Economic Sustainability of High–Speed and High–Capacity Railways

Abstract

:1. Introduction

- Specially built high–speed lines equipped for speeds generally equal to or greater than 250 km/h.

- Specially upgraded high–speed lines equipped for speeds of the order of 200 km/h.

- Specially upgraded high–speed lines which have special features as a result of topographical, relief or town–planning constraints, on which the speed must be adapted to each case.

1.1. Type of Railway Sections: Ballasted and Ballastless

- Maintenance costs (ballastless tracks are cheaper than ballasted ones, especially in the long–term period; cf. [20]).

- Noise (ballastless tracks are noisier than ballasted ones; i.e., 2–4 dB (A) at 100–260 km/h; cf. [17]).

- Vibration (if softer rail fasteners are used, ballastless tracks can allow producing lesser ground–borne vibrations that are lower than for the ballasted ones, e.g., about 3 dB lower at frequencies lower than 64 Hz; cf. [22]).

- Stability (ballastless tracks provide higher longitudinal and lateral stability than the ballasted ones [20]).

- Ballastless tracks should not be used in areas prone to earthquakes or with softer soils (cf. [20]).

- When used in HSRs, ballasted tracks are open to the risk of flying ballast (i.e., trains travelling at high speeds can cause an aerodynamic force that displaces one or more ballast particles from the track. These particles can damage locomotives, railcars, and tracks, and can injure workers near tracks). This is a safety as well as an economic concern; cf. [20].

- Service life (ballastless tracks are more prone to fatigue failure than ballasted ones, especially when being used as HCR; cf. [23]. This could have consequences in terms of life cycle analyses).

- Environmental impact (for low service lives, e.g., lower than 60 years, ballasted tracks have lower environmental impacts. Note that the environmental impact of ballastless tracks depends also on the production of the steel for the track slab (cf. [23])).

1.2. High–Speed and High–Capacity Rail (HSR/HCR) Systems

- Special Trains: “train sets” are needed instead of conventional trains consisting of locomotives and cars. This depends on several reasons, such as the power–to–weight ratio, aerodynamics, reliability, and safety constraints.

- Special dedicated lines able to allow speeds above 200–220 km/h. This is a function of (2.1) Layout parameters, such as horizontal and vertical profiles, and the cant. (2.2) Transverse sections, track quality, catenary, and power supply. (2.3) Particular environmental conditions to ensure sustainability.

- Purpose–built signalling system line: above 200 km/h, in–cab signalling must be used instead of side signals, which may not always be observed in good time by the drivers.

- An HSR is a complex system that includes the state of the art in many different fields, such as infrastructure, stations, rolling stock, operations, maintenance strategy and corresponding facilities, financing, marketing, management, and legal issues and regulations [25].

1.3. Railway Costs

- The cost of design and planning. These costs are regulated by national standards (e.g., ministerial decree 17 June 2026 for Italy [48]). When construction works are higher than 25 million euros, they cannot be higher than 10% of the total cost of infrastructure.

- The costs of land acquisition and management (sometimes called ancillary costs, see Assessment of unit costs (standard prices) of rail projects [47]). They mainly depend on the type of land.

- The cost of the track (or permanent way, cf. [47], or superstructure). This includes the cost of rails, fastening systems, sleepers, ballast (crib, top, and bottom ballast, cf. [49]), and switches. The increase in axle load implies the increase in cost of many components, including rails, ballast, and subgrade, due to the use of better materials (e.g., modulus increase for subgrade) and/or different geometry (e.g., for rails and ballast, cf. [50]). The increase in construction costs depends on many factors because it basically derives from a design concept, namely having the same expected life of tracks and viaducts or accepting an appreciable increase in maintenance costs. Based on the proportionality between stresses and loads, a very approximate figure for the increase in terms of costs would be 30%. This estimate has intrinsic limitations because the deterioration depends on many factors, including [51]: (1) The type of failure (e.g., rail fatigue, rail surface defects, fatigue of other components, and track geometry deterioration). (2) The tonnage. The daily tonnage may vary, for example, from less than 10,000 t/day to more than 40,000 t/day and, for the sake of dimensioning and maintenance; it is derived in terms of equivalent tonnage. This latter, in turn, depends on speed, real load for daily passenger traffic, real load for daily freight traffic, maximum axle load and geometry of wheels. (3) The total load (static and dynamic). (4) The speed. (5) At least four supplementary factors, partly dependent on the type of failure. For the track, based on the above, and based on ORE D161 rp3 (Dynamic vehicle track interaction phenomena from the point of view of track maintenance), [51] points out that the increase in cost (maintenance) depends on axle load, track quality, and speed, and that the increase in axle load from 20 t to 22.5 t implies higher maintenance costs (+8–10%, the remaining factors being constant):

- ○

- To this end, it is important to note that this is consistent with road pavement–related studies and, namely, with [52] expression of the equivalent axle load factor:

- ○

- with a coefficient f2 = 4 in the Asphalt Institute formula

- ○

- and, finally, with (3) AASHTO and Asphalt Institute equivalent axle load factors.

- The increase of cost for track and viaduct construction due to higher axle loads is herein taken into account through a factor (hereafter called “ACF”, high capacity factor, where high capacity here stands for open to freight traffic). Note that this pertains to the paradigm shift toward Lean, Agile, Resilience and Green (LARG) solutions [7], as the opposite of the AVAC (HS–HC) solutions.

- The cost of the platform (cf. [53]). This does not include the superstructure and it is usually termed building cost [44]. This cost depends on the length and type of (1) Viaducts and bridges. (2) Tunnels. (3) Earthworks. These latter do not include the cost of ballast, while including the cost of the soils (layers) below the ballast (e.g., sub–ballast, blanket, and subgrade (placed soil and natural ground). More specifically, they include tracking, roading, cleanfill sites, cut and fill operations, quarrying/mining and transport, and re–contouring [47].

- The cost of fencing and noise barriers.

- High–speed lines are classified as newly built infrastructure that can be operated at a speed that is equal to or higher than 250 km/h or that results from an upgrade of a pre–existing line which can then be operated at speeds of at least 200 km/h.

- Conventional lines are classified as newly built infrastructure that can be operated at a speed lower than 250 km/h or an existing line that can be operated at a lower speed than 200 km/h.

- Lower slope–increased length of the track–higher construction cost and maintenance cost.

- Freight traffic–increased gauge clearance–increased construction and maintenance cost.

- Increased load–increased cost of the platform (rails sleepers and ballast and blanket and subgrade).

- Increased load–increased rail maintenance cost.

- (1)

- CO2 emission related to the transport of 100 passengers/km of 4, 14, and 17 tonnes for HSRs, private cars and aeroplanes, respectively.

- (2)

- Noise of an HSR train is 80–90 dB (A) at different speeds. It was estimated that, if no barriers are used and when a train travels at a speed of 280 km/h, a corridor of 150 m is needed to decrease the noise level at an acceptable value of 55 dB (A).

