A Traceability Framework to Enable Circularity in the Built Environment

Abstract

1. Introduction

- RQ1: What are the main traceability standards, guidelines, and strategies to enable circularity in the built asset industry?

- RQ2: How can these standards, guidelines, and strategies be structured and linked through an integrated approach for future studies and implementations?

2. Background

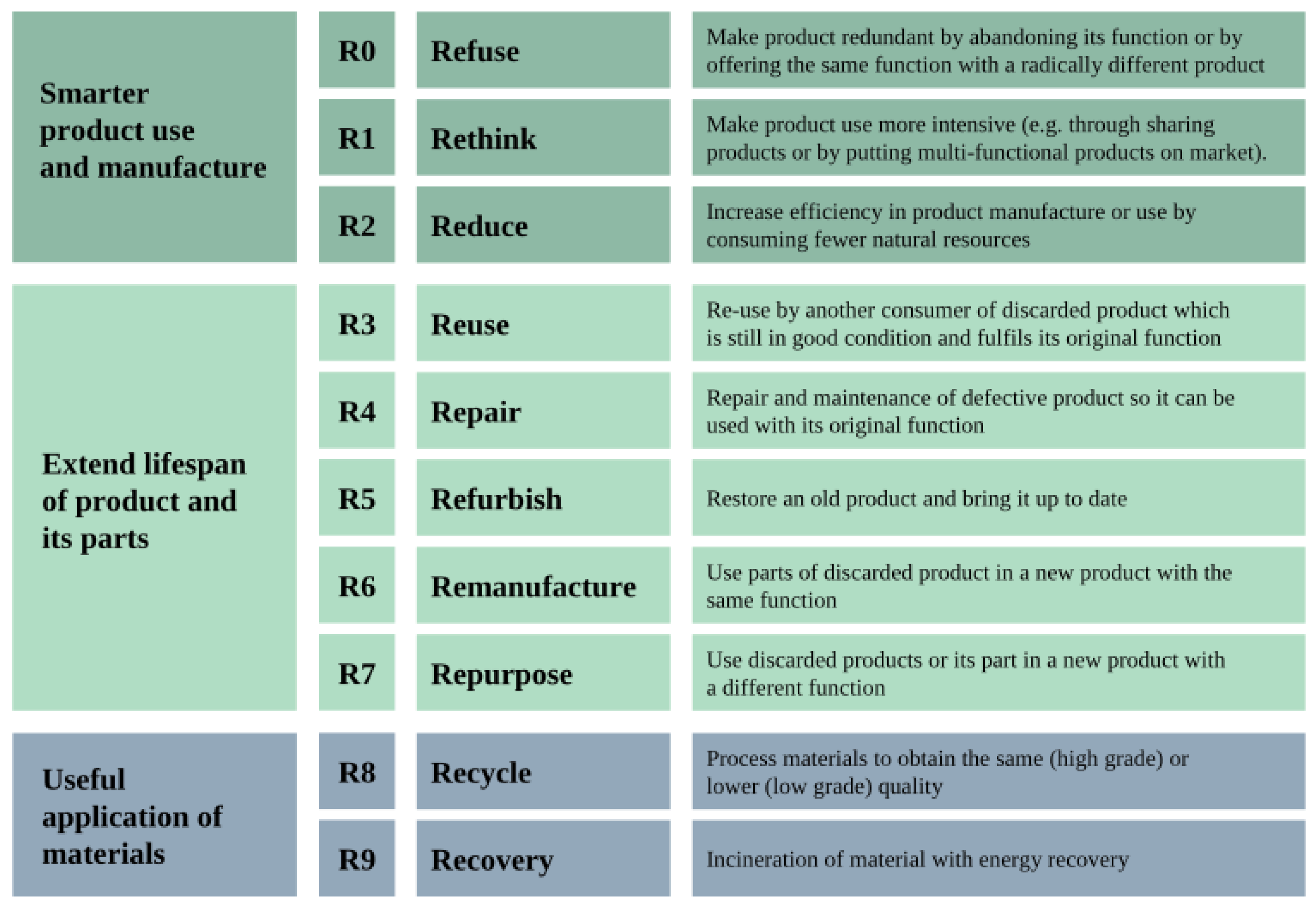

2.1. Circular Economy in the Built Environment

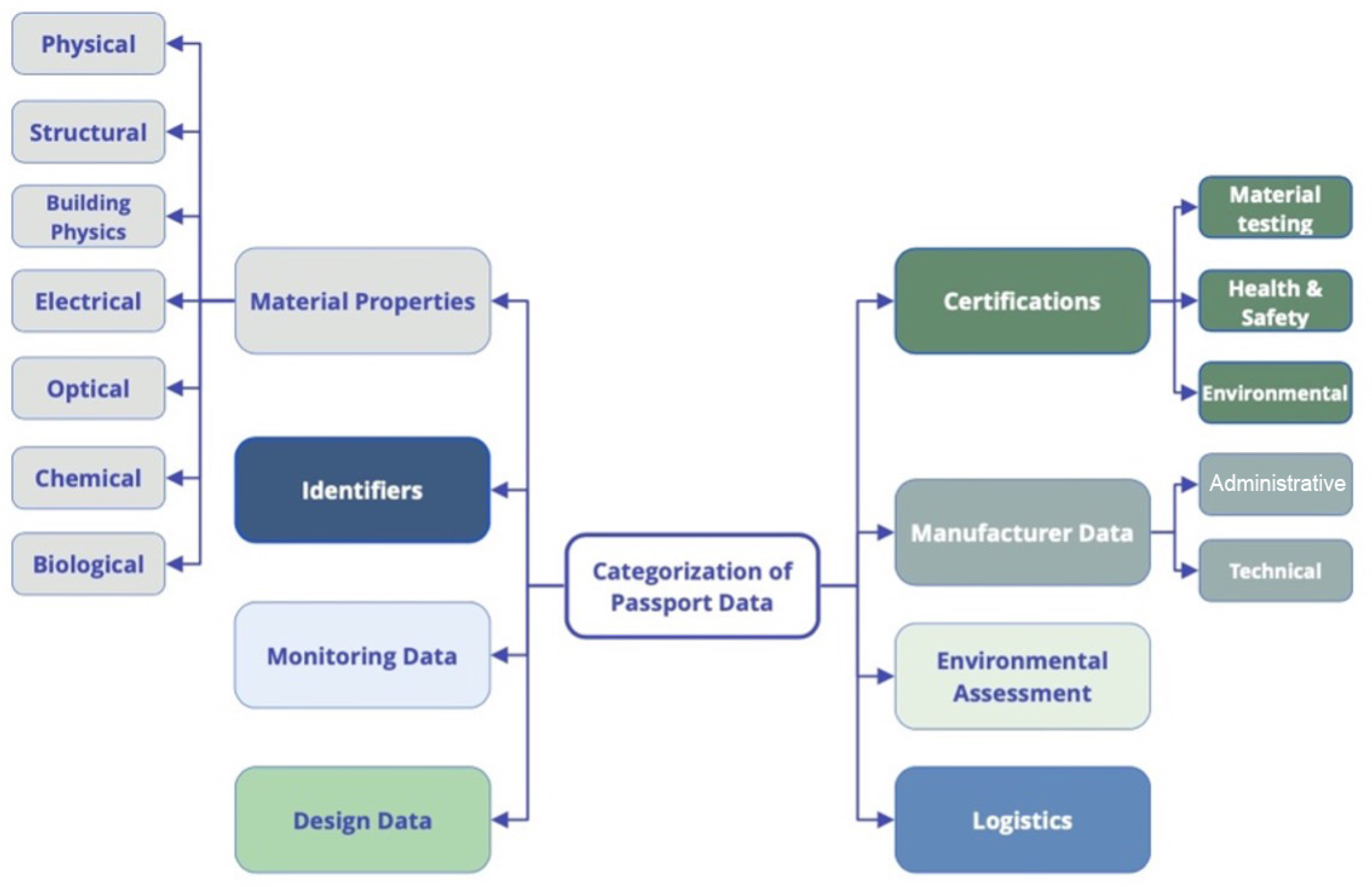

- Buildings As Material Banks (BAMB): this MP describes data and their implementation strategies in the built environment. All necessary information about materials and products pertaining to CE is hierarchically categorized into several levels (Figure 1) such as material properties, certifications, logistics, etc. The project has also established a digital platform which connects individual components of the buildings by displaying their uses and values in the marketplace [31].

