1. Introduction

Industrial innovation is the core topic of the innovation-driven development strategy, and it is the key measure used to improve the security and controllable level of China’s industrial chain and to realize the optimization and upgrading of the industrial structure. After more than 40 years of continuous accumulation since its reform and opening, China has become the world’s second-largest economy and largest manufacturing country, but many industrial fields in China are still “big but not strong”. For example, China has been the world’s largest automobile-production country for 12 years, since 2009, but so far, it has failed to master the independent intellectual property rights of core technologies, such as automatic test equipment (ATE), continuously variable transmission (CVT), and high-end hydraulic components and seals. Moreover, the domestic passenger-car market is still dominated by foreign brands, and less than half are independent brands. Industry hollowing, including products without technology, markets without brands, and equity without intellectual property rights, has led to a series of problems such as the “bottleneck” of core technologies, the low added value of products, and low-end industrial locking, which seriously threaten stable industrial development and national economic security [

1]. Improving the level of independent industrial innovation is the key to solving these problems and enhancing the self-supporting capacity of industry and supply chains [

2,

3].

The advanced manufacturing industry is a manufacturing field formed by the interweaving of the industrialization of high and new technologies and the high-tech development of traditional industries, located at the top of the manufacturing sector’s innovation and value chains. The innovative development of the advanced manufacturing industry is the most significant focus of the new round of industrial revolution and international competition, as well as the strategic focus for China to enhance its comprehensive national strength and participate in international competition [

4,

5]. That is to say, the highest priority in industrial innovation is the enhancement of the level of independent innovation in the advanced manufacturing industry, which plays core and supporting roles in building a modern industrial system and has guiding and boosting effects on innovation in surrounding industries [

6]. At present, the scientific and technological revolution represented by the new generation of information technology is booming, leading to a profound and historic change in the production mode of the manufacturing industry [

7]. With the new round of scientific and technological revolution and industrial transformation trends, the advanced manufacturing industry faces an important strategic development opportunity. The acceleration of the innovative development of the Industrial Internet, as well as the fundamental reform of the production model and enterprise form of the manufacturing industry, and raising the digitization, network, and intelligence level of the manufacturing industry, are long-term strategic goals of the Chinese government, since these factors are of great significance for reaching the commanding heights of industrial competition, accelerating the construction of China’s manufacturing and network power, and achieving high-quality economic development.

As the main bodies in industrial innovation, enterprises in advanced manufacturing and the new generation of information-technology industries play an irreplaceable leading role in industrial technology innovation, enterprise-management innovation, business-model innovation, and other aspects [

8,

9]. The key to enhancing the driving force of the innovative development of advanced manufacturing industries is to fully mobilize the enthusiasm for innovation in advanced manufacturing enterprises and the new generation of information-technology enterprises and give full play to their leading role to create a favorable industrial innovation ecology with enterprises as the main bodies and facilitate the in-depth collaboration of governments, enterprises, universities, and research institutions [

10]. At the same time, the network trend of the global value chain has introduced great changes in the form of global economic competition. Global economic competition is no longer the competition between individual enterprises, nor does it entirely take place between industrial chains and single business; rather, it has gradually evolved into competition between industrial innovation ecosystems [

11].

The concept of the innovation ecosystem originated in ecological theory, which mainly explores the relationships between different living organisms in nature and the relationships between living organisms and their surrounding environments. Ecological theory has become an important theoretical basis for guiding the development of industrial clusters, including the manufacturing industry and automobile industry [

12,

13,

14]. The formation of the industrial innovation ecosystem is similar to that of the natural ecosystem, which gradually moves from individuals to clusters and then to populations and tribes. It is constructed by many related subjects and is a process of mutual competition, cooperation, and the joint promotion of its continuous evolution [

15,

16]. The industrial innovation ecosystem is mainly formed through the interweaving of ecological networks with knowledge exchange and information transmission in the innovation process, which is the basic path to the improvement of technological innovation ability and an important route for the effective allocation of innovation resources [

17,

18].

However, there is a close relationship between the AMEIE and sustainability. The AMEIE is a systematic innovation ecological environment formed by the participation of upstream and downstream enterprises in the industrial chain, research institutions, and the government. It can also ensure the rationalization of resource allocation and the realization of environmental protection. Furthermore, in the AMEIE, more environmentally friendly and sustainable methods of production and consumption can be achieved through technological innovation, which is conducive to sustainability. In addition, sustainability can provide continuous opportunities and resources to the AMEIE, and the synergistic development of both can create more economic, social, and environmental benefits.

To summarize, the AMEIE is a complex symbiotic system with multiple subjects and multiple interfaces. In this paper, the evolution equilibrium of the AMEIE is clearly shown by descriptions of the system of symbiotic evolution between enterprise entities. This is expected to reflect the impact of competition and cooperation between members of the ecosystem’s symbiotic evolution and, thus, further optimize the innovation ecosystem by improving subjects’ cooperation to attain long-term benefits and mutually beneficial outcomes [

19].

2. Literature Review

The AMEIE is the intersection and integration of two research fields: advanced manufacturing and the industrial innovation ecosystem, and policies and practices in the manufacturing-innovation ecosystem. The existing research is reviewed according to these factors in this paper.

2.1. Advanced Manufacturing

With the introduction and application of new information technology in the manufacturing industry, various advanced manufacturing models and national strategies have been proposed and increasingly valued. The symbiotic relationship between digitization, the Industrial Internet, the Internet of Things, and the advanced manufacturing industry has been the subject of focus in many foreign studies [

20] on topics such as “Industrie 4.0”, network physical production systems, intelligent factories, intelligent manufacturing, “Internet plus Manufacturing,” and cloud manufacturing. The use these models and strategies to achieve the effective coordination and supply–demand matching of various manufacturing resources and capabilities is one of the common themes studied by scholars. Kabugo and Aazam believe that the industrial Internet of Things (IIoT) and “Industrie 4.0” will be composed of sensor networks, actuators, robots, machines, equipment, business processes, and personnel, and an overview of the architecture is presented in their research [

21,

22]. Simultaneously, other scholars discussed big data and digital twin technology in the advanced manufacturing industry [

5]. These studies start from the perspective of technical economics but rarely feature in-depth analyses from the perspective of management economics. On one hand, the implementation path and action framework of the advanced manufacturing industry have been explored in Chinese research [

23], and on the other hand, the literature is dedicated to focusing on the deep integration of the advanced manufacturing industry and the producer-services industry [

24]. Based on the coupling-coordination-degree model, Yang. et al. validated a development-evaluation-index system integrating advanced manufacturing and modern services in Guangdong Province. Using this index system, the development of advanced manufacturing and modern services in Guangdong in recent years was comprehensively evaluated. Research shows that the integration of “two industries” in 2019 initially reached a high level, but there is still a need to strengthen the upgrading of industrial structures, increase the development of industrial clusters, and optimize the integration of industrial chains [

25]. In these numerous documents, there is still a lack of in-depth analyses of the construction of ecological networks in advanced manufacturing.

