Failure Mechanism and Control Technology for Coal Roadway in Water-Rich Area

Abstract

1. Introduction

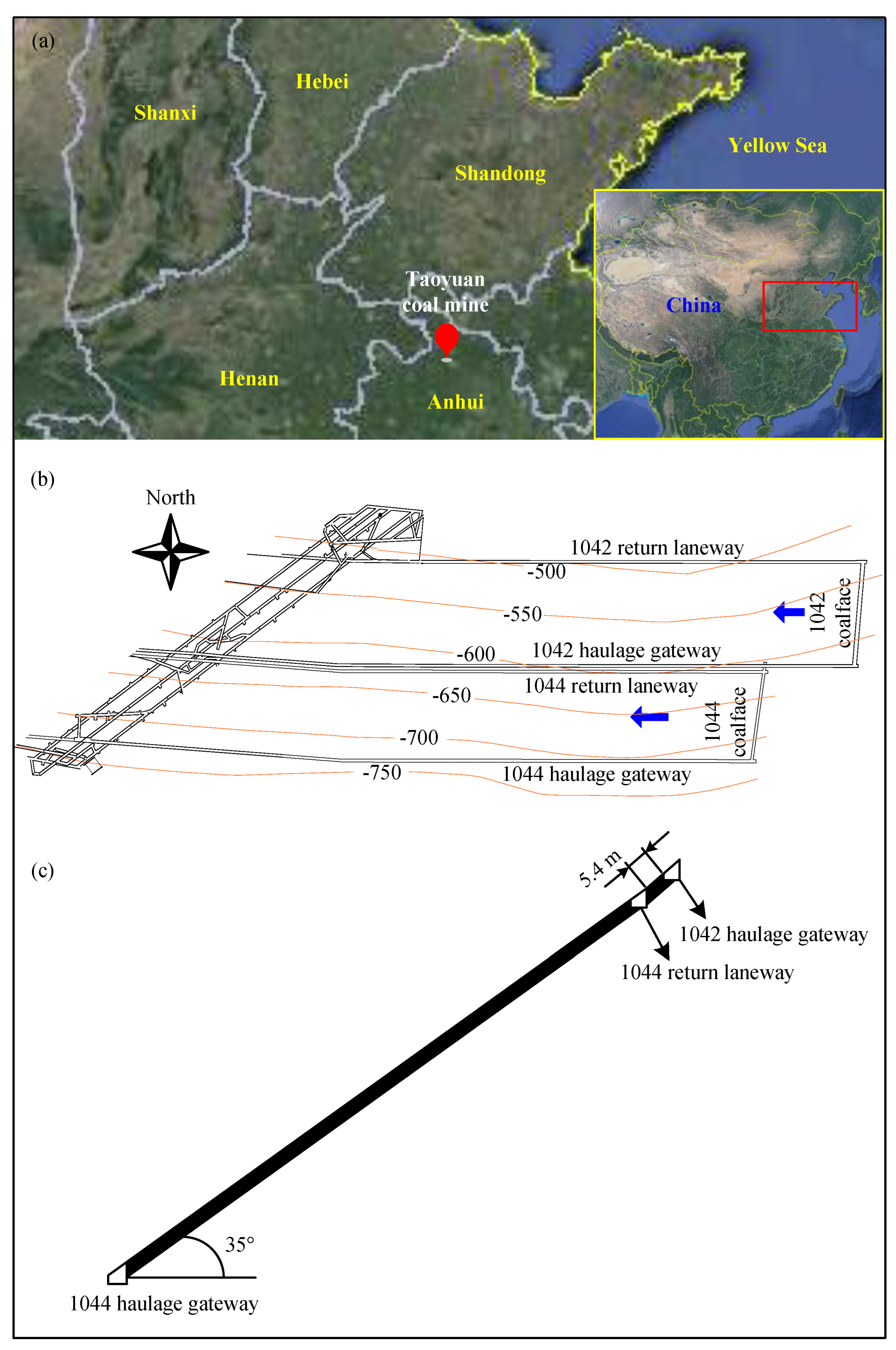

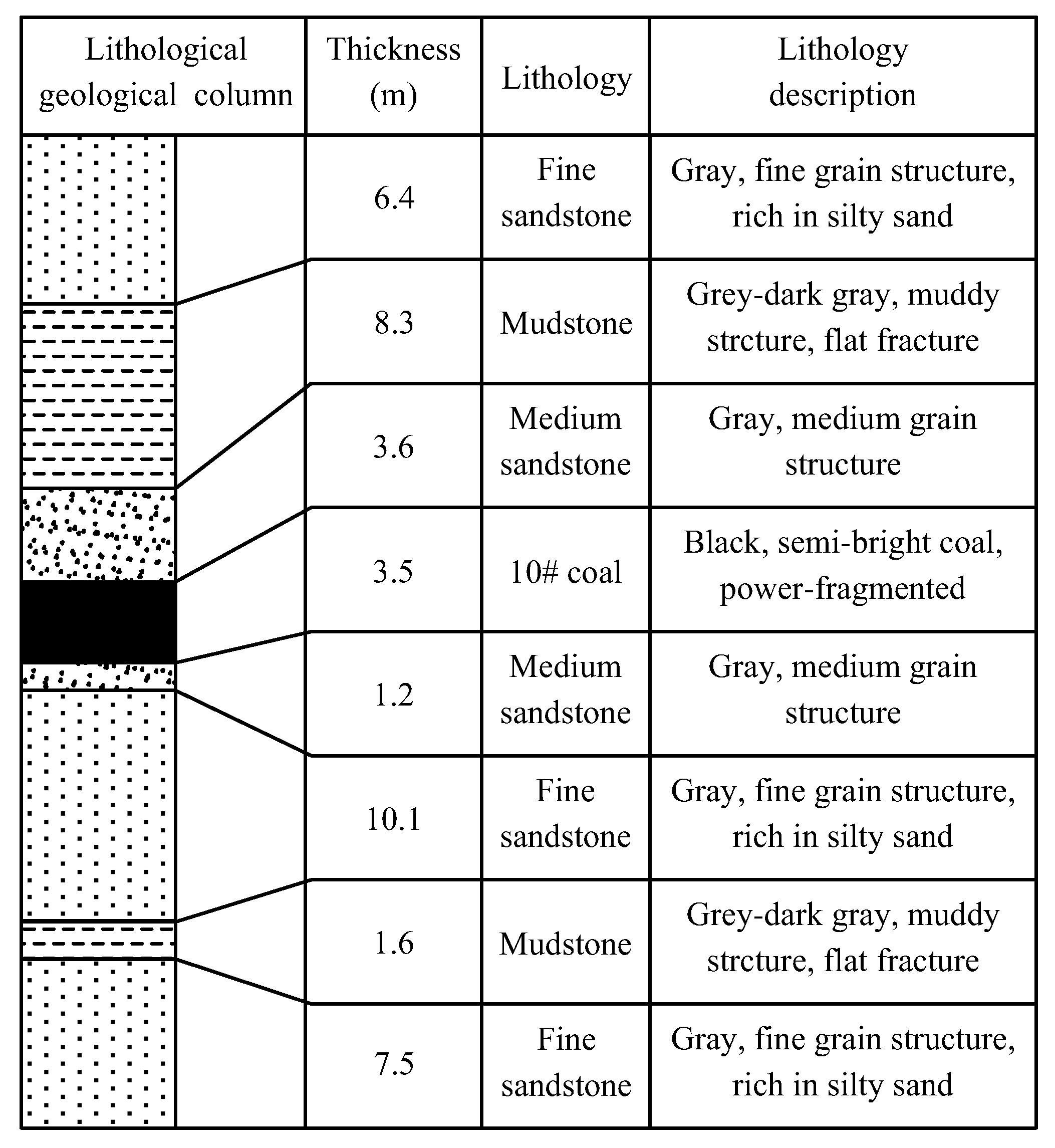

2. Engineering Background

3. Failure Mechanism Analyses

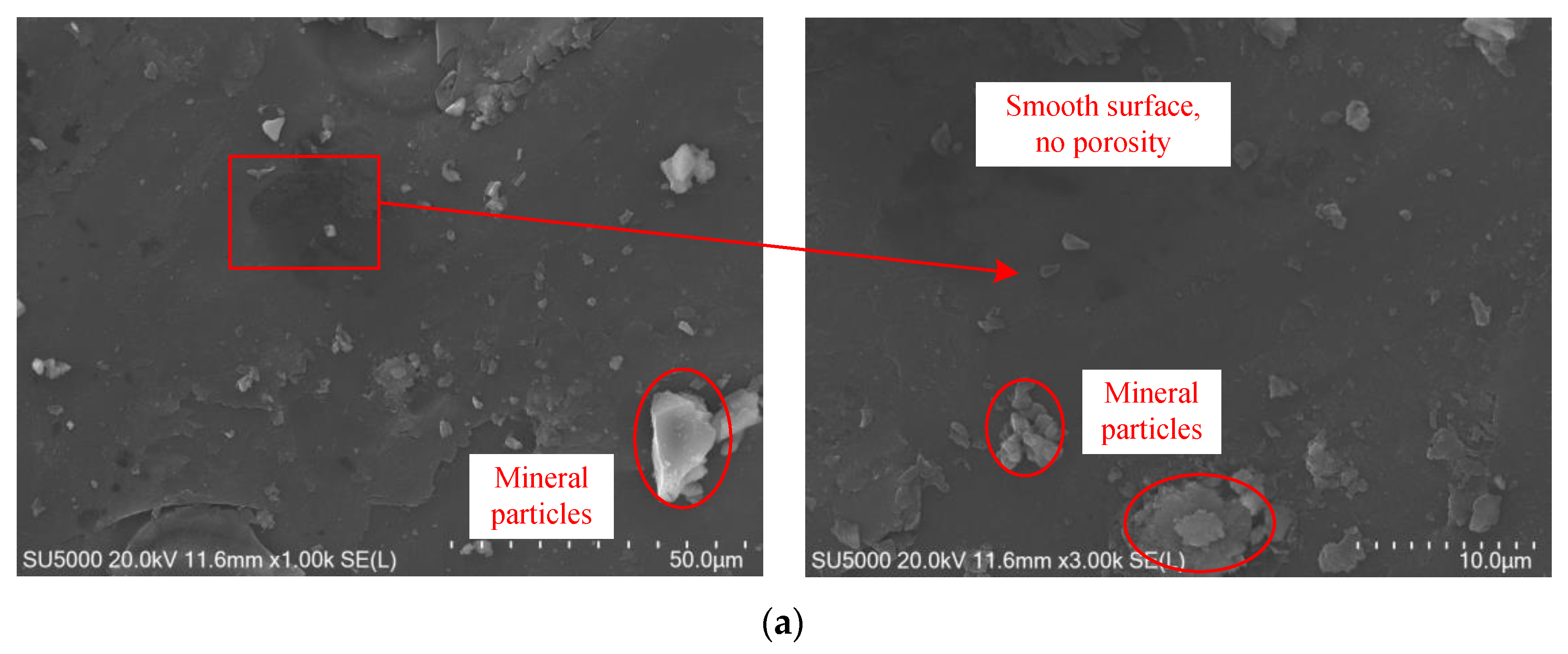

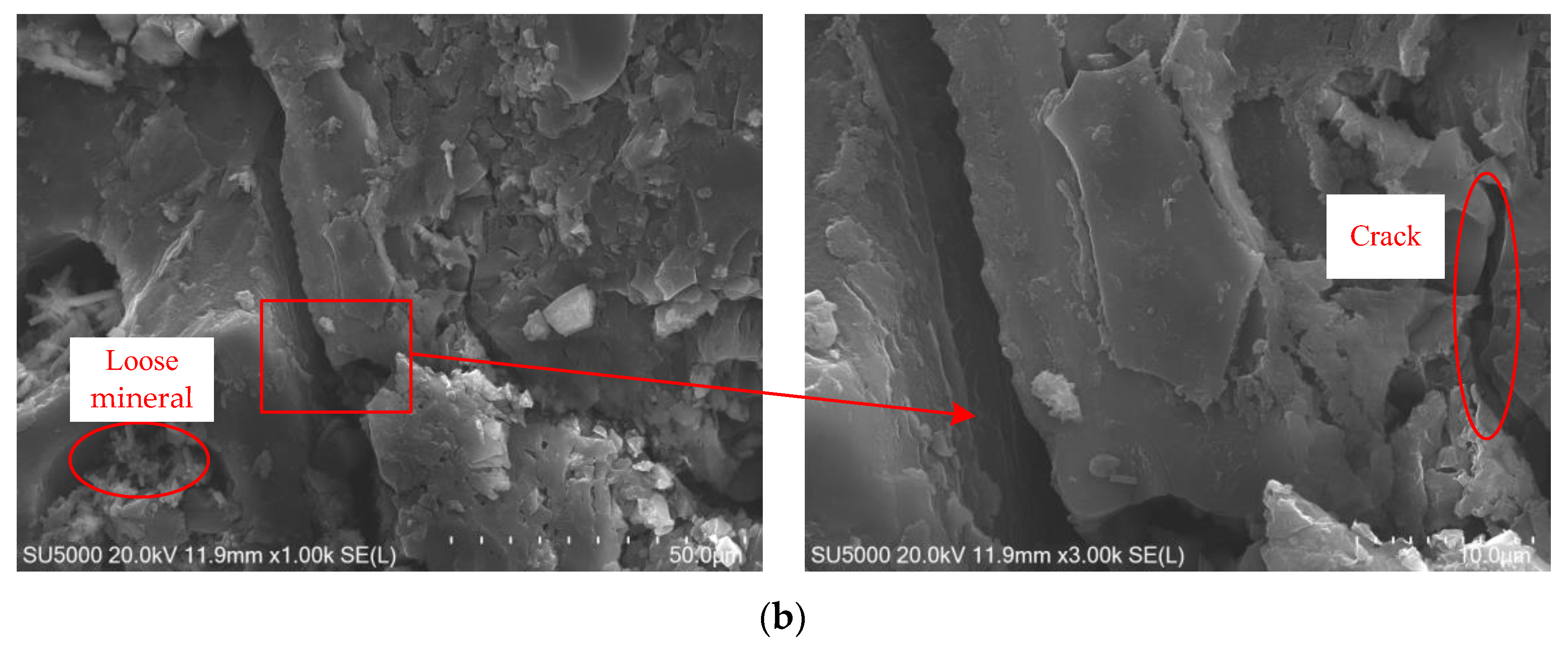

3.1. Microscopic Pattern

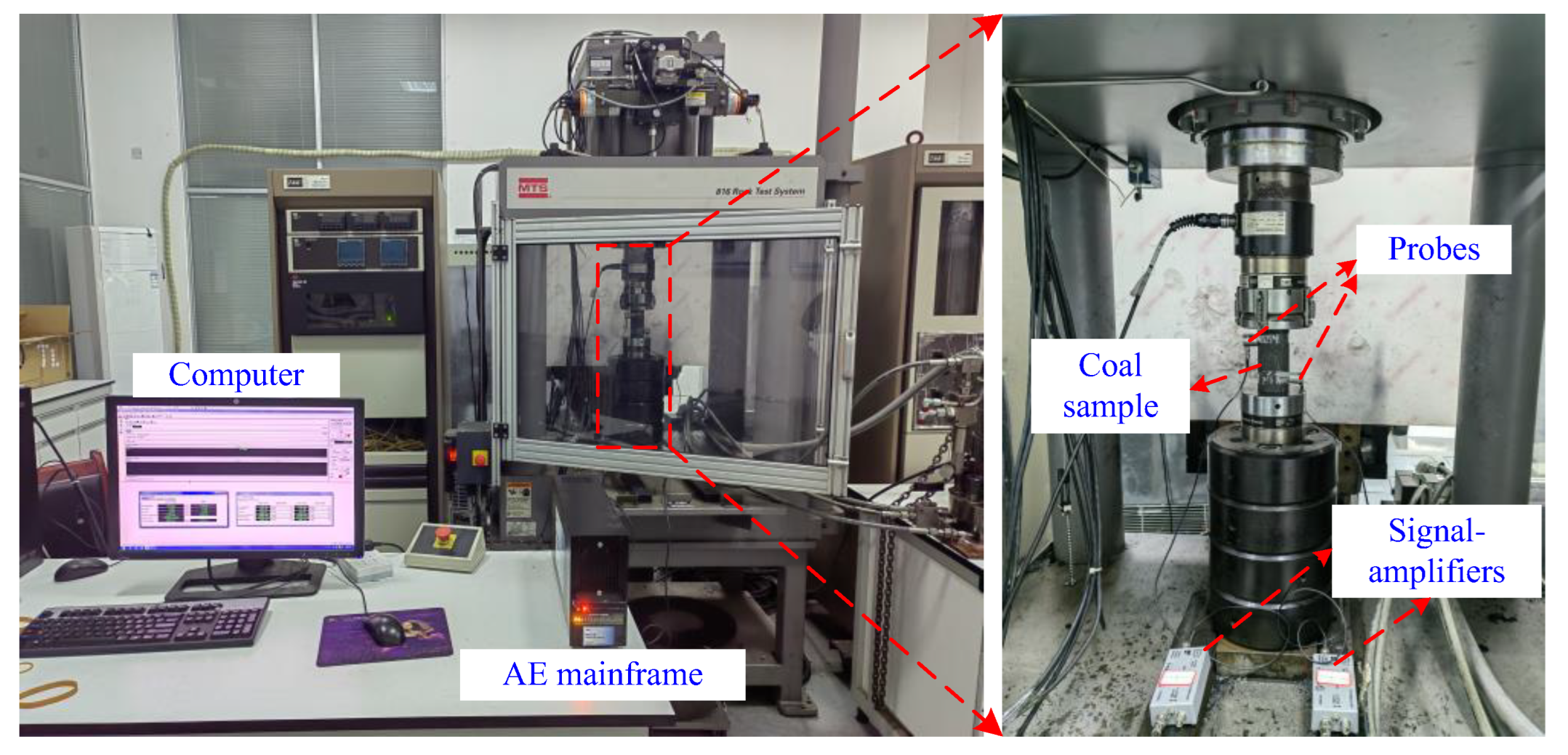

