Analysis of Noise Levels in Typical Passenger Cars

Abstract

1. Introduction

2. Materials and Methods

- Model—X3 G01, standard version;

- Type of fuel—diesel;

- Engine power—125 kW;

- Displacement—1995 dm3;

- Engine fueling mode—normal;

- SUV.

- The vehicle could not be loaded during the test;

- During the test, the vehicle should be disconnected from trailers (semi-trailers); this does not apply to inseparable vehicles;

- Before the test, the vehicle’s engine was brought to its normal operating temperature.

- If the vehicle’s cooling system was equipped with an automatically actuated blower, the system would operate normally during measurement;

- If the diesel engine of the vehicle was equipped with a fuel enrichment system, the lever of this system would be set to the “no load” position;

- The test vehicle was to be placed in the middle of the test area with the drive system in neutral position and the clutch and parking brake engaged.

- Measurement A—measurement of the noise level from the exhaust system at idle speed;

- Measurement AA—measurement of the noise level from the exhaust system at maximum engine revolutions (75% of rotational speed);

- Measurement B—measurement of the noise level at the front of the vehicle at idle speed;

- Measurement BB—measurement of the noise level at the front of the vehicle at maximum engine speed;

- Measurement C—measurement of the noise level above the engine compartment at idle speed;

- Measurement CC—measurement of the noise level above the engine compartment at maximum engine speed;

- Measurement D—measurement of the noise level inside the vehicle at idle speed;

- Measurement DD—measurement of the noise level inside the vehicle at maximum engine speed;

- Measurement E—measurement of the noise level 200 mm away from the vehicle at idle speed;

- Measurement EE—measurement of the noise level 200 mm away from the vehicle at maximum engine speed;

- Measurement F—measurement of noise level 4000 mm away from the vehicle at idle speed;

- Measurement FF—noise level measurement 4000 mm away from the vehicle at maximum engine speed.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krishnamurthy, N.; Hansen, J.H.L. Car noise verification and application. Int. J. Speech Technol. 2014, 17, 167–181. [Google Scholar] [CrossRef]

- Council Directive 70/157/EEC of 6 February 1970 on the Approximation of the Laws of the Member States Relating to the Permissible Sound Level and the Exhaust System of Motor Vehicles. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A31970L0157 (accessed on 1 February 2023).

- Directive 97/24/EC of the European Parliament and of the Council of 17 June 1997 on Certain Components and Characteristics of Two or Three-Wheel Motor Vehicles. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A31997L0024 (accessed on 1 February 2023).

- Regulation (EU) No 540/2014 of the European Parliament and of the Council of 16 April 2014 on the Sound Level of Motor Vehicles and of Replacement Silencing Systems and Amending Directive 2007/46/EC and Repealing Directive 70/157/EEC Text with EEA Relevance. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32014R0540 (accessed on 27 March 2023).

- Directive 2001/43/EC of the European Parliament and of the Council of 27 June 2001 Amending Council Directive 92/23/EEC Relating to Tires for Motor Vehicles and Their Trailers and Their Fitting. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A32001L0043 (accessed on 1 February 2023).

- Regulation (EU) 2020/740 of the European Parliament and of the Council of 25 May 2020 on the Labelling of Tyres with Respect to Fuel Efficiency and Other Parameters Amending Regulation (EU) 2017/1369 and Repealing Regulation (EC) No 1222/2009. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32020R0740 (accessed on 1 February 2023).

- Environmental Protection Act. 21 April 2001 (Journal of Laws 2020 Pos. 1219). Available online: https://leap.unep.org/countries/pl/national-legislation/environment-protection-act (accessed on 1 February 2023).

- Ordinance of the Minister of the Environment of 15 October 2013 on the Permissible Noise Levels in the Environment (Journal Laws 2014 Item 112). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20140000112 (accessed on 1 May 2023). (In Polish)

- Sitepu, H.M.; Rahim, M.A.; Sembiring, M.T. Used tires recycle management and processing: A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 801, 012116. [Google Scholar] [CrossRef]

- Przydatek, G.; Budzik, G.; Janik, M. Effectiveness of selected issues related to used tyre management in Poland. Environ. Sci. Pollut. 2022, 29, 31467–31475. [Google Scholar] [CrossRef]

- Chen, H.; Samarasinghe, P.; Abhayapala, T.D. In car noise field analysis and multi-zone noise cancellation quality estimation. In Proceedings of the 2015 Asia-Pacific Signal and Information Processing Association Annual Summit and Conference (APSIPA), Hong Kong, China, 16–19 December 2015; pp. 773–778. [Google Scholar]

- Li, T.; Wang, M.; He, Y.; Wang, N.; Yang, J.; Ding, R.; Zhao, K. Vehicle engine noise cancellation based on a multi-channel fractional-order active noise control algorithm. Machines 2022, 10, 670. [Google Scholar] [CrossRef]

- Camacho, A.; Pinero, G.; De Diego, M.; Gonzalez, A. Exploring roughness perception in car engine noises through complex cepstrum analysis. Acta Acust. 2008, 94, 130–140. [Google Scholar] [CrossRef]

- Meyer, R.; Benetto, E.; Igos, E.; Lavandier, C. Analysis of the different techniques to include noise damage in life cycle assessment. A case study for car tires. Int. J. Life Cycle Assess. 2017, 22, 744–757. [Google Scholar] [CrossRef]

- Cheer, J. Active sound control in the automotive interior. In Future Interior Concepts; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, S.K. Prediction of structure-borne noise caused by the powertrain on the basis of the hybrid transfer path. Proc. Inst. Mech. Eng. Part. D J. Autom. Eng. 2009, 23, 485–502. [Google Scholar] [CrossRef]

- Fritschi, L.; Brown, L.; Kim, R.; Schwela, D.; Kephalopolous, S. Burden of Disease from Environmental Noise: Quantification of Healthy Years Life Lost in Europe; World Health Organisation: Geneva, Switzerland, 2011; ISBN 9789289002295. [Google Scholar]

- Wellmann, T.; Govindswamy, K.; Tomazic, D. Impact of the Future Fuel Economy Targets on Powertrain, Driveline and Vehicle NVH Development. SAE Int. J. Veh. Dyn. Stab. NVH 2017, 1, 428–438. [Google Scholar] [CrossRef]

- Qin, Y.; Tang, X.; Jia, T.; Duan, Z.; Zhang, J.; Li, Y.; Zheng, L. Noise and vibration suppression in hybrid electric vehicles: State of the art and challenges. Renew. Sustain. Energy Rev. 2020, 124, 109782. [Google Scholar] [CrossRef]

- Judd, S.L.; Overbye, T.J. An evaluation of PHEV contributions to power system disturbances and economics. In Proceedings of the 2008 40th North American Power Symposium, Calgary, AB, Canada, 28–30 September 2008. [Google Scholar]

- Taymaz, I.; Benli, M. Emissions and fuel economy for a hybrid vehicle. Fuel 2014, 115, 812–817. [Google Scholar] [CrossRef]

- Ibarra, D.; Ramírez-Mendoza, R.; López, E. Noise emission from alternative fuel vehicles: Study case. Appl. Acoust. 2017, 118, 58–65. [Google Scholar] [CrossRef]

- Directive 2002/49/EC of the European Parliament and of the Council of 25 June 2002 Relating to the Assessment and Management of Environmental Noise. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32002L0049&from=EN (accessed on 27 March 2023).

