Fuzzy Front-End Vertical External Involvement, Corporate Social Responsibility and Firms’ New Product Development Performance in the VUCA Age: From an Organizational Learning Perspective

Abstract

1. Introduction

2. Theoretical Background and Hypothesis Development

2.1. Theoretical Foundation

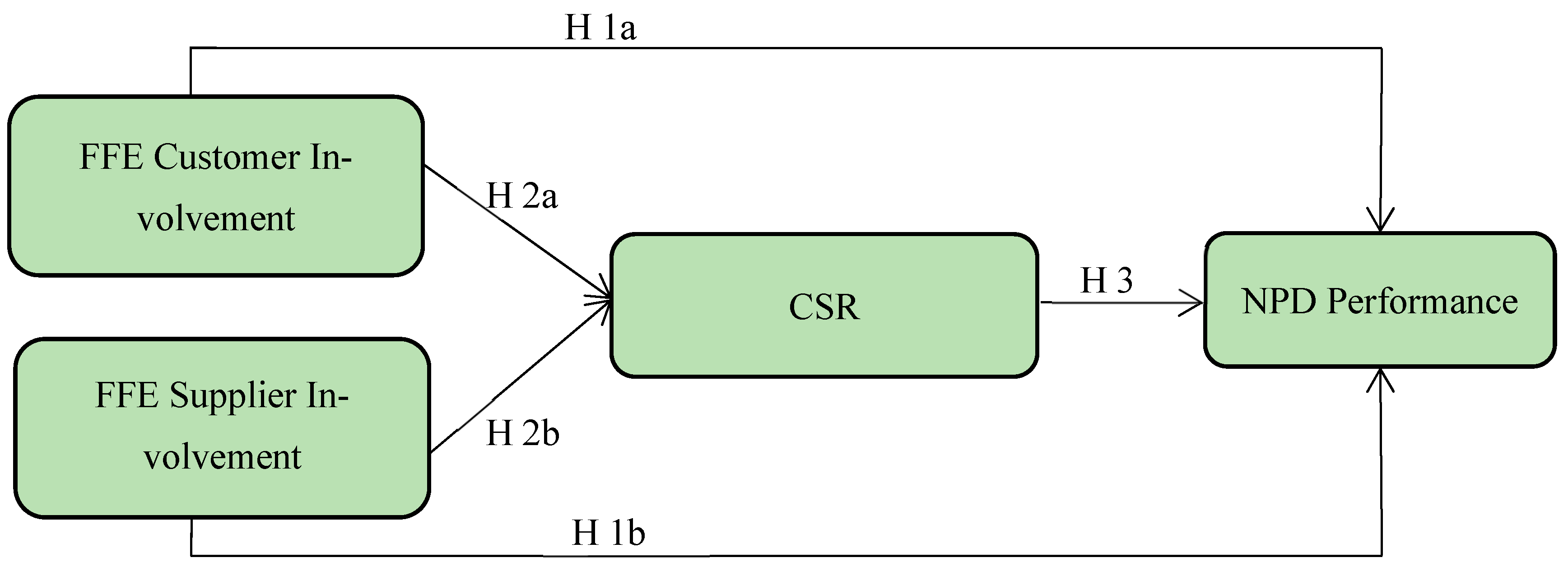

2.2. FFE Vertical External Involvement and NPD Performance

2.3. FFE Vertical External Involvement and CSR

2.4. CSR and NPD Performance

2.5. The Mediating Effect of CSR

3. Methodology

3.1. Sample and Data Collection

3.2. Variables and Measurements

4. Results and Analysis

4.1. Reliability and Validity

4.2. Hypothesis Testing

5. Conclusions

5.1. Discussion

5.2. Theoretical Contributions

5.3. Practical Implications

5.4. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FFE | Fuzzy Front-end |

| CSR | Corporate Social Responsibility |

| NPD | New Product Development |

| OL | Organizational Learning |

| VUCA | Volatility, Uncertainty, Complexity and Ambiguity |

References

- Jin, X.; Zhang, M.; Sun, G.; Cui, L. The impact of COVID-19 on firm innovation: Evidence from Chinese listed companies. Finance Res. Lett. 2022, 45, 102–133. [Google Scholar] [CrossRef]

