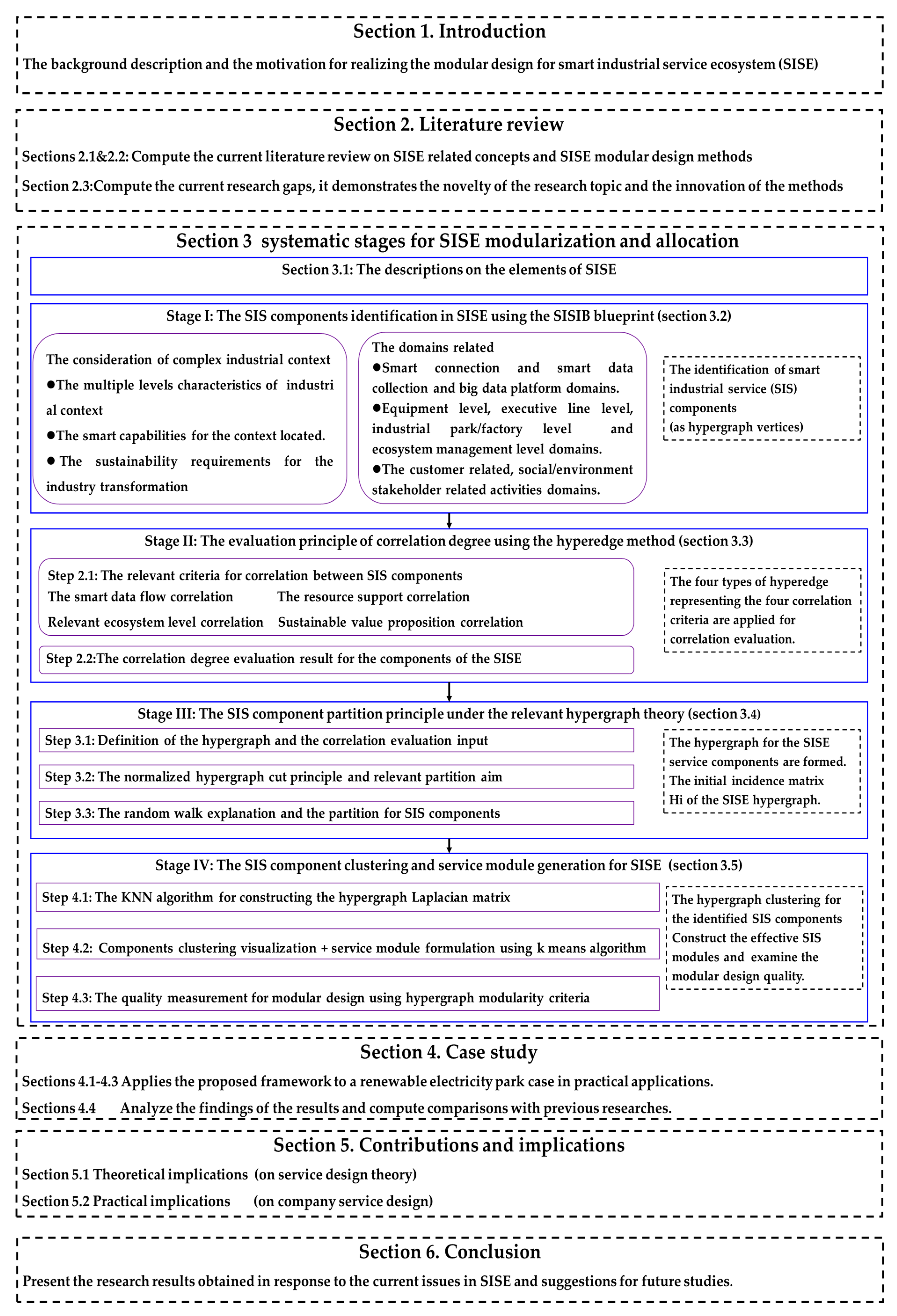

Modularization Design for Smart Industrial Service Ecosystem: A Framework Based on the Smart Industrial Service Identification Blueprint and Hypergraph Clustering

Abstract

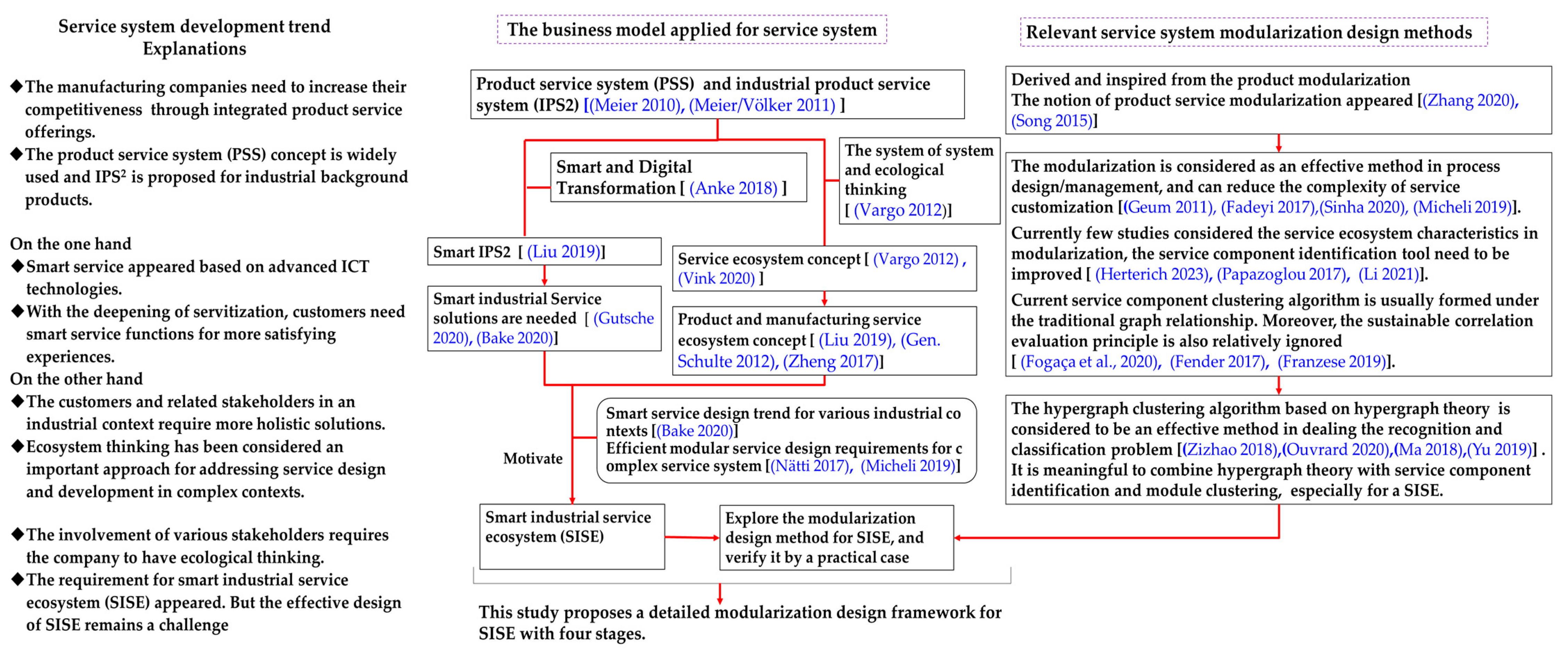

1. Introduction

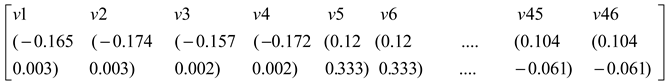

2. Literature Review

2.1. Smart Industrial Service Ecosystem-Related Concepts

2.1.1. Smart IPS2

2.1.2. Service Ecosystem

2.1.3. SISE: A Smart Service Solution for a Complex Industrial Context

2.2. Service Modular Design Methods

2.2.1. Service Component Identification Process

2.2.2. Service Component Cluster Methods

| References | Service Process Analysis and Service Component Identification | Correlation Evaluation for Service Components Identified | Service Component Modular Algorithm | |||||