- EN IEC 60942:2018-0 Electroacoustics—Acoustic Calibrators. Available online: https://standards.iteh.ai/catalog/standards/clc/bf76110c-d49e-497a-a87a-b48bcfbd2cba/en-iec-60942-2018 (accessed on 30 April 2023).

- Regulation of the Minister of Infrastructure of 10 February 2006 on Detailed Requirements for Stations Conducting Technical Inspections of Vehicles (Journal of Laws of 2006, No. 40, Item 275). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20060400275/O/D20060275.pdf (accessed on 28 February 2023). (In Polish)

- Ferrari, C.L.; Cheer, J.; Mautone, M. Investigation of an engine order noise cancellation system in a super sports car. Acta Acust. 2023, 7, 1. [Google Scholar] [CrossRef]

- Regulation of the Minister of Infrastructure of 31 December 2002 on the Technical Conditions of Vehicles and the Scope of Their Correct Standard (Journal of Laws of 2003, No. 32, Item 262). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20030320262 (accessed on 1 February 2023). (In Polish)

- Miloradović, D.; Glišović, J.; Lukić, J. Regulations on Road Vehicle Noise–Trends and Future Activities. Mobil. Veh. Mech. 2017, 43, 57–72. [Google Scholar] [CrossRef]

- Wróbel, A.; Łazarz, B.; Czech, P.; Matyja, T.; Witaszek, M. Effect of selected operating conditions on passenger car noise (Wpływ wybranych warunków eksploatacyjnych na hałas samochodów osobowych). Tech. Transp. Szyn. 2015, 22, 1696–1702. [Google Scholar]

- Chiatti, G.; Chiavola, O.; Palmieri, F. Vibration and acoustic characteristics of a city-car engine fueled with biodiesel blends. Appl. Energy 2017, 185, 664–670. [Google Scholar] [CrossRef]

- Lee, Y.; Nasiri, A. Real Time Active Noise Control of Engine Booming in Passenger Vehicles; SAE Technical Paper; 2007-01-0411; SAE: Warrendale, PA, USA, 2007; 2007-01-0411. [Google Scholar]

- Ambroszko, W. Sources of noise in automotive vehicles. Studies of noise in road traffic in a selected locality and assessment of its impact on safety (Źródła hałasu w pojazdach samochodowych. Badania hałasu w ruchu drogowym w wybranej miejscowości i ocena jego wpływu na bezpieczeństwo). AUTOBUSY—Tech. Eksploat. Syst. Transp. 2019, 24, 120–127. (In Polish) [Google Scholar]

- Samarasinghe, P.N.; Zhang, W.; Abhayapala, T.D. Recent Advances in active noise control inside automobile cabins: Toward quieter cars. IEEE Signal. Process. Mag. 2016, 33, 61–73. [Google Scholar] [CrossRef]

- Lee, S.K. Objective Evaluation of Interior Sound Quality in Passenger Cars during Acceleration. J. Sound Vib. 2008, 310, 149–168. [Google Scholar] [CrossRef]

- Lee, S.K.; Lee, S.; Back, J.; Shin, T. A new method for active cancellation of engine order noise in a passenger car. Appl. Sci. 2018, 8, 1394. [Google Scholar] [CrossRef]

- Xiong, J. A study on psychoacoustics-based high-mileage automobile vibration and noise robustness evaluation modeling. Int. J. Interact. Des. Manuf. IJIDeM 2022. [Google Scholar] [CrossRef]

- Fastl, H.; Zwicker, E. Psycho-Acoustics: Facts and Models, 3rd ed.; Springer: Berlin, Germany, 2007; p. 417. [Google Scholar]

- Yu, L.; Dai, S.; Wang, P. Design of noise reduction method for light bus. Automob. Technol. Mater. 2015, 30, 33–37. [Google Scholar]

- Sandberg, U.; Goubert, L. Persuade—A European project for exceptional noise reduction by means of poroelastic road surfaces. In Proceedings of the 40th International Congress and Exposition on Noise Control Engineering 2011 (INTER-NOISE 2011), Osaka, Japan, 4–7 September 2011; pp. 673–684. [Google Scholar]

- Pilewski, S.; Łazarz, B.; Czech, P.; Witaszek, K.; Witaszekm, M. Driving comfort of selected passenger cars as an effect of noise recorded inside the vehicle (Komfort jazdy wybranymi samochodami osobowymi jako skutek hałasu rejestrowanego wewnątrz pojazdu). Tech. Transp. Szyn. 2015, 22, 1226–1230. (In Polish) [Google Scholar]

- Noh, H.M. Improvement of noise reduction performance in bellows using multilayer perforated panels. Adv. Mech. Eng. 2021, 13, 1–11. [Google Scholar] [CrossRef]

- Klöckner, C.A.; Nayum, A.; Mehmetoglu, M. Positive and negative spillover effects from electric car purchase to car use. Transp. Res. Part D Transp. Environ. 2013, 18, 32–38. [Google Scholar] [CrossRef]

- Richter, J.L. A circular economy approach is needed for electric vehicles. Nat. Electron. 2022, 5, 5–7. [Google Scholar] [CrossRef]

