Abstract

Nowadays, a large amount of municipal solid waste incineration bottom ash (IBA) is produced from waste incineration plants; therefore, it is still a challenge for IBA management. To investigate the potential of microbially-induced carbonate precipitation (MICP) for IBA treatment, a harmless biobinder was prepared by using biosolutions with different bacterial concentrations. A series of tests were carried out on the sample of the IBA treated with different biosolutions, such as leaching behavior, sequential extraction, pH dependence, pore distribution, and microscopic morphology. The results showed that Zn, Cu, and Pb in the IBA after biotreatment were all below the standard limitation. In the sample with 108 cells/mL bacterial concentration, the leaching concentrations of Zn, Cu, Pb, and Cr were 0.39 mg/L, 0.12 mg/L, 0.025 mg/L, and 0.021 mg/L, respectively, and the average immobilization ratio reached 76.4%. The results of the characterization and microscopic morphology showed that biomineralization generated a large number of bioprecipitates and biogels, which formed a compact structure to reduce the pore size of samples, thus immobilizing the heavy metals. The bacteria could change the chemical speciation and bonds of the heavy metals by induction, which turned the heavy metals into stable compounds. Additionally, the lowest leaching concentration of Zn, Cu, Pb, and Cr appeared at pH of 8–10.5. This study analyzed the feasibility of bacterial concentration for IBA solidification/stabilization and provides a new biotechnology idea for IBA management.

1. Introduction

The amount of municipal solid waste (MSW) is increasing. According to the report from the China Statistics Bureau, the output of MSW was 2.4 × 107 t in China in 2020, and it continues to increase with an annual rate of 6–8% [1]. Incineration is the common method for recycling MSW. Hence, many residues are landfilled after incineration, which occupies land and wastes resources. The incinerated residues are divided into incineration fly ash (IFA) and bottom ash (IBA), which contain many heavy metals. Compared with IBA, IFA has a higher content of some toxic substances, such as polychlorinated dibenzo-p-dioxin (PCDDs) and dibenzofurans (PCDFs). Therefore, IFA is regarded as a hazardous waste, while IBA is regarded as general industrial waste (less hazardous solid waste).

Due to it being less harmful, IBA has been selected as an admixture in the preparation of many materials, such as ceramics [2], geopolymers [3], and lightweight concrete [4]. The IBA must be treated harmlessly before recycling. The earliest research [5] shows that weathering could effectively reduce the leaching concentration of some heavy metals in IBA. Zn, Cu, and Pb were the principal heavy metals to be released from the IBA, and the weathered IBA could be used as secondary building materials. Many scholars have used the solidification/stabilization [6,7] method (where solidification refers to heavy metals being physically enveloped in the sample and cannot migrate and where stabilization refers to the chemical speciation of the heavy metals changing to a stable composition by ion exchange or other chemical processes) to treat IBA. Early studies showed that the IBA was treated with cement binder [8,9], and the results showed that cement could stabilize the harmful substances in IBA and improve the mechanical properties of samples made with IBA. According to the variation trend of the long-term leaching concentration, Yang et al. [10] divided the heavy metals in IBA into three categories. Cu, Cd, and Pb were included in the first category; their leaching concentrations increase with the leaching time. The second category included Zn and Sn, whose leaching concentration first increases and then decreases. Ni was included in the third category, and its leaching concentration first decreases and then increases. The recent research [11] showed that the treated IBA was used as a binder to improve the flexural strength of the wood cement composites and increase the thermal conductivity of the composites by 47%. Bernasconi and Garrabrants et al. [12,13] also reported that pH has an effect on the leaching concentration of heavy metals. The pH dependence test results show that the leaching concentrations of some heavy metals (such as As and Cr) in a weakly alkaline solution (pH of 8–9) are very low, but the leaching concentrations beyond this range will increase significantly. On the other hand, the leaching concentration of some heavy metals (such as Cd and Mn) decreased continuously with increasing alkalinity. Furthermore, an interesting result was reported by Grazulyte et al. [14]. The weathered IBA could completely replace fine and coarse aggregate to prepare concrete.

At present, it is cement or cement-based materials that are still used as a binder to treat IBA. Considering that the generation of conventional cement releases greenhouse gases, the idea of using biological methods to replace the cement binder was proposed [15]. As reported by Fan et al. [16], the cement binder can effectively reduce the leaching concentration of heavy metals in IBA, and thus the treated IBA can be applied to polymers and concrete. A large amount of carbon dioxide will be emitted in the process of cement production, so it is recommended to find a low-carbon and environmentally friendly binder to replace cement. Microbially induced carbonate precipitation (MICP) has been wildly used in geotechnical engineering, and it has been widely recognized. The principle is that bacteria induce calcium carbonate precipitation through their metabolism; the main reaction steps are as follows: urea produces NH2COOH and NH3 (in Equation (1)), catalyzed by urease bacteria [17]. These two products further react with H2O to generate NH4+ and OH-, and carbonic acid reacts with hydroxide ions to generate carbonate ions (in Equations (2)–(4)) [18]. The negative charge on the surface of the cell wall adsorbs the cation of Ca2+ to generate Cell-Ca2+. Finally, the Cell-CaCO3 reacts with the to generate Cell-CaCO3 precipitation (in Equations (5) and (6)) [19].

Few studies have reported using MICP to treat IFA [20]; however, there are almost no studies on the treatment of IBA by different concentrations of biobinder. Whether the biobinder can be used to solidify/stabilize the heavy metals in IBA is still unclear. Therefore, this study aims to investigate the effect of IBA being treated with the biobinder. A series of tests were carried out, such as leaching concentration, sequential extraction, and pH dependence, to analyze the growth of bacteria in IBA and study the effects of bacterial concentration on the leaching concentration of Zn, Cu, Pb, and Cr. The effects of bacterial concentration on the chemical speciation of the noted heavy metals were also analyzed. Additionally, the solidification/stabilization mechanism of biobinder on Zn, Cu, and Pb in IBA was also discussed in depth.

2. Materials and Experiments

2.1. Solid Waste

IBA was collected from a waste incineration plant in Wuhan, China. Municipal solid waste (MSW) was burned in an incinerator at 1000–1100 °C for approximately 10 s to generate the IBA, thus the contents of PCDFs and PCDDs in the IBA were below the standard [21]. The particle size of the original IBA was large, some of which were 1–2 cm in diameter. Hence, the IBA was ground in a grinder (AM 420) for 30 min and then analyzed by a laser particle size analyzer (Mastersizer 3000, Malvern, UK). The results showed that the average particle size of the ground IBA was 6.51 μm. The X-ray fluorescence (XRF, PANalytic Axios, Almelo, The Netherlands) test results showed that the IBA contained 43.51 wt.% CaO and 21.36 wt.% SiO2.