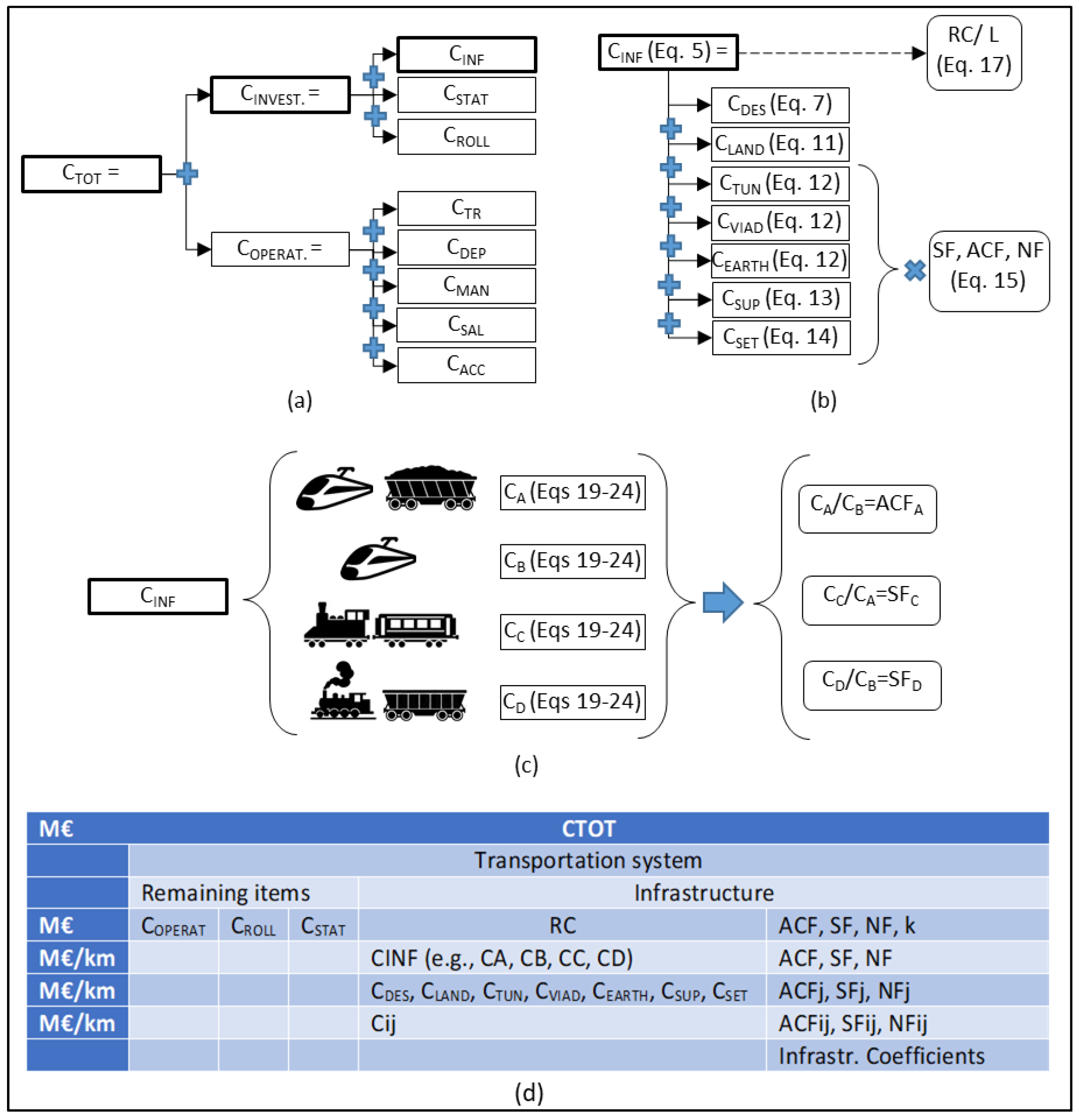

2. Objectives and Scopes

- Task 1: Analysis of the literature (see Section 1).

- Task 2: Set up of the model (cf. Equation (10), see Section 3).

- Task 3: Calibration of the model (see Section 4.1).

- ○

- Sub–Task 3.1: Speed factor (herein called “SF”, based on [54]).

- ○

- Sub–Task 3.2: National Factor (herein called “NF”) and High–Capacity factor (herein called “ACF”).

- Task 4: Validation (see Section 4.2).

