An Approach to Understanding the Hydration of Cement-Based Composites Reinforced with Untreated Natural Fibers

Abstract

1. Introduction

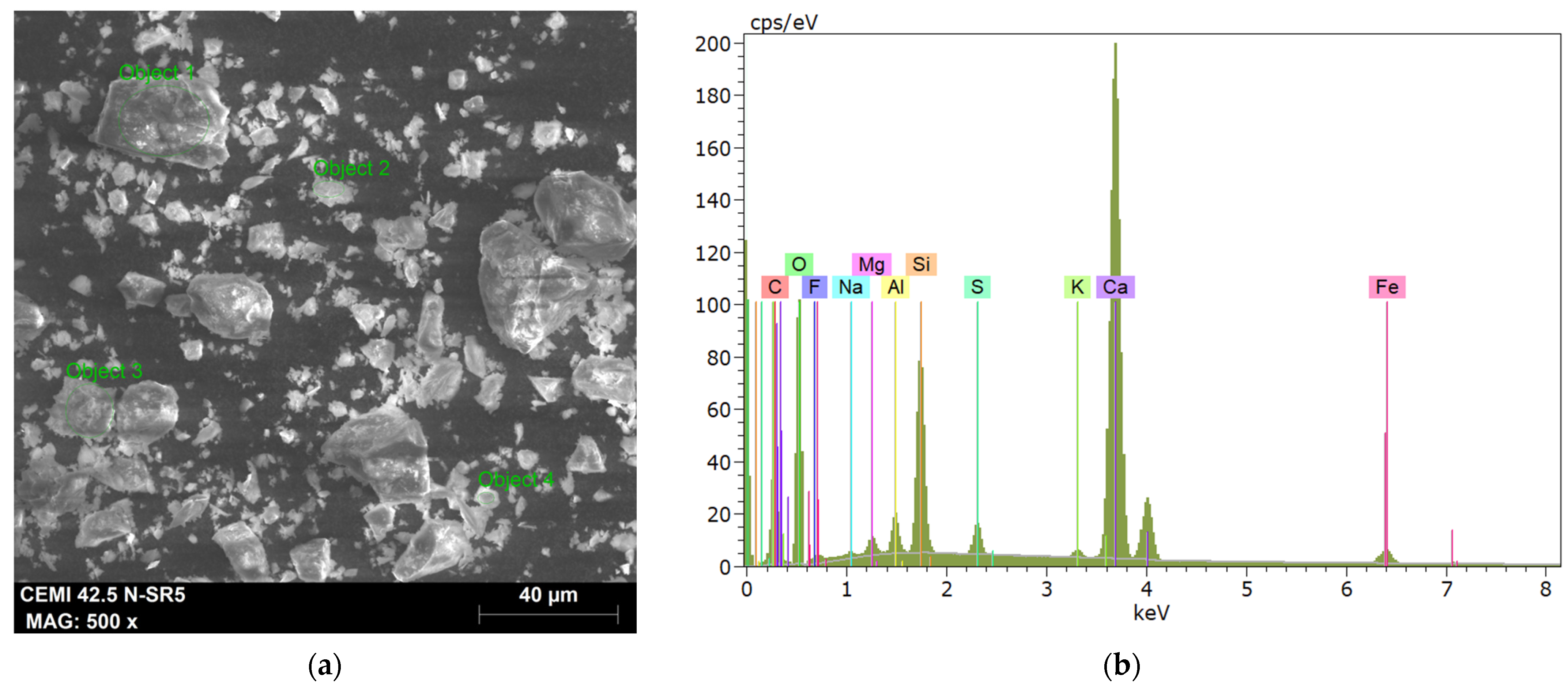

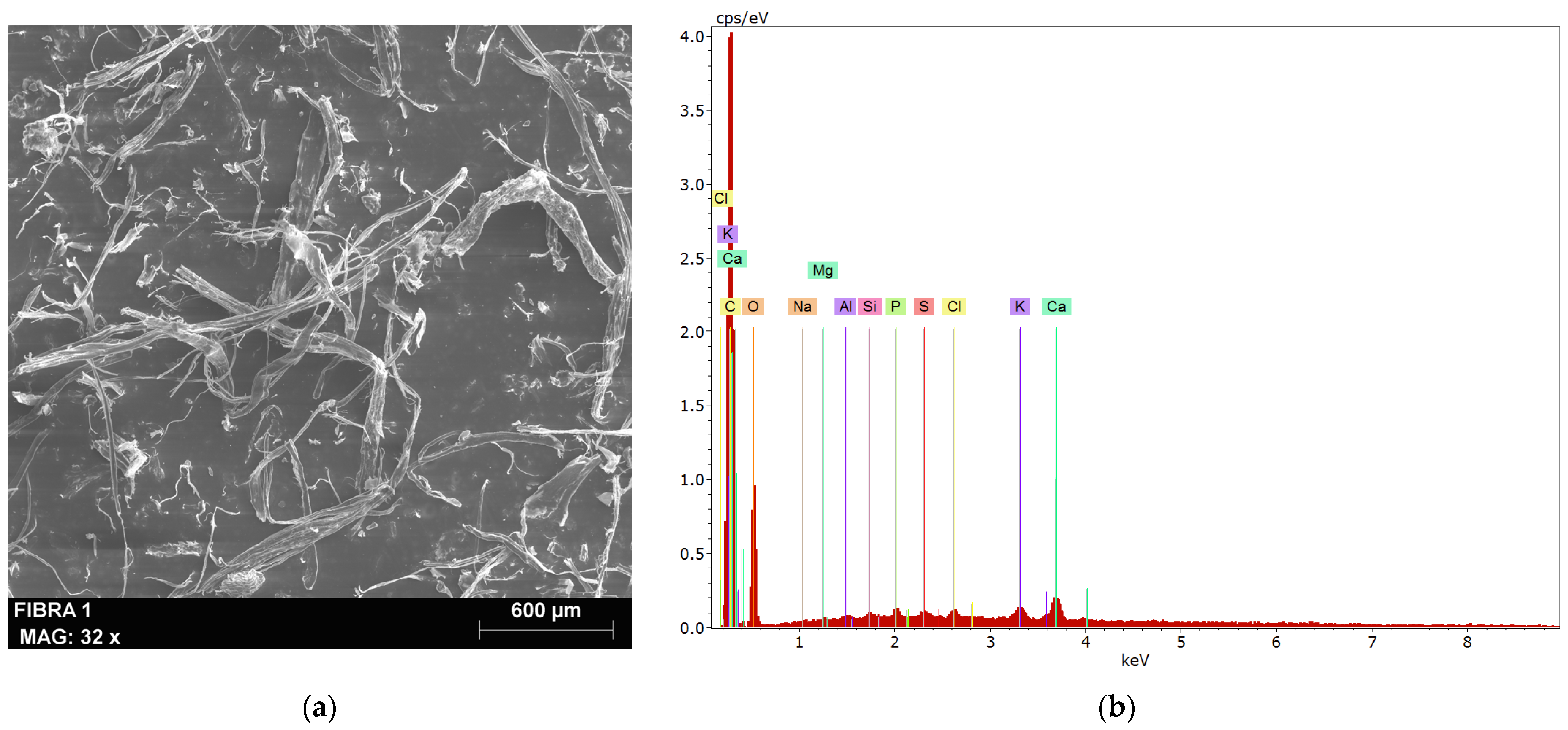

2. Materials and Methods

2.1. Materials

2.2. Test Methods

74 44 100 18

100 56 44

3. Results and Discussion

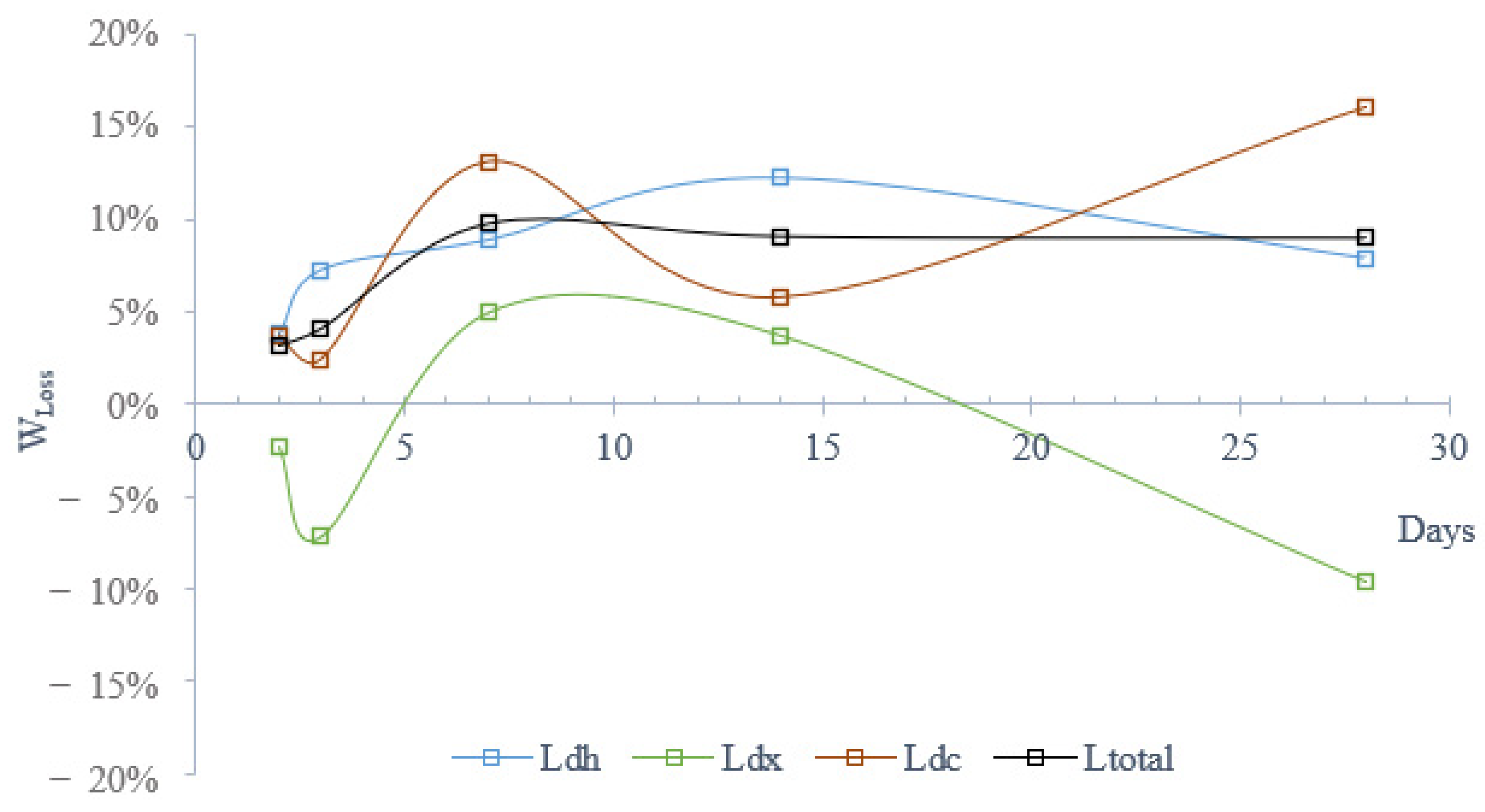

3.1. Differential Thermal and Thermogravimetric Analysis (TGA/dTGA)

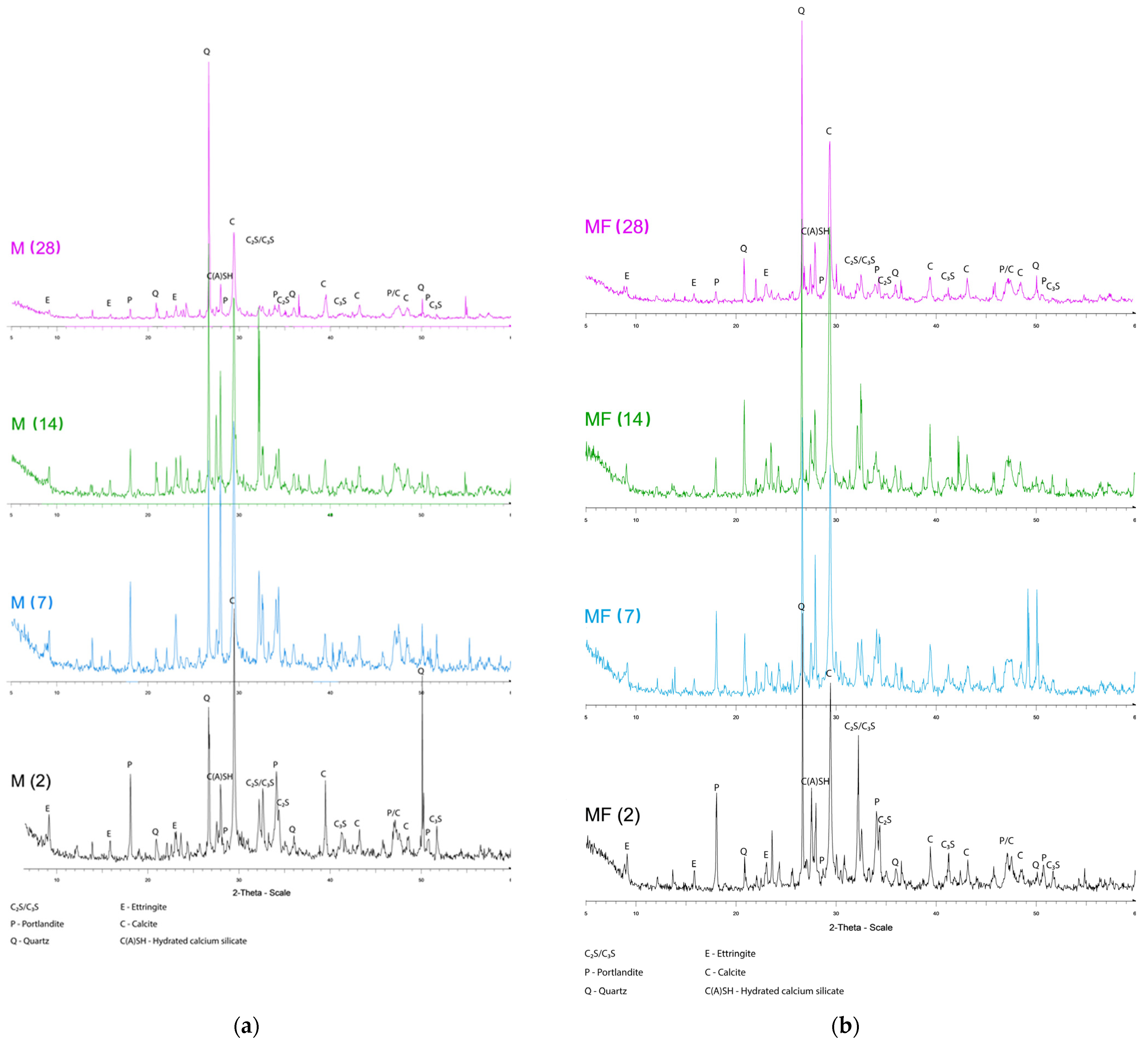

3.2. X-ray Diffraction (XRD)

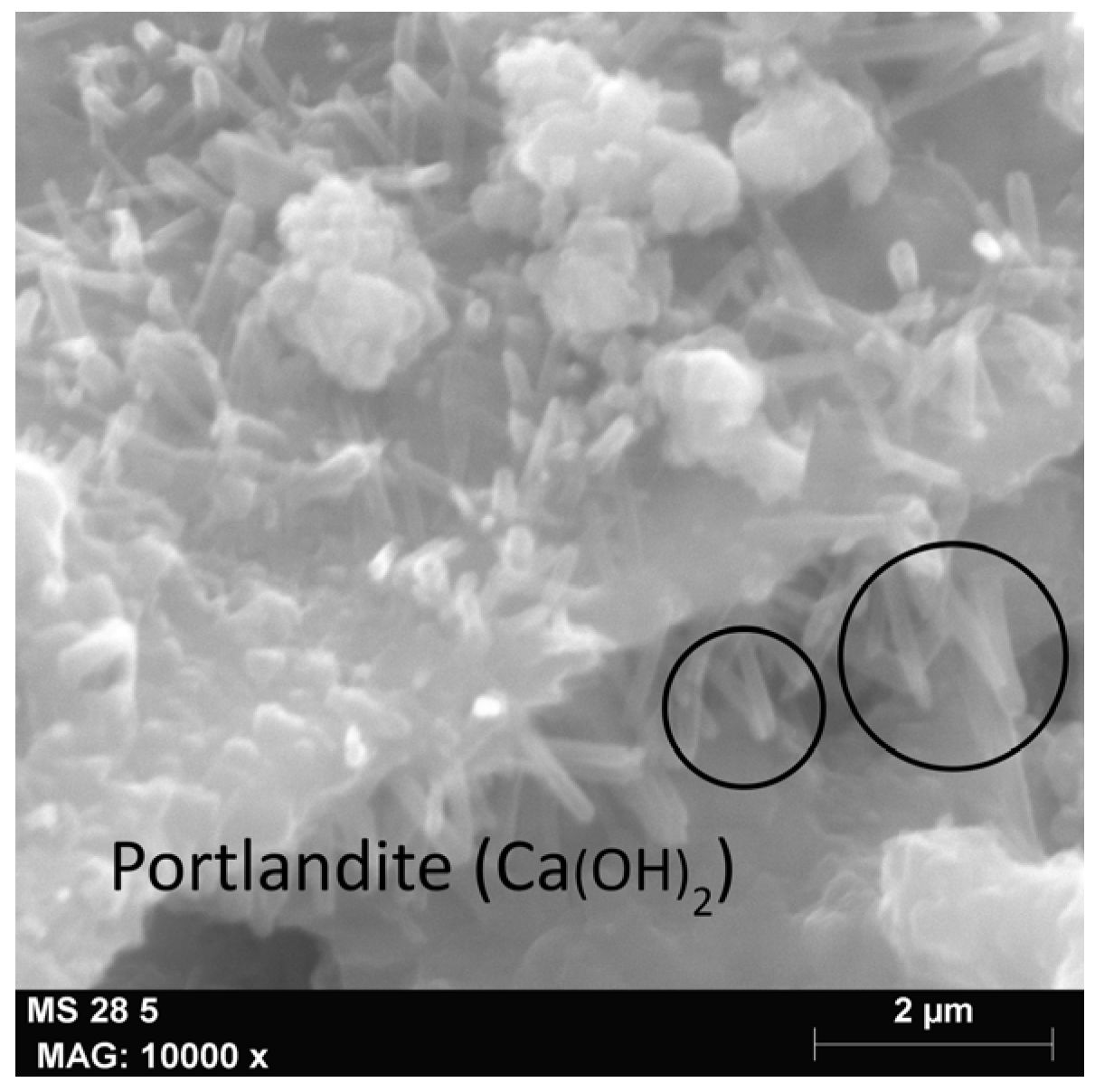

