Influence of Gas Pressure on the Failure Mechanism of Coal-like Burst-Prone Briquette and the Subsequent Geological Dynamic Disasters

Abstract

1. Introduction

2. Materials and Methods

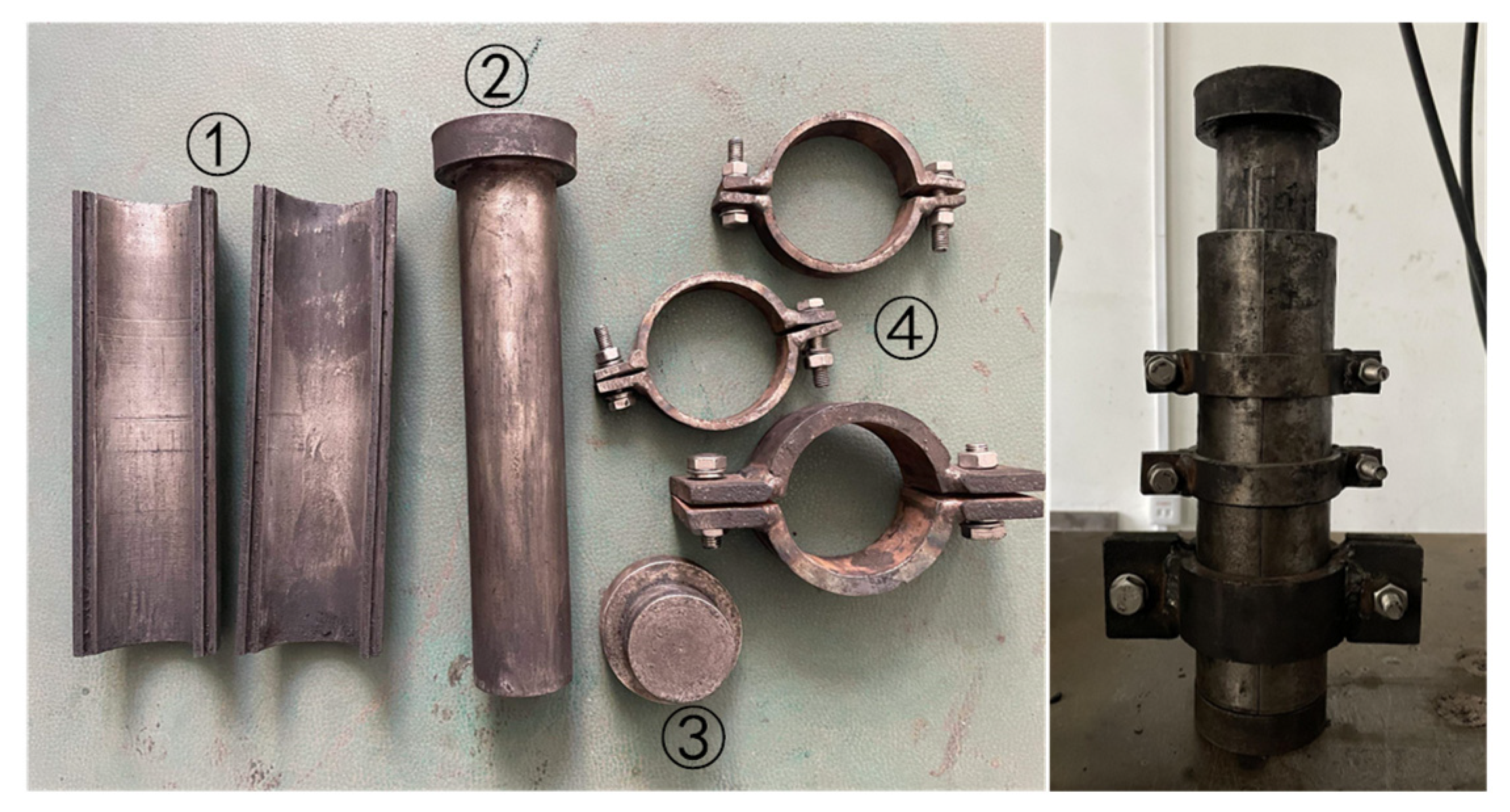

2.1. Mold Design

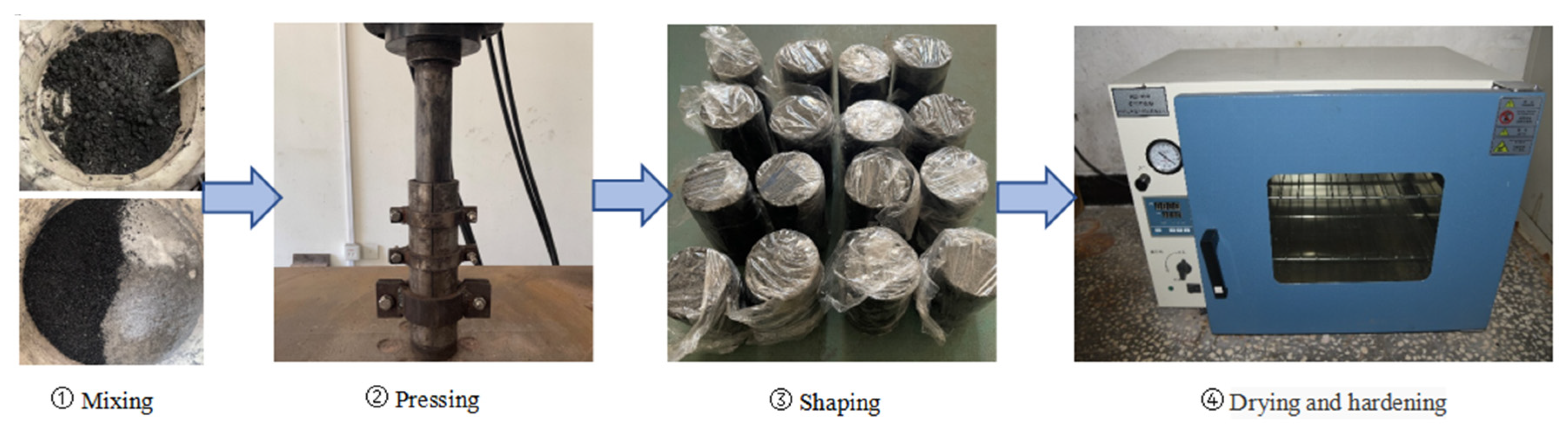

2.2. Specimen Preparation

2.3. New Multi-Phase (Solid–Gas Coupling) Testing Facility

2.4. Testing Scheme

3. Results

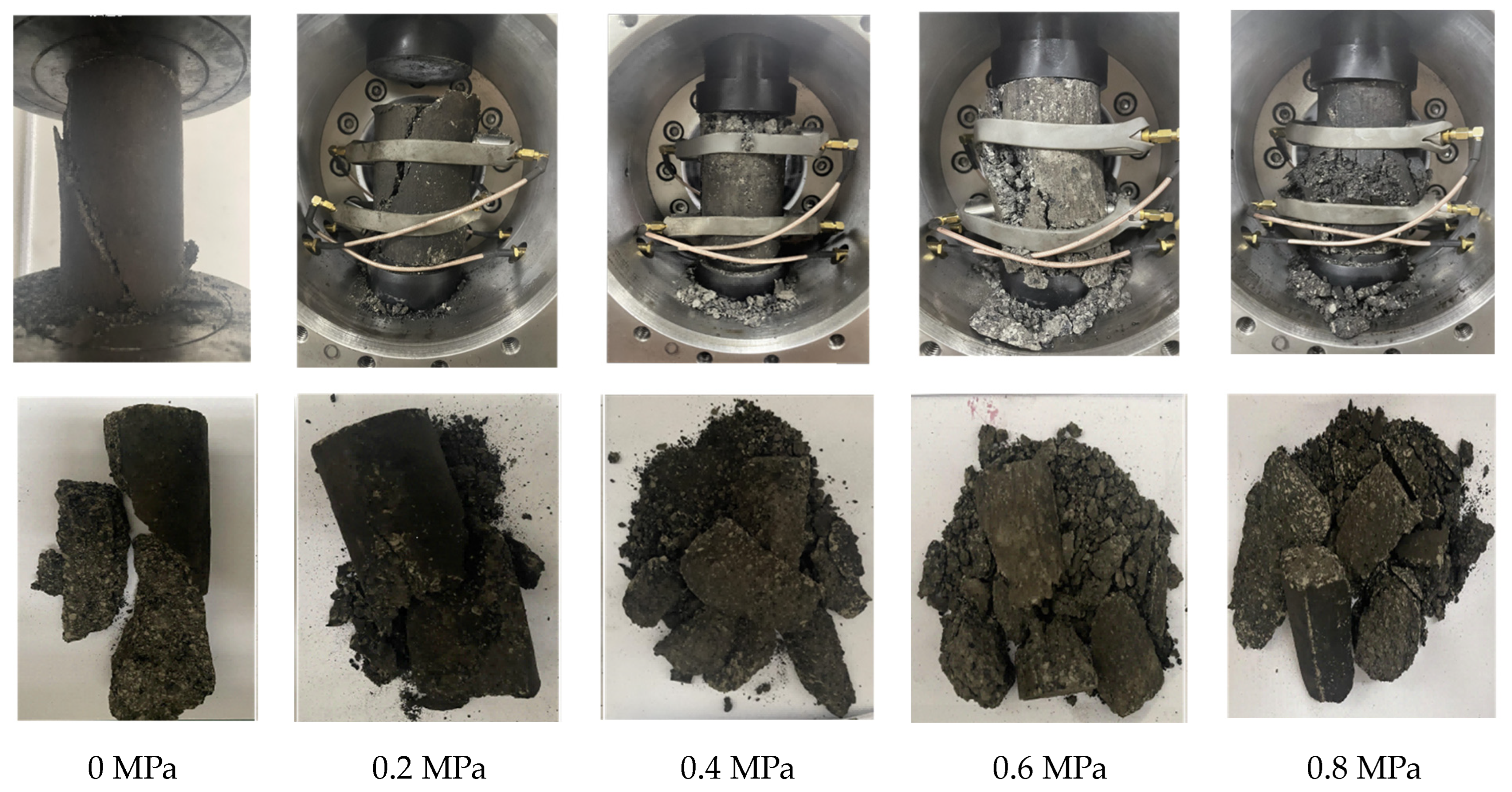

3.1. The Effect of Gas on Coal Failure Modes