- Koen, P.; Ajamian, G.; Burkart, R.; Clamen, A.; Davidson, J.; D’Amore, R.; Elkins, C.; Herald, K.; Incorvia, M.; Johnson, A.; et al. Providing clarity and a common language to the “fuzzy front end”. Res. Technol. Manag. 2001, 44, 46–55. [Google Scholar] [CrossRef]

- Koen, P.A.; Bertels, H.M.J.; Kleinschmidt, E. Managing the front end of innovation—Part I: Results from a three-year study. Res. Technol. Manag. 2014, 57, 34–43. [Google Scholar] [CrossRef]

- Khurana, A.; Rosenthal, S.R. Towards holistic “front ends” in new product development. J. Prod. Innov. Manag. 1998, 15, 57–74. [Google Scholar] [CrossRef]

- Cooper, R.G.; Kleinschmidt, E.J. Determinants of timeliness in product development. J. Prod. Innov. Manag. 1994, 11, 381–396. [Google Scholar] [CrossRef]

- Markham, S.K. The impact of front-end innovation activities on product performance. J. Prod. Innov. Manag. 2013, 30, 77–92. [Google Scholar] [CrossRef]

- Nobelius, D.; Trygg, L. Stop chasing the Front End process—Management of the early phases in product development projects. Int. J. Proj. Manag. 2002, 20, 331–340. [Google Scholar] [CrossRef]

- Christiansen, J.K.; Gasparin, M. Drawing things together in the fuzzy front end with black-boxes. In Proceedings of the 26th Innovation and Product Development Management Conference, CBS, Leicester, UK, 9–11 June 2019; pp. 1–20. [Google Scholar]

- Chen, J.; Chen, Y.; Vanhaverbeke, W. The influence of scope, depth, and orientation of external technology sources on the innovative performance of Chinese firms. Technovation 2011, 31, 362–373. [Google Scholar] [CrossRef]

- Stevens, E. Fuzzy front-end learning strategies: Exploration of a high-tech company. Technovation 2014, 34, 431–440. [Google Scholar] [CrossRef]

- Chesborough, H.; Vanhaverbeke, W.; West, J. Open Innovation: Researching A New Paradigm; OUP: Oxford, UK, 2006. [Google Scholar]

- Kim, J.; Wilemon, D. Focusing the fuzzy front–end in new product development. R&D Manag. 2002, 32, 269–279. [Google Scholar] [CrossRef]

- Zhang, Q.; Doll, W.J. The fuzzy front end and success of new product development: A causal model. Eur. J. Innov. Manag. 2001, 4, 95–112. [Google Scholar] [CrossRef]

- Zhang, Q.; Cao, M.; Doll, W. Fuzzy front end of innovation: A dual theoretical rationale. J. Bus. Ind. Mark. 2019, 34, 176–191. [Google Scholar] [CrossRef]

- Wang, Y.; Hong, A.; Li, X.; Gao, J. Marketing innovations during a global crisis: A study of China firms’ response to COVID-19. J. Bus. Res. 2020, 116, 214–220. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.M.; Trimi, S. Convergence innovation in the digital age and in the COVID-19 pandemic crisis. J. Bus. Res. 2021, 123, 14–22. [Google Scholar] [CrossRef]

- Tomlinson, P.R. Co-operative ties and innovation: Some new evidence for UK manufacturing. Res. Policy 2010, 39, 762–775. [Google Scholar] [CrossRef]

- Donaldson, T.; Preston, L.E. The stakeholder theory of the corporation: Concepts, evidence, and implications. Acad. Manag. Rev. 1995, 20, 65–91. [Google Scholar] [CrossRef]

- Juntunen, J.K.; Halme, M.; Korsunova, A.; Rajala, R. Strategies for integrating stakeholders into sustainability innovation: A configurational perspective. J. Prod. Innov. Manag. 2019, 36, 331–355. [Google Scholar] [CrossRef]