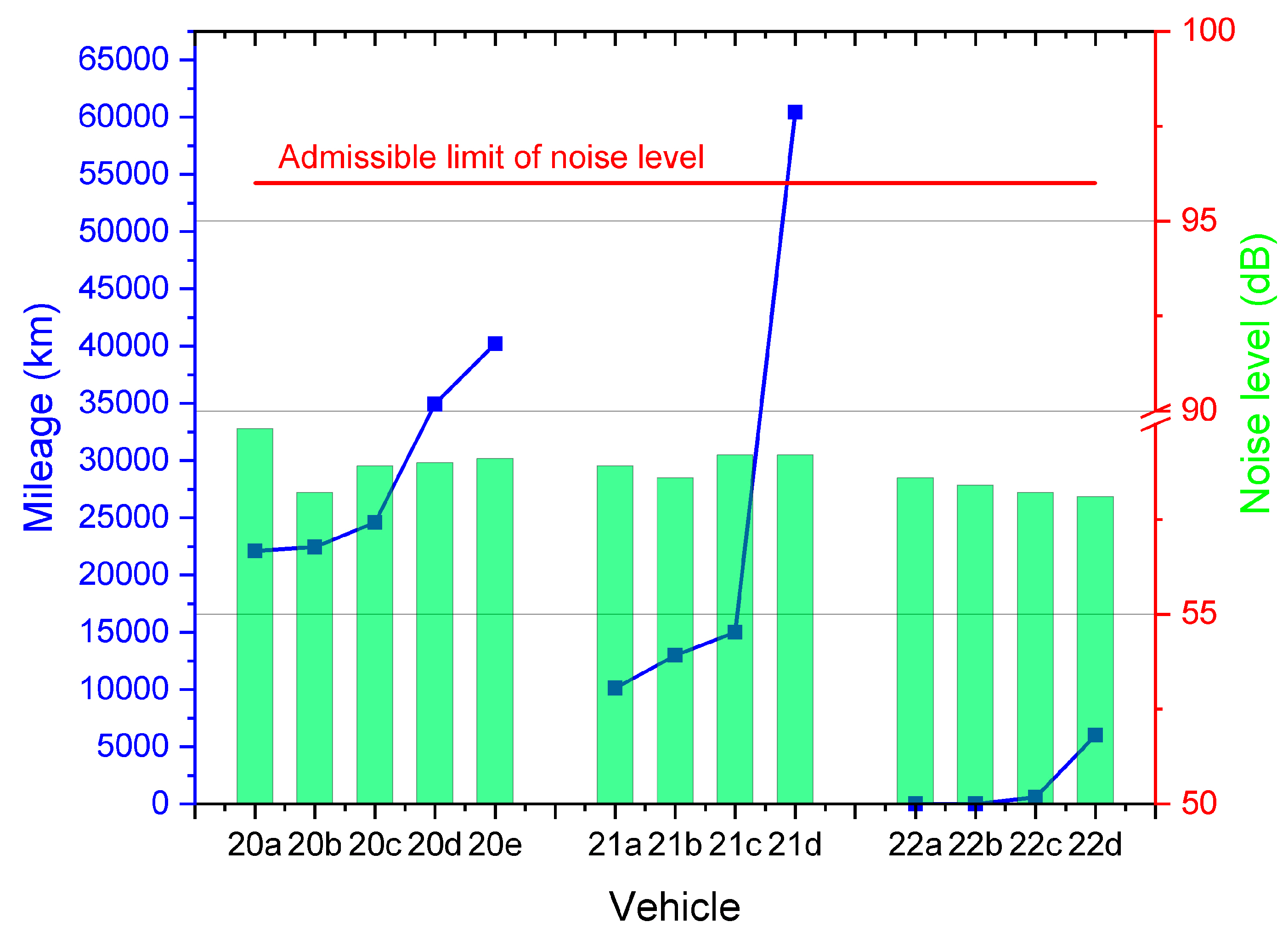

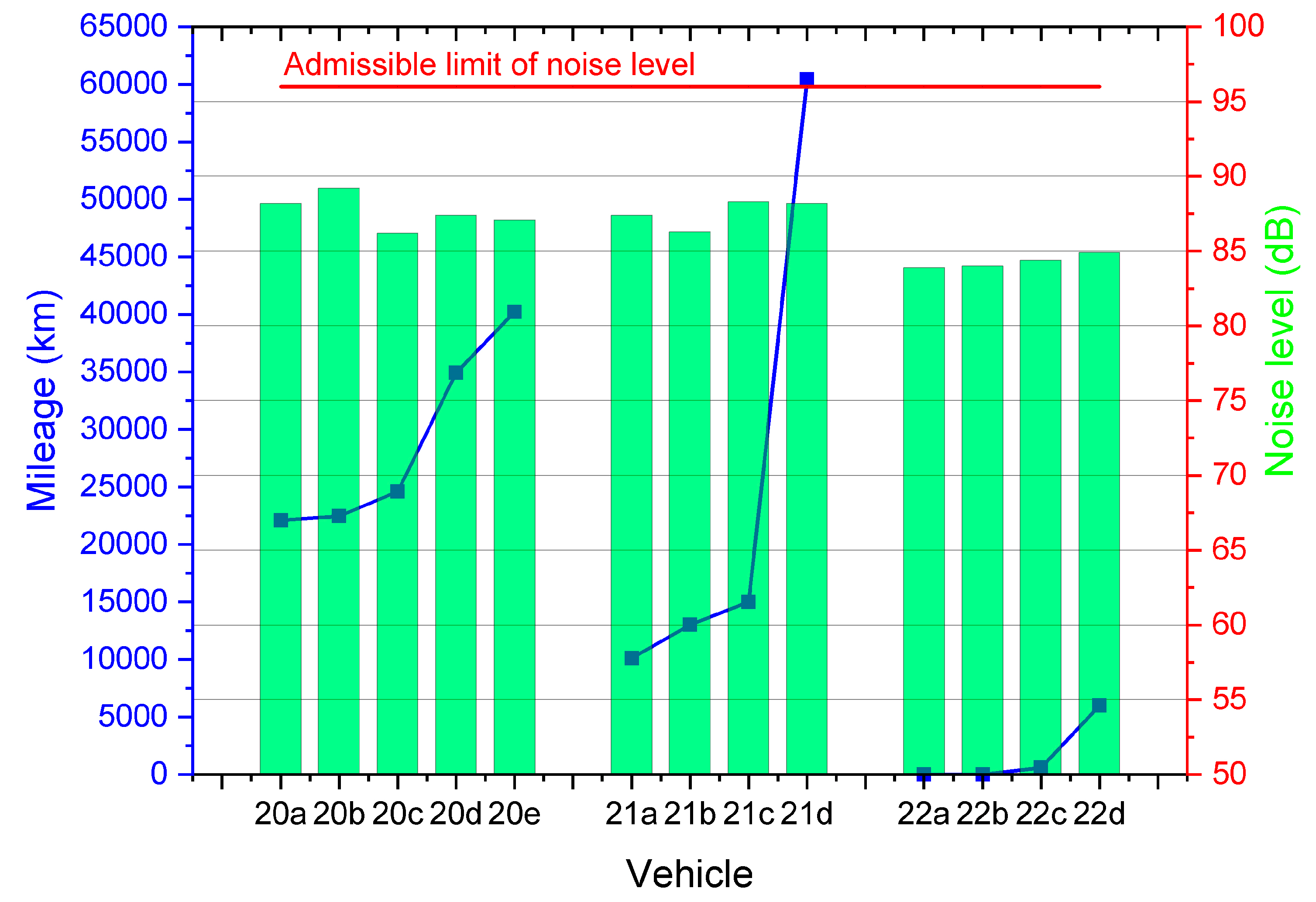

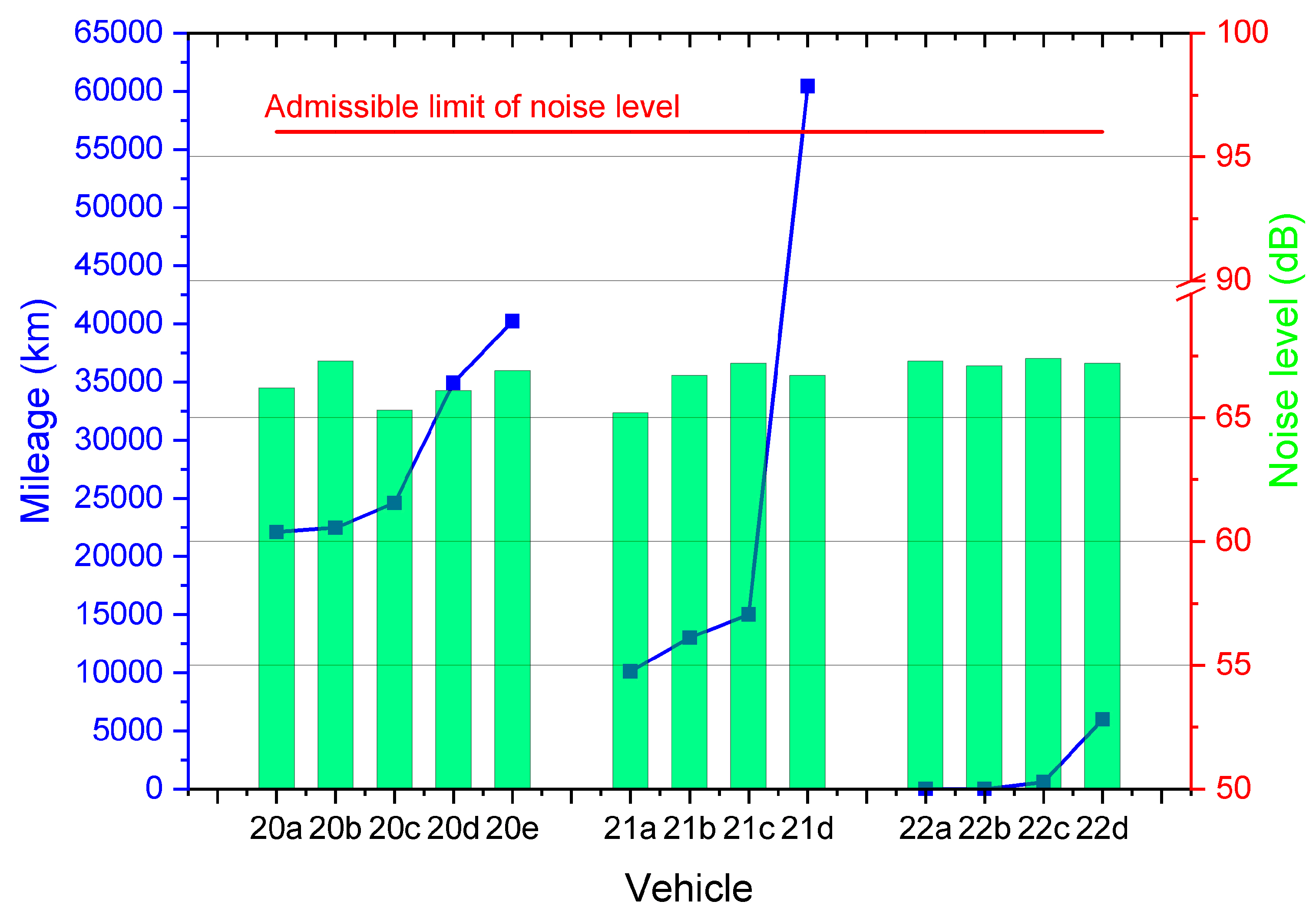

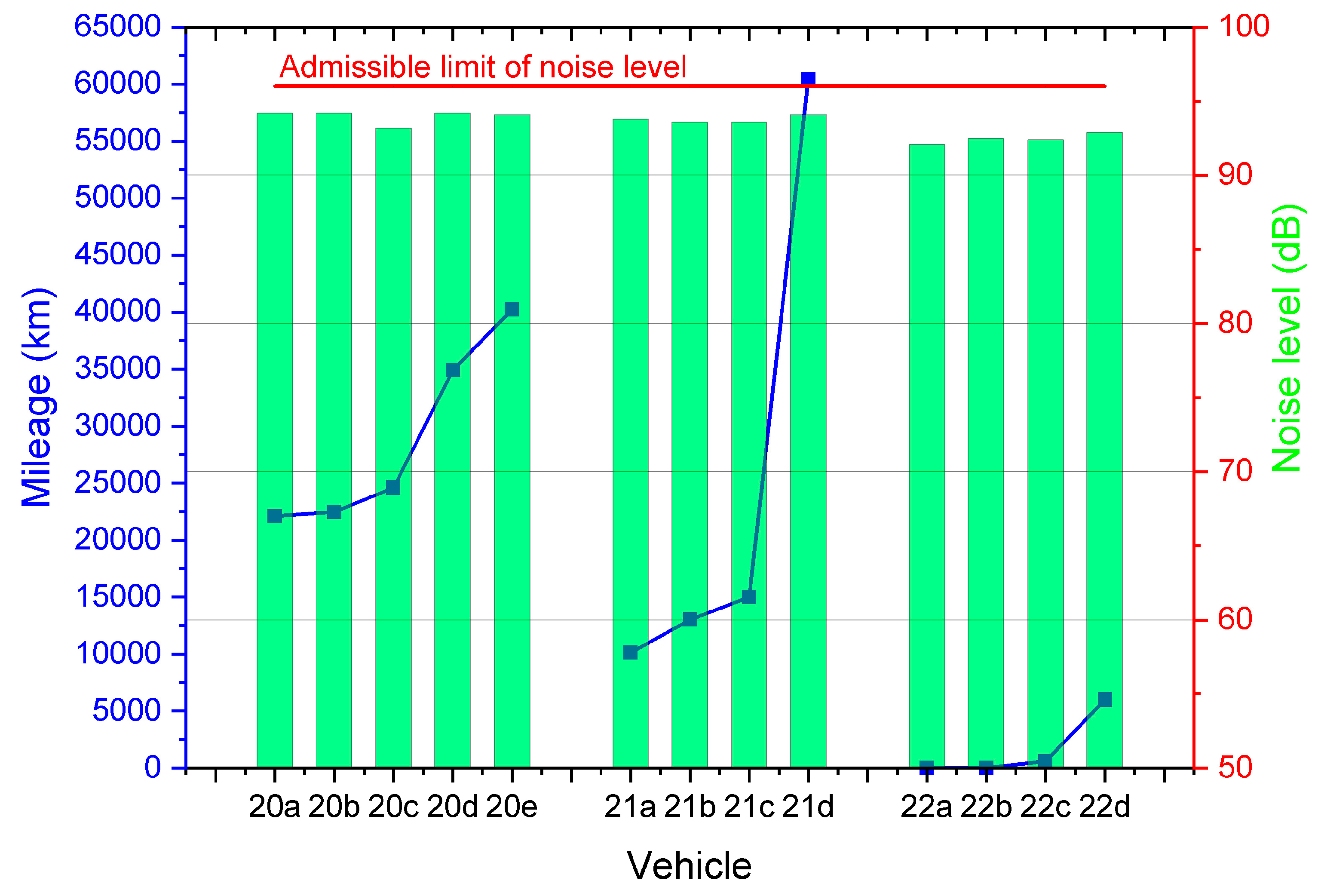

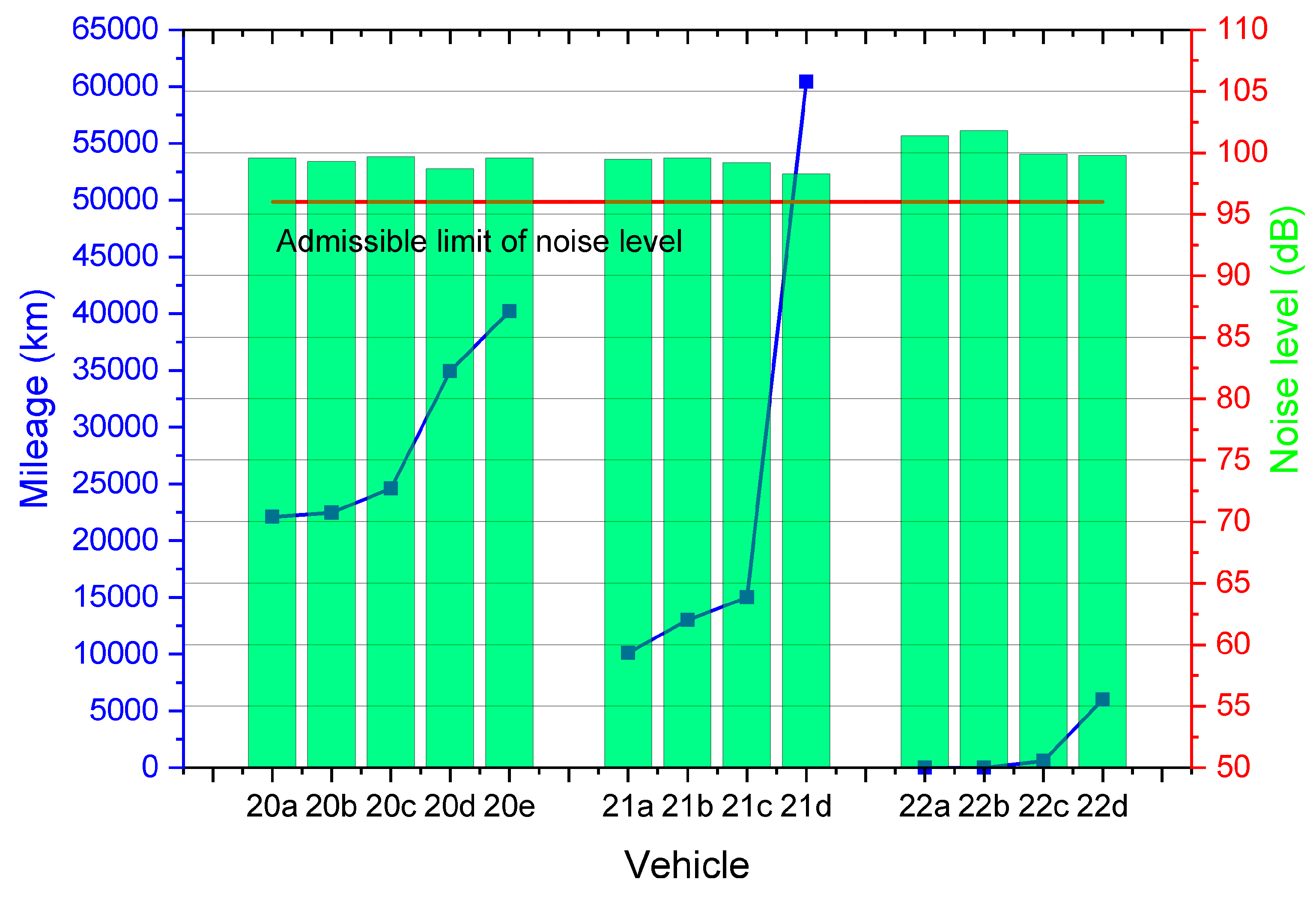

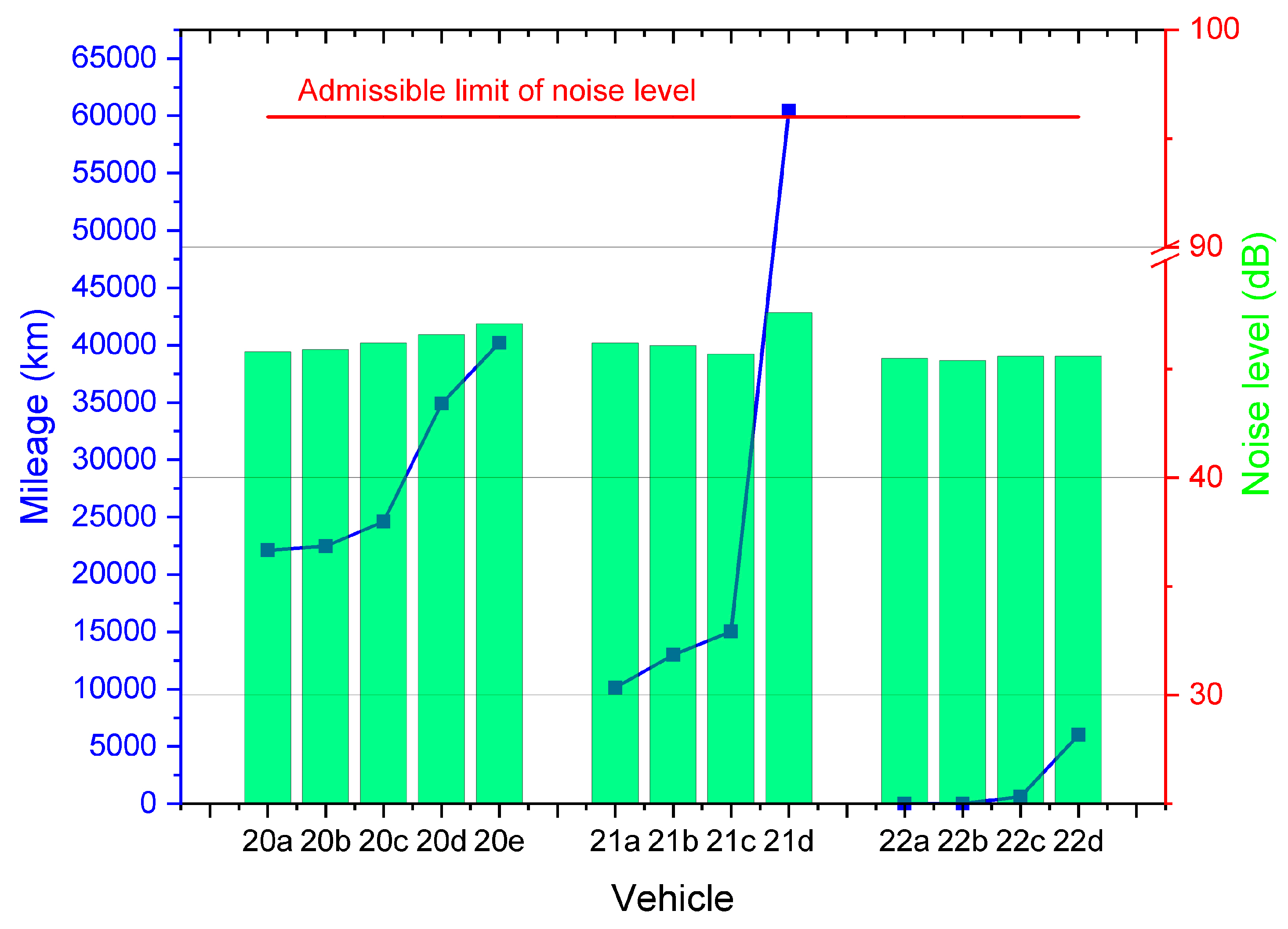

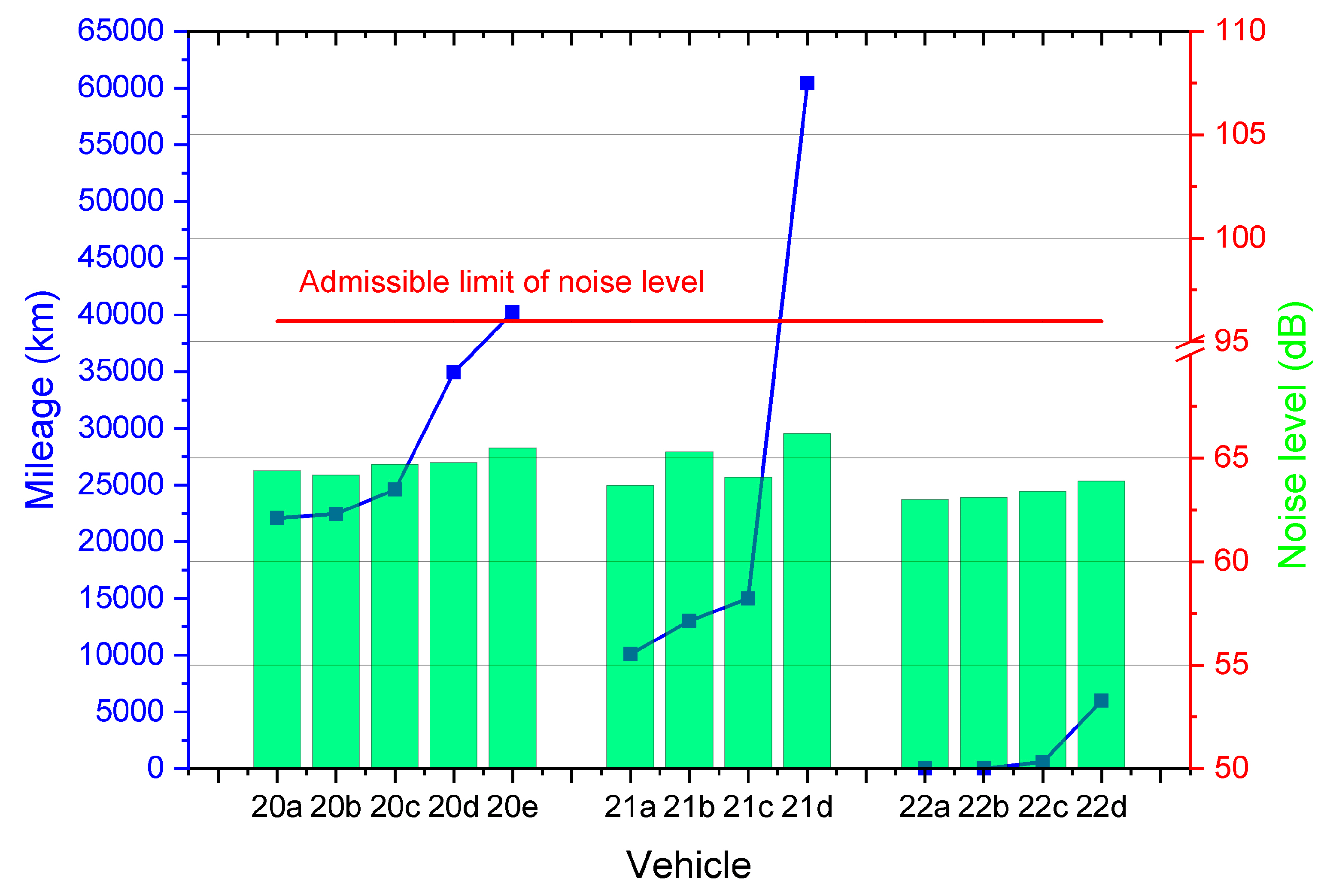

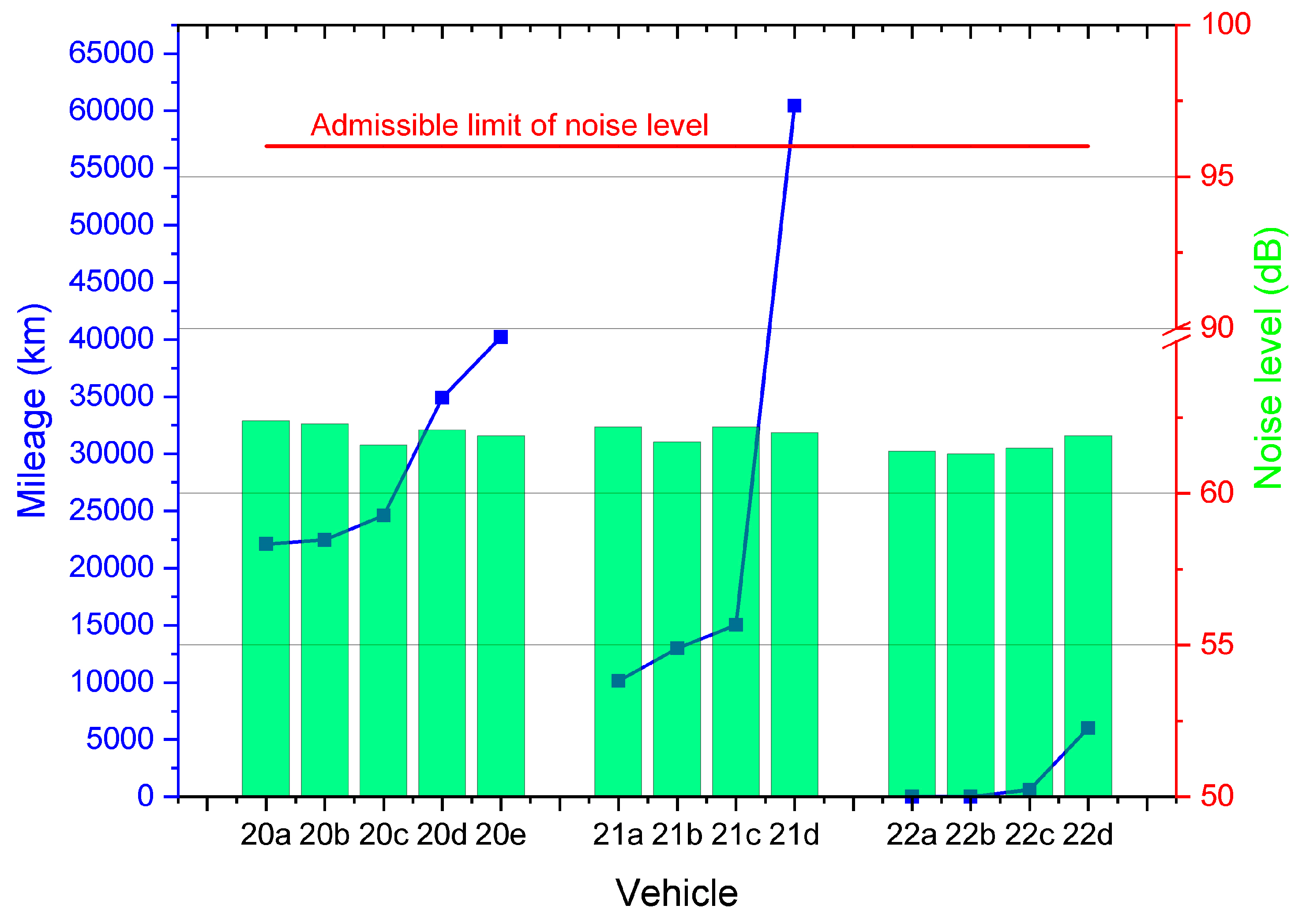

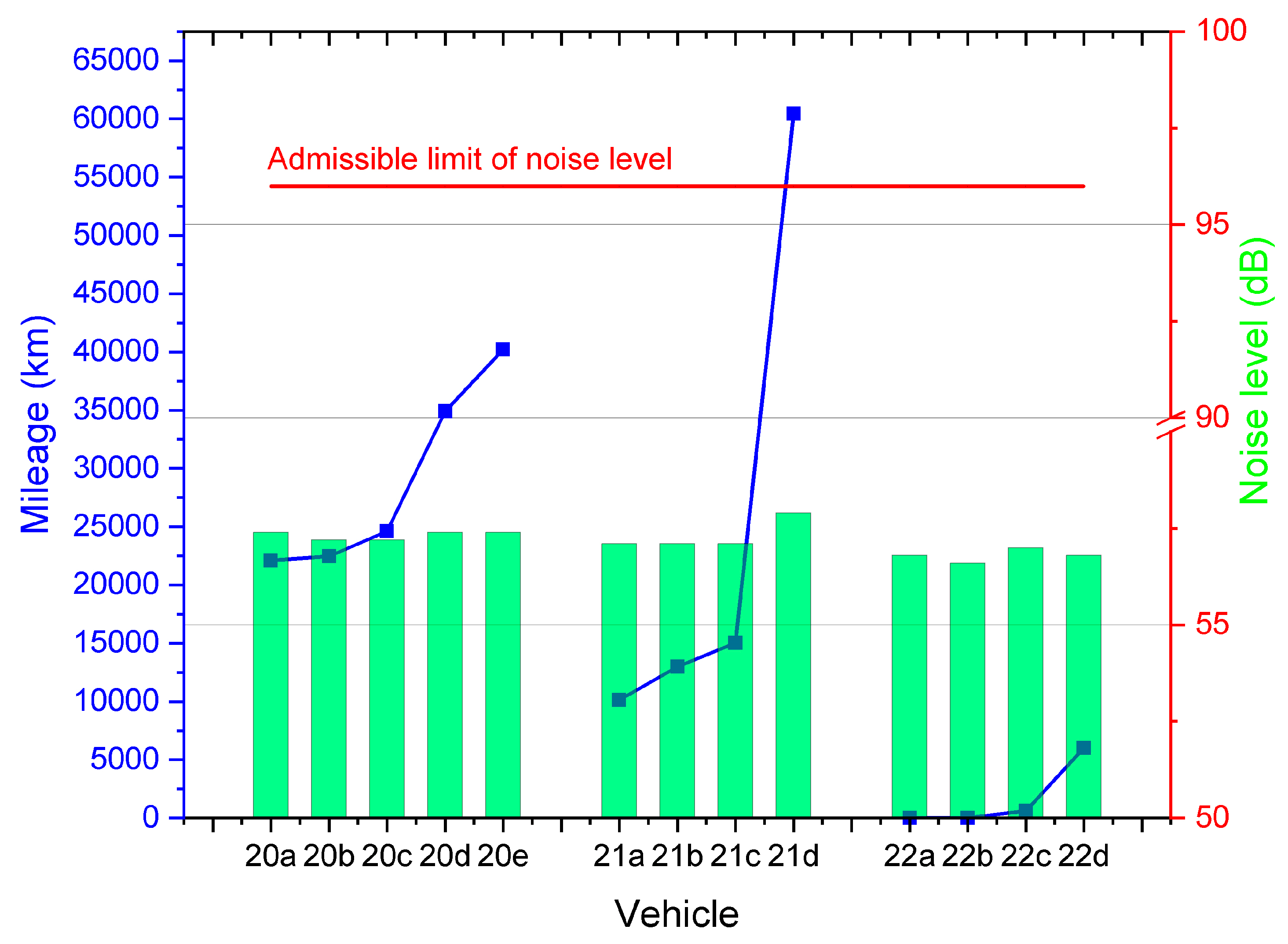

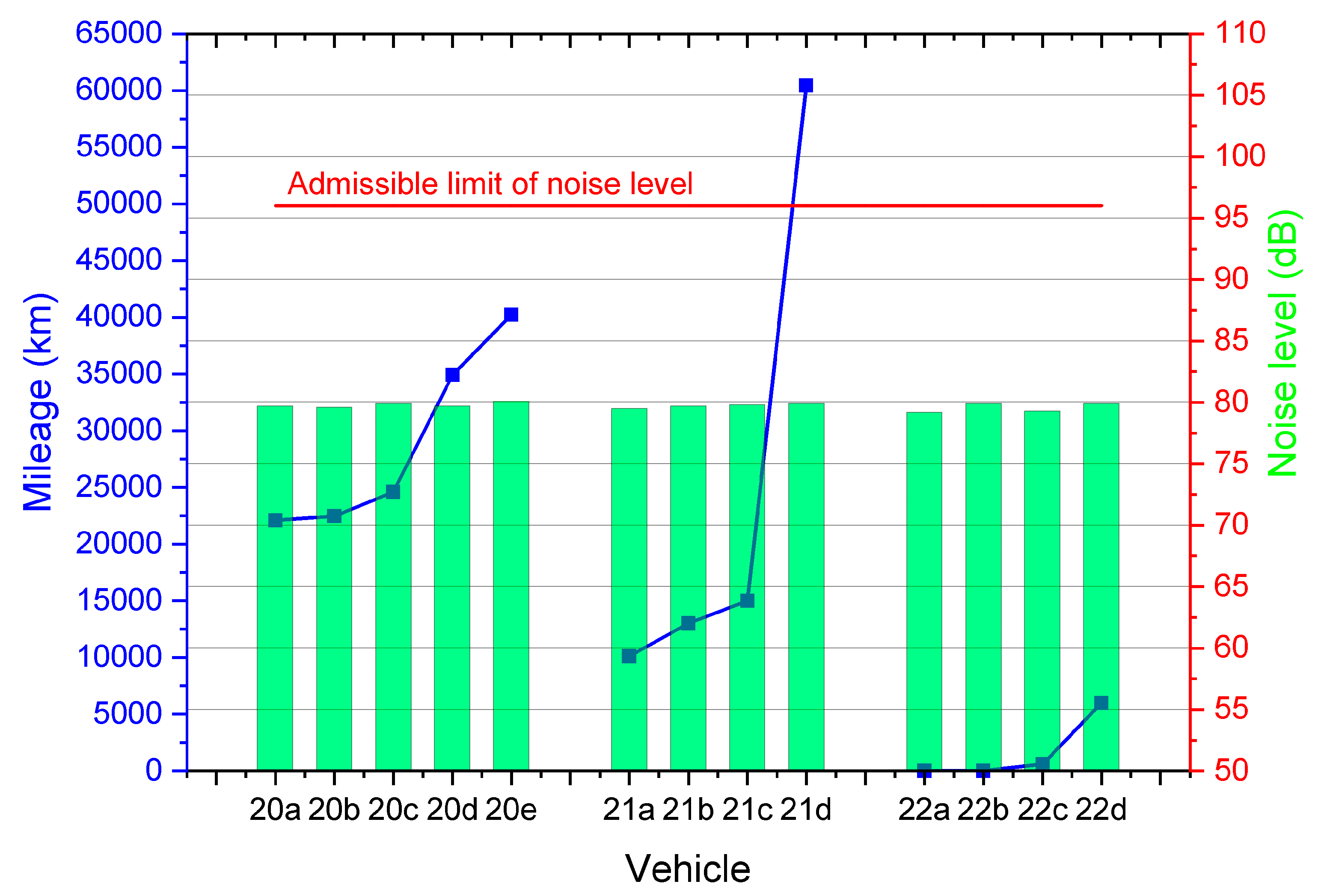

| Number of Cars | Year of Production | Mileage (km) | Vehicle Code |

