Abstract

Sustainability concepts should be adopted via new technologies to achieve the greatest possible gains without compromising the objectives of projects. In this research, we empirically investigated the influence of identified drivers on the implementation of robotics in the building sector of developing countries. To this end, with a view to sustainable building projects, the drivers of robotics were derived from the literature, which were subsequently contextually adjusted using a survey method through the exploratory factor analysis (EFA) method. The results of EFA revealed that the drivers of robotics can be classified into three primary constructs: technology, industry, and culture. However, the benefits of implementing robotics can be grouped into two primary constructs: resources and environment. Therefore, in this study, we employed partial least squares structural equation modeling (PLS-SEM) to evaluate the connections amongst drivers and applications of robotics in Nigeria’s building industry. The results indicated that the input to the implementation of robotics in Nigeria’s building industry via the drivers of robotics has a considerable influence at a small scale, with an impact of 14.5%. The findings of this study can serve as a guide for policymakers looking to improve their projects and increase sustainability by using robotics in the building sector.

1. Introduction

The architectural, engineering, construction, and operations (AECO) industry is a basis of a country’s economy, expected to accounting for approximately 15% of global GDP by 2030 [1,2]. The building industry is one of the key sectors of the economy that define the healthy lifestyle and well-being of the population of any country [3]. Building projects utilize approximately 40% of global power and is responsible for up to one-third of global greenhouse gas emissions in both rich and developing countries [4]. Given the growing concentration of people and economic activity in many cities, such projects are critical to the accomplishment of global sustainability goals [5]. Furthermore, increased urbanization in these cities has resulted in an increase in urban populations [6]. Nonetheless, in a rapidly changing and urbanizing world, building allocation cannot keep up with demand [7]. Significant changes in the building industry have been recorded in many developing countries, driven by the need to attain national objectives [8]. It was reported that 828 million impoverished people in developing nations live in slums and substandard housing, and this population is expected to grow to 1.4 billion by 2020 [7,9,10]. These regions have experienced tremendous growth, with an emphasis on the importance of building to ensure a basic way of life [11]. Consequently, all governments have prioritized inexpensive building projects by enacting a variety of affordable building technologies and laws [3]. However, a debate continues regarding whether such structures are affordable for low-income earners [7]. In addition, the building industry in these countries is not competitive, as it cannot meet global requirements for sustainable development. Such projects are marred by multiple resource challenges, such as budget breaks, delays in scheduling, non-completion, high risk of failure, and poor quality, making it difficult to achieve the anticipated goals. These projects face multiple challenges [12,13]. Considering the low level of investment in this sector, many projects have been cancelled or suspended [14]. In all developing countries, the building industry meets the demands of the government demand, society, and consumers, consequently lagging other comparable businesses [15] Furthermore, the problem of sustainability in the low-income building industry has not been solved and considered [16]. As a result, the necessity of “sustainable buildings” that are ecologically friendly and resource-efficient has been stressed in the literature. Wolstenholme et al. [17] argue that implementing effective and sustainable building practices will revolutionize the building industry. Moreover, building stakeholders are unable to quantify the environmental impacts of structures as they are created [18]. As a result, robotics implementation may be integrated throughout the life cycle of a project through sustainability techniques [19,20].

The use of robotics in building has been acknowledged as one of the most radical advances for building projects [21]. Skibniewski [22] characterized the application of robotics in the construction industry as sophisticated construction equipment capable of being teleoperated, gathering and processing sensory data, and being numerically controlled for autonomous job implementation. According to Mahbub [23], robotics implementation entails the use of self-controlled mechanical and electrical gear with intelligent control mechanisms for building jobs and operations. Several building firms have already begun to employ modern construction technology to decrease waste and resource consumption [21]. The implementation of on-site robotics construction technologies has proven to provide several advantages, including considerable waste reduction, major time savings, flexible working conditions, and increased quality but at a high initial cost [24,25]. At the business level, long-term economic value in terms of payback duration and return on investment may be used to analyze the financial viability of investments in robotics deployment [26].

Although robotics have come to represent a popular instrument for solving building difficulties in a number of industrialized countries, particularly in terms of investigating the functions of computerized technologies to accelerate various sorts of construction markets, [27], most emerging countries have yet to seriously consider such technology. In the building industry of third-world nations, only an insignificant proportion of construction firms have successfully implemented robotics prefabrication in their projects. Notwithstanding the low implementation rate of robotics, there has been continuous research on innovative robotics and automation technologies incorporated into building sites. A groundbreaking technological advancement is the invention of 3D printing robots [28], which can be used to structurally print innocuous concrete buildings and bridges [29]. Humanoid robotics technology is (e.g., exoskeleton) another such invention, combining human intelligence with the speed, efficiency, and power of a robotics system fastened to the human body. Thus, it provides the capacity to manage constricted and complex tasks [30].

Apart from these innovative inventions, the building industry has not taken full advantage of the open possibilities offered by these technologies. Whereas many industries have depended on and thoroughly explored the application of robotic technologies, such as the motorized medical profession, the universal application of robotics in the building sector is overdue as a result of many impediments [31]. The implementation of robotics in the building industry is quite sluggish. When generating different types of building jobs, the use of several single-task assembly robots is required [32], and robotics technology implementation is expected to enhance the sustainability of the building industry, as well as to solve issues such as labor shortages and safety hazards, particularly in high-rise buildings [33].

Kim et al. [34] argued that the low level of automation in the building sector delays other industries. An investigation involving 11 significant building firms and public organizations in Europe revealed that apart from the perception that automated and robotic systems can enhance output, safety, and health [35], there are substantial threats to the implementation of robotics. These include technical and commercial risks and the high cost of implementation [36]. However, some studies have attempted to classify drivers of adoption, especially for definite activities in the building industry; these experiments have primarily focused on global building firms instead of the building industry in third-world nations building, such as in Nigeria. The existing literature has not presented an all-inclusive analysis that recognizes the impediments to the conventional implementation of robotics in building activities within Nigeria’s building industry. Consequently, filling this gap requires advanced knowledge concerning construction in third-world nations, especially Nigeria. To that end, we formulated the following research questions to be answered in this study. What are the benefits and impact of robotics in Nigeria’s building industry? What are the requirements and drivers needed to implement robotics in Nigeria’s building industry? Accordingly, this study was carried out to fill the existing gap by mathematically studying the connection concerning robotics drivers and adoption and the impact of implementing robotics in the building industry using the partial least squares modeling technique. We used the global–local context (GLC), which emphasizes the worldwide importance of the study subject. Furthermore, this strategy both represents and accentuates the issues under consideration. Thus, the method has been embraced by “developing” countries, including Nigeria, as the local environment is geared to produce such clarity (i.e., establishing its importance). The outputs from this study can be useful in enabling numerous attractive benefits for many building professionals, such as policymakers, project bidders, and architects [37], not only in Nigeria but also in other developing countries where building projects are carried out in the same way. This study will offer valuable insight that can help in decision making with respect to successful construction projects by enhancing building resources and improving the entire building environment through robotics implementation.

2. Model Development and Research Background

In 1921, Karel Capek coined the concept of robotics. At present, robots are utilized on farms, in workplaces, homes, streets, and other public places, such as restaurants, malls, and amusement parks, in the form of drones, humanoids, and self-driving vehicles. Robotics has been a promising and evolving field of science and engineering since the 1920s. Initially, robots were utilized for complex routinized tasks and limited to factories and warehouses, whereas they are currently an integral part of human society. At present, robots are applied for various purposes, such as in food manufacturing [38], therapeutic training [39], teaching [40], and drain cleanup [41]. The pace of automation is expanding very precipitously, which is apparent from the rate at which robots are applied in the construction industry. Robots have made significant advances in the socioeconomic perceptions of human society [42]. Consequently, the global manufacturing network paradigm is evolving, with increased use of artificial intelligence and robots enabling manufacturing intelligence and smart production [43].

Robots are grouped into two major classes: field and service robots. The latter are applied in domestic contexts, such as homes, public parks, and restaurants and are typically referred to as humanoids. Field robots are specific and unique robots designed to operate in a specific milieu, such as ground, aerial, and marine applications [42]. The developments of robotics can be grouped into three generations. The first generation comprised robots primarily used for carrying out repeated tasks and for automation. Those dealing with weaponry, the development of tasks, entertainment, and research are termed second-generation robots. Those concerned with intelligence that can co-operate and coexist with humans constitute third-generation robots. These robots are primarily applied to understand patterns of behavior and natural languages and respond to human behavior [44,45,46].

