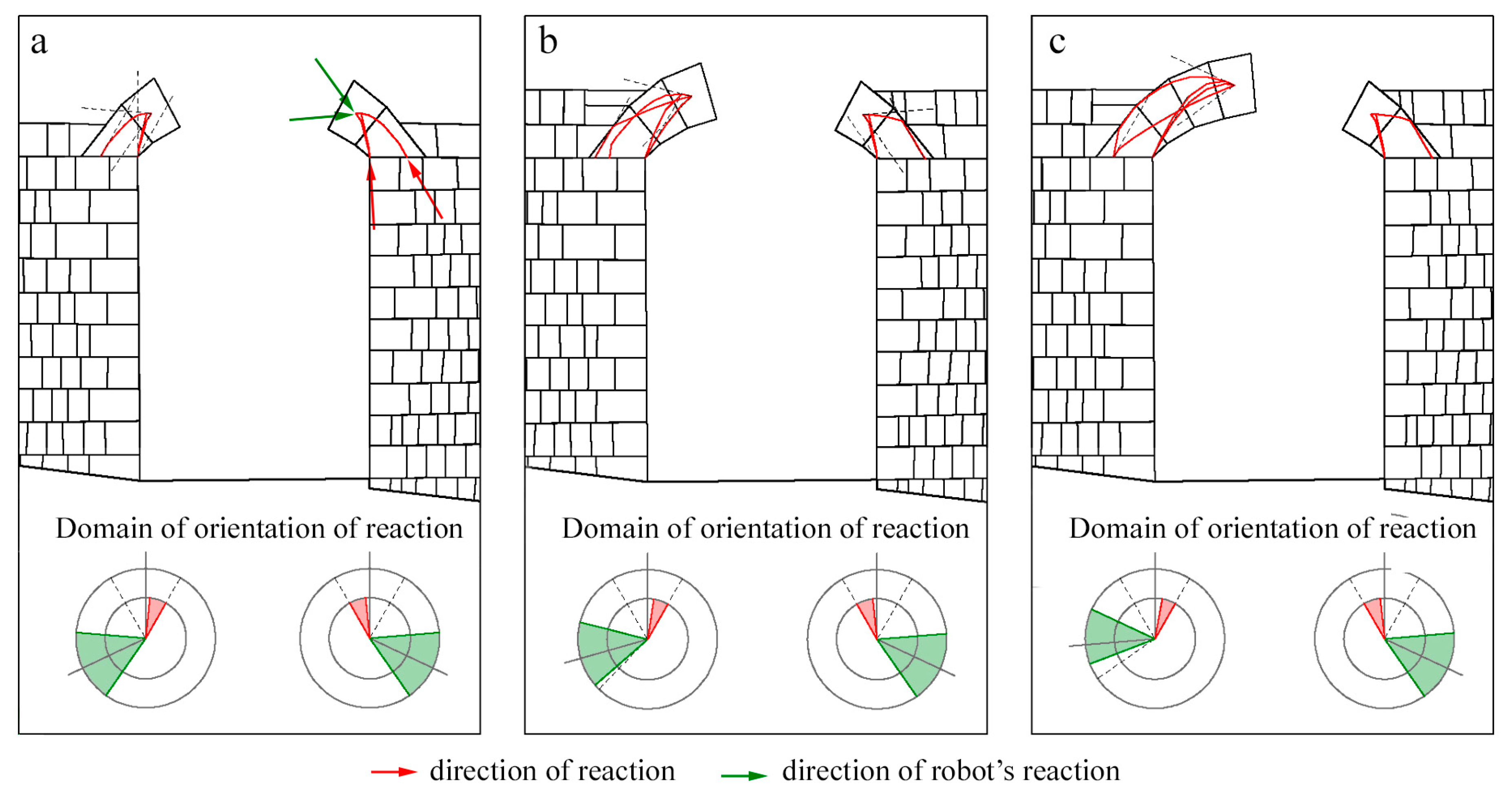

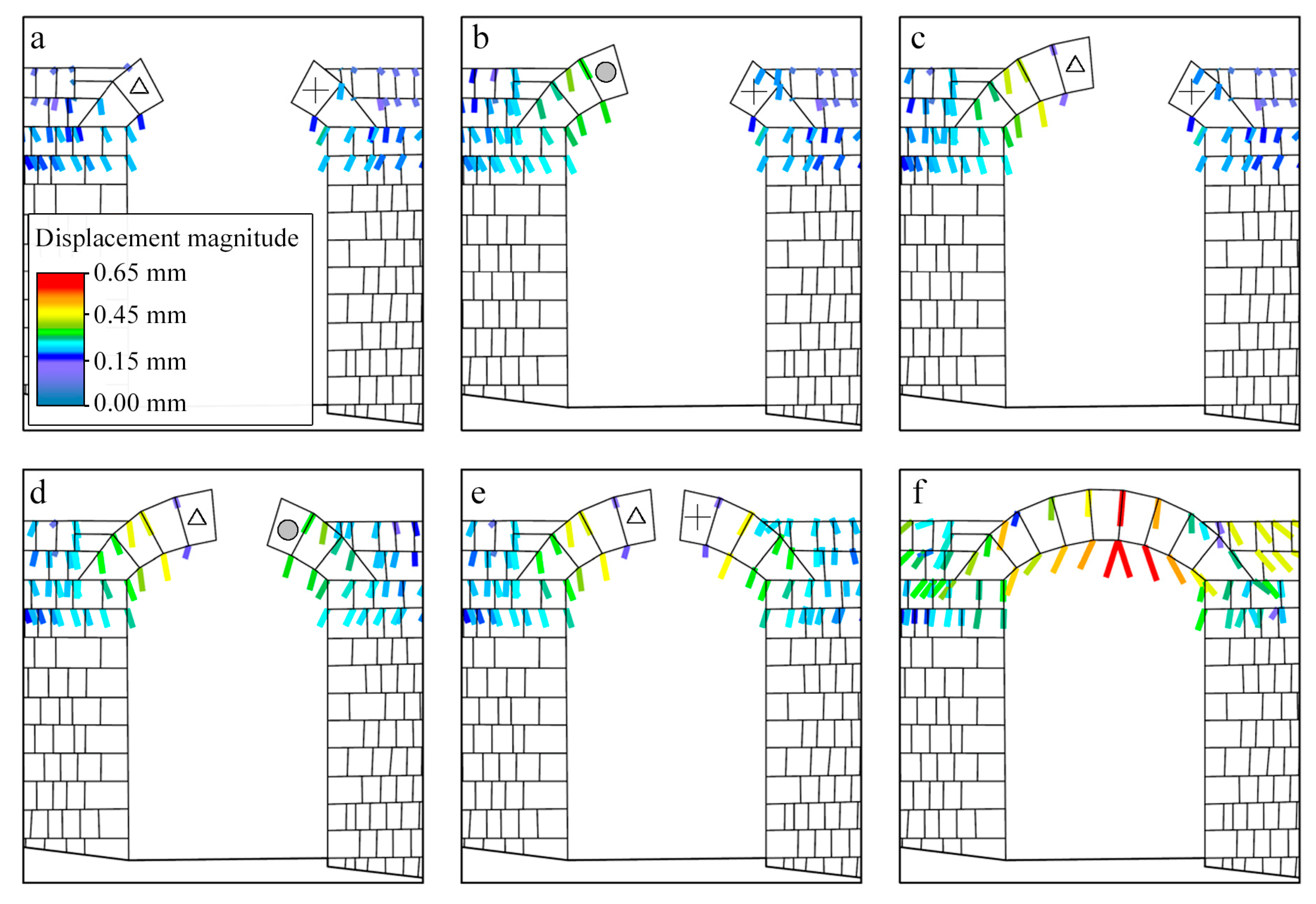

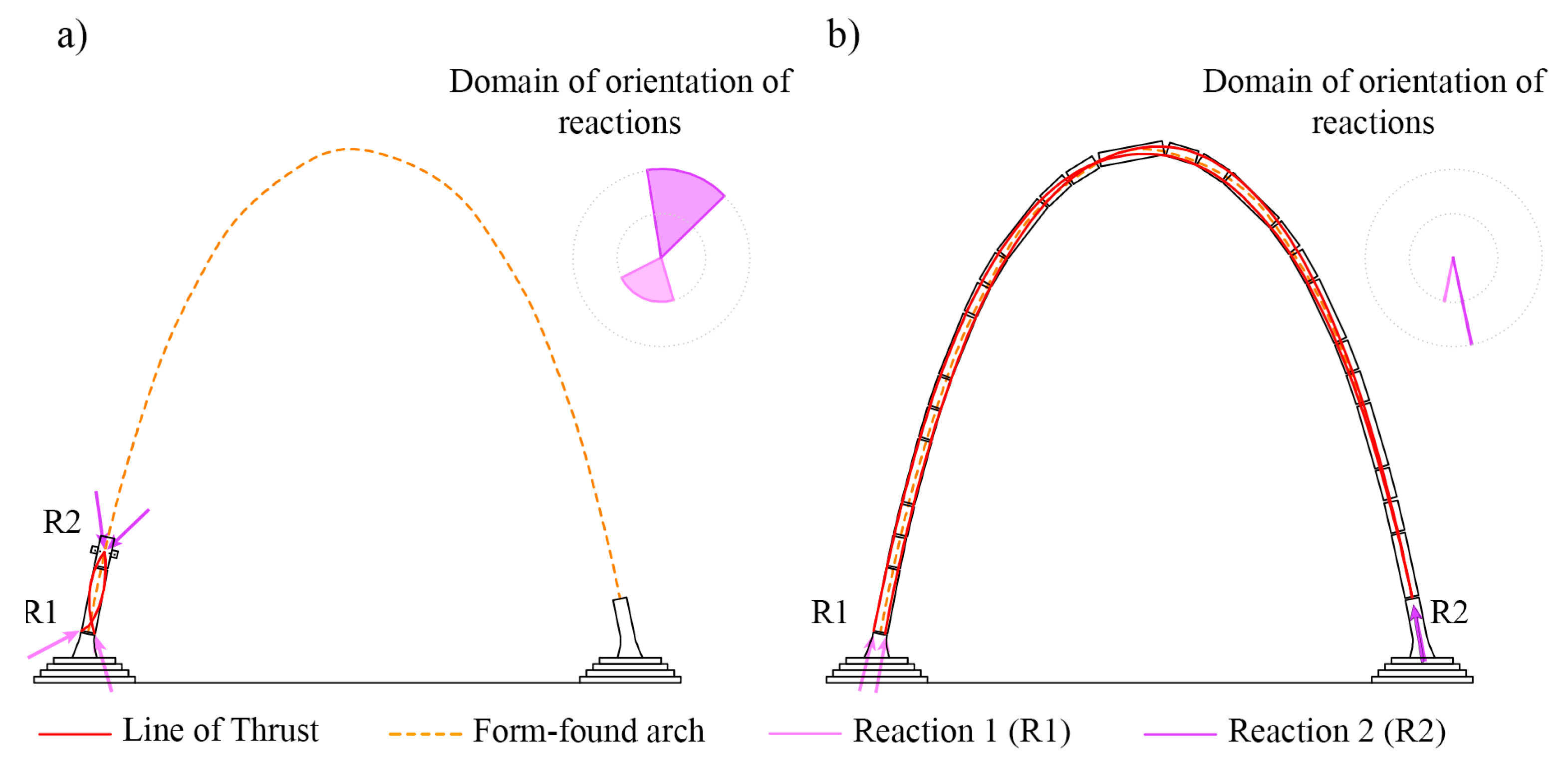

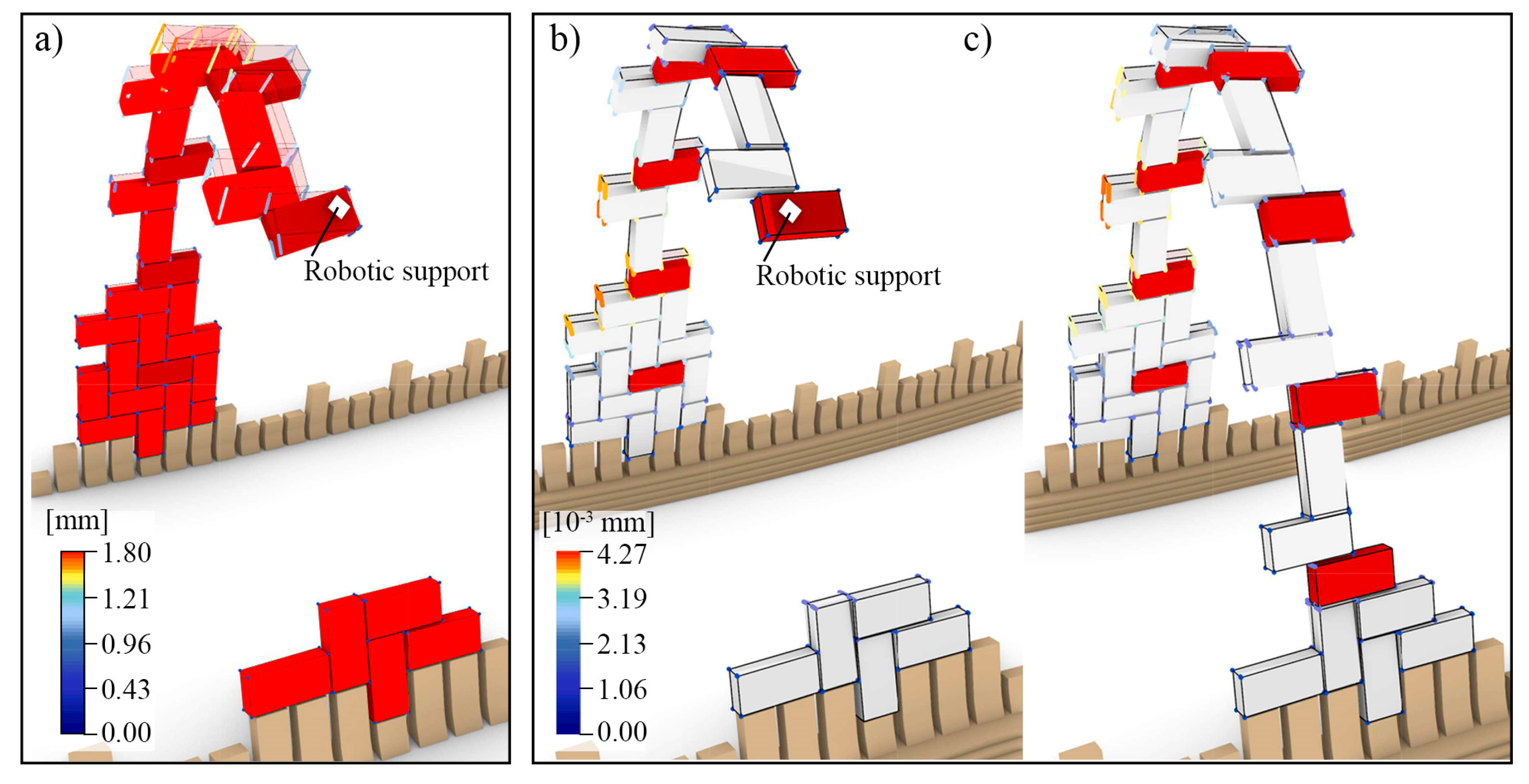

6. The Construction of the Voussoir Arch

6.1. Case Study: Masonry Historical Arch

6.2. Case Study: Anatomy of Structure Masonry Historical Arch

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CF | Construction Factor |

| AEC | Architecture, Engineering, and Construction |

| PVT | Pitched Vaulting Technique |

| CTVT | Clay Tube Vaulting Technique |

| TVT | Tile Vaulting Technique |

| HVT | Herringbone Vaulting Technique |

References

- Parascho, S.; Han, I.X.; Walker, S.; Beghini, A.; Bruun, E.P.G.; Adriaenssens, S. Robotic vault: A cooperative robotic assembly method for brick vault construction. Constr. Robot. 2020, 4, 117–126. [Google Scholar] [CrossRef]

