Flexural Capacity of Cross-Shaped Concrete-Filled Steel Tubular Column–Steel Beam Joints with Side-Plate Connections

Abstract

:1. Introduction

2. Development of the Finite Element Model

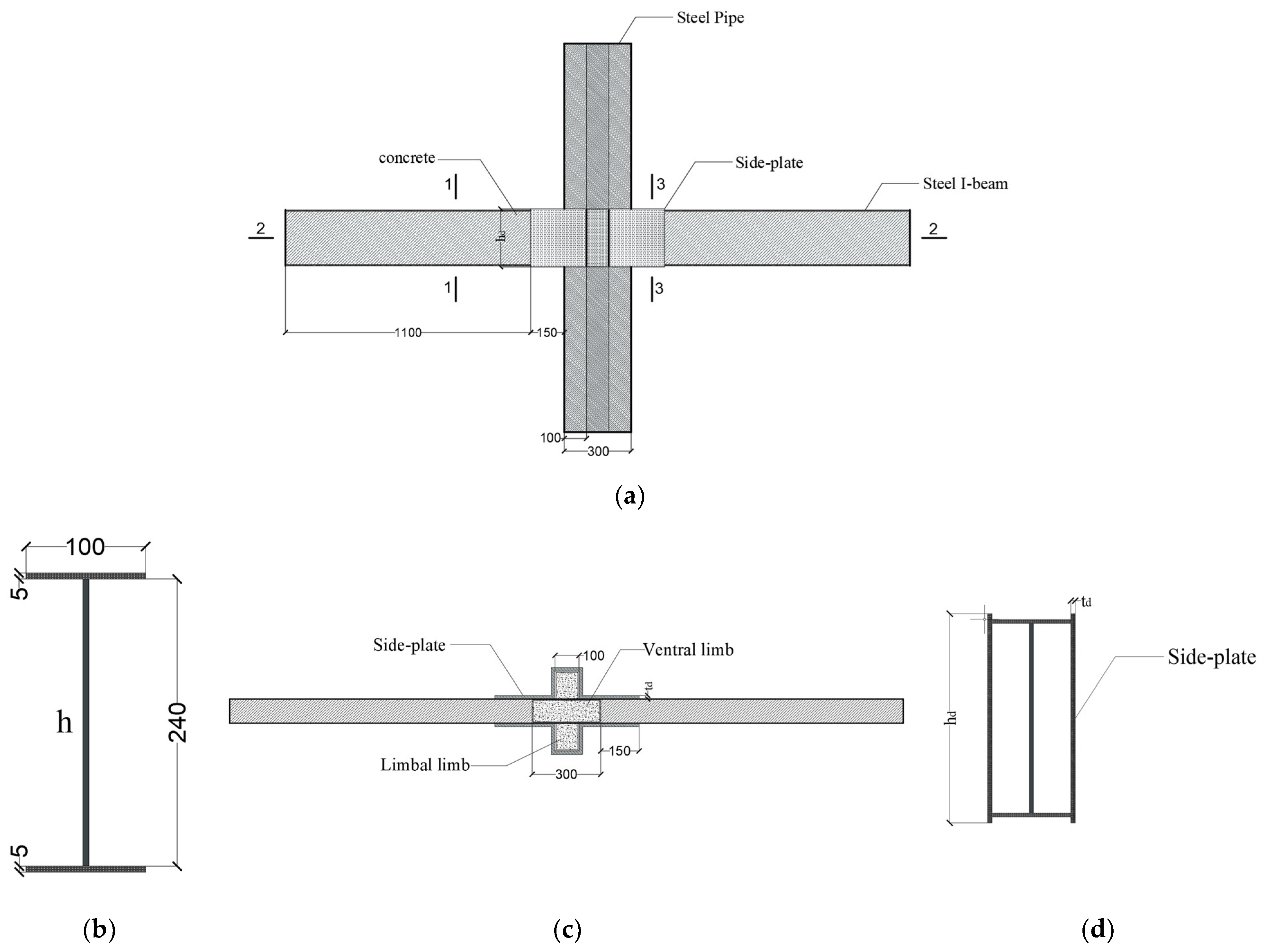

2.1. Joint Detailing

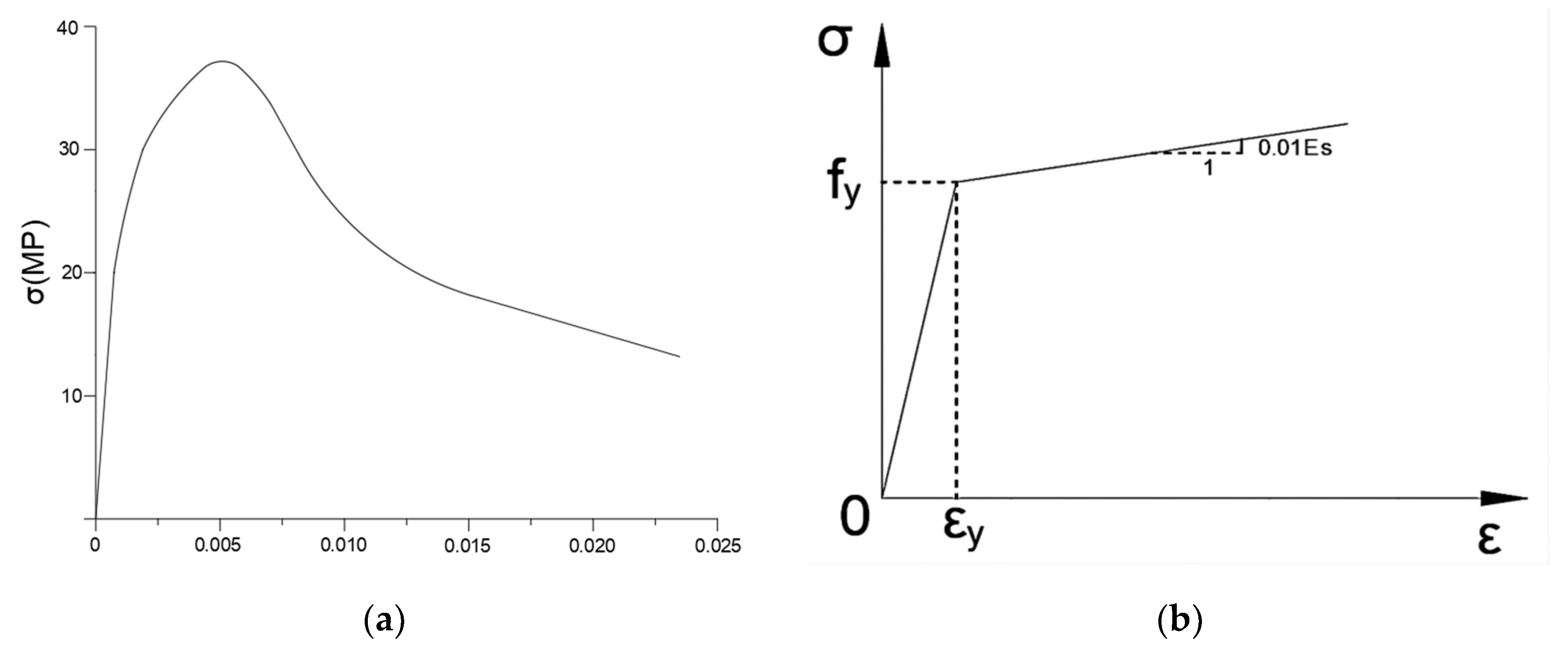

2.2. Material Constitutive Model and Element Selection

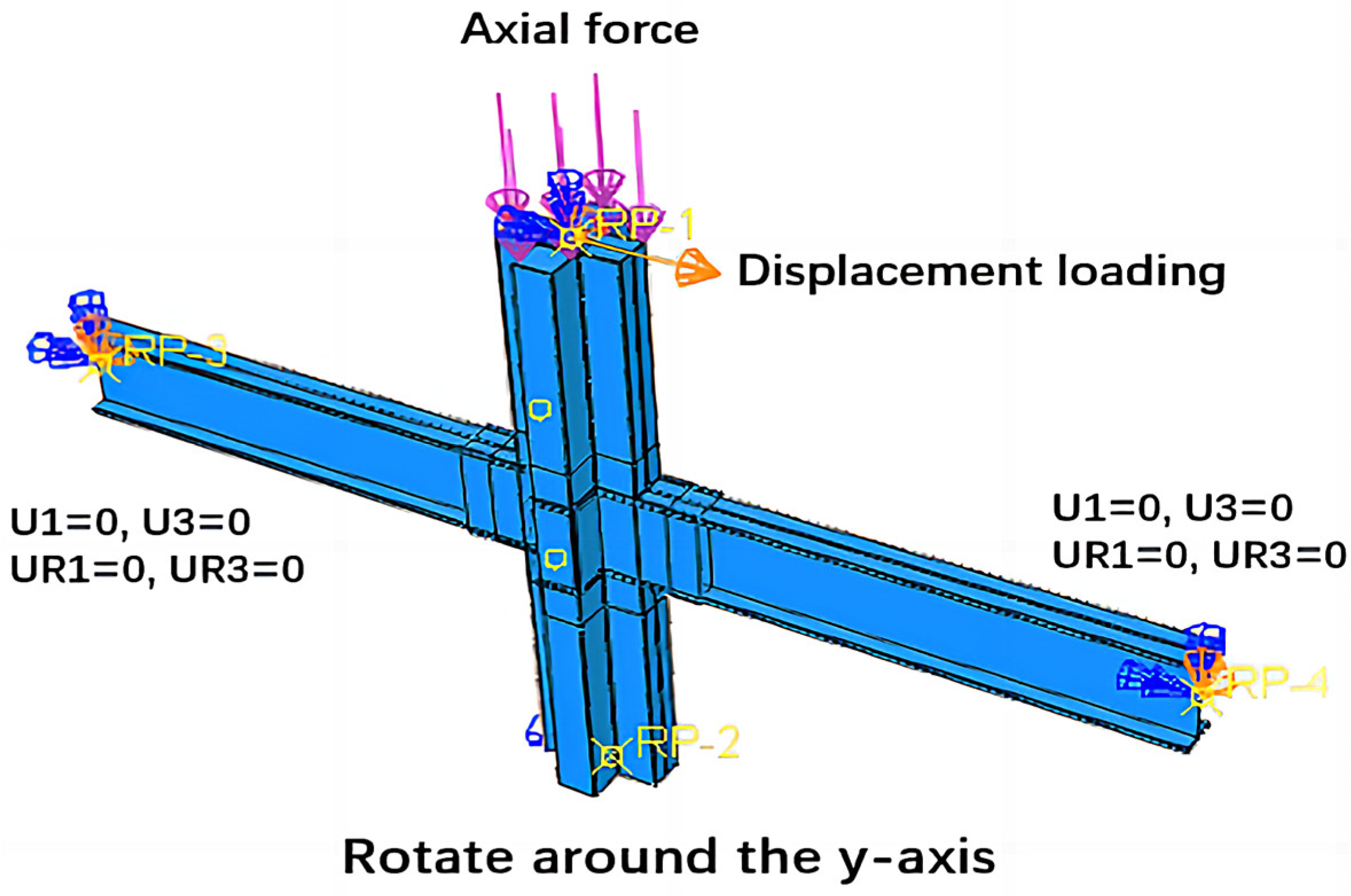

2.3. Contact, Boundary Condition, and Loading