The application of robotics offers active customer care and involvement through decision making. Rockart [47] described drivers as locales in which findings guarantee a company’s commercial success if adequate. Chan et al. [48] and Yu et al. [49] concur that drivers can be deemed as essential for managing planning and field actions to guarantee achievement [50]. Based on Dillon and Morris’ [51] definition of technology implementation, the operator’s readiness to employ technology in day-to-day life to complete assignments specifies customer acceptance. Other studies, including [52], have examined the implementation of technology in everyday life. The analyzed theories typically see the drivers of technology implementation as achievement aspects [53,54,55].

The theory of reasoned action (TRA) is concerned with the elements of intentionally planned behaviors [56]. A task abstraction module (TAM) was pioneered to evaluate operator adoption of high-tech modernizations [57]. the unified theory of acceptance and use of technology (UTAUT) is, likewise, a well-established theory developed on the basis of TRA and TAM [52]. Additionally, precise methods and tools are needed to boost the implementation of robotics developed for building projects. Robotics constitute a technique that entails the application of approaches that proffer a motivation to achieve improved project and environmental resources. The speediest innovations in automation and robotics are driven by software programming methods that enable applications to find patterns, conduct analysis, and make predictions according to various sources of data. Many types of methods are used in nearly all industries to enhance the precision, quality, and pace of specialized processes.

The building industry is dominated by equipment and plants that generate considerable emissions. If robotic machinery is used in place of such equipment, it can reduce environmental pollution and create a friendly environment. This includes robots whose primary function may not affect the environment, although they might have considerable environmental consequences. Robots are designed to explore their effect on the environment, although they have substantial environmental effects. Robots are also designed to delve into new environments that are impenetrable by humans [58]. The desire for modernization in the building industry hinges on the willingness of the industry to adopt novel technologies. Implementing novel technologies tends to lessen some obstacles that can affect the building industry. Carmona [59] argued in favor of building technology, arguing that the intrinsically conservative nature of the sector has failed to transform construction processes. However, results have lagged, despite the availability of new methods that can reduce construction costs.

Consequently, the application of new building methods can aid in the expansion of the effectiveness of tasks and reduce the high costs devoted to building projects. Among the significant benefits of robotics, implementation improves working conditions by avoiding contact with dangerous tasks and reducing such tasks among workers. Robotics implementation can boost occupational safety by performing unsafe tasks in hazardous areas that would otherwise have to be performed by humans [60,61]. Robotics implementation has led to a reduction in injuries to workers and laborers. Issues stem from the quality of work delivered by employees and the repetitiveness of tasks performed, and labor costs can be reduced if fewer workers are required. Currently in the construction industry, human tasks are being supplemented with robots to cut down on the number of workers. Table 1 and Table 2 show the benefits and drivers of robotics adoption, respectively. Likewise, Figure 1 shows the conceptual framework for the present study.

Table 1.

Drivers leading the application of robotics for construction projects.

Table 2.

Benefits through the adoption of robotics for construction projects.

Figure 1.

Impact of robotics drivers on robotics implementation.

3. Research Methodology

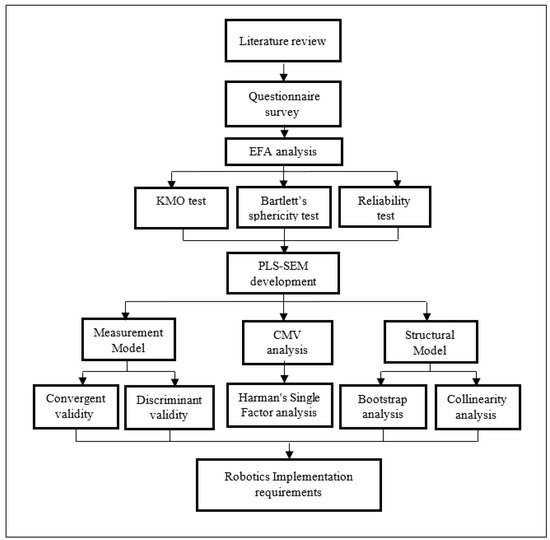

The study approach involves creating a theoretical model that summarizing a literature review used to create transitional theories (or hypotheses) that were verified by employing experimental proof [78]. A three-stage procedure was established for the conceptual modeling process: (i) identifying the model’s construct, (ii) grouping the model’s constructs, and (ii) itemizing the connections between the model’s constructs [79]. The model’s results were obtained following this process, as shown in Figure 1. The study plan was based on the work of Tanko et al. [80], as illustrated in Figure 2. Because the use of robotics is comparatively new in Nigeria, in this study, we employed a stratified sampling approach to attain a particular subpopulation group [81]. This method was proposed to help researchers collect highly reliable and accurate data because the current survey is associated with a topic concerning robotics. The benefits of stratified sampling, as highlighted by Sharma [82], are as follows: (i) “Decreasing bias in sample case selection, this also implies that perhaps the sample will represent a substantial portion of the surveyed populations; (ii) Allow the sample to be generalized to the population. The population difference is considered by stratification, along with all three sectors (client, contractor, and consultant) and most five subsectors in Nigeria” [83]. Respondents reported robotics drivers and adoption benefits on an experience and knowledge basis utilizing a five-point Likert scale, with scores of 5 and 1 representing very high and very low, respectively, with high, average, and low scores falling between 5 and 1. This scoring system has been broadly applied in many studies, including those concerned with construction management [84,85,86,87,88,89,90]. The study was designed to provide stakeholders with a variety of solutions based on practice in a range of construction schemes.

Figure 2.

Research design.

The size of the sample was determined according to [91]. More than thirty (30) cases were considered adequate for further examination, including mean, median, and mode for a normal distribution curve [92]. In contrast, Harris and Schaubroeck [93] argued that a sample size of at least 200 is required to warrant vigorous SEM. A very intricate path model requires a sampling size of 200 or more, as suggested by Kline [94], whereas a sampling size greater than 100 was considered satisfactory by Yin [95]. Because in this analysis, we employed the SEM method, 104 participants were recruited among 180 construction experts. The participants were personally recruited and completed a self-administered questionnaire for SEM evaluation, with a response rate of approximately 68%, which was deemed satisfactory for this study [96,97].

3.1. Exploratory Factor Analysis

Exploratory factor analysis (EFA) was conducted to examine the groups mentioned above based on a questionnaire distributed to experts in Nigeria’s construction industry. Between 150 and 300 samples or observations are required for EFA [98]. However, Pallant [99] argued that the investigators have some leeway concerning the sampling size for factor analysis. Thus, the use of larger sampling sizes is advocated relative to the number of variables involved. Shen [100] suggested that a set of 20 to 50 variables or parameters is appropriate for factor analysis. Because the individual aspects are not sufficiently determined if the quantity of variables exceeds this limit, some analyses required fewer variables if the sampling size is sufficiently large [14,101]. The population included in the present study was considered a good representative sample across the relevant ranges [98]. Accordingly, the ten identified variables and the completed questionnaires acquired from 104 respondents in the current analysis were, likewise, deemed suitable for factor analysis [98,102].

3.2. Analytical Method (Structural Equation Modeling)

To examine the implementation of robotics, we conducted a literature review, and four models were compared in order to develop an optimal model of robotics implementation that guarantees practical construction projects. The considered models were multiple linear regression (MLR), structural equation modeling (SEM), artificial neural network (ANNs) and system dynamics (SD). Owing to the connections among non-observed variables, a regression model was not applied. This is a major limiting factor for the application of regression model [103]. Likewise, SD could not be applied because the nature of the survey data is unconnected to the period. ANNs are also a projecting tool, and the purpose of the analysis is to analyze the effects of the drivers of robotics adoption on robotics implementation. The SEM technique explains the relationship between many quantifiable and non-observable variables, making it appropriate for the analysis in this study [104]. Amaratunga et al. [105] explained that SEM is a valuable instrument for tackling errors within variables. This SEM analysis technique was used to generate a model and determine the relationships among robotics drivers and robotics implementation. Byrne [73] noted that SEM is a widely recognized non-experimental investigation used for parameter evaluation and hypothesis testing [106]. Similarly, Ringle et al. [107] confirmed that this technique has been improved over many decades in a research journal bulletin issued in MIS (Management Information Systems) Quarterly. Furthermore, Yuan et al. [108] concluded that SEM is a thoroughly understood and prevalent form of data analysis in the social sciences.