- Adriaenssens, S.; Gramazio, F.; Kohler, M.; Menges, A.; Pauly, M. Advances in Architectural Geometry 2016; VDF Hochschulverlag AG: Zürich, Switzerland, 2016. [Google Scholar]

- Latteur, P.; Goessens, S.; Mueller, C. Masonry construction with drones. In Proceedings of the IASS Annual Symposium: Spatial Structures in the 21st Century, Tokyo, Japan, 26–30 September 2016; Volume 2016. [Google Scholar]

- Bruckmann, T.; Boumann, R. Simulation and optimization of automated masonry construction using cable robots. Adv. Eng. Inform. 2021, 50, 101388. [Google Scholar] [CrossRef]

- Wu, K.; Kilian, A. Designing Compression-Only Arch Structures Using Robotic Equilibrium Assembly. In Impact: Design with All Senses; Gengnagel, A., Baverel, O., Burry, J., Ramsgaard Thomsen, M., Weinzierl, S., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 608–622. [Google Scholar]

- Thomson, J. Brick-Laying Machine. U.S. Patent 772191A, 11 October 1904. [Google Scholar]

- Willmann, J.; Block, P.; Hutter, M.; Byrne, K.; Schork, T. Robotic Fabrication in Architecture, Art and Design 2018: Foreword by Sigrid Brell-Cokcan and Johannes Braumann, Association for Robots in Architecture; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Bock, T.; Linner, T. Robot-Oriented Design: Design and Management Tools for the Deployment of Automation and Robotics in Construction; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Thoma, A.; Adel, A.; Helmreich, M.; Wehrle, T.; Gramazio, F.; Kohler, M. Robotic Fabrication of Bespoke Timber Frame