Abstract

Blockchain technology, as a well-known technology in financial spaces, has many advantages in non-financial industries and supply chains. Two of the main benefits of blockchain technology are smart contracts and distributed decision-making processes. These features can be especially useful in implementing Industry 4.0. Moreover, this technology can increase productivity in supply chains by enhancing transparency, reducing operational costs, and improving monitoring and supervision throughout the lifecycle of products. In this paper, we introduce a blockchain-based architecture for a supply chain in cloud architecture. This approach leads to the more efficient implementation of Industry 4.0 and increases sustainability in the supply chain. In this study, we aim to investigate whether the proposed blockchain-based platform affects sustainability in the supply chain. From a sustainability perspective, we solve the large-scale problem of a cloud-based production–distribution system in centralized and distributed states. The results of the solution indicate a significant improvement in the decentralized state compared to the centralized state and this improvement enhances sustainability in the supply chain. We verify the proposed model by considering an axiomatic design algorithm. In the distributed model, the system cost is reduced by up to 45%, and the solving time is decreased by approximately 51% in pessimistic conditions and by about 87% in optimistic conditions. These improvements directly enhance economic and environmental sustainability, resulting in reduced energy consumption.

1. Introduction

Supply chains and networks have improved and changed substantially. Many current research studies on supply chains cover various issues, including digitalization, mechanization, internet of things (IoT), Industry 4.0, and cloud supply chains. Industry 4.0 is one of these changes, first mentioned by the German Economic Development Agency, referring to a set of actions and technologies that enable a real-time connection between the physical and digital realms [1,2,3]. Industry 4.0 somehow represents the fourth industrial revolution from a practical perspective as it has been introduced after three previous industrial revolutions. These three revolutions are: (1) using steam power to mechanize industrial machines; (2) using electricity in various industries and machinery; (3) using electronics and information technology to promote automation in various industries [4]. In the fourth-generation industry, we encounter smart (intelligent) factories, products, and services enabled by intelligent-based models through the development of various technologies, especially the IoT, hence the term industrial internet and Cloud-based platforms [5].

One of the advantages of Industry 4.0 is that it enhances sustainability in the supply chain. Previous research has mainly stressed the impact of Industry 4.0 on minimizing costs and the environmental effects associated with sustainability. Furthermore, Industry 4.0 can also realize various desirable social parameters concerning sustainability [6]. Given the economic dimensions of sustainability, using ubiquitous information and communications technology (ICT) infrastructure can considerably reduce supply chain costs [7]. Moreover, various small and medium-sized enterprises (SMEs) can dramatically reduce supply chain costs by taking advantage of cloud-based computing and intelligentization in several forms [8,9].

Blockchain, as an instrument for realizing Industry 4.0, enables the rewarding of green behaviors in the supply chain through the tokenization incentives. It also facilitates cost reduction and promotes sustainability in the supply chain by increasing visibility and ease of information transfer. For example, with universal access to data, the bullwhip effect in supply chain decreases and unnecessary production is prevented. Additionally, by recording logistics data in real time without the need for extensive human resources, many costs are reduced, and data are recorded efficiently and accurately [10,11,12].

In digital platforms and ecosystems, the term cloud supply chain refers to the integration of all operational processes such as logistics, warehousing, manufacturing, procurement, sales, and returns and all supply chain flows such as material, informational, and financial flows and all supply chains actors such as suppliers, manufacturers, distributors, and customers [13]. Therefore, the cloud-based production–distribution system is a part of the cloud supply chain. Since research in the field of usage of blockchain technology in a cloud-based production–distribution system is rare, and this is a part of the cloud supply chain, we will review the literature on the cloud supply chain.

This study addresses the impacts of using blockchain technology in a supply chain problem, the realization of Industry 4.0, and the improvement of supply chain sustainability. Blockchain technology, or distributed ledger technology (DLT), refers to databases distributed in a network with no central administrators and which are fully managed and directed by network members. This technology has led to several positive effects in various financial and non-financial areas, enhances performance, and reduces systems’ costs by eliminating the central administrator [14,15]. Since central computers or the central cloud computing system is in charge of decision making in Industry 4.0, blockchain technology will be expected to cover the weaknesses of such systems, exclude the administrator (central entity) from the decision-making process, and involve a distributed network of different individuals in the decision-making process. This innovation accelerates decision-making, reduces costs, and minimizes the imposition of administrators’ preferences on the system.

A number of articles have examined the use of blockchain to enhance sustainability in the supply chain. Most of these articles have qualitatively explored the issue and have not delved into mathematical modeling or quantitative analysis. Furthermore, these articles have utilized blockchain to increase transparency, trust, tracking, etc. However, in this article, blockchain is employed for solving the distributed service composition problem in the supply chain, a use case that has not been extensively studied in the literature. Additionally, the findings indicate that this application of blockchain in the supply chain leads to increased sustainability.

The paper’s structure from the second chapter onward is as follows: The second chapter reviews the related theoretical background. The third chapter introduces the methodology, which includes a mathematical model, solution approach, and verification using Axiomatic design. The fourth chapter presents the results. The fifth chapter discusses the results, and the sixth chapter provides a summary of the paper’s content and proposes ideas for future research.

2. Theoretical Background

Blockchain technology was first presented by an anonymous person or a team called Satoshi Nakamoto in 2008 [16]. In 2014, the next generation of blockchain technology was introduced, which makes it possible to script smart contracts and distributed autonomous organizations [17,18]. Blockchain technology has many advantages in supply chain management. Supply chain transparency and traceability are improved by utilizing blockchain [19], adoption of blockchain in the global supply chain will maximize effectiveness by increasing visibility and transparency and eliminating the middleman or third party [20]. Blockchain adoption in the supply chain will support and improve digitalizing processes in a supply chain [21]. Additionally, blockchain has an influence on decision making and facilitates inter-organization processes in the global supply chain [22]. The effectiveness of blockchain implementation in international trades and global supply chains was investigated systematically and analytically in Reference [23] and the authors concluded that applying blockchain will be beneficial for firms facing considerable demand volatility in the supply chain.