2.2. Biobinder Preparation

Bacillus Licheniformis (Strain Code: CGMCC 1.10314), a commonly used mineralizing bacterium, was purchased from China General Microbiological Culture Collection Center (CGMCC). Medium components included 10 g of peptone, 5 g of NaCl powder, 3 g of beef extract powder, and 1 L of deionized water [22]. The noted compositions were mixed in a 1 L beaker, and then the pH of the solution was adjusted to 7.2 ± 0.2 by 0.1 mol/L NaOH solution. The prepared medium was placed in an oven at 105 °C for 6 h. A 1 mol/L urea solution was used as the nitrogen source and a 1 mol/L calcium nitrate solution was used as the calcium source, because NO3- is chemically inactive [23] and cannot react with the substances in IBA. The bacteria (the calculation of biomass was described in the next paragraph), the culture medium, the urea solution, and the Ca(NO3)2 solution were mixed in a mass ratio of 1:100:50:50. The mixture was poured into a conical flask and then oscillated in an oscillator at 21 °C for 24 h. After the oscillation, the preparation of the biobinder was finished.

A total of 1 g of the ground IBA and 1 g of biobinder was mixed fully and oscillated in an oscillator for 24 h. Using ultraviolet spectrophotometer (UV1100, Shanghai, China), their OD600 (the absorbance optical density of bacteria at 600 nm wavelength (i.e., biomass values) [24] was analyzed. The relationship between the OD600 value and the number of bacteria is as follows: biomass equals OD600 value multiplied by 8.88 × 108. The biomass value was calculated referring to the OD600 value, and the biomasses were prepared to 104, 105, 106, 107, 108, and 109 cells/mL, respectively.

2.3. Preparation of Sample

This study aims to investigate the effect of binders with different biomass on the IBA, which means using the biobinder to cement IBA. Thus, the samples were prepared by mixing the ground IBA with biobinders with 103, 104, 105, 106, 107, and 108 cells/mL of biosolutions, respectively, and their codes were named BI1–BI6. The control was the ground IBA with 103 cells/mL of the inactivated bacteria. The ratio of biobinder–IBA (L/S) was 0.6, referring to the preliminary test result. The IBA and biobinder are poured into a blender and then stirred at a speed of 60 rpm for 10 min to reach a good working performance of the samples. According to the Chinese standard “B/T 17,671–1999”, the stirred samples were poured into a 40 mm × 40 mm × 40 mm mold. To avoid cross-contamination between the samples, each sample was sealed with plastic wrap, and each sample was separated by an acrylic plate. The samples were demoulded 24 h after preparation and then placed in a curing chamber at 21 °C and 95% release density.

2.4. Toxicity Characteristic Leaching Test

The toxicity characteristic leaching procedure (TCLP) test was used to analyze the leaching behavior of the heavy metals in the IBA. A total of 5 g of the samples was put into 96.5 mL of deionized water, and the mixture after stirring was cooled to 21 °C. Analyzed by a pH meter, the pH of the mixed solution was more than 5, thus glacial acetic acid was selected as the extraction solution. The pH of the extract was adjusted to 2.88 ± 0.05 by 0.1 mol/L NaOH solution and the sample was poured into a mill and ground for 10 min. The ground powders with the extract (glacial acetic acid) were mixed at a solid–liquid ratio of 1:20, and then they were put into an oscillator at 32 rpm and 21 °C for 20 h. The supernatant was filtered with a 0.45 μm microporous membrane, and 20 mL of the filtrate was put into an inductively coupled plasma mass spectrometer (ICP-MS) to analyze the concentrations of the heavy metals Zn, Cu, Pb, and Cr (the reason is explained in Section 3.1).

2.5. pH Dependence Test

Since pH is very important to the leaching concentration of heavy metals, the relationship between pH and the leaching behavior of the heavy metals was analyzed by the pH dependence test. According to the leaching environmental assessment framework (LEAF), this method is a parallel batch pH dependence test. The pH of biosolution was adjusted to 2.0, 4.0, 5.5, 7.0, 8.0, 9.0, 10.5, 12.0, and 13.0 [12]. For each pH target, a 20 g subsample of granular IBA (or size-reduced biotreated IBA) was contacted with HNO3 (because the calcium source solution used was Ca(NO3)2) diluted in deionized water at a constant liquid-to-solid ratio (L/S) of 0.6. All extractions were oscillated with an oscillator for 48 h. The final pH was measured prior to vacuum filtration through the 0.45 mm membrane and then the filtrate was collected for analysis.

2.6. Sequential Extraction

The chemical speciation of heavy metals in the samples was analyzed by the extraction method, and the speciation extractions are described by Xiang et al. [25]. The morphology of analysis includes carbonate bound, organic matter bound, Fe-Mn oxide bound, exchangeable bound, and residual bound. Since the composition of bioprecipitation is carbonate, this study mainly analyzed the relationship between residual bound and carbonate bound.

2.7. Characterization Methods

The samples were characterized by the X-ray diffraction (XRD, D8, Japan), thermogravimetric analysis derivative thermogravimetry (TGA-DTG), Fourier transform infrared (FTIR), and mercury intrusion porosimetry (MIP) tests, and the samples cured for 28 days were tested. The samples were ground in a mortar and then passed through a 200-mesh sieve. The ground samples were put into the XRD tester (D8). The angle was set to 10–70°, and the test rate was set to 2°/min. The FTIR (Nicolet IS50, USA) was used to detect chemical bonds in the samples. A total of 20 mg of ground sample was analyzed by the FTIR tester. The mode was the light transmission, and the test range was 400–1600 cm−1. The pore distribution in the samples was analyzed by an automatic mercury intrusion instrument (AutoPore Iv 9510, USA). The tested pore size range was 5–10,000 nm, the contact angle was 130°, and the test gas was nitrogen. The sample was ground into the particles with a diameter of 1–1.5 cm, and 1.5 g of the ground particles were put into the instrument for the test. TGA was used to test the mass loss of calcium salt to obtain the change in calcium salt content in the sample. The test model of the TGA instrument was TA, and the test range was 30–1000 °C. DTG was the derivative of TGA and time, which was calculated automatically by the TGA instrument.

2.8. Microstructural Analysis

A scanning electron microscopy (SEM, Sigma 300, Germany) instrument was used to analyze the microscopic morphology of samples. The core of the samples was cut into a 2 mm × 2 mm × 5 mm block, and they were sprayed gold and then put into the tester. Spraying gold (Solid, 99% of purity, China) aimed to make samples easier to photograph. The acceleration voltage was 0.3–30 kV, and the magnification range was 5–10,000 times. The control, BI1, BI3, and BI6 were used as the studied samples to investigate the effect of bacterial concentration on IBA.

