1. Introduction

There is an increasing interest in measuring social impact from different sides, including public and private investors. The GECES [

1] expert group on social economy and social enterprises gave the following definition to measuring social impact “The reflection of social outcomes as measurement, both long-term and short-term, adjusted for the effects achieved by others (alternative attribution), for effects that would have happened anyway (deadweight), for negative consequences (displacement) and for effects declining over time (drop off)”.

The EU has developed standards for the assessment of the sustainability aspects of new and existing construction works (buildings and civil engineering works) [

2]. They describe methodologies for the assessment of the sustainability of construction works covering the assessment of environmental, social, and economic performance (aspect and impacts). On the other hand, the previous research trends focused more on the technical (environmental and economic) aspects rather than the social performance. Some reasons can be referred to as the lack of data, difficulties in conducting social sciences, and lack of standard methods for quantifying social impacts.

The importance of quantifying social impacts is crucial for achieving stakeholder engagement for emerging concepts. The current trends in research and development focus on the transition from a linear construction into a circular and efficient sector [

3,

4]. The linear production model drives unmanageable economic growth which is unsustainable in the long run [

5]. A circular economy may resolve this—and bring about a list of social benefits. These benefits may include new employment opportunities, increased cooperation and sense of community by participation in the sharing economy, and co-ownership of a physical product aiming for sharing functions and services by the user group [

6].

In the scope of the circular economy, social assessment is not yet a well-developed or often-applied practice. Walker et al. [

7] mention several challenges, and most are related to the difficulty of measuring social indicators. The most frequently observed reason for not including a social assessment was the lack of knowledge to execute one, followed by the complexity of the methodology, the lack of a standardised method, the available methods not being ‘best practice’ for social assessment, and lack of supply chain data. A low personnel number may further explain the lack of resources in SMEs to include social assessment activities.

In this context, this study adopts a social life cycle assessment (S-LCA) approach for achieving comprehensive and quantifiable outcomes. The aim of this study is to assess the social impact of a circular and bio-based housing prototype developed in KU Leuven Ghent Technology Campus in the scope of the Interreg 2 seas project CBCI [

8]. For this purpose, existing social impact assessment studies were reviewed, and it was seen that there is a lack of research efforts on circular construction practices. Deriving from the existing literature, the study considers two hypotheses regarding the methodology:

In order to explore these hypotheses, an assessment framework for circular and bio-based construction methods, including production and construction life cycle phases, was developed. For demonstrative reasons, the framework was applied to the case study and social impacts for several stakeholders were analyzed. In the end of the study, construction industry-specific suggestions were also provided to the existing guidelines.

2. Literature Review

In this section, existing documents regulating social impact assessment in the construction industry are reviewed together with the current literature.

2.1. S-LCA Standards and Guidelines

Social performance of a building is one of the pillars of the sustainability framework (together with environmental and economic performance). One of the prominent assessment methods for social impact is through a social life cycle assessment (S-LCA). The assessment of social performance differs from economic and environmental assessments as it requires, besides quantitative, also descriptive approaches. Where methods leading to a quantitative result are not available for assessment criteria and indicators, a checklist analysis approach is adopted to make the descriptive approach quantifiable.

The goal of an S-LCA is to quantify the social performance of the object of assessment by means of the compilation and application of information relevant to a description of the social quality of the object. The governing standard is EN 16309—sustainability of construction works—assessment of social performance of buildings [

9] (hereafter referred to as ‘standard’). The standard focuses on the use stage of a building by considering the following performance categories: accessibility, adaptability, health and comfort, impacts on the neighbourhood, maintenance, and safety and security. However, as the recommended life cycle module for S-LCA only covers the use stage, this approach may not be relevant for the assessment of a circular construction product.

Besides the standard, there have been efforts to develop the ‘Guidelines for Social Life Cycle Assessment of Products and Organizations’ [

10] (hereafter referred to as ‘guidelines’). The importance of the guidelines lies in the provision of necessary information on impact categories and indicators and data collection methods [

11]. Currently, it does not include sector-specific recommendations or case studies from the construction sector [

12].

2.2. S-LCA in the Construction Industry

In this section, an overview of S-LCA studies in the construction sector is provided. The keywords used to define the boundaries of this overview are ‘life cycle’ and ‘social LCA’ OR ‘social assessment’, and ‘construction’ OR ‘buildings’ OR ‘built environment’. Only studies related to the building sector are considered. As shown in

Table 1, the collection of studies is limited in number but geographically widespread. In addition, these studies commonly referred to the aforementioned S-LCA guidelines. The majority of the studies are conducted at the building level. Furthermore, there is a tendency to integrate S-LCA with the general sustainability frameworks.

A few studies have used S-LCA to compare different construction materials and techniques. Dong and Ng [

14] developed a framework to support the local construction industry in the social impact assessment of construction works. The framework was tested on a case-study building in Hong Kong and compared several construction practices. Hosseinijou et al. [

13] used a similar approach to assess the social impact of a case-study building assumed to have either a steel or concrete structural frame. The social impact assessment was integrated to a material flow analysis in order to identify relevant flows of materials in the life cycle, as well as social hot spots to analyze through interviews. Liu and Qian [

18] developed a framework to compare steel and concrete structural frames, including not only the production and construction stages but also the operation and maintenance stages. Hossain [

17] introduced a similar study on social sustainability for recycled construction materials. Balasbaneh and Sher [

21] developed a multi-criteria assessment method in order to compare different types of concrete constructions, including environmental, economic, and social aspects, from the production to the operation stage.