References [24,25] addressed a comprehensive review of blockchain technology’s main applications, disruptions, and challenges of its adoption in supply chain management. Reference [26] developed a framework to design a mindful pilot project for the adoption of blockchain technology in the supply chain. Reference [27] conducted some interviews with supply chain executives to understand the benefits and challenges of blockchain adoption in a general supply chain.

Blockchain could support the development of a sustainable supply chain through its intrinsic merits such as transparency, traceability, security, and enhancing environmental, social, and economic dimensions of sustainability [28,29,30]. Table 1 presents dominant research studies about blockchain’s effects on sustainability and sustainable supply chain.

Table 1.

Dominant research studies on blockchain adoption in sustainable supply chains.

In Reference [32], potential applications of blockchain and smart contracts were examined in sustainable supply chain management. In this paper, four categories of blockchain technology adoption barriers were introduced: inter-organizational, intra-organizational, technical, and external barriers.

Globalization and global competition between supply chains necessitate the use of distributed supply sources around the world. In addition to the complexities of supply chain management in a distributed and global environment, the dynamism of the supply chain has increased, and consumer priorities have led to customization and reduced product life cycles [48].

Distributed supply chain management is one of the successful methods of large-scale optimization. Firstly, in distributed dynamic programming, an attempt is made to solve a large-scale problem by performing parallel calculations on a network of computers [49]. Based on this concept, Reference [50] proposed distributed supply chain management, which has a cooperative integration between all the partners in the network and has shown that this algorithm performs better than decentralized supply chain management.

According to the literature review, very little research has been conducted on the applications of blockchain technology in sustainable supply chain management. Moreover, the benefits of blockchain technology in the implementation of Industry 4.0, such as transparency, tracking, making smart, etc., have not been sufficiently examined. Therefore, in this research, an attempt is made to study the effects of the implementation of blockchain technology in Industry 4.0 and its interaction effects on increasing the sustainability of the supply chain and to propose an architecture in this regard.

3. Methodology

In this section, we first define the problem and model the desired problem, as well as describing the solution approach. Since the goal of this paper is to examine the extent of improvement in supply chain sustainability using the proposed blockchain-based architecture, we initially present a mathematical model of a production–distribution problem, which serves as an example of a supply chain problem. We then outline a solution method for this problem, which will be further elaborated on in subsequent sections to address the decentralized problem-solving approach.

An architecture should not only be functional in terms of quantity, but it should also be functional in terms of practicality and meet the requirements of the customers. In the proposed architecture, service demanders and manufacturers are those who use this architecture, and it should be guaranteed that requirements have been met by using this architecture. Based on the literature, by axiomatic design, we should guarantee that the design is well-defined and is based on the practical requirements. In this section, it is shown that the design components of the proposed blockchain-based architecture are exactly based on the principles of axiomatic design.

3.1. Blockchain Application in Implementing Industry 4.0

As mentioned above, Industry 4.0 refers to using information technology (IT) in the intelligentization of supply chain processes. Various technologies are necessary for implementing Industry 4.0. The three main infrastructural technologies included in the implementation are cyber-physical systems, IoT, and cloud computing. These technologies make processes and decisions intelligent. In the absence of blockchain technology, central entities (administrators) make decisions in Industry 4.0, leading to problems in the supply chain layers or supply network. Blockchain technology makes decisions in the proposed architecture in this study.

With a large number of stakeholders, supply chains face many challenges and complications, such as insufficient transparency and tracking, the complexity of risk management, the reciprocal impacts members’ activities on other members in the chain, the need for reputation, and recognizing the members’ history to build trust, and so forth. However, thanks to its transparent and decentralized structure, blockchain technology can overcome many such challenges.

Another advantage of the blockchain with application in the supply chain is smart contracts. Smart contracts are written in computer code and, as such, are digital agreements between parties of a transaction and are transferred to the blockchain in which they are executed automatically when predetermined conditions are satisfied. Smart contracts eliminate many waste processes of decision making in the supply chain. Given the supply chain members’ equal access to the information in smart contracts, all members have an equal share in the decision-making process [51].

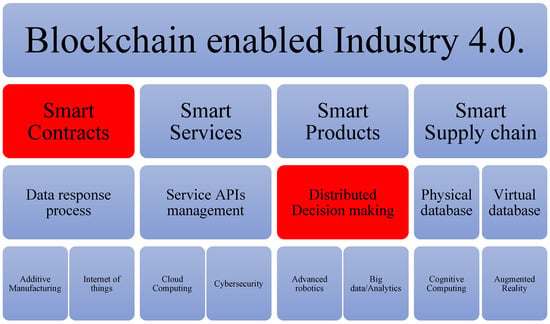

Figure 1 displays the Industry 4.0 architecture based on blockchain. The figure shows the two main components added to Industry 4.0 using blockchain in different colors. The first improvement made possible by blockchain in this system is the shift in the decision-making process from centralized mode to distributed mode. The second improvement is the introduction of the smart contracts concept, which significantly contributes to the relationship between different members of the supply chain and the management of the relationships between them.

Figure 1.

Industry 4.0 architecture based on blockchain. (The red elements represent the impact of integrating blockchain in the architecture of Industry 4.0.)

3.1.1. Distributed Decision Making

Individuals known as miners use blockchain technology to proceed with the decision-making processes in Industry 4.0, and this technology has removed the need for a centralized unit to solve decision-making problems. As mentioned above, one of the main principles in blockchain technology is the consensus mechanism designating that any miner whose response satisfied the conditions outlined in this mechanism can add their proposed block to the blockchain. Here, based on the conditions of the problem, a consensus mechanism called proof of optimality is introduced in which different miners suggest a response to each decision-making problem, attempting to make the proposed response the optimal solution to the problem. It is possible that their proposed solution may not be optimal, but they try to make their proposed response not only feasible but also close to optimal.