The SEM technique was used in the current analysis because it has been widely applied in studies concerning the construction industry [109]. This approach enabled us to test hypothesized relationships simultaneously [110]. In order to establish the relationships between robotics drivers and robotics implementation, we used the partial least squares model (PLS) [111], which includes both formative and reflective variables. It enables examination of the drivers within robotics and the effects of robotics implementation. PLS-SEM, on the other hand, allows for the comprehensive testing of complicated models for their similarity with the data, as well as the testing of explicit assumptions about parameters for their similarity with the data [112]. In the PLS, the computing model defines the relationsships among the constructs (i.e., robotics drivers) and the experiential pointers (or drivers) [113,114]. In this study, the goal of the data reduction procedure was to decrease the number of variables and parameters in the research model to a reasonable amount relative to the sample size/parameters estimated in the SEM ratio [115].

4. Results

4.1. Characteristics of the Respondents

Data on the characteristics of the respondents were collected for background information, including the profession of the respondent, professional qualifications, academic qualifications, and years of professional experience. Table 3 shows the profession of the respondents who completed the questionnaire; a proportion of 28.8% of respondents were architects, 28.8% were quantity surveyors, 11.5% were builders, 25% wre engineers, and 5.8% were project managers. Table 3 shows the years of professional experience of the respondents; a proprotion of 32.7% of respondents had fewer than 5 years of professional experience, 32.7% had 6 to 10 years of professional experience, 21.2% had 11 to 15 years of professional experience, 11.5% had 16 to 20 years of professional experience, and 1.9% had more than 21 years of professional experience. Table 3 shows the knowledge level of the respondents about robotics, with three possible responses; a proportion of 73.1% of respondents anwered ‘Yes’ to this question about knowledge of robotics, 21.2% answered ‘No’, and 5.8% answered ‘Maybe’ indicating that they were not sure about the answer to the question. Table 3 shows the knowledge level of the respondents about the use of robotics in the construction industry, with three possible responses; a prorportion of 71.2% of the respondents answered ‘Yes’, 21.2% answered ‘No’, and while 7.7% answered ‘Maybe’ indicating that they were not sure about the answer to the question.

Table 3.

Characteristics of the respondents.

4.2. Identifying and Categorizing the Model’s Constructs

A total of 20 elements pertinent to robotics drivers and 12 items regarding the benefits of robotics implementation were examined using EFA. Many recognized factorability parameters were employed for model construction. The KMO is a homogeneity of factor dimension widely applied to assess whether partial associations between items are negligible [116,117,118]. The KMO index must be between 0 and 1 for effective factor analysis and should have a value of at least 0.6 [98]. Bartlett’s sphericity test also indicates whether the correlation matrix is identical. An appropriate factor analysis requires Bartlett’s sphericity test, as suggested by Pallant [119]. A p-value <0.05 is considered significant [120]. The initial results for robotics drivers and benefits of robotics implementation show that the Kaiser–Meyer–Olkin sample suitability ratios were 0.730. and 0.882, respectively. These values are greater than the recommended Bartlett’s value of the sphericity test. It was significant for robotics drivers (x2(45) = 123.511, p < 0.05) and for benefits of robotics implementation (x2 (66) = 270.008, p < 0.05). Moreover, the entire diagonal of the anti-image’s correlation matrix are above 0.5 and putative, given the insertion of individual elements in the factor analysis. The preliminary communalities are estimations of variance within variables measured among all components, and lower values (<0.3) designate variables that do not fit the solution factor. In the current analysis, all initial communalities were greater than the threshold, and all factor loadings were above 0.

The results of exploratory factor analysis for all ten elements relevant to robotics drivers indicated two factors with eigenvalues or more than 1. The total variance and the eigenvalues described by the two factors were 57.915%. It is noteworthy that D 1 was excluded from the primary analysis, owing to cross loading, as shown in Table 4. Additionally, the EFA results revealed that all 12 elements were relevant to the robotics implementation benefits with three extracted. EFA results also identified ten elements relevant to the robotics derivers, with three extracted factors with eigenvalues of more than 1. The total variance and the eigenvalues described by the three factors were 59.88%. However, as shown in Table 4 and Table 5, three cross-loading factors (RI 5, RI 8, and RI 9) were excluded from the main study.

Table 4.

Factor loadings of robotics drivers.

Table 5.

Factor loadings of robotics benefits.

For the factors extracted by EFA, statistical reliability was determined. Factors for individual phases of the factor (or group) were measured based on the maximum factor loading for each parameter in the matrix structure. The table also shows that the reliability test was satisfactory. According to Nunnally [121], Cronbach alpha value should be higher than 0.6 for recently developed dimensions, although the expected value was 0.7, and values greater than 0.8 were deemed reliable. Therefore, the total Cronbach values were satisfactory, as they were higher than 0.6, and usual correlations of variables were above 0.3 for all factors, suggesting harmonious inner variables [122].

4.3. Common Method Bias

Calculation of variance errors that influence the validity of samples is referred to as general process bias, i.e., the statistical error variance for the observed and expected variables [123]. It is calculated using Harman’s single-factor model, which suggests different construction measures [124]. In this analysis, a single-factor test was used for variance calculation [125]. If the overall variance of the variables is less than 50%, the traditional method bias has a minimal impact on the results [124,126]. “When such a single-factor test is conducted, a high common method variance may exist if all factors come down to one single factor or a special factor accounts for the majority of total covariance over all variables” [127]. As shown in Table 6, the first set of variables accounts for 47.9% of the overall variance, indicating that the common method variance cannot be influenced by less than 50% [124].

Table 6.

Common method variance.

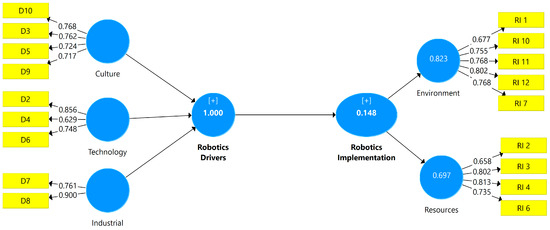

4.4. First-Order Construct Measurement Model

The SEM shown in Figure 3 duplicates the theoretical study model presented in Figure 1. As shown in Table 1 and Table 2, the model constructs of each robotics driver and implementation benefits model were comprehensive and categorized based on elements obtained from the literature. According to Hair Jr et al. [128], the evaluation model requires an estimate of (i) an indicator’s reliability, (ii) merged reliability, (iii) extracted average variance, and (iv) discriminant ability. In the current analysis, the PLS algorithm was applied 300 iterations using the following settings [129] recommended by Wong [130]: weighing scheme, weighing path, data matrix with a mean 0, variance of 1, highest interactions of 300, abort criterion of 1.0 × 10−5, and initial weights of 1.0.

Figure 3.

SEM model with R2 values and path coefficients.

Typically, indicators with external loadings in the range of 0.40 to 0.70 must be considered for elimination if removal of the indicator results in a significant increase in the reliability of the composite and AVE [131]. External load variables below 0.60 were found to disagree with this prerequisite and were eliminated for further analysis, as suggested in [128]. At this level, roughly one-half of an indicator’s variance is described by its components. The intensity at which the variance was described is higher than the variance error. Figure 3 and Table 4 show the external loadings for all variables of the measurement model. Thus, all external loads were greater than 0.60, which was deemed acceptable. Because the Cronbach alpha limits computational sensitivity with respect to the number of variables considered, the core constancy of composite reliability (cr) was evaluated according to Hair Jr et al. [128]; values greater than 0.70 were considered acceptable. For exploratory research, values greater than 0.60 are deemed suitable [130]. All models met the cr threshold of >0.70 and were therefore accepted, as summarized in Table 7. The AVE is a technique that is commonly used to estimate the convergent cogency of constructs within models with values higher than 0.50 [132,133], suggesting an acceptable value as recommended in [130]. All constructs passed this test, as shown in Table 7.

Table 7.

The results of convergent validity.

For constructs differing considerably from other constructs, discriminant analysis was accurately defined based on the observed standards. Consequently, the establishment of discriminative validity (DV) indicates that a construct is typical and describes singularities that are not clearly defined by the remaining constructs within the model [134]. DV can be computed by applying two types of methods: the cross-loading criterion and Fornell and Larcker’s (1981) criterion. The square root of the AVE of the individual construct in the initial technique can be equated to the correlation of an individual construct with any other construct to estimate discriminant validity. The square root of the AVE should be greater than the correlation among the dormant parameters based on the Fornell and Larcker [135] values. The results confirming the discriminant validity of the measurement model are presented in Table 8 [136].

Table 8.