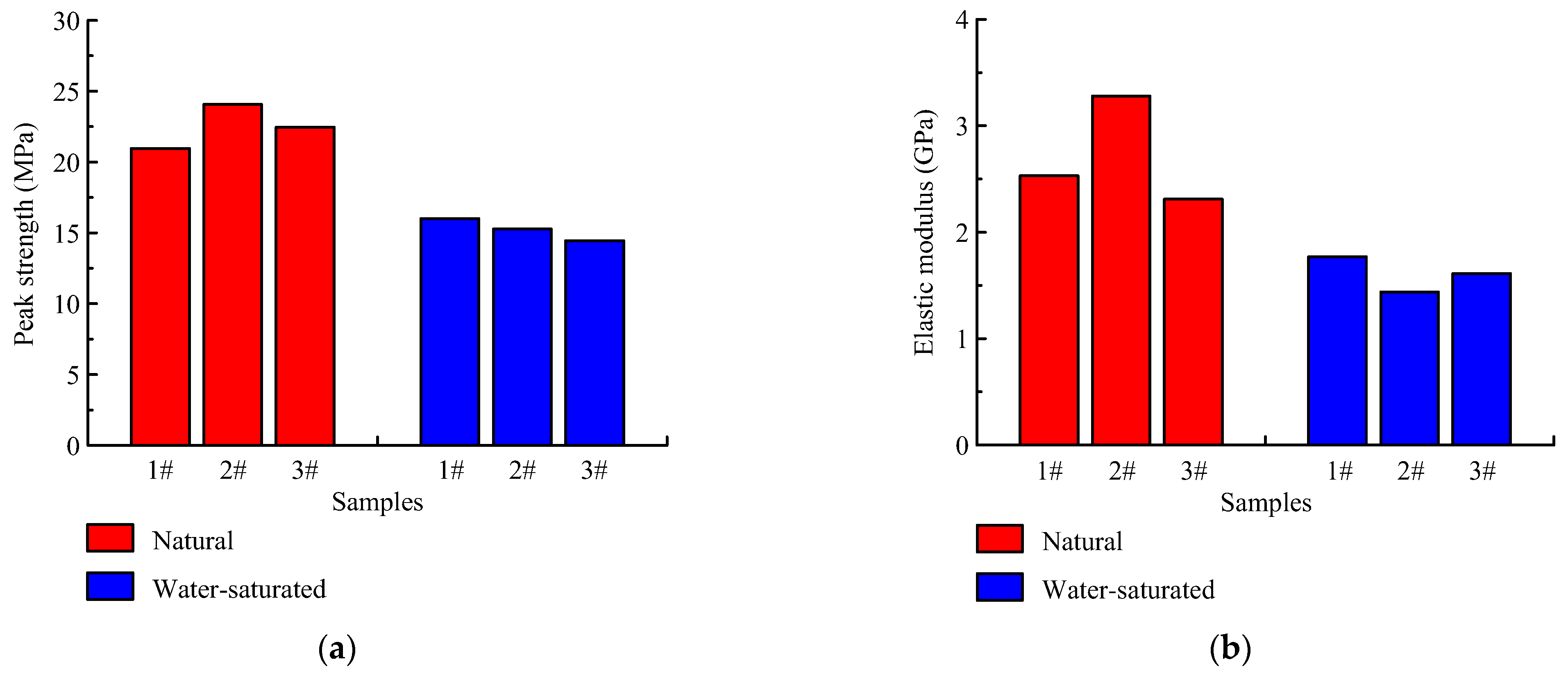

3.2. Macro Mechanical Characteristics

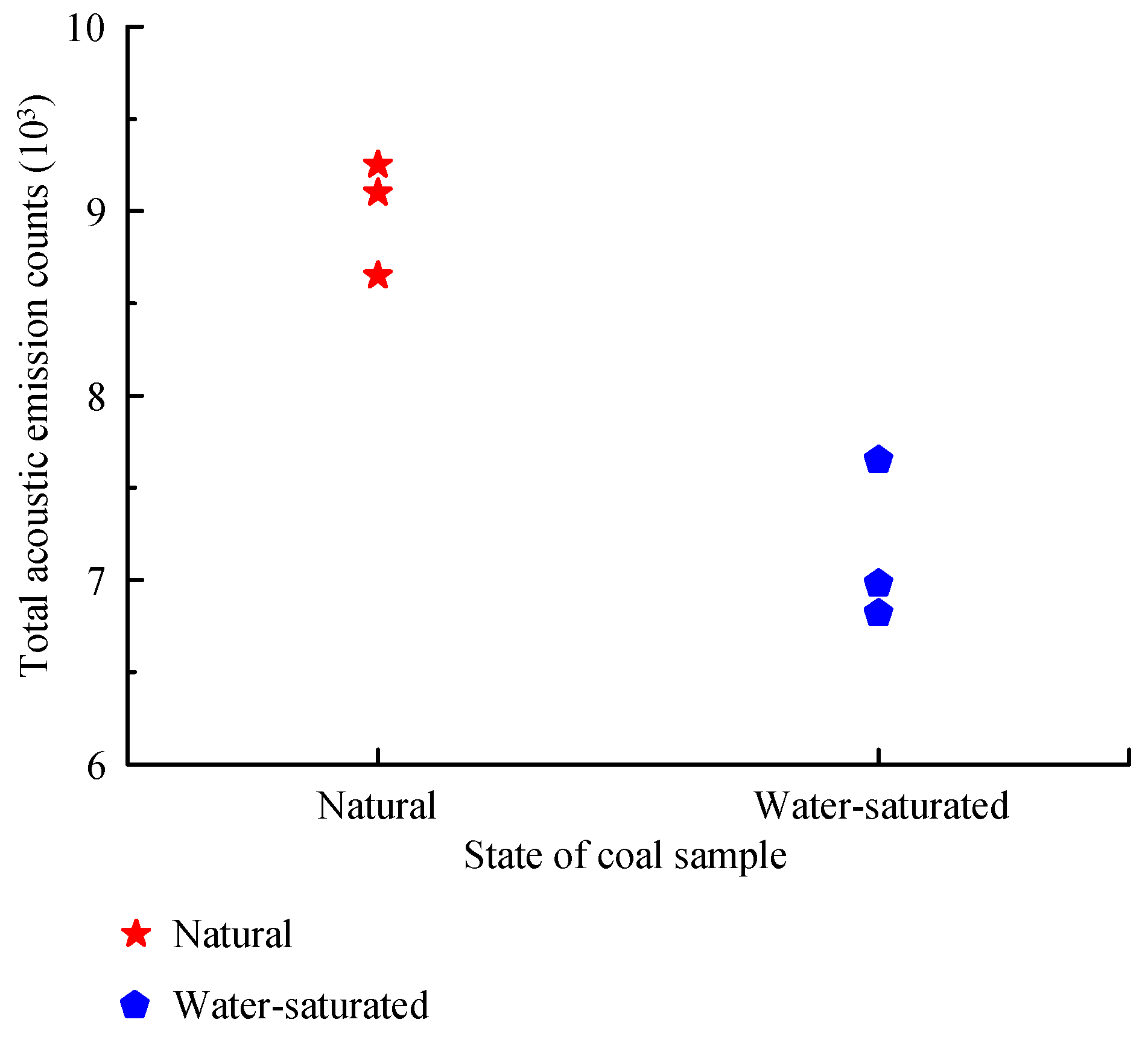

- (1)

- In the compaction stage, the primary cracks in the coal sample are compacted and no new cracks generated, which resulting in weak acoustic emission activity and fewer acoustic emission counts;

- (2)

- In the elastic deformation stage, only linear elastic deformation occurs in the coal samples, and there is no new crack initiation inside. In this stage, the acoustic emission activity is also weak;

- (3)

- In the plastic deformation stage, the number of new cracks in the coal sample gradually increases, and the damage of the coal sample intensifies, leading to intense acoustic emission activities and a significant increase in acoustic emission counts;

- (4)

- At the point of peak strength, the coal sample is destroyed instantaneously and releases a large amount of energy, the intensity of acoustic emission reaches the peak, and the single ringing count exceeds 500 times;

- (5)

- In the post peak failure stage, the acoustic emission activity is still continuing, but the acoustic emission count decreases.