Modules. In Robotic Fabrication in Architecture, Art and Design 2018; Springer International Publishing: Zurich, Switzerland, 2018; pp. 447–458. [Google Scholar]

- Dörfler, K.; Sandy, T.; Giftthaler, M.; Gramazio, F.; Kohler, M.; Buchli, J. Mobile Robotic Brickwork. In Robotic Fabrication in Architecture, Art and Design 2016; Reinhardt, D., Saunders, R., Burry, J., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 204–217. [Google Scholar]

- Parascho, S.; Han, I.X.; Beghini, A.; Mike, M.; Bruun, E.P.G.; Adriaenssens, S.A. Design and Robotic Fabrication Method for Complex Masonry Structures. Adv. Archit. Geom. 2021, 25, 350–375. [Google Scholar]

- Goessens, S.; Mueller, C.; Latteur, P. Feasibility study for drone-based masonry construction of real-scale structures. Autom. Constr. 2018, 94, 458–480. [Google Scholar] [CrossRef]

- Nwaogu, J.M.; Yang, Y.; Chan, A.P.C.; Chi, H. Application of drones in the architecture, engineering, and construction (AEC) industry. Autom. Constr. 2023, 150, 104827. [Google Scholar] [CrossRef]

- Paoletti, I. Mass customization with additive manufacturing: New perspectives for multi performative building components in architecture. Procedia Eng. 2017, 180, 1150–1159. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Bonswetch, T.; Hobel, D.; Gramazio, F.; Kohler, M. The Informed Wall: Applying additive digital fabrication techniques on architecture. In Proceedings of the 25th Annual Conference of the Association for Computer-Aided Design in Architecture: Synthetic, Louisville, KY, USA, 12–15 October 2006; pp. 489–495. [Google Scholar]