3.2. The Effect of Gas on Burst Proneness

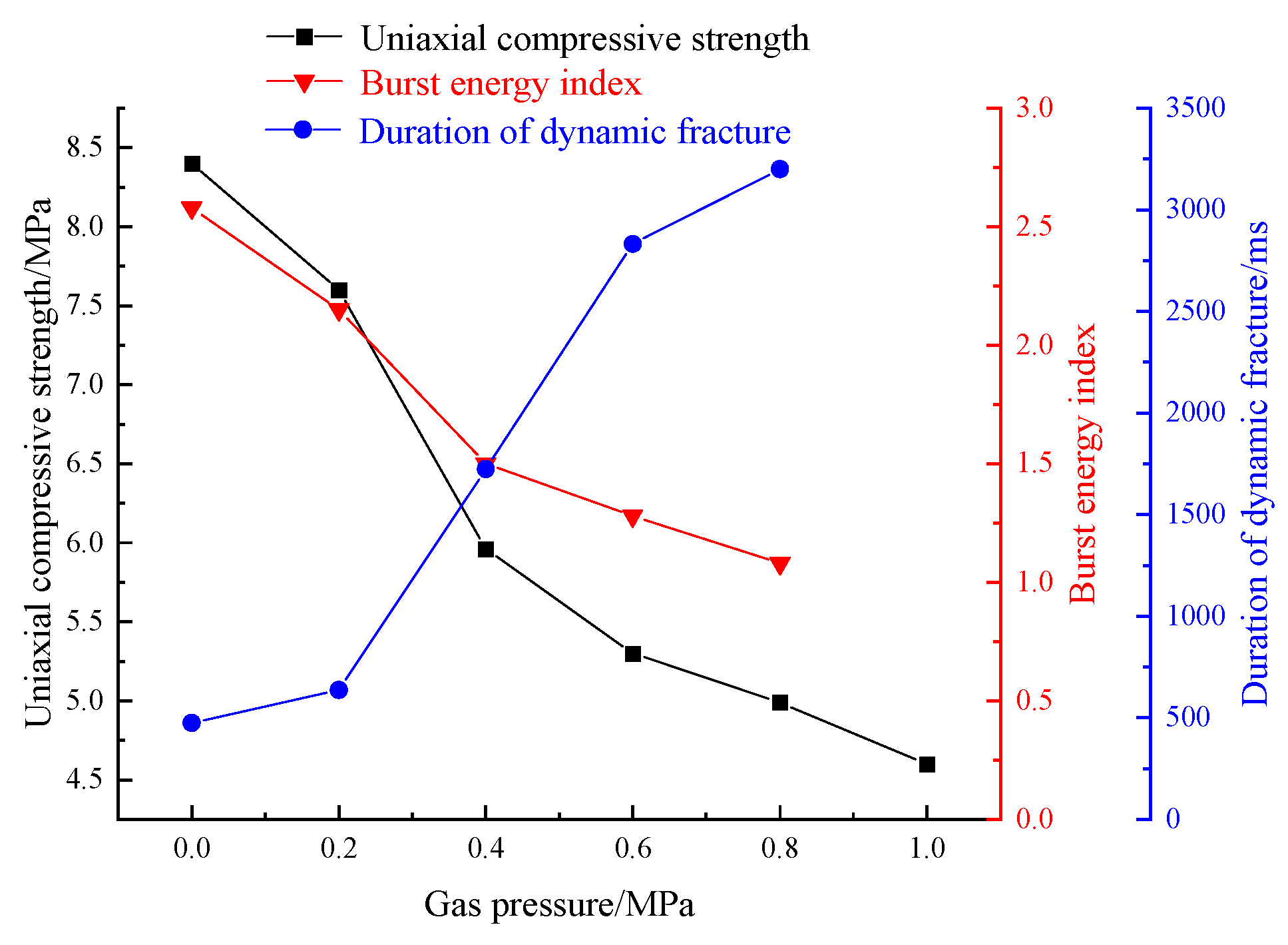

3.2.1. Uniaxial Compressive Strength

3.2.2. Duration of Dynamic Fracture

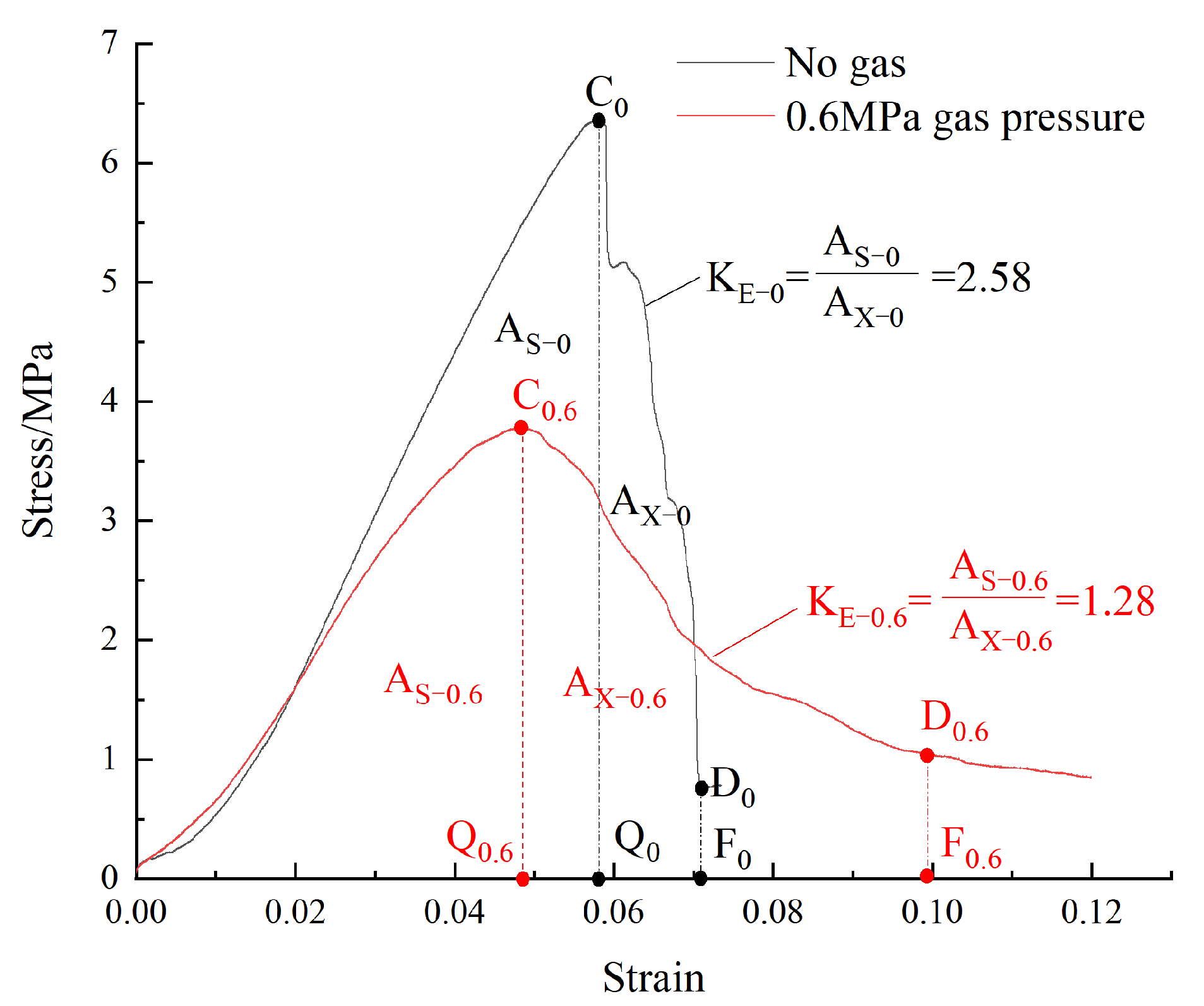

3.2.3. Burst Energy Index

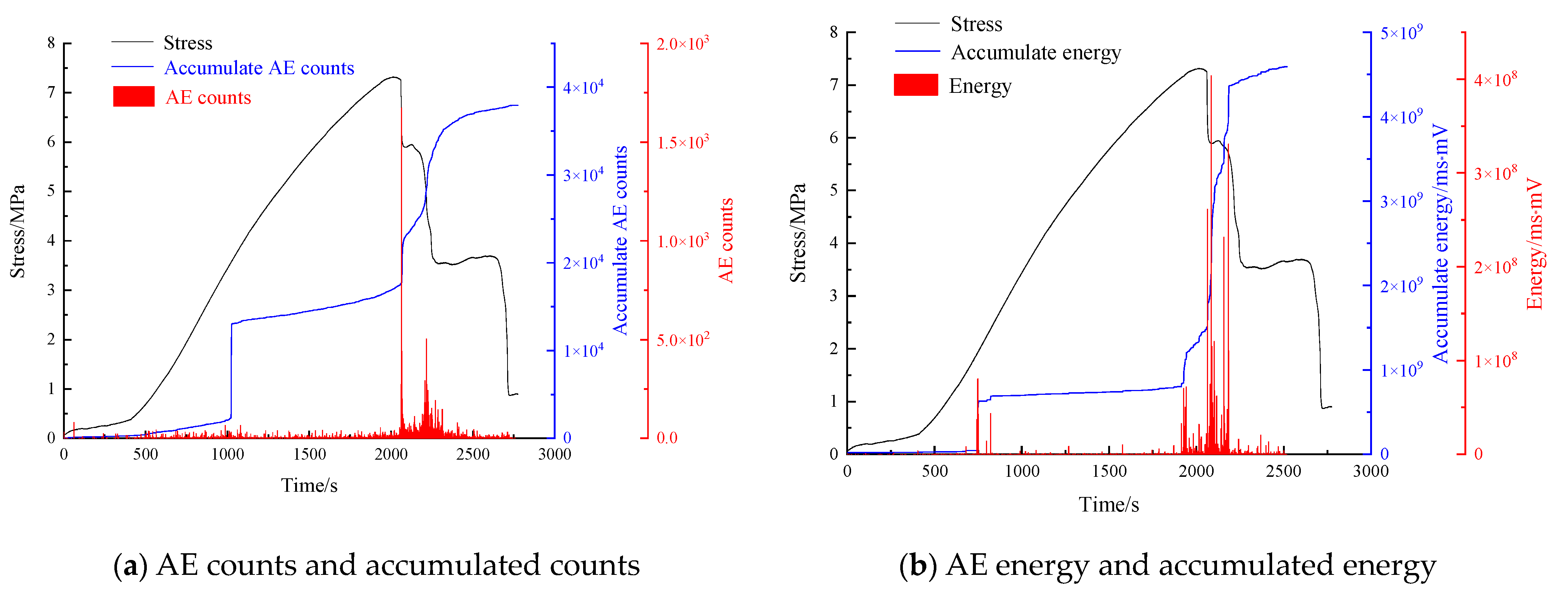

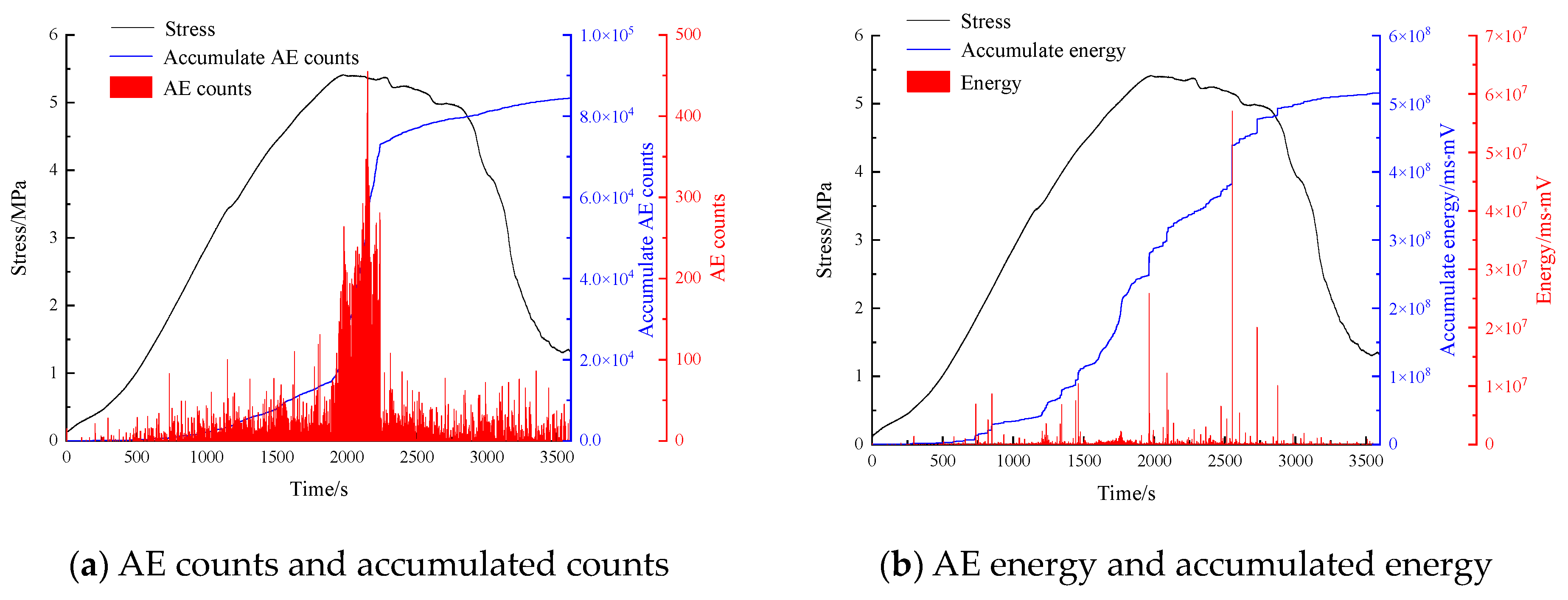

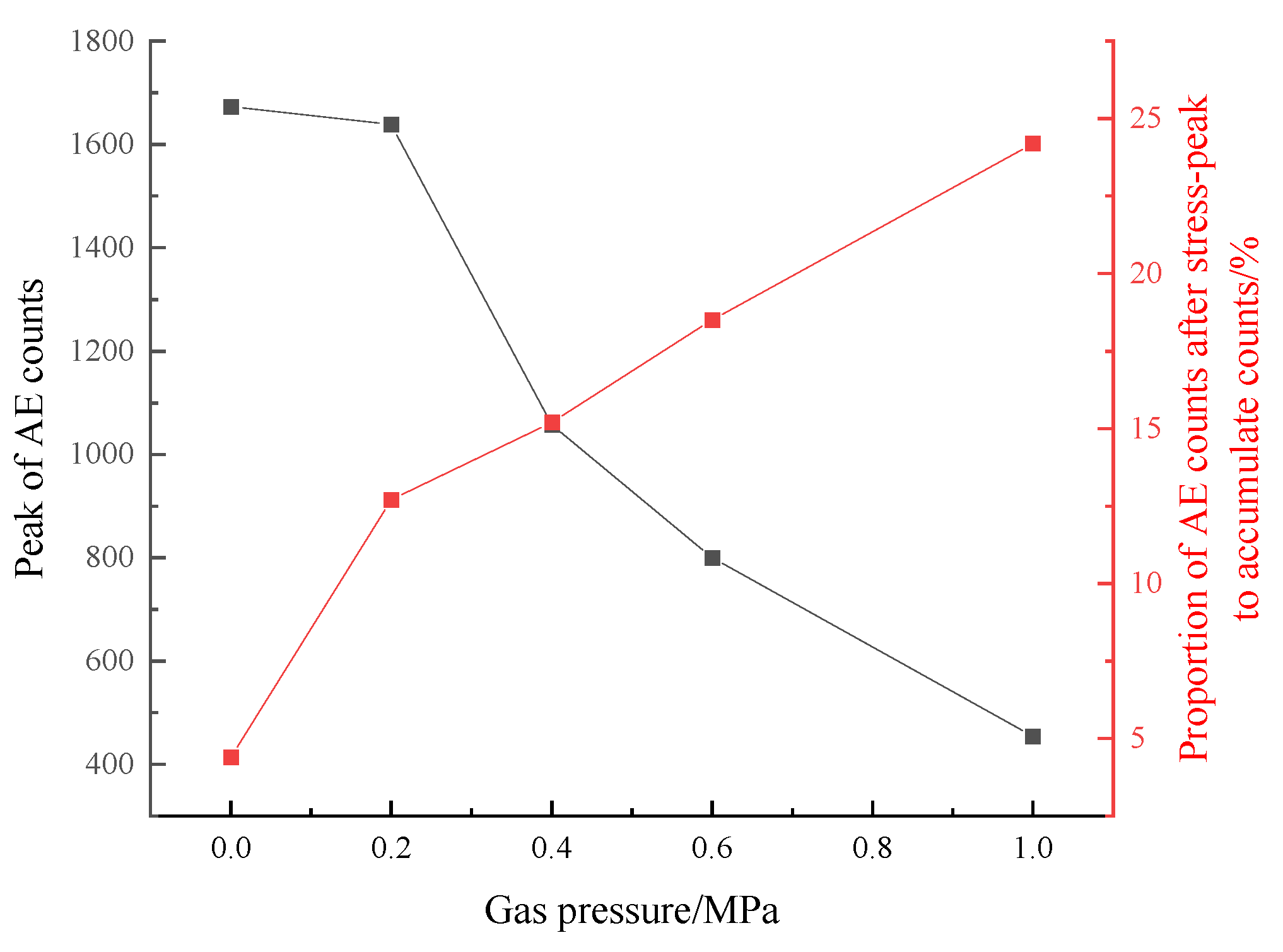

3.3. AE Data Analysis for Gas-Saturated Coal Specimen

4. Discussion

5. Conclusions

- (1)

- A new multi-phase (solid–gas coupling) testing facility composed of a servo control loading system with a solid–gas coupling device, a gas supply system, an acoustic emission (AE) monitoring system, and an external monitoring system has been developed. The preparation of burst-prone coal briquettes was performed for the first time. This provides an experimental basis to determine the influence of gas on the failure mode and burst proneness of specimens.

- (2)

- The gas content has a great influence on the failure mode of coal specimens. With an increase in gas pressure, the macroscopic damage pattern of coal specimens gradually changes from bursting-ejecting of large pieces to stripping–shedding of small fragments adhered to mylonitic coal.

- (3)

- The gas pressure affects the burst proneness index of coal specimens and causes the weakening and loss of the burst properties of coal specimens. The compressive strength of the coal specimen decreases with the increase in gas pressure, and the critical gas pressure for the loss of burst proneness is 0.4 MPa. The duration of dynamic fracture of coal specimens increases with the increase in gas pressure, and the critical gas pressure for the loss of burst proneness is 0.2 MPa. The burst energy index decreases with the increase in gas pressure, and the critical gas pressure for the loss of burst proneness is 0.6 MPa. The duration of dynamic fracture is more sensitive to gas pressure.

- (4)