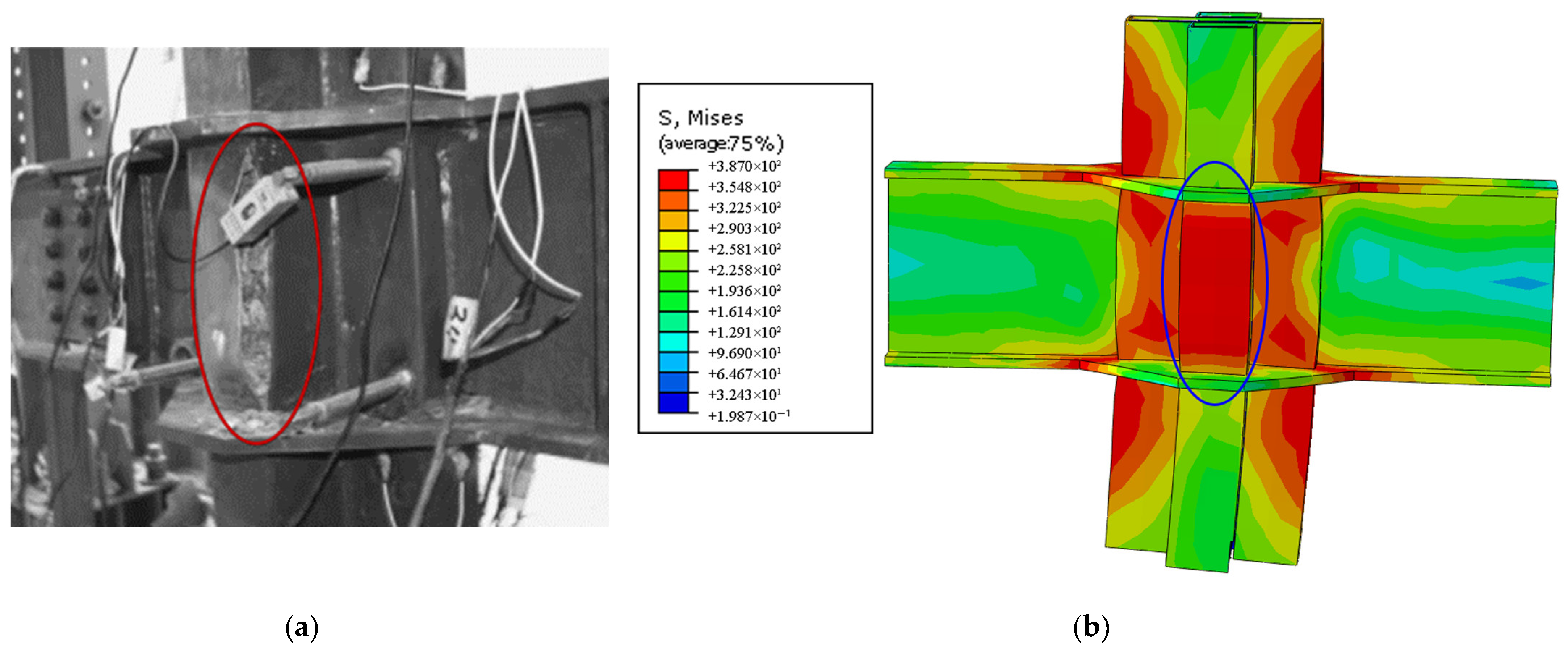

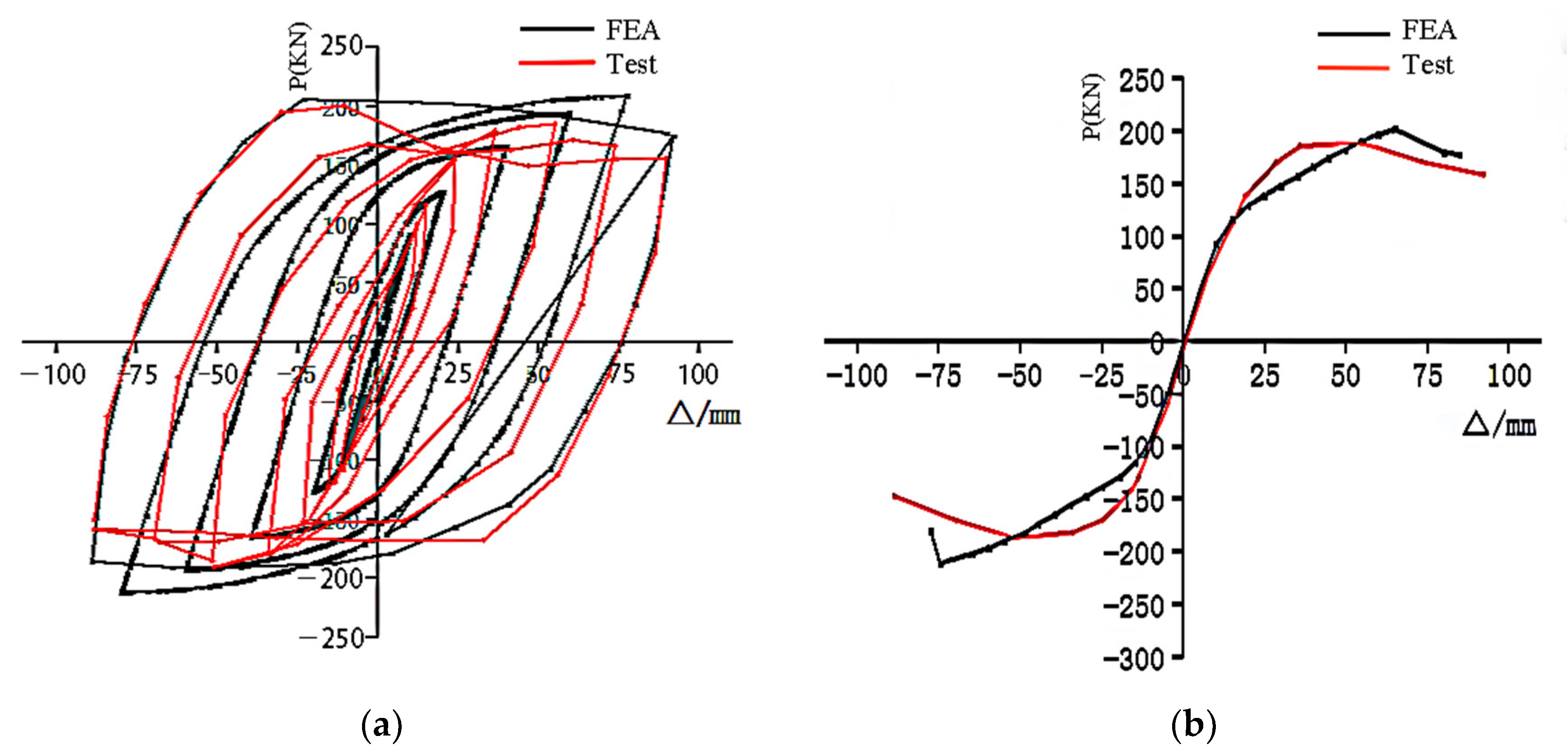

2.4. Calibration of the Finite Element Model

3. Results and Discussion

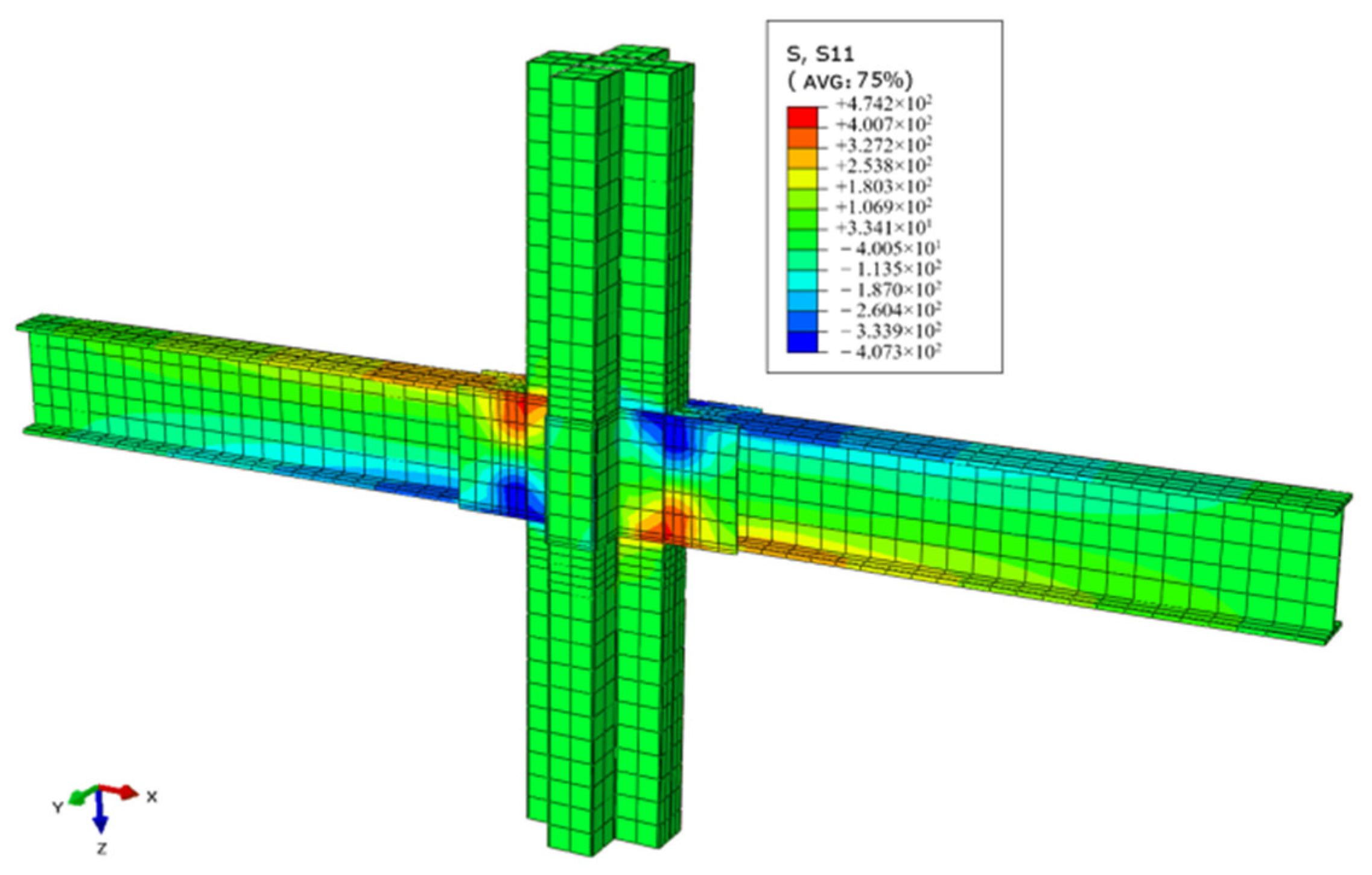

3.1. Mechanical Characteristics and Failure Modes

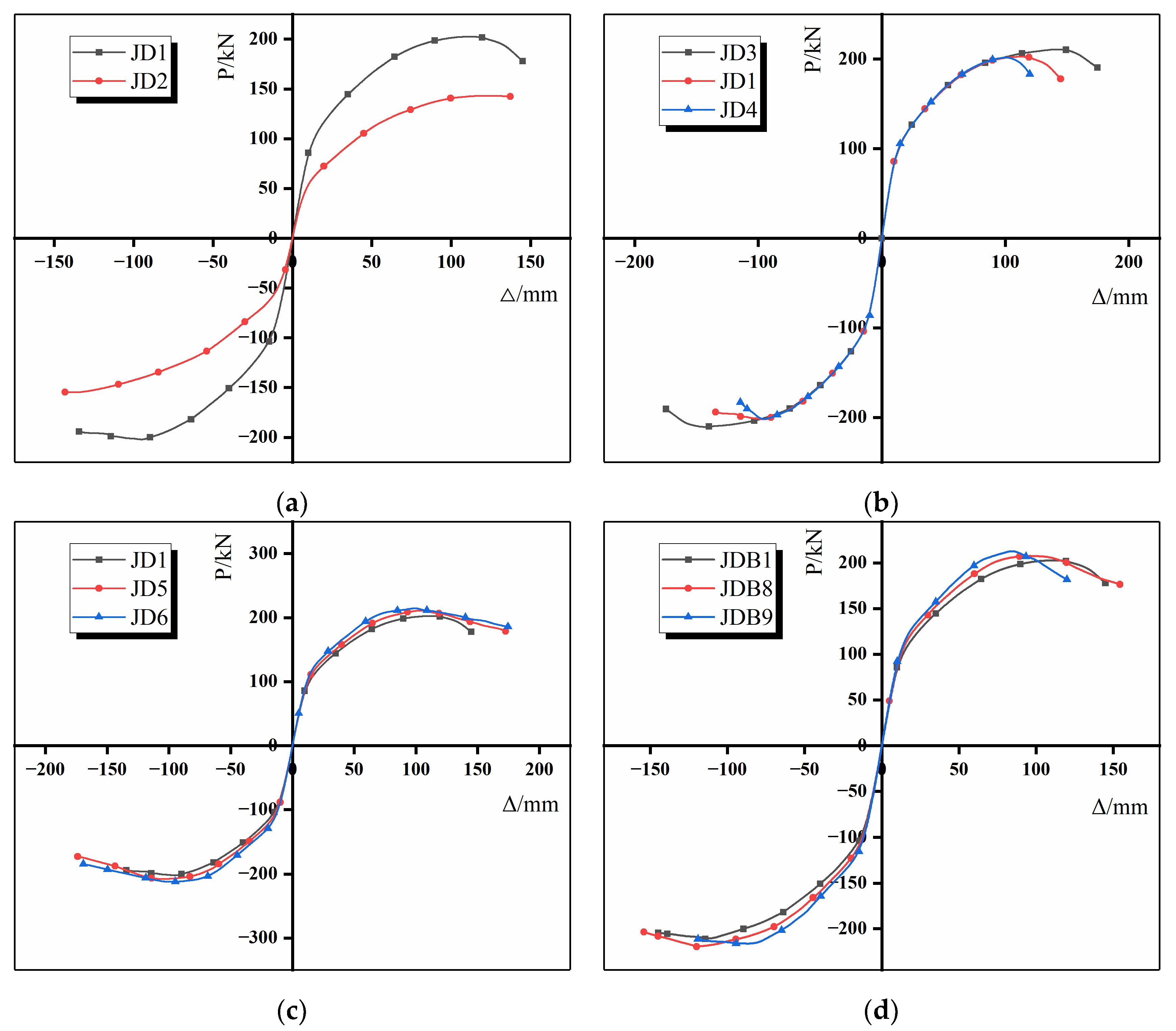

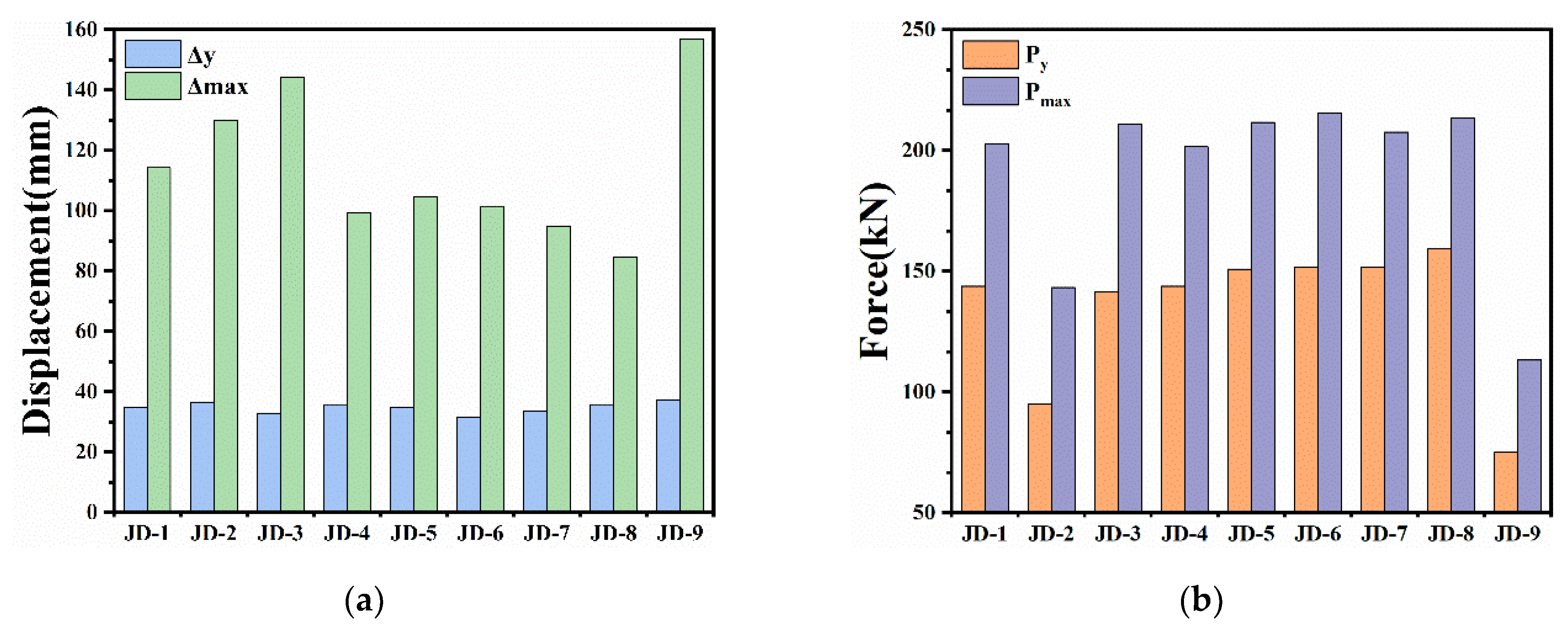

3.2. Parametric Study

3.3. Force Transmission Mechanism and Tensile Strength of Joints

