Abstract

The traditional mode of cooperation between enterprises still suffers from major problems, including data privacy leakage, data falsification, and inefficient collaboration in data sharing. These challenges make it difficult for enterprises to ensure that their cooperative suppliers adopt sustainable practices in standards identification and operation processes. This paper proposes a “Value–Standard–Process” collaborative framework for blockchain-based enterprise data governance that helps ensure a high degree of data security, a high reliability of collaborative tasks, and a high transparency of value transformation. First, this paper proposes a new collaborative mode for blockchain-based manufacturing in the sharing economy, including the non-linear dynamic evaluation and value balancing mechanism of data with multiple attributes, a trusted data governance mechanism for blockchain-based manufacturing, and a smart contract generation mechanism for value-driven collaboration. Second, this paper explains these three components and the implementation of the overall framework. Third, this paper verifies the applicability and achievability of the proposed framework through experiments. Establishing the value-driven multi-level blockchain-based collaboration mode facilitates the effective flow of production factors and promotes trust in the digital economy of sustainability.

1. Introduction

Thanks to advanced technologies, such as industrial big data, modes of production are transitioning toward ecological and collaborative approaches and increasing supply chain connectivity [1]; these approaches and connectivity optimize the standards for shared resources, reduce digital resource waste in data management, and achieve overall sustainability in production [2]. This transformation has profoundly affected the forms of cooperation between enterprises and the way they maintain competitiveness [3], shifting from order-driven to value-driven business cooperation. Barriers to data sharing and information flow synchronization can mean that products are unable to meet sustainability indicators [4]. Therefore, it is necessary to improve the competitiveness and production decisions of these enterprises and to encourage them to exchange data that support production decisions and service enhancements through standardization in production processes and data formats. The use of cloud manufacturing and data processing has been proposed as a means to address the challenges arising from collaborative manufacturing chains consisting of multi-perspective [5], multi-process [6], and multi-supplier collaboration [7] based on data value. Abou Zakaria Faroukhi et al. defined the data value chain (DVC) as a system that is driven by data and can extract reliable value and divide it into four phases: data generation, collection, analysis, and exchange [8]. To address privacy issues in data exchange, Xinhua Dong et al. proposed a proxy re-encryption algorithm based on heterogeneous ciphertext conversion to effectively protect the delivery and use of sensitive data on big data sharing platforms. This is achieved by monitoring user processes and measuring the value-added services provided to enterprises, balancing the sensitivity of data versus the information security issues associated with sharing it [9]. In terms of heterogeneous resource integration, Ming Li et al. proposed a blockchain-based digital twin resource sharing platform to achieve reuse, sharing, and protection of digital resources [10]. Beatriz Andres et al. proposed a new model of CMData to identify the data needed to collaborate on replenishment, generation, and delivery plans, meeting the need for data sharing between participants [11]. In terms of the interactive need for data value, Mohammad Najjar suggested that data information can be transformed into value through hardware, while also pointing out the need to share data between suppliers [12]. By studying the role of blockchain technology in enhancing environmental supply chain performance, Summer K. Mohamed et al. showed that blockchain can be used for green information sharing in order to create more resilient, sustainable supply chains that provide value to enterprises [13].

In other words, current cloud manufacturing and data processing technologies are primarily designed to meet the needs of transferring and sharing digital resources in a centralized environment through the trust in the platform, encrypted processing of data, and enhanced transmission protocols. However, most of the existing models need to address several challenges: (1) they are frameworks designed in a centralized integration environment [14], where collaborating enterprises have difficulties ensuring the confidentiality of their own shared data and lack trust in the source of the data, making it difficult to develop trust between enterprises; (2) the lack of a mechanism to reconcile the perceived differences in data value under the different value perspectives of the participants does not adequately reflect the potential value of the data or stimulate a willingness to interact with the data; and (3) there is a lack of mechanisms to reconcile the workflows of the collaborating enterprises. After data sharing, enterprises still need to go through layers of authorization and complicated management processes in order to transform the value of the data. Therefore, there is a need to develop a multidimensional and collaborative data governance mechanism between industry chains in a sharing economy environment to achieve credible value sharing and transformation of data in the process of internal and external collaboration to advance sustainable production practices.

To address these challenges, this paper proposes a value-driven collaborative platform based on blockchain and edge computing technologies, aiming to provide distributed data interaction services for enterprises in the production ecosystem and meet the data sharing needs of different enterprises. Therefore, the innovation points of the blockchain collaboration platform proposed in this paper are summarized as follows:

- A non-linear dynamic evaluation and value balancing mechanism of data elements with multiple attributes to realize the value assessment and balance. In the scenario of rapid product iteration and frequent demand changes, participants at different levels of an organization have different perceptions of data value, and it is difficult to reach an effective consensus on the value of data, such as sales, orders, storage and logistics data, involved in production. These data from the product lifecycle provide the main basis for participants to specify their own business and production plans. Thus, with the support of the balanced consensus on the value of data, participants can understand the current production as well as the needs and decision-making arrangements for the next stage of production planning.