2.2. Industrial Innovation Ecosystem

According to current research, the industrial innovation ecosystem refers to a loose network of interconnected organizations with cooperative and competitive relations, characterized by self-organization, self-regulation, and self-development, and it creates value through the sharing of knowledge, technologies, information, and other resources [

26,

27]. From a micro-level perspective, previous studies analyzed the impact of technology, products, firm capabilities, and dependent relationships on the successful commercialization of innovation, especially the impact of core firms on the corporate-innovation ecosystem in which they are embedded [

28]. From the perspective of industrial architecture, an industrial ecosystem is considered a specific type of industrial architecture. The structural characteristics of industry architecture influence ecosystem-value creation and value-distribution patterns [

29]. From the perspective of macro strategy, the construction of ecosystem strategies is a decisive factor in the innovation ecosystem. Unlike traditional strategies, which focus on competitive advantage, the key to innovation-ecosystem strategies is the improve the synergy and adaptation of ecosystem members. Ecosystem strategies evolve with the location of the members in and the evolution of the ecosystem. Therefore, the ecosystem strategy should be selected according members’ locations to match their roles, and it should be continuously adjusted [

15]. In our opinion, the research on the industrial innovation ecosystem can be further divided into four branches. The first is value creation and acquisition. By encouraging industrial linkages and technological progress, more value can be created in the industrial innovation ecosystem [

30]. The second is leading enterprises. The management and coordination role of leading enterprises in innovation and value acquisition is an important feature of the industrial innovation ecosystem. Further, the network structure of leading enterprises is conducive to researching the interaction mechanisms within the industrial innovation ecosystem. The third is knowledge advantages. This refers to the superiority in knowledge and skills, sustainability, and profitability of an industrial innovation ecosystem compared with its competitors. This is mainly reflected in intellectual property rights, cost-leading operation systems, and high-quality products or services [

31]. The final topic branch includes specific research scenarios. The research on the industrial innovation ecosystem mainly focuses on the safety-evaluation system of the manufacturing industry and the composition, technology diffusion, public governance, and external-resource management [

32] of the manufacturing-innovation ecosystem.

2.3. Policies and Practices Included in the Manufacturing-Innovation Ecosystem in Typical Countries

In major countries, the advanced manufacturing industry is developed via the dimensions of layout design, capacity construction, talent cultivation, and ecological optimization [

33]. In Germany, the intelligent manufacturing industry 4.0 with automation and informatization is committed to establishing and exporting world standards for intelligent manufacturing using technology in order to establish and expand the first-mover advantage and world influence of Germany’s intelligent manufacturing technology. France attaches great importance to providing accurate services to small- and medium-sized manufacturing enterprises by improving the public-service-platform system for industrial technology, as well as strengthening foreign exchange and publicity in its industry, in an attempt to become one of the top-tier manufacturing countries once more. Meanwhile, South Korea is striving to promote a new generation of information technology to empower the manufacturing industry; in this case, more intelligent factories have been created, and more investment has been allocated to interdisciplinary education to enhance technological innovation in the manufacturing industry. In Japan, the manufacturing-development strategy has been clarified through annual manufacturing white papers. Recently, advanced manufacturing fields, including robotics, the Industrial Internet, and artificial intelligence, have received more policy support. Through a series of policies and measures, such as digital talent cultivation, a standardization strategy, and industrial-innovation-assistance mechanisms, an intelligent manufacturing-development system has been formed gradually. In the United States, key areas such as integrated circuits, intelligent manufacturing, and advanced materials are taken seriously. The construction of manufacturing-innovation centers and industrial alliances, the optimization of the innovation-and-entrepreneurship environment, the cultivation of various talents, and the adjustment of global trade strategies benefit the return and revitalization of the national manufacturing industry. For example, several studies were conducted analytic and empirical analyses that consider how knowledge and sources of innovation flow between key participants within the Massachusetts manufacturing-innovation ecosystem. The results showed that the Massachusetts manufacturing-innovation ecosystem is rich in terms of assets but relatively poor in terms of the interconnectedness between these assets. Moreover, non-market state-supported manufacturing intermediaries primarily focus on the supply side, point solutions that work with individual firms, rather than demand-driven innovation and technological upgrading for small- and medium-sized enterprises (SMEs) [

34]. This proves that the pathways and opportunities for building and fostering the AMEIE are essential and necessary.

In China, in contrast, innovation is mostly led by the promotion of the manufacturing industry; that is, the innovation in production technologies, processes, and products through the expertise of the manufacturing industry’s experience is a combination of applied research and production processes. With the interweaving of product and process innovation, the advantages are gradually shown. However, in the long run, only balanced development can form a virtuous innovation cycle. Compared to incremental innovation led by manufacturing, basic research-driven innovation is often disruptive. Thereby, an increase in investment in basic research, as well as the cultivation and introduction of elite talents are essential approaches to shortening China’s innovation cycle. In the commercialization of scientific and technological achievements in China, the barriers to transformation are similar to those in developed countries. By establishing independent non-profit transformation research centers attached to scientific research institutions and attracting the participation of industries, China promotes the combination of funds, R&D, engineering, production, marketing, and other business modes to identify and cultivate research achievements with commercial prospects and to optimize the structure of the innovation ecosystem so that an effective path from basic research to new-product production can be created. Whether domestically or abroad, the strategic deployment and practice of the AMEIE are the only ways to fully stimulate the vitality of various innovation entities and build a strong industrial innovation system.

In current research, it can be seen that the innovation ecosystem provides an important theoretical basis for studying regions, industries, and the sustainable competitive advantages of enterprises. The feasibility of the innovation-ecosystem theory for exploring manufacturing innovation can be determined by the industrial relevance, systematic characteristics, and knowledge structure of manufacturing. Hence, research on the AMEIE is of urgent significance for improving the innovation ability of China’s manufacturing industry and cultivating world-class technological enterprises. However, currently, the relevant research is still relatively scattered, and there is an urgent need for a comprehensive, in-depth, and systematic theoretical study of the AMEIE.

3. Materials and Methods

According to ecological theory, populations depend on environmental resources to survive and develop. When two populations rely on the same or similar resources, they compete because these resources are limited [

35]. However, there are large differences in competitiveness between different species. When the living space is compressed to a certain level, the less competitive biological population is driven to expand the ecological resources that it depends on for survival, which helps to increase the expansion and growth of the ecosystem [

36]. In essence, the evolution of AMEIE from generation to growth is a process in which the innovation population continues to increase, the ability of innovation species is continuously enhanced, and the innovation level continuously increases. Therefore, based on the theory of biological population evolution [

37,

38], the evolution model of AMEIE is established below.

3.1. Method Selection

From the ecology perspective, the changes in various populations within AMEIE are obviously constrained by influencing factors, such as technology, resources, and institutions. Therefore, the evolution of population size is density-dependent, which is consistent with the logistic law of biological population growth. Since the logistic growth model has been widely used to explore the evolution of population-size growth caused by the interactions between various populations, it offers a good explanation of the evolutionary regularity of the relationship between multiple subjects compared to the ordinary game model. Thus, this paper investigates how the competitiveness and cooperation between advanced manufacturing enterprises, new-generation information-technology enterprises, and innovation-service organizations affect the symbiotic evolution of AMEIE and the evolutionary direction of symbiotic scenarios through different relationships using the logistic growth model.