3. Modelling

4. Results and Discussions

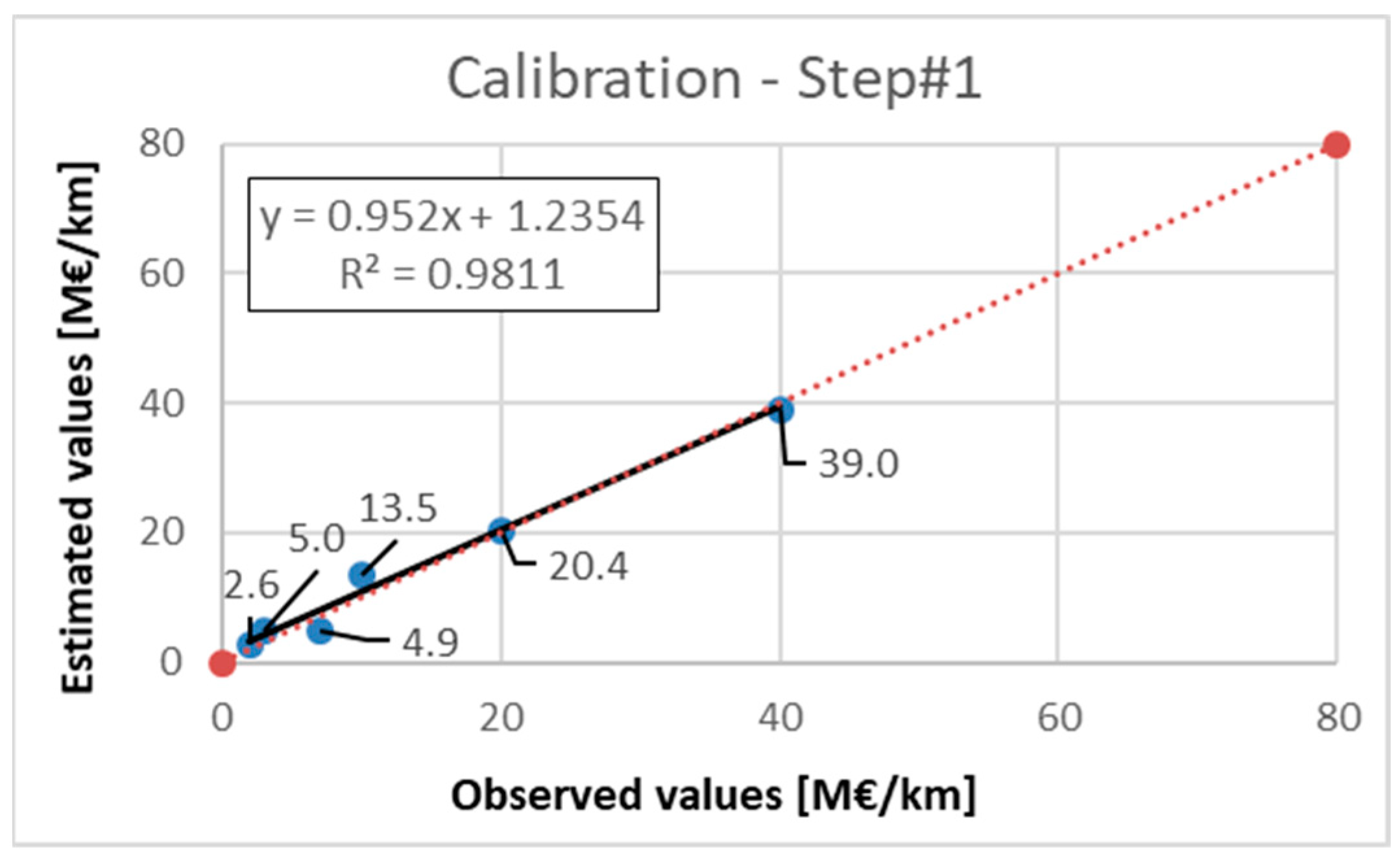

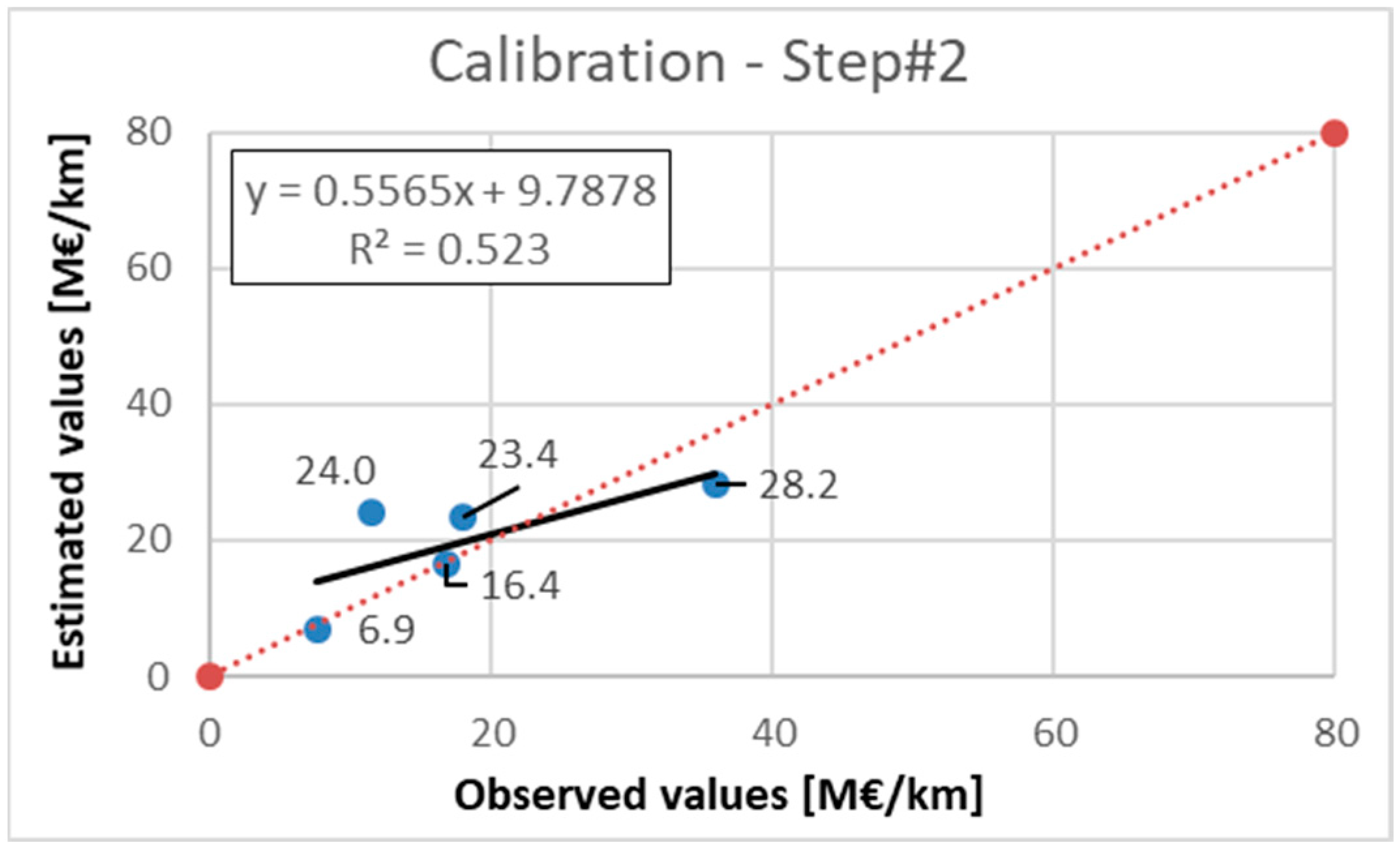

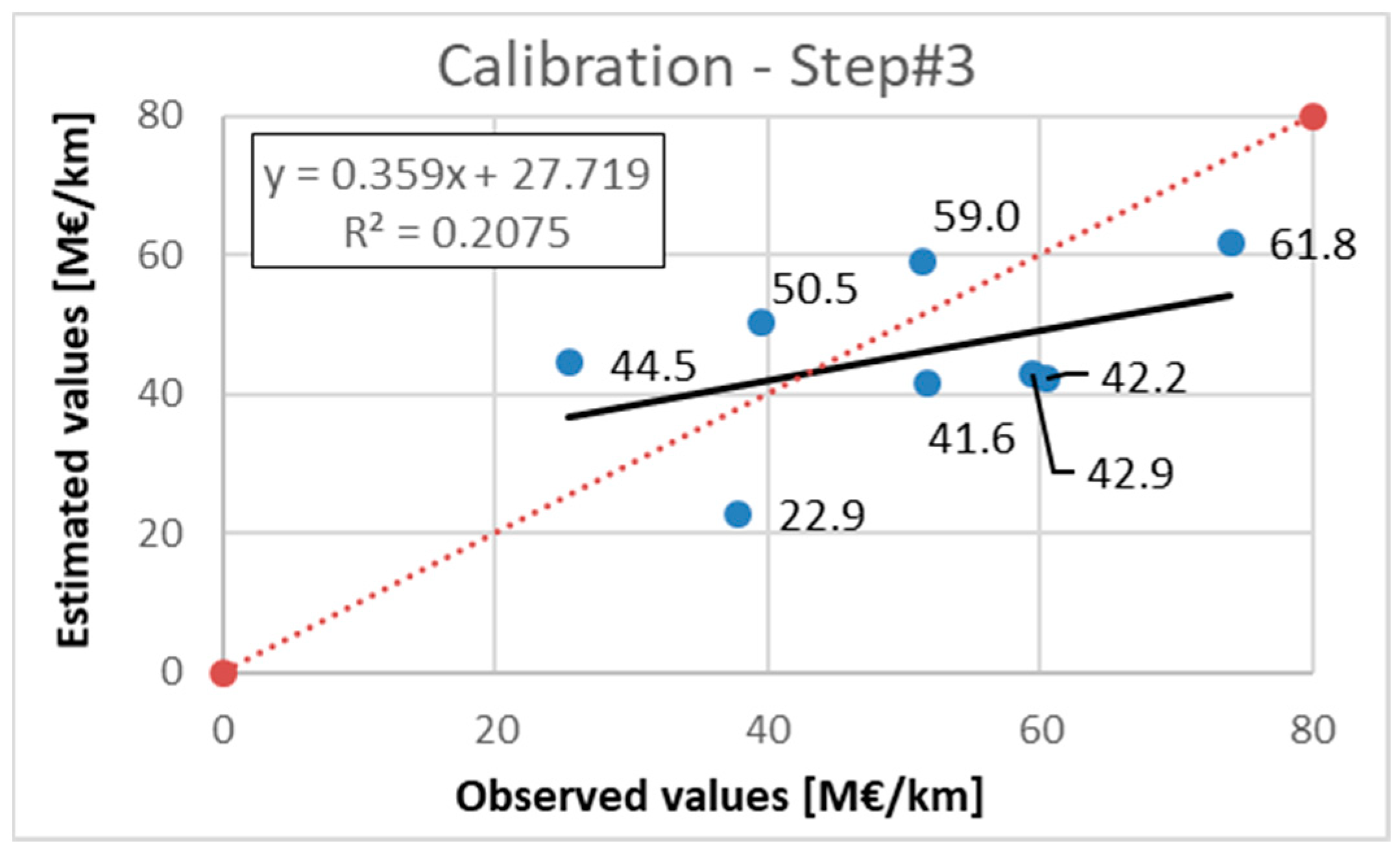

4.1. Model Calibration

- δ = 1.69;

- Tunnels: CuT = 45.58 M€/km;

- Viaducts: CuV = 40.46 M€/km;

- Earthworks (>0.5m): CuE = 2.13 M€/km;

- Superstructure: CuSTR = 1.00 M€/km;

- Signalling (S), electrification (E), and telecommunication (T):CuSET = 1.29 M€/km;

- Land acquisition and ancillary = CLAND = 0.40 M€/km.

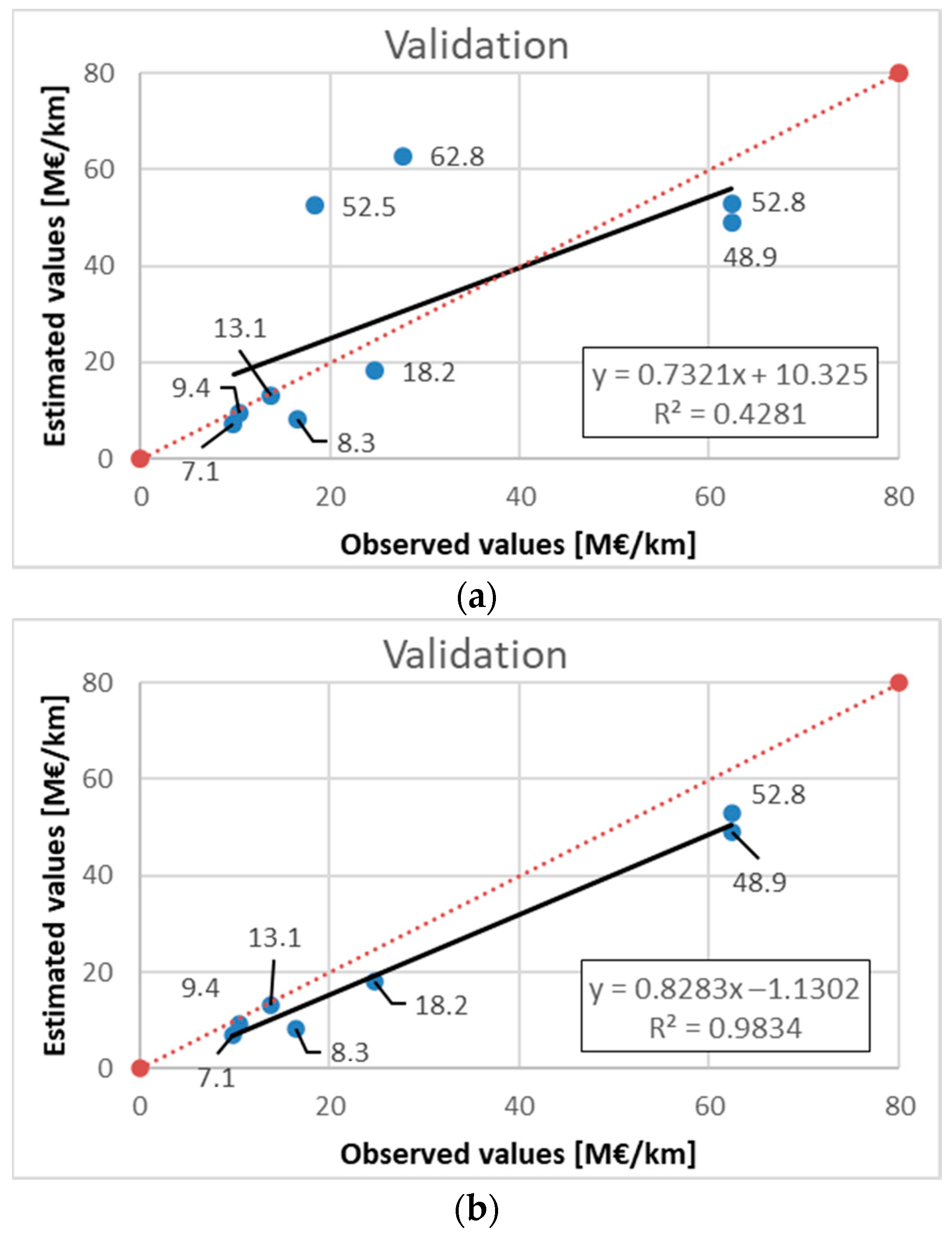

4.2. Model Validation

- Collecting the following inputs: cost of the land acquisition (CLAND; or use Equation (11)), cost of the platform (CPLATFORM; or costs of Equation (12) or % and unit costs of Equation (12)), train speed (S), railway type (e.g., single or double line), train/axle loads, cost of the superstructure (CSUP; or all the costs of Equation (13) or estimate them based on similar project in the same nation), and cost of the signalling, electrification and telecommunication (CSET; or all the costs of Equation (14) or estimate them based on similar project in the same nation).

- Estimating the following parameters: national factor (NF) and high–capacity factor (ACF) based on similar projects and Table 6, and speed–related factor (δ) based on similar projects.

- Deriving the following factor/parameter: speed factor (SF; Equation (6)), and cost of the infrastructure design (CDES; Equation (8)).

- Estimating the infrastructure cost using the proposed model (Equation (15)), for the same context.

- Using the values (factors and parameters) herein derived to perform tentative estimates.

5. Discussions and Conclusions

- Under given conditions, it is possible to explain, through a national factor, why Italian HSR/HCR project costs are sometimes among the highest ones (based on the data set used in this study the average infrastructure cost for Italy is about 48 M€, while for Spain and France is about 17.5 M€). Importantly, apart from modelling, this could depend also on environmental factors (e.g., noise barriers) and mitigation strategies (e.g., funds for schools).