- A trusted sharing and governance mechanism of data for blockchain-based production. The multi-layer suppliers in the industry follow different levels of data standards, resulting in the expanded data scale, the wide variety of data types, and the high data maintenance and access control cost. This causes a serious lag in value transformation and utilization efficiency when data is shared by enterprises. Therefore, with the support of a trusted data gateway, the standardization, formatting, and trustworthiness of data can be realized independently to ensure the authenticity and consistency of the data acquired by enterprises, thus enhancing the efficiency of data utilization.

- A value-driven mechanism for smart contract collaboration. Traditional enterprise collaborative processes require iterative negotiation and authorization of layers of data management and collaboration, resulting in a large amount of private data requiring various audits and departmental negotiations without efficient utilization. Therefore, with the support of a workflow-based smart contract collaboration mechanism, a new collaboration mode with value-driven, publicly auditable collaboration rules and tamper-evident collaboration records can be utilized to meet the need of a new collaborative workflow reconfiguration.

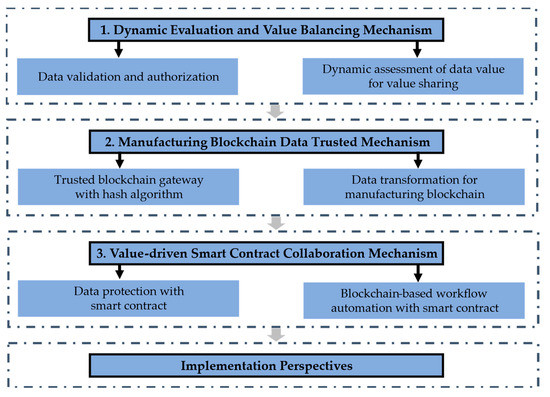

The sections of this paper are structured as follows, as shown in Figure 1: Section 2 provides a review of blockchain and privacy-preserving technologies. Section 3 introduces the concept of collaborative production. Section 4 focuses on describing the key architecture and supporting technologies for realizing a value-based data governance mechanism for the production chain. Section 5 shows the implementation route of the framework proposed in this paper and conducts feasibility experiments in order to validate the new mode of multidimensional collaborative production. Section 6 draws conclusions and states what can be further researched.

Figure 1.

The structure of the article.

2. Literature Review

2.1. Blockchain

Blockchain is a distributed database system that stores transaction data and other information and allows it to be shared among members of the network nodes [15]. On the blockchain, data records are stored in blocks and, after being identified by a hash, form a chain structure with previous blocks [16]. Hash encryption guarantees the security of data on the blockchain and ensures that the data is reliable [17]; this prevents malpractices, such as tampering, forgery, and fraud [18], which, to some extent, ensures the authenticity of the data blocks [19]. As a distributed data structure, blockchain does not require a central governing structure, but rather is maintained by all members of the chain [20] and is therefore suitable for storing public data that needs to be circulated and verified. As such, it can maintain a transparent and trustworthy transaction environment [21].

Blockchain, as an emerging technology, has received widespread attention from industry. The successful application of blockchain can achieve supply chain sustainability in social, environmental, and economic terms, allowing enterprises to collaborate and share information so that sustainable products are produced, delivered, and returned [22]. Bill Wang et al. applied blockchain technology to sustainability issues in the fast fashion sector to achieve agility and accuracy in monitoring and securing management measures for the reuse of chain materials [23]. Alexandre Dolgui et al. proposed a blockchain-oriented control system applied to the supply chain to achieve a trade-off between delivery times and contract costs for each supplier in order to support multi-objective decision making in supply chains [24]. Zhi Li et al. proposed a production capacity evaluation system for supply chain networks by combining Internet of Things (IoT), machine learning, and blockchain technologies to achieve open and distributed data storage and sharing to improve the sustainability of production management [25]. Ali Vatankhah Barenji et al. proposed a blockchain-based network to eliminate third-party trust issues in business-to-business collaboration, enabling peer-to-peer communication and transactions between users and service providers, effectively improving the scalability issues of SME collaboration [26]. Jasur Salikhov et al. developed a contractual coordination model based on “cost and revenue sharing” to improve the efficiency of resource usage with information sharing to promote sustainability in manufacturing through blockchain [27]. Jiewu Leng et al. proposed a decentralized, blockchain-based model for the automated execution and validation of transactions between manufacturers in order to address the trust problem in the social manufacturing paradigm, providing a basis for decentralized manufacturers to collaborate in the manufacturing ecology [28]. Basim Aljabhan et al. proposed a perceptive craving game search (PCGS) optimization algorithm in data management to guarantee the privacy of data, and pointed out that the application of blockchain has already had an impact on environmental sustainability and even environmental protection [29].

2.2. Privacy Protection

In recent years, various technologies related to big data and data mining have emerged. With the proper processing, analysis, and mining of data, it is possible to improve inter-enterprise cooperation and decision-making. However, such collaboration can lead to privacy violations [30], making it necessary to adopt privacy protection measures. Privacy protection is a way to use data value in the process of using data, such as for transmission and processing, without sacrificing data elements or comprising privacy.