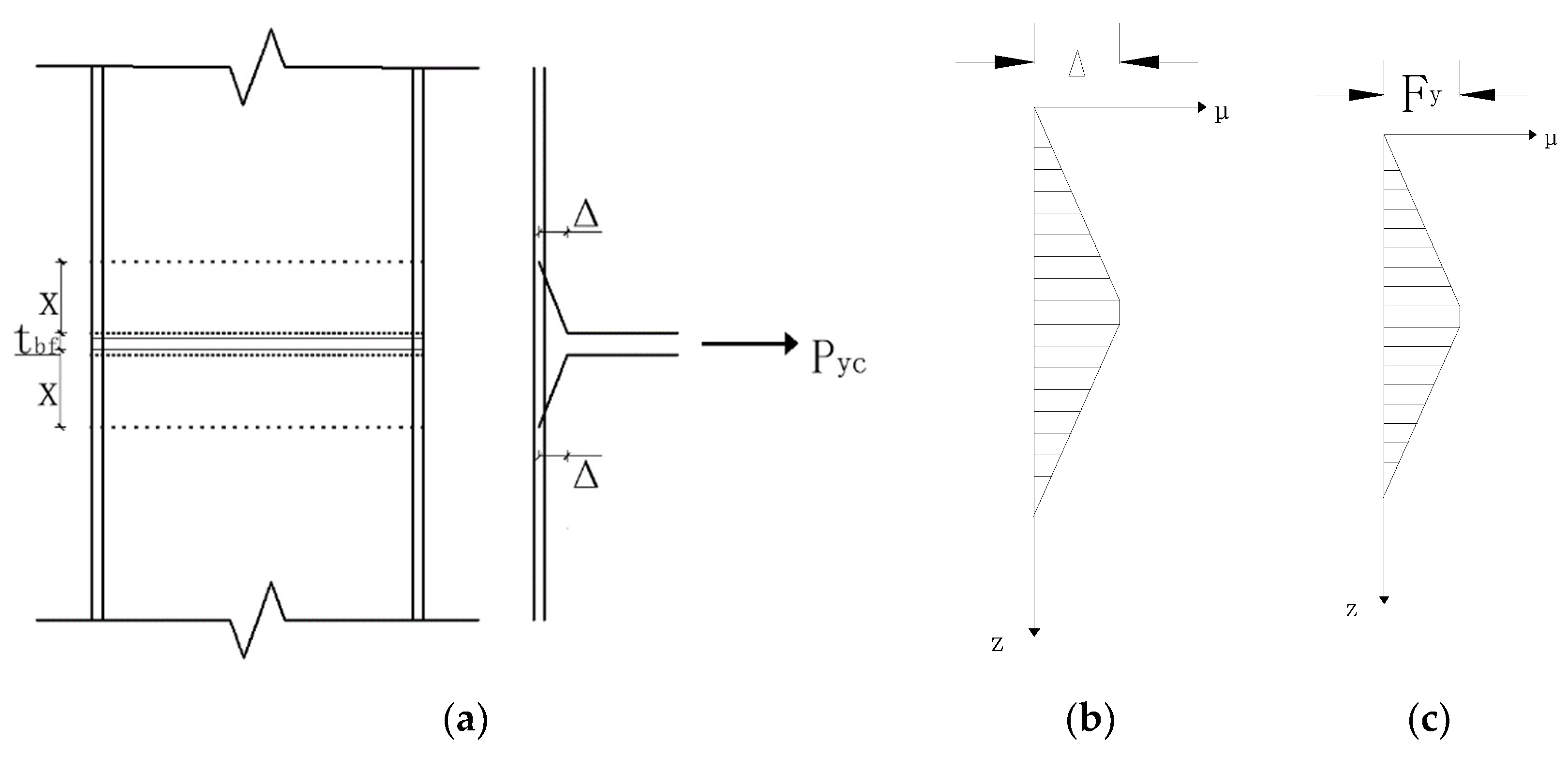

3.3.1. Calculating the Ultimate Tensile Strength of a Square Steel Tube Column Flange by the Yield Line Theory

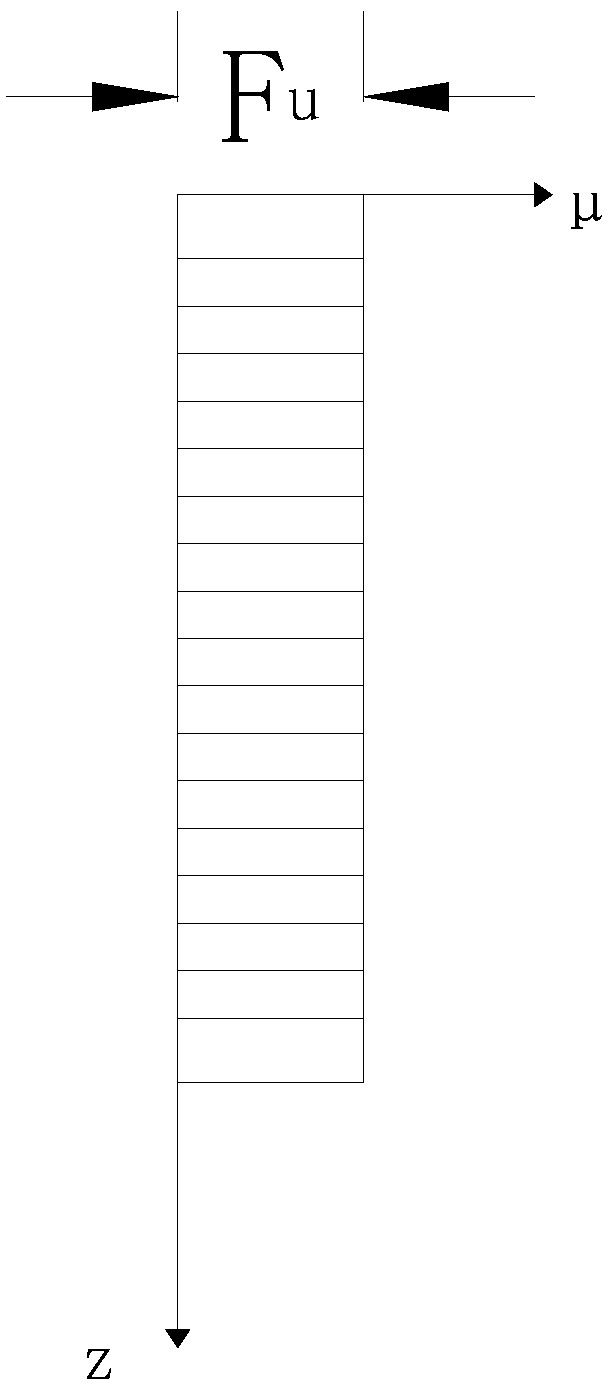

3.3.2. Ultimate Tensile Capacity of the Side Plates

3.3.3. Ultimate Flexural Capacity of the Joints

3.4. Ultimate Flexural Capacity of the Joints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Mu | Ultimate flexural capacity of joints |