- 3XN Architects: this MP provides guidelines to collect CE data across a building’s lifecycle stages. The collected data need to be linked to a database enabling traceability of all building components and parts with their technical and functional specifications [37].

- Madaster: this project frames MP data based on the building’s layers (e.g., structure, skin, services, etc.). The MP also provides circularity indicators to calculate the amount of virgin, recycled, reused, and renewable materials that are incorporated within a building. Madaster’s cloud platform can connect to Building Information Modeling (BIM)-based models and allows users to create and develop a unique passport for buildings or objects [38].

2.2. Concept of Traceability across Domains

2.3. Traceability in the Built Asset Industry

2.4. Summary of Research Gaps

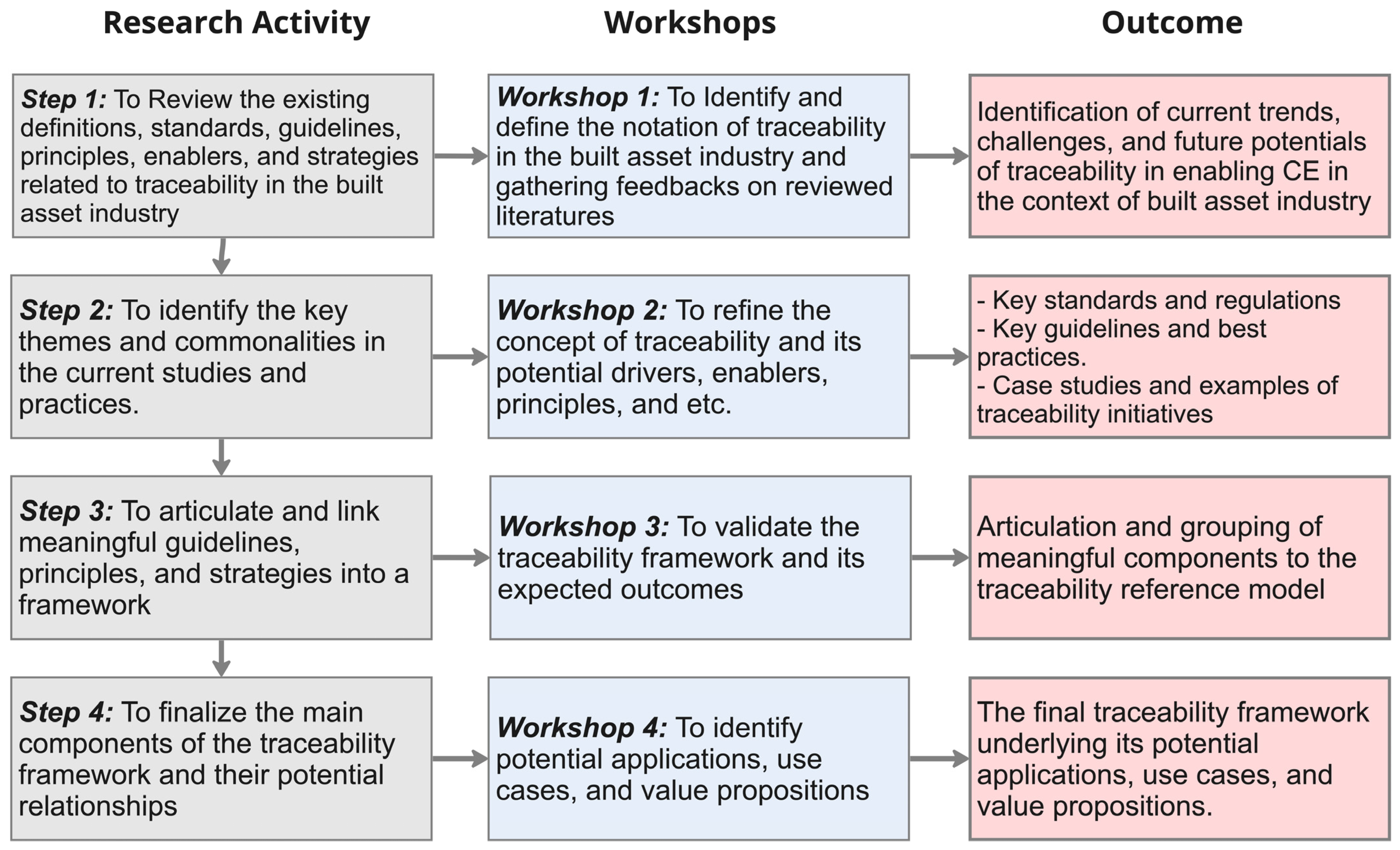

3. Materials and Methods

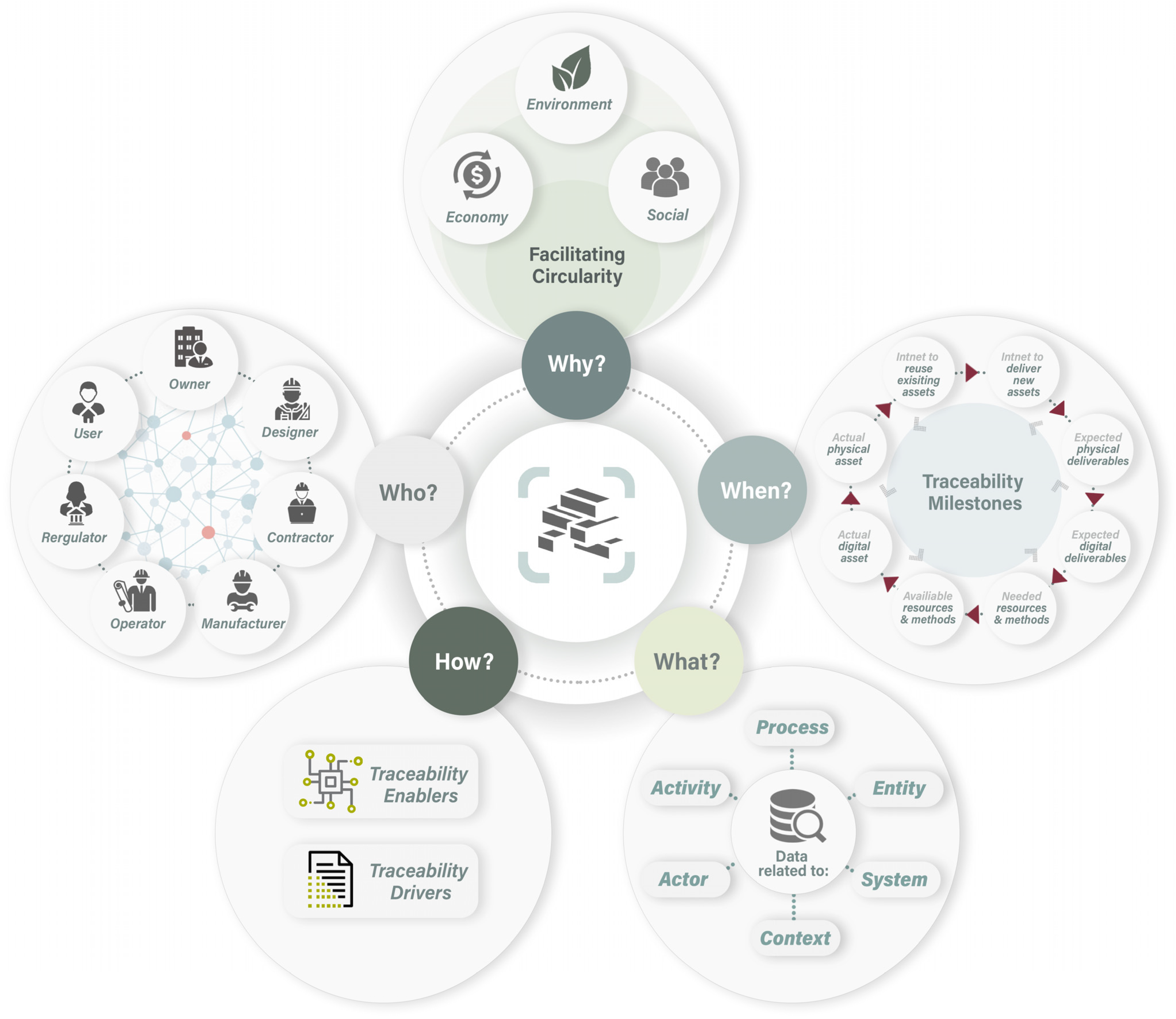

3.1. Adoption of a Traceability Reference Model

- Why are we tracing: refers to the purposes and drivers of traceability to all stakeholders. The framework should cover specific needs and goals of stakeholders and provide a rationale for why traceability is necessary in each case. Some possible drivers for traceability include improving quality control, ensuring compliance with regulatory requirements, increasing transparency and accountability, supporting sustainability and environmental goals, and reducing risk and liability in specifying, procuring, installing, and reusing or recycling products and materials.

- What are we tracing: refers to the materials, products, or systems that require traceability and the data elements that need to be traced for each item. Determining what needs to be traced can be influenced by various factors, such as regulatory requirements, project-specific requirements, and stakeholder needs.

- How are we tracing: refers to the strategies and enablers that are used to trace and manage data and how stakeholders are involved in the process. The framework should provide guidance on how data are captured, managed, and shared and how stakeholders can access and use the data.

- Who is tracing: refers to the stakeholders responsible for implementing and maintaining traceability and how they can contribute to and benefit from the traceability efforts. This includes various stakeholders involved in the built asset industry, such as designers, manufacturers, suppliers, contractors, and owners. The framework should also provide guidance on the roles and responsibilities of each stakeholder in the traceability process.