Recently, several researchers have attempted to apply privacy-preserving techniques to data mining scenarios. Wenjia Wu et al. integrated deep learning and differential privacy techniques to propose a data protection algorithm based on SDIN, which can provide effective privacy protection for industrial data [31]. Ya-Nan Cao et al. used blockchain to solve the problems of privacy protection and identity authentication in the process of data collection and electricity trading in smart electricity grids [32]. Sina Shaham et al. proposed a machine learning-based anonymization framework for spatiotemporal trajectory datasets that protects users’ location trajectory information when it is published in public datasets [33]. Emmanuel Antwi-Boasiako et al. provided a framework for collaborative deep learning and its training phase provided a homomorphic encryption method to manage critical privacy in training datasets [34]. Lixin Liu et al. proposed privacy-preserving protocols that balance the boundaries of accountability and privacy protection and demonstrated their practicality for metadata leakage in healthcare systems [35].

3. Collaborative Production

In the production ecosystem of Industry 4.0 [36], there are three modes of integration: intra-enterprise integration, end-to-end integration of a single supply chain, and the horizontal integration of a composite supply chain [37], of which horizontal integration is the most important feature of collaborative production. Collaborative production refers to the use of computer technology and information technology to realize an advancement in the design, manufacturing, management, and business between the upstream and downstream parts of supply chain and enterprises [38]. This process is divided into three stages: value collaboration, standard collaboration, and process collaboration.

In the value collaboration stage, multi-level operators in the industry, such as customers, manufacturers, suppliers, and external resources and other vertical units are driven by the value chain of the project and networked around the needs of the industry chain [6], realizing the consistent value recognition of various data elements in the supply chain, breaking down the barriers to collaboration due to the value of the data constituted, and stimulating a willingness to circulate resources between enterprises, thus promoting dynamic demand and business interoperability between participants at different levels.

In the standard collaboration stage, various data elements in the industry chain achieve data governance, and heterogeneous data can be mutually authenticated, audited, and authorized among operators at all levels to ensure authenticity and consistency; meanwhile, the real-time value of the data elements can be optimized, which can support continuous data sharing and integration.

In the process collaboration stage, the peer-to-peer data management mode of the traditional process is broken through at each level of the industry chain, and the communication rules and collaboration records of each enterprise department are fully recognized and authenticated. This solves the problems of data security and authority control that lead to inefficient use and difficulties in collaboration concerning private data, realizing an enterprise-level collaboration in which the rules can be publicly audited and the records cannot be tampered with, thereby meeting the new collaborative workflow reconstruction needs of rapid adjustment of process logic for participants at different levels.

4. Blockchain-Based Collaborative Platform for Enterprise Data Governance

The purpose of the research described here is to develop a general mechanism to provide support and encouragement for multi-level enterprises in selecting partners that follow sustainability in product, environmental, and social latitudes, which enable the various participants to operate in production more efficiently through data sharing, transforming the value of various data across interactions. Three key research priorities are identified. They are (1) to develop a consensus mechanism for evaluating and balancing the value of data from different perspectives; (2) to establish standards for data sharing and transformation that are applicable to different stages of production collaboration among enterprises; and (3) to develop a data value-based process modeling mechanism that is compatible with various business interactions inside and outside the enterprise.

4.1. Non-Linear Dynamic Evaluation and Value Balancing Mechanism of Data Elements with Multi-Attributes

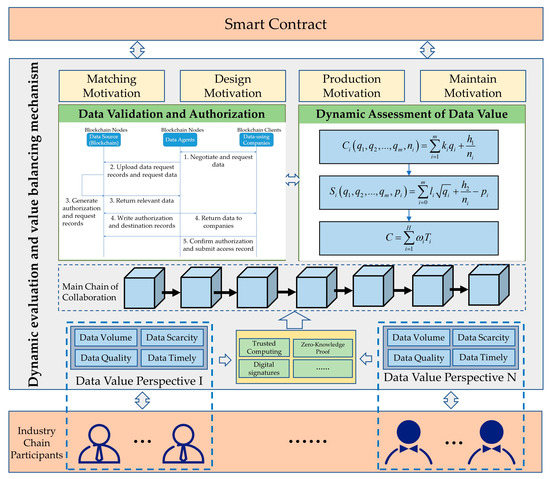

To achieve consensus on data value and effective data sharing, a non-linear dynamic evaluation and value balancing mechanism based on blockchain with multiple data attributes is proposed in order to achieve different perspectives on data value among the upstream and downstream participants in the industry chain. As shown in Figure 2, this mechanism mainly includes data validation and cross authorization, dynamic assessment of data value, and incentives for value sharing.

Figure 2.

Non-Linear dynamic valuation and value balancing mechanism.

4.1.1. Data Validation and Authorization

To reduce the storage pressure on the blockchain system, on-chain and off-chain data collaboration technology is used. For the data collected by each participant from the collaboration phase, on the one hand, confidential data with privacy protection needs will be uploaded to the distributed collaboration system. On the other hand, the system uses blockchain technology to extract the collaboration information that needs to be interacted with the data carrier using a hashing algorithm to generate summary information about the data elements, which includes the unique hash value identification, the source of the data, and operation information about the equipment. At the same time, the blockchain SDK uploads the summary information to the masterchain by calling the smart contract autonomously.