3. Results and Discussion

3.1. Characteristics of Bacterial Growth and Untreated IBA

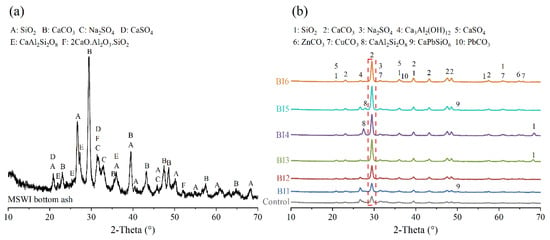

The contents of heavy metals in IBA were analyzed by a heavy-metal tester (Genis 9000, China), and the results are shown in Table 1. Zn, Cu, Pb, and Cr were rich in IBA, which were 3592.63 mg/kg, 1006.92 mg/kg, 261.15 mg/kg, and 203.21 mg/kg, respectively. Their total contents were all much higher than the limitation referring to national solid waste standard “GB16889-2008”. To analyze the TCLP test results, the TCLP standard is also given in Table 1 according to the Chinese standard “HJT300-2007”. Furthermore, the XRD results of the original IBA are shown in Figure 3a. It can be seen that quartz, gypsum, and calcite are the major components of IBA.

Table 1.

Distribution of heavy metals.

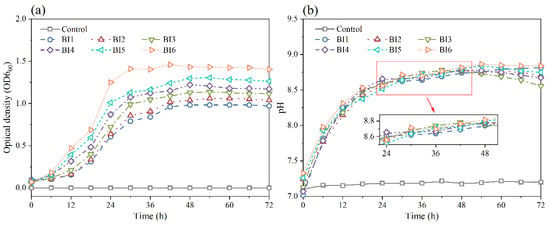

The optical density test procedure was described in detail in Section 2.2., and the OD600 value ranges from 0.8 to 1.6 (up to the standard for bacterial growth [26]) (Figure 1). The pH values of the samples are tested by a pH meter (PHS-3C, China), and the suitable pH for bacterial growth is 7–9 [22]. During incubation, the pH values increase simultaneously with time. The pH values of all sample BIs are 8.5–8.8, which may be related to the bacterial metabolism and the pH of IBA. Additionally, as can be seen from Figure 1b, there is no significant difference in pH values of all the samples. Therefore, it is indicated that the mixing of IBA and biobinder is allowed, that is, the IBA does not inhibit the growth of bacteria.

Figure 1.

Results of bacterial growth in IBA. (a) Optical density and (b) pH values.

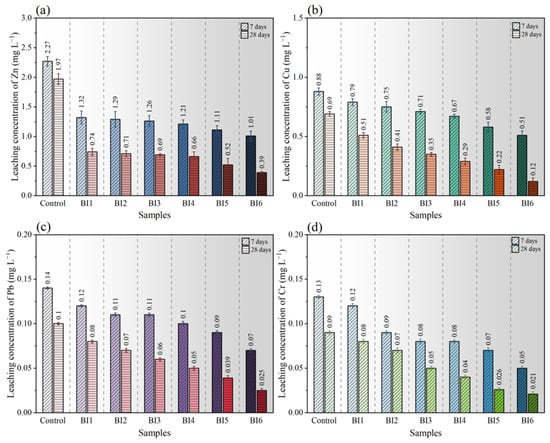

3.2. Toxicity Characteristic Leaching Procedure

Referring to the results in Table 1, the TCLP test was carried out for the heavy metal elements whose initial concentration exceeded the standard, namely Zn, Cu, Pb, and Cr. The test results are shown in Figure 2. The leaching concentrations of the heavy metals analyzed at 7 days are higher than that at 28 days. Interestingly, at 7 days and 28 days, the difference in the leaching concentrations of the heavy metals in the sample control is small. With the increase in the bacterial concentration, the difference in the leaching concentrations of the heavy metals becomes greater between 7 days and 28 days. This is related to the amount of bioprecipitation and biomass [27], which means that the heavy metals are enveloped in biogels. At 28 days, the immobilization ratios of Zn, Cu, Pb, and Cr in sample BI6 are 80.2%, 82.6%, 75.0%, and 76.6%, respectively. This shows that the concentration of biobinder is positively correlated with the immobilization ratios of heavy metals.

Figure 2.

Leaching concentrations of (a) Zn, (b) Cu, (c) Pb, and (d) Cr.

Note that at 28 days, the bacterial concentration significantly improved the immobilization effect of biogel on heavy metals. Especially from samples BI5 to BI6, the immobilization ratio increases by 12.1%. This is related to the growth cycle of bacteria [28]. Additionally, the immobilization ratio of sample control is the lowest, which may be due to the fact that the addition of inactivated bacteria leads to poor mineralization [29].

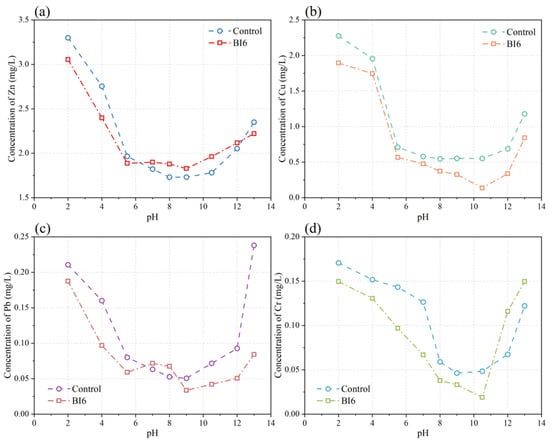

3.3. pH Dependence Analysis

The pH dependence of biobinder on heavy metals in IBA is shown in Figure 3. As reported by Bernasconi et al. [13], pH depends on surface complexation, mineral composition, and solid (or dissolved) organic matter. As can be seen from Figure 3, the general trend of Zn and Cu concentration decreases with the increase of pH, while their leaching concentration increases slightly during a pH of 10–13. However, the general trend of Pb and Cr concentration is U-shaped [12], which means that the leaching concentration of Pb and Cr is very low when pH is 8–10, while the leaching concentration on both sides of the curve increases. Interestingly, the concentration of Zn and Pb after biotreatment at pH 7–9 is higher than that of the control. Since the large molar mass of Zn and Pb leads to inactive chemical properties, it is difficult to precipitate Zn and Pb during biomineralization [30]. On the contrary, the leaching concentration of the biotreated Cu and Cr at pH 2–10.5 was lower than that of the control.

Figure 3.

pH dependence results of control and biotreated IBA (BI6). The types of heavy metals correspond to the tested heavy metals in the TCLP test. (a) Zn, (b) Cu, (c) Pb, and (d) Cr.