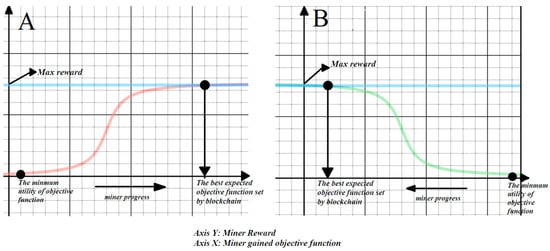

Whenever a miner decides that their proposed solution is fit enough, they present it to other miners within a decentralized network. If no other miner claims to have a better solution in the specified time window, the solution is accepted and added to the blockchain. The successful miner also receives a reward in the form of a cryptocurrency, proportional to their proposed solution’s fitness. Figure 2 is a schematic representation of the reward function chart in which miners are reluctant to provide solutions to the network for problems with low fit rates because even if other miners do not reject their solution, they do not receive a considerable reward. However, a miner does not spend much time to find an outstanding response either, since another miner with a relatively good solution may be able to form the next block, wasting all efforts of that miner looking for a perfect response. Hence, in the proposed consensus mechanism, it is expected to obtain a fit response at an optimal speed in addition to achieving good responses (based on different objective functions, Figure 2A represents the reward function for the minimization objective function, while Figure 2B represents the reward function for the maximization objective function).

Figure 2.

Schematic representation of the reward function chart (blue line represents upper bound of objective function). (A) Schematic representation of the reward function (presented by red color) for minimization objective function; (B) Schematic representation of the reward function (presented by green color) for maximization objective function. (Reprinted from Ref. [52].)

Furthermore, since different miners need optimal algorithms and hardware to obtain good solutions, they constantly try to improve their algorithms and hardware to obtain greater cryptocurrency rewards, but the factory or supply chain trustee does not pay for algorithm development or infrastructure anymore and pays only as needed in cryptocurrency. SMEs can highly take advantage of this model known as the pay as you go model in cloud systems, which dramatically reduces their capital sedimentation costs and provides them with the ability to develop and grow alongside large companies in the supply chain.

3.1.2. Smart Contracts

Smart contracts can help make the interaction between different supply chain members more manageable and smarter. Smart contracts allow for tracing the origin of the goods, automatic payment after fulfilling the obligations, and assigning unchangeable points in the related blockchain to various suppliers based on their trading records [51]. Smart contracts control the number of orders per member of the supply chain and prevent over-ordering or ordering less than needed. Additionally, smart contracts leverage the transparency made possible by blockchain to somewhat reduce the bullwhip effect in the supply chain [53].

Decentralized supply chains can be easily formed using smart contracts. For instance, Reference [54] has used these contracts to study two revenue sharing models and wholesale price contracts in the decentralized supply chain. These two proposed models determine the optimal parameters of smart contracts for the whole chain using artificial intelligence (AI).

The smart contract benefits both the supplier and buyer, this decreases the possibility of non-payment during the credit period for the supplier and guarantees on-time delivery, and provides product tracking for the buyer [55].

3.2. Problem Definition

In the present study, the consensus mechanism entitled proof of optimality is debated, in which different solvers try to solve an optimization problem in the decentralized environment. Indeed, different miners try to solve part of the main problem, and every miner that finds the optimal solution faster publishes their solution on the network. This consensus mechanism should be investigated from the economic, environmental, and social aspects for examining it from a sustainability perspective. In the proposed model of this study, it is possible to see miners monetizing the microcomputing resources (a problem that is not achieved in the centralized mode easily). Hence, it is expected that the mentioned model will create a higher level of satisfaction at the social level. Moreover, it can be seen that this model solves the optimization problem faster than the centralized model. There is a direct relationship between solving the problem of time and the energy consumption of computing resources. Consequently, energy consumption is reduced, and the environment is less damaged, and the environmental goals of sustainability can be achieved. Furthermore, reducing the time to solve optimization problems leads to enhancing productivity and reducing costs in the entire system, which is part of the economic goals of sustainability. Moreover, system costs are reduced by monetizing unused microcomputing resources, and there is no need to provide centralized microcomputing systems; spending is only based on pay as you go, which is the economic goal of sustainability.

Reference [56] investigated the production–distribution planning problem that considers the production and distribution activity in a supply chain. In this study, a production–distribution planning problem with a very large scale is examined to compare the speed of the proposed model with the centralized model to solve the optimization problem, which it is not possible to solve with exact methods in a short time due to the dimensions and nature of the problem. This problem is solved in various centralized and distributed conditions. We take into account a cloud-based production distribution system where N manufacturers spread across various locations offer various manufacturing service types. With constrained resources, each manufacturer provides a range of services. Tasks are submitted to the cloud platform by service demanders. In this platform, every task has a due date, and any delays results in a penalty that must be paid. Depending on the kind of service that is required, each task is broken down into several subtasks. The cloud manager assigns subtasks to manufacturers for each task to optimize performance. For a given subtask, several manufacturers provide varying manufacturing costs and processing times. Additionally, there are numerous modes of transportation available to distribute tasks among various manufacturers, and each one has a set unit cost and carbon emission rate for each unit of travel time. Furthermore, as the speeds of the modes vary, the travel times between the two manufacturers vary for each of them. Moreover, each transportation system is assigned a carbon quota by the government, and if its carbon emissions exceed that limit, it must pay a penalty. As previously stated, carbon emission for a unit distance is taken into account for each mode of transportation. Each task’s completion time takes into account service time, waiting time, and transportation time.

For the first subtask, we assume that each task is transported for free from an artificial node to the designated manufacturer to receive the necessary service type. Upon completion, each task must be delivered to its corresponding destination node. As a result, it is assumed that each task has a zero-processing time subtask that must be completed in the destination node. Other assumptions related to this model are given as follows:

- Number of tasks, manufacturers, and subtasks are known;

- Every type of vehicle is available at all times;

- Each vehicle can carry only one subtask in each of its movements, and the possibility of transporting two or more subtasks simultaneously does not exist;

- All parameters are deterministic;

- Delay is allowed beyond the deadline and there is no limit on the amount of delay.

Mathematical Model

Table 2 describes the notations that will be used in the mathematical model for easy reference.

Table 2.

Description of notations.

The objective function is the minimization of the system’s costs, including processing costs, transportation costs, and the penalties for delay and extra carbon.