| Pud | Ultimate horizontal tensile force of the side plates |

| hb | Height of the steel beams |

| tb | Thickness of the steel beam flanges |

| td | Thickness of the side plates |

| hd | Height of the side plates |

| ed | Ultimate strength of the side plates |

| fu | Ultimate tensile strength of steel |

| Puc′ | Ultimate tensile capacity of column flanges |

| Puc | Ultimate tensile capacity of square steel pipe flange |

| tbf | Thickness of tension flange of steel beam |

| Bc | Width of concrete-filled square steel tube column |

| Ec | Work done by tension flange of steel beam to square steel tube column |

| Δ | Virtual displacement |

| fy,a | Yield strength of welds at the connection between steel pipe flange and web |

| fy,cf | Yield strength of steel plate at the connection between steel pipe flange and web |

| fy,acf | = min(fy,a, fy,cf) |

| tcf | Thickness of steel pipe column wall |

References

- Wang, Q.T.; Chang, X. Analysis of concrete-filled steel tubular columns with “T” shaped cross section (CFTTS). Steel Compos. Struct. 2013, 15, 41–55. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Zeng, S.X. Design of L-shaped and T-shaped concrete-filled steel tubular stub columns under axial compression. Eng. Struct. 2020, 207, 110262. [Google Scholar] [CrossRef]