|---|---|---|---|---|---|---|---|---|

| Method | Service Process Identification Visibility | Service System Macro Levels Consideration | Correlation Degree Aspect Focus | Linguistic Vagueness Consideration | Method | Modular Result Visualization | Smart Learning Algorithm in Partition | |

| [30] | Product–service blueprint | ✓ | ✗ | TBL-sustainability | ✗ | N/A | ✗ | ✗ |

| [32] | DSM | ✗ | ✗ | Economic- Better maintenance | ✗ | Idicula-Gutierrez-Thebeau-Algorithm | ✗ | ✓ |

| [16] | Fuzzy DSM | ✗ | Partially | Economic-Better profit | ✓ | Fuzzy Similar Matrix | ✗ | ✗ |

| [14] | FRA | ✗ | ✗ | Economic- Better efficiency | ✓ | Fuzzy clustering algorithm | ✗ | ✗ |

| [58] | BPMN | ✓ | Partially | TBL-sustainability | ✗ | N/A | ✗ | ✗ |

| [34] | Manufacturing service blueprint | ✓ | ✗ | Economic/ environment Better maintenance | ✗ | N/A | ✗ | ✗ |

| [35] | Smart service blueprint | ✓ | Partially | Economic/ Better competitiveness | ✗ | N/A | ✗ | ✗ |

| [11] | Product–service blueprint | ✓ | ✗ | Economic/Better profit + maintenance | ✓ | Maximum spanning tree | ✓ | ✗ |

| [36] | Product operation netlist | ✓ | ✗ | Economic/Better profit and fewer cost | ✗ | Graph theory and Louvain | ✓ | ✓ |

| [13] | Smart product–service blueprint | ✓ | ✗ | Economic- | ✓ | Graph theory | ✓ | ✓ |

| This study | SISIB | ✓ | ✓ | TBL-sustainability | ✓ | Hypergraph Theory/learning algorithm | ✓ | ✓ |