Equation (2) states that each subtask of each task must be processed by a manufacturer. Constraint (3) states that a subtask of a task is processed by a manufacturer only when one of the transportation modes receives the previous subtask which is processed by a manufacturer and delivers that to the selected manufacturer for that subtask. Constraint (4) states that a manufacturer can only perform a subtask of a task that is delivered from one of the available transportation modes. Constraint (5) states that subtasks of a task must be performed respectively. Constraints (6) and (7) schedule subtasks with the same service type. Equations (8) and (9) compute the delay time in processing each task. Equations (10) and (11) compute the extra carbon. Constraint (12) indicates the resource limitations of each manufacturer. Constraints (13) and (14) determine the type and sign of the variables.

3.3. Solution Method

For solving the problem on a large scale, a genetic algorithm is developed that we discuss in the following.

3.3.1. Initial Population

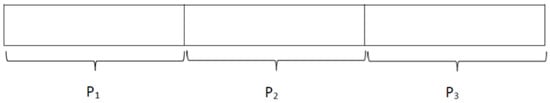

The suggested chromosome has three substrings, each with a length equal to the total number of available subtasks in their respective cloud platform. This length is calculated by summing the subtasks of each task. For example, if there are three tasks in a cloud platform, and each task has five subtasks, the length of each substring would be 15, resulting in a total chromosome length of 45. The overall structure of a chromosome is shown in Figure 3.

Figure 3.

Structure of a chromosome.

The numbers in P1 indicate the order of subtasks within each task, while the numbers in P2 indicate the manufacturer’s index. Therefore, this substring, along with P1, specifies which manufacturer processes each subtask of each task. Similarly, the numbers in P3 indicate the index for each transportation mode. Thus, the genes in P3 determine the transportation mode used to deliver each subtask to the allocated manufacturer and, ultimately, to the destination.

3.3.2. Fitness Function

The goal of the algorithm is to find solutions with the highest fitness. If zi is the objective function value for chromosome i, then the fitness of this chromosome can be calculated as .

3.3.3. Genetic Operators

These operators help the genetic algorithm to approach the global optimal solution. The crossover operator helps with convergence, and the mutation operator causes diversity in the generated solutions.

Crossover

As mentioned earlier, each chromosome is composed of three sub-strings. A two-point crossover is used to perform a crossover on each substring. In sub-strings P2 and P3, the crossover operator does not generate inconsistent solutions (an inconsistent solution is one where each subtask of each task is not allocated to a manufacturer), but the crossover operator in substring P1 can produce such solutions. To address this problem, a correction process is performed. In this process, each child inherits the middle segment from one parent, while in the side segments, it inherits the gene from the other parent until it does not lead to an inconsistent solution. The remaining genes are filled randomly.

Mutation

A swap mutation is applied to each sub-string of the chromosome.

3.3.4. Stopping Condition

If the best fitness value does not change for a certain number of consecutive iterations, the algorithm will stop. This stopping criterion is known as a convergence criterion, and it helps to prevent the algorithm from running indefinitely and to save computational resources.

3.4. Verifying the Proposed Model

The axiomatic design idea was first created and popularized by Prof. Nam Suh [57]. The motivation for the creation of this framework was to develop a regulated basis for designing in a systematic, generalizable, and rigorous field [58].

In all design methods, aligning physical components to the customer’s requirement properly is the main goal. Hence, in axiomatic design, four general domains, customer domain, functional domain, physical domain, and process domain, have been considered [59]. In the customer domain, the expectations and requirements of a customer will be defined. Functional requirements (FR) in functional domains state the necessities by engineering words and express what we want to achieve. To translate FRs in an operational and tangible manner, they are mapped into design parameters (DP) that exist in the physical domain. The process domain consists of process variables that determine how to implement or exploit DPs [60]. The design process is transforming Customer requirements to FRs and then to DPs [57]. The relationship between two domains is called mapping and a good mapping process creates an efficient design.

Two chief axioms from prevalent principles for engineering activities exist in the axiomatic design. According to the independence axiom, each DP can be adjusted to satisfy its corresponding FR solely without affecting other FRs. In other words, this axiom states each DP should be defined independently for the corresponding FR. Based on the information axiom the best design has minimum content and is functionally an uncoupled design. Axiomatic design in the first step needs a satisfying independence axiom. If several designs satisfy the independence axiom, the second axiom is employed and the best design is the one that satisfies the information axiom with the best result.

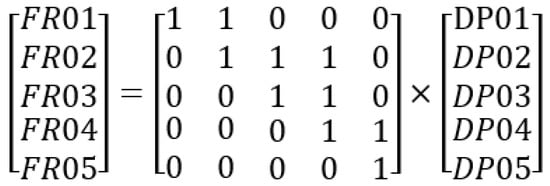

Transforming matrices allow the relationship between the customer domain and process domain to be represented. This relationship should be stated as follows using vector notations:

The matrix A in the above equation is called a design matrix which is used for the assessment of independence axioms. If this matrix is diagonal, the design is called an uncoupled design and each DP can satisfy the corresponding FR independently, therefore, the suggested design perfectly accomplishes the independence axiom. If the design matrix is triangular, the design is called a decoupled design. In decoupled design, if the design sequence is correct, the independence axiom is satisfied. The final approach to the design matrix is that its connected state is neither diagonal nor triangular. As each DP cannot independently satisfy an FR, the independence axiom will not be satisfied in this case.

To create a detailed design, a zigzagging approach was proposed by Stiassnie and Shpitalni in 2007 [61]. In this approach, high-level FR and DP are decomposed and in a zigzagging method, decomposition will be continued. This process will continue until the highest-level FRs are satisfied entirely.

Study of the Model Verifying by Axiomatic Design Theory

One of the most important decision-making issues in Industry 4.0 and supply networks is the service composition problem. Blockchain should enhance the effectiveness and productivity of decision making in this paradigm. In this paper, we claim the distributed nature of the blockchain should increase the decision-making process in this issue as an example. In this section, an investigation of the proposed model verifying was studied.