3.2. Hypothesis Development

The AMEIE comprises three symbiotic subjects: advanced manufacturing enterprises, new-generation information-technology enterprises, and innovation-service organizations. The populations of three symbiotic entities are limited by complex environmental factors (e.g., resources, technology, and institutions), similar to the evolution of natural ecosystems, which experience a process ranging from survival to extinction [

39].

The growth of advanced manufacturing enterprises is represented by the change in their population sizes. A growing population size indicates the good growth of advanced manufacturing enterprises. Namely, the larger the population size, the better the growth of advanced manufacturing enterprises. This means that the greater the access and occupancy of heterogeneous innovation resources and technologies in AMEIE, the higher the value created and owned. However, smaller populations mean that advanced manufacturing enterprises are declining and collapsing, which leads to a reduction in the share of system resources and technologies and lower value creation. When the heterogeneous innovation resources and technology-acquisition opportunities or share are zero, advanced manufacturing enterprises tend to die out [

40].

Advanced manufacturing enterprises, new-generation information-technology enterprises, and innovation-service organizations all feature the characteristics of logistic growth, while the natural growth rate of the independent population remains unchanged. Limited by resources and technology, a reduction trend is shown in these three populations after they expand to a certain scale. In particular, the maximum population size is reached, where the marginal input of a certain type of population is equal to the marginal output [

41].

In symbiotic evolution, the growths of various populations are affected by those of others, showing mutual restraint or mutual promotion [

42]. Moreover, the symbiotic coefficient describes the direction and degree of mutual influence between subjects.

3.3. Symbiotic Evolution Models of AMEIE

As described in

Section 3.2, the evolution process of AMEIE assumes that the three-population evolutionary game can be modeled as a logistic process. Before the formal model construction, we need to set and describe the parameters involved in the model. According to practice [

43], the notations are summarized in

Table 1.

Thus, according to the logistic equation, the dynamic evolution equation of AMEIE is proposed as follows [

44]:

where

,

,

, are, respectively, the development trends of

M,

I, and

O, and

,

,

are, respectively, the proportion of subjects’ surplus resources in the total sums, which reflect the limitation of the three symbiotic subjects due to resource consumption.

Since the turn of the twenty-first century, the innovation paradigm has gradually changed from that of the traditional innovation system to the innovation ecosystem [

45]. Due to stability, persistence, and coordinated coexistence among species, the natural ecosystem has become an important way for economic management scholars to learn from the innovation ecosystem and obtain management ideas [

46]. Related research covers all aspects of the connotation characteristics, system structure, case analyses, and other theories and applications of the innovation ecosystem [

47,

48].

Generally, the population size and evolutionary mode of the symbiotic subjects in AMEIE influence each other, there is a complex and dynamic coupling relationship between subjects, and a multi-party cooperation-and-coordination mechanism is gradually formed. Based on the differentiated coupling relationship [

49], the symbiotic dynamic evolution model through the extended logistic model is summarized by Equation (2):

3.4. Stability Analysis

According to the value range of the symbiotic coefficient above, the symbiotic relationship of AMEIE is reflected in

Table 2.

Moreover, a Jacobian matrix of symbiosis evolution models is proposed from Equation (2):

Combined with F(

) = 0, F(

) = 0, F(

) = 0, the evolution-equilibrium point of the model is obtained, as shown in

Table 3.

Table 4 describes the stability judged by the sign of

and

according to matrix (4).

4. Results

The numerical results of simulation replications depend on the values of the various symbiotic coefficients, and several cases exist.

4.1. Simulation

In the innovation ecosystem of advanced manufacturing enterprises, the cross-border flow of innovation resources between innovation subjects produces new values through the division of labor and cooperation. These new values are recycled, distributed, and reused among the innovation subjects, reflecting the influence of the strength of the symbiotic relationship on the changes in various group sizes. Following the ecological research practice of exploring the relationships between organisms or species in certain environments, the following section analyzes the symbiotic evolution process of three types of innovation subject in the innovation ecosystem of advanced manufacturing enterprises through a simulation to determine how the three interact with each other. The symbiotic evolution model is simulated in its steady state for a while, and then the population size is calculated using Equation (2), described in

Section 3.3. In general, there are no definite relationships between

SM-I,

SI-M, and

SM-O and

SO-M,

SI-O, and

SO-I. For the convenience of the study, only the situation in which

SM-I,

SI-M,

SM-O,

SO-M,

SI-O, and

SO-I are independent of each other is discussed.

Suppose that

= 0.05,

= 0.03,

= 0.02, and

NM = 1000,

NI = 1000,

NO = 1000 and the evolution period t = 900 subject to specific resource conditions. The symbiotic evolution process of advanced manufacturing enterprises, new-generation information-technology enterprises, and innovative-service organizations and the law under different value combinations are discussed. The simulation replications were carried out using the software MATLAB 2016 under different value combinations of symbiotic coefficients. The specific simulation results are shown in

Figure 1,

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7.