2.2.3. Hypergraph Clustering Mechanism and Current Application

2.3. Current Research Gaps

3. The Systematic Framework for SISE Modularization and Allocation

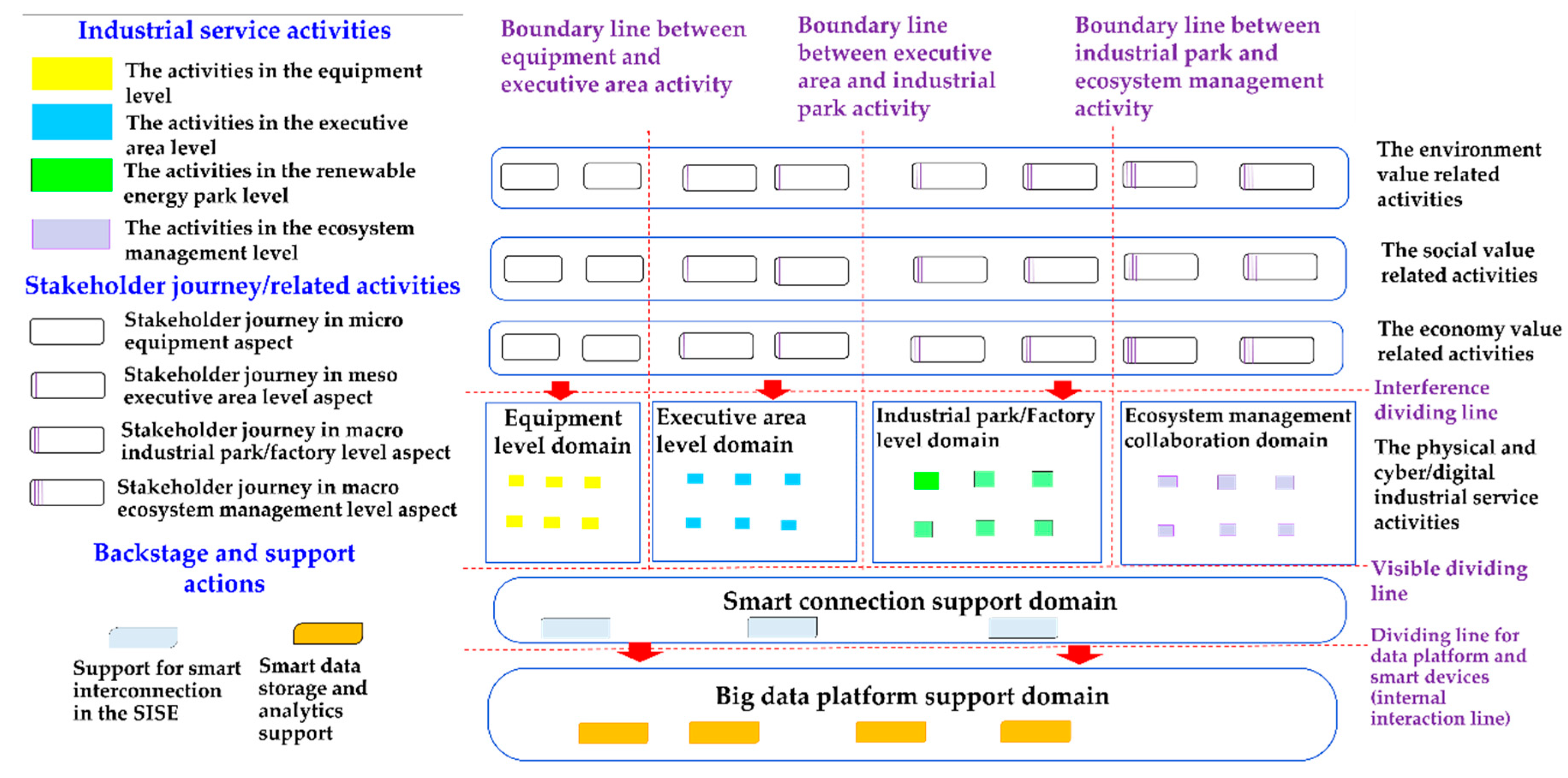

3.1. The SISE Model and an Overview of the Proposed Framework

3.2. The SIS Components Identification Using the SISIB (Stage I)

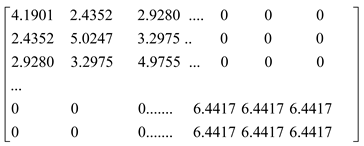

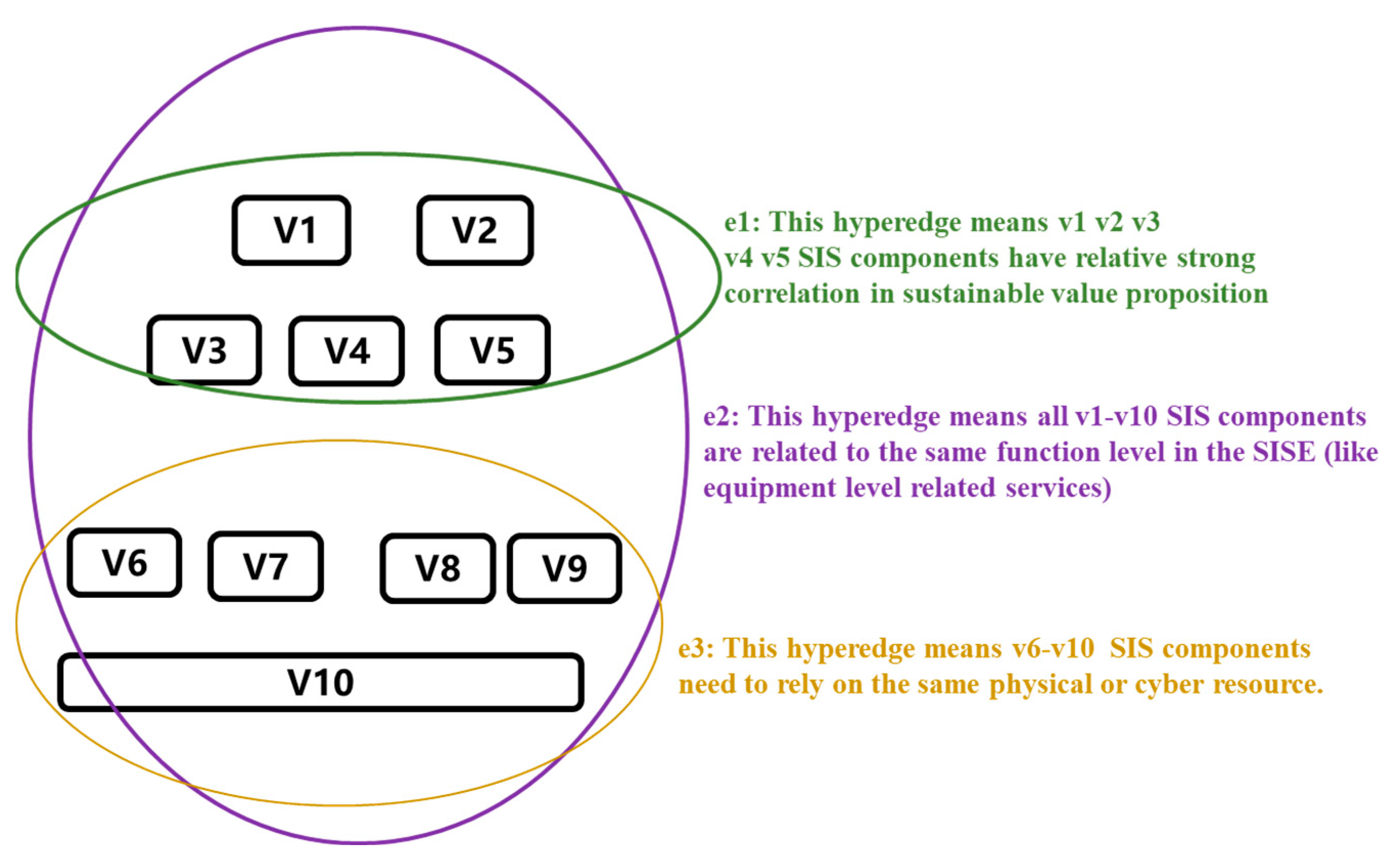

3.3. The Smart Collaboration and Sustainable Correlation Evaluation Using the Hyperedge Method (Stage II)

- (1)

- Smart data flow correlation: The SISE contains several components in the background smartness and data support part domain. The components that have interactions in data and information can be seen as correlated to smart data flow, including smart interconnection, real-time monitoring, and operation data flow.

- (2)

- Resource support correlation: In the operation of SISE, two or more related service components may be related to the same type of support resource. The support resources needed in SISE include equipment parts, operation technology management, and human resource management. The service components that require a certain type of resource can be considered to be aggregated into one service module to enhance the module functionality and improve the design efficiency.

- (3)

- Ecosystem level correlation: The SISE contains four levels of the functional layer, including a relatively microscopic product/equipment level that mainly focuses on equipment maintenance. The mesoscopic executive line/workstation level mainly focuses on the operation service for functional zones. The two more macroscopic park or ecosystem management levels are also considered in these criteria as some SIS components are related to more holistic system process management.

- (4)

- Sustainable value proposition correlation: Since various stakeholders may be involved in the SISE service process, their value propositions can exceed ordinary economic benefits. Therefore, this criterion is especially important for the SISE design. The components that have a value proposition related to economic, social, or environmental improvement should be considered into one edge and aggregated into one service module.