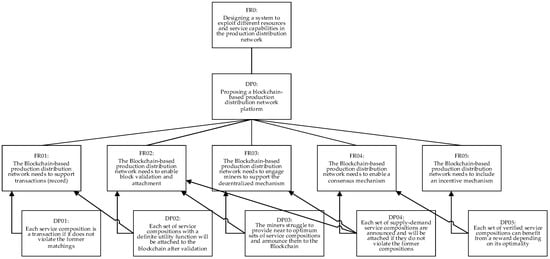

To verify the proposed blockchain-based supply network platform, the paper investigates the design matrix based on defining the FRs and DPs. This approach uses the zigzag method to decompose the master FR and DP as:

First-Level FR:

Designing a platform to exploit different resources and service capabilities in the production–distribution network to enhance sustainability and development in Industry 4.0.

First-Level DP:

Proposing a blockchain-based production–distribution platform.

To decompose the first-level DP, the paper addresses five major FRs in the second level which have been yielded from the literature of the blockchain as:

- FR01: The blockchain-based production–distribution network needs to support transaction (a record);

- FR02: The blockchain-based production–distribution network needs to enable block validation and attachment;

- FR03: The blockchain-based production–distribution network needs to engage miners to support the decentralized mechanism;

- FR04: The blockchain-based production–distribution network needs to enable a consensus mechanism;

- FR05: The blockchain-based production–distribution network needs to include an incentive mechanism.

To fulfill the above-mentioned FRs for a blockchain-based production–distribution network, the following DPs are proposed:

- DP01: Each service composition is a transaction if it does not violate the former matchings;

- DP02: Each set of service compositions with a definite utility function will be attached to the blockchain after validation;

- DP03: The miners struggle to provide near-to-optimum sets of service composition and announce them for attaching to the blockchain;

- DP04: Each set of service composition is announced and will be attached if it does not violate the former supply–demand compositions;

- DP05: Each set of verified service composition can benefit from a reward depending on its optimality and then it will be attached to the cloud supply blockchain.

To investigate the design matrix, the dependencies of FRs and DPs are analyzed as shown in Figure 4. The design matrix is illustrated in Figure 5.

Figure 4.

The zig-zag decomposition of functional requirements and design parameters. The mapping between FRs and DPs are presented by arrows.

Figure 5.

Design matrix.

The configuration of DPs has formed a triangular design matrix which is equivalent to a decoupled design. The definition of the proposed platform structure is not complex and can be achieved based on the axiomatic design theory.

4. Results

Since the problem at hand is known to be NP-hard, commercial solvers can only solve small instances. Therefore, a genetic algorithm is proposed to solve large-scale problems. To demonstrate the inefficiency of commercial solvers in solving this problem for large instances, we conducted experiments on small instances and analyzed the exponential growth in computational time. The name of each instance is in the format of three numbers: the number of manufacturers, the number of tasks, and the number of subtasks, respectively. All experiments were performed on a computer with an Intel Core i5-7200U CPU operating at 2.50 GHz and 8 GB RAM, running on the Windows 10 64-bit operating system.

As shown in Table 3, commercial solvers are only able to solve very small instances of the problem. Therefore, we have opted to use a genetic algorithm to tackle larger instances.

Table 3.

Results of the exact method.

Genetic Algorithm Performance

We use the Taguchi method for parameter tuning in our algorithm. We consider three levels for each parameter. The levels for population size are 800, 1000, and 1200, for max consecutive iteration, they are 30, 40, 50, for crossover rate, they are 0.85, 0.9, 0.95, and for mutation rate, they are 0.03, 0.05, and 0.1.

Based on the signal-to-noise ratio in the Taguchi method, the combination of the population size 800, max consecutive iteration 50, crossover rate 0.95, and mutation rate 0.1 results in the best solutions.

To examine the efficiency of the proposed architecture, a problem with 70 manufacturers, and 70 tasks, each having five subtasks, is studied. In this problem, there are two transportation modes to transport subtasks, and each subtask can demand one of the five services proposed by the manufacturer. The above problem is solved in both a centralized condition and distributed mode with two to four miners, assuming that every miner solves part of the main problem.

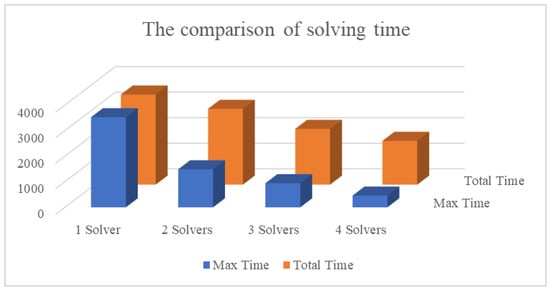

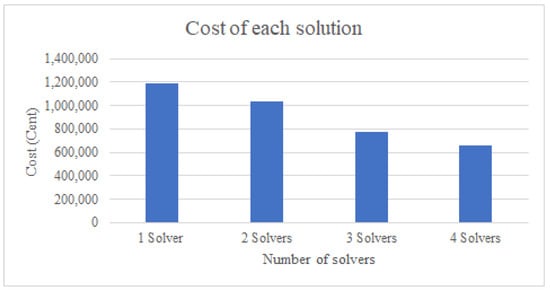

The solutions are compared in terms of the time and cost for each solution. To compare the solving time and the value of the objective function in centralized and decentralized modes, each problem is run ten times. Since the goal is to reach an acceptable solution in the shortest time possible, the solution obtained in the shortest time is reported. It is important to note that in the decentralized mode, the solution obtained in the shortest time in each cluster in ten iterations is reported, and the sum of the objective functions and solution times of the problem are reported.

In the decentralized method, the solving time in the optimistic and pessimistic conditions is considered the longest time of solving the sub-problem and the total solution time of all miners, respectively. Furthermore, the cost of the solution is the total cost of every miner’s solution. The comparison of the solving time of every solution is shown in Figure 6, and the speed of solving in the decentralized method is higher in the optimistic condition. Increasing the number of miners enhances the speed of the solution. Additionally, even in the pessimistic condition, achieving a solution in the decentralized condition is faster than in the centralized one. According to Figure 7, the solutions obtained from decentralized solutions are better than the centralized ones, and increasing the number of miners leads to much better solutions and the total cost of the system will be decreased.