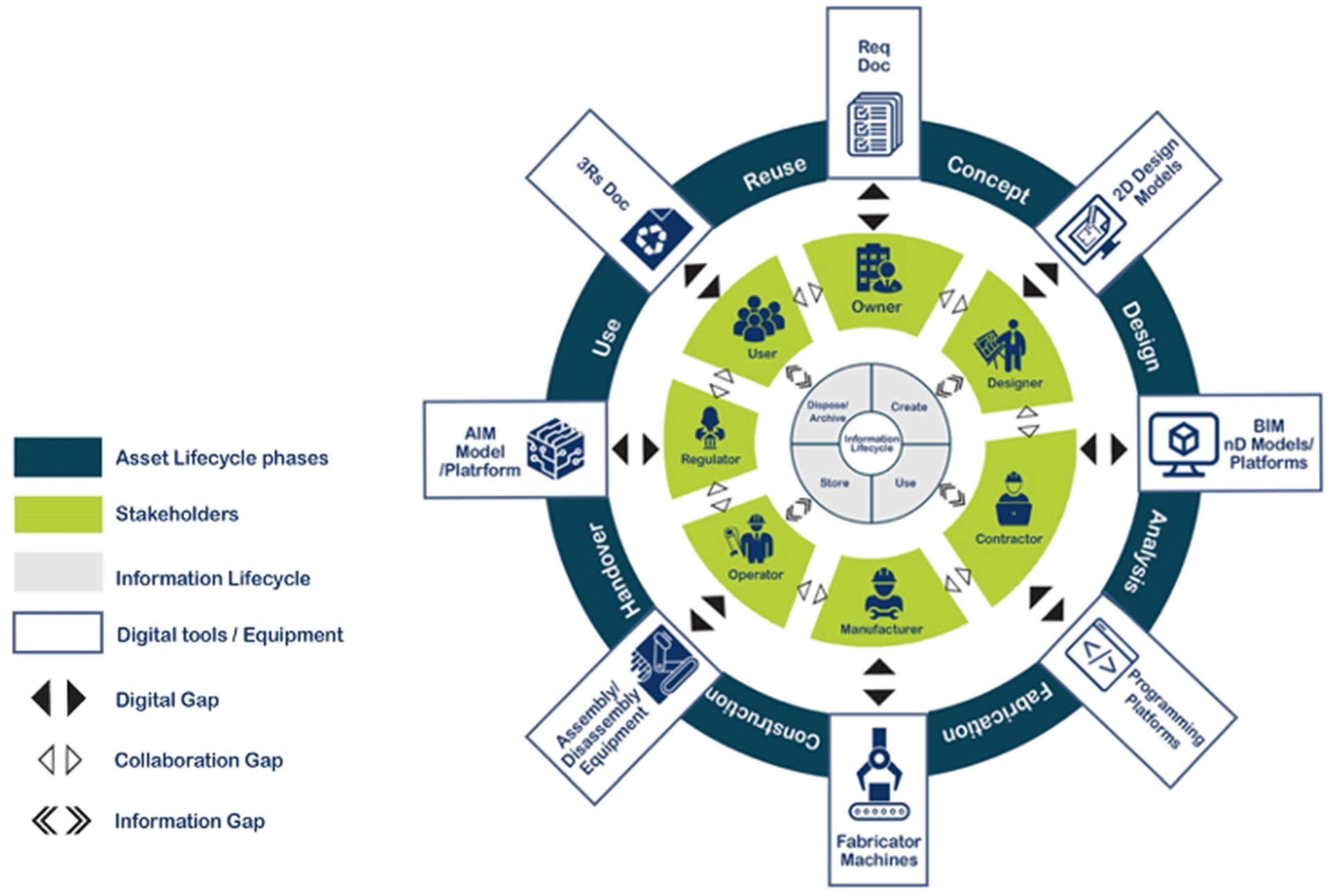

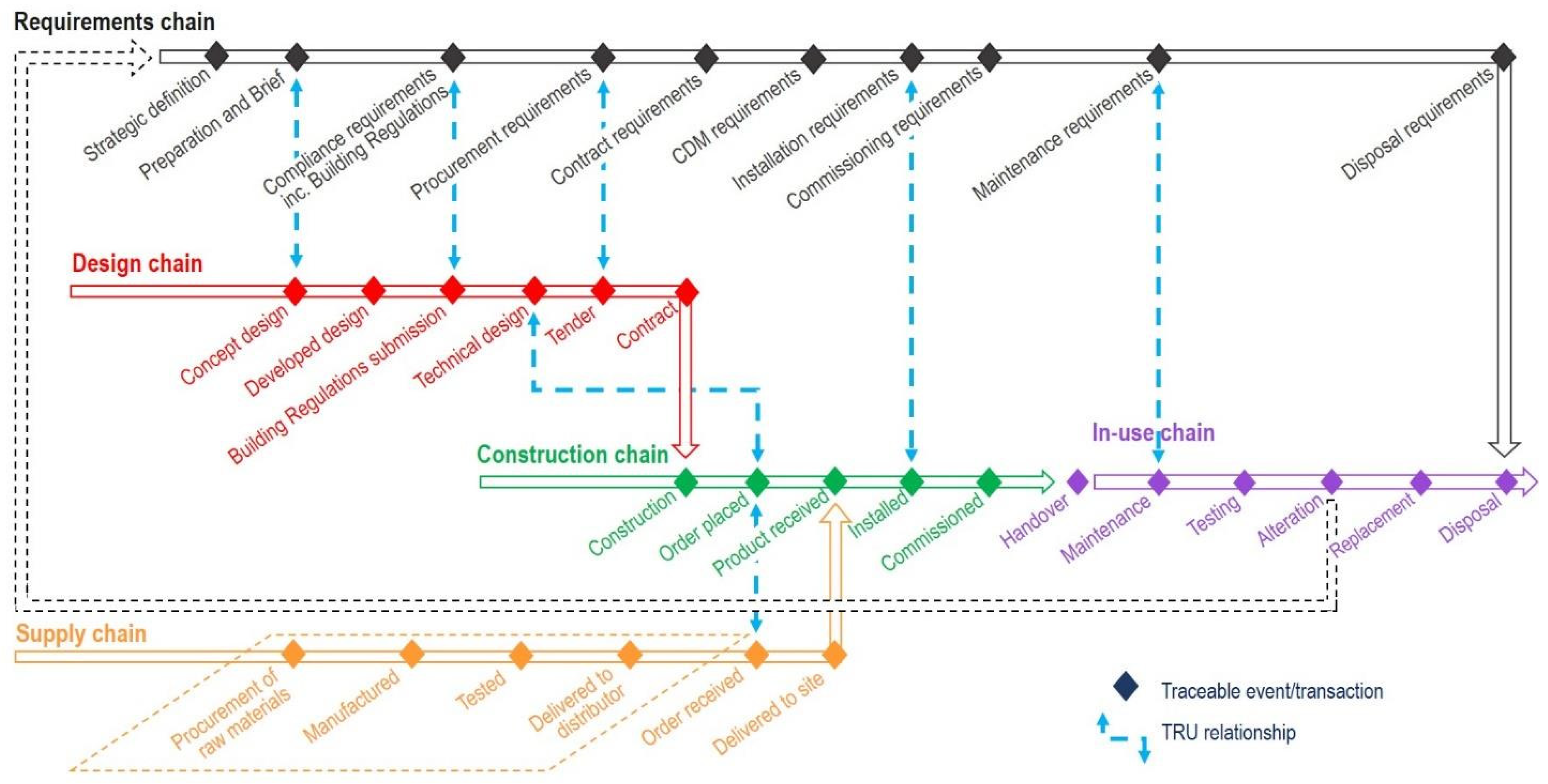

- When are we tracing: refers to the specific stages or chains of the asset’s lifecycle when traceability is necessary, as well as any time constraints or deadlines that may apply. For example, traceability may be necessary during the design and planning stage to ensure that the specified materials and components meet the required specifications and standards. It may also be necessary during the construction stage to ensure that the specified materials and components are actually installed in the building, and that they meet the required quality standards.

3.2. Developing the Traceability Framework

4. A Traceability Framework for the Built Asset Industry

4.1. Why: The Importance of the Sustainable Development

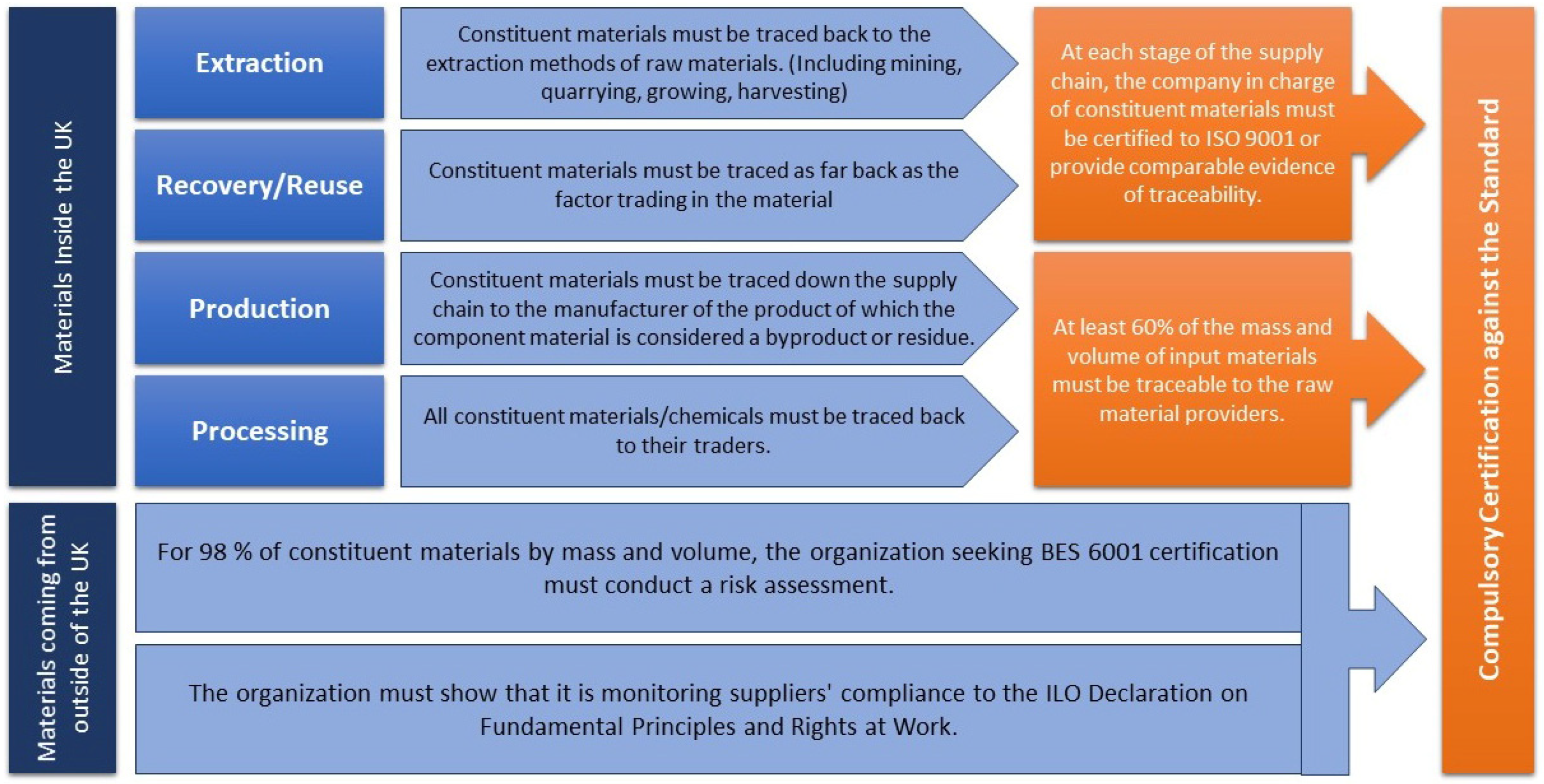

4.2. What: The Main Data Types Enabling Traceability

4.3. When: The Role of Traceability across Lifecycle Stages

4.4. Who: Effective Collaboration and Coordination

- Shared vision and objectives: develop a shared vision and set of objectives for the traceability project that align with the CE goals of all stakeholders involved [100].

- Communication and information sharing: foster open and effective communication channels and process knowledge management between stakeholders and share relevant information about the traceability project and its progress [98].

- Incentives and benefits: identify and communicate the incentives and benefits that arise from the successful implementation of traceability, such as improved efficiency, cost savings, and enhanced reputation for all project members [101].

- Continuous improvement and evaluation: continuously evaluate the traceability system and its impact on CE goals and use the feedback to improve the system and increase stakeholder buy-in [104].