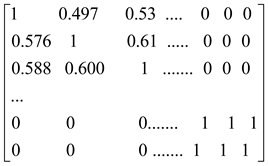

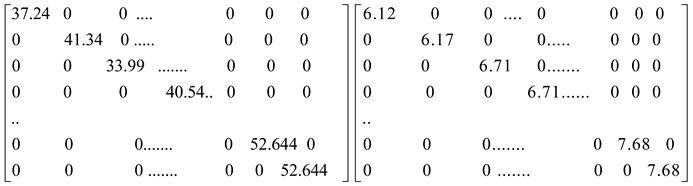

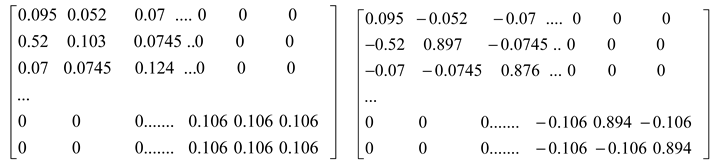

3.4. The SIS Component Partition Principle under the Relevant Hypergraph Theory (Stage III)

3.5. The SIS Component Clustering and Service Module Generation for SISE (Stage IV)

4. Case Study

4.1. Identification of SIS Components for Smart Renewable Energy Park Service System (Stage I)

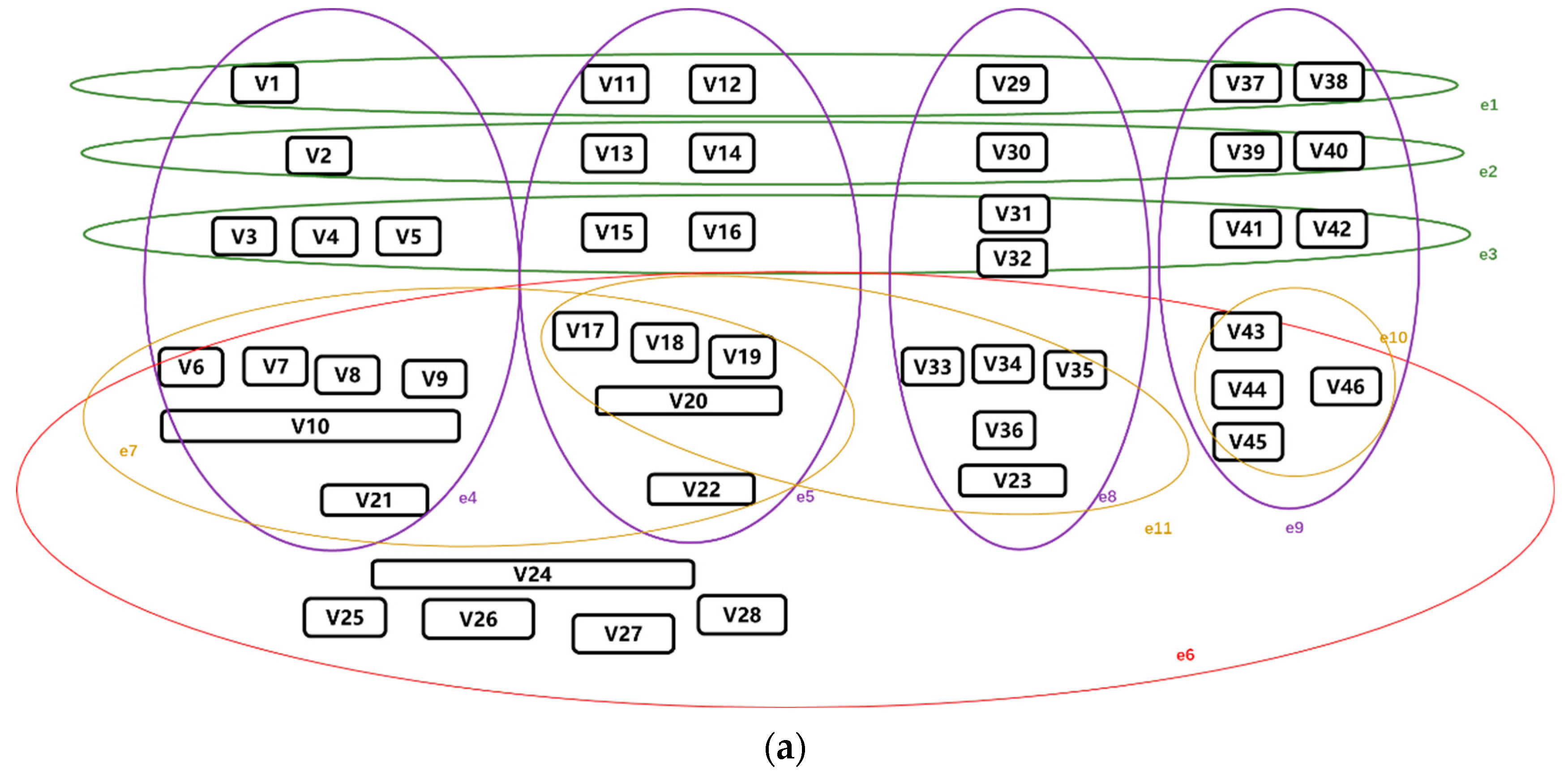

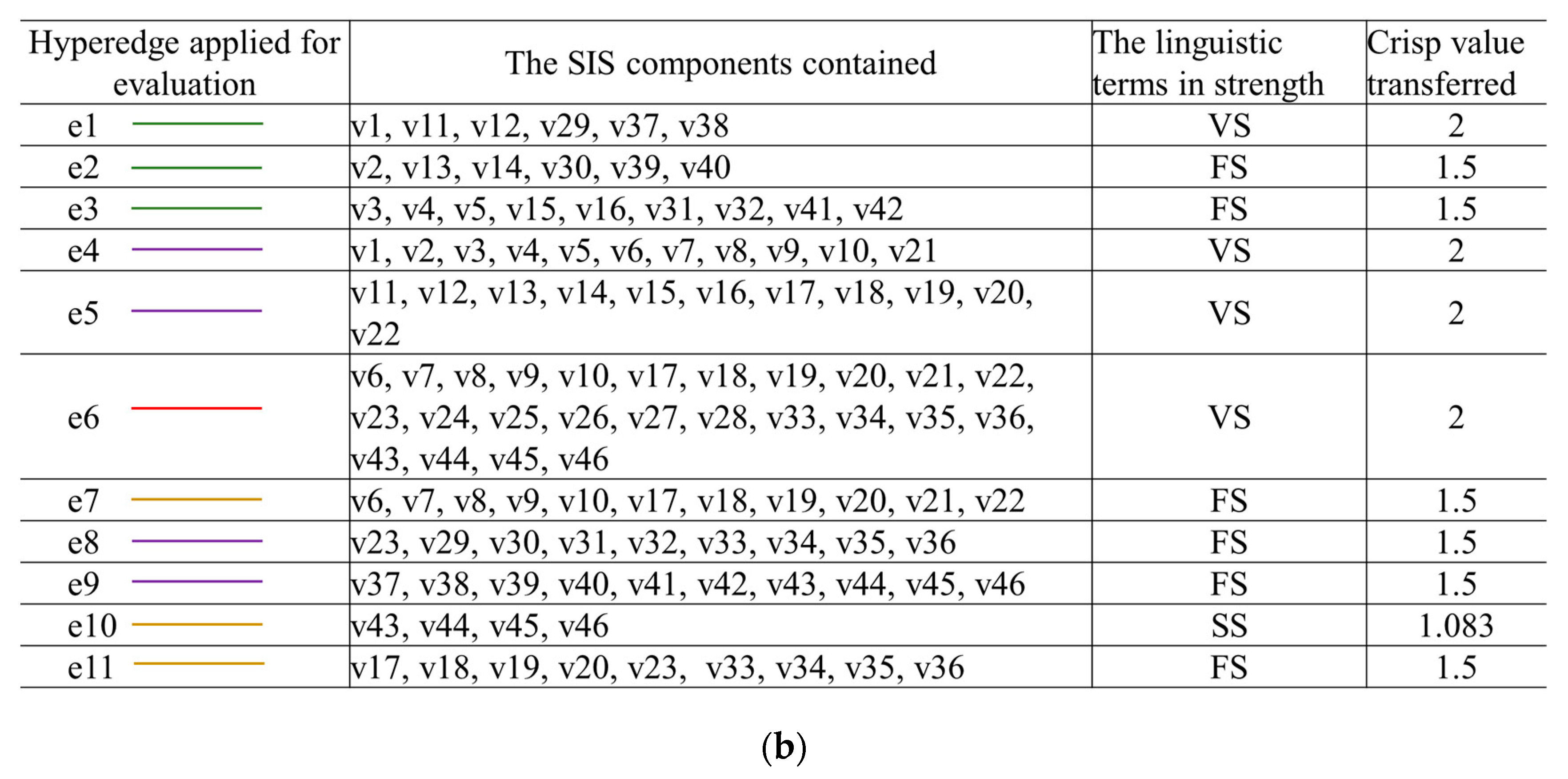

4.2. Smart and Sustainable Correlation Relevance Evaluation for SRSE Service Component (Stage II)

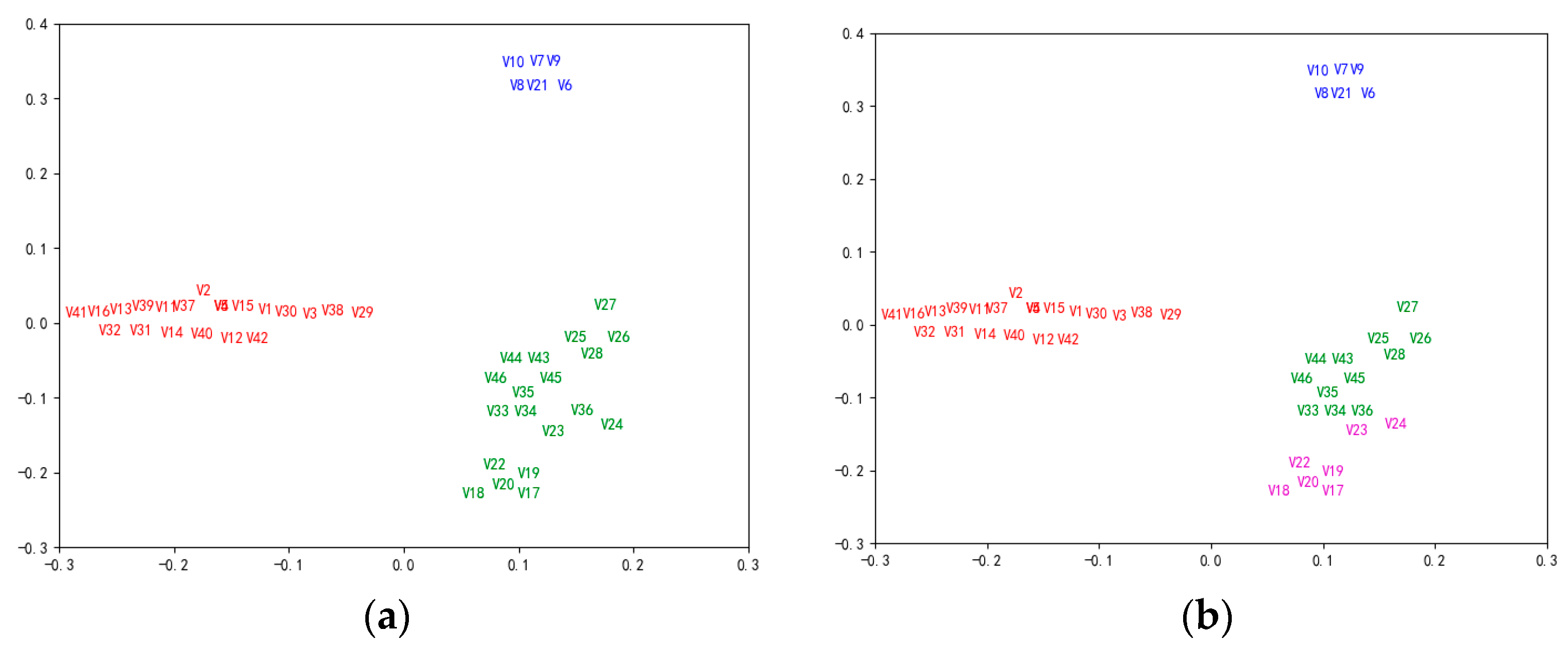

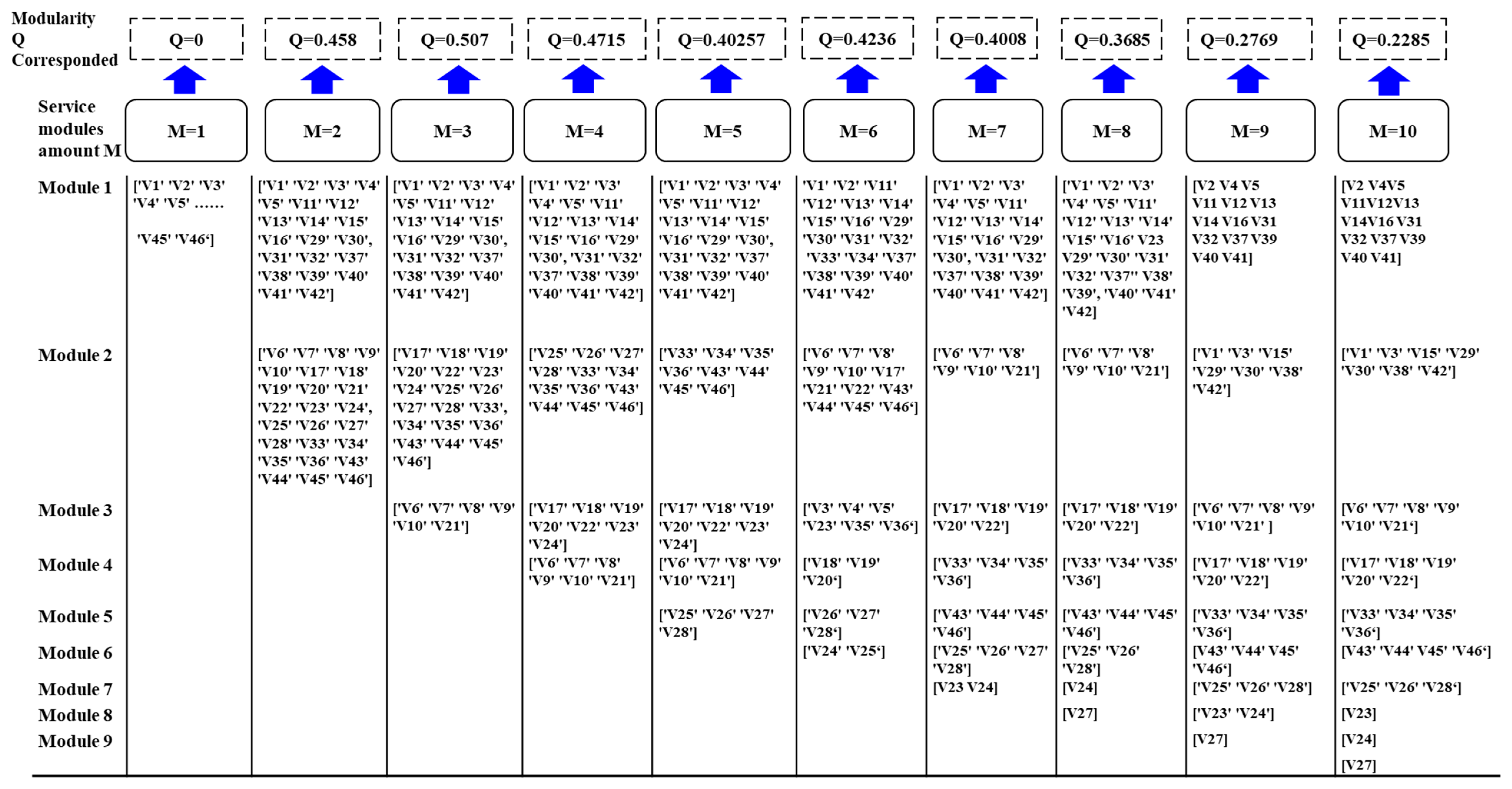

4.3. The Partition of SRSE System Modules Based on Hypergraph Clustering (Stages III and IV)

4.4. Findings of the Results and Comparisons

5. Contributions and Implications

5.1. Theoretical Implications

5.2. Practical Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meier, H.; Roy, R.; Seliger, G. Industrial Product-Service Systems—IPS2. CIRP Ann. 2010, 59, 607–627. [Google Scholar] [CrossRef]

- Meng, Z.; Chen, Z.; Sun, Z.-H.; Ming, X. Smart product service requirements identification and evaluation: A hybrid method. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 13–16 December 2021. [Google Scholar]

- Chang, Y.; Ming, X.; Chen, Z.; Zhou, T.; Liao, X.; Song, W. Stakeholder requirement evaluation of smart industrial service ecosystem under Pythagorean fuzzy environment for complex industrial contexts: A case study of renewable energy park. Adv. Eng. Inform. 2023, 55, 101823. [Google Scholar] [CrossRef]

- Anthony, B. Distributed ledger and decentralised technology adoption for smart digital transition in collaborative enterprise. Enterp. Inf. Syst. 2021, 1–34. [Google Scholar] [CrossRef]