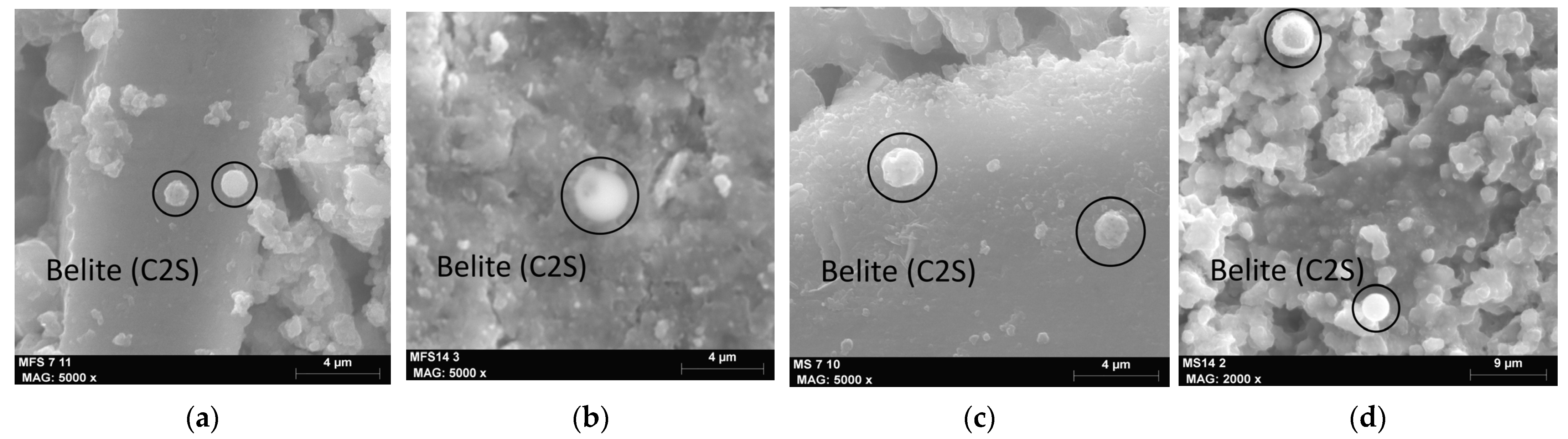

3.3. SEM–EDX

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Riofrio, A.; Cornejo, M.; Baykara, H. Environmental performance of bamboo fibers and sugarcane bagasse reinforced metakaolin-based geopolymers. Case Stud. Constr. Mater. 2022, 17, e01150. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Gioffré, M.; Navarra, G.; Cavalagli, N.; Lo Iacono, F.; Gusella, V.; Pepi, C. Effect of hemp bio composite strengthening on masonry barrel vaults damage. Constr. Build. Mater. 2023, 367, 130100. [Google Scholar] [CrossRef]