4.5. How: Traceability Enablers and Drivers

5. Discussion

6. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Laski, J.; Burrows, V. From Thousands to Billions: Coordinated Action Towards 100% Net Zero Carbon Buildings by 2050. 2017. Available online: https://apo.org.au/node/118366 (accessed on 13 March 2023).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- MahmoumGonbadi, A.; Genovese, A.; Sgalambro, A. Closed-loop supply chain design for the transition towards a circular economy: A systematic literature review of methods, applications and current gaps. J. Clean. Prod. 2021, 323, 129101. [Google Scholar] [CrossRef]

- Grafström, J.; Aasma, S. Breaking circular economy barriers. J. Clean. Prod. 2021, 292, 126002. [Google Scholar] [CrossRef]

- Charef, R.; Ganjian, E.; Emmitt, S. Socio-economic and environmental barriers for a holistic asset lifecycle approach to achieve circular economy: A pattern-matching method. Technol. Forecast. Soc. Chang. 2021, 170, 120798. [Google Scholar] [CrossRef]

- Kumar, M.; Raut, R.D.; Jagtap, S.; Choubey, V.K. Circular economy adoption challenges in the food supply chain for sustainable development. Bus. Strateg. Environ. 2022, bse.3191. [Google Scholar] [CrossRef]

- Mousavi, A.; Sarhadi, M.; Lenk, A.; Fawcett, S. Tracking and traceability in the meat processing industry: A solution. Br. Food J. 2002, 104, 7–19. [Google Scholar] [CrossRef]

- Jaeger, B.; Upadhyay, A. Understanding barriers to circular economy: Cases from the manufacturing industry. J. Enterp. Inf. Manag. 2020, 33, 729–745. [Google Scholar] [CrossRef]

- Fischer, A.; Pascucci, S. Institutional incentives in circular economy transition: The case of material use in the Dutch textile industry. J. Clean. Prod. 2017, 155, 17–32. [Google Scholar] [CrossRef]

- Giovanardi, M.; Konstantinou, T.; Pollo, R.; Klein, T. Internet of Things for building façade traceability: A theoretical framework to enable circular economy through life-cycle information flows. J. Clean. Prod. 2023, 382, 135261. [Google Scholar] [CrossRef]

- Santana, S.; Ribeiro, A. Traceability Models and Traceability Systems to Accelerate the Transition to a Circular Economy: A Systematic Review. Sustainability 2022, 14, 5469. [Google Scholar] [CrossRef]

- Corallo, A.; Latino, M.E.; Menegoli, M.; Pontrandolfo, P. A systematic literature review to explore traceability and lifecycle relationship. Int. J. Prod. Res. 2020, 58, 4789–4807. [Google Scholar] [CrossRef]

- Katenbayeva, A.; Jacqui, G.; Anvuur, A.; Ghumra, S. Developing a Theoretical Framework of Traceability for Sustainability in the Construction Sector. 2017. Available online: https://hdl.handle.net/2134/23842 (accessed on 13 March 2023).

- Trautman, D.; Goddard, E.; Nilsson, T. Traceability—A Literature Review. Available online: https://era.library.ualberta.ca/items/921e1026-7e1a-4add-a631-5114d6a2171f (accessed on 13 March 2023).

- Garcia-Torres, S.; Albareda, L.; Rey-Garcia, M.; Seuring, S. Traceability for sustainability—Literature review and conceptual framework. Supply Chain Manag. Int. J. 2019, 24, 85–106. [Google Scholar] [CrossRef]

- Hackitt, D.J. Building a Safer Future. 2018. Available online: https://www.longworth-uk.com/wp-content/uploads/2018/07/Building-a-Safer-Future-Overview.pdf (accessed on 20 January 2023).

- Watson, R.; Kassem, M.; Li, J. Traceability for Built Assets: Proposed Framework for a Digital Record. In Proceedings of the Creative Construction Conference 2019, Budapest, Hungary, 29 June–2 July 2019; Budapest University of Technology and Economics: Budapest, Hungary, 2019; pp. 496–501. [Google Scholar]

- Voorter, J.; Koolen, C. The Traceability of Construction and Demolition Waste in Flanders via Blockchain Technology: A Match Made in Heaven? J. Eur. Environ. Plan. Law 2021, 18, 347–369. [Google Scholar] [CrossRef]

- Falleri, J.-R.; Huchard, M.; Nebut, C. Towards a traceability framework for model transformations in Kermeta. In ECMDA-TW’06: ECMDA Traceability Workshop; Sintef ICT: Trondheim, Norway, 2006. [Google Scholar]

- Verberne, J. Building Circularity Indicators: An Approach for Measuring Circularity of a Building; Eindhoven University of Technology: Eindhoven, The Netherlands, 2016. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.H.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Sohal, A.; De Vass, T. Australian SME’s experience in transitioning to circular economy. J. Bus. Res. 2022, 142, 594–604. [Google Scholar] [CrossRef]

- Dan, M.C.; Østergaard, T. Circular Fashion: The New Roles of Designers in Organizations Transitioning to a Circular Economy. Des. J. 2021, 24, 1001–1021. [Google Scholar] [CrossRef]

- Wuni, I.Y. Mapping the barriers to circular economy adoption in the construction industry: A systematic review, Pareto analysis, and mitigation strategy map. Build. Environ. 2022, 223, 109453. [Google Scholar] [CrossRef]

- Cantú, A.; Aguiñaga, E.; Scheel, C. Learning from Failure and Success: The Challenges for Circular Economy Implementation in SMEs in an Emerging Economy. Sustainability 2021, 13, 1529. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data- and stakeholder management framework for the implementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350. [Google Scholar] [CrossRef]

- Pitkänen, K.; Karppinen, T.K.M.; Kautto, P.; Pirtonen, H.; Salmenperä, H.; Savolahti, H.; Schubin, E.; Myllymaa, T. How to measure the social sustainability of the circular economy? Developing and piloting social circular economy indicators in Finland. J. Clean. Prod. 2023, 392, 136238. [Google Scholar] [CrossRef]

- Debacker, W.; Manshoven, S.; Denis, F. D1 Synthesis of the State-of-the-Art: Key Barriers and Opportunities for Materials Passports and Reversible Building Design in the Current System; BAMB Horizon. 2016. Available online: http://www.bamb2020.eu/wp-content/uploads/2016/03/D1_Synthesis-report-on-State-of-the-art_20161129_FINAL.pdf (accessed on 13 March 2023).

- Kedir, F.; Bucher, D.F.; Hall, D.M. A Proposed Material Passport Ontology to Enable Circularity for Industrialized Construction. In Proceedings of the EC3 Conference 2021, Online Events, 19–28 July 2021; pp. 91–98. [Google Scholar]

- Heinrich, M.; Lang, W. Materials Passports-Best Practice; Technische Universität München, Fakultät für Architektur: Munich, Germany, 2019; p. 74. [Google Scholar]

- Honic, M.; Kovacic, I.; Rechberger, H. Concept for a BIM-based Material Passport for buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012073. [Google Scholar] [CrossRef]

- Plociennik, C.; Pourjafarian, M.; Nazeri, A.; Windholz, W.; Knetsch, S.; Rickert, J.; Ciroth, A.; Precci Lopes, A.D.C.; Hagedorn, T.; Vogelgesang, M.; et al. Towards a Digital Lifecycle Passport for the Circular Economy. Procedia CIRP 2022, 105, 122–127. [Google Scholar] [CrossRef]

- Jensen, S.F.; Kristensen, J.H.; Adamsen, S.; Christensen, A.; Waehrens, B.V. Digital product passports for a circular economy: Data needs for product life cycle decision-making. Sustain. Prod. Consum. 2023, 37, 242–255. [Google Scholar] [CrossRef]

- Hoosain, M.S.; Paul, B.S.; Raza, S.M.; Ramakrishna, S. Material Passports and Circular Economy. In An Introduction to Circular Economy; Liu, L., Ramakrishna, S., Eds.; Springer: Singapore, 2021; pp. 131–158. ISBN 9789811585098. [Google Scholar]

- Holla, A. External Supervisor: Monique Fledderman; VMRG: Nieuwegein, The Netherlands, 2017; p. 180. [Google Scholar]