Combined with the pH results (in Figure 1b), the pH of biosolution is about 8.5 and IBA is about 10.2. Hence, the leaching concentration of heavy metals at a pH of 8–10.5 should be discussed in depth. In the pH range of 8 to 10.5, the leaching concentrations of Cu and Cr gradually decrease with increasing pH, while the lowest leaching concentrations of Zn and Pb appear in this range. This is because pH can change the solubility of metal precipitation, which is the main reason for the increase or decrease in the leaching concentration of heavy metals [13]. Meanwhile, it also reflects that pH contributes to the leaching of heavy metals in IBA.

3.4. X-ray Diffraction and Thermogravimetric Analysis

The core of MICP technology is to induce the formation of carbonate precipitate. As can be seen from the peaks in the red frame in Figure 4b, the CaCO3 contents in the sample BIs increase with the concentration of the bacteria. This indicates that increasing the bacterial concentration can improve biomineralization, namely by increasing the bioprecipitation of CaCO3. The solidification ability of biobinder is closely related to the formulation of CaCO3, and the biobinder produced by the MICP reaction has a compact structure [31], which can make some contribution to reducing the leaching concentration of heavy metals in the samples to a certain extent. Compared to the sample control, some new compounds are formed in the sample BIs, such as CuCO3, ZnCO3, CaPbSiO6, and so on. Divalent metal ions have the same valence state as calcium ions, thus the bacteria induce them to react with and other anions to generate precipitates [32].

Figure 4.

XRD results of (a) MSWI bottom ash and (b) the sample BIs with different concentration biosolutions. The red mark refers to the CaCO3 (at 29.5°).

Referring to Figure 4a,b, it is demonstrated that many carbonates are generated in the samples after biotreatment; especially Cu2+, Zn2+, and Pb2+ are precipitated as the precipitations of CuCO3, ZnCO3, and PbCO3, even the co-precipitation of CaPbSiO6 is generated [33]. Note that the peak value of PbCO3 is small because the content of Pb in IBA is not as high as that of Zn and Cu (in Table 1). In conclusion, it is preliminarily speculated that MICP technology changes the chemical morphology of heavy metals in IBA.

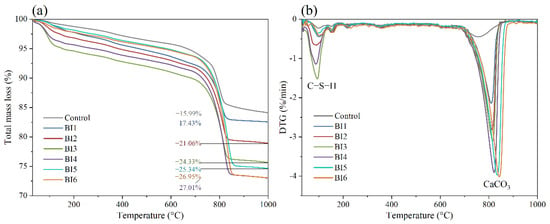

TGA is used to analyze the loss of combustion of the components in the sample, and the results are given in Figure 5a,d. It can be seen from Figure 5a that the total mass loss of the BIs is larger than that of the control. Overall, the total mass loss increases with the increasing concentration of the biosolution. The DTG curve (in Figure 5b) was used to analyze the composition causing mass loss. Figure 5b shows two peaks in the DTG curve: the peak at 30–150 °C indicates calcium silicate hydride (C-S-H), and the peak at 700–850 °C indicates CaCO3. The formation of the C-S-H peak is due to the reaction of CaO in IBA with H2O. According to the intensity of the diffraction peak, the content of C-S-H is small. It is noteworthy that the C-S-H peaks of BI3 and BI4 are larger than those of other samples, indicating that biosolution can improve the activity of CaO in IBA, but the concentration of the biosolution has an optimal range, namely 1 × 103–1 × 104 cells/mL. The high content of C-S-H in BI4 also leads to the largest total mass loss value of BI4 (the value is −27.01% in Figure 5a). From the peak of 700–850 °C, it can be seen that there is a large amount of bioprecipitated CaCO3 in the sample BIs, while a small amount is seen in the sample control. The tendency of the peak value of CaCO3 increases with the increasing concentration of the biosolution because the increase in the concentration of the biosolution improves the mineralization rate and accelerates the mineralization reaction [22]. Interestingly, the peak values of CaCO3 in samples BI4, BI5, and BI6 are the highest and very close, while the peak values of CaCO3 in other samples are quite different. This indicates that when the concentration of the biosolution exceeds 1 × 104 cells/mL, the influence of biosolution concentration on biomineralization begins to decrease, leading to a decrease in the generation of CaCO3.

Figure 5.

TGA test results of the samples. (a) Total mass loss and (b) DTG curves. Where C-S-H refers to calcium silicate hydrate.

In summation, the increase in the concentration of the biosolution can promote mineralization. A high concentration of the biosolution generates more mineralized products of CaCO3, which polymerizes to form a closed biogel to contribute to the fixation of heavy metals in IBA. Combined with the results of the TCLP test, it can be seen that the descending range of Zn, Cu, Pb, and Cr concentration reduces with the increasing biosolution concentration, which corresponds to the peak value of CaCO3 in the DTG curve. This indicates that the increase of CaCO3 content will improve the performance of the biogel for heavy metals’ solidification, leading to a decrease in the leaching concentration of heavy metals. This is consistent with the SEM results.

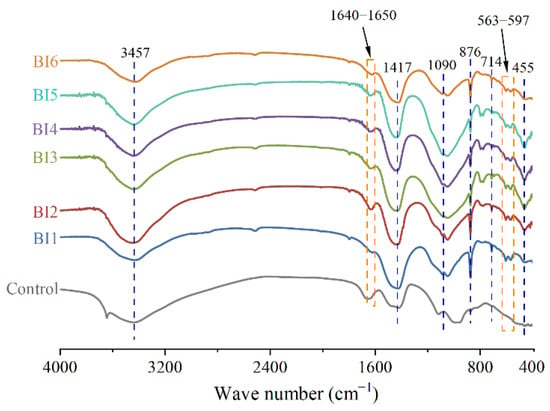

3.5. Fourier Transform Infrared

To investigate the effect of bacterial concentration on the chemical bonds of IBA components, the FTIR test results were given in Figure 6. The peaks at 455 cm−1 and 1090 cm−1 are a bending vibration of Si-O (δSi-O) [34] and Si-O stretching vibration [35], respectively. The Si-O-Al deformation vibration [36] is at the peak of 563–597 cm−1. Note that these peaks appear in the sample BIs but not in the sample control. This indicates that the chemical bonds of Si-O and Si-O-Al in the silica change due to the induction of bacteria, and they react with the metal ions to generate CaPbSiO6 and CaAl2Si2O8. This is consistent with the results of XRD (in Figure 4b); the SiO2 in IBA can react with calcium ions and metal ions and then precipitate as the noted compound salt.

Figure 6.

FTIR analysis of the samples. Where the lines refer to a fixed value, and the frames refer to a range value.