Other studies have used multi-criteria assessment methods including social aspects in order to provide a full sustainability assessment of buildings. For example, Chen et al. [

20] used criteria to assess the social impact of building renovations focusing on the operation stage of buildings. Thanu et al. [

25] developed a similar approach to assess the social impacts of new buildings. Soust-Verdaguer et al. [

22] and LLatas et al. [

23] assessed environmental, economic, and social impacts of a case-study building in the early design stage and used BIM in order to facilitate the life cycle inventory. However, a limitation of these studies [

22,

23] is the use of a single parameter (i.e., working hours) to express social impacts.

Some studies explored indicators for the social impact assessment of buildings. For example, Santos et al. [

15] and Yıldız et al. [

19] used factor analysis to identify social aspects relevant for new buildings and building renovations, respectively. Finally, Rizal Taufiq et al. [

24] assessed the social impacts of different materials commonly used in constructions at different levels (i.e., process, company, and country) in order to understand the implications of scaling up a social impact assessment. This is the only reviewed study including all the stages of the life cycle.

In these studies, the functional unit selection does not follow a common standard, in which some studies considered a whole building as their unit, whereas another adopted a common unit of 1 m2. It was also observed that the set of indicators were individually unique for all studies. Depending on these insights, this study also explored the needs for conducting an S-LCA study on circular and bio-based building.

There are also several studies that focus on the social impacts of construction with other methodologies than S-LCA. Mesa et al. [

26] provided a thorough overview of studies that focus on environmental and social life cycle impacts of construction demolition waste (CDW). Locurcio et al. [

27] introduced a multi-criteria composite indicator to enable performance analysis of real estate investments, trying to respond whether the investors should renovate or reconstruct. Ibrahim et al. [

28] and Wang et al. [

29] developed frameworks to evaluate the socio-economic impacts of construction projects on society. Related to social impacts, there are several studies on the impact of circular economy methods for CDW [

30,

31,

32].

It should also be noted that social impact assessment can still be considered as an emerging concept in the construction sector, and adapting it to circular construction would need further research and discussions. It would also be acceptable to claim that case study applications are one of the methods to close the gaps in the literature.

3. Materials and Methods

This study follows the suggestions of the available standard and guidelines, but also sought for innovation in S-LCA methodology. S-LCA is a comprehensive method which is also capable of providing quantifiable results. These characteristics match with the goal of this study: inclusion of several stakeholder groups and to display the social impacts in a tangible manner. As

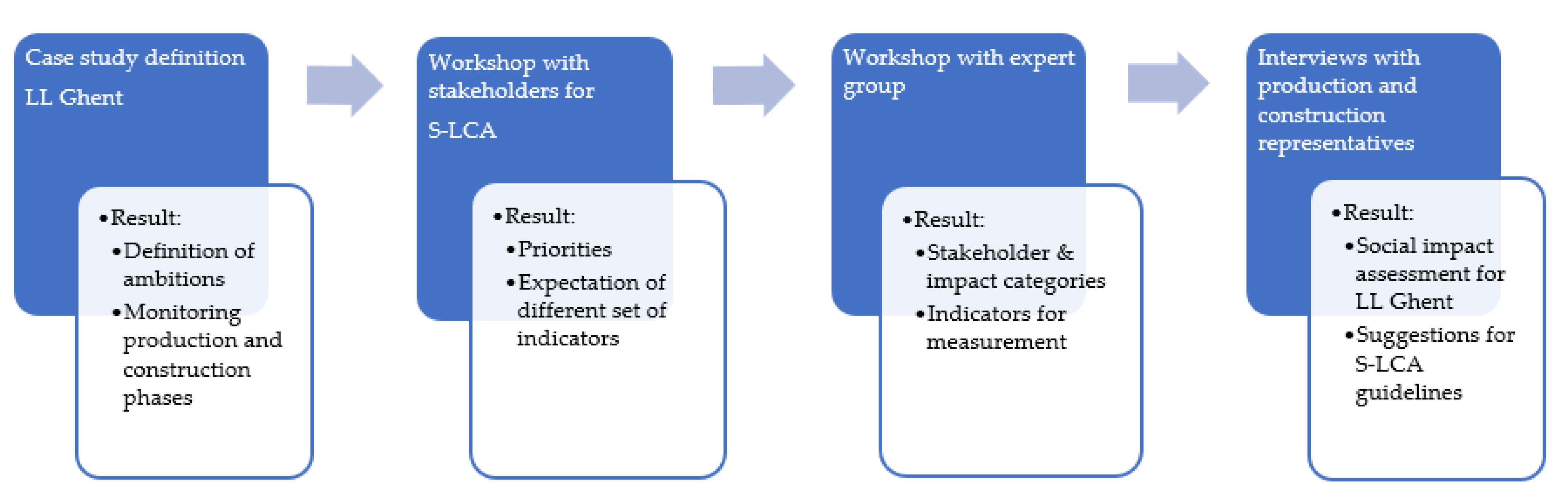

Figure 1 displays, the workflow of the study includes the definition of the case study called LL Ghent, two workshops for setting up the S-LCA, and the assessment of circular and bio-based construction practices via interviews with producers and constructors of LL Ghent.

In the literature, it was seen that existing categories or indicators may not be sufficient to consider some emerging processes. In order to ensure that this study assesses correct impacts categories and indicators, two workshops were conducted with different focus groups for determining the system boundaries of the study. The focus groups were categorized as (i) the expert group who draw the boundaries and (ii) the implementation group who validates the suggestions.