- 3XN Architects. Buidling a Circular Future, 3rd ed.; 3XN Architects: Copenhagen, Denmark, 2018. [Google Scholar]

- Druijff, B. BIM-Based Material Passport in Madaster during the Operational and Maintenance Phase of a Building. Bachelor’s Thesis, University of Twente, Enschede, The Netherlands, 2019. [Google Scholar]

- Kintscher, L.; Lawrenz, S.; Poschmann, H. A Life Cycle Oriented Data-Driven Architecture for an Advanced Circular Economy. Procedia CIRP 2021, 98, 318–323. [Google Scholar] [CrossRef]

- Lawrenz, S.; Nippraschk, M.; Wallat, P.; Rausch, A.; Goldmann, D.; Lohrengel, A. Is it all about Information? The Role of the Information Gap between Stakeholders in the Context of the Circular Economy. Procedia CIRP 2021, 98, 364–369. [Google Scholar] [CrossRef]

- Saaksvuori, A.; Immonen, A. Product Lifecycle Management; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-78173-8. [Google Scholar]

- European Environment Agency. Circular Economy in Europe: Developing the Knowledge Base; European Environment Agency: Copenhagen, Denmark, 2016. [Google Scholar]

- de Lange, P.; Bähre, B.; Finetti-Imhof, C.; Klamma, R.; Oppermann, L. Socio-Technical Challenges in the Digital Gap between Building Information Modeling and Industry 4.0. In Proceedings of the STPIS@CAiSE, Essen, Germany, 13 June 2017; pp. 33–46. [Google Scholar]

- Poirier, E.; Forgues, D.; Staub-French, S. Collaboration through innovation: Implications for expertise in the AEC sector. Constr. Manag. Econ. 2016, 34, 769–789. [Google Scholar] [CrossRef]

- Gotel, O.C.Z.; Finkelstein, C.W. An analysis of the requirements traceability problem. In Proceedings of the IEEE International Conference on Requirements Engineering, Colorado Springs, CO, USA, 18–22 April 1994; IEEE Computer Society Press: Colorado Springs, CO, USA, 1994; pp. 94–101. [Google Scholar]

- Wang, K.-S. Intelligent and integrated RFID (II-RFID) system for improving traceability in manufacturing. Adv. Manuf. 2014, 2, 106–120. [Google Scholar] [CrossRef]

- Kamara, J.M.; Anumba, C.J.; Evbuomwan, N.F.O. Establishing and processing client requirements—A key aspect of concurrent engineering in construction. Eng. Constr. Archit. Manag. 2000, 7, 15–28. [Google Scholar] [CrossRef]

- Brandín, R.; Abrishami, S. Information traceability platforms for asset data lifecycle: Blockchain-based technologies. Smart Sustain. Built Environ. 2021, 10, 364–386. [Google Scholar] [CrossRef]

- Riexinger, G.; Doppler, J.P.; Haar, C.; Trierweiler, M.; Buss, A.; Schöbel, K.; Ensling, D.; Bauernhansl, T. Integration of Traceability Systems in Battery Production. Procedia CIRP 2020, 93, 125–130. [Google Scholar] [CrossRef]

- Mora-Cantallops, M.; Sánchez-Alonso, S.; García-Barriocanal, E.; Sicilia, M.-A. Traceability for Trustworthy AI: A Review of Models and Tools. Big Data Cogn. Comput. 2021, 5, 20. [Google Scholar] [CrossRef]

- Pinheiro, C. Requirements traceability. Perspect. Softw. Requir. 2004, 91–113. [Google Scholar] [CrossRef]

- Folinas, D.; Manikas, I.; Manos, B. Traceability data management for food chains. Br. Food J. 2006, 108, 622–633. [Google Scholar] [CrossRef]

- Zhou, W.; Piramuthu, S. IoT and Supply Chain Traceability. In Future Network Systems and Security; Doss, R., Piramuthu, S., Zhou, W., Eds.; Communications in Computer and Information Science; Springer International Publishing: Cham, Switzerland, 2015; Volume 523, pp. 156–165. ISBN 978-3-319-19209-3. [Google Scholar]

- Bougdira, A.; Akharraz, I.; Ahaitouf, A. A traceability proposal for industry 4.0. J. Ambient Intell. Humaniz. Comput. 2020, 11, 3355–3369. [Google Scholar] [CrossRef]

- Jansen-Vullers, M.H.; van Dorp, C.A.; Beulens, A.J.M. Managing traceability information in manufacture. Int. J. Inf. Manag. 2003, 23, 395–413. [Google Scholar] [CrossRef]

- Li, X.; Lv, F.; Xiang, F.; Sun, Z.; Sun, Z. Research on Key Technologies of Logistics Information Traceability Model Based on Consortium Chain. IEEE Access 2020, 8, 69754–69762. [Google Scholar] [CrossRef]

- Aiello, G.; Enea, M.; Muriana, C. The Expected Value of the Traceability Information. Eur. J. Oper. Res. 2015, 244, 176–186. [Google Scholar] [CrossRef]

- Mader, P.; Gotel, O.; Philippow, I. Getting back to basics: Promoting the use of a traceability information model in practice. In Proceedings of the 2009 ICSE Workshop on Traceability in Emerging Forms of Software Engineering, Vancouver, BC, Canada, 18 May 2009; IEEE: Vancouver, BC, Canada, 2009; pp. 21–25. [Google Scholar]

- Dalvit, C.; De Marchi, M.; Cassandro, M. Genetic traceability of livestock products: A review. Meat Sci. 2007, 77, 437–449. [Google Scholar] [CrossRef]

- Dalvit, C.; De Marchi, M.; Targhetta, C.; Gervaso, M.; Cassandro, M. Genetic Traceability of Meat Using Microsatellite Markers. Food Res. Int. 2008, 41, 301–307. [Google Scholar] [CrossRef]

- Bonizzi, I.; Feligini, M.; Aleandri, R.; Enne, G. Genetic traceability of the geographical origin of typical Italian water buffalo Mozzarella cheese: A preliminary approach. J. Appl. Microbiol. 2007, 102, 667–673. [Google Scholar] [CrossRef] [PubMed]

- Lago, P.; Muccini, H.; van Vliet, H. A scoped approach to traceability management. J. Syst. Softw. 2009, 82, 168–182. [Google Scholar] [CrossRef]

- Cleland-Huang, J.; Gotel, O.C.Z.; Huffman Hayes, J.; Mäder, P.; Zisman, A. Software traceability: Trends and future directions. In Proceedings of the Future of Software Engineering Proceedings, Hyderabad, India, 31 May–7 June 2014; ACM: Hyderabad, India, 2014; pp. 55–69. [Google Scholar]

- Cleland-Huang, J.; Chang, C.K.; Christensen, M. Event-based traceability for managing evolutionary change. IEEE Trans. Softw. Eng. 2003, 29, 796–810. [Google Scholar] [CrossRef]

- Cleland-Huang, J.; Chang, C.K.; Ge, Y. Supporting Event Based Traceability through High-Level Recognition of Change Events. In Proceedings of the 26th Annual International Computer Software and Applications, Oxford, UK, 26–29 August 2002; IEEE Computer Society: Oxford, UK, 2002; pp. 595–600. [Google Scholar]

- Cleland-Huang, J.; Chang, C.K.; Sethi, G.; Javvaji, K.; Haijian, H.; Jinchun, X. Automating speculative queries through event-based requirements traceability. In Proceedings of the IEEE Joint International Conference on Requirements Engineering, Essen, Germany, 9–13 September 2002; IEEE Computer Society: Essen, Germany, 2002; pp. 289–296. [Google Scholar]

- Pauzi, Z.; Capiluppi, A. Applications of natural language processing in software traceability: A systematic mapping study. J. Syst. Softw. 2023, 198, 111616. [Google Scholar] [CrossRef]