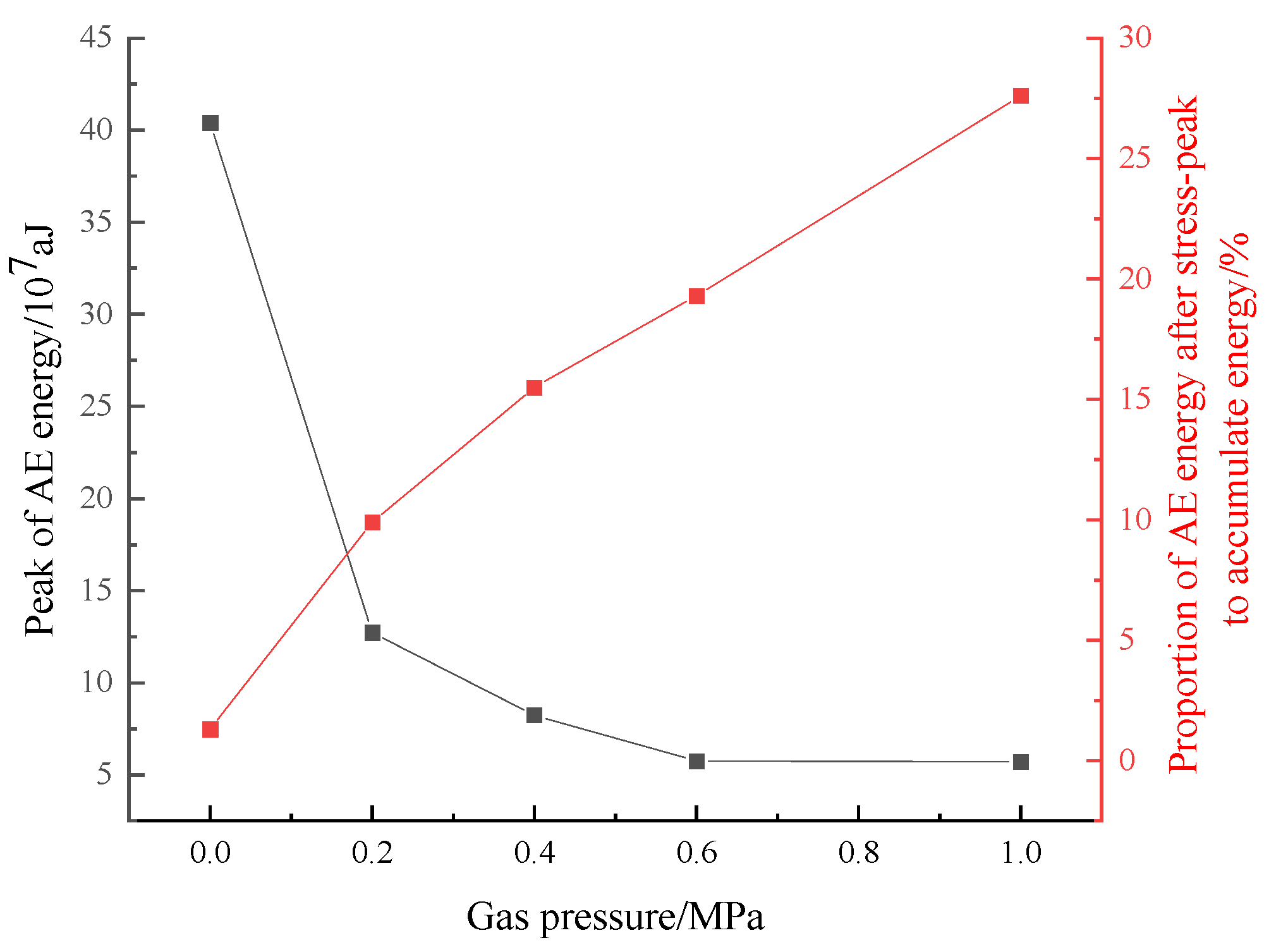

- The ratio of the AE counts and energy after the stress peak to the accumulated AE counts and energy increases with the increase in gas pressure, which shows that the consumed energy after the stress peak increases. This eventually leads to the loss of burst proneness of the coal specimen.

- (5)

- Based on the test results, it is suggested that when identifying the burst proneness of deep, high-gas-content coal seams, it is necessary to account for the corresponding gas pressure in the environment in the relevant burst proneness tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Balovtsev, S.V.; Skopintseva, O.V.; Kolikov, K.S. Aerological risk management in preparation for mining of coal mines. Sustain. Dev. Mt. Territ. 2022, 14, 107–116. [Google Scholar] [CrossRef]

- Bosikov, I.I.; Martyushev, N.V.; Klyuev, R.V.; Savchenko, I.A.; Kukartsev, V.V.; Kukartsev, V.A.; Tynchenko, Y.A. Modeling and complex analysis of the topology parameters of ventilation networks when ensuring fire safety while developing coal and gas deposits. Fire 2023, 6, 95. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, G.Z.; Hu, Q.T.; Jin, H.W. Inducing and Transforming Conditions from Rockburst to Coa-l Gas Outburst in a High Gassy Coal Seam. J. Min. Saf. Eng. 2010, 27, 572–575. [Google Scholar]

- Wang, T.; Wang, Z.H.; Liu, H.B.; Guan, Y.P.; Zhan, S.J. Discussion about the mechanism of gas disaster induced by coal bump. J. China Coal Soc. 2014, 39, 371–376. [Google Scholar]

- Sun, X.P.; Ma, Z.Y.; Zhang, F. Analysis on Causes of Abnormal Gas Emission from Working Faces with Rock Burst and Research on Its Treatment Technology. Coal Technol. 2021, 40, 122–125. [Google Scholar]

- Yan, W.W. Cause analysis and prevention technology of abnormal gas emission in working face with rock burst danger. China Energy Environ. Prot. 2021, 43, 24–27. [Google Scholar]

- Zhang, F.; Ma, Z.Y. Mechanism of abnormal gas emission from mining face with rock burst danger and its control. China Energy Environ. Prot. 2021, 43, 16–20. [Google Scholar]