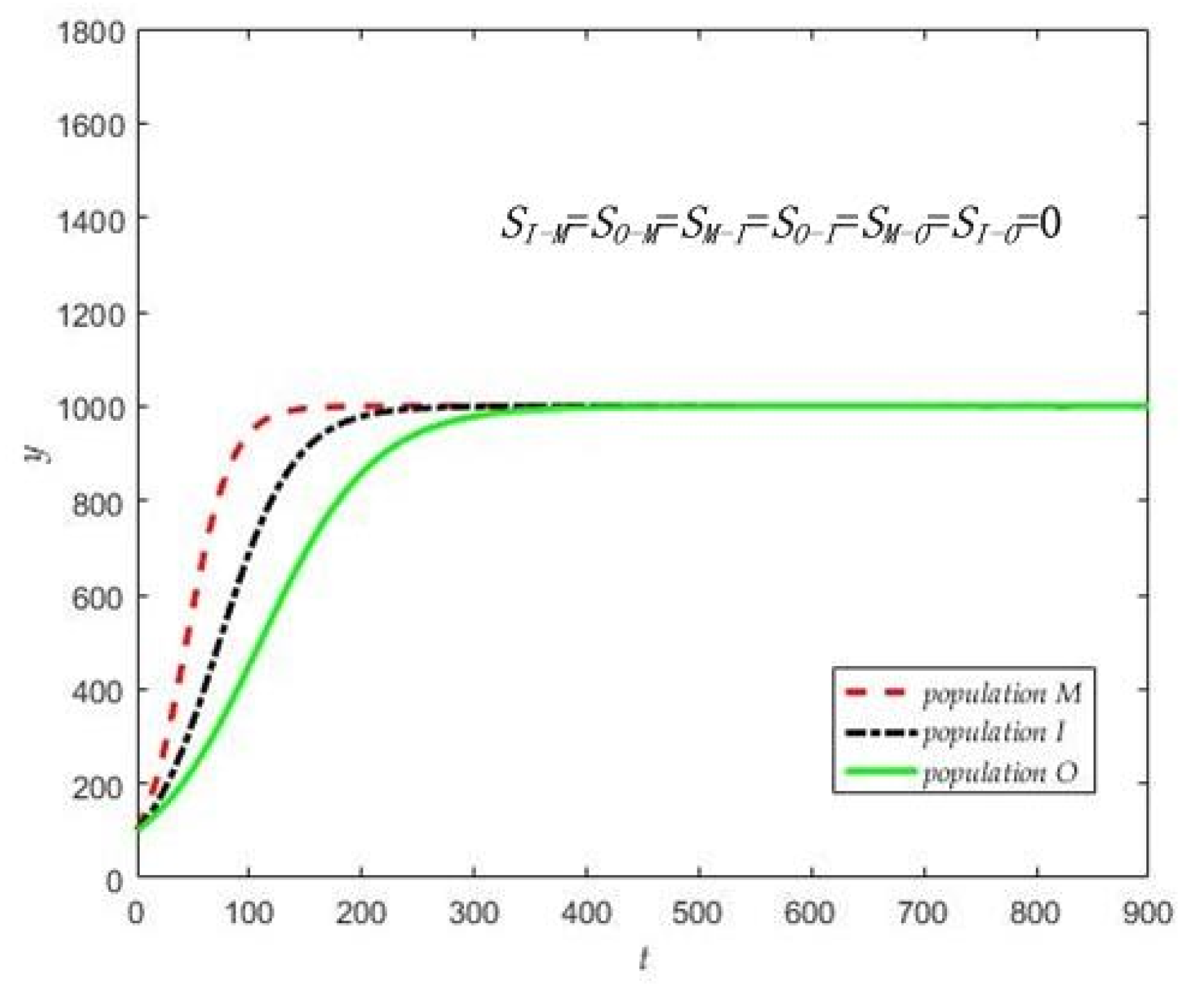

4.2. Case 1: Independent-Coexistence Evolution

Subject to independent coexistence, the coefficients are all zero, which suggests that the three subjects have no connection and interference with each other in the process of evolution. The subjects’ independent evolutionary speeds are only related to their own growth rates. After a period of time, when the system is stable, the upper limit of their population size is the maximum size when they develop independently, as shown in

Figure 1.

Figure 1.

Evolution results subject to independent coexistence.

Figure 1.

Evolution results subject to independent coexistence.

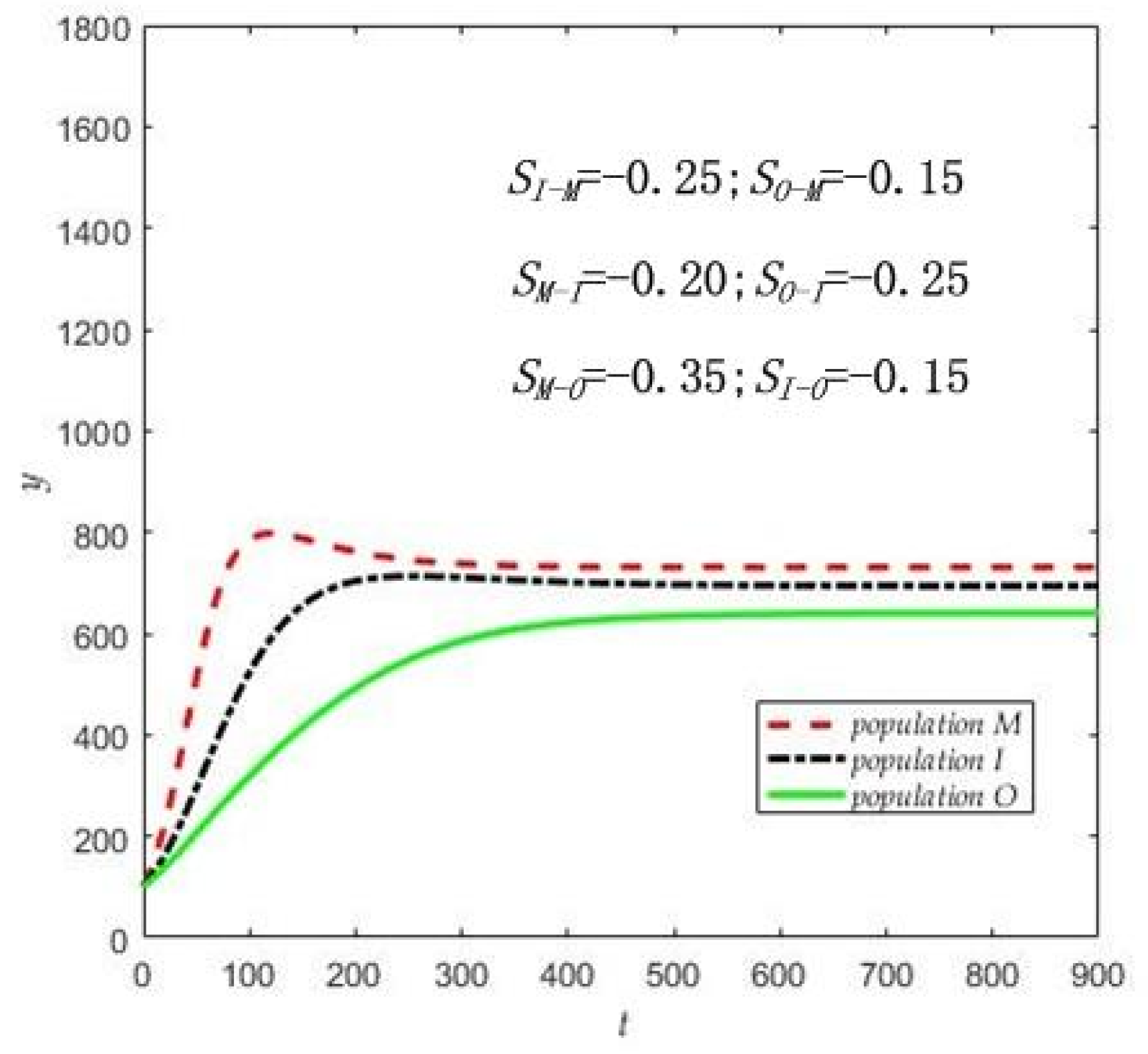

4.3. Case 2: Competition-Symbiosis Evolution

In the case of competition symbiosis, the value of S needs to be further classified. When −1 < S < 0, it is the normal competition mode, and let

SI-M = −0.25,

SO-M = −0.15,

SM-I = −0.20,

SO-I = −0.25,

SM-O = −0.35, and

SI-O = −0.15.

Figure 2 shows the numerical results. In this case, the development of advanced manufacturing enterprises is not only related to itself, but it is also affected by the new generation of information-technology enterprises and innovation-service organizations. In addition to the constraints of the resources and environment, the development process of advanced manufacturing enterprises experienced fluctuations from rise to fall and eventually did not reach the optimum size. The new generation of information-technology enterprises and innovation-service organizations are also affected by the other subjects; however, they all face obstacles to further development.