- Paris, V.; Lepore, N.; Brunn, E.P.G.; Ruscica, G.; Piccioni, M.D.; Beghini, A.; Parascho, S.; Adriaenssens, S. Robotic Construction of a Self-Balancing glass masonry vault: DEM study of stability during the construction stages. In Proceedings of the IASS Annual Symposia, Surrey, UK, 23–27 August 2021. [Google Scholar]

- Paris, V. Equilibrium of Self-Balanced Shells. Cross-Herringbone Technology; Collana Della Scuola di Alta Formazione Dottorale; University of Bergamo: Bergamo, Italy, 2021. [Google Scholar]

- Chaturvedi, S.; Ochsendorf, J. Global environmental impacts due to cement and steel. Struct. Eng. Int. 2004, 14, 198–200. [Google Scholar] [CrossRef]

- Barbosa, F.; Woetzel, J.; Mischke, J. Reinventing Construction: A Route of Higher Productivity; Technical Report; McKinsey Global Institute: New York, NY, USA, 2017. [Google Scholar]

- Heyman, J. The stone skeleton. Int. J. Solids Struct. 1966, 2, 249–279. [Google Scholar] [CrossRef]

- Montanino, A.; De Gregorio, D.; Olivieri, C.; Iannuzzo, A. The continuous Airy-based for stress-singularities (CASS) method: An energy-based numerical formulation for unilateral materials. Int. J. Solids Struct. 2022, 256, 111954. [Google Scholar] [CrossRef]

- Marmo, F. ArchLab: A MATLAB tool for the Thrust Line Analysis of masonry arches. Curved Layer. Struct. 2021, 8, 26–35. [Google Scholar] [CrossRef]

- Marmo, F.; Rosati, L. Reformulation and extension of the thrust network analysis. Comput. Struct. 2017, 182, 104–118. [Google Scholar] [CrossRef]

- Angelillo, M.; Lourenço, P.B.; Milani, G. Masonry behaviour and modelling. In Mechanics of Masonry Structures; Angelillo, M., Ed.; In CISM International Centre for Mechanical Sciences; Springer: Vienna, Austria, 2014; pp. 1–26. [Google Scholar]

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Towards a Zero-Emission. In Efficient and Resilient Buildings and Construction Sector; Global Alliance for Building and Construction: Nairobi, Kenya, 2021. [Google Scholar]

- Mirabella Roberti, G.; Lombardini, N.; Falter, H. Late Roman domes in clay tubes: Historical and numerical study of San Vitale in Ravenna. In Spatial Structures: Heritage, Present and Future; International Association of Shell and Space Structures: Milan, Italy, 1995; Volume 2, pp. 1237–1244. [Google Scholar]

- Huerta Fernández, S. The Geometry and Construction of Byzantine Vaults: The Fundamental Contribution of Auguste Choisy; Instituto Juan de Herrera: Madrid, Spain, 2009. [Google Scholar]

- Moya Blanco, L. Bóvedas Tabicadas; Dirección General de Arquitectura: Madrid, Spain, 1947. [Google Scholar]

- Lancaster, L.C. Innovative Vaulting in the Architecture of the Roman Empire: 1st to 4th Centuries CE.; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Huerta Fernández, S. La construcción tabicada y la teoría cohesiva de Rafael Guastavino; Instituto Juan de Herrera: Madrid, Spain, 2006. [Google Scholar]

- Huerta Fernández, S. Wedges and plate-bandes: Mechanical theories after De la Hire. In L’architrave, le Plancher, la Plate-Forme. Nouvelle Histoire de la Construction. Architecture Essais; Gargiano, R., Ed.; Presses polytechniques et Universitaires Romandes: Lausanne, Switzerland, 2012; pp. 405–435. [Google Scholar]

- Block, P.; DeJong, M.; Davis, L.; Ochsendorf, J. Tile vaulted systems for low-cost construction in Africa. ATDF J. 2010, 7, 4–13. [Google Scholar]