In order to allow all participants in the industry chain to collaborate through data elements, the data authentication technology is combined with group signature and zero-knowledge proof technology, and the data collaboration technology on and off the chain is used to achieve authentication and ensure that the rights and interests of enterprises over the data they own are not infringed. Meanwhile, smart contracts are used to coordinate the different perceptions of the value of data elements by different participants in a frequently changing environment between enterprises, and to achieve enterprise-level data interaction and business collaboration based on a consensus concerning the value.

4.1.2. Dynamic Assessment of Data Value and Incentive for Value Sharing

In the blockchain collaboration network, value is constructed by data statistics and value assessment of the blockchain nodes, and the incentive model is constructed based on the value of the nodes to realize data sharing, transmission, and transaction.

The data is evaluated in the form of transaction through the auction model. In this process, the key attributes of the data owner are evaluated by assessing each sub-attribute of data quality, the price per unit of data, and the quantity of data represented by and , respectively. Based on this, the cost function of the data owner is set as:

This function influences the decision of the data owner in the trading process.

Subsequently, under the scoring auction mechanism, both parties to the transaction offer trading strategies that maximize their desired returns based on their costs, and finally the winner is determined based on the corresponding scoring function.

After completing a transaction, the smart contract updates each participant’s contribution based on the participant’s overall assessment, which is quantified as the contribution level.

In blockchain networks, reputation describes satisfaction of nodes that have direct transaction. Node reputation is defined as follows: for nodes in the open network, , and for the set of nodes that have direct transactions with N within the window H (number of transactions), to denote the nodes within the satisfaction time series, thus obtaining the node’s reputation degree C.

Each participant in the industry chain can choose the partner with the greatest interest in data sharing and collaborative production, and at the same time set up a compound collaborative incentive mechanism, such as demand matching, collaborative design, production collaboration, and system maintenance, to continuously increase the willingness of enterprises to upload high quality interactive data on the one hand and motivate them to participate in maintaining the entire R and D collaborative network on the other.

4.2. Blockchain-Based Trusted Data Governance Mechanism

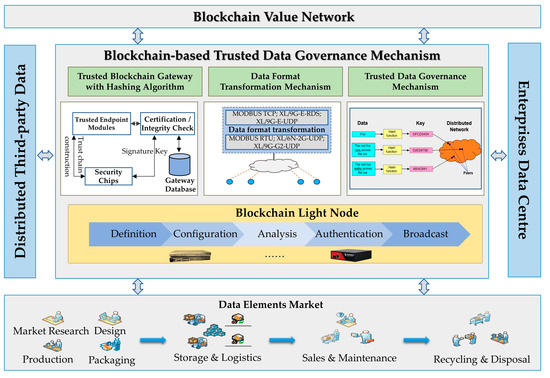

Since the multi-layer supply chain involves extended-level suppliers following different levels of data standards, there are highly complex challenges involved in this process, such as standards identification, coordination, and data privacy issues. In order to ensure the interconnection of data elements in the process of multi-layer collaboration in the industrial chain, a trusted mechanism for manufacturing data elements based on blockchain technology is proposed. As shown in Figure 3, the mechanism mainly includes a trusted hash gateway and a format conversion mechanism.

Figure 3.

Trusted data governance mechanism.

4.2.1. Trusted Blockchain Gateway with Hash Algorithms

In the process of collaborative production, in order to verify the authenticity and consistency of data in the database of cooperative enterprises without management authority, blockchain light nodes are set up in enterprises to define, configure, analyze, verify, and broadcast the collected data, and connect each light node into the blockchain gateway system so that the data can be uploaded to the blockchain data element market. A secure chip is used to build the trusted edge computing endpoint module to achieve authentication and integrity verification of data, and to realize a highly portable and encapsulated IoT gateway trusted platform module. The module will use hashing algorithms to measure the integrity of data elements and ensure the authenticity of each data message collected from the source of the device and supply chain. This is a compressed mapping that can increase the density of information in the data to some extent and reduce the storage space required. At the same time, this mapping relationship is one-way indecipherable. For different input data, the same output hash value may be obtained, but it is not possible to reverse the mapping to determine the input value, i.e., there are only encryption methods and no reverse deciphering methods. However, the authenticity and integrity of the data can be verified by a single hash value.

4.2.2. Blockchain-Based Data Transformation

In an environment of highly coupled interactions, such as product development in the industrial chain, in order to achieve the interconnection of data elements, the data collected in the collaborative production process is encapsulated into block data by using edge computing devices, and data of arbitrary length, format, and source are converted into fixed-length hash. This is achieved by means of pre-mapping with the help of hashing algorithms to realize MODBUS TCP, XL/9G-E-RDS, while other transmission protocols are converted into MODBUS RTU, XL/6N-2G-UDP and other data formats that meet the requirements of blockchain, completing the purpose of converting data formats of different systems into standard formats that meet the blockchain system criteria. As the data storage space of each block is limited, various multi-source heterogeneous data collected will be stored in the distributed cloud database; at the same time, information such as the hash values and data abstracts will be uploaded to the blockchain for storage and display. When different service applications request access, they search with abstract information on the blockchain and then use the Kadenlia protocol, the nodes IP addresses, and port numbers of both sides to locate the data in the decentralized system. The data in the cloud database is then accessed through pre-defined service interfaces for visualization and analytics techniques to use the data.