- Cleland-Huang, J.; Marrero, W.; Berenbach, B. Goal-Centric Traceability: Using Virtual Plumblines to Maintain Critical Systemic Qualities. IEEE Trans. Softw. Eng. 2008, 34, 685–699. [Google Scholar] [CrossRef]

- Islam, S.; Manning, L.; Cullen, J.M. A Hybrid Traceability Technology Selection Approach for Sustainable Food Supply Chains. Sustainability 2021, 13, 9385. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.-M.; Zhang, Y.-J. Agricultural Product Quality Traceability System Based on the Hybrid Mode. In Proceedings of the 2018 4th Annual International Conference on Network and Information Systems for Computers (ICNISC), Wuhan, China, 19–21 April 2018; IEEE: Wuhan, China, 2018; pp. 392–395. [Google Scholar]

- Wang, S.; Li, T.; Yang, Z. Exploring Semantics of Software Artifacts to Improve Requirements Traceability Recovery: A Hybrid Approach. In Proceedings of the 2019 26th Asia-Pacific Software Engineering Conference (APSEC), Putrajaya, Malaysia, 2–5 December 2019; IEEE: Putrajaya, Malaysia, 2019; pp. 39–46. [Google Scholar]

- de Lusignan, S.; Liaw, S.-T.; Krause, P.; Curcin, V.; Vicente, M.; Michalakidis, G.; Agreus, L.; Leysen, P.; Shaw, N.; Mendis, K. Key Concepts to Assess the Readiness of Data for International Research: Data Quality, Lineage and Provenance, Extraction and Processing Errors, Traceability, and Curation: Contribution of the IMIA Primary Health Care Informatics Working Group. Yearb. Med. Inform. 2011, 20, 112–120. [Google Scholar] [CrossRef]

- Pearson, S.; May, D.; Leontidis, G.; Swainson, M.; Brewer, S.; Bidaut, L.; Frey, J.G.; Parr, G.; Maull, R.; Zisman, A. Are Distributed Ledger Technologies the panacea for food traceability? Glob. Food Secur. 2019, 20, 145–149. [Google Scholar] [CrossRef]

- Moe, T. Perspectives on Traceability in Food Manufacture. Trends Food Sci. Technol. 1998, 9, 211–214. [Google Scholar] [CrossRef]

- Senneset, G.; Forås, E.; Fremme, K.M. Challenges regarding implementation of electronic chain traceability. Br. Food J. 2007, 109, 805–818. [Google Scholar] [CrossRef]

- Anastasiadis, F. Designing a Traceability Framework for Sustainable Agri-Food Supply Chains. In Food Policy Modelling; Mattas, K., Baourakis, G., Zopounidis, C., Staboulis, C., Eds.; Cooperative Management; Springer International Publishing: Cham, Switzerland, 2022; pp. 73–82. ISBN 978-3-031-08316-7. [Google Scholar]

- Glass, J.; Achour, N.; Parry, T.; Nicholson, I. Engaging small firms in sustainable supply chains: Responsible sourcing practices in the UK construction industry. Int. J. Agile Syst. Manag. 2012, 5, 29. [Google Scholar] [CrossRef]

- Wohlrab, R.; Steghofer, J.-P.; Knauss, E.; Maro, S.; Anjorin, A. Collaborative Traceability Management: Challenges and Opportunities. In Proceedings of the 2016 IEEE 24th International Requirements Engineering Conference (RE), Beijing, China, 12–16 September 2016; IEEE: Beijing, China, 2016; pp. 216–225. [Google Scholar]

- Ramesh, B.; Jarke, M. Toward reference models for requirements traceability. IEEE Trans. Softw. Eng. 2001, 27, 58–93. [Google Scholar] [CrossRef]

- Ouertani, M.Z.; Baïna, S.; Gzara, L.; Morel, G. Traceability and management of dispersed product knowledge during design and manufacturing. Comput.-Aided Des. 2011, 43, 546–562. [Google Scholar] [CrossRef]

- BRE Global Ltd. BES 6001: ISSUE 3.0; Framework Standard for Responsible Sourcing; BREGroup: Watford, UK, 2014. [Google Scholar]

- Norton, T.; Beier, J.; Shields, L. A Guide to Traceability. 2014. Available online: https://bregroup.com/services/standards/bes-6001-the-framework-standard-for-responsible-sourcing/ (accessed on 25 March 2023).

- Beliatis, M.J.; Jensen, K.; Ellegaard, L.; Aagaard, A.; Presser, M. Next Generation Industrial IoT Digitalization for Traceability in Metal Manufacturing Industry: A Case Study of Industry 4.0. Electronics 2021, 10, 628. [Google Scholar] [CrossRef]

- EU. EEA Regulation (EU) No 305/2011 of the European Parliament and of the Council. EUR-Lex; 2011. Available online: https://www.legislation.gov.uk/eur/2011/305/contents (accessed on 20 March 2023).

- Wright, B. Compilation of Various Questions and Answers about EPA Traceability Protocol for Gaseous Calibration Standards. 2020. Available online: https://www.epa.gov/sites/default/files/2020-04/documents/questions_answers_protocol_200331.pdf. (accessed on 20 March 2023).

- Sarsam, S.I. Sustainable and Green Roadway Rating System. Int. J. Sci. Res. Environ. Sci. 2015, 3, 99–106. [Google Scholar] [CrossRef]

- Pang, T.Y.; Pelaez Restrepo, J.D.; Cheng, C.-T.; Yasin, A.; Lim, H.; Miletic, M. Developing a Digital Twin and Digital Thread Framework for an ‘Industry 4.0′ Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Li, J.; Kassem, M.; Watson, R. A Blockchain and Smart Contract-Based Framework to Inrease Traceability of Built Assets. In Proceedings of the 37th CIB W78 Information Technology for Construction Conference (CIB W78), São Paulo, Brazil, 2–4 June 2020; pp. 347–362. [Google Scholar]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Toriello, M. Creating the Digital Thread. INSIGHT 2022, 25, 34–37. [Google Scholar] [CrossRef]

- Wang, J.; Chi, H.-L.; Shou, W.; Chong, H.-Y.; Wang, X. A Coordinated Approach for Supply-Chain Tracking in the Liquefied Natural Gas Industry. Sustainability 2018, 10, 4822. [Google Scholar] [CrossRef]

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and locating components in a precast storage yard utilizing radio frequency identification technology and GPS. Autom. Constr. 2007, 16, 354–367. [Google Scholar] [CrossRef]

- Durmiševic’, E. Reversible building design. In Designing for the Circular Economy; Charter, M., Ed.; Routledge: Abingdon, UK; New York, NY, USA, 2018; pp. 344–359. ISBN 978-1-315-11306-7. [Google Scholar]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Succar, B.; Poirier, E. Lifecycle information transformation and exchange for delivering and managing digital and physical assets. Autom. Constr. 2020, 112, 103090. [Google Scholar] [CrossRef]

- Succar, B. Information Milestone. Available online: https://bimdictionary.com/en/information-milestone/1 (accessed on 20 March 2023).