3.3. In Situ Stresses

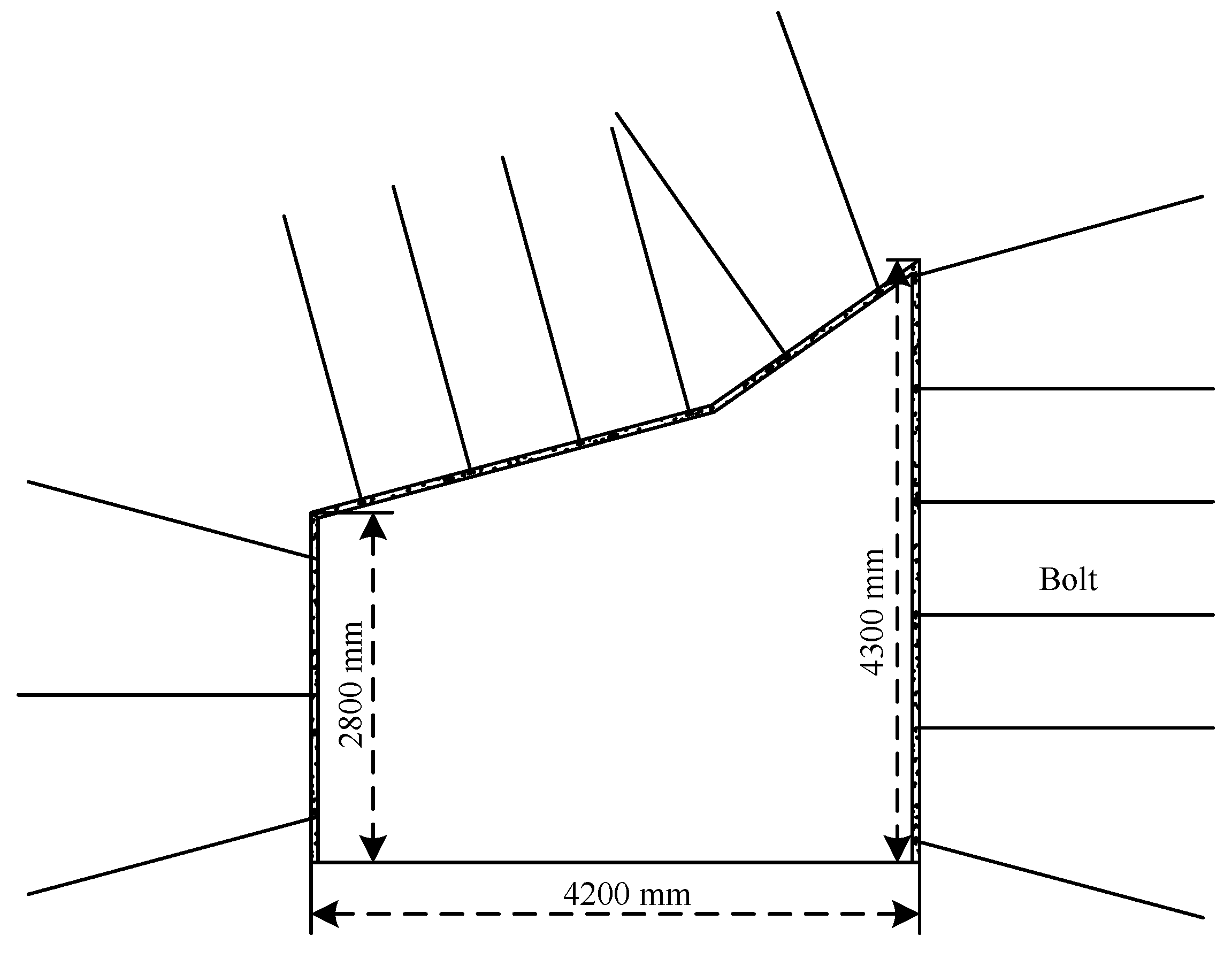

4. New Design Structure and Parameters

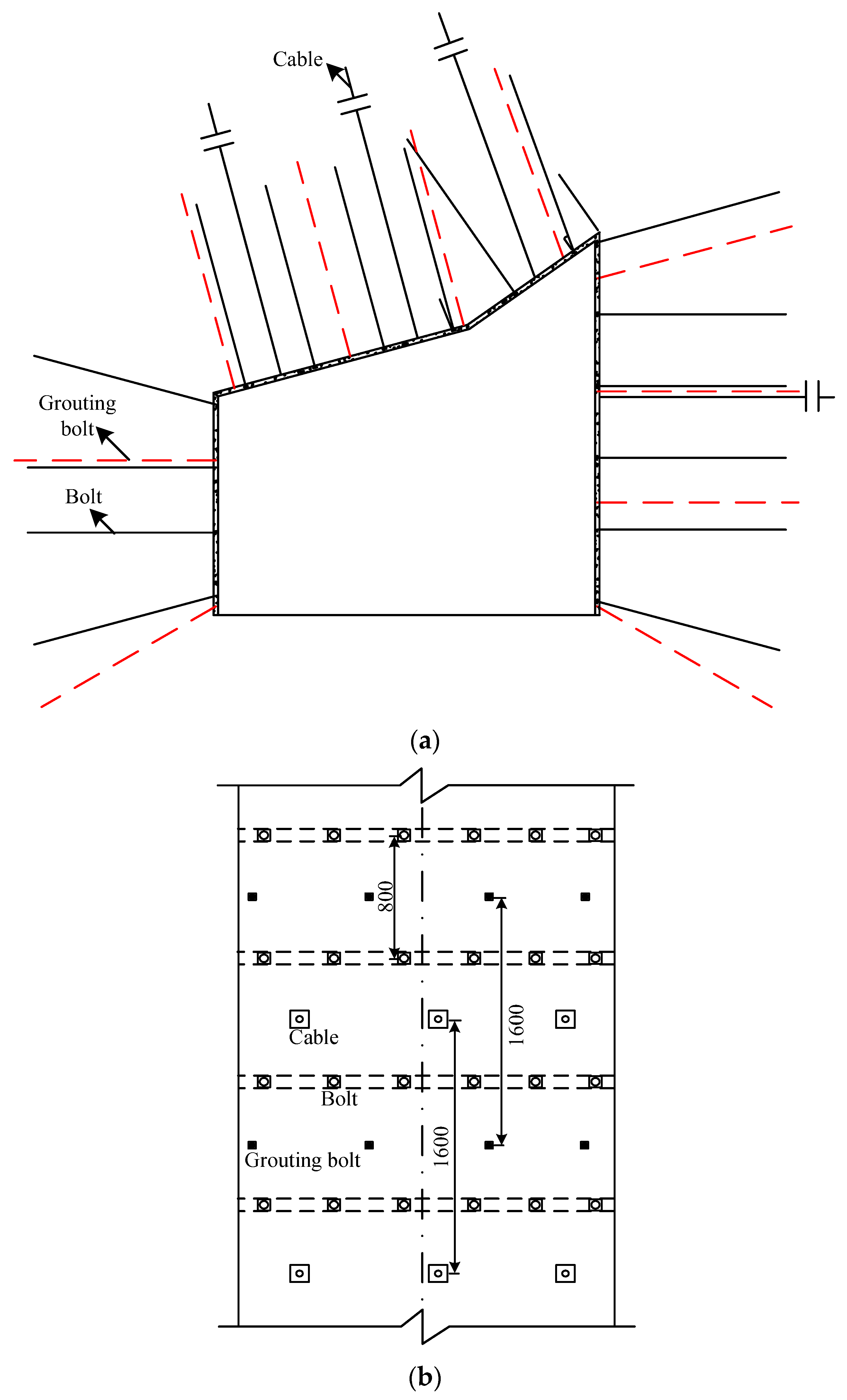

- (1)

- Firstly, bolts, cables, and wire mesh should be installed immediately after excavation to prevent the roof collapse of roadway.

- (2)

- Secondly, concrete is required to be sprayed onto the roadway surface to isolate air and water. In addition, the concrete solidified on the roadway surface can effectively prevent the outflow of grout and ensure the grouting quality.

- (3)

- Finally, grouting bolts are used to inject grout into the surrounding rock of the roadway to seal the cracks, reconstruct the fractured rock mass, improve the strength of the surrounding rock, and control the deformation of the roadway.

- (1)

- Bolt parameters: there are fifteen bolts with diameter of 20 mm and length of 2.4 m in the roadway cross section, including six bolts in the roof, three bolts in the left rib, and six bolts in the right rib. The spacing between the bolts in the roof and ribs along the roadway radial is 0.8~0.9 m. The row spacing of bolts of two adjacent cross sections is 0.8 m. The anchoring force of each bolt is not less than 80 kN, and all bolts should be pretensioned with a pretension load of 300 N•m. The anchorage length of each bolt must be greater than 0.6 m.

- (2)

- Cable parameters: there are four cables with diameter of 17.8 mm in the roadway cross section, including three cables with length of 6.3 m in the roof and one cable with length of 4 m in the right rib. The spacing between the cables in the roof along the roadway cross section is 1.6 m. The row spacing of bolts of two adjacent cross sections is 1.6 m, too. The cables are made of levorotary rebar steel with a tensile strength of 500 MPa.

- (3)

- Metal mesh parameters: the metal mesh with length of 2 m and width of 1 m is made of steel bar that has a diameter of 6 mm. The metal mesh is fixed on the whole roadway surface through bolt tray and nut. The grid of the metal mesh has a length/width ratio of 0.1. Two adjacent metal meshes are connected by iron wire.

- (4)

- Shotcreting parameters: concrete in strength grade of C20 with thickness of 100 mm is sprayed evenly to the roadway surface. The concrete composition is cement:sand:stone = 1:2:2. Enough water should be sprayed for curing in time after spraying.

- (5)

- Grouting bolt parameters: there are ten grouting bolts with breaking strength no less than 15 t in a roadway cross section including four in the roof, two in the left rib, and four in the right rib. The grouting bolts have a diameter of 25 mm and a length of 2.5 m. The spacing between the grouting bolts in the roof and ribs along the roadway radial is 1.2~1.6 m. The row spacing of grouting bolts of two adjacent cross sections is 1.6 m. The anchorage length of each grouting bolt must be larger than 1.5 m. Some slurry outlet holes with diameter of 6 mm are evenly distributed on the surface of each grouting bolt.