- Despite the high variability of infrastructure costs (mainly observed for the Italian projects), the proposed model allowed for obtaining high accuracy (R–square value = 0.98) in the estimation of the observed values.

- It is possible to explain part of the variance of results based on the following factors: (i) Speed of the line (Speed factor, SF); (ii) National factor, NF; (iii) Type of traffic and possibility of using the line for freight trains (K).

- At the same time, analyses demonstrate that the ACF, pertaining to tonnage, does not have an appreciable impact on the cost per kilometre. In contrast, freight trains impact track geometry (e.g., gradients) and the overall cost needed to link two destinations.

- Importantly, it is envisaged that the NF could be related to many elements, including mitigation actions (e.g., noise barriers and other funds addressing the improvement of conditions of life for the areas where the railway passes).

- For economic sustainability, it is envisaged that the transition towards railways that are high speed and also high capacity (in the sense specified above) implies higher expenses because of the high–capacity factor (ACF) and because of the longer track factor (K). Results and analyses demonstrate that while ACF is quite uncertain (due to the fact that many variables could mask its effect and the design is not LCC–based), K is definitely greater than 1. Furthermore, it is noteworthy to point out that lower gradients (freight trains) could imply higher percentages of viaducts and tunnels, having, in the end, consequences on ACF itself.

- Authors are aware of the limitations of the study (e.g., related to several low R–square values in calibration), because of the uncertainties in the information gathered and because many supplementary variables could be considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, Y.; Yang, Y.; Dong, S. Comprehensive Sustainability Evaluation of High–Speed Railway (HSR) Construction Projects Based on Unascertained Measure and Analytic Hierarchy Process. Sustainability 2018, 10, 408. [Google Scholar] [CrossRef] [Green Version]

- Gherghina, Ş.C.; Onofrei, M.; Vintilă, G.; Armeanu, D.Ş. Empirical Evidence from EU–28 Countries on Resilient Transport Infrastructure Systems and Sustainable Economic Growth. Sustainability 2018, 10, 2900. [Google Scholar] [CrossRef] [Green Version]

- Rungskunroch, P.; Yang, Y.; Kaewunruen, S. Does High–Speed Rail Influence Urban Dynamics and Land Pricing? Sustainability 2020, 12, 3012. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Schraven, D.; de Bruijne, M.; de Jong, M.; Hertogh, M. Navigating Transitions for Sustainable Infrastructures–The Case of a New High–Speed Railway Station in Jingmen, China. Sustainability 2019, 11, 4197. [Google Scholar] [CrossRef] [Green Version]

- Økland, A.; Olsson, N.O.E.; Venstad, M. Sustainability in Railway Investments, a Study of Early–Phase Analyses and Perceptions. Sustainability 2021, 13, 790. [Google Scholar] [CrossRef]

- European Commission. 96/48/EC Council Directive of 23 July 1996 on the Interoperability of the Trans–European High–Speed Rail System. Off. J. Eur. Union 1996, 235, 6–24. [Google Scholar]

- Russo, F. Which High–Speed Rail? LARG Approach between Plan and Design. Futur. Transp. 2021, 1, 13. [Google Scholar] [CrossRef]

- Russo, F. Alta Velocità al Sud: Linee Ferroviarie Adattate o Costruite? Available online: https://perfondazione.eu/alta–velocita–al–sud–linee–ferroviarie–adattate–o–costruite/ (accessed on 15 September 2022).

- Pallavera, M. Linee AV/AC, le Ferrovie di Nuova Generazione. Available online: https://ilmegliodiinternet.it/cose–ferrovia–avac/ (accessed on 15 September 2022).

- Connor, P. High Speed Railway Capacity: Understanding the Factors Affecting Capacity Limits for a High Speed Railway. In Proceedings of the International Conference on High Speed Rail, Birmingham, UK, 8–10 December 2014. [Google Scholar]

- Doll, C.; Köhler, J.; Schade, W.; Simon, M.; Hasselt, E.v.; Vanelslander, T.; Sieber, N. European Freight Scenarios and Impacts. Summary Report 2: European Rail Freight Corridors for Europe—Storyline and Responsibilities; Fraunhofer: Karlsruhe, Germany, 2018. [Google Scholar]

- IL Mezzogiorno in Movimento. Proposte e Progetti Verso IL Next Generation EU—Quaderno N.1/2021. Available online: www.sipotra.it/wp–content/uploads/2021/01/il–mezzogiorno–in–movimento.–proposte–e–progetti–verso–il–next–generation–eu–quaderno–n.–1–2021.pdf (accessed on 16 September 2022).

- Merenda, M.; Praticò, F.G.; Fedele, R.; Carotenuto, R.; Corte, F.G. Della A Real–Time Decision Platform for the Management of Structures and Infrastructures. Electronics 2019, 8, 1180. [Google Scholar] [CrossRef] [Green Version]

- Raczyński, J. Technical Parameters of High Speed Lines as the Determinant for Selection of Rolling Stock. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 180. [Google Scholar]

- Herics, O.; Obermayr, T.; Puricella, P.; T’Joen, L.; Bode, M.; Böckem, D.; Fara, G.; Klis–Lemieszonek, A.; Odins, N.; Smid, M.; et al. A European High–Speed Rail Network: Not a Reality but an Ineffective Patchwork; European Union: Luxembourg, 2018. [Google Scholar]

- Kaewunruen, S.; Sresakoolchai, J.; Peng, J. Life Cycle Cost, Energy and Carbon Assessments of Beijing–Shanghai High–Speed Railway. Sustainability 2020, 12, 206. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Jeong, H.; Thompson, D.; Squicciarini, G. The Noise Radiated by Ballasted and Slab Tracks. Appl. Acoust. 2019, 151, 193–205. [Google Scholar] [CrossRef]

- Pratico, F.G.; Moro, A.; Ammendola, R. Modeling HMA Bulk Specific Gravities: A Theoretical and Experimental Investigation. Int. J. Pavement Res. Technol. 2009, 2, 115–122. [Google Scholar] [CrossRef]

- Schilder, R.; Diederich, D. Installation Quality of Slab Track—A Decisive Factor for Maintenance. RTR Spec. 2007. Available online: https://www.yumpu.com/en/document/view/25757280/installation-quality-of-slab-track-a-a-decisive-factor-for-maintenance (accessed on 16 September 2022).