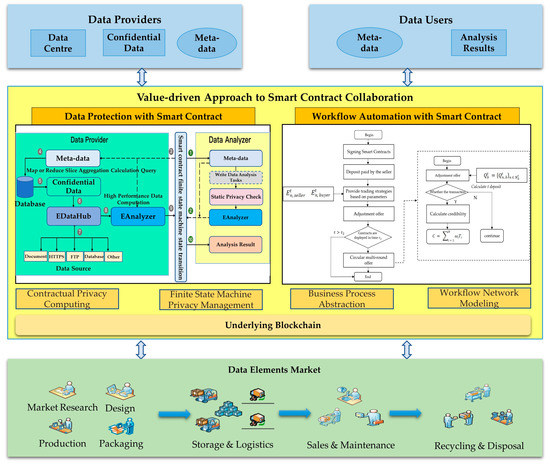

4.3. Smart Contract Generation for Value-Driven Collaboration

In order to break through the traditional product industry chain data management mode with repeated negotiation, layers of authorization, and cumbersome processes, a value-driven, publicly auditable, and tamper-evident collaboration records smart contract collaboration method is proposed. As shown in Figure 4, this collaboration method includes a decision mode data management method and a privacy data calculation mechanism.

Figure 4.

Smart Contract Generation for Value-driven Collaboration.

4.3.1. Data Protection with Smart Contract

The arithmetic rules of the privacy data uploaded by each participant are described as a finite state machine through a smart contract. Using this, we can check whether the data source has completed the state transformation from input data to output data by using static binary analysis. After the smart contract passes the automatic identification of data privacy state transitions, it can ensure that the data is used and converted to value in the way described by the publisher. The data units generated from different collaborative processes are composed according to the requirements of the collaborative tasks; for upstream and downstream enterprises, only the input and output privacy data flow graphs are displayed. The privacy data set is processed and analyzed using high-performance analytics, and the smart contract is used to accept only ciphertext data; the public and private keys are used to verify whether the data is the complete data generated autonomously by the high-performance data analytics program, thus ensuring the confidentiality of the data computation use process and the accuracy of the computation results. In this case, only the data user can obtain the calculation results with the help of the private key and the smart contract.

4.3.2. Blockchain-Based Workflow Automation with Smart Contract

In order to improve the auditability, security, and generality of smart contracts, a workflow network-based smart contract generation method is proposed. The generation of smart contracts mainly includes visual modeling, simulation, verification, and translation. In the visual modeling phase, the graphical workflow network model can improve the auditability of smart contracts. The simulation phase of the workflow network is used to implement the execution of variations to test business logic. The validation of the workflow network model ensures the legitimacy of the model in order to detect and avoid errors. The contract translation phase enables the conversion of Petri Net Markup Language (PNML) to contract code by means of tag mapping. It is worth noting that the formal smart contract model is programming language independent and can be translated into smart contract code in different languages, thus improving the generality of smart contracts.

5. Implementation Perspectives

To verify the feasibility and rationality of the proposed framework, an experimental implementation is provided through software development. First, a multi-attributes value assessment method is used to enable enterprise collaborators to reach a consensus on the shared data and provide a basis for collaborative cooperation. Second, the identification, comparison, and conversion of data formats are used to complete the unification of data formats among enterprises and promote the efficiency of inter-enterprise collaboration. Finally, the modeling of the data sharing business is completed through the workflow network, and the collaboration of data among various departments in each enterprise is completed by using smart contracts.

5.1. Data Value Assessment and Balance

According to the theoretical knowledge of the auction model, the value consensus process continues as long as the utility is greater than zero, as shown in Algorithm 1. First, the data provider needs to provide the data user with the corresponding parameters, such as the desired data value N, data quality S, etc. Then a circular value consensus process is conducted among different enterprises, and the information sharing platform scores and calculates each shared data based on the provided parameters. Based on the ranking of the scores , the set of enterprises that have the possibility to reach a consensus on the value of the shared data is selected. These enterprises are analyzed in the next step in order to select the optimal enterprises that can reach consensus.

| Algorithm 1 Multi-attributes Auction-based Value Algorithm |

| Input: T, N, U, q, Q Output: 1: for do // Cyclic steps to bring participants to consensus |