After determining adequate indicators, two sets of questionnaires were developed and an S-LCA was conducted on LL Ghent. The scope of the S-LCA considers the product level and assesses the impact of LL Ghent during production and construction phases.

3.1. Case Study Building—LL Ghent

In the aforementioned CBCI project, a case-study building called ‘LL Ghent’ was adopted to test the S-LCA methodology for circular and bio-based constructions.

LL Ghent was developed through a research through design (RtD) approach in order to explore technical, financial, and legal frameworks with the ultimate goal of creating an energy- and material-efficient building prototype. Additional preliminary studies were conducted, such as (i) an overview of evaluation tools to be utilized in the assessment of circularity [

33] and (ii) an integrated decision support that combines environmental life cycle analysis and circularity assessment by using several impact categories that are monetized into a unit of €/m

2 [

34]. Based on these preliminary studies, several ambitions for LL were identified:

Bio-based → → 75% (in volume);

Demountable → 0.7 demountability index;

Passive house → U value 0.15 W/m2·k;

Social economy → 10% of investment.

A multi-criteria analysis was conducted to support the procurement of the LL Ghent. The criteria were based on output specifications rather than material specifications. A design-build (DB) tender was launched for the building structure and envelope and a design-build-operate-maintain (DBOM) tender for the technical devices. After both tenders, a consortium of partners were formed to co-create the LL Ghent as a circular and bio-based prototype in which several material and methods were tested. This study focuses only on the works that have been executed in the framework of the first tender.

The final product is a circular and bio-based living lab realized in KU Leuven Ghent Technology Campus with a hybrid structure that is composed of a prefabricated bio-based wall and floor panels with a steel frame structure. These panels are assembled to and around cross-laminated timber (CLT) staircase components. The geometry of LL was inspired by a typical 19th–20th century terraced house typology: two full storeys and one story under a sloping roof (see

Figure 2). The front and rear façades have floor-to-ceiling windows. The roof is a classic pitched roof, with a skylight on one side. The side walls are typical blind waiting walls that enables for the final fitting of the prototype in an urban terraced house context. The footprint of the building is 33 m

2 and total gross floor area is 98.8 m

2. The total area of the front façades (west, east) is 56 m

2 and that of the side façades (north, south) is 129 m

2. The window area in all façades is 22.7 m

2. The roof has an area of 46 m

2.

The production of the building components took place in off-site facilities and then assembly and finishing works were conducted on-site. Several sub-contractors were included together with a specific social worker company. In this context, as there were previous studies on the environmental impacts of LL, another aim of this study was to integrate a social assessment and achieve a full sustainability assessment.

3.2. Case Study Process

In order to initiate a framework for developing a life cycle inventory, two workshops were conducted. The first workshop was set to determine the goal and system boundaries of the S-LCA together with the stakeholders and project administration. The scope of the study was determined as the social impact assessment of production and construction phases due to the fact that circular methods in LL target a higher construction quality to increase reusability in the end of life. Use phase had to be omitted as the building was not commissioned during the period of this study.

A second workshop was held in order to identify the impact categories and indicators that are relevant for the construction methods utilized in LL Ghent. For this workshop, experts from the CBCI project environment and observing parties were invited. The participation analysis of the workshop can be seen in

Table 2.

In this workshop, after an introduction to the S-LCA standards and guidelines, the participants from different stakeholder categories were requested to select impact categories (among the examples in the guidelines, or provide a new one) with respective importance rankings. The rankings are crucial to differentiate the specific priorities for the circular and bio-based approach. The participants were asked to rank the importance of impact categories on a scale of 1-to-10 (1 implies not important and 10 is means a most important category). Then, these rankings were utilized as weighting factors during the calculation. As a second step, they were also required to provide indicators for these impacts. There were several impact categories suggested that are not in the list of the guidelines. Those with similar characteristics were included in the existing categories (ease of assembly under health and safety, learning while working under occupational improvement). In addition, two new impact categories were considered of importance: affordability and use of local materials. Therefore, a list of 13 impact categories under 4 stakeholder categories were adopted as seen in

Table 3.

As the impact categories and indicators were determined, the experts appointed relevant impact categories to each construction method that was utilized in LL Ghent. Moreover, the construction methods were weighted for their importance. The impact categories that are related to construction methods and weighting factors can be seen in

Table 4.

After the determination of impact categories and indicators, the means of data collection were prepared in the format of questionnaires. Two different sets of questionnaires were developed: the first one for production and second one for construction phase.

The first questionnaire for the production phase is based on the stakeholder and impact categories and related indicators that were previously determined (see

Table 3). For each impact category, one or more questions were prepared. The questionnaire was conducted with a representative from the production contractor, workers, and CBCI experts. The second questionnaire for the construction phase is based on the construction methods and related indicators that were previously determined (see

Table 4). Several impact categories were appointed to each construction method and questions were prepared for each impact category accordingly. The questionnaire was conducted with a representative from the construction contractor and workers.