Correlation of latent variables and discriminant validity (Fornell–Larcker).

The cross-loading criterion was employed to measure discriminative validity. This technique represents an attempt to establish the loadings of indicators based on the assumed dormant construct, which must be greater than the loadings on the remaining construct in a rows, which means that the indicator’s (items) loadings for each construct must be greater than the loadings of alternative constructs. Table 9 shows that the loading of each point of the allotted dormant construct is greater than the cross loading on the alternative constructs in a row.

Table 9.

Cross-loading testing of the discriminant validity of indicators.

4.5. Measurement Model (Second-Order Construct)

The significant variables (dependent and independent variables) were categorized as second-order static variables, and the momentous input of all first-order dormant variables was then examined by employing the bootstrap method. The individual construct of the robotics drivers was determinative, and robotics implementation was found to be an insightful construct. Significant correlations among the formative indicators of the measurements model were not characteristically projected. Furthermore, significant correlations among the formative variables indicating collinearity is deemed awkward [134]. Analysis of the value of the variable inflation factor (VIF) revealed collinearity between the construct’s formative variables. For this assessment, the internal VIF values were used to evaluate collinearity problems related to the formative–reflective form of second-order constructs. The three (3) first-order subscales of robotics drivers comprised culture, technology, and industry. For culture, maximum external loading was observed (β = 0.621, p < 0.001), as indicated in Table 10, followed by industry (β = 0.277, p < 0.001) and technology (β = 0.369, p < 0.001). According to these findings, all VIF values were less than 3.5, signifying that those subdomains contributed individually to higher-order constructs.

Table 10.

Second-order model testing by means of bootstrapping for foundational constructs.

Robotics implementation was identified as a second-order construct within the re model with two subsamples, comprising two components, i.e., environment (β = 0.907, p < 0.001) and resources (β = 0.907, p < 0.001), which contributed considerably to robotics implementation as a static second-order variable; standardized coefficient paths (external loadings) were greater than 0.7 and statistically significant, as indicated by Table 11.

Table 11.

Second-order model testing by means of bootstrapping for weighty second-order constructs.

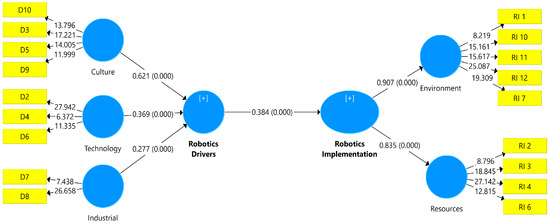

4.6. Path Analysis: Structural Model

Path analysis (PA) is a linear statistical technique that is ideal for management and social sciences. Likewise, PA is an essential tool for concurrent examination of multifaceted associations [98]. Primary phase analysis requires the application of SEM. This model is applicable for the evaluation of associations among studied concepts. After model fitting, SEM is the subsequent primary phase within SEM analysis. SEM can be used to detect relationships among variables. In SEM, the connections between factors are described in detail. The connections among exogenous (or dependent) and independent variables are shown by the data [137,138]. SEM evaluation is based on the model’s total fit, with theorized variable estimations trailed by importance, size, and direction [137]. The last component involves confirmation of the proposed analytical relationship on the basis of the research hypotheses presented in Figure 1.

SEM was applied to the research hypothesis. The effect of robotics drivers on robotics implementation was studied using PLS-SEM based on the study framework. The related research model hypothesis is illustrated in Figure 4. Within the context of the bootstrapping methodology, the consequence of the model’s hypothesis was estimated. Arbitrary resampling of the fundamental dataset comprised the process of bootstrapping to produce new samples of comparable size to the basic set of data. This approach tests the consistency of datasets and their statistical implications and, consequently, the error of the computed coefficient’s path [139]. The standardized coefficient path (β) and p-values, as well as the significance of the pathway, are presented in Figure 4. Table 12 presents the results of the bootstrapping method, indicating the p-values of the model path. According to the results, the effects of robotics drivers on robotics implementation were significant and positive (p = <0.001, β = 0.384).

Figure 4.

Bootstrapping analysis.

Table 12.

Relative path for the model.

4.7. Exploratory Supremacy of the SEM Model

The model results reveal robust reliability of each item, as well as the discriminatory and cogent validity of the measurement model. Besides calculating the variance within the dependent variable, which the model can define, the exploratory supremacy of the SEM model can be tested. Concerning the dependent variables within the model, the PLS algorithm reinforced squared multiple (R2) relationships. The R2 established by the PLS algorithm is comparable to the standard regression [140].

The value of R2 signifies the sum of variance and can be explained using the independent variable within dependent variables. Consequently, higher R2 values increase the analytical capacity of the SEM model. In the current analysis, the R2 values were calculated by employing the Smart-PLS algorithm, as shown in Table 13. The adjusted R2 for robotics implementation, as the significant dependent variable within the model, was 0.139, suggesting that the independent (or exogeneous) static variable (robotics drivers) can explain 13.9% of robotics implementation. These results imply that the effect of robotics drivers is insignificant, as argued by Chin [93].

Table 13.

Coefficient of determination (R2).

4.8. Predictive Relevance of the Structural Model

A significant component of the proposed model is its capacity to assess analytical significance. A blindfolding protocol was employed for individual dependent variables to assess the redundancy measures of cross validation. The results showed that project accomplishment with values of Q2 (0.057) was greater than 0, suggesting that the autonomous construct has predictive relevance for the supported construct analyzed in this study [141]. The Q2 value is greater than zero, as shown in Table 14. Thus, it can be assumed that the model has exceptional predictive significance.

Table 14.

Predictive relevance (Q2).

5. Discussion

A wide range of equipment is used on construction sites [142]. However, “the selection of a variant of a life cycle of a building among a vast number of alternatives is an important problem in project management” [143]. Overall, there are fewer aspects within the construction industry than in other industries, comprising aspects such as productivity, quality, and product functions [144], and firms operate in a market that is becoming more complicated and dynamic in the current epoch and global environment [145]. Nevertheless, sustainable construction projects effectively promote environmental sustainability and social development. Implementation of robotics technologies among experts and meaningful actions can substantially improve the realization of construction projects. Automated systems and robotics have transformative potential and offer numerous benefits to the building, architecture, engineering, and construction industries [146,147]. A comprehensive foundation for identification of relationships among robotics drivers and their benefits in the proposed model was incorporated in an SEM analysis, in addition to statistics generated by model evaluations. As a result of revision and analysis, some fascinating results were discovered.

EFA analysis shows that the drivers of robotics implementation can be categorized into three main categories (culture, technology, and industry). The PLS-SEM results show that the greatest impact of these categorizes on robotics drivers was derived from cultural drivers, with an external path of 0.63, followed by technology and industrial drivers, with external paths of 0.399 and 0.277, respectively. EFA results likewise indicate that the implantation of robotics can be grouped into two significant groups: environment and resources, with external paths of 0.90 and 0.86, respectively. The independent and dependent variables were analyzed revealing the effect of robotics drivers and robotics implementation. The findings show that the robotics drivers contribute approximately 14.0% to implementation of robotics in the building industry.

Robotics drivers also exhibit a significant correlation with robotics implementation, with a β value of 0.384, achieving significance once an organization or a company implements one component of robotics drivers. Furthermore, robotics technology is improved by 0. 384 due to environmental and resources elements. The results show that the implementation of some robotics drivers supports the people engaged in implementing robotics technology for projects with the goal of sustaining the client’s resources and meeting environment obligations.

The environmental aspect was found to be the most important, with an exterior loading score of 0.79. “Environmental benefits arise from enhanced rational use and reduction of the extraction of natural resources, reduction of water and energy consumption, conscious and orderly development” [148]. It has been argued that robotic systems can enhance the construction environment by reducing fatalities and liberating employees from performing hazardous assignments [16]. In this regard, the implementation of robotics is a possible solution to expand environmental resources and sustainability in many ways, including by reducing construction waste, saving natural resources, improving the safety of the workplace, and supporting an improved living atmosphere [21]. Furthermore, participants must reflect on how risks are reduced by robotics in construction firms, which can justify the high initial cost of investing and improving the construction environment [149].

To enhance the construction environment in the design stage, diverse automation design software and tools can be applied, in combination with parametric mechanisms, such as basic 2D drawing kits with parametric regulations via a wholly integrated 3D AutoCAD interface [23]. However, the formation of design concepts must be entrusted to an individual. Computers can provide considerable support through storage capacity and the ability to evaluate and maintain highly integrated and complex data designs [150], with tasks are carried out much faster compared to manual approaches, providing consistent and predictable productivity that reduces management oversight.