- Han, L.-H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Han, L.H.; Wang, W.D.; Tao, Z. Performance of circular CFST column to steel beam frames under lateral cyclic loading. J. Constr. Steel Res. 2011, 67, 876–890. [Google Scholar] [CrossRef]

- Shariati, M.; Grayeli, M.; Shariati, A.; Naghipour, M. Performance of composite frame consisting of steel beams and concrete filled tubes under fire loading. Steel Compos. Struct. 2020, 36, 587–602. [Google Scholar] [CrossRef]

- Alatshan, F.; Osman, S.A.; Hamid, R.; Mashiri, F. Stiffened concrete-filled steel tubes: A systematic review. Thin-Walled Struct. 2020, 148, 106590. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, X.; Qunying, Y.E.; Luo, C. Structural Design of Guangzhou New China Mansion. J. Build. Struct. 2000, 3, 2–9. [Google Scholar]

- Xing, C.; Chen, Z.; Luo, C. Structural Design of the Guangzhou Minghui Commercial Building. Build. Struct. 2006, 36, 29–32. [Google Scholar]

- Liu, X.; Xu, C.; Liu, J.; Yang, Y. Research on special-shaped concrete-filled steel tubular columns under axial compression. J. Constr. Steel Res. 2018, 147, 203–223. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, Z.; Liu, H. Seismic behavior of special shaped column composed of concrete filled steel tubes. J. Constr. Steel Res. 2012, 75, 131–141. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Yang, Y.L.; Zhang, S.M.; Liu, J.P. Seismic behaviors of concrete-filled T-shaped steel tube columns. Key Eng. Mater. 2009, 400–402, 677–683. [Google Scholar] [CrossRef]

- Miller, D.K. Lessons learned from the Northridge earthquake. Eng. Struct. 1998, 20, 249–260. [Google Scholar] [CrossRef]

- Xu, C.X.; Wu, Z.J.; Zeng, L. Experimental research on seismic behaviors of T-shaped concrete-filled steel tubular frame joints. In Proceedings of the 4th International Conference on Technology of Architecture and Structure (ICTAS 2011), Xi’an University Architecture & Technol, Xi’an, China, 22–24 September 2011; pp. 38–41. [Google Scholar]

- Chengxiang, X.; Bo, W.; Jicheng, Z.; Jinjun, M. Experimental research on seismic behavior of interior joints in the composite frame consisting of CFST crisscross section columns and steel beams. Build. Struct. 2012, 42, 80–83. [Google Scholar] [CrossRef]

- Li, Y.T.; Xu, C.X.; Du, G.F. Seismic performance of T-shaped CFT column to steel frame beam connection-experimental study. In Proceedings of the 4th International Conference on Structures and Building Materials (ICSBM), Guangzhou, China, 15–16 March 2014; p. 951. [Google Scholar]

- Xue, J.Y.; Li, H.C.; Chen, X.; Lu, X.; Tu, G.X.; Zhong, R.B. Experimental research on seismic damage of T-shaped CFST column to steel beam joints. Structures 2022, 38, 1380–1396. [Google Scholar] [CrossRef]

- Li, H.C.; Xue, J.Y.; Chen, X.; Tu, G.X.; Lu, X.; Zhong, R.B. Experimental research on seismic damage of cross-shaped CFST column to steel beam joints. Eng. Struct. 2022, 256, 113901. [Google Scholar] [CrossRef]

- Kim, C.H.; Lee, E.T. Cyclic Behavior of Beam-to-Concrete Filled Steel Tube Column Connections. Int. J. Steel Struct. 2005, 5, 399–406. [Google Scholar]

- Xiong, Q.Q.; Zhang, W.; Chen, Z.H.; Du, Y.S.; Zhou, T. Experimental Study of the Shear Capacity of Steel Beam-to-L-CFST Column Connections. Int. J. Steel Struct. 2019, 19, 704–718. [Google Scholar] [CrossRef]

- Xiong, Q.Q.; Wu, W.B.; Zhang, W.; Chen, Z.H.; Liu, H.B.; Su, T.C. Study on the progressive collapse resistance of CP-FBSP connections in L-CFST frame structure. Steel Compos. Struct. 2022, 44, 423–436. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, S.Y.; Xiong, Q.Q.; Chen, Z.H.; Liu, H.B.; Su, T.C.; Du, Q.Z. Investigation of side plate connections in an S-CFST column frame under a column-loss scenario. Structures 2021, 32, 1302–1319. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Z.H.; Xiong, Q.Q.; Zhou, T.; Rong, X.; Du, Y.S. Experimental seismic behaviour of L-CFST column to H-beam connections. Steel Compos. Struct. 2018, 26, 793–808. [Google Scholar] [CrossRef]

- Huang, Y.Q.; Hao, J.P.; Bai, R.; Fan, C.L.; Xue, Q. Mechanical Behaviors of Side-Plate Joint Between Walled Concrete-Filled Steel Tubular Column and H-Shaped Steel Beam. Adv. Steel Constr. 2020, 16, 346–353. [Google Scholar] [CrossRef]

- Liu, J.C.; Yang, Y.L.; Liu, J.P.; Zhou, X.H. Experimental investigation of special-shaped concrete-filled steel tubular column to steel beam connections under cyclic loading. Eng. Struct. 2017, 151, 68–84. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, Y.L.; Li, B.Y.; Liu, J.P.; Chen, Y.F. Mechanical behavior of T-shaped CFST column to steel beam joint. J. Constr. Steel Res. 2021, 187, 106774. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, Y.L.; Li, B.Y.; Liu, J.P. Research on seismic behavior of special-shaped CFST column to H-section steel beam joint. Adv. Struct. Eng. 2021, 24, 2870–2884. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, Y.L.; Li, B.Y.; Liu, J.P.; Yan, W.X.; Chen, Y.F. Shear resistance of multi-cell special-shaped CFST column to H-section steel beam joint. Structures 2022, 41, 419–433. [Google Scholar] [CrossRef]