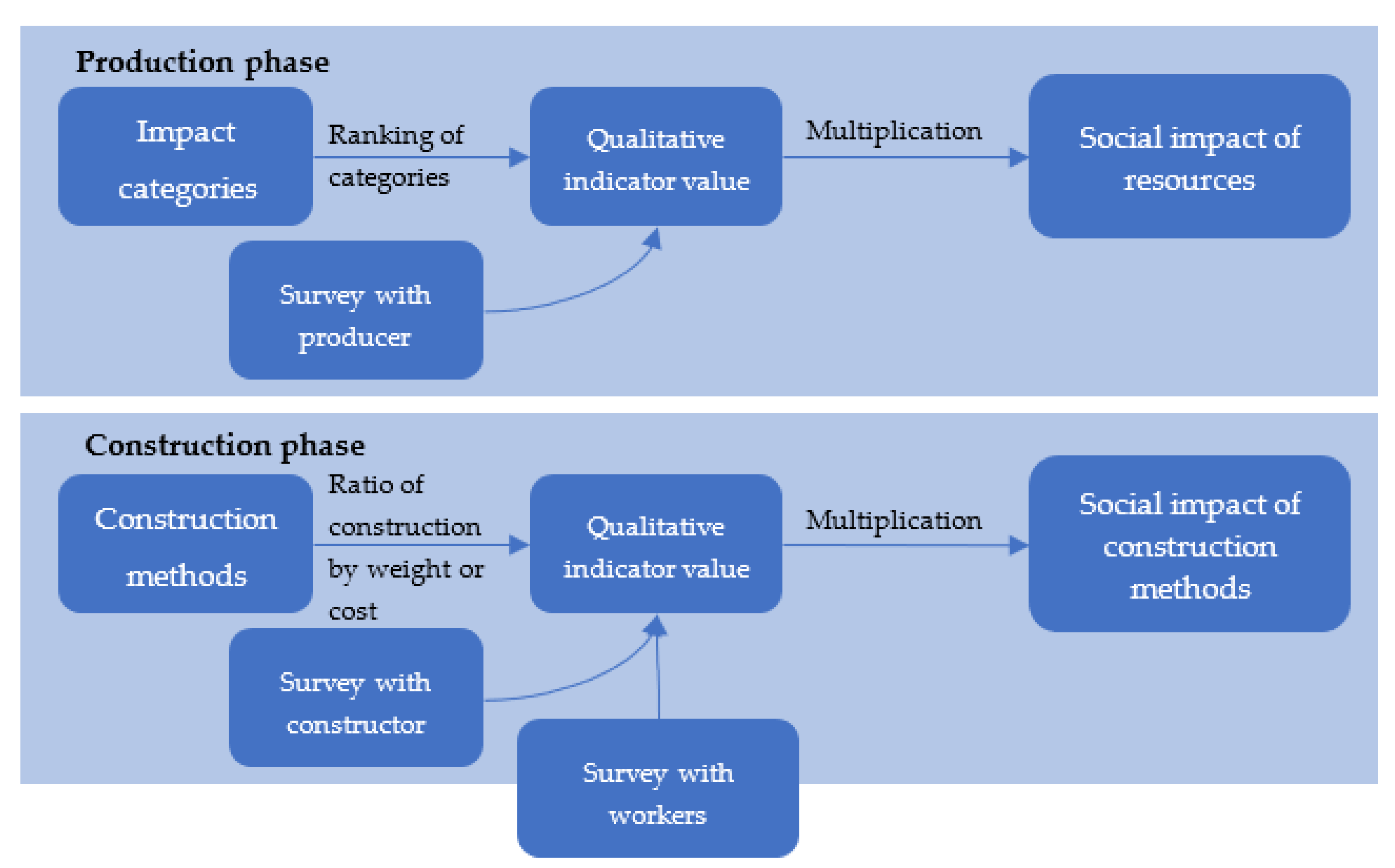

In

Figure 3, the flow of the impact assessment framework can be seen as an overview. Based on this framework, the next section displays the results of the interviews and calculations.

4. Results

In this section, the results of the questionnaires were first quantified for the production and construction phases of LL Ghent. They were interpreted according to responses for each impact category under four stakeholder categories. Then, the results are discussed from the perspective of each stakeholder category. This approach is expected to reflect stakeholder-centered thinking into the findings of the study.

4.1. Production Phase

The questionnaire responses were quantified based on a Likert scale (from 1 to 5). The scale implies that a significant positive social impact is denoted with 5, a score of 3 refers to a neutral state where there is no impact, and 1 refers to a significantly negative social impact. Then, these figures were normalized to a scale between −1 and 1. Each response on the Likert scale is transferred to a quartile between the scale of −1 and 1 (i.e., a Likert score of 1.5 is normalized to −0.75, and a Likert score of 4 is normalized to 0.5). In this way, the results would be comparable with other social LCA studies that follow the guidelines.

In the calculation, the weighting factors were utilized for prioritizing certain impact categories. These weighting factors reflect the current perspective of the expert group. It is foreseen that the weighting factors could vary depending on the purpose of the study or experts included. They may also change depending on the future developments of the construction sector.

The responses regarding the social impact of LL Ghent in the production phase are dominated by two keywords: (i) prefabrication and (ii) prototype. Prefabrication has an overall positive impact with regards to all stakeholder categories. Prototype has been associated with a few negative impacts such as a not fully automated production line, extra working hours due to unexpected reasons, etc. However, most of these negative impacts can be potentially mitigated or avoided in future follow-up productions similar to LL Ghent.

According to the general results in

Table 5, it was seen that there was a positive impact towards the workers, local community, and society. Nevertheless, there was no significant impact on how consumers currently assess a product like LL Ghent.

4.2. Construction Phase

A similar calculation method was conducted for the construction phase, with a certain distinction. This time, several impact categories were appointed to a certain construction method and the impact of each construction method is calculated as a first step (see

Table 6a). Then, the scores were weighted and normalized to a −1 and 1 scale. Finally, these scores were grouped under each stakeholder category by using the cost-wise ratio of each construction method in total cost of LL, so that it would represent the social perspectives (see

Table 6b). This implies that one particular impact category (i.e., occupational improvement) may be affected by several construction methods (i.e., demountable façade and technical systems). In the end, a final score for each stakeholder category was achieved.