- Li, Z.H.; Zhang, Y.; Liang, Y. Mechanism study on compound disaster of rock burst and gas outburst. Coal Sci. Technol. 2021, 49, 95–103. [Google Scholar]

- Chen, B. Stress-induced trend: The clustering feature of coal mine disasters and earthquakes in China. Int. J. Coal Sci. Technol. 2020, 7, 676–692. [Google Scholar] [CrossRef]

- Gao, B.B.; Ren, C.N.; Dong, Q.; Chen, L.W. Study on dynamic behavior law and microseismic monitoring in stoping process of roadway with high gas and wide coal pillar. Shock Vib. 2021, 2021, 1–14. [Google Scholar] [CrossRef]

- Zhang, J.G.; Lan, T.W.; Wang, M.; Gao, M.Z.; Rong, H. Prediction method of deep mining dynamic disasters and its application in Pingdingshan mining area. J. China Coal Soc. 2019, 44, 1698–1706. [Google Scholar]

- Zhai, C.; Xiang, X.W.; Xu, J.Z.; Wu, S.L. The characteristics and main influencing factors affecting coal and gas outbursts in Chinese Pingdingshan mining region. Nat. Hazards 2016, 82, 507–530. [Google Scholar] [CrossRef]

- Kong, X.G.; Yang, S.R.; Wang, E.Y.; Li, S.G.; Lin, H.F.; Ji, P.F. Fracture evolution and gas emission characteristics of raw coal samples subjected to instantaneous disturbance of impact load. Chin. J. Rock Mech. Eng. 2022. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, Q.X.; Ren, T.; Li, X.C.; Gao, K.; Li, C.Y.; Li, X.P.; Yuan, H.H. Study on the damage and fracture characteristics of coal rock based on the X-ray micro-CT scanning technology and statistical strength theory. Coal Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Ouyang, Z.H.; Zhang, G.H.; Li, Q.W.; Lai, X.P.; Qin, H.Y.; Zhao, X.D.; Zhou, X.X. Study on the rock burst tendentiousness of coal under different gas pressures. Arab. J. Geosci. 2019, 13, 179–187. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Pan, Y.S.; Jiang, F.X.; Dou, L.M.; Ju, Y. State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 2014, 39, 205–213. [Google Scholar]

- Amin, M.; Ming, C. Analysis of rockburst in tunnels subjected to static and dynamic loads. J. Rock Mech. Geotech. Eng. 2017, 9, 1031–1040. [Google Scholar]