- Liu, X.C.; Wu, X.T.; Chen, X.S. Seismic performance of joint between L-shaped CFST column and H-section beam with lower plate and extended flange plate. Eng. Struct. 2022, 261, 114283. [Google Scholar] [CrossRef]

- Li, B.Y.; Yang, Y.L.; Liu, J.P.; Liu, X.G.; Cheng, Y.; Chen, Y.F. Behavior of T-shaped CFST column to steel beam connection with U-shaped diaphragm. J. Build. Eng. 2021, 43, 102518. [Google Scholar] [CrossRef]

- Han, L.H. Concrete-Filled Steel Tubular Structures-Theory and Practice, 3rd ed.; Science Press: Beijing, China, 2016. [Google Scholar]

- Dassault Systèmes Simulia. ABAQUS Analysis User’s Manual (Version 6.14); Dassault Systèmes Simulia: Providence, RI, USA, 2016. [Google Scholar]

- Zhou, Q. Design and Construction Manual for Steel and Concrete Structures; China Architecture & Building Press: Beijing, China, 1991. [Google Scholar]

- Tong, M. Study on Seismic Performance of Concrete-Filled Steel Tube (CFST) Column-Beam Joints with Double Side Plates. Ph.D. Thesis, Wuhan University, Wuhan, China, 2013. [Google Scholar]

- Chen, Q. Research on Seismic Performance and Load-Carrying Capacity of Joints between Concrete-Filled Square Steel Tubular Special-Shaped Columns and Steel Beams; China Architecture & Building Press: Beijing, China, 2014. [Google Scholar]

- JGJ101-2015; Specification of Testing Methods for Earthquake Resistant Building. China Architecture & Building Press: Beijing, China, 2015.

- Lu, L.H. The Static Strength of I-Beam to Rectangular Hollow Section Column Connections. Ph.D. Thesis, Universiteit Delft, Delft, The Netherlands, 1997. [Google Scholar]

- Liu, J.X. Study on Earthquake Resistant Behavior of Reinforced Concrete Beam to T-Shaped Concrete-Filled Rectangular Composite Tubular Column Exterior Joint. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2015. [Google Scholar]

- Nie, J.G.; Qin, K.; Zhang, G.B. Experimental research and theoretical analysis on flexural capacity of connections for concrete-filled steel square tubular columns with inner diaphragms. J. Archit. Civ. Eng. 2005, 22, 42–49+54. [Google Scholar]

| Number | Plate/No Side Plate | Axial Compression Ratio | Side Plate Height | Side Plate Thickness | Factor |

|---|---|---|---|---|---|

| JD 1 | side plate | 0.3 | 266 | 4 | Benchmark model |

| JD 2 | no side plate | 0.3 | side plate/No side plate | ||

| JD 3 | side plate | 0.2 | 266 | 4 | axial compression ratio |

| JD 4 | side plate | 0.4 | 266 | 4 | |

| JD 5 | side plate | 0.3 | 286 | 4 | Side plate height |

| JD 6 | side plate | 0.3 | 306 | 4 | |

| JD 7 | side plate | 0.3 | 266 | 5 | Side plate thickness |

| JD 8 | side plate | 0.3 | 266 | 6 | |

| JD 9 | side plate | 0.3 | 266 | 4 | Not filled with concrete |

| Pattern Number | Yield State | Limit State | ||

|---|---|---|---|---|

| Py (kN) | Δy (mm) | Pmax (kN) | Δmax (mm) | |

| JD-1 | 143.89 | 34.66 | 202.83 | 114.3 |

| JD-2 | 95.19 | 36.59 | 143.31 | 129.9 |

| JD-3 | 141.62 | 32.65 | 210.94 | 144.16 |

| JD-4 | 143.89 | 35.84 | 201.72 | 99.34 |

| JD-5 | 150.96 | 34.66 | 211.73 | 104.57 |

| JD-6 | 151.81 | 31.65 | 215.46 | 101.2 |

| JD-7 | 151.81 | 33.65 | 207.6 | 94.95 |

| JD-8 | 159.59 | 35.84 | 213.38 | 84.51 |

| JD-9 | 75.13 | 37.21 | 113.28 | 157.03 |

| Joint Number | Mus | Mud | Mu | Mu′ | Mu/Mu′ |

|---|---|---|---|---|---|

| JD1 | 86.79 | 52.36 | 139.15 | 136.91 | 1.02 |

| JD2 | 86.79 | 86.79 | 96.73 | 0.90 | |

| JD3 | 89.13 | 52.36 | 141.49 | 142.38 | 0.99 |

| JD4 | 83.44 | 52.36 | 135.8 | 136.16 | 1.00 |

| JD5 | 86.79 | 56.30 | 143.06 | 142.92 | 1.00 |

| JD6 | 86.79 | 60.23 | 147.02 | 145.92 | 1.01 |

| JD7 | 86.79 | 65.45 | 152.24 | 140.13 | 1.09 |

| JD8 | 86.79 | 78.54 | 165.33 | 144.03 | 1.15 |

| JD9 | 68.88 | 68.88 | 76.46 | 0.90 | |

| Mean value | 1.02 | ||||

| Standard deviation | 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Li, F.; Yan, M.; Li, Q. Flexural Capacity of Cross-Shaped Concrete-Filled Steel Tubular Column–Steel Beam Joints with Side-Plate Connections. Sustainability 2023, 15, 541. https://doi.org/10.3390/su15010541

Zhao Y, Li F, Yan M, Li Q. Flexural Capacity of Cross-Shaped Concrete-Filled Steel Tubular Column–Steel Beam Joints with Side-Plate Connections. Sustainability. 2023; 15(1):541. https://doi.org/10.3390/su15010541

Chicago/Turabian StyleZhao, Yi, Fuli Li, Menghui Yan, and Qinglu Li. 2023. "Flexural Capacity of Cross-Shaped Concrete-Filled Steel Tubular Column–Steel Beam Joints with Side-Plate Connections" Sustainability 15, no. 1: 541. https://doi.org/10.3390/su15010541

APA StyleZhao, Y., Li, F., Yan, M., & Li, Q. (2023). Flexural Capacity of Cross-Shaped Concrete-Filled Steel Tubular Column–Steel Beam Joints with Side-Plate Connections. Sustainability, 15(1), 541. https://doi.org/10.3390/su15010541