- Verma, S.K.; Dwivedi, V.K.; Dwivedi, S.P. Utilization of Reinforced Palm Fibers Used for Composite Materials—A Review. In Advances in Mechanical and Energy Technology; Springer: Singapore, 2023; pp. 187–196. [Google Scholar]

- Martinelli, F.R.B.; Ribeiro, F.R.C.; Marvila, M.T.; Monteiro, S.N.; Filho, F.D.C.G.; Azevedo, A.R.G.D. A Review of the Use of Coconut Fiber in Cement Composites. Polymers 2023, 15, 1309. [Google Scholar] [CrossRef] [PubMed]

- Guizzardi, G.Z.; da Silva Machado, M.; Michelon, W.; Vicente Filipak Vanin, D. On the mechanical behaviour of natural sisal fibre reinforced cement paste. Proc. Inst. Civ. Eng. Constr. Mater. 2022. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Lima, T.E.S.; Reis, R.H.M.; Oliveira, M.S.; Candido, V.S.; Monteiro, S.N. Guaruman fiber: A promising reinforcement for cement-based mortars. Case Stud. Constr. Mater. 2022, 16, e01029. [Google Scholar] [CrossRef]

- Mydin, M.A.O.; Nawi, M.N.M.; Odeh, R.A.; Salameh, A.A. Potential of Biomass Frond Fiber on Mechanical Properties of Green Foamed Concrete. Sustainability 2022, 14, 7185. [Google Scholar] [CrossRef]

- Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Vázquez, A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 2008, 15, 149–159. [Google Scholar] [CrossRef]

- Poletto, M.; Júnior, H.L.O.; Zattera, A.J. Thermal Decomposition of Natural Fibers: Kinetics and Degradation Mechanisms. In Reactions and Mechanisms in Thermal Analysis of Advanced Materials; 2015; pp. 515–545. Available online: https://onlinelibrary.wiley.com/doi/10.1002/9781119117711.ch21 (accessed on 1 January 2022).