- (6)

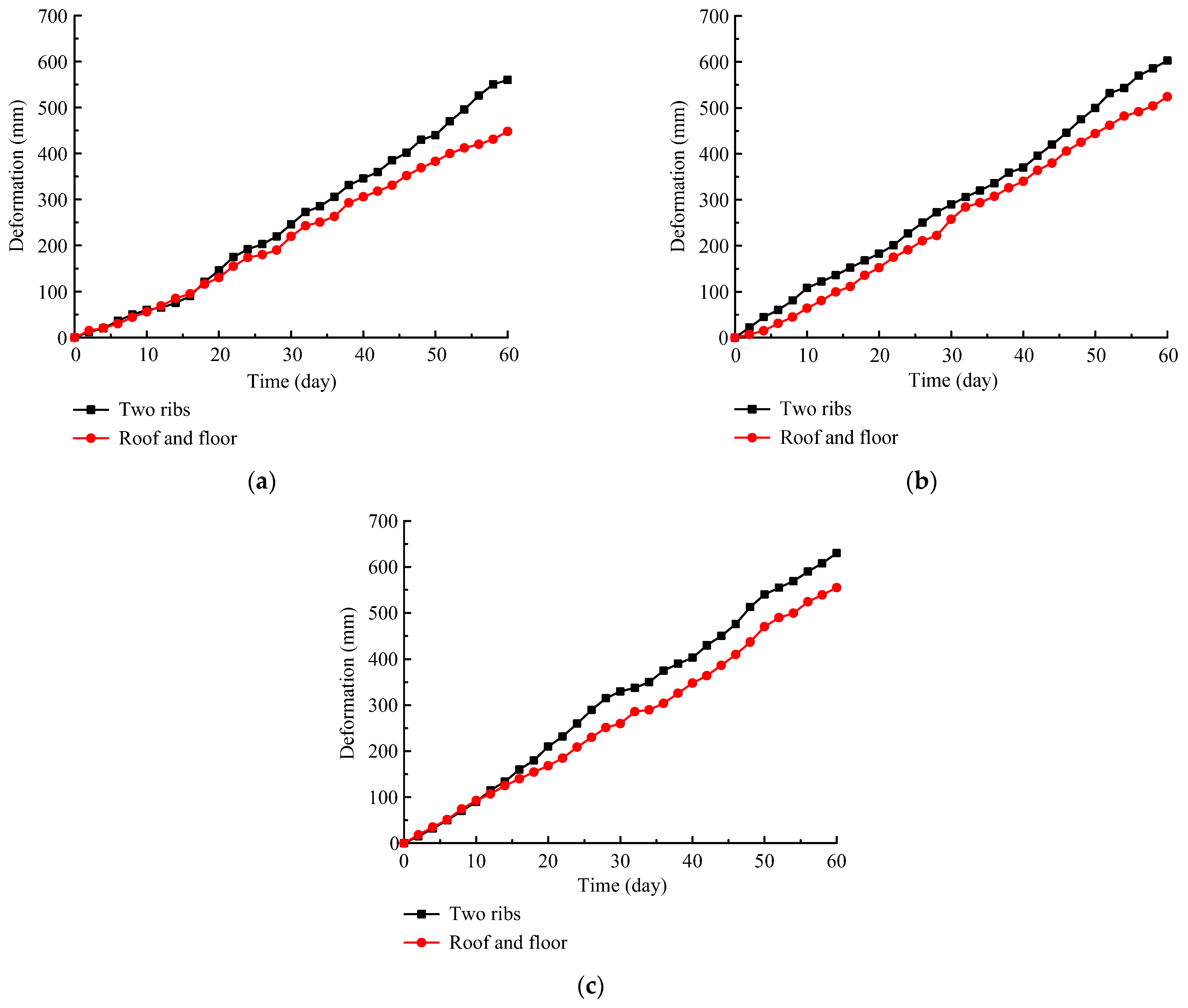

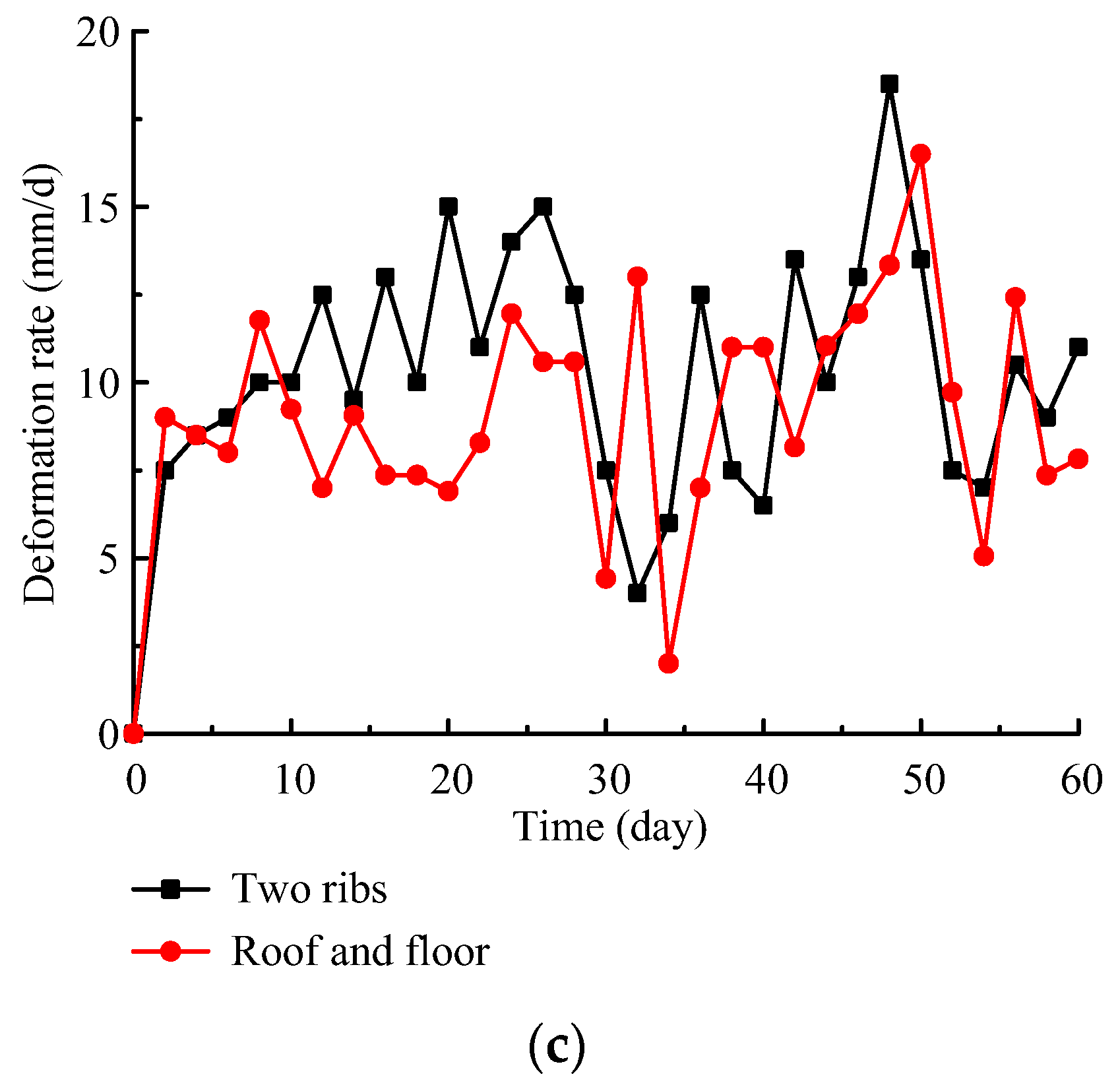

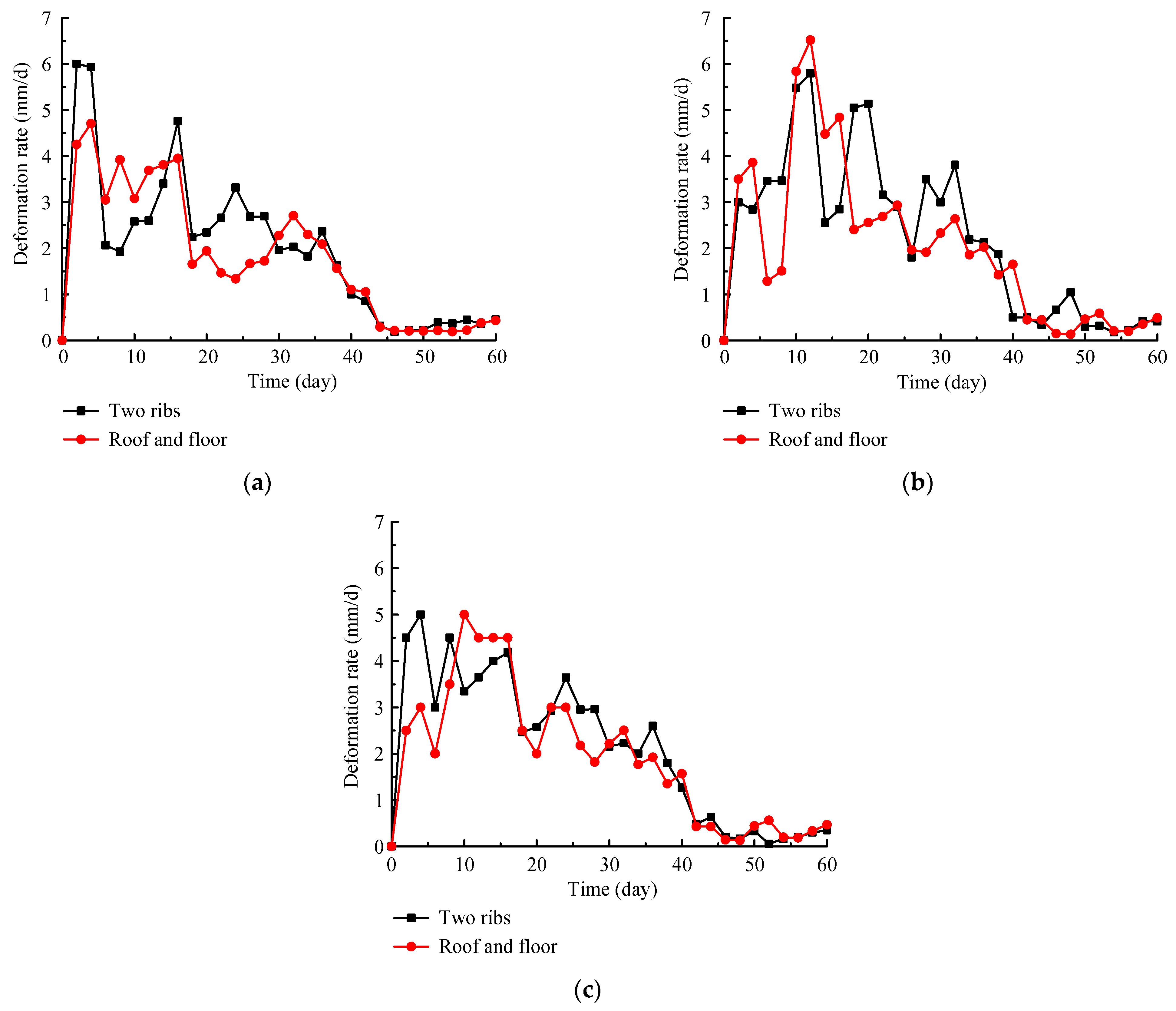

5. On-Site Monitoring

6. Conclusions

- (1)

- SEM scanning results show that due to the dissolution of some minerals by water molecules, micro cracks between particles gradually develop and extend, and obvious fissures are formed in the water-saturated coal sample. Macro mechanical test results show that the strength of water-saturated coal decreases significantly compared with natural coal. Therefore, the surrounding rock of 1044 return laneway in a water-rich area experiences large deformations under high vertical in-situ stress.

- (2)

- Based on the failure mechanism, a new optimal support design was proposed, which included bolt, cable, metal mesh, shotcrete, and grouting. Furthermore, the construction sequence and detailed support parameters were also introduced.

- (3)

- A field test with the new support design was performed in 1044 return laneway. Results show that the new support can reduce the deformation by at least 90% compared with the original support. With the new support technology, the long-term stability of the roadway in a water-rich area can be effectively ensured, which provides a significant reference for the support design of roadway with similar geologic conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, H.J.; Tang, H.L.; Wu, Y.C.; Wang, K.; Xu, C. Gas seepage in underground coal seams: Application of the equivalent scale of coal matrix-fracture structures in coal permeability measurements. Fuel 2021, 288, 119641. [Google Scholar] [CrossRef]

- Fu, Q.; Yang, K.; He, X.; Wei, Z.; Yang, Q. Characteristics of Strata Behavior and Differentiated Control of Fully Mechanized MiningWorking Face with Abnormal Roof. Sustainability 2022, 14, 13354. [Google Scholar] [CrossRef]