|---|---|---|---|

| 1 | 2020 | 22,100 | 20a |

| 2 | 2020 | 22,453 | 20b |

| 3 | 2020 | 24,602 | 20c |

| 4 | 2020 | 34,920 | 20d |

| 5 | 2020 | 40,211 | 20e |

| 6 | 2021 | 10,121 | 21a |

| 7 | 2021 | 13,002 | 21b |

| 8 | 2021 | 15,021 | 21c |

| 9 | 2021 | 60,432 | 21d |

| 10 | 2022 | 10 | 22a |

| 11 | 2022 | 15 | 22b |

| 12 | 2022 | 600 | 22c |

| 13 | 2022 | 6012 | 22d |

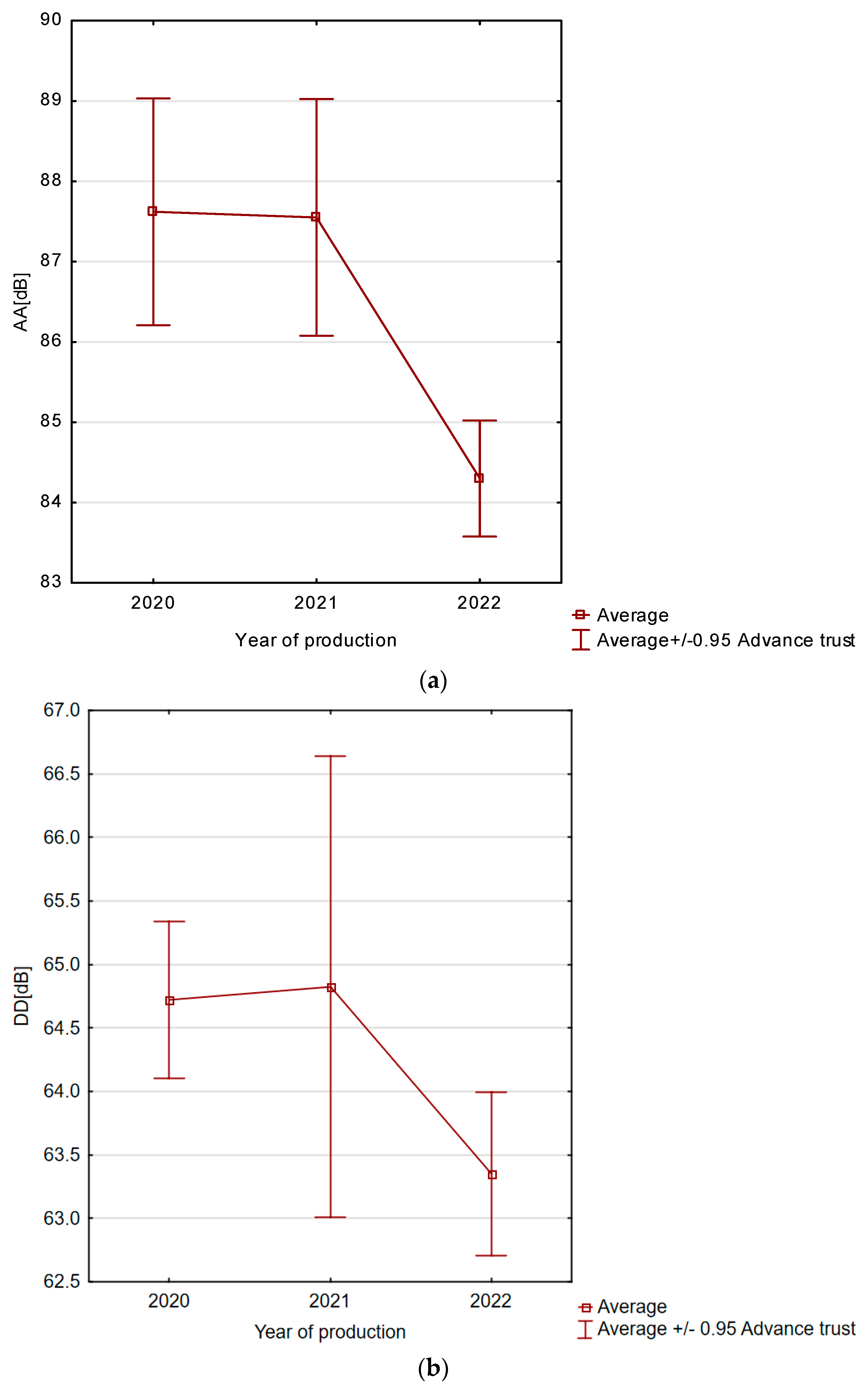