- Popescu, M.-C.; Popescu, C.-M.; Lisa, G.; Sakata, Y. Evaluation of morphological and chemical aspects of different wood species by spectroscopy and thermal methods. J. Mol. Struct. 2011, 988, 65–72. [Google Scholar] [CrossRef]

- Slopiecka, K.; Bartocci, P.; Fantozzi, F. Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl. Energy 2012, 97, 491–497. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Spec. Issue Biocompos. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; Thomas, D.G. Correlation between hydration of cement and durability of natural fiber-reinforced cement composites. Corros. Sci. 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Bilba, K.; Arsene, M.-A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part Appl. Sci. Manuf. 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Cooke, A.M. Durability of Autoclaved Cellulose Fiber Cement Composites; Building Materials and Technology Pty Ltd.: Sydney, NSW, Australia, 2007. [Google Scholar]

- Pehanich, J.L.; Blankenhorn, P.R.; Silsbee, M.R. Wood fiber surface treatment level effects on selected mechanical properties of wood fiber–cement composites. Cem. Concr. Res. 2004, 34, 59–65. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; de Andrade Silva, F.; Fairbairn, E.M.R.; de Almeida Melo Filho, J. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Melo Filho, J.A.; Toledo Filho, R.D.; Fairbairn, E.M.R.; Hegger, J.; Brameshuber, W.; Will, N. Mechanical Behavior and Durability of Compression Moulded Sisal Fiber-Cement Mortar Laminates (SFCML). In Proceedings of the 1st International RILEM Conference on Textile Reinforced Concrete, Aachen, Germany, 6–7 September 2006; Rilem Publications S.A.R.L.: Paris, France; pp. 171–180. [Google Scholar]

- de Gutiérrez, R.M.; Díaz, L.N.; Delvasto, S. Effect of pozzolans on the performance of fiber-reinforced mortars. Nat. Fibre Reinf. Cem. Compos. 2005, 27, 593–598. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cem. Concr. Res. 2007, 37, 1531–1543. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H.; John, V.M.; Cincotto, M.A. Developments on vegetable fibre–cement based materials in São Paulo, Brazil: An overview. Nat. Fibre Reinf. Cem. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Potential of alternative fibre cements as building materials for developing areas. Infrastruct. Dev. 2003, 25, 585–592. [Google Scholar] [CrossRef]

- Fu, T.; Montes, F.; Suraneni, P.; Youngblood, J.; Weiss, J. The Influence of Cellulose Nanocrystals on the Hydration and Flexural Strength of Portland Cement Pastes. Polymers 2017, 9, 424. [Google Scholar] [CrossRef] [PubMed]

- Reixach, R.; Claramunt, J.; Chamorro, M.A.; Llorens, J.; Pareta, M.M.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M. On the path to a new generation of cement-based composites through the use of lignocellulosic micro/nanofibers. Materials 2019, 12, 1584. [Google Scholar] [CrossRef] [PubMed]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Bhusan Das, B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. A review of the factors affecting the properties and performance of hemp aggregate concretes. J. Build. Eng. 2020, 31, 101323. [Google Scholar] [CrossRef]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on fiber-reinforced concrete using industrial hemp fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Pantawee, S.; Sinsiri, T.; Jaturapitakkul, C.; Chindaprasirt, P. Utilization of hemp concrete using hemp shiv as coarse aggregate with aluminium sulfate [Al2(SO4)3] and hydrated lime [Ca(OH)2] treatment. Constr. Build. Mater. 2017, 156, 435–442. [Google Scholar] [CrossRef]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Sha, W.; O’Neill, E.A.; Guo, Z. Differential scanning calorimetry study of ordinary Portland cement. Cem. Concr. Res. 1999, 29, 1487–1489. [Google Scholar] [CrossRef]

- Monteagudo, S.M.; Moragues, A.; Gálvez, J.C.; Casati, M.J.; Reyes, E. The degree of hydration assessment of blended cement pastes by differential thermal and thermogravimetric analysis. Morphological evolution of the solid phases. Thermochim. Acta 2014, 592, 37–51. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Barakat, S. Foreword. In Handbook of Thermal Analysis of Construction Materials; Ramachandran, V.S., Paroli, R.M., Beaudoin, J.J., Delgado, A.H., Eds.; William Andrew Publishing: Norwich, NY, USA, 2002; pp. vii–viii. ISBN 978-0-8155-1487-9. [Google Scholar]

- Bhatty, J.I. Hydration versus strength in a portland cement developed from domestic mineral wastes—A comparative study. Thermochim. Acta 1986, 106, 93–103. [Google Scholar] [CrossRef]