Figure 6.

The comparison of solving time of every solution.

Figure 7.

The comparison of the cost of every solution.

Overall, with the above points, it is expected that the total system’s cost will be reduced by enhancing decentralization, and better solutions will be obtained in a shorter time.

5. Discussion

Among the reviewed articles, some have discussed the applications of blockchain in increasing sustainability in the supply chain through literature reviews, case studies, and questionnaires [31,34,36,37,38,39,40,41,43]. Others have examined the challenges and obstacles of blockchain adoption in the supply chain [28,32], while some have proposed an architecture for utilizing blockchain in sustainable supply chains [33,35,44,45]. Few articles have quantitatively examined the impact of blockchain on sustainability, with only one of them utilizing mathematical modeling for quantitative analysis [35,42,47]. This article, using blockchain, has optimized the input parameters of the modeling [35].

In the proposed model of this study, it is possible to observe miners monetizing micro-computing resources, which is not easily achieved in the centralized mode. Hence, it is expected that this model will create a higher level of social satisfaction. Moreover, this model solves the optimization problem faster than the centralized model. There is a direct relationship between the time it takes to solve the problem and the energy consumption of computing resources. Consequently, energy consumption is reduced, leading to less environmental damage and the achievement of environmental sustainability goals.

Furthermore, reducing the time required to solve optimization problems enhances productivity and reduces costs in the entire system, contributing to the economic goals of sustainability. Additionally, system costs are reduced by monetizing unused microcomputing resources, eliminating the need for centralized computing systems. Spending is based on a pay-as-you-go model, aligning with the economic goal of sustainability. Therefore, the proposed model of this study improves sustainability in three aspects, and the improvement in two aspects is qualitatively examined.

Although this article has its advantages, the discussion of distribution has been considered in the form of allocation, where only the type of vehicle needs to be determined for the transportation of each subtask between the two manufacturers, and it is assumed that every type of vehicle is always available.

The results obtained in this paper provide insights for development of service composition platform for XaaS oriented production systems. It can provide the small and medium size companies to provide their production and logistics resources. Moreover, the solvers which can be imagined to be stakeholders with computational capabilities can enable optimized matching of demanders and service providers. As sustainability is an important perspective for production and manufacturing services, the blockchain ecosystems can use the architecture in this paper for promoting the sustainability perspectives of production and manufacturing operations.

In conclusion, the implications of our proposed blockchain-based supply chain architecture extend beyond the immediate benefits of cost reduction and increased processing speed. The enhanced transparency, optimized resource utilization, improved productivity, and potential for service composition platforms have wide-ranging implications for sustainability in the supply chain.

Furthermore, by utilizing smart contracts, it is possible to manage relationships between different members of the supply chain without a central governing authority and prevent the imposition of biases or preferences by such a central entity on the system. As a result of this change, it is expected that the relationships among the members in the supply chain will become more sustainable.

Additionally, the adoption of blockchain can facilitate the integration of emerging technologies such as Internet of Things (IoT) devices and Artificial Intelligence (AI) algorithms, enabling real-time monitoring, predictive analytics, and optimization of supply chain processes. These advancements contribute to the development of a more sustainable, efficient, and future-ready supply chain ecosystem. Especially, the proposed architecture in this paper can be used as a reference model for practitioners to develop start-ups for the next generation of logistics service provision over cloud solutions. This can initiate the idea of 5PL (5th party logistics) which benefits from an XaaS approach for connecting service demanders and providers with a distributed approach. Finally, using the token model based on the proposed architecture, the sustainability perspectives of manufacturing and logistics for helping societies can be enhanced. This will create traceability and resolution to the business processes of manufacturing and logistics services.

6. Conclusions

In summary, this paper has presented a comprehensive investigation into a blockchain-based architecture for supply chain systems. Our research demonstrates that the distributed nature of blockchain technology holds significant potential for enhancing the productivity of decision-making processes within the supply chain. Moreover, the decentralized decision-making approach contributes to the advancement of Industry 4.0 and smart supply chains. A schematic reward function in the distributed decision-making process has been investigated in this paper.

The results of our study unequivocally highlight the superiority of the distributed mode (blockchain mode) over the centralized mode in terms of solution speed and quality. Notably, the final solutions achieved were up to 45% better in quality compared with the centralized mode. Additionally, there was a substantial improvement of approximately 87% in solution speed in the optimistic state (miners’ activities carried out in parallel and simultaneously), and a 51% improvement was observed in the pessimistic state (miners’ activities performed in tandem and series). These enhancements in solution time effectively reduce costs while achieving the sustainability goals of the supply chain. Combining the implementation of Industry 4.0 principles with our proposed architecture can foster the development of a sustainable supply chain ecosystem.

We have rigorously validated our proposed model using the axiomatic design algorithm, confirming its reliability and effectiveness. As a valuable suggestion for future research, we recommend addressing the distribution problem by approaching it as a vehicle routing problem, which can lead to more optimized and efficient transportation solutions. Furthermore, we propose the adoption of a tokenization model that offers robust and quantitative compensation for miners, ensuring fair incentives within the blockchain-based system.

In conclusion, our study sheds light on the immense benefits of blockchain technology in the context of supply chains, emphasizing its potential to revolutionize decision-making processes and foster sustainability. By embracing decentralized decision making and leveraging blockchain’s capabilities, organizations can establish resilient, transparent, and environmentally conscious supply chains. This research serves as a foundation for further exploration and advancement in the field, paving the way for more sustainable and efficient supply chain operations.

Author Contributions

Conceptualization, S.-A.R. and O.F.V.; methodology, S.-A.R.; writing—original draft preparation, S.-A.R.; writing—review and editing, A.H. and O.F.V.; visualization, S.-A.R.; supervision, A.H. and O.F.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are openly available in figshare at http://doi.org/10.6084/m9.figshare.22736768, accessed on 6 May 2023.