- Anthony, B. Deployment of distributed ledger and decentralized technology for transition to smart industries. Environ. Syst. Decis. 2023, 43, 298–319. [Google Scholar] [CrossRef]

- Kortum, H.; Rebstadt, J.; Hagen, S.; Thomas, O. Integrating Data and Service Lifecycle for Smart Service Systems Engineering: Compilation of a Lifecycle Model for the Data Ecosystem of Smart Living. 2022. Available online: https://scholarspace.manoa.hawaii.edu/items/a415b33b-a4a4-4833-a08a-bf96a030b99a (accessed on 9 May 2023).

- Beverungen, D.; Kundisch, D.; Wünderlich, N. Transforming into a platform provider: Strategic options for industrial smart service providers. J. Serv. Manag. 2021, 32, 507–532. [Google Scholar] [CrossRef]

- Herterich, M.M.; Dremel, C.; Wulf, J.; Brocke, J.V. The emergence of smart service ecosystems—The role of socio-technical antecedents and affordances. Inf. Syst. J. 2022, 33, 524–566. [Google Scholar] [CrossRef]

- Khan, M.A.; Wuest, T. Towards a framework to design upgradable product service systems. Procedia CIRP 2018, 78, 400–405. [Google Scholar] [CrossRef]

- Zhang, F.; Ding, H.; Zhang, N. Productive service demands modularization for CNC machine tools based on the improved AP clustering algorithm. Neural Comput. Appl. 2019, 32, 1567–1579. [Google Scholar] [CrossRef]

- Song, W.; Wu, Z.; Li, X.; Xu, Z. Modularizing product extension services: An approach based on modified service blueprint and fuzzy graph. Comput. Ind. Eng. 2015, 85, 186–195. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, S.; Chen, S. Healthcare process modularization using design structure matrix. Adv. Eng. Inform. 2019, 39, 320–330. [Google Scholar] [CrossRef]

- Chen, Z.; Ming, X.; Vareilles, E.; Battaia, O. Modularization of smart product service: A framework integrating smart product service blueprint and weighted complex network. Comput. Ind. 2020, 123, 103302. [Google Scholar] [CrossRef]