- Svendsen, M.F.; Haugland, S.A.; Grønhaug, K.; Hammervoll, T. Marketing strategy and customer involvement in product development. Eur. J. Mark. 2011, 45, 513–530. [Google Scholar] [CrossRef]

- Aune, T.; Gressetvold, E. Supplier involvement in innovation processes: A taxonomy. Int. J. Innov. Manag. 2011, 15, 121–143. [Google Scholar] [CrossRef]

- Lau, A.K.W. Supplier and customer involvement on new product performance. Ind. Manag. Data Syst. 2011, 111, 910–942. [Google Scholar] [CrossRef]

- Khurana, A.; Rosenthal, S.R. Integrating the fuzzy front end of new product development. Sloan Manag. Rev. 1997, 38, 103–120. [Google Scholar]

- Turyakira, P.; Venter, E.; Smith, E. The impact of corporate social responsibility factors on the competitiveness of small and medium-sized enterprises. S. Afr. J. Econ. Manag. Sci. 2014, 17, 157–172. [Google Scholar] [CrossRef]

- Dodgson, M. Organizational learning: A review of some literatures. Organ. Stud. 1993, 14, 375–394. [Google Scholar] [CrossRef]

- Backman, M.; Börjesson, S.; Setterberg, S. Working with concepts in the fuzzy front end: Exploring the context for innovation for different types of concepts at Volvo Cars. R&D Manag. 2007, 37, 17–28. [Google Scholar] [CrossRef]

- Lynn, G.S.; Akgün, A.E. Innovation strategies under uncertainty: A contingency approach for new product development. Eng. Manag. J. 1998, 10, 11–18. [Google Scholar] [CrossRef]

- Verworn, B. A structural equation model of the impact of the “fuzzy front end” on the success of new product development. Res. Policy 2009, 38, 1571–1581. [Google Scholar] [CrossRef]

- Reid, S.E.; de Brentani, U. Market vision and the front end of NPD for radical innovation: The impact of moderating effects. J. Prod. Innov. Manag. 2012, 29, 124–139. [Google Scholar] [CrossRef]

- Thanasopon, B.; Papadopoulos, T.; Vidgen, R. The role of openness in the fuzzy front-end of service innovation. Technovation 2016, 47, 32–46. [Google Scholar] [CrossRef]

- Alam, I. Removing the fuzziness from the fuzzy front-end of service innovations through customer interactions. Ind. Mark. Manag. 2006, 35, 468–480. [Google Scholar] [CrossRef]

- Verworn, B.; Herstatt, C.; Nagahira, A. The fuzzy front end of Japanese new product development projects: Impact on success and differences between incremental and radical projects. R&D Manag. 2007, 38, 1–19. [Google Scholar] [CrossRef]

- Menguc, B.; Auh, S.; Yannopoulos, P. Customer and supplier involvement in design: The moderating role of incremental and radical innovation capability. J. Prod. Innov. Manag. 2014, 31, 313–328. [Google Scholar] [CrossRef]

- Laage-Hellman, J.; Lind, F.; Perna, A. The role of openness in collaborative innovation in industrial networks: Historical and contemporary cases. J. Bus. Ind. Mark. 2021, 36, 116–128. [Google Scholar] [CrossRef]

- Casaló, L.; Flavián, C.; Guinalíu, M. The impact of participation in virtual brand communities on consumer trust and loyalty. Online Inf. Rev. 2007, 31, 775–792. [Google Scholar] [CrossRef]

- Chen, L.S.-L.; Wang, M.C.-H.; Cheng, J.M.-S.; Kuntjara, H. Consumer involvement and brand loyalty in services: Evidence from the commercial airline industry in Taiwan. Int. J. Serv. Stand. 2008, 4, 437–452. [Google Scholar] [CrossRef]

- Lin, I.J.; Yang, S.-M.; Wu, J.-T.B. The Impact of a Customer Profile and Customer Participation on Customer Relationship Management Performance. Available online: https://aisel.aisnet.org/iceb2003/87 (accessed on 17 August 2022).