The results include insights on five construction methods: bio-based materials, demountable façade and technical systems, prefabrication, and reused materials. The evaluation on the construction phase put forward a couple of highlights: (i) the adverse impact of circular materials on affordability and (ii) the overall positive impact of construction methods on the workers and local community. It must be noted that the negative impact of the affordability seems to be compensated by several other positive aspects related to the local community. However, uncertainties in the end of life yields an unexpected decrease on the social impact on society.

4.3. Stakeholder Analysis

In this sub-section, social impacts are discussed from the perspective of each stakeholder category. In the previous sub-sections, impacts of individual preferences on materials or methods during production and construction were discussed. Then, it is quite important to group the impact into each stakeholder category to discuss the impacts of the technical decision on social groups.

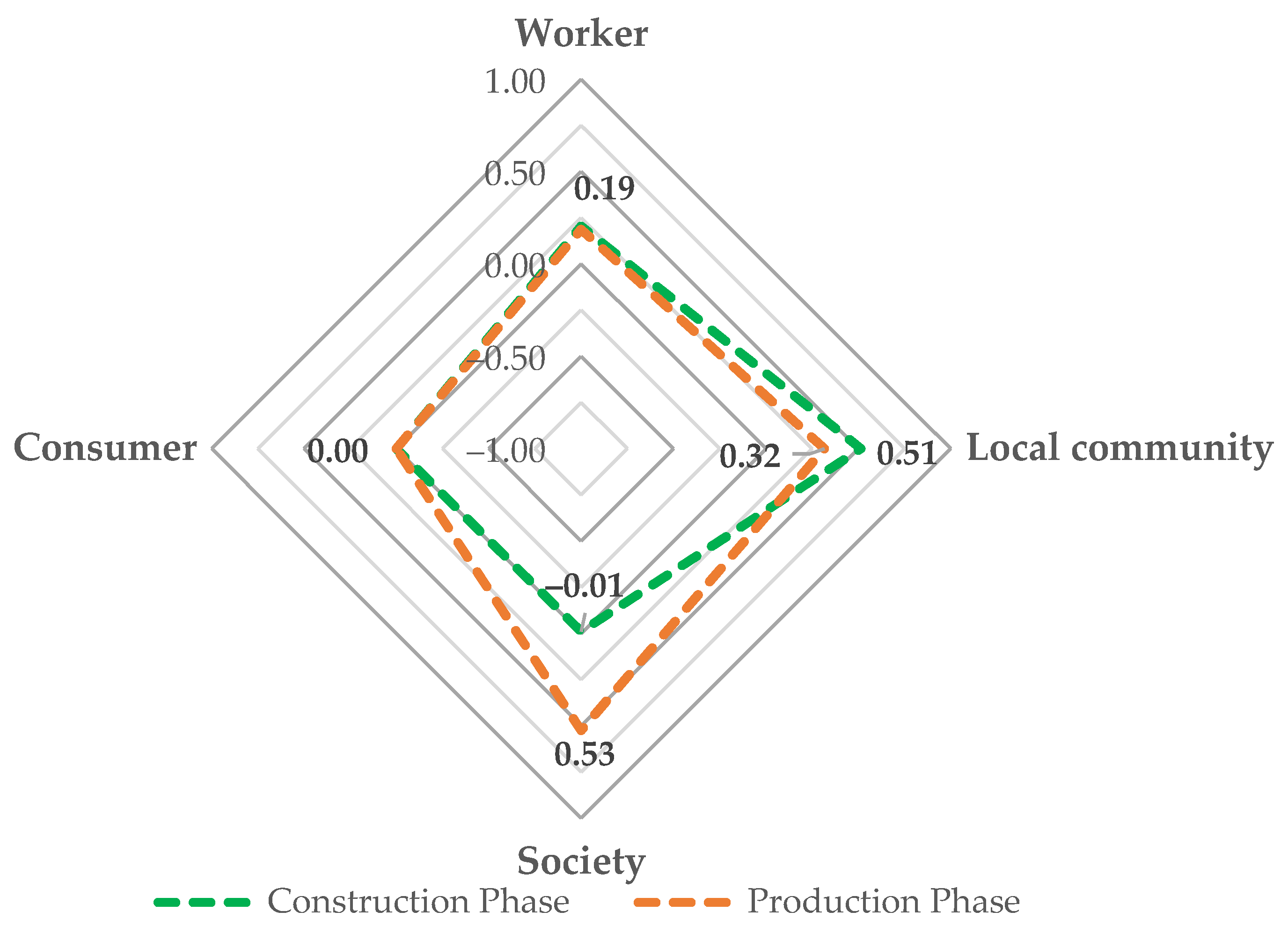

Figure 4 provides a general overview of social impacts and shows that the LL Ghent has a positive impact for almost all stakeholder categories. In the following sub-sections, these impacts are analysed in detail.

4.3.1. Workers

The impact of prefabrication was expected to be significant on the workers. This was also evident from the volume of discussion in this section during the interviews. However, the first two impact categories of health and safety and working hours were adversely affected by the fact that this production was a first-time for the producer. Hence, some of the safety aspects or optimization on the production line were not possible. For example, it was noted that the scores for these impact categories could be higher (by 1 point) for the next productions of the LL prototype. It was also acknowledged that the production process has provided a good learning opportunity for all workers.