The peak at 714 cm−1 is v4 of CO3 [37], 876 cm−1 represents out-of-plane bending vibration (v2) [38], and the peak at 1417 cm−1 represents C-O symmetric stretching vibration (v3) [39]. These peaks increase with the concentration of bacteria. Especially at 876 cm−1, there is almost no peak in the sample control, while the peaks in other sample BIs are strong. This indicates that biomineralization has a significant impact on the chemical bond of . This can be explained by two reasons. On the one hand, after MICP treatment, a large number of biogels are generated, in which the main component is CaCO3 [40]. On the other hand, some divalent heavy metal cations react with carbonate ions to generate carbonates, such as CuCO3 (in Figure 4b). The peaks at 1640–1650 cm−1 and 3457 cm−1 are H-O-H bending vibration [38] and stretching vibration [41], respectively. These two peaks represent the chemical bond of water molecules. With the reaction of biomineralization [42], the biosolution gradually forms the biogels, resulting in the consumption of H2O in the sample.

The FTIR results show the changes in Si-O, C-O, and other bonds, which cannot be analyzed by the XRD test. Referring to the results of the FTIR and XRD tests, it proves that one of the biobinder methods to deal with heavy metals in IBA is stabilization, that is, to change the chemical bonds of molecules.

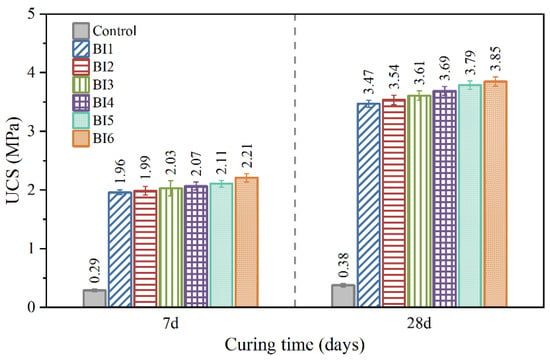

3.6. Unconfined Compressive Strength

As can be seen from Figure 7, the strength of samples cured for 28 days is 1–2 MPa higher than that of the samples cured for 7 days, except for the sample control. The bacteria in the sample control have no activity and cannot form a cementing agent, and the cementing ability of the biosolution itself is very weak, thus its strength values are very low, and they are all less than 0.4 MPa. At 7 days, the strength value of sample BIs (from BI1 to BI6) increases from 1.96 MPa to 2.21 MPa, while at 28 days, it increases from 3.47 MPa to 3.85 MPa. This shows that the increase in the bacterial concentration and curing time can improve the strength of sample BIs, but the rise is not high. As mentioned in the relevant literature [22], the structure of CaCO3 generated by MICP is compact. However, due to the smooth surface of calcite, the strength value of biotreated samples is generally 2–10 MPa. But this strength value meets the strength standard of architectural coating and backfills. Additionally, the growth peak is observed from 3 to 10 days after inoculation, during which the biomass is the largest. The biomineralization is improved at this time, resulting in the strength of sample BIs at 28 days being 50–70% higher than that at 7 days. This has been confirmed in the literature [43].

Figure 7.

Unconfined compressive strength of the sample control and BIs.

The bacterial concentration increases the number of bioprecipitates, causing the biogel to become dense, and thus the strength of the sample is improved. This result can be seen in the XRD test (in Figure 4b). Additionally, it can be speculated that the precipitates of ZnCO3, CuCO3, and PbCO3 generated by the reaction of divalent heavy metals with carbonate ions also make a certain contribution to the improvement of strength.

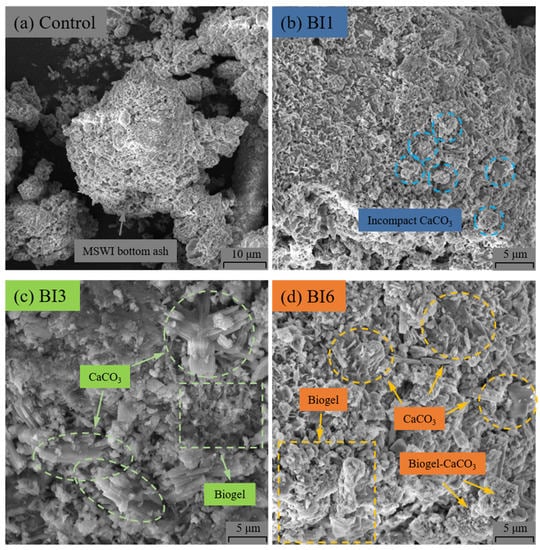

3.7. Scanning Electron Microscope Analysis

The effect of the bacterial concentration on IBA was further analyzed by microscopic morphology. The SEM images are shown in Figure 8. It can be seen from Figure 8 that the microscopic morphologies of the samples with different bacterial concentrations are significantly different. In Figure 8a, there is a small amount of flocculation (composition of the biosolution after drying) on the surface of the IBA particles, which is not generated by MICP because the added bacteria in sample control are inactivated. It is reported by Ramachandran et al. [44] that the inactivated bacterial solution can still form a gel, but its cementing property is very weak. It can be seen from sample BI1 (in Figure 8b) that there are many incompact CaCO3 precipitates on the surface of IBA particles, and these precipitates have small shapes and even incomplete structures. The bacterial concentration of sample BI3 (in Figure 8c) is 105 cells/mL, thus the generated CaCO3 is the whole prismatic and widely distributed. Meanwhile, many biogels are attached to the surface of IBA, which are not observed in the samples with low bacterial concentrations, such as the control and BI1. Additionally, referring to sample BI6 (in Figure 8d), it is observed that there is a large number of bioprecipitates in the image, and the pores between these precipitates are filled with the biogel, which improves the compactness of the sample.

Figure 8.

SEM results of samples (a) control, (b) BI1, (c) BI3, and (d) BI6. CaCO3 is a complete square columnar, biogel is fibrous flocculent, and biogel-CaCO3 refers to biogel being attached to CaCO3 [22,45].