Acknowledgments

The authors appreciate the precious comments of the editor and anonymous reviewers which enhanced and improved the quality and robustness of this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Olsen, T.L.; Tomlin, B. Industry 4.0: Opportunities and challenges for operations management. Manuf. Serv. Oper. Manag. 2020, 22, 113–122. [Google Scholar]

- Valilai, O.F.; Houshmand, M. A Manufacturing Ontology Model to Enable Data Integration Services in Cloud Manufacturing using Axiomatic Design Theory. In Cloud-Based Design and Manufacturing (CBDM); Springer: Berlin/Heidelberg, Germany, 2014; pp. 179–206. [Google Scholar] [CrossRef]

- Valilai, O.F.; Houshmand, M. A collaborative and integrated platform to support distributed manufacturing system using a service-oriented approach based on cloud computing paradigm. Robot. Comput.-Integr. Manuf. 2013, 29, 110–127. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Peron, M.; Fragapane, G. Cloud Material Handling Systems: Conceptual Model and Cloud-Based Scheduling of Handling Activities. In Scheduling in Industry 4.0 and Cloud Manufacturing; Sokolov, B., Ivanov, D., Dolgui, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 87–101. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Lee, J.Y.; Yoon, J.S.; Kim, B.-H. A big data analytics platform for smart factories in small and medium-sized manufacturing enterprises: An empirical case study of a die casting factory. Int. J. Precis. Eng. Manuf. 2017, 18, 1353–1361. [Google Scholar] [CrossRef]

- Houshmand, M.; Valilai, O.F. A layered and modular platform to enable distributed CAx collaboration and support product data integration based on STEP standard. Int. J. Comput. Integr. Manuf. 2013, 26, 731–750. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Lobo, C.R.; Wicaksono, H.; Valilai, O.F. Implementation of Blockchain Technology to Enhance Last Mile Delivery Models with Sustainability Perspectives. IFAC-Pap. 2022, 55, 3304–3309. [Google Scholar] [CrossRef]

- Shah, S.S.; Pirayesh, A.; Valilai, O.F. Using Blockchain Technology for 3D Printing in Manufacturing of Dental Implants in Digital Dentistry. In Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar]

- Ivanov, D.; Dolgui, A.; Sokolov, B. Cloud supply chain: Integrating industry 4.0 and digital platforms in the “Supply Chain-as-a-Service”. Transp. Res. Part E Logist. Transp. Rev. 2022, 160, 102676. [Google Scholar] [CrossRef]

- ElMamy, S.B.; Mrabet, H.; Gharbi, H.; Jemai, A.; Trentesaux, D. A Survey on the Usage of Blockchain Technology for Cyber-Threats in the Context of Industry 4.0. Sustainability 2020, 12, 9179. [Google Scholar] [CrossRef]

- Khanfar, A.A.A.; Iranmanesh, M.; Ghobakhloo, M.; Senali, M.G.; Fathi, M. Applications of Blockchain Technology in Sustainable Manufacturing and Supply Chain Management: A Systematic Review. Sustainability 2021, 13, 7870. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System; Bitcoin: Las Vegas, NV, USA, 2008. [Google Scholar]

- Buterin, V. A next-generation smart contract and decentralized application platform. White Pap. 2014, 3, 1–2. [Google Scholar]

- Crosby, M.; Pattanayak, P.; Verma, S.; Kalyanaraman, V. Blockchain technology: Beyond bitcoin. Appl. Innov. 2016, 2, 71. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Arha, H. Understanding the Blockchain technology adoption in supply chains-Indian context. Int. J. Prod. Res. 2019, 57, 2009–2033. [Google Scholar] [CrossRef]

- Korpela, K.; Hallikas, J.; Dahlberg, T. Digital supply chain transformation toward blockchain integration. In Proceedings of the 50th Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 4–7 January 2017. [Google Scholar]

- Ferdows, K. Keeping up with growing complexity of managing global operations. Int. J. Oper. Prod. Manag. 2018, 38, 390–402. [Google Scholar] [CrossRef]

- Yoon, J.; Talluri, S.; Yildiz, H.; Sheu, C. The value of Blockchain technology implementation in international trades under demand volatility risk. Int. J. Prod. Res. 2020, 58, 2163–2183. [Google Scholar] [CrossRef]

- Chang, Y.; Iakovou, E.; Shi, W. Blockchain in global supply chains and cross border trade: A critical synthesis of the state-of-the-art, challenges and opportunities. Int. J. Prod. Res. 2020, 58, 2082–2099. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Telles, R.; Bonilla, S.H. Blockchain and supply chain management integration: A systematic review of the literature. Supply Chain. Manag. Int. J. 2020, 25, 241–254. [Google Scholar] [CrossRef]

- Van Hoek, R. Developing a framework for considering blockchain pilots in the supply chain–lessons from early industry adopters. Supply Chain. Manag. Int. J. 2019, 25, 115–121. [Google Scholar] [CrossRef]

- Wang, Y.; Singgih, M.; Wang, J.; Rit, M. Making sense of blockchain technology: How will it transform supply chains? Int. J. Prod. Econ. 2019, 211, 221–236. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Dey, S.; Saha, S.; Singh, A.K.; McDonald-Maier, K. FoodSQRBlock: Digitizing Food Production and the Supply Chain with Blockchain and QR Code in the Cloud. Sustainability 2021, 13, 3486. [Google Scholar] [CrossRef]

- Tijan, E.; Aksentijević, S.; Ivanić, K.; Jardas, M. Blockchain Technology Implementation in Logistics. Sustainability 2019, 11, 1185. [Google Scholar] [CrossRef]

- Adams, R.; Kewell, B.; Parry, G. Blockchain for Good? Digital Ledger Technology and Sustainable Development Goals. In Handbook of Sustainability and Social Science Research; Springer: Berlin/Heidelberg, Germany, 2018; pp. 127–140. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Nayak, G.; Dhaigude, A.S. A conceptual model of sustainable supply chain management in small and medium enterprises using blockchain technology. Cogent Econ. Financ. 2019, 7, 1667184. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. A supply chain transparency and sustainability technology appraisal model for blockchain technology. Int. J. Prod. Res. 2020, 58, 2142–2162. [Google Scholar] [CrossRef]