- Deng, J.; Liu, X.; Jing, G.; Bian, Z. Probabilistic Risk Analysis of Flying Ballast Hazard on High–Speed Rail Lines. Transp. Res. Part C Emerg. Technol. 2018, 93, 396–409. [Google Scholar] [CrossRef]

- SÁRIK, V. Decision–Making Model for Track System of High–Speed Rail Lines: Ballasted Track, Ballastless Track or Both? Master’s Thesis, School of Architecture and Built Environment KTH Railway Group KTH Royal Institute of Technology, Stockholm, Sweden, 2018. [Google Scholar]

- Ntotsios, E.; Thompson, D.J.; Hussein, M.F.M. A Comparison of Ground Vibration Due to Ballasted and Slab Tracks. Transp. Geotech. 2019, 21, 100256. [Google Scholar] [CrossRef]

- Pons, J.J.; Villalba Sanchis, I.; Insa Franco, R.; Yepes, V. Life Cycle Assessment of a Railway Tracks Substructures: Comparison of Ballast and Ballastless Rail Tracks. Environ. Impact Assess. Rev. 2020, 85, 106444. [Google Scholar] [CrossRef]

- Fedele, R.; Pratico, F.G.; Carotenuto, R.; Giuseppe Della Corte, F. Instrumented Infrastructures for Damage Detection and Management. In Proceedings of the 5th IEEE International Conference on Models and Technologies for Intelligent Transportation Systems (MT–ITS 2017), Naples, Italy, 26–28 June 2017; pp. 526–531. [Google Scholar]

- Leboeuf, M. High Speed Rail Fast Track to Sustainable Mobility; International Union of Railways: Paris, France, 2018. [Google Scholar]

- Praticò, F.G.; Vaiana, R. Improving Infrastructure Sustainability in Suburban and Urban Areas: Is Porous Asphalt the Right Answer? and How? In WIT Transactions on the Built Environment; WIT Press: Southampton, UK, 2012. [Google Scholar]

- Wikipedia High–Speed Rail in the United States. Available online: https://en.wikipedia.org/wiki/High–speed_rail_in_the_United_States#First_attempts:_1960–1992 (accessed on 25 September 2022).

- High Speed Rail Alliance TGV—Leader of the Integrated Network Approach. Available online: https://www.hsrail.org/tgv–leader–integrated–network–approach (accessed on 22 September 2022).

- Adif Adif Alta Velocidad. Available online: https://www.adifaltavelocidad.es/ (accessed on 16 September 2022).

- Italferr High Speed—High Capacity. Available online: www.italferr.it/content/italferr/en/proejct–studies/italy/alta–velocita–––alta–capacita.html (accessed on 22 September 2022).

- Caratteristiche Tecniche delle Principali Linee Internazionali Ferroviarie (Allegato II). Available online: https://www.gazzettaufficiale.it/atto/serie_generale/caricaArticolo?art.progressivo=0&art.idArticolo=17&art.versione=1&art.codiceRedazionale=089G0159&art.dataPubblicazioneGazzetta=1989–04–24&art.idGruppo=0&art.idSottoArticolo1=10&art.idSottoArticolo=1&art (accessed on 22 September 2022).

- Pagliara, F.; Mauriello, F.; Russo, L. A Regression Tree Approach for Investigating the Impact of High Speed Rail on Tourists’ Choices. Sustainability 2020, 12, 910. [Google Scholar] [CrossRef] [Green Version]

- United Nations Economic Commission for Europe. Trans–European Railway High–Speed–Master Plan Study Phase 2—A General Background to Support Further Required Studies; United Nations Economic Commission for Europe: Geneva, Switzerland, 2021. [Google Scholar]

- RFI AV/AC Napoli–Bari. Available online: https://www.napolibari.it/ (accessed on 22 September 2022).

- RFI AV/AC Palermo—Catania—Messina. Available online: https://www.palermocataniamessina.it/content/fsipalermocataniamessina/it/il–progetto.html (accessed on 19 September 2022).

- RFI. Nuova LineA av Salerno—Reggio Calabria Lotto 1A: Battipaglia—Romagnano (Dossier di Progetto); RFI: Paris, France, 2022. [Google Scholar]

- Italferr Linea AV/AC Bologna–Firenze. Available online: https://www.italferr.it/content/italferr/it/progetti–e–studi/italia/alta–velocita–––alta–capacita/bologna–firenze.html (accessed on 25 September 2022).

- Direttissima Roma–Firenze. Available online: https://www.italferr.it/content/italferr/it/progetti–e–studi/italia/alta–velocita–––alta–capacita/firenze–roma.html (accessed on 17 September 2022).

- Asse Ferroviario Torino—Lione. Available online: https://presidenza.governo.it/osservatorio_torino_lione/ (accessed on 17 September 2022).

- RFI. Raddoppio Linea Roma—Pescara (Lotti 1 e 2)—Dossier di Progetto; RFI: Paris, France, 2022. [Google Scholar]

- Lombardi, F. AV/AC Treviglio Brescia. Available online: https://www.saipem.com/sites/default/files/2020-03/AV_Treviglio_Brescia_Cepav_Due.pdf (accessed on 17 September 2022).

- Ministero delle Infrastrutture e della Mobilità Sostenibili. Contratto di Programma 2017–2021 Parte Investimenti Appendice N. 5 Alla Relazione Informativa—Schede Interventi CdP–I Agg. 2017–2021; Ministero delle Infrastrutture e della Mobilità Sostenibili: Rome, Italy, 2017.

- Beria, P.; Grimaldi, R. An Early Evaluation of Italian High Speed Projects. Tema 2011, 4, 15–28. [Google Scholar]

- Gattuso, D.; Restuccia, A. A Tool for Railway Transport Cost Evaluation. Procedia–Soc. Behav. Sci. 2014, 111, 549–558. [Google Scholar] [CrossRef] [Green Version]

- Campione, D. IL Frecciarossa_1000. Available online: https://www.ferrovie.it/portale/articoli/782 (accessed on 28 September 2022).

- Railwaypro Italy to Connect All Ports to the National Railway Network. Available online: https://www.railwaypro.com/wp/italy–to–connect–all–ports–to–the–national–railway–network/ (accessed on 28 September 2022).

- PWC. Assessment of Unit Costs (Standard Prices) of Rail Projects (CAPital EXpenditure) REGIO Rail Unit Cost Tool Instructions; European Union: Luxembourg, 2018. [Google Scholar]

- Ministero della Giustizia. Decreto Ministeriale 17 Giugno 2016—Approvazione delle Tabelle dei Corrispettivi Commisurati al Livello Qualitativo delle Prestazioni di Progettazione Adottato ai Sensi Dell’art. 24, Comma 8, Del Decreto Legislativo N. 50 Del 2016. Available online: https://www.bosettiegatti.eu/info/norme/statali/2016_dm_17_06_tariffe.htm (accessed on 24 September 2022).