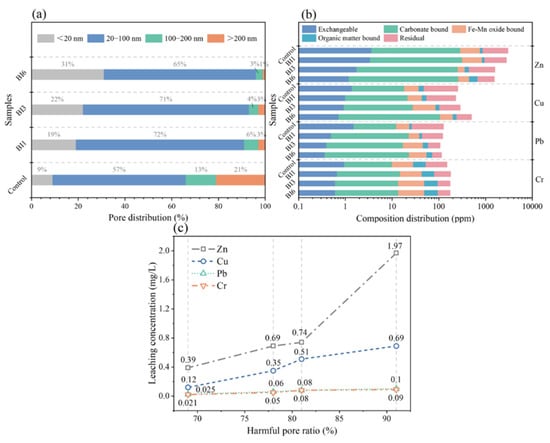

It can be concluded from Figure 8 that the low concentration of bacteria can reduce the effect of biomineralization; the generated bioprecipitation is incompact and the structure is incomplete. With the increase in the bacterial concentration, the bioprecipitate becomes large and has a large complete structure, as well as combines with the biogel to form a compact cementing structure. The compact structure can reduce the porosity in the sample (in Figure 9a) to immobilize Zn, Cu, and Pb. This shows that the appropriate concentration of bacteria can promote the reaction between calcium ions and carbonate ions, and Zn, Cu, Pb, and Cr are also precipitated as heavy metal carbonate referring to Figure 4b. Hence, the MICP treatment has a positive effect on the immobilization of heavy metals in IBA.

Figure 9.

(a) Pore distribution, (b) chemical speciation distribution of heavy metals in samples control, BI1, BI3, and BI6, and (c) relationship between harmful pore ratio and leaching concentration of the heavy metals, where harmful refers to pore size greater than 20 nm.

3.8. Distribution of Pore and Chemical Speciation

To further analyze the mechanism of the immobilization of heavy metals by the biobinder, the pore size and chemical speciation distribution were analyzed. The analysis results are shown in Figure 9. The pore size distribution of the sample is shown in Figure 9a, where pores less than 20 nm are harmless, pores 20–100 nm are less harmful, pores 100–200 nm are harmful, and pores more than 200 nm are very harmful [46,47]. The small pore size (less than 100 nm) ratios of samples BI1, BI3, and BI6 are 91%, 93%, and 96%, respectively. However, the ratio of this pore size in the sample control is only 66%. Additionally, in the sample control, the macropore (more than 100 nm) accounted for 34%, which belongs to harmful and very harmful pores. This shows that the biobinder can improve the pore size distribution of the samples. Bacterial concentration increases the ratio of less harmful pores and harmless pores, which improves the compactness of the samples and is conducive to immobilizing the heavy metals. Combined with Figure 8, the increased bacterial concentration accelerates the reaction between Ca2+ and , thus a large number of the generated bioprecipitates can fill the pores in the samples. Additionally, the relationship between a harmful pore ratio and leaching concentration of the heavy metals is analyzed according to the TCLP results and pore distribution results; the results are given in Figure 9c. It can be seen that the leaching concentration of the tested heavy metals increases with the increasing ratio of harmful pores. Especially for Zn and Cu ions, when the ratios of harmful pores decrease from 91% to 69%, their leaching concentrations decrease by 80.20% and 82.61%, respectively. This indicates that the reduction of the harmful pore ratio can reduce the leaching concentration of the heavy metals. Combined with the SEM results, it can be shown that the increase in the biosolution concentration can improve the microstructural properties of samples, resulting in a compact structure and a reduced proportion of harmful pores, thus improving the physical envelope of the heavy metals. This is consistent with the results of Fan et al. [16].

The five chemical speciation distributions are shown in Figure 9b, where the stable chemical speciation includes carbonate bound and Fe-Mn oxide bound, while exchangeable bound and residual bound are unstable speciations [48]. Taking Zn as an example, the concentration of carbonate bound in the sample control is 261.29 mg/L, and the concentration of its residual bound is 2194.12 mg/L. The concentrations of carbonate bound and residual bound in the sample BI6 are 283.07 mg/L and 885.73 mg/L, respectively. The increased bacterial concentration decreases the concentration of residual bound and increases the concentration of carbonate bound. The XRD results (in Figure 4b) also showed that new compounds, such as ZnCO3, CuCO3, and PbCO3, were generated in the biotreated IBA. Interestingly, it can be seen from Figure 9b that the changing trend of the chemical speciation of Cu, Pb, and Cr is similar to that of Zn, which means that the carbonate bound increases with the increase of biosolution concentration, but the residual bound is opposite. This indicates that biotreatment can change the chemical speciation of heavy metals in IBA to change from unstable residual bound to stable carbonate bound, which is the reason why MICP can stabilize the heavy metals [32]. Combined with the FTIR test results (in Figure 6), the increase in the intensity of the chemical bond of indicates an increase in carbonate compounds, which corresponds to the increase in carbonate bound (in Figure 9b). Referring to a series of characterization tests in this study and the results of the previous studies [49], the principle is summarized as follows: (Equations (1)–(4)) is generated by the catalysis of urease. Meanwhile, the bacteria can adsorb Ca2+, Zn2+, Cu2+, Pb2+, and Cr2+ (in Equations (5) and (7)) due to the negative charge on its surface [42]. Finally, cations react with carbonate ions to generate carbonate precipitation (in Equations (6) and (8)) by the induction of bacteria [50].

The results of pore size and chemical speciation show that there are two ways to solidify heavy metals in IBA by biotreatment. One way is solidification, that is, the biogel and bioprecipitation generated by MICP form a compact structure to encapsulate heavy metals, thus the migration of heavy metals is reduced. The second way is stabilization, which converts the heavy metals into stable speciation of carbonate bound by changing chemical speciation and chemical bonds under the induction of bacteria.

4. Conclusions

This study reported a novel biobinder with different bacterial concentrations for noted heavy metals solidification/stabilization. The effects of MICP technology on the leaching concentration, pH dependence, micromorphology, chemical morphology, and pore size distribution of IBA were investigated; the results are as follow:

- (i)

- Biotreatment can effectively reduce the leaching concentrations of Zn, Cu, Pb, and Cr in IBA. At 28 days, the leaching concentrations of samples from BI1 to BI6 are all below the national standard.

- (ii)

- The higher the bacterial concentration, the lower the leaching concentration of the heavy metals. Especially in the samples with high bacterial concentration, the average immobilization ratios among Zn, Cu, Pb, and Cr reached 65.3%–76.4%, respectively.

- (iii)

- A high concentration of bacteria can improve biomineralization and increase the production of the biogel and bioprecipitate, as well as forming a compact cementing structure.

- (iv)

- The bivalent heavy metal ions were precipitated as heavy metal carbonate by induction of the bacteria, which increased the concentration of carbonate-bound speciation.

- (v)

- This work confirms the feasibility of the biobinder for IBA solidification/stabilization. This lays a foundation for the management of MICP in IBA and breaks the traditional idea of using a cement-based binder.