The performance of resources is described as a mixture of features needed for services required by the building project stakeholders and a foundation for the assessment of fitness and user satisfaction [151]. Resources factors had an exterior loading of 0.861, which was deemed reasonable. Results indicate that it is important to identify the components necessary for a project’s success, which is one of the conventional benefits of implementing robotics technologies. These results are in line with those reported by Mao et al. [152], who argued that an autonomous classification robot based on image recognition might aid in the reduction in the amount of labor required for recycling activities. Pradhananga et al. [102] also posited that robotics implementation has many economic benefits and enhances the speed, quality, and productivity of construction. Additionally, robotic implementation has the potential to address some of the challenges associated with construction. Robotics might help to increase off-site construction, resulting in triple bottom-line benefits (economic, environmental, and social) by enabling more accurate building, closing the gap between intended and real energy usage [153].

Automation and construction robots are divided into three classes based on IAARC: those that improve existing construction equipment and factories, enthusiastic robots, and comparatively less cognitive (or intelligent) robots. For instance, the Obayashi Corporation’s ABCs scheme improved construction schedules for forty (40)-story buildings within six months, and its Big Canopy system reduced the number of on-site workers required for concrete-strengthened structures by 75% [154]. Furthermore, the implementation of robotics can enable effective prefabrication, delivery, and supply of components to be undertaken according to the project schedule [155,156,157,158]. Automation implementation can also help to increase the coordination of planning throughout the project life cycle in terms of design, manufacturing, transportation, and installation, which are generally regards as difficult tasks by contractors due to the nature of the building industry, which is fragmented and varied and involves many parties [155,157]. The improved predictability and production quality associated with the adoption of engineering robots have led to an intensification of margins [159].

Based on the results reported above, we can conclude that robotics drivers will impact the success of the implementation of robotics technology under the influence of environmental and resource considerations. The obtained results concerning the achievement of robotics technology implementation through robotics drivers confirmed our study hypothesis. Therefore, the study objective was achieved. Our results also corroborate the existing literature, which indicates that environmental and resource considerations impact the implementation of robotics and that these variables influence the success of a project [160].

6. Conclusions

The construction industry is highly dependent on robotics in various countries, although this dependence is uncertain in third-world nations. Nigeria had experienced numerous loopholes and construction quality incongruities involving large-scale projects. This is typical of many developing countries. To improve these conditions, robotics technologies need to be implemented. To confirm the relationships between drivers of robotics and robotics implementation constructs, a PLS-SEM method was adopted.

Based on information gathered from 104 building experts, one direct and eight indirect paths were authenticated as essential for the development of a structural model. Moreover, the connections among factors via indirect and direct paths amongst drivers and robotics implementation indicators and components were verified. The obtained results show that the adoption of robotics as mediated by the investigated drivers (proposed in the model) can enhance the sustainability of construction projects in terms of environmental and resource considerations. Significant findings of this study and its practical implications are as follows:

- Previous studies focused less on activities relating to robotics adoption and it is drivers. In this analysis, we narrowed the existing gap by examining the connection between robotics drivers and the adoption of robotics. The reported finding contribute significantly to the existing literature with respect to the management of building engineering by advancing the state of the art in robotics methods and requirements. Furthermore, the present study can serve as a basis for future research using analytically confirmed approaches concerning the implementation of robotics drivers, which a powerful and positive impact on robotics implementation in the construction industry. Moreover, the current research can inspire additional research works concerning construction projects.

- Although Nigeria is classified as a third-world nation with high population growth, most of its inhabitants have lower and medium income levels. There is a dire need for additional studies on the construction industry, owing to low environmental performance, especially concerning robotics drivers and robotics implementation. Such studies can inspire additional investigations on robotics drivers and implementation both within Nigeria and its neighboring countries. The results reported herein lay a foundation for robotics implementation both within and outside Nigeria. Our results can support the Nigerian construction industry by offering ways to reduce project costs and boost project resources.

- This analysis has many implications for experts in the construction industry, as well as contractors and project owners seeking to ensure the success of their projects by adopting robotics. The results reported herein can help stakeholders to adopt robotics by emphasizing the goal of the project with respect to resource and environmental requirements, which can impact the magnitude of the project’s success.

7. Limitations and Future Research

We believe that research is a journey and not a destination. Therefore, we recommend research in the following areas:

- In this research, we investigated the application of robotics for construction projects in Nigeria. Further research can be carried out by implementing robotics in construction projects.

- Assessment of the effect of robotics on the performance of students in higher education institutions in Nigeria.

- Current applications of building automation in Nigeria should be identified.

Based on the results of our study on the benefit of robotics in the construction industry, we propose the following recommendations:

- Higher education institutions should train student on the application of new technologies and their applicability to construction projects. This will help to bring about enhanced student knowledge, which can be implemented after graduation.

- Construction firms should educate construction professionals, such as architects, quantity surveyors, builders, project managers, and engineers on the importance and advantages of the application of robotics in the construction industry, and training should be organized.

- Members should also be encouraged to adopt robotics in the construction industry so as to catch up with the ongoing trend in the construction industry and maintain relevance.

- Suppliers should ensure that the cost of purchasing robotics equipment is reduced so that it can be easily accessible by various stakeholder in the construction industry.

Author Contributions

Research Idea: A.F.K.; Conceptualization, A.F.K. and A.E.O.; methodology, A.F.K. and A.E.O.; software, A.F.K.; validation, All Authors, formal analysis, A.F.K.; investigation, A.F.K. and A.E.O.; resources, All authors; data curation, All authors.; writing—original draft preparation, and A.F.K. and A.E.O.; writing—review and editing, All authors.; visualization, All authors.; supervision, A.F.K. and A.E.O.; project administration, A.F.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study is supported via funding from Prince sattam bin Abdulaziz University project number (PSAU/2023/R/1444).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Olanrewaju, O.; Idiake, J.; Oyewobi, L. Property, Global economic recession: Causes and effects on Nigeria building construction industry. J. Surv. Constr. 2018, 9, 9–18. [Google Scholar]

- Olanrewaju, O.I.; Babarinde, S.A.; Chileshe, N.; Sandanayake, M. Drivers for implementation of building information modeling (BIM) within the Nigerian construction industry. J. Financ. Manag. Prop. Constr. 2021, 26, 366–386. [Google Scholar] [CrossRef]

- Chan, A.P.; Adabre, M.A. Bridging the gap between sustainable housing and affordable housing: The required critical success criteria (CSC). Build. Environ. 2019, 151, 112–125. [Google Scholar] [CrossRef]

- Sbci, U. Buildings and Climate Change: Summary for Decision-Makers; United Nations Environmental Programme, Sustainable Buildings and Climate Initiative: Paris, France, 2009; pp. 1–62. [Google Scholar]

- Sharifi, A.; Dawodu, A.; Cheshmehzangi, A. Limitations in assessment methodologies of neighborhood sustainability assessment tools: A literature review. Sustain. Cities Soc. 2021, 67, 102739. [Google Scholar] [CrossRef]

- Li, J.; Sun, W.; Song, H.; Li, R.; Hao, J. Toward the construction of a circular economy eco-city: An energy-based sustainability evaluation of Rizhao city in China. Sustain. Cities Soc. 2021, 71, 102956. [Google Scholar] [CrossRef]

- Gan, X.; Zuo, J.; Wu, P.; Wang, J.; Chang, R.; Wen, T. How affordable housing becomes more sustainable? A stakeholder study. J. Clean. Prod. 2017, 162, 427–437. [Google Scholar] [CrossRef]

- Mousa, A. A Business approach for transformation to sustainable construction: An implementation on a developing country. Resour. Conserv. Recycl. 2015, 101, 9–19. [Google Scholar] [CrossRef]

- Al-Saadi, R.; Abdou, A. Factors critical for the success of public–private partnerships in UAE infrastructure projects: Experts’ perception. Int. J. Constr. Manag. 2016, 16, 234–248. [Google Scholar] [CrossRef]

- Bezuidenhout, L. From Welfare to Community Development—The Role of Local Congregations as Agents of Development in the Mangaung Metropolitan Area; University of the Free State: Bloemfontein, South Africa, 2019. [Google Scholar]

- Durdyev, S.; Ismail, S.; Ihtiyar, A.; Abu Bakar, N.F.S.; Darko, A. A partial least squares structural equation modeling (PLS-SEM) of barriers to sustainable construction in Malaysia. J. Clean. Prod. 2018, 204, 564–572. [Google Scholar] [CrossRef]