- Loukili, A.; Khelidj, A.; Richard, P. Hydration kinetics, change of relative humidity, and autogenous shrinkage of ultra-high-strength concrete. Cem. Concr. Res. 1999, 29, 577–584. [Google Scholar] [CrossRef]

- Pane, I.; Hansen, W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem. Concr. Res. 2005, 35, 1155–1164. [Google Scholar] [CrossRef]

- Mounanga, P. Experimental Study of the Behavior of Cement Pastes at Very Young Age: Hydration, Shrinkage, Thermophysical Properties. Ph.D. Thesis, University of Nantes, Nantes, France, 2003. [Google Scholar]

- Kim, T.; Olek, J. Effects of Sample Preparation and Interpretation of Thermogravimetric Curves on Calcium Hydroxide in Hydrated Pastes and Mortars. Transp. Res. Rec. 2012, 2290, 10–18. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl. Surf. Sci. 2014, 289, 511–523. [Google Scholar] [CrossRef]

- Xie, X.; Gou, G.; Wei, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Influence of pretreatment of rice straw on hydration of straw fiber filled cement based composites. Constr. Build. Mater. 2016, 113, 449–455. [Google Scholar] [CrossRef]

- Delhomme, F.; Prud’homme, E.; Julliot, C.; Guillot, T.; Amziane, S.; Marceau, S. Effect of hemp on cement hydration: Experimental characterization of the interfacial transition zone. Results Chem. 2022, 4, 100440. [Google Scholar] [CrossRef]

- UNE-EN 196-1:2018; Methods of Testing Cement—Part 1: Determination of Strength. AENOR: Madrid, Spain, 2018.

- UNE 146901:2018; Aggregates. Designation. AENOR: Madrid, Spain, 2018.

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H.; Lee, Y.Y. Fiber-reinforced alkali-activated concrete: A review. J. Build. Eng. 2022, 45, 103638. [Google Scholar] [CrossRef]

- Sanjuán, M.; Cristina, A. La nueva norma europea de especificaciones de cementos comunes UNE-EN 197-1:2011. Mater. Constr. 2012, 62, 425–430. [Google Scholar] [CrossRef]

- UNE-EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. AENOR: Madrid, Spain, 2011.

- UNE-EN 1015-11:2020; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. AENOR: Madrid, Spain, 2020.

- ASTM E1131-20; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM: West Conshohocken, PA, USA, 2020.

- Kim, W.-K.; Hong, G.; Kim, Y.-H.; Kim, J.-M.; Kim, J.; Han, J.-G.; Lee, J.-Y. Mechanical Strength and Hydration Characteristics of Cement Mixture with Highly Concentrated Hydrogen Nanobubble Water. Materials 2021, 14, 2735. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zhang, M. Hydration of cement and pore structure of concrete cured in tropical environment. Cem. Concr. Res. 2006, 36, 1947–1953. [Google Scholar] [CrossRef]

- Collet, F.; Pretot, S. Experimental investigation of moisture buffering capacity of sprayed hemp concrete. Constr. Build. Mater. 2012, 36, 58–65. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Xu, Z.; Li, S.; Luo, X.; Chen, G. Combined effect of slag and clay brick powder on the hydration of blended cement. Constr. Build. Mater. 2021, 299, 123996. [Google Scholar] [CrossRef]

- Davila, F.J.; John, V.M. Formación de etringita tardía en elementos de construcción. Rev. Colomb. Mater. 2014, 231–237. [Google Scholar] [CrossRef]

- Saillio, M.; Baroghel-Bouny, V.; Pradelle, S.; Bertin, M.; Vincent, J.; d’Espinose de Lacaillerie, J.-B. Effect of supplementary cementitious materials on carbonation of cement pastes. Cem. Concr. Res. 2021, 142, 106358. [Google Scholar] [CrossRef]

- Peschard, A.; Govin, A.; Grosseau, P.; Guilhot, B.; Guyonnet, R. Effect of polysaccharides on the hydration of cement paste at early ages. Cem. Concr. Res. 2004, 34, 2153–2158. [Google Scholar] [CrossRef]

- Cruz, L.; Herrera Penagos, S.; Gómez, L.; Alvarez, K.; Arcila, J. Efecto del SiC en el Comportamiento a Oxidación de un Material Compuesto Carbono-Carbono. Rev. Prospect. Univ. Autónoma Caribe 2011, 9, 7–13. [Google Scholar]

- Gauna, A. Relaciones entre lo carbonatación del cemento portland, el grado de cocción del clínker y algunos fenómenos expansivos en el ensayo de autoclave. Mater. Constr. 2013, 26, 89–100. [Google Scholar] [CrossRef]