Author Contributions

Z.L.: writing—original draft. N.W.: resources and methodology. Y.S.: funding acquisition. J.X.: review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The support of the Innovation Program for College Students [grant number 2022BKY19] is gratefully acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data is displayed in the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xiang, J.; Qiu, J.; Yuan, J.; Fu, H.; Yang, Y.; Gu, X. Study on denitrifying biogrout to immobilize heavy metals in bottom ash in an anaerobic environment and its immobilization mechanism. J. Environ. Chem. Eng. 2022, 10, 108084. [Google Scholar] [CrossRef]

- Rambaldi, E.; Esposito, L.; Andreola, F.; Barbieri, L.; Lancellotti, I.; Vassura, I. The recycling of MSWI bottom ash in silicate based ceramic. Ceram. Int. 2010, 36, 2469–2476. [Google Scholar] [CrossRef]

- Wongsa, A.; Boonserm, K.; Waisurasingha, C.; Sata, V.; Chindaprasirt, P. Use of municipal solid waste incinerator (MSWI) bottom ash in high calcium fly ash geopolymer matrix. J. Clean. Prod. 2017, 148, 49–59. [Google Scholar] [CrossRef]

- Polozhyi, K.; Reiterman, P.; Keppert, M. MSWI Bottom Ash as an Aggregate for a Lightweight Concrete. Adv. Mater. Res. 2014, 1054, 254–257. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Fernandez, A.I.; Nadal, R.; Espiell, F. Short-term natural weathering of MSWI bottom ash. J. Hazard. Mater. 2000, 79, 287–299. [Google Scholar] [CrossRef]

- Hashemi, S.S.G.; Bin Mahmud, H.; Ghuan, T.C.; Chin, A.B.; Kuenzel, C.; Ranjbar, N. Safe disposal of coal bottom ash by solidification and stabilization techniques. Constr. Build. Mater. 2019, 197, 705–715. [Google Scholar] [CrossRef]

- Anastasiadou, K.; Christopoulos, K.; Mousios, E.; Gidarakos, E. Solidification/stabilization of fly and bottom ash from medical waste incineration facility. J. Hazard. Mater. 2012, 207, 165–170. [Google Scholar] [CrossRef]

- Pecqueur, G.; Crignon, C.; Quenee, B. Behaviour of cement-treated MSWI bottom ash. Waste Manag. 2001, 21, 229–233. [Google Scholar] [CrossRef]

- Singh, D.; Kumar, A. Factors affecting properties of MSWI bottom ash employing cement and fiber for geotechnical applications. Environ. Dev. Sustain. 2020, 22, 6891–6905. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Tian, S.C.; Liu, L.L.; Wang, X.D.; Zhang, Z.T. Recycling ground MSWI bottom ash in cement composites: Long-term environmental impacts. Waste Manag. 2018, 78, 841–848. [Google Scholar] [CrossRef]

- Caprai, V.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. MSWI bottom ash as binder replacement in wood cement composites. Constr. Build. Mater. 2019, 196, 672–680. [Google Scholar] [CrossRef]

- Garrabrants, A.C.; Kosson, D.S.; Brown, K.G.; Fagnant, D.P.; Helms, G.; Thorneloe, S.A. Demonstration of the use of test results from the Leaching Environmental Assessment Framework (LEAF) to develop screening-level leaching assessments. Waste Manag. 2021, 121, 226–236. [Google Scholar] [CrossRef] [PubMed]

- Bernasconi, D.; Caviglia, C.; Destefanis, E.; Agostino, A.; Boero, R.; Marinoni, N.; Bonadiman, C.; Pavese, A. Influence of speciation distribution and particle size on heavy metal leaching from MSWI fly ash. Waste Manag. 2022, 138, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Grazulyte, J.; Vaitkus, A.; Sernas, O.; Zalimiene, L. The impact of MSWI bottom ash as aggregate on concrete mechanical performance. Int. J. Pavement Eng. 2021, 23, 2903–2911. [Google Scholar] [CrossRef]

- Xiang, J.; Qiu, J.; Zheng, P.; Sun, X.; Zhao, Y.; Gu, X. Usage of biowashing to remove impurities and heavy metals in raw phosphogypsum and calcined phosphogypsum for cement paste preparation. Chem. Eng. J. 2023, 451, 138594. [Google Scholar] [CrossRef]

- Fan, C.; Wang, B.; Qi, Y.; Liu, Z. Characteristics and leaching behavior of MSWI fly ash in novel solidification/stabilization binders. Waste Manag. 2021, 131, 277–285. [Google Scholar] [CrossRef]

- Pei, R.; Liu, J.; Wang, S.; Yang, M. Use of bacterial cell walls to improve the mechanical performance of concrete. Cem. Concr. Compos. 2013, 39, 122–130. [Google Scholar] [CrossRef]

- Okwadha, G.D.O.; Li, J. Optimum conditions for microbial carbonate precipitation. Chemosphere 2010, 81, 1143–1148. [Google Scholar] [CrossRef]

- Kua, H.W.; Gupta, S.; Aday, A.N.; Srubar, W.V. Biochar-immobilized bacteria and superabsorbent polymers enable self-healing of fiber-reinforced concrete after multiple damage cycles. Cem. Concr. Compos. 2019, 100, 35–52. [Google Scholar] [CrossRef]

- Chen, P.; Zheng, H.; Xu, H.; Gao, Y.X.; Ding, X.Q.; Ma, M.L. Microbial induced solidification and stabilization of municipal solid waste incineration fly ash with high alkalinity and heavy metal toxicity. PLoS ONE 2019, 14, e0223900. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Chen, L.; Guo, B.; Tan, Y.; Sasaki, K.; Tsang, D.C.W. Designing novel magnesium oxysulfate cement for stabilization/solidification of municipal solid waste incineration fly ash. J. Hazard. Mater. 2022, 423, 127025. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.P.; Xiang, J.C.; Zhang, W.Q.; Zhao, Y.L.; Sun, X.G.; Gu, X.W. Effect of microbial-cemented on mechanical properties of iron tailings backfill and its mechanism analysis. Constr. Build. Mater. 2022, 318, 10. [Google Scholar] [CrossRef]

- Ma, Q.; Xiang, J.C.; Yang, Y.C.; Xiao, H.L.; Wan, J. Study on the mechanical properties of flax fiber-reinforced silty clay contaminated by zinc-ion solution. Environ. Technol. 2021, 42, 1071–1083. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, X.Z. Self-healing of concrete cracks by use of bacteria-containing low alkali cementitious material. Constr. Build. Mater. 2018, 167, 1–14. [Google Scholar] [CrossRef]

- Xiang, J.; Qiu, J.; Li, Z.; Chen, J.; Song, Y. Eco-friendly treatment for MSWI bottom ash applied to supplementary cementing: Mechanical properties and heavy metal leaching concentration evaluation. Constr. Build. Mater. 2022, 327, 127012. [Google Scholar] [CrossRef]