| 2: // Initialize participant parameters |

| 3: for do |

| 4: // Calculate the ranking score |

| 5: if then |

| 6: |

| 7: else |

| 8: |

| 9: end if |

| 10: end for |

| 11: // Calculate the second screening score |

| 12: if then // Reach consensus and break out of the cycle |

| 13: break from line 3 |

| 14: else |

| 15: // Update consensus group members |

| 16: end if |

| 17: end for |

| 18: return // Return to the two participants who reached consensus |

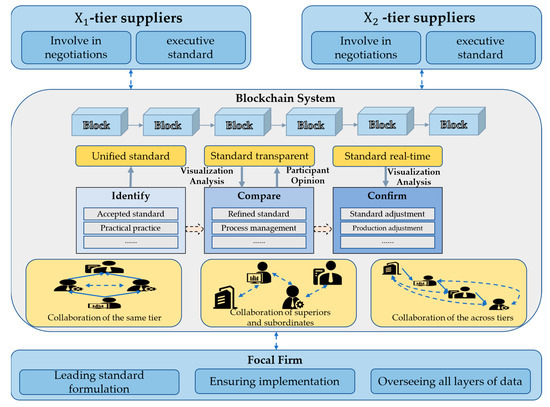

5.2. Blockchain-Based Standard Collaboration

The process of identifying different formats for data sharing between enterprises is divided into three steps, as shown in Figure 5: (1) identifying the data formats used by each collaborating enterprise; (2) comparing the data format differences between enterprises with direct data sharing relationships; and (3) determining the direction of data format adaptation. Each step is implemented automatically with the authentication of a smart contract. The system completes the uploading of data information and standards by connecting trusted gateways to enterprises’ IoT devices and is adopted by enterprises at all levels of the industry chain. After ensuring that the data formats and sources are reliable, detailed information on the differences between data standards is discovered using visualization techniques, while the standards of the data involved are automatically analyzed through smart contracts. Finally, blockchain systems can use visualization technology to directly realize the direction of the adjustment of data formats and standards to ensure that shared data is not hindered by format issues.

Figure 5.

Data standards synchronization for multi-level participants.

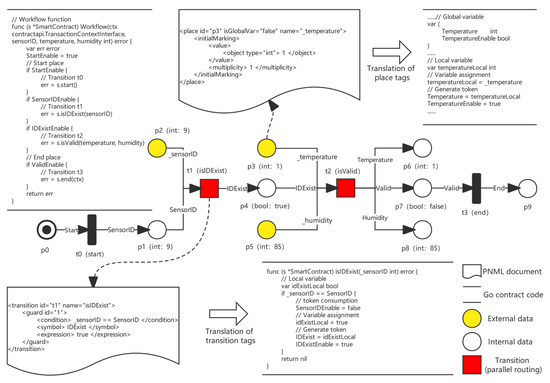

5.3. Smart Contract-Based Process Modeling

This section gives an example of smart contract generation that shows how to generate Go language-based smart contract code templates via a workflow network, as shown in Figure 6. These are stored in the form of PNML documents, a standard extensible markup language transformed with the Petri net model for describing and defining state and transfer rules in workflow nets. A workflow net includes at least three elements: variation, library house, and arc.

Figure 6.

A case study of smart contract modeling.

Variations are represented in the PNML documentation by the <transaction> tag, and during the translation process of a smart contract, the variation is translated into a variation function that can only be called by internal functions. In the translated smart contract, the name of the change function starts in lower case, which in Go means that only functions inside the package can call it, not external functions.

The place of the Petri net is represented in the PNML document by the <place> tag; during the translation of the smart contract, the <place> tag will be translated into a set of global variables: a value type variable representing the value of the place and a bool type variable representing the state of the place. A change in the state of the place is achieved by changing the value type variable and the bool type variable.

Arcs are represented in the PNML document by the <arc> tag; in the contract code, arcs are represented by workflow functions. The main business logic of the workflow function is to determine the change function that should be executed based on the state of the workflow repository.

6. Conclusions

This paper proposes a blockchain-based multi-dimensional collaboration framework. Based on the elaboration of the content of multi-dimensional collaboration, it constructs a multi-dimensional industry governance mechanism of “Value–Standard–Process” collaboration. It can further explore the value of multiple heterogeneous data elements, stimulate the data inter flow and transactions to promote the free flow of value-based data elements, and use data elements as indicators to support and motivate participants to adopt sustainable practices in social, economic, and environmental terms.

The contributions of this paper are summarized as follows: (1) proposes a mechanism for dynamic value evaluation and balancing for multi-attributes data in “Value–Standard –Process” collaborative production. The mechanism facilitates the shift of data management from a permission-based to a value-driven approach by using value-balancing incentives to enable “value collaboration” and to reach consensus on the value of data from a differentiated value perspective; (2) proposes a trusted data governance mechanism to achieve “standard collaboration” based on blockchain to realize the fusion of different data standards with multi-user attributes and multi-dimensional data on a multi-layer industry, ensuring the consistency and authenticity of data up and down the industry; And (3) proposes a mechanism to reconfigure collaborative processes through smart contracts. Through formalized smart contract modeling techniques, “process collaboration” is realized, making data elements available but not visible, and the collaboration process not public but the collaboration logic publicly available. Upstream and downstream industry chains can share their digital information on this framework and can also use the flow of data elements and value transformation to serve their core tasks. Furthermore, data elements can be provided to assess sustainability metrics for upstream and downstream enterprises in production and data management.

Future research can be conducted in the following two areas: (1) the current research has systematically implemented the proposed architecture and verified its feasibility, so a follow-up would need to collect specific data in collaborative production and verify it from a more realistic perspective; (2) the amount of data generated in enterprise production is huge, and not all the data collected through the trusted gateway system is used for sharing. Therefore, further experiments and statistical models are needed to determine the module size for data sharing so that the collected data can accurately match the data sharing requirements and also match the optimal block size and upload time for the blockchain.