The condition of workers on-site is greatly influenced by non-toxic bio-based materials usage with less precautions against skin irritations or mouth masks, and ease of assembly due to the modular and demountable prefabricated components. Nevertheless, the lack of certification and regulations on reused materials posed some risks on safety conditions. Moreover, the increase in the working hours due to unexpected delays in the first-time processes had a negative impact. The unique characteristic of the construction methods provided a great opportunity for occupational improvement for the workers.

4.3.2. Local Community

As the production of components took place in an off-site enclosed facility (significantly different than a conventional construction that takes place on-site), there are significant positive impacts on safety and healthy living conditions. It was seen that there was a considerable decrease in production waste. Due to the fact that all components of prefabricated wall panels are derived from local sources in Belgium, there is a positive impact on local materials and employment.

Nevertheless, it was acknowledged that the current market of bio-based materials is not favorable for affordable production. Although, it was also noted that possible follow-up production of similar buildings could be much more feasible for the producer with a fully automated production line.

The prefabricated bio-based components have a high positive impact on safety and healthy living conditions in the local community. As the construction duration on-site is significantly decreased when compared with conventional construction, there is a huge benefit from avoiding disturbances in the local area. Bio-based materials (especially the innovative blown-in insulation) have been proved to be high performing materials that provide a better indoor environment. On the other hand, reused materials have an uncertainty regarding thermal performance, so that caused a decrease for accessing better resources by the community.

It was acknowledged that there is a high recognition of benefits of prefabrication by the public. However, the low rate of affordability can be considered as the obstacle against having even higher positive impact on the local community.

4.3.3. Society

The society category considers the activities that ensure the end-of-life responsibilities and commitment to sustainability by the society. In the case of LL Ghent, the end-of-life responsibilities heavily rely on the special expertise of the producer. Without their involvement, it would not be feasible to repair or dismantle the components. Furthermore, it was foreseen that certain user manuals can be prepared in the future to enable self-builders to work on the LL components.

The end-of-life responsibilities are linked to the demountable façade and technical services. It was seen that due to the first-time experience in LL Ghent, some of the post-intervention documents for dismantling the components are not as elaborative as intended. A detailed end-of-life manual that is publicly shared would have a better impact. It was noted that the current rules and regulations do not require such documents during commissioning. This condition was considered as an unintentional obstacle against commitment to sustainability. This point is emphasized as a future improvement.

4.3.4. Consumer

The transparency of information on LL Ghent relevant for consumers was questioned in this category. Only the general information for advertisement and publicity is currently accessible by the users. Also, there is not a strategy foreseen by the producer for the dissemination of additional data to the public.

Due to the lack of public documents regarding the construction methods that are used in LL Ghent, the consumers may not have access to relevant data. This was considered as a non-impactful topic. However, as mentioned in the Society section, there are plans for improving the transparency of the information in the future.

5. Discussion

This study proposes an S-LCA framework for circular and bio-based constructions and provides an integrated view of experts, producers, contractors, and workers on the social impact of a circular building prototype in a quantified format. At the same time, this study raises several discussion points related to method development and limitations, as well as current gaps.

A few limitations of this study can be highlighted. First, the scope of the study does not include the use phase due to the fact that the LL Ghent was not commissioned at the time of the research. It is possible to conduct S-LCA on expected impacts (in the use phase) but there is no clear method on how to combine an actual impact with an expected impact. The social impact in the use phase of LL is a possibility for a future study.

Second, there is a lack of a validated set of indicators for buildings in the literature and in the global S-LCA method, as already highlighted by Alvarenga et al. [

35]. For this reason, this study used workshops with focus groups to determine specific impact categories and indicators. This approach can cause a dependency on the expert groups who determine the impact categories and indicators. It is possible that a different set of impact categories and indicators could be selected by a different expert group. As the method also used weighting factors from the expert group, the mentioned impact may even be greater. Nevertheless, this approach provides a tangible link between the stakeholders and the object. Therefore, the method may be more successful when the aim is to assess the object from the perspective of specific stakeholders and not from a global perspective.

As this study evolves around the case study of LL Ghent, there is a significant impact of criteria definition on the content and results of this study; both impact categories and all construction methods were defined according to the LL Ghent. In this context, they are quite specific to circular and bio-based building components. Construction-related activities tend to differ significantly when compared to the other studies such as Dong and Ng [

14]. This is related to the unique characteristics of each building typology, and the contribution of the results is specific to the building typology and construction method. On the other hand, this study could have benefited from common indicators or questionnaires.

Besides the limitations, the results of this study display similarities to previous case studies of Dong and Ng [

14], Liu and Qian [

18], and Balasbaneh and Sher [

21] depending on the positive social impacts on worker and local community categories. The precast/prefabricated construction methods were the significant factor affecting the working conditions for workers and yield less disturbance for the local community. When compared with studies on circular economy/construction, the impact on the society through end-of-life responsibilities is similar with the study of Hossain et al. [

17].

Regarding some general discussion in the literature, Hackenhaar et al. [

36] discussed that existing LCA studies lack a criticality on raw material extraction. Even though this study does not possess a general raw material criticality, this aspect was considered through the assessment of reused systems. There is also a tendency to use hotspot analysis through quantitative databases on country-specific risks such as the social hotspot database (SHDB) [

37]. On the other hand, such databases are useful to compare similar construction methods that take place in different regions. As this study required comparison of different construction methods that rely on local industries in a singular region, the level of detail in SHDB was not sufficient. A future study can compare the qualitative results of this study with a detailed input-output model specific for Belgium (Flanders).