- Feng, T.; Sun, L.; Zhang, Y. The effects of customer and supplier involvement on competitive advantage: An empirical study in China. Ind. Mark. Manag. 2010, 39, 1384–1394. [Google Scholar] [CrossRef]

- Drucker, P.F. The Essential Drucker; Routledge: London, UK, 2007. [Google Scholar]

- United Nations Industrial Development Organization. What Is CSR? United Nations Industrial Development Organization: Vienna, Austria, 2020. [Google Scholar]

- Sen, S.; Bhattacharya, C.B. Does doing good always lead to doing better? Consumer reactions to corporate social responsibility. J. Mark. Res. 2001, 38, 225–243. [Google Scholar] [CrossRef]

- Mason, C.; Simmons, J. Embedding corporate social responsibility in corporate governance: A stakeholder systems approach. J. Bus. Ethics 2014, 119, 77–86. [Google Scholar] [CrossRef]

- Liu, J.; Ma, Y.; Appolloni, A.; Cheng, W. How external stakeholders drive the green public procurement practice? An organizational learning perspective. J. Public Procure. 2021, 21, 138–166. [Google Scholar] [CrossRef]

- Hassi, L.; Wever, R. Practices of a “Green” Front End of Innovation: A Gateway to Environmental Innovation. In The 14th European Roundtable on Sustainable Production and Consumption (ERSCP). The 6th Environmental Management for Sustainable Universities (EMSU); Wever, R., Quist, J., Tukker, A., Woudstra, J., Boons, F., Beute, N., Eds.; Faculty of Industrial Design Engineering: The Delft, The Netherlands, 2010; pp. 1–27. [Google Scholar]

- Qi, G.; Zeng, S.; Tam, C.; Yin, H.; Zou, H. Stakeholders’ influences on corporate green innovation strategy: A case study of manufacturing firms in China. Corp. Soc. Responsib. Environ. Manag. 2013, 20, 1–14. [Google Scholar] [CrossRef]

- Azadegan, A.; Dooley, K.J. Supplier innovativeness, organizational learning styles and manufacturer performance: An empirical assessment. J. Oper. Manag. 2010, 28, 488–505. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. The link between competitive advantage and corporate social responsibility. Harv. Bus. Rev. 2006, 84, 78–92. [Google Scholar] [PubMed]

- Pan, X.; Oh, K.-S.; Wang, M. Strategic orientation, digital capabilities, and new product development in emerging market firms: The moderating role of corporate social responsibility. Sustainability 2021, 13, 12703. [Google Scholar] [CrossRef]

- Mithani, M.A. Innovation and CSR—Do they go well together? Long Range Plan. 2017, 50, 699–711. [Google Scholar] [CrossRef]

- Sandmeier, P.; Jamali, N.; Kobe, C.; Enkel, E.; Gassmann, O.; Meier, M. Towards a structured and integrative front-end of product innovation. In Proceedings of the R&D Management Conference (RADMA), Lisbon, Portugal, 7 July 2004; pp. 1–10. [Google Scholar]

- Murphy, S.A.; Kumar, V. The front end of new product development: A Canadian survey. R&D Manag. 1997, 27, 5–15. [Google Scholar] [CrossRef]

- Kim, J.; Wilemon, D. Accelerating the fuzzy front-end of NPD projects: Methods and management. Int. J. Eng. Manag. Econ. 2010, 1, 80–101. [Google Scholar] [CrossRef]

- Chase, R.B. The service factory. Harv. Bus. Rev. 1989, 67, 61–69. [Google Scholar] [CrossRef]

- Prahalad, C.K.; Ramaswamy, V. Co-opting customer competence. Harv. Bus. Rev. 2000, 78, 79–90. [Google Scholar]

- Carr, A.S.; Pearson, J.N. The impact of purchasing and supplier involvement on strategic purchasing and its impact on firm’s performance. Int. J. Oper. Prod. Manag. 2002, 22, 1032–1053. [Google Scholar] [CrossRef]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2021, 41, 63–73. [Google Scholar] [CrossRef]