- Wohlrab, R.; Knauss, E.; Steghöfer, J.-P.; Maro, S.; Anjorin, A.; Pelliccione, P. Collaborative traceability management: A multiple case study from the perspectives of organization, process, and culture. Requir. Eng. 2020, 25, 21–45. [Google Scholar] [CrossRef]

- Ramesh, B. Process Knowledge Management with Traceability. IEEE Softw. 2002, 19, 50–52. [Google Scholar] [CrossRef]

- Bozoglu, J. Collaboration and coordination learning modules for bim education. J. Inf. Technol. Constr. 2016, 21, 152–163. [Google Scholar]

- Gotel, O.; Cleland-Huang, J.; Hayes, J.H.; Zisman, A.; Egyed, A.; Grunbacher, P.; Antoniol, G. The quest for Ubiquity: A roadmap for software and systems traceability research. In Proceedings of the 2012 20th IEEE International Requirements Engineering Conference (RE), Chicago, IL, USA, 24–28 September 2012; IEEE: Chicago, IL, USA, 2012; pp. 71–80. [Google Scholar]

- Liu, H. Combating unethical producer behavior: The value of traceability in produce supply chains. Int. J. Prod. Econ. 2022, 244, 108374. [Google Scholar] [CrossRef]

- Mejías, A.M.; Bellas, R.; Pardo, J.E.; Paz, E. Traceability management systems and capacity building as new approaches for improving sustainability in the fashion multi-tier supply chain. Int. J. Prod. Econ. 2019, 217, 143–158. [Google Scholar] [CrossRef]

- Rival, A.; Montet, D.; Pioch, D. Certification, labelling and traceability of palm oil: Can we build confidence from trustworthy standards? OCL 2016, 23, D609. [Google Scholar] [CrossRef]

- Dömges, R.; Pohl, K. Adapting traceability environments to project-specific needs. Commun. ACM 1998, 41, 54–62. [Google Scholar] [CrossRef]

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital Product Passports as Enabler of the Circular Economy. Chem. Ing. Tech. 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Alani, Y.; Dawood, N.; Patacas, J.; Rodriguez, S.; Dawood, H. A semantic common model for product data in the water industry. J. Inf. Technol. Constr. 2021, 26, 566–590. [Google Scholar] [CrossRef]

- Lucky, M.N.; Pasini, D.; Spagnolo, S.L. Product Data Management for Sustainability: An Interoperable Approach for Sharing Product Data in a BIM Environment. IOP Conf. Ser. Earth Environ. Sci. 2019, 296, 012053. [Google Scholar] [CrossRef]

- Eadie, R.; Browne, M.; Odeyinka, H.; McKeown, C.; McNiff, S. BIM implementation throughout the UK construction project lifecycle: An analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Jiang, S.; Jiang, L.; Han, Y.; Wu, Z.; Wang, N. OpenBIM: An Enabling Solution for Information Interoperability. Appl. Sci. 2019, 9, 5358. [Google Scholar] [CrossRef]

- Shafiq, M.T.; Matthews, J.; Lockley, S.R. A study of BIM collaboration requirements and available features in existing model collaboration systems. J. Inf. Technol. Constr. 2013, 18, 148–161. [Google Scholar]

- Kwon, S.; Monnier, L.V.; Barbau, R.; Bernstein, W.Z. Enriching standards-based digital thread by fusing as-designed and as-inspected data using knowledge graphs. Adv. Eng. Inform. 2020, 46, 101102. [Google Scholar] [CrossRef]

- Singh, V.; Willcox, K.E. Engineering Design with Digital Thread. AIAA J. 2018, 56, 4515–4528. [Google Scholar] [CrossRef]

- David, J.; Jarvenpaa, E.; Lobov, A. Digital Threads via Knowledge-Based Engineering Systems. In Proceedings of the 2021 30th Conference of Open Innovations Association FRUCT, Oulu, Finland, 27–29 October 2021; IEEE: Oulu, Finland, 2021; pp. 42–51. [Google Scholar]

- O’Grady, T.M.; Brajkovich, N.; Minunno, R.; Chong, H.-Y.; Morrison, G.M. Circular Economy and Virtual Reality in Advanced BIM-Based Prefabricated Construction. Energies 2021, 14, 4065. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- Zahrizan, Z.; Ali, N.M.; Haron, A.T.; Marshall-Ponting, A.; Hamid, Z.A. Exploring the adoption of building information modelling (BIM) in the malaysian construction industry: A qualitative approach. Int. J. Res. Eng. Technol. 2013, 2, 384–395. [Google Scholar] [CrossRef]

| Ref | Definition | Context | Year |

|---|---|---|---|

| [46] | “The ability to trace the history, application, or location of an entity by means of recorded identifications”. | ISO8402 | 1994 |

| [41] | “The ability to access any or all information relating to that which is under consideration, throughout its e tire lifecycle, by means of recorded identifications”. | Food industry | 2018 |

| [47] | “Client requirements have to be presented in a manner that will facilitate: (…) [t]he traceability of design decisions to original requirements throughout the life cycle of the facility”. | AEC 1 | 2000 |

| [48] | “Traceability involves knowing where the product or raw material comes from, real-time location throughout the supply chain, and its conditions regarding pre-set quality at each stage of the roadmap”. | AEC | 2021 |

| [13] | “The ability to follow information related to a product through its supply chain” (p. 3) providing a number of uses: quality and safety, minimizing scandals that damage company reputations, improved supply chains, and enhancing trust”. | AEC | 2017 |

| Model | Description | Ref |

|---|---|---|

| Physical traceability | This model is focused on tracking and tracing physical products, such as food and manufacturing products, through the supply chain. | [52,53,54] |

| Information traceability | This model is focused on tracking and tracing the flow of information, such as data and records, within the supply chain. | [55,56,57,58] |

| Genetic traceability | This model is focused on tracking and tracing the genetic makeup of biological products, such as seeds, livestock, and crops. | [59,60,61] |

| Process traceability | This model is focused on tracking and tracing the processes and steps involved in the production of products, such as manufacturing processes and quality control procedures. | [62,63] |

| Event traceability | This model is focused on tracking and tracing specific events or activities, such as deliveries, shipments, and product recalls. | [64,65,66] |

| Systemic traceability | This model is focused on tracking and tracing the interactions and relationships between different elements within the supply chain, such as suppliers, manufacturers, distributors, and consumers. | [67,68] |

| Hybrid traceability | This model combines elements of different traceability models to provide a comprehensive and integrated traceability system. | [69,70,71] |

| Participant ID | Professional Background | Interest | Educational Level |

|---|---|---|---|

| 1 | Project manager | Environmental management—sustainable development. | Master’s |

| 2 | Project consultant | Construction materials—sustainable development—energy efficiency. | Diploma |

| 3 | Senior director and consultant | Technology research (chemistry and materials) and sustainable innovation. | Ph.D. |

| 4 | Professor | Construction materials—lifecycle assessment. | Ph.D. |

| 5 | Project director | Traceability systems for contaminated soils. | Bachelor’s |

| 6 | Marketing director | Traceability and transparency along the supply chain—traceability solutions for natural resources and environment. | Bachelor’s |

| 7 | Engineer | Evaluation of carbon reduction and circular economy strategies—life cycle assessment and circularity concepts. | Bachelor’s |

| 8 | Project consultant | CRD waste management—sustainable development | Master’s |

| 9 | Construction consultant | Sustainability metrics—sustainable business development | Master’s |

| 10 | BIM specialist | BIM—information requirement management research/improvement initiatives | Master’s |

| 11 | Architectural designer | BIM management—raw and residual materials—traceability solutions | Diploma |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Davari, S.; Jaberi, M.; Yousfi, A.; Poirier, E. A Traceability Framework to Enable Circularity in the Built Environment. Sustainability 2023, 15, 8278. https://doi.org/10.3390/su15108278

Davari S, Jaberi M, Yousfi A, Poirier E. A Traceability Framework to Enable Circularity in the Built Environment. Sustainability. 2023; 15(10):8278. https://doi.org/10.3390/su15108278

Chicago/Turabian StyleDavari, Saman, Meisam Jaberi, Adam Yousfi, and Erik Poirier. 2023. "A Traceability Framework to Enable Circularity in the Built Environment" Sustainability 15, no. 10: 8278. https://doi.org/10.3390/su15108278

APA StyleDavari, S., Jaberi, M., Yousfi, A., & Poirier, E. (2023). A Traceability Framework to Enable Circularity in the Built Environment. Sustainability, 15(10), 8278. https://doi.org/10.3390/su15108278