- Luo, Y.; Gong, F.Q.; Zhu, C.Q. Experimental investigation on stress-induced failure in D-shaped hard rock tunnel under water-bearing and true triaxial compression conditions. Bull. Eng. Geol. Environ. 2022, 81, 76. [Google Scholar] [CrossRef]

- Hadizadeh, J.; Law, R.D. Water-weakening of sandstone and quartzite deformed at various stress and strain rates. Int. Rock Mech. Min. Sci. Geomech. 1991, 28, 431–439. [Google Scholar] [CrossRef]

- Nam, S.W.; Bobet, A. Radial deformations induced by groundwater flow on deep circular tunnels. Rock Mech. Rock Eng. 2007, 40, 23–39. [Google Scholar] [CrossRef]

- Fan, H.; Wang, L.; Wang, S.; Jiang, C. A new unified solution for deep tunnel in water-rich area considering pore water pressure. Geofluids 2021, 2021, 6696757. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kim, B.M.; Shin, J.H.; Lee, I.M. The ground reaction curve of underwater tunnels considering seepage forces. Tunn. Undergr. Space Technol. 2010, 25, 315–324. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, L.G.; Li, S.C.; Wang, Q.; Liu, P.; Li, X.J. Roof collapse mechanisms for a shallow tunnel in two-layer rock strata incorporating the influence of groundwater. Eng. Fail. Anal. 2019, 98, 215–227. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Qi, X.; Zhu, T. Research on application of the bolt-truss coupling support technology in roadway with water-rich and soft rock. Front. Earth Sci. 2022, 10, 842672. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, Q.; Hu, Z.; Yang, S.; Peng, C.; Zhang, X.; Li, Z.; Wang, X. Research on the influence of groundwater in coastal areas on the stress and deformation characteristics of integrated pipe gallery. Geofluids 2022, 2022, 3463752. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Dutta, P. Stability of rectangular tunnel in Hoek–Brown rocks under steady-state groundwater flow. Geotech. Lett. 2020, 10, 524–534. [Google Scholar] [CrossRef]