Figure 2.

Evolution results subject to normal competition symbiosis.

Figure 2.

Evolution results subject to normal competition symbiosis.

When the symbiotic coefficient of one type of subject to the other two kinds of subjects is lower than −1, it is in the cutthroat competition mode. We can fix

SI-M = −0.25,

SO-M = −0.15,

SM-I = −1.10,

SO-I = −0.25,

SM-O = −1.30, and

SI-O = −0.15, and the numerical result can be obtained, as shown in

Figure 3. For this case, the symbiotic coefficients of the new generation of information-technology enterprises and innovation-service organizations are excessively high, which suggests that the resource consumption is serious, resulting in a short development process of the two subjects and then a trend of decline. Conversely, advanced manufacturing enterprises continue to develop and expand and finally break the upper limit of the population size in the competition.

Figure 3.

Evolution results subject to cutthroat-competition symbiosis.

Figure 3.

Evolution results subject to cutthroat-competition symbiosis.

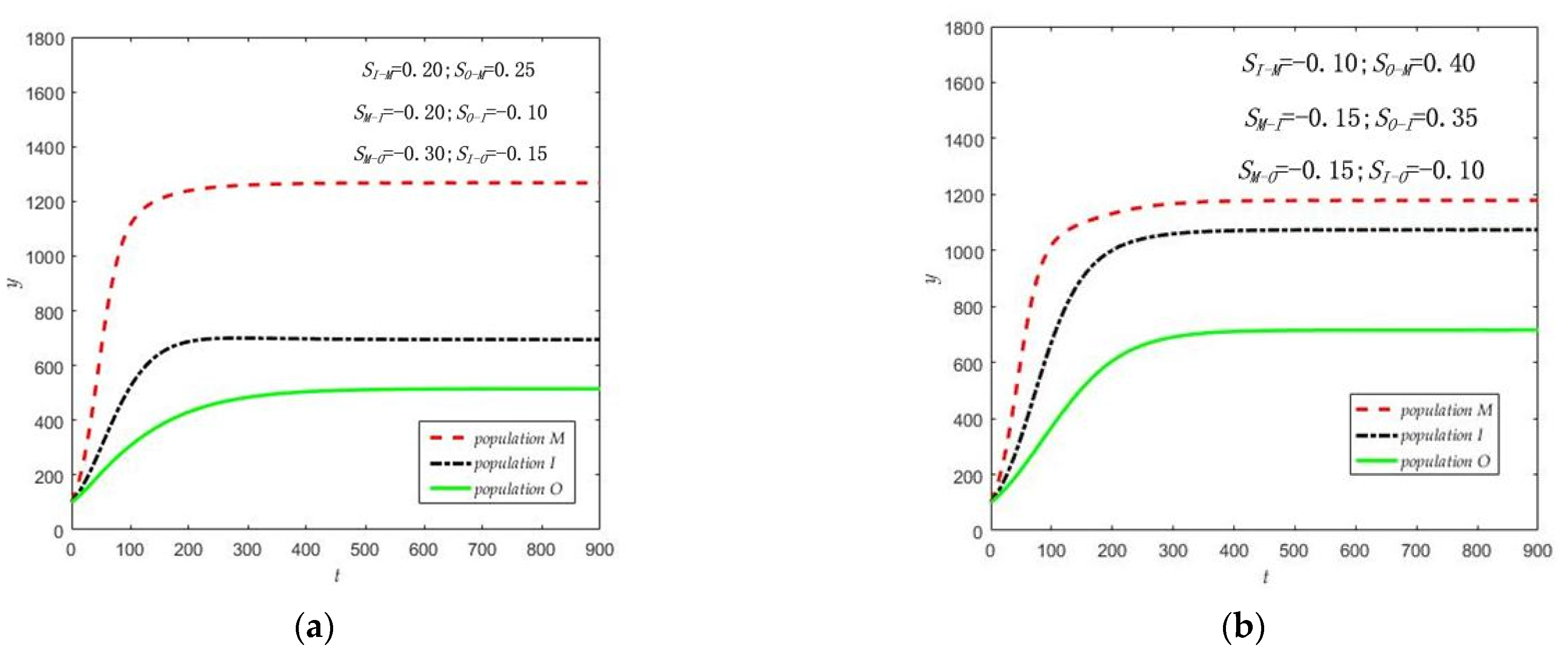

4.4. Case 3: Parasitic Symbiosis Evolution

According to the different values of S, parasitic symbiosis can be subdivided into two cases: (1) the sum of the symbiotic coefficients of any two populations is lower than zero, and that of the other is higher than zero; and (2) the sum of the symbiotic coefficients of any two populations is higher than zero, and that of the other is lower than zero.

For the first case, we can fix

SI-M = 0.20,

SO-M = 0.25,

SM-I = −0.20,

SO-I = −0.10,

SM-O = −0.30, and

SI-O = −0.15, indicating that advanced manufacturing enterprises are parasitized in the new generation of information-technology enterprises and innovation-service organizations, as shown in

Figure 4a. It appears that advanced manufacturing enterprises benefit from parasitism and maximize their own interests. However, the population size of the new generation of information-technology enterprises and innovation service organizations is restricted by the resource occupation of advanced manufacturing enterprises. For the second case, we can fix

SI-M = −0.10,

SO-M = 0.40,

SM-I = −0.15,

SO-I = 0.35,

SM-O = −0.15, and

SI-O = −0.10, indicating that advanced manufacturing enterprises and the new generation of information-technology enterprises are parasitized in innovation-service organizations, as shown in

Figure 4b. This indicates that due to the reduction in the resources of innovation service organizations for the sake of parasitism, the upper limit of its population size decreased to a level lower than the maximum size subject to independent development, while the upper limits of the population size of the advanced manufacturing enterprises and new-generation information technology enterprises increased to levels higher than their maximum size subject to independent development.

Figure 4.

(a) Evolution results subject to population M parasitized in population I and population O; (b) evolution results subject to population M and population I parasitized in population O.

Figure 4.

(a) Evolution results subject to population M parasitized in population I and population O; (b) evolution results subject to population M and population I parasitized in population O.