- Davis, L.; Rippmann, M.; Pawlofsky, T. Innovative funicular tile vaulting: A prototype vault in Switzerland. Struct. Eng. 2012, 90, 46–56. [Google Scholar]

- Olivieri, C.; Iannuzzo, A.; Fortunato, A.; DeJong, M.J. The effect of concentrated loads on open-well masonry spiral stairs. Eng. Struct. 2022, 272, 114952. [Google Scholar] [CrossRef]

- Olivieri, C.; Adriaenssens, S.; Cennamo, C. A novel graphical assessment approach for compressed curved structures under vertical loading. Int. J. Space Struct. 2023, 38, 09560599231161424. [Google Scholar] [CrossRef]

- Paris, V.; Ruscica, G.; Mirabella Roberti, G. Graphical modelling of hoop force distribution for equilibrium analysis of masonry domes. Nexus Netw. J. 2021, 23, 855–878. [Google Scholar] [CrossRef]

- Paris, V.; Pizzigoni, P.; Adriaenssens, S. Statics of self-balancing masonry domes constructed with a cross-herringbone spiraling pattern. Eng. Struct. 2020, 215, 110440. [Google Scholar] [CrossRef]

- Cundall, P.A. Formulation of a three-dimensional distinct element model—Part I. A scheme to detect and represent contacts in a system composed of many polyhedral blocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 25, 107–116. [Google Scholar] [CrossRef]

- Hart, R.; Cundall, P.A.; Lemos, J. Formulation of a three-dimensional distinct element model—Part II. Mechanical calculations for motion and interaction of a system composed of many polyhedral blocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 25, 117–125. [Google Scholar] [CrossRef]

- Lemos, J.V. Discrete Element Modeling of Masonry Structures. Int. J. Archit. Herit. 2007, 1, 190–213. [Google Scholar] [CrossRef]

- Simon, J.; Bagi, K. Discrete Element Analysis of the Minimum Thickness of Oval Masonry Domes. Int. J. Archit. Herit. 2016, 10, 457–475. [Google Scholar] [CrossRef]

- Han, I.X.; Bruun, E.P.G.; Marsh, S.; Tavano, M.; Adriaenssens, S.; Parascho, S. From Concept to Construction: A Transferable Design and Robotic Fabrication Method for a Building-Scale Vault. In Proceedings of the 40th Annual Conference of the Association for Computer Aided Design in Architecture, Online, 24–30 October 2020. [Google Scholar]

- Bruun, E.P.G.; Pastrana, R.; Paris, V.; Beghini, A.; Pizzigoni, A.; Parascho, S.; Adriaenssens, S. Three cooperative robotic fabrication methods for the scaffold-free construction of a masonry arch. Autom. Constr. 2021, 129, 103803. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paris, V.; Ruscica, G.; Olivieri, C.; Mirabella Roberti, G. A Systemic Approach to Simulate the Construction Process of Self-Supporting Masonry Structures. Sustainability 2023, 15, 9596. https://doi.org/10.3390/su15129596

Paris V, Ruscica G, Olivieri C, Mirabella Roberti G. A Systemic Approach to Simulate the Construction Process of Self-Supporting Masonry Structures. Sustainability. 2023; 15(12):9596. https://doi.org/10.3390/su15129596

Chicago/Turabian StyleParis, Vittorio, Giuseppe Ruscica, Carlo Olivieri, and Giulio Mirabella Roberti. 2023. "A Systemic Approach to Simulate the Construction Process of Self-Supporting Masonry Structures" Sustainability 15, no. 12: 9596. https://doi.org/10.3390/su15129596

APA StyleParis, V., Ruscica, G., Olivieri, C., & Mirabella Roberti, G. (2023). A Systemic Approach to Simulate the Construction Process of Self-Supporting Masonry Structures. Sustainability, 15(12), 9596. https://doi.org/10.3390/su15129596