- Mpye, G.D.; Gräbe, P.J. The Effect of Increased Axle Loading on the Behavior of Heavily Overconsolidated Railway Foundation Materials. Transp. Geotech. 2021, 27, 100493. [Google Scholar] [CrossRef]

- Lidmila, M.; Horníček, L.; Krejčiříková, H.; Tyc, P. Prerequisites for Increasing the Axle Load on Railway Tracks in the Czech Republic. Acta Polytech. 2008, 48. [Google Scholar] [CrossRef] [PubMed]

- Esveld, C. Modern Railway Track; MRT–Productions: Zaltbommel, The Netherlands, 2001. [Google Scholar]

- Deacon, J.A.; Fin, F.N.; Hudson, W.R.; Hindermann, W.L.; Warden, W.B.; Monismith, C.L. Load Equivalency in Flexible Pavements. Assoc. Asph. Paving Technol. Proc. 1969, 38, 465–494. [Google Scholar]

- Andrés, A.; Mónica, G.; Gutiérrez, L. Costs and RAMS Methodologies (Superstructure). In Proceedings of the Dissemination Workshop, Paris, France, 10 June 2015. [Google Scholar]

- Attinà, M.; Basilico, A.; Botta, M.; Brancatello, I.; Gargani, F.; Gori, V.; Wilhelm, F.; Menting, M.; Odoardi, R.; Piperno, A.; et al. Assessment of Unit Costs (Standard Prices) of Rail Projects (CAPital EXpenditure); Final Report Contract No 2017CE16BAT002; European Union: Luxembourg, 2018. [Google Scholar]

- Campos, J.; de Rus, G. Some Stylized Facts about High–Speed Rail: A Review of HSR Experiences around the World. Transp. Policy 2009, 16, 19–28. [Google Scholar] [CrossRef] [Green Version]

- Amos, P.; Bullock, D.; Sondhi, J. High–Speed Rail: The Fast Track to Economic Development? World Bank: Washington, DC, USA, 2010. [Google Scholar]

- Barrón, I.; Campos, J.; Gagnepain, P.; Nash, C.; Ulied, A.; Vickerman, R. Economic Analysis of High Speed Rail in Europe; Fundacion BBVA: Bilbao, Spain, 2009. [Google Scholar]

- Preston, J.; Albalate, D.; Bel, G. The Economics of Investment in High Speed Rail; International Transport Forum: Leipzig, Germany, 2013. [Google Scholar]

- Odolinski, K. Estimating the Impact of Traffic on Rail Infrastructure Maintenance Costs. J. Transp. Econ. Policy 2019, 53, 334–350. [Google Scholar]

- Pyrgidis, C.; Christogiannis, E. The Problems of the Presence of Passenger and Freight Trains on the Same Track. Procedia—Soc. Behav. Sci. 2012, 48, 1143–1154. [Google Scholar] [CrossRef] [Green Version]

- Boehm, M.; Arnz, M.; Winter, J. The Potential of High–Speed Rail Freight in Europe: How Is a Modal Shift from Road to Rail Possible for Low–Density High Value Cargo? Eur. Transp. Res. Rev. 2021, 13, 4. [Google Scholar] [CrossRef]

- Watson, I.; Ali, A.; Bayyati, A. Freight Transport Using High–Speed Railways. Int. J. Transp. Dev. Integr. 2019, 3, 103–116. [Google Scholar] [CrossRef]

- TAV Brescia–Verona: 17 km di Gallerie e 7 Anni di Lavori, la Maxi–Opera da 2,5 Miliardi di Euro. Available online: https://www.bresciatoday.it/attualita/tav–brescia–verona–dettagli.html (accessed on 22 September 2022).

- Campione, D. Da Milano a Bologna a 300 km/h; Ferrovie.it: Roma, Iyaly, 2008. [Google Scholar]

- Italferr Linea AV/AC Roma–Napoli. Available online: https://www.italferr.it/content/italferr/it/progetti–e–studi/italia/alta–velocita–––alta–capacita/roma–napoli.html (accessed on 17 September 2022).

- RFI. Torino–Milano: IL Tracciato. Available online: http://www.rfi.it/cms/v/index.jsp?vgnextoid=c502d770cb64c110VgnVCM1000003f16f90aRCRD (accessed on 17 September 2022).

- AV/AC Verona—Bivio Vicenza. Available online: https://veronapadova.it/gare–area–trasparenza/i–bandi–di–gara/ (accessed on 17 September 2022).

- Linea AV/AC Verona–Padova. Available online: https://www.otinord.it/progetti/linea_av_ac_verona_padova (accessed on 21 September 2022).

- Railway Technology.com Perpignan–Figueres. Available online: https://www.railway–technology.com/projects/perpignan/ (accessed on 23 September 2022).

- The Figueras–Perpignan High–Speed Line. Available online: https://www.globalrailwayreview.com/article/2478/the–figueras–perpignan–high–speed–line/ (accessed on 20 September 2022).

| Type | Ballasted |

|---|---|

| Strengths | More reliable (used for 150 years). Lower construction costs. Good drainage properties. Higher elasticity. Higher noise absorption levels. Simpler maintenance (e.g., components replacement, and geometry correction). Good subgrade settlements resistance and good movements compensation. |

| Weaknesses | Relatively short lifetime (20–30 years). High maintenance requirements. Heavier and have a higher structural height (not recommended on bridges and in tunnels). Not recommended for high speeds (proper design or proper improvements can reduce this problem). Lower lateral and longitudinal resistance (can cause “floating” track at high speeds, especially in curves). Ballast flight (also called ballast pick–up or churning) at high speeds. Ice flight in cold climate countries at high speeds. Not accessible to emergency vehicles. |

| Type | Ballastless |

| Strengths | More available. Long lifetime (up to 60 years). Very little to no maintenance requirements (maintenance costs about 20–30% lower, lower units of personnel on the track, lower number of accidents/injuries, and minimized or avoided vegetation control). Higher lateral and longitudinal resistance. No settlement problems (due to stable subsoil). Recommended for high speeds (higher longitudinal and lateral stability). Recommended on bridges and in tunnels. Accessible to emergency vehicles. Possibility to use electromagnetic wheel brakes (lower structural height and weight, which is good for bridges– and tunnel–related applications). |

| Weaknesses | Higher investment/construction costs (1.2–3 times higher). Poor subgrade settlements and movements compensation (this leads to structural damages). Very strict requirements for the subsoil and substructure. Complicated and cost–intensive maintenance (especially after a derailment). Noisier (absorbing materials on top of the track are needed to minimize the problem). |

| Ref. | Details | Rail Slope for High–Speed Lines (Passenger Traffic Only) [mm/m; ‰] | Rail Slope for High–Capacity Lines (Freight Traffic Only) [mm/m; ‰] | Italy Rail Slope for High–Speed and High–Capacity Lines (Mixed Traffic) [mm/m; ‰] |

|---|---|---|---|---|

| [31,33] | International lines | 35 (max value) | 12.5 (max value) | – |

| [34] | AVAC Napoli–Bari | – | – | 13 (max value) |

| [35] | AVAC Palermo–Catania–Messina | – | – | 12–12.5 |

| [36] | AV Battipaglia–Romagnano | – | 12–18 (18 for difficult topography) | – |

| [37] | AVAC Bologna–Firenze | – | – | 15 (max value) |

| [38] | AVAC Roma–Firenze | – | – | 8 (max value; most of the line is straight) |

| [39] | AVAC Torino–Lyone | – | 33 (old line) | 12.5 (new line) |

| [40] | Roma–Pescara | – | ≥25 (old line) | – |

| [41] | AVAC Treviglio–Brescia | – | – | 15 (max value) |

| [42] | Potenza–oggia | – | – | 28 (old line) |

| Palermo–Trapani | – | 5 (old line) | – | |

| AVAC Brennero lotto 1–Fortezza–Ponte Gardena | – | – | 23 (old line) 12 (new line) | |