- Manupati, V.K.; Schoenherr, T.; Ramkumar, M.; Wagner, S.M.; Pabba, S.K.; Inder Raj Singh, R. A blockchain-based approach for a multi-echelon sustainable supply chain. Int. J. Prod. Res. 2020, 58, 2222–2241. [Google Scholar] [CrossRef]

- Roeck, D.; Sternberg, H.; Hofmann, E. Distributed ledger technology in supply chains: A transaction cost perspective. Int. J. Prod. Res. 2020, 58, 2124–2141. [Google Scholar] [CrossRef]

- Di Vaio, A.; Varriale, L. Blockchain technology in supply chain management for sustainable performance: Evidence from the airport industry. Int. J. Inf. Manag. 2020, 52, 102014. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Sarkis, J. Blockchain practices, potentials, and perspectives in greening supply chains. Sustainability 2018, 10, 3652. [Google Scholar] [CrossRef]

- Kshetri, N. Blockchain and sustainable supply chain management in developing countries. Int. J. Inf. Manag. 2021, 60, 102376. [Google Scholar] [CrossRef]

- Sahoo, S.; Kumar, S.; Sivarajah, U.; Lim, W.M.; Westland, J.C.; Kumar, A. Blockchain for sustainable supply chain management: Trends and ways forward. Electron. Commer. Res. 2022, 1–56. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The effect of blockchain technology on supply chain sustainability performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Yousefi, S.; Tosarkani, B.M. An analytical approach for evaluating the impact of blockchain technology on sustainable supply chain performance. Int. J. Prod. Econ. 2022, 246, 108429. [Google Scholar] [CrossRef]

- Dutta, P.; Chavhan, R.; Gowtham, P.; Singh, A. The individual and integrated impact of Blockchain and IoT on sustainable supply chains: A systematic review. Supply Chain. Forum Int. J. 2023, 24, 103–126. [Google Scholar] [CrossRef]

- Jraisat, L.; Jreissat, M.; Upadhyay, A.; Kumar, A. Blockchain Technology: The Role of Integrated Reverse Supply Chain Networks in Sustainability. Supply Chain. Forum Int. J. 2023, 24, 17–30. [Google Scholar] [CrossRef]

- Corazza, L.; Zhang, J.; Arachchilage, D.K.; Scagnelli, S.D. Blockchain and Sustainability Disclosure: A Scenario-Based Application for Supply Chains. Sustainability 2023, 15, 571. [Google Scholar] [CrossRef]

- Khan, S.A.; Mubarik, M.S.; Kusi-Sarpong, S.; Gupta, H.; Zaman, S.I.; Mubarik, M. Blockchain technologies as enablers of supply chain mapping for sustainable supply chains. Bus. Strategy Environ. 2022, 31, 3742–3756. [Google Scholar] [CrossRef]

- Biswas, D.; Jalali, H.; Ansaripoor, A.H.; De Giovanni, P. Traceability vs. sustainability in supply chains: The implications of blockchain. Eur. J. Oper. Res. 2023, 305, 128–147. [Google Scholar] [CrossRef]

- Radke, A.M.; Tseng, M.M. Design considerations for building distributed supply chain management systems based on cloud computing. J. Manuf. Sci. Eng. 2015, 137, 040906. [Google Scholar] [CrossRef]

- Bertsekas, D. Distributed dynamic programming. IEEE Trans. Autom. Control. 1982, 27, 610–616. [Google Scholar] [CrossRef]

- Silva, C.A.; Sousa, J.M.C.; Runkler, T.A.; Da Costa, J.S. Distributed supply chain management using ant colony optimization. Eur. J. Oper. Res. 2009, 199, 349–358. [Google Scholar] [CrossRef]

- Law, A. Smart Contracts and Their Application in Supply Chain Management. Master’s Thesis, Massachusetts Institute of Technology, Cambridg, MA, USA, 2017. [Google Scholar]

- Radmanesh, S.-A.; Haji, A.; Valilai, O.F. Blockchain-based cloud manufacturing platforms: A novel idea for service composition in XaaS paradigm. PeerJ Comput. Sci. 2021, 7, e743. [Google Scholar] [CrossRef] [PubMed]

- De Giovanni, P. Blockchain and smart contracts in supply chain management: A game theoretic model. Int. J. Prod. Econ. 2020, 228, 107855. [Google Scholar] [CrossRef]

- De Giovanni, P. Digital supply chain through dynamic inventory and smart contracts. Mathematics 2019, 7, 1235. [Google Scholar] [CrossRef]

- Raj, P.V.R.P.; Jauhar, S.K.; Ramkumar, M.; Pratap, S. Procurement, traceability and advance cash credit payment transactions in supply chain using blockchain smart contracts. Comput. Ind. Eng. 2022, 167, 108038. [Google Scholar] [CrossRef]

- Zeynivand, M.; Ranjbar, H.; Radmanesh, S.A.; Valilai, O.F. Alternative process routing and consolidated production-distribution planning with a destination oriented strategy in cloud manufacturing. Int. J. Comput. Integr. Manuf. 2021, 34, 1162–1176. [Google Scholar] [CrossRef]

- Suh, N.P. The Principles of Design; Oxford University Press: New York, NY, USA, 1990. [Google Scholar]

- Suh, N.P. Designing-in of quality through axiomatic design. IEEE Trans. Reliab. 1995, 44, 256–264. [Google Scholar] [CrossRef]

- Cebi, S.; Kahraman, C. Indicator design for passenger car using fuzzy axiomatic design principles. Expert Syst. Appl. 2010, 37, 6470–6481. [Google Scholar] [CrossRef]

- Gebala, D.A.; Suh, N.P. An application of axiomatic design. Res. Eng. Des. 1992, 3, 149–162. [Google Scholar] [CrossRef]

- Stiassnie, E.; Shpitalni, M. Incorporating lifecycle considerations in axiomatic design. CIRP Ann. 2007, 56, 1–4. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).