- Yin, G.Z.; Li, X.; Lu, J.; Li, M.H. Disaster-causing mechanism of compound dynamic disaster in deep mining under static and dynamic load conditions. J. China Coal Soc. 2017, 42, 2316–2326. [Google Scholar]

- Dai, L.; Pan, Y.; Zhang, C.; Wang, A.; Canbulat, I.; Shi, T. New criterion of critical mining stress index for risk evaluation of roadway rockburst. Rock Mech. Rock Eng. 2022, 55, 4783–4799. [Google Scholar] [CrossRef]

- Song, Z.L.; Han, P.B.; Li, W.P.; Yin, G.Z.; Li, M.H.; Kang, X.T. Impact of energy dissipation of coal samples with rockburst tendency from gas in its failure process. J. China Coal Soc. 2015, 40, 843–849. [Google Scholar]

- Xu, J.; Jiang, J.D.; Xu, N.; Liu, Q.S.; Gao, Y.F. A new energy index for evaluating the tendency of rockburst and its engineering application. Eng. Geol. 2017, 230, 46–54. [Google Scholar] [CrossRef]

- Espinoza, D.N.; Pereira, J.-M.; Vandamme, M.; Dangla, P.; Vidal-Gilbert, S. Desorption–induced shear failure of coal bed seams during gas depletion. Int. J. Coal Geol. 2015, 137, 142–151. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Zhang, C.; Fang, X.; Li, S. The Characterization of Bituminous Coal Microstructure and Permeability by Liquid Nitrogen Fracturing Based on μCT Technology. Fuel 2020, 262, 116635. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Xue, J.; Zhang, C.; Fang, X. Experimental studies on the changing characteristics of the gas flow capacity on bituminous coal in CO2-ECBM and N2-ECBM. Fuel 2021, 291, 120115. [Google Scholar] [CrossRef]

- Zhu, L.Y.; Pan, Y.S.; Li, Z.H.; Xu, L.M. Mechanisms of rockburst and outburst compound disaster in deep mine. J. China Coal Soc. 2018, 43, 3042–3050. [Google Scholar]

- Zhang, G.H.; Ouyang, Z.H.; Qi, Q.X.; Li, H.Y.; Deng, Z.G.; Jiang, J.J. Experimental research on the influence of gas on coal burst tendency. J. China Coal Soc. 2017, 42, 3159–3165. [Google Scholar]

- Gao, B.B.; Wang, Z.G.; Li, H.M.; Su, C.D. Experimental study on the effect of outburst-proneness of coal by gas pressure. J. China Coal Soc. 2018, 43, 140–148. [Google Scholar]

- Zhang, X.; Tang, J.; Yu, H.; Pan, Y. Gas pressure evolution characteristics of deep true triaxial coal and gas outburst based on acoustic emission monitoring. Sci. Rep. 2002, 12, 21738. [Google Scholar] [CrossRef]

- Hui, L.; Zeng, C.F.; Dong, Z.; Dong, D. Simulation Experiment and Acoustic Emission Study on Coal and Gas Outburst. Rock Mech. Rock Eng. 2017, 50, 2193–2205. [Google Scholar]

- GB/T25217.2-2010; Methods for Test, Monitoring and Prevention of Rock Burst-Part 2: Classification and Laboratory Test Method on Bursting Liability of Coal. General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China and China Standardization Administration: Beijing, China, 2010.

- Ding, X.; Xiao, X.C.; Wu, D.; Lv, X.F.; Pan, Y.S.; Bai, R.X. Study on mechanical constitutive relationship and damage evolution of gas-bearing coal based on initial pore-cracks. Mater. Rep. 2021, 35, 18096–18103. [Google Scholar]

| Category | I | II | III | |

|---|---|---|---|---|

| Burst Proneness | None | Weak | Strong | |

| Index | Duration of dynamic fracture | |||

| Elastic strain energy index | ||||

| Bursting energy index | ||||

| Uniaxial compressive strength | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wang, Z.; Hui, Q.; Zhang, Z.; Zhang, Z.; Huo, B.; Chen, Y.; Liu, J. Influence of Gas Pressure on the Failure Mechanism of Coal-like Burst-Prone Briquette and the Subsequent Geological Dynamic Disasters. Sustainability 2023, 15, 7856. https://doi.org/10.3390/su15107856

Chen Y, Wang Z, Hui Q, Zhang Z, Zhang Z, Huo B, Chen Y, Liu J. Influence of Gas Pressure on the Failure Mechanism of Coal-like Burst-Prone Briquette and the Subsequent Geological Dynamic Disasters. Sustainability. 2023; 15(10):7856. https://doi.org/10.3390/su15107856

Chicago/Turabian StyleChen, Ying, Zhiwen Wang, Qianjia Hui, Zhaoju Zhang, Zikai Zhang, Bingjie Huo, Yang Chen, and Jinliang Liu. 2023. "Influence of Gas Pressure on the Failure Mechanism of Coal-like Burst-Prone Briquette and the Subsequent Geological Dynamic Disasters" Sustainability 15, no. 10: 7856. https://doi.org/10.3390/su15107856

APA StyleChen, Y., Wang, Z., Hui, Q., Zhang, Z., Zhang, Z., Huo, B., Chen, Y., & Liu, J. (2023). Influence of Gas Pressure on the Failure Mechanism of Coal-like Burst-Prone Briquette and the Subsequent Geological Dynamic Disasters. Sustainability, 15(10), 7856. https://doi.org/10.3390/su15107856