| Paola–Cosenza | – | 12 (new line) | – | |

| AVAC Brennero tunnel | – | – | 6.7 (Austrian side) 4 (Italian side) | |

| [43] | Third Giovi pass | – | 35 (max value) | – |

| Double Track, High Speed | |||

|---|---|---|---|

| Literature | Conventional | Model Variable | |

| Design and planning | <10% [48] | ||

| Land acquisition | 0.4 | ||

| Rails | 0.16 [53] | 1.1–1.7 [47] | 1 |

| Fastening systems + Sleepers | 0.22 [53] | ||

| Ballast | 0.14 [53] | ||

| Switches | 0.22 [53] | ||

| Viaducts and bridges | 20–50 [54] | 35 | |

| Tunnels | 20–70 [54] | 40 | |

| Earthworks | 3.4 [47]; 1–4 [44] | 0.9 [47] | 2.3 |

| Signalling | 0.3–1 [44]; 0.5 [47] | 0.3 [47] | 1.3 |

| Electrification | 0.7–1.2 [44]; 0.6 [47] | 0.6 [47] | |

| Telecommunication | 0.19 [47] | 0.3 [47] | |

| Fencing and noise barriers | 0.8 [47] | ||

| Cost Item | Task | Amount |

|---|---|---|

| CSTUD | Feasibility study, preliminary study and project. | 0.01–0.1 M€/km. 0.3–3% of the total investment |

| CLAND | Acquisition of land and rights, which depend on population density. | N.A. |

| CBUILD | Preparation of the ground, embankments, drainage, structures (walls, water ducts, bridges, tunnels, overpasses and underpasses), fences and noise–protection equipment, service access roads, interim financial charges, general expenses, and initial additional maintenance. | Single track *: 21–85 M€/km. Double track *: 51–140 M€/km. |

| CTRACK | Acquisition and installation of ballast, sleepers, rail fastening, rails, welds or fish–plates, laying, and initial additional maintenance. | 0.2–0.6 M€/km for rail mass of 50–70 kg/m. |

| CELECT | Electrification of substations, catenary, lowering the floor in tunnels, raising overpasses, modification of signalling equipment along the track and in stations, and telecommunications equipment. | Single track *: 0.5–0.9 M€/km. Double track *: 0.7–1.2 M€/km. |

| CSIGN | Acquisition and installation of cables, automatic block system, spot repetition of signal (automatic train protection or advanced train protection), cab signal (automatic train control), the radio link between the dispatcher and the train, and level crossing with light and acoustic signals and automatic barriers. | Single track *: 0.3–0.5 M€/km. Double track *: 0.3–1.0 M€/km. |

| Cost Item | Task | Amount |

|---|---|---|

| CTR | Powering the trains, which depends on the number of trains per kilometre (i.e., the product of runs and the total length of the line), of the unit cost of the power source (i.e., electricity or diesel, e.g., measured in €/kWh and €/litres, respectively), and of the unit consumption (measured in kWh/km for electric trains, and litre/km for diesel trains). | Electric regional train *: 0.2–0.9 €/km. Diesel train: 0.8–1.9 €/km. |

| CDEP | Depreciation of the rolling stock cost over a given period (usually 20 years). | Recent fleets: about 33% of the total cost of the service; Old fleets (≥20 years): 8–10% of the total cost of the service. |

| CMAN | Maintenance of the rolling stocks, which depends on fixed management costs (about 30–40% of total maintenance cost), variable costs for worn parts replacement (5–10%), fixed and variable costs related to the workshops (50–60%), and exterior and interior cleaning of rolling stock (0.05–0.1%). | e.g.: Local and suburban trains: 2.5 €/train–km for electric trains, and 3.5 €/train–km for diesel trains. |

| CSAL | Ground services (operating personnel or indirect personnel) and services on board the train (e.g., drivers, conductors and ticket inspectors). Ground personnel cost is independent of service, while onboard personnel cost depends on the operating time. | N.A. |

| CACC | Access to the service. This depends on the company that provides the service. | e.g.: Local and suburban trains: About 0.1–5.2 €/train–km. |

| Railway Type | Tentative Values | |

|---|---|---|

| ACF | SF | |

| A = High–speed and high–capacity (HSHT = AVAC) | >1 | =1 |

| B = High speed (without freight traffic, HS = AV) | =1 | =1 |

| C = Conventional (V < 250 km/h, mixed traffic; AC) | >1 | <1 |

| D = Low–speed and low–capacity | =1 | <1 |

| Ref. | Case Study | Use | Number of Cases |

|---|---|---|---|

| [54] | Baumgartner 2000 (M€/km for double tracks with speeds equal to 100 and 300 km/h for easy, average, and difficult topographies, for double track tunnels and easy and complex bridges). | CALIBRATION. Estimation of the unit cost of tunnels and bridges, and the parameter δ. | 6 International cases (SF based on Equation (3), ACF = NF = 1) |

| [29] | Spanish HS lines: Cordoba–Malaga; Madrid–Siviglia; Barcellona–Figueres (French border); Madrid–Galizia; Madrid–Valladolid. | CALIBRATION. Estimation of the National Factor (NF) for five Spanish lines. | 5 Spanish cases (SF based on Equation (3), ACF = NF = 1) |

| [34,35,36,37,39,41,63,64] | Italian HSHC lines: Battipaglia–Romagnano (1st batch); Brescia–Verona; Napoli–Bari; Palermo–Catania–Messina; Torino–Lione (Italian side); Treviglio–Brescia; Milano–Bologna; Bologna–Firenze. | CALIBRATION. Estimation of the National Factor (NF) and High–Capacity Factor (ACF) for Italy. | 8 Italian cases (SF based on Equation (3)) |

| [29,65,66,67,68,69,70] | Italian HSHC lines: Roma–Napoli; Torino–Milano; Verona–Vicenza; Verona–Padova (different sections). Spanish HS lines: Madrid–Toledo; Antequera–Granada; Almería–Murcia; Valladolid–Venta de Baños–Palencia–León. French HS line: Figueres–Perpiñan | VALIDATION. By using the NFs and the ACF mentioned above, the model (Equation (10)) was validated using four Italian lines, four Spanish lines, and one French line. | 4 Italian cases + 4 Spanish cases + 1 French case = 9 cases (SF based on Equation (3)) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Praticò, F.G.; Fedele, R. Economic Sustainability of High–Speed and High–Capacity Railways. Sustainability 2023, 15, 725. https://doi.org/10.3390/su15010725

Praticò FG, Fedele R. Economic Sustainability of High–Speed and High–Capacity Railways. Sustainability. 2023; 15(1):725. https://doi.org/10.3390/su15010725

Chicago/Turabian StylePraticò, Filippo Giammaria, and Rosario Fedele. 2023. "Economic Sustainability of High–Speed and High–Capacity Railways" Sustainability 15, no. 1: 725. https://doi.org/10.3390/su15010725

APA StylePraticò, F. G., & Fedele, R. (2023). Economic Sustainability of High–Speed and High–Capacity Railways. Sustainability, 15(1), 725. https://doi.org/10.3390/su15010725