| Value/Research Points | Unit | A | AA | B | BB | C | CC | D | DD | E | EE | F | FF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. | (dB) | 59.9 | 89.2 | 67.4 | 94.2 | 75.2 | 101.8 | 47.6 | 66.2 | 62.4 | 78.5 | 57.9 | 80.1 |

| Min. | 58.1 | 83.9 | 65.2 | 92.1 | 73.2 | 98.3 | 45.4 | 63 | 61.3 | 77.1 | 56.6 | 79.2 | |

| Arithmetic average | 58.8 | 86.6 | 66.7 | 93.5 | 74.2 | 99.7 | 46.1 | 64.3 | 61.9 | 77.7 | 57.2 | 79.7 | |

| Standard deviation | 0.51 | 1.79 | 0.75 | 0.76 | 0.56 | 0.95 | 0.66 | 0.96 | 0.36 | 0.43 | 0.33 | 0.26 | |

| Median | 58.9 | 87.1 | 66.9 | 93.6 | 74.1 | 99.6 | 45.9 | 64.2 | 61.9 | 77.8 | 57.1 | 79.7 |

| Variable | Correlation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | AA | B | BB | C | CC | D | DD | E | EE | F | FF | |

| Mileage | 0.532275 | 0.658989 | −0.246762 | 0.748879 | −0.493777 | −0.740735 | 0.934106 | 0.895711 | 0.445739 | 0.67302 | 0.936536 | 0.534013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przydatek, G.; Ryniewicz, A.; Irimia, O.; Tomozei, C.; Mosnegutu, E.; Bodziony, M. Analysis of Noise Levels in Typical Passenger Cars. Sustainability 2023, 15, 7910. https://doi.org/10.3390/su15107910

Przydatek G, Ryniewicz A, Irimia O, Tomozei C, Mosnegutu E, Bodziony M. Analysis of Noise Levels in Typical Passenger Cars. Sustainability. 2023; 15(10):7910. https://doi.org/10.3390/su15107910

Chicago/Turabian StylePrzydatek, Grzegorz, Andrzej Ryniewicz, Oana Irimia, Claudia Tomozei, Emilian Mosnegutu, and Marcin Bodziony. 2023. "Analysis of Noise Levels in Typical Passenger Cars" Sustainability 15, no. 10: 7910. https://doi.org/10.3390/su15107910

APA StylePrzydatek, G., Ryniewicz, A., Irimia, O., Tomozei, C., Mosnegutu, E., & Bodziony, M. (2023). Analysis of Noise Levels in Typical Passenger Cars. Sustainability, 15(10), 7910. https://doi.org/10.3390/su15107910