- Kissi, E.; Boateng, E.; Adjei-Kumi, T. Strategies for implementing value management in the construction industry of Ghana. In Proceedings of the DII-2015 Conference on Infrastructure Development and Investment Strategies for Africa, Livingstone, Zambia, 16–18 September 2015; pp. 255–267. [Google Scholar]

- Adeyemi, L.A.; Idoko, M. Developing Local Capacity for Project Management—Key to Social and Business Transformation in Developing Countries; Project Management Institute: Newtown Square, PA, USA, 2008. [Google Scholar]

- Kim, S.-Y.; Lee, Y.-S.; Thanh, N.V.; Truong, V.L. Barriers to Applying Value Management in the Vietnamese Construction Industry. J. Constr. Dev. Ctries 2016, 21, 55–80. [Google Scholar] [CrossRef]

- Jekale, W. Performance for Public Construction Projects in Developing Countries: Federal Road and Educational Building Projects in Ethiopia; Norwegian University of Science & Technology: Trondheim, Norway, 2004. [Google Scholar]

- Li Manman, P.G.; Mukherjee, P.; Mukherjee, A.; Yang, L.; Ghosh, U.; Menon, V.G.; Nkenyereye, L. Distributed Artificial Intelligence Empowered Sustainable Cognitive Radio Sensor Networks: A Smart City on-demand Perspective. Sustain. Cities Soc. 2021, 75, 103265. [Google Scholar] [CrossRef]

- Wolstenholme, A. Never Waste a Good Crisis: A Review of Progress Since Rethinking Construction and Thoughts for Our Future; Loughborough University: Loughborough, UK, 2009. [Google Scholar]

- Russell-Smith, S.V.; Lepech, M.D. Cradle-to-gate sustainable target value design: Integrating life cycle assessment and construction management for buildings. J. Clean. Prod. 2015, 100, 107–115. [Google Scholar] [CrossRef]

- Linner, T.; Bock, T. Evolution of large-scale industrialisation and service innovation in Japanese prefabrication industry. Constr. Innov. 2012, 12, 156–178. [Google Scholar] [CrossRef]

- Castro-Lacouture, D. Construction automation. In Springer Handbook of Automation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1063–1078. [Google Scholar]

- Bock, T.; Linner, T. Site Automation; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Skibniewski, M.J. Current status of construction automation and robotics in the United States of America. In Proceedings of the 9th International Symposium on Automation and Robotics in Construction, Tokyo, Japan, 3–5 June 1992; pp. 17–24. [Google Scholar]

- Mahbub, R. An Investigation into the Barriers to the Implementation of Automation and Robotics Technologies in the Construction Industry; Queensland University of Technology: Brisbane, Australia, 2008. [Google Scholar]

- Bock, T.; Linner, T. Construction Robots: Volume 3: Elementary Technologies and Single-Task Construction Robots; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Hasegawa, Y. Robotization in Construction; Kogyo Chosakai: Tokyo, Japan, 1999. [Google Scholar]

- Saidi, K.S.; Bock, T.; Georgoulas, C. Robotics in construction. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1493–1520. [Google Scholar]

- Everett, J.G.; Saito, H. Construction Automation: Demands and Satisfiers in the United States and Japan. J. Constr. Eng. Manag. 1996, 122, 147–151. [Google Scholar] [CrossRef]

- Pradhananga, P.; ElZomor, M.; Kasabdji, G.S. Identifying the Challenges to Adopting Robotics in the US Construction Industry. J. Constr. Eng. Manag. 2021, 147, 05021003. [Google Scholar] [CrossRef]

- Kim, P.; Chen, J.; Cho, Y.K. Autonomous Mobile Robot Localization and Mapping for Unknown Construction Environments. In Proceedings of the ASCE Construction Research Congress (CRC) 2018, New Orleans, LA, USA, 2–4 April 2018. [Google Scholar] [CrossRef]

- Kim, S.; Moore, A.; Srinivasan, D.; Akanmu, A.; Barr, A.; Harris-Adamson, C.; Rempel, D.M.; Nussbaum, M.A. Potential of exoskeleton technologies to enhance safety, health, and performance in construction: Industry perspectives and future research directions. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 185–191. [Google Scholar] [CrossRef]

- Bryson, L.S.; Maynard, C.; Castro-Lacouture, D.; Williams, I.; Robert, L. Fully autonomous robot for paving operations. In Proceedings of the Construction Research Congress 2005: Broadening Perspectives, San Diego, CA, USA, 5–7 April 2005; pp. 1–10. [Google Scholar]

- Ding, L.; Jiang, W.; Zhou, Y.; Zhou, C.; Liu, S. BIM-based task-level planning for robotic brick assembly through image-based 3D modeling. Adv. Eng. Inform. 2019, 43, 100993. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S. Construction automation and robotics for high-rise buildings over the past decades: A comprehensive review. Adv. Eng. Informat. 2019, 42, 100989. [Google Scholar] [CrossRef]

- Kim, M.J.; Chi, H.-L.; Wang, X.; Ding, L. Automation and Robotics in Construction and Civil Engineering. J. Intell. Robot. Syst. 2015, 79, 347–350. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L.; Beach, T.; Demian, P. Augmented and Virtual Reality in Construction: Drivers and Limitations for Industry Adoption. J. Constr. Eng. Manag. 2020, 146, 04020079. [Google Scholar] [CrossRef]

- Bogue, R. What are the prospects for robots in the construction industry? Ind. Robot. Int. J. Robot. Res. Appl. 2018, 45, 1–6. [Google Scholar] [CrossRef]

- Gonzalez-Caceres, A.; Bobadilla, A.; Karlshøj, J. Implementing post-occupancy evaluation in social housing complemented with BIM: A case study in Chile. Build. Environ. 2019, 158, 260–280. [Google Scholar] [CrossRef]

- Khan, Z.; Khalid, A.; Iqbal, J. Towards realizing robotic potential in future intelligent food manufacturing systems. Innov. Food Sci. Emerg. Technol. 2018, 48, 11–24. [Google Scholar] [CrossRef]

- Foote, J.R.; Valea, F.A. Robotic surgical training: Where are we? Gynecol. Oncol. 2016, 143, 179–183. [Google Scholar] [CrossRef]

- O’Bannon, B.W.; Thomas, K. Mobile phones in the classroom: Preservice teachers answer the call. Comput. Educ. 2015, 85, 110–122. [Google Scholar] [CrossRef]

- Abidin, A.S.Z.; Zaini, M.H.; Pauzi, M.F.A.M.; Sadini, M.M.; Chie, S.C.; Mohammadan, S.; Jamali, A.; Muslimen, R.; Ashari, M.F.; Jamaludin, M.S.; et al. Development of Cleaning Device for In-pipe Robot Application. Procedia Comput. Sci. 2015, 76, 506–511. [Google Scholar] [CrossRef]

- Alsamhi, S.H.; Ma, O.; Ansari, M.S.J.T.S. Survey on artificial intelligence based techniques for emerging robotic communication. Telecommun. Syst. 2019, 72, 483–503. [Google Scholar] [CrossRef]

- Chien, C.-F.; Tseng, M.-L.; Tan, R.R.; Tan, K.; Velek, O. Industry 3.5 for Sustainable Transition and Total Resource Management. Resour. Conserv. Recycl. 2020, 152, 104482. [Google Scholar]

- Andreas, V.; Gunawan, A.A.S.; Budiharto, W. Anita: Intelligent Humanoid Robot with Self-Learning Capability Using Indonesian Language. In Proceedings of the 2019 4th Asia-Pacific Conference on Intelligent Robot Systems (ACIRS), Nagoyam Japan, 13–15 July 2019; pp. 144–147. [Google Scholar]

- Fraune, M.R.; Oisted, B.C.; Sembrowski, C.E.; Gates, K.A.; Krupp, M.M.; Šabanović, S. Effects of robot-human versus robot-robot behavior and entitativity on anthropomorphism and willingness to interact. Comput. Hum. Behav. 2020, 105, 106220. [Google Scholar] [CrossRef]

- Phillips, A.; Vinoo, A.; Fitter, N.T. May I Draw Your Attention? Initial Lessons from the Large-Scale Generative Mark Maker. IEEE Robot. Autom. Lett. 2020, 5, 691–698. [Google Scholar] [CrossRef]

- Rockart, J.F. Chief executives define their own data needs. Harv. Bus. Rev. 1979, 57, 81–93. [Google Scholar] [PubMed]