- Sun, J.; Chai, N.; Pi, G.; Zhang, Z.; Fan, B. Modularization of Product Service System Based on Functional Requirement. Procedia CIRP 2017, 64, 301–305. [Google Scholar] [CrossRef]

- Yin, Z.; Gao, Q.; Ji, X. A New Service Module Partition Approach for Product Service System Based on Fuzzy Graph and Dempster-Shafer Theory of Evidence. Math. Probl. Eng. 2018, 2018, 8346859. [Google Scholar] [CrossRef]

- Geng, X.; Jin, Y.; Zhang, Y. Result-oriented PSS Modular Design Method based on FDSM. Procedia CIRP 2019, 83, 610–615. [Google Scholar] [CrossRef]

- Zheng, H.; Feng, Y.; Tan, J.; Zhang, Z. An integrated modular design methodology based on maintenance performance con-sideration. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 313–328. [Google Scholar] [CrossRef]

- Mata, A.S.D. Complex Networks: A Mini-review. Braz. J. Phys. 2020, 50, 658–672. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Lv, F.; Gong, Y.; Metaxas, D.N. Unsupervised image categorization by hypergraph partition. IEEE Trans. Pattern Anal. Mach. Intell. 2011, 33, 1266–1273. [Google Scholar] [CrossRef]

- Meier, H.; Völker, O.; Funke, B. Industrial Product-Service Systems (IPS2). Int. J. Adv. Manuf. Technol. 2011, 52, 1175–1191. [Google Scholar] [CrossRef]

- Anke, J.; Wellsandt, S.; Thoben, K.-D. Modelling of a Smart Service for Consumables Replenishment A Life Cycle Perspective. Enterp. Model. Inf. Syst. Archit. Int. J. 2018, 13, 17-1. [Google Scholar]

- Liu, Z.; Ming, X. A framework with revised rough-DEMATEL to capture and evaluate requirements for smart industrial product-service system of systems. Int. J. Prod. Res. 2019, 57, 7104–7122. [Google Scholar] [CrossRef]

- Schulte, J.K.G.; Steven, M. Risk Management of Industrial Product-Service Systems (IPS2)—How to Consider Risk and Uncertainty over the IPS2 Lifecycle? Springer: Berlin/Heidelberg, Germany, 2012; pp. 37–42. [Google Scholar] [CrossRef]

- Gutsche, K.; Droll, C. Enabling or Stressing? Smart Information Use Within Industrial Service Operation. In Digital Human Modeling and Applications in Health, Safety, Ergonomics and Risk Management. Human Communication, Organization and Work. HCII 2020; Lecture Notes in Computer Science; Duffy, V., Ed.; Springer: Cham, Switzerland, 2020; Volume 12199. [Google Scholar] [CrossRef]

- Vargo, S.L.; Akaka, M.A. Value Cocreation and Service Systems (Re)Formation: A Service Ecosystems View. Serv. Sci. 2012, 4, 207–217. [Google Scholar] [CrossRef]

- Vink, J.; Koskela-Huotari, K.; Tronvoll, B.; Edvardsson, B.; Wetter-Edman, K. Service Ecosystem Design: Propositions, Process Model, and Future Research Agenda. J. Serv. Res. 2020, 24, 168–186. [Google Scholar] [CrossRef]

- Zheng, M.; Ming, X.; Wang, L.; Yin, D.; Zhang, X. Status Review and Future Perspectives on the Framework of Smart Product Service Ecosystem. Procedia CIRP 2017, 64, 181–186. [Google Scholar] [CrossRef]

- Bake, J.S.; Pereira Pessôa, M.V.; Sipke, H. Mapping challenges and methodologies for providing PSS—A thematic and descriptive analysis. Cogent Bus. Manag. 2020, 7, 1809945. [Google Scholar] [CrossRef]

- Nätti, S.; Ulkuniemi, P.; Pekkarinen, S. Implementing Modularization in Professional Services—The Influence of Varied Knowledge Environments. Knowl. Process. Manag. 2017, 24, 125–138. [Google Scholar] [CrossRef]

- Geum, Y.; Park, Y. Designing the sustainable product-service integration: A product-service blueprint approach. J. Clean. Prod. 2011, 19, 1601–1614. [Google Scholar] [CrossRef]

- Fadeyi, J.A.; Monplaisir, L.; Aguwa, C. The integration of core cleaning and product serviceability into product modularization for the creation of an improved remanufacturing-product service system. J. Clean. Prod. 2017, 159, 446–455. [Google Scholar] [CrossRef]

- Sinha, K.; Han, S.Y.; Suh, E.S. Design structure matrix-based modularization approach for complex systems with multiple de-sign constraints. Syst. Eng. 2020, 23, 211–220. [Google Scholar] [CrossRef]

- Micheli, G.J.; Trucco, P.; Sabri, Y.; Mancini, M. Modularization as a system life cycle management strategy: Drivers, barriers, mechanisms and impacts. Int. J. Eng. Bus. Manag. 2019, 11, 1847979018825041. [Google Scholar] [CrossRef]

- Papazoglou, M.P.; Elgammal, A. The manufacturing blueprint environment: Bringing intelligence into manufacturing. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation (ICE/ITMC), Madeira Island, Portugal, 27–29 June 2017; pp. 750–759. [Google Scholar] [CrossRef]

- Li, F.; Lu, Y. Engaging end users in an AI-enabled smart service design—The application of the smart service blueprint scape (SSBS) framework. Proc. Des. Soc. 2021, 1, 1363–1372. [Google Scholar] [CrossRef]

- Fogaça, M.; Kahng, A.B.; Monteiro, E.; Reis, R.; Wang, L.; Woo, M. On the superiority of modularity-based clustering for de-termining placement-relevant clusters. Integration 2020, 74, 32–44. [Google Scholar] [CrossRef]

- Fender, A.; Emad, N.; Petiton, S.; Naumov, M. Parallel Modularity Clustering. Procedia Comput. Sci. 2017, 108, 1793–1802. [Google Scholar] [CrossRef]

- Franzese, N.; Groce, A.; Murali, T.M.; Ritz, A. Hypergraph-based connectivity measures for signaling pathway topologies. PLoS Comput. Biol. 2019, 15, e1007384. [Google Scholar] [CrossRef]

- Zizhao, Z.; Lin, H.; Gao, Y. Dynamic Hypergraph Structure Learning. In Proceedings of the Twenty-Seventh International Joint Conference on Artificial Intelligence, Stockholm, Sweden, 13–19 July 2018. [Google Scholar]

- Ouvrard, X. Hypergraphs: An introduction and review. arXiv 2020, arXiv:2002.05014. [Google Scholar]

- Ma, X.; Liu, W.; Li, S.; Tao, D.; Zhou, Y. Hypergraph p-Laplacian Regularization for Remotely Sensed Image Recognition. IEEE Trans. Geosci. Remote Sens. 2018, 57, 1585–1595. [Google Scholar] [CrossRef]

- Yu, N.; Gao, Y.-L.; Liu, J.-X.; Wang, J.; Shang, J. Robust hypergraph regularized non-negative matrix factorization for sample clustering and feature selection in multi-view gene expression data. Hum. Genom. 2019, 13, 46. [Google Scholar] [CrossRef]

- Frow, P.; McColl-Kennedy, J.R.; Payne, A.; Govind, R. Service ecosystem well-being: Conceptualization and implications for theory and practice. Eur. J. Mark. 2019, 53, 2657–2691. [Google Scholar] [CrossRef]

- Cimini, C.; Rondini, A.; Pezzotta, G.; Pinto, R. Smart manufacturing as an enabler of servitization: A framework for the business transformation towards a smart service ecosystem. In Proceedings of the 23rd Summer School “Francesco Turco”-Industrial Systems Engineering 2018, Palermo, Italy, 12–14 September 2018; pp. 341–347. [Google Scholar]