6. Conclusions

This study shows that circular construction methods can have positive social impacts, such as (i) a healthy and safe working environment for workers and (ii) decreased on-site construction activities with positive effects on workers and local communities. Specifically, prefabrication methods have a significant impact on the well-being of the local community, as well as workers. Emerging concepts such as demountable construction methods provide learning opportunities for the workers. Overall, this study concluded that circular construction may have additional social benefits besides environmental benefits.

As the assessment in this study was conducted on a prototype, several points could be potentially improved. For example, low affordability and uncertainties on bio-based and reused materials were acknowledged by interviewees as the origins of the drawbacks below:

Affordability could be certainly improved as the process is optimized and when mass production is initiated. This does not necessarily imply that such buildings would be accessible to the general public or low-income groups as long as positive social impacts are integrated to the current building design and commissioning processes. This is also a reason why social impact assessment should gradually be a legal requirement (just as environmental impact assessments are) for building permits. In that way, the value of social impacts can be acknowledged and this generated value may be fed back to the design and affordability of construction.

For facilitating such a reflection of the social impacts of construction to legal processes, there is a need for standardized indicators and databases. Together with the previous studies in the same domain, this study provided valuable impact categories and indicators that are specific for several construction methods. Researchers would greatly benefit from a collection of construction methods and materials in an industry-specific guideline.

In order to enhance the value of social impact on construction, there are several efforts to integrate S-LCA into multi-criteria assessments. For the case of LL Ghent, monetized environmental LCA results derived in a previous study [

34] may be integrated with social LCA. For such a goal, there is a critical need for more data on the conversion of social risks and impacts into monetary values. Then, such a study could provide one way of integrating the environmental and social pillars at the building level. This is considered as a future study in the scope of life cycle sustainability assessment domain.

Author Contributions

Conceptualization, N.C.K. and A.V.; methodology, N.C.K.; validation, N.C.K., C.P. and A.V.; formal analysis, N.C.K.; investigation, N.C.K.; writing—original draft preparation, N.C.K.; writing—review and editing, C.P. and A.V.; visualization, N.C.K.; supervision, C.P. and A.V.; project administration, A.V.; funding acquisition, A.V. All authors have read and agreed to the published version of the manuscript.

Funding

The research is part of the Circular Bio-based Construction Industry (CBCI) project. CBCI is funded by the European Union Regional Development Fund Interreg 2 Seas Mers Zeeen (2S05-036).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Euclid Network GECES (Commission Expert Group on the Social Economy and Social Enterprises). Available online: https://euclidnetwork.eu/2020/09/geces/ (accessed on 15 November 2022).

- EN 15643-1:2010; Sustainability of Construction Works—Sustainability Assessment of Buildings—Part 1: General Framework. CEN: Brussels, Belgium, 2010.

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Iacovidou, E.; Hahladakis, J.N.; Purnell, P. A systems thinking approach to understanding the challenges of achieving the circular economy. Environ. Sci. Pollut. Res. 2021, 28, 24785–24806. [Google Scholar] [CrossRef] [PubMed]

- Ellen MacArthur Foundation. Growth Within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Walker, A.M.; Opferkuch, K.; Roos Lindgreen, E.; Simboli, A.; Vermeulen, W.J.V.; Raggi, A. Assessing the social sustainability of circular economy practices: Industry perspectives from Italy and the Netherlands. Sustain. Prod. Consum. 2021, 27, 831–844. [Google Scholar] [CrossRef]

- CBCI Interreg 2seas Circular Biobased Construction Industry. The European Union Regional Development Fund Interreg 2 Seas Mers Zeeen (2S05-036). Available online: https://www.interreg2seas.eu/nl/CBCI (accessed on 14 October 2022).

- EN 16309:2014; Sustainability of Construction Works—Assessment of Social Performance of Buildings—Calculation Methodology. CEN: Brussels, Belgium, 2014.

- UNEP. Guidelines for Social Life Cycle Assessment of Products and Organizations; Benoît Norris, C., Traverso, M., Neugebauer, S., Ekener, E., Schaubroeck, T., Russo Garrido, S., Berger, M., Valdivia, S., Lehmann, A., Finkbeiner, M., Arcese, G., Eds.; United Nations Environment Programme (UNEP): Paris, France, 2020. [Google Scholar]

- Benoît-Norris, C.; Vickery-Niederman, G.; Valdivia, S.; Franze, J.; Traverso, M.; Ciroth, A.; Mazijn, B. Introducing the UNEP/SETAC methodological sheets for subcategories of social LCA. Int. J. Life Cycle Assess. 2011, 16, 682–690. [Google Scholar] [CrossRef]

- Life Cycle Initiative. Pilot Projects on Guidelines for Social Life Cycle Assessment of Products and Organizations; Traverso, M., Mankaa, M.N., Valdivia, S., Roche, L., Luthin, A., Garrido, S.R., Neugebauer, S., Eds.; Life Cycle Initiative: Paris, France, 2022. [Google Scholar]

- Hosseinijou, S.A.; Mansour, S.; Shirazi, M.A. Social life cycle assessment for material selection: A case study of building materials. Int. J. Life Cycle Assess. 2014, 19, 620–645. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A social life cycle assessment model for building construction in Hong Kong. Int. J. Life Cycle Assess. 2015, 20, 1166–1180. [Google Scholar] [CrossRef]

- Santos, P.; Gervásio, H.; Pereira, A.; Simões da Silva, L.; Bettencourt, A. Comparative life cycle social assessment of buildings: Health and comfort criterion. Matériaux Tech. 2016, 104, 601. [Google Scholar] [CrossRef]