- Chan, A.P.C.; Ho, D.C.K.; Tam, C.M. Design and Build Project Success Factors: Multivariate Analysis. J. Constr. Eng. Manag. 2001, 127, 93–100. [Google Scholar] [CrossRef]

- Yu, A.T.; Shen, Q.; Kelly, J.; Lin, G. A Value Management Approach to Strategic Briefing: An Exploratory Study. Arch. Eng. Des. Manag. 2006, 2, 245–259. [Google Scholar] [CrossRef]

- Saraph, J.V.; Benson, P.G.; Schroeder, R.G. An Instrument for Measuring the Critical Factors of Quality Management. Decis. Sci. 1989, 20, 810–829. [Google Scholar] [CrossRef]

- Dillon, A.; Morris, M.G. User acceptance of information technology: Theories and models. Annu. Rev. Inf. Sci. Technol. 1996, 31, 3–32. [Google Scholar]

- Venkatesh, V.; Thong, J.Y.; Xu, X. Consumer acceptance and use of information technology: Extending the unified theory of acceptance and use of technology. MIS Q. 2012, 36, 157–178. [Google Scholar] [CrossRef]

- Tanaka, F.; Matsuzoe, S. Children Teach a Care-Receiving Robot to Promote Their Learning: Field Experiments in a Classroom for Vocabulary Learning. J. Hum.-Robot Interact. 2012, 1, 78–95. [Google Scholar] [CrossRef]

- Jaipal-Jamani, K.; Angeli, C. Effect of robotics on elementary preservice teachers’ self-efficacy, science learning, and computational thinking. J. Sci. Educ. Technol. 2017, 26, 175–192. [Google Scholar] [CrossRef]

- Broadbent, E.; Feerst, D.A.; Lee, S.H.; Robinson, H.; Albo-Canals, J.; Ahn, H.S.; MacDonald, B.A. How Could Companion Robots Be Useful in Rural Schools? Int. J. Soc. Robot. 2018, 10, 295–307. [Google Scholar] [CrossRef]

- Azjen, I. Understanding Attitudes and Predicting Social Behavior; Prentice-Hall: Englewood Cliffs, NJ, USA, 1980. [Google Scholar]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Sanghavi, D.; Parikh, S.; Raj, S.A. Industry 4.0: Tools and implementation. Manag. Prod. Eng. Rev. 2019, 10, 3–13. [Google Scholar]

- Carmona, M. Housing Design Quality: Through Policy, Guidance, and Review; Taylor & Francis: Abingdon, UK, 2001. [Google Scholar]

- Pasquale, F. New Laws of Robotics: Defending Human Expertise in the Age of AI; Belknap Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Calo, R.; Froomkin, A.M.; Kerr, I. Robot Law; Edward Elgar Publishing: Cheltenham, UK, 2016. [Google Scholar]

- Akshatha, D.; Vimala, M.; Sahana, S.; Manjula, M. Robotics in construction technology. J. Int. J. Adv. Res. Sci. Eng. 2017, 6, 547–553. [Google Scholar]

- Carra, G.; Argiolas, A.; Bellissima, A.; Niccolini, M.; Ragaglia, M. Robotics in the construction industry: State of the art and future opportunities. In ISARC, Proceedings of the International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018; IAARC Publications: London, UK, 2018; vol. 35, pp. 1–8. [Google Scholar]

- Mahbub, R. Readiness of a Developing Nation in Implementing Automation and Robotics Technologies in Construction: A Case Study of Malaysia. J. Civ. Eng. Arch. 2012, 6, 858–866. [Google Scholar]

- Manzo, J.; Manzo, F., IV; Bruno, M.R. The Impact of Construction Apprenticeship Programs in Minnesota; Economic Policy Institute: Washington, DC, USA, 2019. [Google Scholar]

- Johannessen, J.-A. The Workplace of the Future: The Fourth Industrial Revolution, the Precariat and the Death of Hierarchies; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- West, D.M. What Happens If Robots Take the Jobs? The Impact of Emerging Technologies on Employment and Public Policy; The Brookings Institution: Washington, DC, USA, 2015. [Google Scholar]

- Struková, Z.; Líška, M. Application of automation and robotics in construction work execution. J. Interdiscip. Res. 2012, 2, 121–125. [Google Scholar]

- Mistri, P.S.; Rathod, H.A. Remedies over barriers of automation and robotics for construction industry. Int. J. Adv. Res. Eng. Sci. Manag. 2015, 1–4. [Google Scholar]

- Liu, B. Construction Robotics Technologies 2030. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- Akinradewo, O.; Oke, A.; Aigbavboa, C.; Mashangoane, M. Willingness to Adopt Robotics and Construction Automation in the South African Construction Industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pretoria/Johannesburg, South Africa, 29 October–1 November 2018; p. 201. [Google Scholar]

- Elattar, S. Automation and robotics in construction: Opportunities and challenges. Emir. J. Eng. Res. 2008, 13, 21–26. [Google Scholar]

- Manyika, J.; Chui, M.; Miremadi, M.; Bughin, J.; George, K.; Willmott, P.; Dewhurst, M. A Future that Works: AI, Automation, Employment, and Productivity; McKinsey&Company: New York, NY, USA, 2017; Volume 60. [Google Scholar]

- Balaguer, C.; Abderrahim, M. Trends in Robotics and Automation in Construction; IntechOpen: London, UK, 2008. [Google Scholar]

- Kanzaki, T. Prospects for automation and robotics revolutionizing ordinary construction systems through advanced infor-mation technology. In Proceedings of the International Symposium on Automation and Robotics in Construction, Eindhoven, The Netherlands, 21–24 September 2003. [Google Scholar]

- Smith, A.; Anderson, J. AI, Robotics, and the Future of Jobs; Pew Research Center: Washington, DC, USA, 2014; Volume 6, p. 51. [Google Scholar]

- Kaivo-oja, J.; Roth, S. The Technological Future of Work and Robotics; ZBW–Leibniz Information Center for Economics: Hamburg/Kiel, Germany, 2015. [Google Scholar]

- Shields, P.M.; Tajalli, H. Intermediate Theory: The Missing Link in Successful Student Scholarship. J. Public Aff. Educ. 2006, 12, 313–334. [Google Scholar] [CrossRef]

- Christensen, C.M. The Ongoing Process of Building a Theory of Disruption. J. Prod. Innov. Manag. 2005, 23, 39–55. [Google Scholar] [CrossRef]

- Tanko, B.L.; Abdullah, F.; Ramly, Z.M.; Enegbuma, W.I. An implementation framework of value management in the Nigerian construction industry. Built Environ. Proj. Asset Manag. 2018, 8, 305–319. [Google Scholar] [CrossRef]

- Ramly, Z.M.; Shen, G.Q.; Yu, A.T.W. Critical Success Factors for Value Management Workshops in Malaysia. J. Manag. Eng. 2015, 31. [Google Scholar]

- Sharma, G. Pros and cons of different sampling techniques. Int. J. Appl. Res. 2017, 3, 749–752. [Google Scholar]

- Hoxha, D.; Capelleras, J. Fast-growing firms in a transitional and extreme environment: Are they different? J. Small Bus. Enterp. Dev. 2010, 17, 350–370. [Google Scholar] [CrossRef]

- Oke, A.E.; Kinebar, A.F.; Albukhari, I.; Othman, I.; Kingsley, C. Assessment of Cloud Computing Success Factors for Sustainable Construction Industry: The Case of Nigeria. Buildings 2021, 11, 36. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Alsolami, B. Critical Value Management Activities in Building Projects: A Case of Egypt. Buildings 2020, 10, 239. [Google Scholar] [CrossRef]

- Al-Mekhlafi, A.-B.; Isha, A.; Chileshe, N.; Abdulrab, M.; Saeed, A.; Kineber, A. Modelling the Relationship between the Nature of Work Factors and Driving Performance Mediating by Role of Fatigue. Int. J. Environ. Res. Public Health 2021, 18, 6752. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Zayed, T. Value management implementation barriers for sustainable building: A bibliometric analysis and partial least square structural equation modeling. Constr. Innov. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Oke, A.E.; Kineber, A.F.; Albukhari, I.; Dada, A.J. Modeling the robotics implementation barriers for construction projects in developing countries. Int. J. Build. Pathol. Adapt. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the Impact of Building Information Modelling (BIM) Implementation Drivers and Awareness on Project Lifecycle. Sustainability 2021, 13, 8887. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the relationship between Building Information Modelling (BIM) implementation barriers, usage and awareness on building project lifecycle. Build. Environ. Technol. Sci. J. 2021, 207, 108556. [Google Scholar] [CrossRef]