- Mollenkopf, D.A.; Ozanne, L.K.; Stolze, H.J. A transformative supply chain response to COVID-19. J. Serv. Manag. 2021, 32, 190–202. [Google Scholar] [CrossRef]

- Tran, M.K.; Goulding, C.; Shiu, E. The orchestra of ideas: Using music to enhance the ‘fuzzy front end’ phase of product innovation. J. Bus. Res. 2018, 85, 504–513. [Google Scholar] [CrossRef]

- Füller, J.; Matzler, K. Virtual product experience and customer participation—A chance for customer-centred, really new products. Technovation 2007, 27, 378–387. [Google Scholar] [CrossRef]

- Dong, B.; Evans, K.R.; Zou, S. The effects of customer participation in co-created service recovery. J. Acad. Mark. Sci. 2008, 36, 123–137. [Google Scholar] [CrossRef]

- Gummesson, E. Exit services marketing-enter service marketing. J. Cust. Behav. 2007, 6, 113–141. [Google Scholar] [CrossRef]

- Von Hippel, E. Lead users: A source of novel product concepts. Manag. Sci. 1986, 32, 791–805. [Google Scholar] [CrossRef]

- Fang, E. Customer participation and the trade-off between new product innovativeness and speed to market. J. Mark. 2008, 72, 90–104. [Google Scholar] [CrossRef]

- Herstatt, C.; Verworn, B.; Nagahira, A. Reducing project related uncertainty in the “fuzzy front end” of innovation—A comparison of German and Japanese product innovation projects. Int. J. Prod. Dev. 2004, 1, 43–65. [Google Scholar] [CrossRef]

- Wagner, S.M. Tapping supplier innovation. J. Supply Chain Manag. 2012, 48, 37–52. [Google Scholar] [CrossRef]

- Potter, A.; Lawson, B. Help or hindrance? Causal ambiguity and supplier involvement in new product development teams. J. Prod. Innov. Manag. 2013, 30, 794–808. [Google Scholar] [CrossRef]

- Krause, D.R.; Handfield, R.B.; Tyler, B.B. The relationships between supplier development, commitment, social capital accumulation and performance improvement. J. Oper. Manag. 2007, 25, 528–545. [Google Scholar] [CrossRef]

- McEvily, B.; Marcus, A. Embedded ties and the acquisition of competitive capabilities. Strateg. Manag. J. 2005, 26, 1033–1055. [Google Scholar] [CrossRef]

- Moran, P. Structural vs. Relational embeddedness: Social capital and managerial performance. Strateg. Manag. J. 2005, 26, 1129–1151. [Google Scholar] [CrossRef]

- Wowak, K.D.; Craighead, C.W.; Ketchen, D.J., Jr.; Hult, G.T.M. Toward a “theoretical toolbox” for the supplier-enabled fuzzy front end of the new product development process. J. Supply Chain Manag. 2016, 52, 66–81. [Google Scholar] [CrossRef]

- Singh, P.J.; Power, D. The nature and effectiveness of collaboration between firms, their customers and suppliers: A supply chain perspective. Supply Chain Manag. 2009, 14, 189–200. [Google Scholar] [CrossRef]

- Reuer, J.J.; Zollo, M.; Singh, H. Post-formation dynamics in strategic alliances. Strateg. Manag. J. 2002, 23, 135–151. [Google Scholar] [CrossRef]

- Li, N.; Pei, X. Integrating supplier innovation in the fuzzy front end: Based on an analysis of the task environment. J. Bus. Ind. Mark. 2022, 37, 2417–2431. [Google Scholar] [CrossRef]

- Hultman, J.; Elg, U. Developing CSR in retail–supplier relationships: A stakeholder interaction approach. Int. Rev. Retail Distrib. Consum. Res. 2018, 28, 339–359. [Google Scholar] [CrossRef]

- Dai, J.; Montabon, F.L.; Cantor, D.E. Linking rival and stakeholder pressure to green supply management: Mediating role of top management support. Transp. Res. E Logist. Transp. Rev. 2014, 71, 173–187. [Google Scholar] [CrossRef]