Author Contributions

Conceptualization, Z.L. and H.H.; methodology, Z.L. and H.H.; formal analysis, Z.L. and F.L.; writing—original draft preparation, Z.L. and F.L.; writing—review and editing, Z.L. and H.H.; funding acquisition, Z.L.; supervision, Z.L. and H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (72071048), Guangzhou Philosophy and Social Science Program (2023GZYB45), Guangdong Provincial Natural Science Foundation (2023A1515012851), and Zhejiang Provincial Natural Science Foundation (LY21F010005). It was also sponsored by the K.C. Wong Magna Fund at Ningbo University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jovanovic, M.; Sjödin, D.; Parida, V. Co-evolution of platform architecture, platform services, and platform governance: Expanding the platform value of industrial digital platforms. Technovation 2022, 118, 102218. [Google Scholar] [CrossRef]

- Gupta, S.; Campos Zeballos, J.; del Río Castro, G.; Tomičić, A.; Andrés Morales, S.; Mahfouz, M.; Osemwegie, I.; Phemia Comlan Sessi, V.; Schmitz, M.; Mahmoud, N.; et al. Operationalizing Digitainability: Encouraging Mindfulness to Harness the Power of Digitalization for Sustainable Development. Sustainability 2023, 15, 6844. [Google Scholar] [CrossRef]

- Hanelt, A.; Bohnsack, R.; Marz, D.; Marante, C.A. A Systematic Review of the Literature on Digital Transformation: Insights and Implications for Strategy and Organizational Change. J. Manag. Stud. 2021, 58, 1159–1197. [Google Scholar] [CrossRef]

- Wei, J.; Yi, X.; Yang, X.; Liu, Y. Blockchain-Based Design of a Government Incentive Mechanism for Manufacturing Supply Chain Data Governance. Sustainability 2023, 15, 6968. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X.; Liu, Z.; Qu, Y.; Yin, D. An overall framework and subsystems for smart manufacturing integrated system (SMIS) from multi-layers based on multi-perspectives. Int. J. Adv. Manuf. Technol. 2019, 103, 703–722. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X.; Bao, Y.; Liao, X. System construction for comprehensive industrial ecosystem oriented networked collaborative manufacturing platform (NCMP) based on three chains. Adv. Eng. Inform. 2022, 52, 101538. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X. Reference subsystems for Smart Manufacturing Collaborative System (SMCS) from multi-processes, multi-intersections and multi-operators. Enterp. Inf. Syst. 2020, 14, 282–307. [Google Scholar] [CrossRef]

- Faroukhi, A.Z.; El Alaoui, I.; Gahi, Y.; Amine, A. Big data monetization throughout Big Data Value Chain: A comprehensive review. J. Big Data 2020, 7, 3. [Google Scholar] [CrossRef]

- Dong, X.; Li, R.; He, H.; Zhou, W.; Xue, Z.; Wu, H. Secure sensitive data sharing on a big data platform. Tsinghua Sci. Technol. 2015, 20, 72–80. [Google Scholar] [CrossRef]

- Li, M.; Li, Z.; Huang, X.; Qu, T. Blockchain-based digital twin sharing platform for reconfigurable socialized manufacturing resource integration. Int. J. Prod. Econ. 2021, 240, 108223. [Google Scholar] [CrossRef]

- Andres, B.; Poler, R.; Sanchis, R. A data model for collaborative manufacturing environments. Comput. Ind. 2021, 126, 103398. [Google Scholar] [CrossRef]

- Najjar, M.S.; Kettinger, W.J. Data Monetization: Lessons from a Retailer’s Journey. MIS Q. Exec. 2013, 213–225. [Google Scholar]

- Mohamed, S.K.; Haddad, S.; Barakat, M.; Rosi, B. Blockchain Technology Adoption for Improved Environmental Supply Chain Performance: The Mediation Effect of Supply Chain Resilience, Customer Integration, and Green Customer Information Sharing. Sustainability 2023, 15, 7909. [Google Scholar] [CrossRef]

- Wu, D.; Rosen, D.W.; Wang, L.; Schaefer, D. Cloud-based design and manufacturing: A new paradigm in digital manufacturing and design innovation. Comput. Aided Des. 2015, 59, 1–14. [Google Scholar] [CrossRef]

- Li, Z.; Barenji, A.V.; Huang, G.Q. Toward a blockchain cloud manufacturing system as a peer to peer distributed network platform. Robot. Comput. Integr. Manuf. 2018, 54, 133–144. [Google Scholar] [CrossRef]

- Iansiti, M.; Lakhani, K.R. The Truth About Blockchain. Harv. Bus. Rev. 2017, 95, 118–127. [Google Scholar]

- Liang, X.; Zhao, J.; Shetty, S.; Li, D. Towards data assurance and resilience in IoT using blockchain. In Proceedings of the MILCOM 2017—2017 IEEE Military Communications Conference (MILCOM), Baltimore, MD, USA, 23–25 October 2017; pp. 261–266. [Google Scholar] [CrossRef]

- Li, Z.; Wang, W.M.; Liu, G.; Liu, L.; He, J.; Huang, G.Q. Toward open manufacturing: A cross-enterprises knowledge and services exchange framework based on blockchain and edge computing. Ind. Manag. Data Syst. 2018, 118, 303–320. [Google Scholar] [CrossRef]

- Weber, I.; Xu, X.; Riveret, R.; Governatori, G.; Ponomarev, A.; Mendling, J. Untrusted Business Process Monitoring and Execution Using Blockchain. In Business Process Management; Springer: Cham, Switzerland, 2016; Volume 9850, pp. 329–347. [Google Scholar] [CrossRef]