- Pavlenko, V.I.; Gorodov, A.I.; Yastrebinsky, R.N.; Cherkashina, N.I.; Karnauhov, A.A. Increasing the Adherence of Metallic Copper to the Surface of Titanium Hydride. ChemEngineering 2021, 5, 72. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Kim, J.-S.; Lehmann, C.; Stephan, D.; Han, T.-S.; Elrahman, M.A. Investigation of phase composition and microstructure of foamed cement paste with different supplementary cementing materials. Cem. Concr. Compos. 2020, 109, 103560. [Google Scholar] [CrossRef]

- Yadav, M.; Saini, A. Opportunities & challenges of hempcrete as a building material for construction: An overview. Int. Conf. Adv. Constr. Mater. Struct. 2022, 65, 2021–2028. [Google Scholar] [CrossRef]

- Giraldo, M.M.A.; Tobón, J.I. Evolución mineralógica del cemento portland durante el proceso de hidratación. DYNA 2006, 73, 69–82. [Google Scholar]

| Authors | Range Values | ||

|---|---|---|---|

| Ldh | Ldx | Ldc | |

| Bhatty [37] | 105–440 °C | 440–580 °C | 580–1000 °C |

| Pane et al. [39] | 140–440 °C | 440–520 °C | 520–1100 °C |

| Monteagudo et al. [34] | 105–430 °C | 430–530 °C | 530–1100 °C |

| Element | Average % | ||

|---|---|---|---|

| Cement | Sand | Fiber | |

| C | 4.00 | 15.34 | 65.99 |

| O | 48.34 | 47.74 | 32.34 |

| Mg | 0.66 | 1.73 | - |

| Al | 1.36 | 7.18 | - |

| Si | 5.47 | 13.75 | - |

| Ca | 35.38 | 0.26 | 1.20 |

| K | 0.83 | 3.75 | 0.47 |

| Na | 0.26 | 0.20 | - |

| S | 0.45 | - | - |

| Fl | 0.80 | - | - |

| Cl | - | 0.01 | 0.01 |

| Fe | 2.46 | 8.69 | - |

| Ti | - | 0.67 | - |

| Mn | - | 0.10 | - |

| Ni | - | 0.60 | - |

| Specimen | Curing Time (Days) | Weight Losses % | Chemically Bound Water | Hydration Degree | |||

|---|---|---|---|---|---|---|---|

| Ldh | Ldx | Ldc | Ltotal | (WB) % | |||

| M2 | 2 | 8.0287 | 1.6333 | 5.2408 | 14.9028 | 11.8107 | 49.21 |

| M3 | 3 | 8.3771 | 1.9306 | 5.0795 | 15.3872 | 12.3903 | 51.63 |

| M7 | 7 | 8.5237 | 1.9035 | 4.6927 | 15.1199 | 12.3512 | 51.46 |

| M14 | 14 | 8.4500 | 2.0200 | 5.4432 | 15.9132 | 12.7017 | 52.92 |

| M28 | 28 | 8.0277 | 2.1218 | 5.4292 | 15.5787 | 12.3755 | 51.56 |

| MF2 | 2 | 8.3505 | 1.5965 | 5.4428 | 15.3898 | 12.1785 | 50.74 |

| MF3 | 3 | 9.0348 | 1.8011 | 5.2054 | 16.0413 | 12.9701 | 54.04 |

| MF7 | 7 | 9.3561 | 2.0033 | 5.4003 | 16.7597 | 13.5735 | 56.56 |

| MF14 | 14 | 9.6306 | 2.0985 | 5.7764 | 17.5055 | 14.0974 | 58.74 |

| MF28 | 28 | 8.7187 | 1.9361 | 6.4663 | 17.1211 | 13.3060 | 55.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llorens, J.; Julián, F.; Gifra, E.; Espinach, F.X.; Soler, J.; Chamorro, M.À. An Approach to Understanding the Hydration of Cement-Based Composites Reinforced with Untreated Natural Fibers. Sustainability 2023, 15, 9388. https://doi.org/10.3390/su15129388

Llorens J, Julián F, Gifra E, Espinach FX, Soler J, Chamorro MÀ. An Approach to Understanding the Hydration of Cement-Based Composites Reinforced with Untreated Natural Fibers. Sustainability. 2023; 15(12):9388. https://doi.org/10.3390/su15129388

Chicago/Turabian StyleLlorens, Joan, Fernando Julián, Ester Gifra, Francesc X. Espinach, Jordi Soler, and Miquel Àngel Chamorro. 2023. "An Approach to Understanding the Hydration of Cement-Based Composites Reinforced with Untreated Natural Fibers" Sustainability 15, no. 12: 9388. https://doi.org/10.3390/su15129388

APA StyleLlorens, J., Julián, F., Gifra, E., Espinach, F. X., Soler, J., & Chamorro, M. À. (2023). An Approach to Understanding the Hydration of Cement-Based Composites Reinforced with Untreated Natural Fibers. Sustainability, 15(12), 9388. https://doi.org/10.3390/su15129388