- Yin, D.; Ming, X.; Zhang, X. Understanding Data-Driven Cyber-Physical-Social System (D-CPSS) Using a 7C Framework in Social Manufacturing Context. Sensors 2020, 20, 5319. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Xue, X.; Zhou, Z. SLE2: The Improved Social Learning Evolution Model of Cloud Manufacturing Service Ecosystem. IEEE Trans. Ind. Inform. 2022, 18, 9017–9026. [Google Scholar] [CrossRef]

- Weinberger, M.; Bilgeri, D.; Fleisch, E. IoT business models in an industrial context. Auto 2016, 64, 699–706. [Google Scholar] [CrossRef]

- Medini, K.; Boucher, X. Specifying a modelling language for PSS Engineering—A development method and an operational tool. Comput. Ind. 2019, 108, 89–103. [Google Scholar] [CrossRef]

- Radenković, M.; Lukić, J.; Despotović-Zrakić, M.; Labus, A.; Bogdanović, Z. Harnessing business intelligence in smart grids: A case of the electricity market. Comput. Ind. 2018, 96, 40–53. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.; Lu, W.; Huang, G.Q. An Internet of Things-enabled BIM platform for modular integrated construction: A case study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- da Costa Fernandes, S.; Martins, L.D.; Rozenfeld, H. Who are the stakeholders mentioned in cases of Product-Service System (PSS) design? In Proceedings of the Design Society: International Conference on Engineering Design, Delft, The Netherlands, 5–8 August 2019; pp. 3131–3140. [Google Scholar]

- Kaartemo, V.; Akaka, M.; Vargo, S. A Service-Ecosystem Perspective on Value Creation: Implications for International Busi-ness. Value Creat. Int. Bus. 2017, 2, 131–149. [Google Scholar]

- Maleki, E.; Belkadi, F.; Boli, N.; Van Der Zwaag, B.J.; Alexopoulos, K.; Koukas, S.; Marin-Perianu, M.; Bernard, A.; Mourtzis, D. Ontology-based framework enabling smart product-service systems: Application of sensing systems for machine health monitoring. IEEE Internet Things J. 2018, 5, 4496–4505. [Google Scholar] [CrossRef]

- Mastrapa, L.H.; Assumpo, M.P.; Velázquez, D.; Gennaro, C.K.; Dias, E. Product-Service System Modularization: A Systematic Review. In Proceedings of the 25th International Joint Conference on Industrial Engineering and Operations Management—IJCIEOM, Rio de Janeiro, Brazil, 8–11 July 2020. [Google Scholar]

- Brusoni, S.; Prencipe, A. Patterns of Modularization: The Dynamics of Product Architecture in Complex Systems. Eur. Manag. Rev. 2011, 8, 67–80. [Google Scholar] [CrossRef]

- Shehab, E.; Tiwari, A.; Annamalai Vasantha, G.V.; Lightfoot, H.; Roy, R. Decision Engineering Report Series: Industrial Product-Service Systems (IPS2): THINK TANK. Available online: https://dspace.lib.cranfield.ac.uk/handle/1826/7173 (accessed on 3 May 2023).

- Peters, C.; Leimeister, J.M. TM3-A modularization method for telemedical services: Design and evaluation. In Proceedings of the 21st European Conference on Information Systems (ECIS), Utrecht, The Netherlands, 5–8 June 2013. [Google Scholar]

- Santana, F.; Nagata, F.; Cursino, D.; Barberato, M.; Leal, C. Using BPMN-Based Business Processes in Requirements Engineering: The Case Study of Sustainable Design. 2016. Available online: https://www.proquest.com/openview/c6d316b7c0400cbfaa96d0bd83c5ec39/1?cbl=1976356&pq-origsite=gscholar&parentSessionId=lS2HAX%2BlQeHDF6CLdKNfJNrcNIPP7cO6iOkO%2F0s7yAw%3D (accessed on 2 May 2023).

- Wei, X.; Cai, L.; Liao, B.; Lu, T. Local-view-assisted discriminative band selection with hypergraph autolearning for hyperspectral image classification. IEEE Trans. Geosci. Remote Sens. 2019, 58, 2042–2055. [Google Scholar] [CrossRef]

- Li, P.; Milenkovic, O. Inhomogeneous Hypergraph Clustering with Applications. Adv. Neural Inf. Process. Syst. 2017, 30. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, C.-H.; Zheng, P.; Li, X.; Song, W. A hypergraph-based approach for context-aware smart product-service system configuration. Comput. Ind. Eng. 2021, 163, 107816. [Google Scholar] [CrossRef]

- Halstenberg, F.A.; Lindow, K.; Stark, R. Leveraging circular economy through a methodology for smart service systems en-gineering. Sustainability 2019, 11, 3517. [Google Scholar] [CrossRef]

- Maglio, P.P.; Lim, C. Innovation and Big Data in Smart Service Systems. J. Innov. Manag. 2016, 4, 11–21. [Google Scholar] [CrossRef]

- Chen, R.; Hua, Q.; Jia, W.; Zhang, M.; Ji, X.; Li, J.; Wang, B.; Liu, J. A hybrid recommendation method and development framework of user interface patterns based on hypergraph theory. Int. J. Innov. Comput. Inf. Control 2017, 13, 1169–1185. [Google Scholar]

- Lee, S.; Kim, M.S.; Park, Y.; Kim, C. Identification of a technological chance in product-service system using KeyGraph and text mining on business method patents. Int. J. Technol. Manag. 2016, 70, 239. [Google Scholar] [CrossRef]

- Euchner, J. Ecosystem Innovation. Res.-Technol. Manag. 2016, 59, 9–10. [Google Scholar] [CrossRef]

- Resman, M.; Pipan, M.; Simic, M.; Herakovic, N. A new architecture model for smart manufacturing: A performance analysis and comparison with the RAMI 4.0 reference model. Adv. Prod. Eng. Manag. 2019, 14, 153–165. [Google Scholar] [CrossRef]

- Li, M.; Zhao, C.; Tang, J. Hybrid image summarization by hypergraph partition. Neurocomputing 2013, 119, 41–48. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Zhang, S.; Metaxas, D.N. Image retrieval via probabilistic hypergraph ranking. In Proceedings of the 2010 IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Francisco, CA, USA, 13–18 June 2010. [Google Scholar]

- Zhou, D.; Huang, J.; Schlkopf, B. Learning with Hypergraphs: Clustering, Classification, and Embedding. In Proceedings of the Advances in Neural Information Processing Systems 19, Proceedings of the Twentieth Annual Conference on Neural Information Processing Systems, Vancouver, BC, Canada, 4–7 December 2006. [Google Scholar]

- Kutlu, A.C.; Ekmekçioğlu, M. Fuzzy failure modes and effects analysis by using fuzzy TOPSIS-based fuzzy AHP. Expert Syst. Appl. 2012, 39, 61–67. [Google Scholar] [CrossRef]

- Zhang, Z.; Bai, L.; Liang, Y.; Hancock, E. Joint hypergraph learning and sparse regression for feature selection. Pattern Recognit. 2017, 63, 291–309. [Google Scholar] [CrossRef]

- Halim, Z.; Sargana, H.M.; Aadam; Uzma; Waqas, M. Clustering of graphs using pseudo-guided random walk. J. Comput. Sci. 2021, 51, 101281. [Google Scholar] [CrossRef]

- Mao, M.; Lu, J.; Han, J.; Zhang, G. Multiobjective e-commerce recommendations based on hypergraph ranking. Inf. Sci. 2018, 471, 269–287. [Google Scholar] [CrossRef]

- Jiang, J.; Wei, Y.; Feng, Y.; Cao, J.; Gao, Y. Dynamic Hypergraph Neural Networks. In Proceedings of the IJCAI, Macao, China, 10–16 August 2019; pp. 2635–2641. [Google Scholar] [CrossRef]