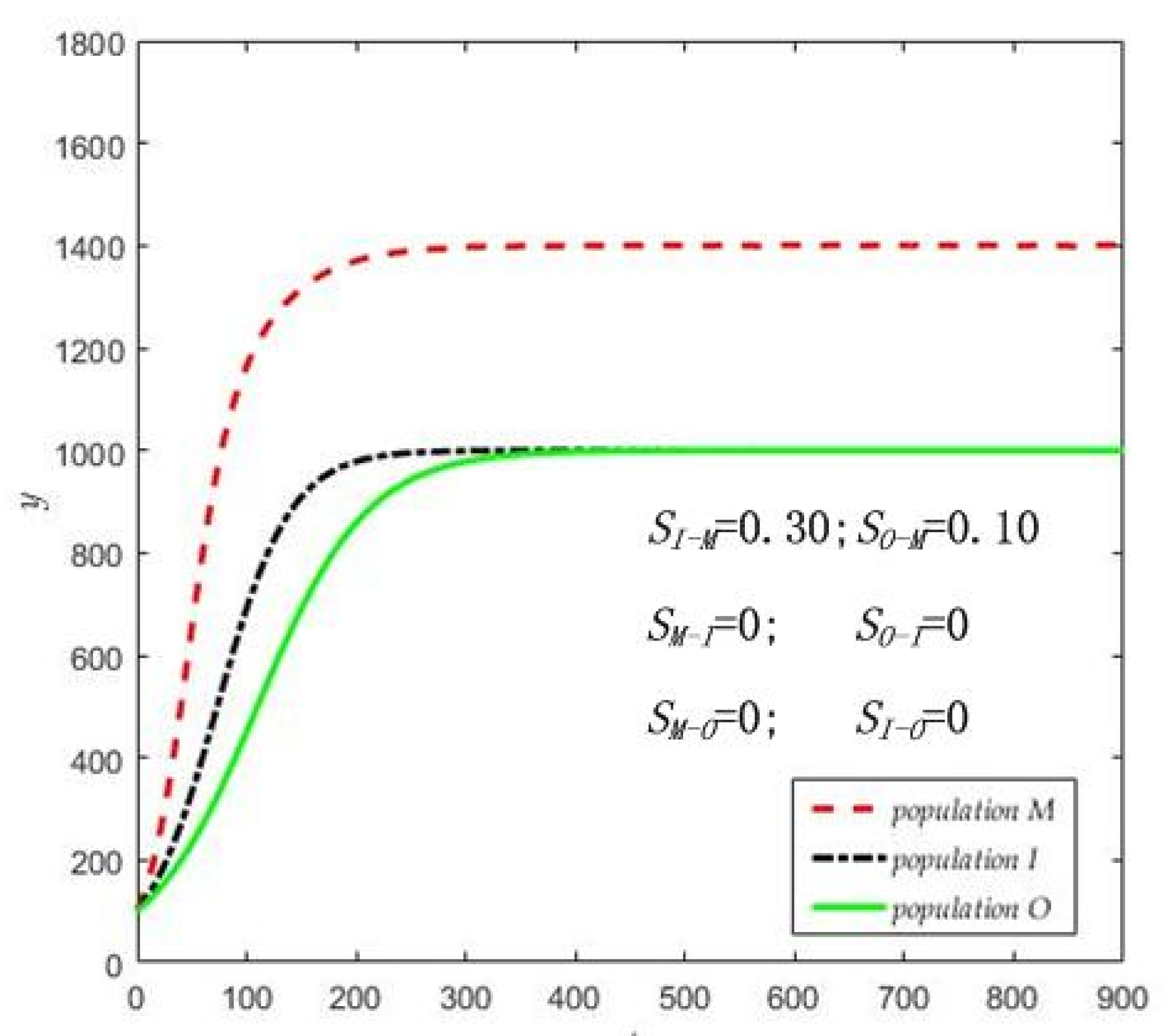

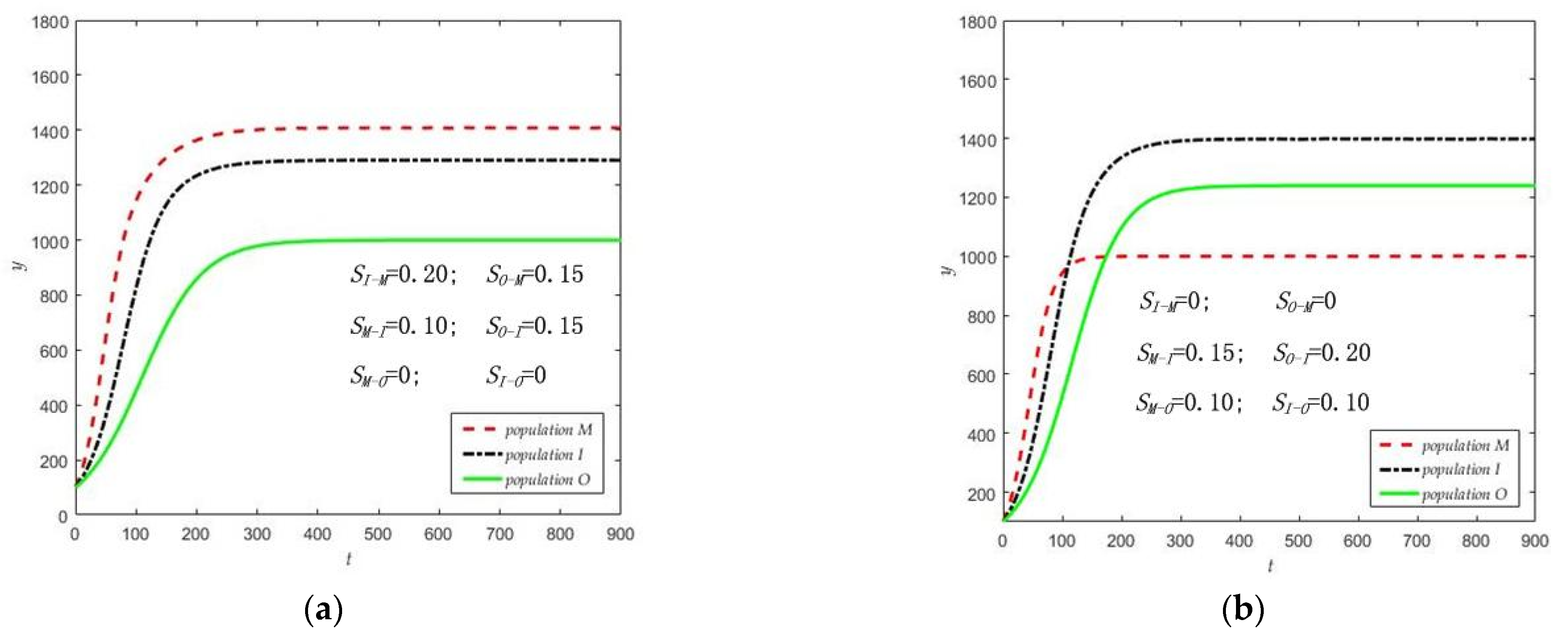

4.5. Case 4: Partial Symbiosis Evolution

Similar to parasitic symbiosis, the partial symbiosis evolution can also be subdivided into two cases according to the different values of S in the case of partial symbiosis: (1) the sum of the symbiotic coefficients of any two populations is equal to zero, and the other is greater than zero, (2) the sum of the symbiotic coefficients of any two populations is greater than zero, and the other is equal to zero.

For the first case, we can fix

SI-M = 0.30,

SO-M = 0.10,

SM-I = 0,

SO-I = 0,

SM-O = 0, and

SI-O = 0, meaning that advanced manufacturing enterprises gain partial interest.