- Liu, X.L.; Wang, W.M.; Guo, H.; Barenji, A.V.; Li, Z.; Huang, G.Q. Industrial blockchain based framework for product lifecycle management in industry 4.0. Robot. Comput.-Integr. Manuf. 2020, 63, 101897. [Google Scholar] [CrossRef]

- Singh, P.; Elmi, Z.; Lau, Y.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. Blockchain and AI technology convergence: Applications in transportation systems. Veh. Commun. 2022, 38, 100521. [Google Scholar] [CrossRef]

- Naseem, M.H.; Yang, J.; Zhang, T.; Alam, W. Utilizing Fuzzy AHP in the Evaluation of Barriers to Blockchain Implementation in Reverse Logistics. Sustainability 2023, 15, 7961. [Google Scholar] [CrossRef]

- Wang, B.; Luo, W.; Zhang, A.; Tian, Z.; Li, Z. Blockchain-enabled circular supply chain management: A system architecture for fast fashion. Comput. Ind. 2020, 123, 103324. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Potryasaev, S.; Sokolov, B.; Ivanova, M.; Werner, F. Blockchain-oriented dynamic modelling of smart contract design and execution in the supply chain. Int. J. Prod. Res. 2020, 58, 2184–2199. [Google Scholar] [CrossRef]

- Li, Z.; Guo, H.; Barenji, A.V.; Wang, W.M.; Guan, Y.; Huang, G.Q. A sustainable production capability evaluation mechanism based on blockchain, LSTM, analytic hierarchy process for supply chain network. Int. J. Prod. Res. 2020, 58, 7399–7419. [Google Scholar] [CrossRef]

- Barenji, A.V.; Li, Z.; Wang, W.M.; Huang, G.Q.; Guerra-Zubiaga, D.A. Blockchain-based ubiquitous manufacturing: A secure and reliable cyber-physical system. Int. J. Prod. Res. 2020, 58, 2200–2221. [Google Scholar] [CrossRef]

- Salikhov, J.; Hayrutdinov, S.; Muminov, T.K. Blockchain-Enabled Sustainable Supply Chain under Information Sharing and Recovery Quality Efforts. Sustainability 2023, 15, 3929. [Google Scholar] [CrossRef]

- Leng, J.; Jiang, P.; Xu, K.; Liu, Q.; Zhao, J.L.; Bian, Y.; Shi, R. Makerchain: A blockchain with chemical signature for self-organizing process in social manufacturing. J. Clean. Prod. 2019, 234, 767–778. [Google Scholar] [CrossRef]

- Aljabhan, B.; Obaidat, M.A. Privacy-Preserving Blockchain Framework for Supply Chain Management: Perceptive Craving Game Search Optimization (PCGSO). Sustainability 2023, 15, 6905. [Google Scholar] [CrossRef]

- Liu, D.; Yan, Z.; Ding, W.; Atiquzzaman, M. A Survey on Secure Data Analytics in Edge Computing. IEEE Internet Things J. 2019, 6, 4946–4967. [Google Scholar] [CrossRef]

- Wu, W.; Qi, Q.; Yu, X. Deep learning-based data privacy protection in software-defined industrial networking. Comput. Electr. Eng. 2023, 106, 108578. [Google Scholar] [CrossRef]

- Cao, Y.-N.; Wang, Y.; Ding, Y.; Guo, Z.; Wu, Q.; Liang, H. Blockchain-empowered security and privacy protection technologies for smart grid. Comput. Stand. Interfaces 2023, 85, 103708. [Google Scholar] [CrossRef]

- Shaham, S.; Ding, M.; Liu, B.; Dang, S.; Lin, Z.; Li, J. Privacy Preserving Location Data Publishing: A Machine Learning Approach. IEEE Trans. Knowl. Data Eng. 2021, 33, 3270–3283. [Google Scholar] [CrossRef]

- Antwi-Boasiako, E.; Zhou, S.; Liao, Y.; Liu, Q.; Wang, Y.; Owusu-Agyemang, K. Privacy preservation in Distributed Deep Learning: A survey on Distributed Deep Learning, privacy preservation techniques used and interesting research directions. J. Inf. Secur. Appl. 2021, 61, 102949. [Google Scholar] [CrossRef]

- Liu, L.; Li, X.; Au, M.H.; Fan, Z.; Meng, X. Metadata Privacy Preservation for Blockchain-Based Healthcare Systems. Database Syst. Adv. Appl. 2022, 13245, 404–412. [Google Scholar] [CrossRef]

- Drath, R.; Horch, A. Industrie 4.0: Hit or Hype? [Industry Forum]. IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Xue, X.; Kou, Y.-M.; Wang, S.-F.; Liu, Z.-Z. Computational Experiment Research on the Equalization-Oriented Service Strategy in Collaborative Manufacturing. IEEE Trans. Serv. Comput. 2018, 11, 369–383. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X.; Bao, Y. Online merchant resource allocation and matching for open community collaborative manufacturing (OCCM) in mass personalization model. Adv. Eng. Inform. 2023, 55, 101872. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).