- Testa, F.; Boiral, O.; Iraldo, F. Internalization of environmental practices and institutional complexity: Can stakeholders pressures encourage greenwashing? J. Bus. Ethics 2018, 147, 287–307. [Google Scholar] [CrossRef]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. J. Purch. Supply Manag. 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Urbinati, A.; Landoni, P.; Cococcioni, F.; De Giudici, L. Stakeholder management in open innovation projects: A multiple case study analysis. Eur. J. Innov. Manag. 2021, 24, 1595–1624. [Google Scholar] [CrossRef]

- Lee, E.-M.; Yoon, S.-J. The effect of customer citizenship in corporate social responsibility (CSR) activities on purchase intention: The important role of the CSR image. Soc. Responsib. J. 2018, 14, 753–763. [Google Scholar] [CrossRef]

- Reputation Institute. Available online: www.environmentalleader.com/2014/12/18/companies-with-thebest-csr-reputations-named/#ixzz3Y2L0FjgV (accessed on 20 August 2022).

- Robinson, S.R.; Irmak, C.; Jayachandran, S. Choice of cause in cause-related marketing. J. Mark. 2012, 76, 126–139. [Google Scholar] [CrossRef]

- Schons, L.; Sipilä, J.; Sen, S.; Mende, G.; Wieseke, J. Are two reasons better than one? The role of appeal type in consumer responses to sustainable products. J. Consum. Psychol. 2018, 28, 644–664. [Google Scholar] [CrossRef]

- Lund-Thomsen, P.; Lindgreen, A. Corporate social responsibility in global value chains: Where are we now and where are we going? J. Bus. Ethics 2014, 123, 11–22. [Google Scholar] [CrossRef]

- Klassen, R.D.; Vachon, S. Collaboration and evaluation in the supply chain: The impact on plant-level environmental investment. Prod. Oper. Manag. 2003, 12, 336–352. [Google Scholar] [CrossRef]

- Chen, L.; Tang, O.; Jia, F. The moderating role of supplier involvement in achieving sustainability. J. Clean. Prod. 2019, 235, 245–258. [Google Scholar] [CrossRef]

- Lau, C.; Lu, Y.; Liang, Q. Corporate social responsibility in China: A corporate governance approach. J. Bus. Ethics 2016, 136, 73–87. [Google Scholar] [CrossRef]

- Kucharska, W.; Kowalczyk, R. How to achieve sustainability?—Employee’s point of view on company’s culture and CSR practice. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 453–467. [Google Scholar] [CrossRef]

- Hart, S.L.; Sharma, S. Engaging fringe stakeholders for competitive imagination. Acad. Manag. Perspect. 2004, 18, 7–18. [Google Scholar] [CrossRef]

- Marin, L.; Martín, P.J.; Rubio, A. Doing good and different! The mediation effect of innovation and investment on the influence of CSR on competitiveness. Corp. Soc. Responsib. Environ. Manag. 2017, 24, 159–171. [Google Scholar] [CrossRef]

- Vilanova, M.; Lozano, J.M.; Arenas, D. Exploring the nature of the relationship between CSR and competitiveness. J. Bus. Ethics 2009, 87, 57–69. [Google Scholar] [CrossRef]

- Zhang, H.; Gupta, S.; Sun, W.; Zou, Y. How social-media-enabled co-creation between customers and the firm drives business value? The perspective of organizational learning and social Capital. Inf. Manag. 2020, 57, 103200. [Google Scholar] [CrossRef]

- Yang, J.; Basile, K. Communicating corporate social responsibility: External stakeholder involvement, productivity and firm performance. J. Bus. Ethics 2022, 178, 501–517. [Google Scholar] [CrossRef]

- Fey, C.F.; Birkinshaw, J. External sources of knowledge, governance mode, and R&D performance. J. Manag. 2005, 31, 597–621. [Google Scholar] [CrossRef]

- Costa, C.; Lages, L.F.; Hortinha, P. The bright and dark side of CSR in export markets: Its impact on innovation and performance. Int. Bus. Rev. 2015, 24, 749–757. [Google Scholar] [CrossRef]