- Wang, Y.C.; Liu, Y.; Li, Y.L.; Jiang, W.; Wang, Y. Experimental study on the failure mechanism of tunnel surrounding rock under different groundwater seepage paths. Geofluids 2021, 2021, 8856365. [Google Scholar] [CrossRef]

- Shi, C.; Cao, C.; Lei, M.; Yang, W. Face stability analysis of shallow underwater tunnels in fractured zones. Arab. J. Geosci. 2016, 9, 24. [Google Scholar] [CrossRef]

- Pan, J.; Guo, Q.; Ren, F.; Cai, M. Comparative analysis of different strength criteria for deep-buried rock roadway under seepage. J. China Coal Soc. 2019, 44, 3369–3378. [Google Scholar]

- Qin, C.; Chian, S.C.; Yang, X.; Du, D. 2D and 3D limit analysis of progressive collapse mechanism for deep-buried tunnels under the condition of varying water table. Int. J. Rock Mech. Min. Sci. 2015, 80, 255–264. [Google Scholar] [CrossRef]

- Hao, M.; Pan, X.; Zhang, B. Deformation failure characteristics and support technology of weakly cemented soft rock roadway under water spraying condition. Safe. Coal Mines 2021, 52, 219–228. [Google Scholar]

- Zhai, W.; He, F.; Xu, X.; Lv, K.; Li, L.; Song, J. Floor heave mechanism in water-rich soft rock roadways and a DS-IBA control approach. Geomat. Nat. Haz. Risk 2022, 13, 2107–2123. [Google Scholar] [CrossRef]

- Lu, H.; Yin, J.; Liu, Q.; Cao, A.; Wei, A.; Zhang, K. A self-dissolved grouting reinforcement method for water-rich soft rock roadway. Bull. Eng. Geol. Environ. 2022, 81, 256. [Google Scholar] [CrossRef]

- Lin, W.; Cheng, J.; Li, D.; Dang, H. Deformation characteristics and control technology of roadway in water-rich soft rock. Geofluids 2022, 2022, 2234334. [Google Scholar] [CrossRef]

- Cheng, J.; Wei, Z.; Bai, J.; Yu, Z.; Xing, K.; Li, Q.; Wang, J.; Li, X.; Zhang, C.; Zhang, Z. Study on floor heave control technology of deep tectonic stress water-rich soft rock roadway based on blasting pressure relief. Coal Sci. Technol. 2022, 50, 117–126. [Google Scholar]

- Jiang, B.; Wang, L.; Lu, Y.; Gu, S.; Sun, X. Failure mechanism analysis and support design for deep composite soft rock roadway: A case study of the Yangcheng coal mine in China. Shock Vib. 2015, 2015, 452479. [Google Scholar] [CrossRef]

- Lu, Y.L.; Wang, L.G.; Zhang, B. An experimental study of a yielding support for roadways constructed in deep broken soft rock under high stress. Min. Sci. Technol. 2011, 21, 839–844. [Google Scholar] [CrossRef]

- Wang, K.; Wang, L.; Ren, B. Failure Mechanism Analysis and Support Technology for Roadway Tunnel in Fault Fracture Zone: A Case Study. Energies 2021, 14, 3767. [Google Scholar] [CrossRef]

- Ma, Z.; Jiang, Y.; Du, W.; Zuo, Y.; Kong, D. Fracture evolution law and control technology of roadways with extra thick soft roof. Eng. Fail. Anal. 2018, 84, 331–345. [Google Scholar] [CrossRef]

- Kang, H.P.; Jiang, P.F.; Huang, B.X.; Guan, X.M.; Wang, Z.G.; Wu, Y.Z.; Gao, F.Q.; Yang, J.W.; Cheng, L.X.; Zheng, Y.F.; et al. Roadway strata control technology by means of bolting-modification-destressing in synergy in 1000 m deep coal mines. J. Chin. Coal Soc. 2020, 45, 845–864. [Google Scholar]

- Wang, L.G.; Lu, Y.L.; Huang, Y.G.; Sun, H.Y. Deep-shallow coupled bolt-grouting support technology for soft rock roadway in deep mine. J. Chin. Univ. Min. Technol. 2016, 45, 11–18. [Google Scholar]

- Wang, F.; Zhang, C.; Wei, S.; Zhang, X.; Guo, S. Whole section anchor-grouting reinforcement technology and its application in underground roadways with loose and fractured surrounding rock. Tunn. Undergr. Space Technol. 2016, 51, 133–143. [Google Scholar]

- Wang, Q.; Pan, R.; Jiang, B.; Li, S.; He, M.; Sun, H.; Wang, L.; Qin, Q.; Yu, H.; Luan, Y. Study on failure mechanism of roadway with soft rock in deep coal mine and confined concrete support system. Eng. Fail. Anal. 2017, 81, 155–177. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, S.C.; Wang, D.C.; Wang, F.Q.; Li, W.T. Experimental Studies on the Mechanical Properties and Deformation & Failure Mechanism of U-type Confined Concrete Arch Centering. Tunn. Undergr. Space Technol. 2016, 51, 20–29. [Google Scholar]

- Kai, Z.; Zhang, G.; Hou, R.; Wu, Y.; Zhou, H. Stress evolution in roadway rock bolts during mining in a fully mechanized longwall face, and an evaluation of rock bolt support design. Rock Mech. Rock Eng. 2015, 48, 333–344. [Google Scholar]

- Li, Z.; Li, J.; Li, H. Effect of concave terrain on explosion-induced ground motion. Int. J. Rock Mech. Min. Sci. 2021, 148, 104948. [Google Scholar] [CrossRef]

- Li, J.; Yuan, W.; Li, H.; Zou, C. Study on dynamic shear deformation behaviors and test methodology of sawtooth-shaped rock joints under impact load. Int. J. Rock Mech. Min. Sci. 2022, 158, 105210. [Google Scholar] [CrossRef]

- Li, S.B.; Wang, L.; Ren, Q.H.; Zhu, C.Q.; Liu, H.Q.; Liu, H.Q.; Chen, L.P. A study on the influence of mining depth on the stress distribution characteristics of stope surrounding rock. Geofluids 2022, 2022, 4178554. [Google Scholar] [CrossRef]

- Li, Z.L.; Wang, L.G.; Ding, K. Effect of Strong Mining on the Fracture Evolution Law of Trick Rise in the Mining Field and Its Control Technology. Geofluids 2022, 2022, 3953650. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Liu, C.; Sun, D.; Shao, J. Application of bolt-grouting reinforcement for broken surrounding rock based on prestressed bolt and self-stress grouting. J. Min. Safe. Eng. 2021, 38, 774–783. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, H.; Niu, X.; Li, S. Failure Mechanism and Control Technology for Coal Roadway in Water-Rich Area. Sustainability 2023, 15, 410. https://doi.org/10.3390/su15010410

Fan H, Niu X, Li S. Failure Mechanism and Control Technology for Coal Roadway in Water-Rich Area. Sustainability. 2023; 15(1):410. https://doi.org/10.3390/su15010410

Chicago/Turabian StyleFan, Hao, Xingang Niu, and Shaobo Li. 2023. "Failure Mechanism and Control Technology for Coal Roadway in Water-Rich Area" Sustainability 15, no. 1: 410. https://doi.org/10.3390/su15010410

APA StyleFan, H., Niu, X., & Li, S. (2023). Failure Mechanism and Control Technology for Coal Roadway in Water-Rich Area. Sustainability, 15(1), 410. https://doi.org/10.3390/su15010410