Figure 5 shows that the upper limit of the population size of the new generation of information-technology enterprises and innovation-service organizations with a zero symbiotic coefficient is unchanged, which is equal to the maximum size subject to independent development, while the upper limit of the population size of the advanced manufacturing enterprises with positive symbiotic coefficients is increased to a level that is higher than the maximum size subject to independent development due to the acquisition of innovative resources from the new generation of information-technology enterprises and innovation-service organizations.

Figure 5.

Evolution results subject to population M gains in partial interest.

Figure 5.

Evolution results subject to population M gains in partial interest.

For the second case, we can fix

SI-M = 0.20,

SO-M = 0.15,

SM-I = 0.10,

SO-I = 0.15,

SM-O = 0, and

SI-O = 0, meaning that advanced manufacturing enterprises and new-generation information-technology enterprises gain partial interest.

Figure 6a implies that the upper limit of the population size of the innovation service organizations with a zero symbiotic coefficient is not changed, which is equal to the maximum size subject to independent development. In contrast, advanced manufacturing enterprises and new-generation information-technology enterprises with positive symbiotic coefficients benefit from the acquisition of the resources of innovation-service organizations, with the result that the upper limits of their population size are higher than their maximum size subject to independent development. In addition, if

SI-M = 0,

SO-M = 0,

SM-I = 0.15,

SO-I = 0.20,

SM-O = 0.10, and

SI-O = 0.10 are taken, it appears that the new generation of information-technology enterprises and innovation-service organizations gain partial benefits, as shown in

Figure 6b. In this case, the upper limit of the population size of the advanced manufacturing enterprises with a zero symbiotic coefficient is equal to the maximum size subject to independent development. Due to the acquisition of resources from advanced manufacturing enterprises, the upper limits of the population size of both the new-generation information-technology enterprises and the innovation-service organizations with positive symbiotic coefficients are higher than their maximum size subject to independent development.

Figure 6.

(a) Evolution results subject to population M and population I gains in partial interest; (b) evolution results subject to population I and population O gains partial interest.

Figure 6.

(a) Evolution results subject to population M and population I gains in partial interest; (b) evolution results subject to population I and population O gains partial interest.

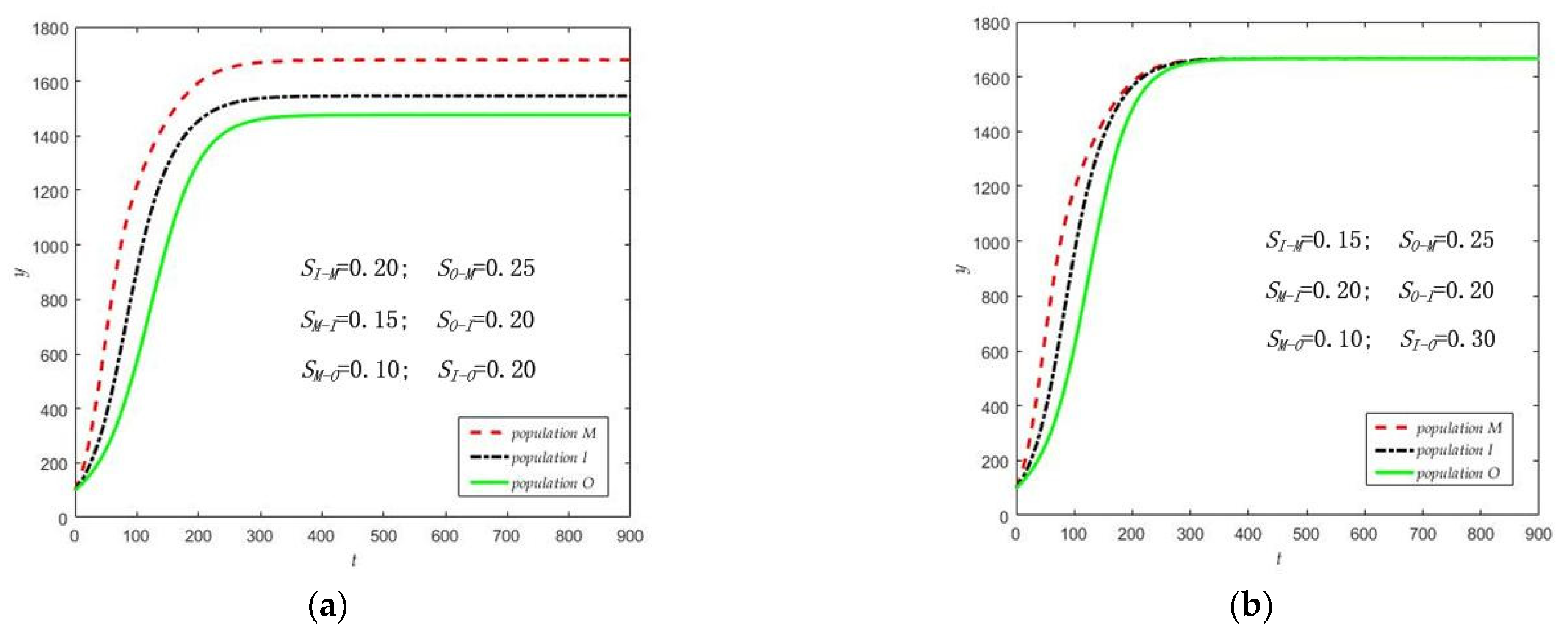

4.6. Case 5: Mutualism-Symbiosis Evolution

In the case of mutualism symbiosis, the symbiotic coefficients between the subjects are all positive. The three types of subject benefit from each other’s interaction and collaboration, so that the upper limits of their population sizes are increased, and the increment is determined by the value of the symbiotic coefficients. When the sum of the symbiotic coefficients of each subject is not equal to the others (e.g.,

SI-M = 0.2,

SO-M = 0.25,

SM-I = 0.15,

SO-I = 0.20,

SM-O = 0.10, and

SI-O = 0.20), this is an asymmetric subdivision of mutualism symbiosis. As shown in

Figure 7a, for each subject in the AMEIE, the larger the symbiotic coefficient, the greater the increment in the upper limit of the population size. Otherwise, if the sum of the symbiotic coefficients of each subject is equal to the others (e.g.,

SI-M = 0.15,

SO-M = 0.25,

SM-I = 0.20,

SO-I = 0.20,

SM-O = 0.10, and

SI-O = 0.30), this is a symmetric subdivision of mutualism symbiosis, as shown in

Figure 7b. In this case, the convergence of the upper limit of the population size tends to be consistent, and the final stable population size of each subject is higher than its maximum size subject to independent development. In other words, in the state of mutualism symbiosis, the optimization of the symbiotic evolution of the AMEIE is achieved, which encourages each subject in the system to break through the environmental and resource constraints to produce mutual benefits and maximize value.

Figure 7.

(a) Evolution results subject to asymmetric mutualism symbiosis; (b) evolution results subject to symmetric mutualism symbiosis.

Figure 7.

(a) Evolution results subject to asymmetric mutualism symbiosis; (b) evolution results subject to symmetric mutualism symbiosis.