- Newman, M.E. Modularity and community structure in networks. Proc. Natl. Acad. Sci. USA 2006, 103, 8577–8582. [Google Scholar] [CrossRef] [PubMed]

- Kumar, T.; Vaidyanathan, S.; Ananthapadmanabhan, H.; Parthasarathy, S.; Ravindran, B. A New Measure of Modularity in Hypergraphs: Theoretical Insights and Implications for Effective Clustering; Springer International Publishing: Cham, Switzerland, 2019; pp. 286–297. [Google Scholar] [CrossRef]

- Holmström, E.; Bock, N.; Brännlund, J. Modularity density of network community divisions. Phys. D Nonlinear Phenom. 2009, 238, 1161–1167. [Google Scholar] [CrossRef]

- Zheng, P.; Chen, C.-H.; Shang, S. Towards an automatic engineering change management in smart product-service systems—A DSM-based learning approach. Adv. Eng. Inform. 2019, 39, 203–213. [Google Scholar] [CrossRef]

- Wu, M.; Liu, Y.; Chung, H.F.; Guo, S. When and how mobile payment platform complementors matter in cross-border B2B e-commerce ecosystems? An integration of process and modularization analysis. J. Bus. Res. 2021, 139, 843–854. [Google Scholar] [CrossRef]

| Linguistic Terms in Hyperedge | Strength on the Fuzzy Score | Crisp Value Transferred |

|---|---|---|

| Very strong correlation (VSC) | (3/2, 2, 5/2) | 2 |

| Fairly strong correlation (FSC) | (1, 3/2, 2) | 1.5 |

| Slightly strong correlation (SSC) | (1, 1, 3/2) | 1.083 |

| No. | Name | Domain | Relevant Smart Function |

|---|---|---|---|

| V1 | Smart classification and recovery of scrapped wind/photovoltaic power equipment | Environmental stakeholder value proposition | Intelligent classification |

| V2 | Operation safety feedback of wind/photovoltaic power equipment | Social stakeholder value proposition | Real-time communication and feedback |

| V3 | Wind/photovoltaic power equipment access to monitoring network | Economical stakeholder value proposition | Predictive Maintenance |

| V4 | Ensure the normal operation of wind/photovoltaic power equipment | Economical stakeholder value proposition | Smart diagnosis and repair |

| V5 | Predictive maintenance of wind/photovoltaic power equipment | Economical stakeholder value proposition | Predictive maintenance |

| V6 | Smart interconnection service of wind/photovoltaic power equipment | Equipment level-related service activity | Smart sensing and connectivity |

| V7 | Real-time status monitoring of wind/photovoltaic power equipment | Equipment level-related service activity | Real-time monitoring |

| V8 | Wind/photovoltaic power equipment fault diagnosis | Equipment level-related service activity | Smart diagnosis |

| V9 | Wind/photovoltaic power equipment accurate repair | Equipment level-related service activity | Smart & accurate repair |

| V10 | The digital twin model of wind/photovoltaic power equipment | Equipment level-related service activity | Digital twin simulation |

| V11 | Feedback of station energy consumption | Environmental stakeholder value proposition | Smart statistical data classification |

| V12 | The noise and radiation pollution statistics for stations | Environmental stakeholder value proposition | Smart statistical data classification |

| … | … | … | … |

| V40 | Rectification and feedback of safety problems | Social stakeholder value proposition | Real-time communication |

| V41 | Economic benefit feedback of new energy power system operation | Economical stakeholder value proposition | Smart and visual report view |

| V42 | Better cooperation system of related stakeholders | Economical stakeholder value proposition | Smart enterprise resource planning |

| V43 | Stakeholder expectation management | Ecosystem management level-related service activity | Management of smart ecosystem |

| V44 | Operation of enterprise resource management system | Ecosystem management level-related service activity | Smart enterprise resource planning |

| V45 | Operation access management of industrial big data platform | Ecosystem management level-related service activity | Big data platform |

| V46 | Service value network management at the ecosystem level | Ecosystem management level-related service activity | Management of smart ecosystem |

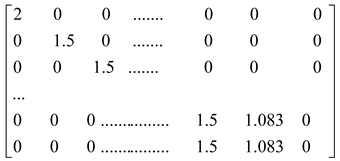

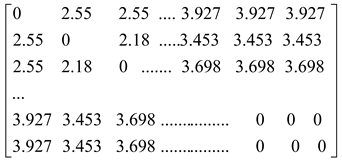

| e1 | e2 | e3 | e4 | e5 | e6 | e7 | e8 | e9 | e10 | e11 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| V1 | 2 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| V2 | 0 | 1.5 | 0 | 1.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| V3 | 0 | 0 | 1.5 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| V4 | 0 | 0 | 1.5 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| V5 | 0 | 0 | 1.5 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| V6 | 0 | 0 | 0 | 2 | 0 | 2 | 1.5 | 0 | 0 | 0 | 0 |

| … | … | … | … | … | … | … | … | … | … | … | … |

| V43 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 1.5 | 1.083 | 0 |

| V44 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 1.5 | 1.083 | 0 |

| V45 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 1.5 | 1.083 | 0 |

| V46 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 1.5 | 1.083 | 0 |

| Comparison with the Current Representative Methods | The Consideration of Smartness and Multi-Level Industrial Context | The Visibility and Clearance of Service Component Identification | The Simplicity of the Evaluation Matrix in Correlation Evaluation | The Maximum Modularity Q that can Gain in Relevant Study |

|---|---|---|---|---|

| This method | Both considered the smart data flow and the multi-level activities in a complex industrial context. | Can clearly identify the service components through the service operation process and also reflect their distributions among various domains. | The effective correlation comparison can be formed with only 12 hyperedges. A 12*46 correlation matrix is enough. | 0.507 |

| Representative DSM-related study [79] | The authors considered the smart connectivity around the smart product. However, their DSM matrix cannot reflect the distribution of service activities at different levels. | Not clear and visible in describing the detailed service operation process. It also cannot reflect the different functional domains of a complex industrial context clearly. | 46 SIS components need to be compared with each other. Need to form a 46*46 correlation matrix | 0.33865 |

| Representative smart product service blueprint-related study [13] | The authors considered the cyber smart function domain for product service in the CPS-based SPS blueprint applied. However, they did not consider more macro activities in the executive line or industrial park levels. | The related service components can be displayed and identified in the relevant service operation process but are rather limited in product-level related activities. | 46 SIS components need to be compared with each other. Need to form a 46*46 correlation matrix | 0.320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.; Ming, X.; Zhang, X.; Bao, Y. Modularization Design for Smart Industrial Service Ecosystem: A Framework Based on the Smart Industrial Service Identification Blueprint and Hypergraph Clustering. Sustainability 2023, 15, 8858. https://doi.org/10.3390/su15118858

Chang Y, Ming X, Zhang X, Bao Y. Modularization Design for Smart Industrial Service Ecosystem: A Framework Based on the Smart Industrial Service Identification Blueprint and Hypergraph Clustering. Sustainability. 2023; 15(11):8858. https://doi.org/10.3390/su15118858

Chicago/Turabian StyleChang, Yuan, Xinguo Ming, Xianyu Zhang, and Yuguang Bao. 2023. "Modularization Design for Smart Industrial Service Ecosystem: A Framework Based on the Smart Industrial Service Identification Blueprint and Hypergraph Clustering" Sustainability 15, no. 11: 8858. https://doi.org/10.3390/su15118858

APA StyleChang, Y., Ming, X., Zhang, X., & Bao, Y. (2023). Modularization Design for Smart Industrial Service Ecosystem: A Framework Based on the Smart Industrial Service Identification Blueprint and Hypergraph Clustering. Sustainability, 15(11), 8858. https://doi.org/10.3390/su15118858