- Santos, P.; Carvalho Pereira, A.; Gervásio, H.; Bettencourt, A.; Mateus, D. Assessment of health and comfort criteria in a life cycle social context: Application to buildings for higher education. Build. Environ. 2017, 123, 625–648. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Dong, Y.H.; Lo, I.M.C.; Cheng, J.C.P. Development of social sustainability assessment method and a comparative case study on assessing recycled construction materials. Int. J. Life Cycle Assess. 2018, 23, 1654–1674. [Google Scholar] [CrossRef]

- Liu, S.; Qian, S. Evaluation of social life-cycle performance of buildings: Theoretical framework and impact assessment approach. J. Clean. Prod. 2019, 213, 792–807. [Google Scholar] [CrossRef]

- Yıldız, S.; Kıvrak, S.; Gültekin, A.B.; Arslan, G. Built environment design—Social sustainability relation in urban renewal. Sustain. Cities Soc. 2020, 60, 102173. [Google Scholar] [CrossRef]

- Chen, X.; Qu, K.; Calautit, J.; Ekambaram, A.; Lu, W.; Fox, C.; Gan, G.; Riffat, S. Multi-criteria assessment approach for a residential building retrofit in Norway. Energy Build. 2020, 215, 109668. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Life cycle sustainability assessment analysis of different concrete construction techniques for residential building in Malaysia. Int. J. Life Cycle Assess. 2021, 26, 1301–1318. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Bernardino Galeana, I.; Llatas, C.; Montes, M.V.; Hoxha, E.; Passer, A. How to conduct consistent environmental, economic, and social assessment during the building design process. A BIM-based Life Cycle Sustainability Assessment method. J. Build. Eng. 2022, 45, 103516. [Google Scholar] [CrossRef]

- LLatas, C.; Soust-Verdaguer, B.; Hollberg, A.; Palumbo, E.; Quiñones, R. BIM-based LCSA application in early design stages using IFC. Autom. Constr. 2022, 138, 104259. [Google Scholar] [CrossRef]

- Fauzi, R.T.; Lavoie, P.; Tanguy, A.; Amor, B. On the possibilities of multilevel analysis to cover data gaps in consequential S-LCA: Case of multistory residential building. J. Clean. Prod. 2022, 355, 131666. [Google Scholar] [CrossRef]

- Thanu, H.; Rajasekaran, C.; Deepak, M. Developing a building performance score model for assessing the sustainability of buildings. Smart Sustain. Built Environ. 2022, 11, 143–161. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene, C.E.; Maury-Ramírez, A. Life cycle assessment on construction and demolition waste: A systematic literature review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Locurcio, M.; Tajani, F.; Anelli, D.; Ranieri, R. A multi-criteria composite indicator to support sustainable investment choices in the built environment. Valori E Valutazioni 2022, 30, 85–100. [Google Scholar] [CrossRef]

- Ibrahim, A.; El-Anwar, O.; Marzouk, M. Socioeconomic impact assessment of highly dense-urban construction projects. Autom. Constr. 2018, 92, 230–241. [Google Scholar] [CrossRef]

- Wang, Y.; Han, Q.; de Vries, B.; Zuo, J. How the public reacts to social impacts in construction projects? A structural equation modeling study. Int. J. Proj. Manag. 2016, 34, 1433–1448. [Google Scholar] [CrossRef]

- Nadazdi, A.; Naunovic, Z.; Ivanisevic, N. Circular Economy in Construction and Demolition Waste Management in the Western Balkans: A Sustainability Assessment Framework. Sustainability 2022, 14, 871. [Google Scholar] [CrossRef]

- Tirado, R.; Aublet, A.; Laurenceau, S.; Habert, G. Challenges and Opportunities for Circular Economy Promotion in the Building Sector. Sustainability 2022, 14, 1569. [Google Scholar] [CrossRef]

- Maury-Ramírez, A.; Illera-Perozo, D.; Mesa, J.A. Circular Economy in the Construction Sector: A Case Study of Santiago de Cali (Colombia). Sustainability 2022, 14, 1923. [Google Scholar] [CrossRef]

- Kayaçetin, N.C.; Verdoodt, S.; Lefevre, L.; Versele, A. Evaluation of Circular Construction Works during Design Phase: An Overview of Valuation Tools. In Sustainability in Energy and Buildings 2021; Littlewood, J.R., Ed.; Smart Innovation, Systems and Technologies; Springer: Berlin, Germany, 2022; Volume 263, pp. 89–100. [Google Scholar]

- Kayaçetin, N.C.; Verdoodt, S.; Lefevre, L.; Versele, A. Integrated decision support for embodied impact assessment of circular and bio-based building components. J. Build. Eng. 2023, 63, 105427. [Google Scholar] [CrossRef]

- Alvarenga, R.A.F.; Cadena Martinez, E.; Zanchi, L.; Zamagni, A.; Sonderegger, T.; Ruiz, E.M. Critical Evaluation of Social Approaches. 2021. Available online: https://orienting.eu/publications/prova-2 (accessed on 16 May 2022).

- Hackenhaar, I.; Alvarenga, R.A.F.; Bachmann, T.M.; Riva, F.; Horn, R.; Graf, R.; Dewulf, J. A critical review of criticality methods for a European Life Cycle Sustainability Assessment. Procedia CIRP 2022, 105, 428–433. [Google Scholar] [CrossRef]

- Social Hotspot Database (SHDB). Available online: http://www.socialhotspot.org/ (accessed on 14 October 2022).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).