In summary, the AMEIE is an adaptive and dynamic system of symbiotic evolution, and its evolution results mainly depend on the symbiotic relationships between various subjects in the AMEIE—that is, the sum of the symbiotic coefficients. Various evolutionary equilibrium results are obtained from various symbiotic relationships, which show a transformation from independent coexistence, competition, parasitism, and from partialism to mutualism. For the change in the competition and cooperation relationships and resource utilization among the system members, the maximum size and growth rate of various innovation populations are constantly changed with the different combinations of symbiotic coefficients. The numerical results of this paper are summarized as follows. When the symbiotic coefficients of the three-population evolutionary model are all zero, the symbiotic relationship is presented as independent coexistence. When the value of the symbiotic coefficients is in the interval (0, 1), the state is the normal competition mode; otherwise, when the symbiotic coefficient of one type of subject to the other two kinds of subject is lower than −1, the state is the cutthroat-competition mode. When the symbiotic coefficients of any two agents are positive (negative), while the symbiotic coefficient of the other is negative (positive), the state is parasitic symbiosis. When the symbiotic coefficients of any two agents are positive (zero) while the symbiotic coefficient of the other is equal to zero (positive), case 4 may occur. When the symbiotic coefficients of the multiple agents are all positive, the system evolution is mutualism symbiosis, which is the optimal evolution path for AMEIE.

5. Discussion

In this study, taking the AMEIE as the research object, the symbiotic evolution model was established based on the introduction of three symbiotic subjects. Through the solution of the equilibrium point, the stability analysis, and the simulation of the evolution models, the evolution of the AMEIE was rigorously discussed. The AMEIE is a complex system composed of the following: advanced manufacturing enterprises, with operating technology, knowledge of manufacturing, management experience, instruments and equipment, and other manufacturing resources as the key resources; a new generation of information-technology enterprises, with big data, artificial intelligence, Internet of Things, sensor technology, cloud computing, and other advanced intelligent information technologies as the key resources; and innovation-service organizations, with R&D technology, talent, finance, consulting services, scientific and technological information services, policies, and other resources as the key resources. All of these factors create value collaboratively in a given symbiotic environment in terms of resource acquisition and innovation interaction. In this system, different subjects are in different niches, and they jointly drive the operation and evolution of the system through the integration and reconstruction of resources. The evolution results depend on the symbiotic relationship between various innovation subjects. The population-size growth of each subject is closely related to the size and growth rate of other subjects in the symbiotic system. When the symbiotic coefficient is positive, each subject benefits from mutualism, and the growth limit of its development increases. The larger the symbiotic coefficient, the more the growth limit rises.

In essence, the AMEIE is an adaptive network ecosystem composed of multiple agents (across the boundaries of industry, organization, and cognition) and the external environment through the pathways of interdependence, interaction, and interference. Its evolution is affected by the interests of each symbiotic unit, as well as the ecological balance. Within the constraints of complex factors, the evolution trend of AMEIE presents complex paths and laws, in which the mutualism symbiotic mode is the best direction for the evolutionary system. Therefore, a symbiotic incentive policy and strategy should be built and improved actively to make the ecosystem evolve through the efficient mode of mutualism. (1) The intensification of the symbiotic relationship between multiple agents in the system is necessary. Through the enhancement in the trust and interaction frequency between members, involving regular multi-channel, diversified, and innovative exchange and learning activities, the establishment of a standardized and appropriate mechanism for the entrance and withdrawal of system members, and an effective communication mechanism, the close cooperative symbiotic relationship will be consolidated. Furthermore, it is possible to create more innovative projects and encourage high-frequency, real-time, full-cycle immersive interactions between core enterprises and supporting organizations. (2) A better symbiotic environment for the AMEIE is needed. The relevant preferential policies and regulatory strategies to encourage the integration of the innovation in the advanced manufacturing industry and the new generation of information technology should be formulated in the status quo government, which can optimize the symbiotic environment and guide the system to evolve into a mutualism symbiotic mode. In addition, a corresponding intellectual-property-protection mechanism and a reasonable benefit-distribution mechanism should be established to prevent various opportunistic behaviors from occurring in the innovation process, reduce the cost of innovation risk, and increase the stability of the symbiotic system. (3) The symbiotic system interface of the AMEIE should be optimized. Specifically, the standardization and institutionalization of innovative activities need to be formulated to remove the obstacles to the symbiotic interface. The construction of cross-border innovation platforms should be continuously improved, the effective exchange of information and knowledge should be ensured, strong connections between multiple subjects and the coordination of innovation resources should be encouraged, more heterogeneous symbiotic agents should be convinced to join the system, and multi-agent cooperation should be undertaken to create more value. The interaction and cooperation of enterprises with users and markets should be bolstered, further expanding the breadth and depth of the advanced manufacturing industry’s value, and gradually forming an industrial network consisting of horizontal business chains and vertical industry flows, with the final result of achieving the evolution of AMEIE from low-end to high-end.

The findings presented above are relevant to previous research. Within the constraints of complex factors, the evolution trend of the AMEIE presents complex paths and laws, in which the mutualism symbiotic mode is the best direction for the evolutionary system. These findings confirm the hypotheses of previous research. In addition, in this paper, the pathways of the evolution of the AMEIE were revealed. That is, members of the AMEIE system should strive to switch from parasitic symbiosis evolution or partial symbiosis evolution to mutualism symbiosis evolution. Moreover, according to the literature review, building and fostering a symbiotic environment and relationships can increase innovation and industrial development. Additionally, some methods and strategies, such as intellectual-property-protection mechanisms, benefit-sharing mechanisms, and cross-border innovation platforms, have been proposed; these are also mentioned and further improved in this paper. Therefore, the conclusions of this paper can be regarded as further extensions and applications of previous studies.

6. Conclusions

The new round of scientific and technological revolution and industrial transformation create new strategic development opportunities for the advanced manufacturing industry. This study was used the ecology theory and a symbiotic perspective to build a conceptual model of ecosystem evolution, with a particular emphasis on introducing the tripartite-innovation main body to build ta dynamic model of symbiotic evolution. Based on an analysis of the equilibrium points and stability conditions of the symbiotic evolution model, different symbiotic evolution scenarios were explored by using a computer simulation with the software MATLAB. The results indicated the following: (1) the advanced manufacturing-innovation ecosystem is a complex system composed of advanced manufacturing enterprises, new-generation information-technology enterprises, and innovation-service organizations and creates value cooperatively in relation to resource acquisition and innovation interaction in a given symbiotic environment; (2) in this innovation ecosystem, the symbiotic evolution results depend on the symbiotic coefficient between subjects; (3) the synergy of these subjects can be maximized through mutualism symbiosis evolution, while system members should strive to switch from parasitic symbiosis evolution or partial symbiosis evolution to mutualism symbiosis evolution.

In essence, the innovation ecosystem of the advanced manufacturing industry is an adaptive network ecosystem that is interdependent, influenced, and coupled with the external environment across the boundaries of industry, organization, and cognition. Its evolution and development are affected by the interests of each symbiotic unit and the ecological balance. This study provides theoretical support and relevant institutional and policy suggestions for upgrading and developing the advanced manufacturing-innovation ecosystem along a mutualistic evolutionary path.