- Badewi, A. Investigating Benefits Realisation Process for Enterprise Resource Planning Systems. Ph.D. Thesis, Cranfield University, Bedford, UK, 2016. [Google Scholar]

- Field, A. Discovering Statistics Using IBM SPSS Statistics; SAGE Publication: New York, NY, USA, 2013. [Google Scholar]

- Harris, M.M.; Schaubroeck, J. Confirmatory Modeling in Organizational Behavior/Human Resource Management: Issues and Applications. J. Manag. 1990, 16, 337–360. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 4th ed.; The Guilford Press: New York, NY, USA, 2018. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods (Applied Social Research Methods), 4th ed.; SAGE Publications: New York, NY, USA, 2009; Volume 5. [Google Scholar]

- Kothari, C. Research Methodology Methods and Techniques, 2nd revised ed.; New Age International Publishers: New Delhi, India, 2009; Volume 20, p. 2018. [Google Scholar]

- Wahyuni, D. The research design maze: Understanding paradigms, cases, methods and methodologies. J. Appl. Manag. Account. Res. 2012, 10, 69–80. [Google Scholar]

- Tabachnick, B.G.; Fidell, L.S.; Ullman, J.B. Using Multivariate Statistics; Pearson: Boston, MA, USA, 2007. [Google Scholar]

- Pallant, J. SPSS Survival Guide; Allen & Unwin: Sydney, Australia, 2005. [Google Scholar]

- Shen, Q. Value management in Hong Kong’s construction industry: Lessons learned. In Proceedings of the SAVE International Conference Proceeding, Hong Kong, 23 March 2012; pp. 260–265. [Google Scholar]

- Ahadzie, D.; Proverbs, D.; Olomolaiye, P. Critical success criteria for mass house building projects in developing countries. Int. J. Proj. Manag. 2008, 26, 675–687. [Google Scholar] [CrossRef]

- Robert, O.K.; Dansoh, A.; Kuragu, J.K.O. Reasons for adopting Public–Private Partnership (PPP) for construction projects in Ghana. Int. J. Constr. Manag. 2014, 14, 227–238. [Google Scholar] [CrossRef]

- Oke, A.E.; Tech, B.; Qs, M. Evaluation of the Administration of Construction Bonds in Lagos and Ondo states, Nigeria. Ph.D. Thesis, The Federal University of Technology, Akure, Nigeria, 2015. [Google Scholar]

- Raza, S.A.; Qazi, W.; Shah, N.; Qureshi, M.A.; Qaiser, S.; Ali, R. Drivers of intensive Facebook usage among university students: An implications of U&G and TPB theories. Technol. Soc. 2020, 62, 101331. [Google Scholar]

- Amaratunga, D.; Kulatunga, U.; Liyanage, C.; Hui, E.C.; Zheng, X. Measuring customer satisfaction of FM service in housing sector. Facilities 2010, 28, 306–320. [Google Scholar] [CrossRef]

- Chen, H.; Liu, H.; Chu, X.; Zhang, L.; Yan, B. A two-phased SEM-neural network approach for consumer preference analysis. Adv. Eng. Inform. 2020, 46, 101156. [Google Scholar] [CrossRef]

- Ringle, C.M.; Sarstedt, M.; Straub, D.W. Editor’s Comments: A Critical Look at the Use of PLS-SEM in “MIS Quarterly”. MIS Q. 2012, 36, 3–14. [Google Scholar] [CrossRef]

- Yuan, K.H.; Wu, R.; Bentler, P.M. Ridge structural equation modelling with correlation matrices for ordinal and continuous data. Br. J. Math. Stat. Psychol. 2011, 64, 107–133. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Zayed, T. Exploring the value management critical success factors for sustainable residential building—A structural equation modelling approach. J. Clean. Prod. 2021, 293, 126115. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2019, 153, 104559. [Google Scholar] [CrossRef]

- Al-Emran, M.; Mezhuyev, V.; Kamaludin, A. Towards a conceptual model for examining the impact of knowledge management factors on mobile learning acceptance. Technol. Soc. 2020, 61, 101247. [Google Scholar] [CrossRef]

- Chandra, D.; Kumar, D. Evaluating the effect of key performance indicators of vaccine supply chain on sustainable de-velopment of mission indradhanush: A structural equation modeling approach. Omega 2021, 101, 102258. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Smith, D.; Reams, R.; Hair, J.F., Jr. Partial least squares structural equation modeling (PLS-SEM): A useful tool for family business researchers. J. Fam. Bus. Strat. 2014, 5, 105–115. [Google Scholar] [CrossRef]

- Camilleri, M.A.; Camilleri, A.C. Remote learning via video conferencing technologies: Implications for research and practice. Technol. Soc. 2022, 68, 101881. [Google Scholar] [CrossRef]

- Prajogo, D.I.; Sohal, A.S. The integration of TQM and technology/R&D management in determining quality and innovation performance. Omega 2006, 34, 296–312. [Google Scholar]

- Vargas, J.R.C.; Mantilla, C.E.M.; Jabbour, A.B.L.D.S. Enablers of sustainable supply chain management and its effect on competitive advantage in the Colombian context. Resour. Conserv. Recycl. 2018, 139, 237–250. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, S. Applied Multivariate Techniques; John and Wiley and Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Alam, M.Z.; Hu, W.; Kaium, M.A.; Hoque, M.R.; Alam, M.M.D. Understanding the determinants of mHealth apps adoption in Bangladesh: A SEM-Neural network approach. Technol. Soc. 2020, 61, 101255. [Google Scholar] [CrossRef]

- Pallant, J. SPSS Survival Manual, 3rd ed.; Open University Press: Maidenhead, UK, 2007; Volume 15. [Google Scholar]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory 3E; Tata McGraw-Hill Education: New York, NY, USA, 1994. [Google Scholar]

- Field, A. Discovering Statistics Using SPSS (3. Baskı); Sage Publications: New York, NY, USA, 2009. [Google Scholar]

- MacKenzie, S.B.; Podsakoff, P.M. Common method bias in marketing: Causes, mechanisms, and procedural remedies. J. Retail. 2012, 88, 542–555. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-Reports in Organizational Research: Problems and Prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Harman, H.H. Modern Factor Analysis; The University of Chicago: Chicago, IL, USA, 1967. [Google Scholar]

- Akhtar, R.; Sultana, S.; Masud, M.M.; Jafrin, N.; Al-Mamun, A. Consumers’ environmental ethics, willingness, and green consumerism between lower and higher income groups. Resour. Conserv. Recycl. 2020, 168, 105274. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, C.; Li, W.; Evans, S.; Yin, Y. Effects of key enabling technologies for seru production on sustainable performance. Omega 2017, 66, 290–307. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: New York, NY, USA, 2016. [Google Scholar]

- Khan, O.; Daddi, T.; Slabbinck, H.; Kleinhans, K.; Vazquez-Brust, D.; De Meester, S. Assessing the determinants of intentions and behaviors of organizations towards a circular economy for plastics. Resour. Conserv. Recycl. 2020, 163, 105069. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.K.-K. Partial least squares structural equation modeling (PLS-SEM) techniques using SmartPLS. Mark. Bull. 2013, 24, 1–32. [Google Scholar]

- Henseler, J.; Ringle, C.M.; Sinkovics, R.R. The use of partial least squares path modeling in international marketing. In New Challenges to International Marketing; Emerald Group Publishing Limited: Bingley, UK, 2009. [Google Scholar]

- Bag, S.; Wood, L.C.; Mangla, S.K.; Luthra, S. Procurement 4.0 and its implications on business process performance in a circular economy. Resour. Conserv. Recycl. 2019, 152, 104502. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, P.; Wei, Y.; Li, Y.; Zhao, H. Measuring the efficiency and driving factors of urban land use based on the DEA method and the PLS-SEM model—A case study of 35 large and medium-sized cities in China. Sustain. Cities Soc. 2019, 50, 101646. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. Partial least squares structural equation modeling: Rigorous applications, better results and higher acceptance. Long Range Plan. 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Chin, W.W.; Newsted, P.R. Structural equation modeling analysis with small samples using partial least squares. Stat. Strat. Small Sample Res. 1999, 1, 307–341. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2006; Volume 6. [Google Scholar]

- Ho, Y.-S. Review of second-order models for adsorption systems. J. Hazard. Mater. 2006, 136, 681–689. [Google Scholar] [CrossRef]