- Kahani, M.; Kalantary, F.; Soudi, M.R.; Pakdel, L.; Aghaalizadeh, S. Optimization of cost effective culture medium for Sporosarcina pasteurii as biocementing agent using response surface methodology: Up cycling dairy waste and seawater. J. Clean. Prod. 2020, 253, 120022. [Google Scholar] [CrossRef]

- Lai, Y.M.; Yu, J.; Liu, S.Y.; Liu, J.F.; Wang, R.K.; Dong, B.W. Experimental study to improve the mechanical properties of iron tailings sand by using MICP at low pH. Constr. Build. Mater. 2021, 273, 121729. [Google Scholar] [CrossRef]

- Liu, J.R.; Su, J.F.; Ali, A.; Wang, Z.; Zhang, R.J. Potential of a novel facultative anaerobic denitrifying Cupriavidus sp. W12 to remove fluoride and calcium through calcium bioprecipitation. J. Hazard. Mater. 2022, 423, 126976. [Google Scholar] [CrossRef]

- Skevi, L.; Reeksting, B.J.; Hoffmann, T.D.; Gebhard, S.; Paine, K. Incorporation of bacteria in concrete: The case against MICP as a means for strength improvement. Cem. Concr. Compos. 2021, 120, 104056. [Google Scholar] [CrossRef]

- Proudfoot, D.; Brooks, L.; Gammons, C.H.; Barth, E.; Bless, D.; Nagisetty, R.M.; Lauchnor, E.G. Investigating the potential for microbially induced carbonate precipitation to treat mine waste. J. Hazard. Mater. 2022, 424, 127490. [Google Scholar] [CrossRef]

- Yue, J.W.; Zhao, L.M.; Zhang, B.X.; Kong, Q.M.; Wang, S.Y.; Wang, H. Effect of Glutinous Rice Slurry on the Reinforcement of Silt in the Yellow River Basin by Microbially Induced Carbonate Precipitation (MICP): Mechanical Property and Microcosmic Structure. Adv. Mater. Sci. Eng. 2021, 2021, 5539854. [Google Scholar] [CrossRef]

- Chen, X.Y.; Achal, V. Biostimulation of carbonate precipitation process in soil for copper immobilization. J. Hazard. Mater. 2019, 368, 705–713. [Google Scholar] [CrossRef] [PubMed]

- Li, X.D.; Poon, C.S.; Sun, H.; Lo, I.M.C.; Kirk, D.W. Heavy metal speciation and leaching behaviors in cement based solidified/stabilized waste materials. J. Hazard. Mater. 2001, 82, 215–230. [Google Scholar] [CrossRef] [PubMed]

- Mollah, M.Y.A.; Yu, W.H.; Schennach, R.; Cocke, D.L. A Fourier transform infrared spectroscopic investigation of the early hydration of Portland cement and the influence of sodium lignosulfonate. Cem. Concr. Res. 2000, 30, 267–273. [Google Scholar] [CrossRef]

- Lodeiro, I.G.; Macphee, D.E.; Palomo, A.; Fernandez-Jimenez, A. Effect of alkalis on fresh C-S-H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernandez-Jimenez, A.; Macphee, D.E. Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O-CaO-Al2O3-SiO2-H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Schuiling, R.D.; Ding, Z.; Hickey, L.; Wharton, D.; Frost, R.L. Vibrational spectroscopic study of syngenite formed during the treatment of liquid manure with sulphuric acid. Vib. Spectrosc. 2002, 28, 209–221. [Google Scholar] [CrossRef]

- Tang, S.W.; Wang, Y.; Geng, Z.C.; Xu, X.F.; Yu, W.Z.; Hubao, A.; Chen, J.T. Structure, Fractality, Mechanics and Durability of Calcium Silicate Hydrates. Fractal Fract. 2021, 5, 47. [Google Scholar] [CrossRef]

- Lo, Y.; Lee, H.M. Curing effects on carbonation of concrete using a phenolphthalein indicator and Fourier-transform infrared spectroscopy. Build. Environ. 2002, 37, 507–514. [Google Scholar] [CrossRef]

- Pham, V.P.; Nakano, A.; van der Star, W.R.L.; Heimovaara, T.J.; van Paassen, L.A. Applying MICP by denitrification in soils: A process analysis. Environ. Geotech. 2018, 5, 79–93. [Google Scholar] [CrossRef]

- Mollah, M.Y.A.; Kesmez, M.; Cocke, D.L. An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) investigation of the long-term effect on the solidification/stabilization (S/S) of arsenic(V) in Portland cement type-V. Sci. Total Environ. 2004, 325, 255–262. [Google Scholar] [CrossRef]

- Xiang, J.; Qiu, J.; Wang, Y.; Gu, X. Calcium acetate as calcium source used to biocement for improving performance and reducing ammonia emission. J. Clean. Prod. 2022, 348, 131286. [Google Scholar] [CrossRef]

- Tirkolaei, H.K.; Bilsel, H. Statistical Modeling of Environmental Factors on Microbial Urea Hydrolysis Process for Biocement Production. Adv. Mater. Sci. Eng. 2015, 2015, 340930. [Google Scholar]

- Ramachandran, S.K.; Ramakrishnan, V.; Bang, S.S. Remediation of concrete using micro-organisms. Aci Mater. J. 2001, 98, 3–9. [Google Scholar]

- Deng, X.J.; Yuan, Z.X.; Li, Y.; Liu, H.; Feng, J.Y.; de Wit, B. Experimental study on the mechanical properties of microbial mixed backfill. Constr. Build. Mater. 2020, 265, 120643. [Google Scholar] [CrossRef]

- Chen, X.D.; Wu, S.X. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 2013, 38, 804–812. [Google Scholar] [CrossRef]

- Renhe, Y.; Baoyuan, L.; Zhongwei, W. Study on the pore structure of hardened cement paste by SAXS. Cem. Concr. Res. 1990, 20, 385–393. [Google Scholar] [CrossRef]

- Li, M.G.; Sun, C.J.; Gau, S.H.; Chuang, C.J. Effects of wet ball milling on lead stabilization and particle size variation in municipal solid waste incinerator fly ash. J. Hazard. Mater. 2010, 174, 586–591. [Google Scholar] [CrossRef]

- Xue, Z.-F.; Cheng, W.-C.; Wang, L.; Hu, W. Effects of bacterial inoculation and calcium source on microbial-induced carbonate precipitation for lead remediation. J. Hazard. Mater. 2022, 426, 128090. [Google Scholar] [CrossRef]

- Kang, C.-H.; Oh, S.J.; Shin, Y.; Han, S.-H.; Nam, I.-H.; So, J.-S. Bioremediation of lead by ureolytic bacteria isolated from soil at abandoned metal mines in South Korea. Ecol. Eng. 2015, 74, 402–407. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).