- Pomering, A.; Dolnicar, S. Assessing the prerequisite of successful CSR implementation: Are consumers aware of CSR initiatives? J. Bus. Ethics 2009, 85, 285–301. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Price, J.M.; Sun, W. Doing good and doing bad: The impact of corporate social responsibility and irresponsibility on firm performance. J. Bus. Res. 2017, 80, 82–97. [Google Scholar] [CrossRef]

- Bocquet, R.; Le Bas, C.; Mothe, C.; Poussing, N. Are firms with different CSR profiles equally innovative? Empirical analysis with survey data. Eur. Manag. J. 2013, 31, 642–654. [Google Scholar] [CrossRef]

- Hur, W.-M.; Moon, T.-W.; Kim, H. When and how does customer engagement in CSR initiatives lead to greater CSR participation? The role of CSR credibility and customer–company identification. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1878–1891. [Google Scholar] [CrossRef]

- Naseem, T.; Shahzad, F.; Asim, G.A.; Rehman, I.U.; Nawaz, F. Corporate social responsibility engagement and firm performance in Asia Pacific: The role of enterprise risk management. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 501–513. [Google Scholar] [CrossRef]

- Carvalho, S.W.; Muralidharan, E.; Bapuji, H. Corporate social ‘irresponsibility’: Are consumers’ biases in attribution of blame helping companies in product–harm crises involving hybrid products? J. Bus. Ethics 2015, 130, 651–663. [Google Scholar] [CrossRef]

- Perera, L.C.R.; Chaminda, J.W.D. Corporate social responsibility and product evaluation: The moderating role of brand familiarity. Corp. Soc. Responsib. Environ. Manag. 2013, 20, 245–256. [Google Scholar] [CrossRef]

- Kemper, J.; Schilke, O.; Reimann, M.; Wang, X.; Brettel, M. Competition-motivated corporate social responsibility. J. Bus. Res. 2013, 66, 1954–1963. [Google Scholar] [CrossRef]

- Shinkle, G.A.; McCann, B.T. New product deployment: The moderating influence of economic institutional context. Strateg. Manag. J. 2014, 35, 1090–1101. [Google Scholar] [CrossRef]

- González-Ramos, M.I.; Donate, M.; Guadamillas, F. Technological posture and corporate social responsibility: Effects on innovation performance. Environ. Eng. Manag. J. 2014, 13, 2497–2505. [Google Scholar] [CrossRef]

- Kennedy, K.; Olivola, C.; Pronin, E. Do we give more of our present selves or our future selves? Psychological distance and prosocial decision making. ACR N. Am. Adv. 2009, 36, 190–194. [Google Scholar]

- Cha, M.-K.; Yi, Y.; Bagozzi, R.P. Effects of customer participation in corporate social responsibility (CSR) programs on the CSR-brand fit and brand loyalty. Cornell Hosp. Q. 2015, 57, 235–249. [Google Scholar] [CrossRef]

- Beverland, M.B.; Ewing, M.T.; Jekanyika Matanda, M. Driving-market or market-driven? A case study analysis of the new product development practices of Chinese business-to-business firms. Ind. Mark. Manag. 2006, 35, 383–393. [Google Scholar] [CrossRef]

- Pedersen, E.R.; Andersen, M. Safeguarding corporate social responsibility (CSR) in global supply chains: How codes of conduct are managed in buyer-supplier relationships. J. Public Aff. 2006, 6, 228–240. [Google Scholar] [CrossRef]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Bansal, P.; Roth, K. Why companies go green: A model of ecological responsiveness. Acad. Manag. J. 2000, 43, 717–736. [Google Scholar] [CrossRef]

- Carroll, A.B. A three-dimensional conceptual model of corporate performance. Acad. Manag. Rev. 1979, 4, 497–505. [Google Scholar] [CrossRef]

- Calderini, M.; Frischen, K.; Giuliano, A. Technology for good: The role of technology in an “everyone a changemaker” world. Soc. Innov. J. 2022, 11, 1–12. [Google Scholar]

- Hortinha, P.; Lages, C.; Lages, L.F. The trade-off between customer and technology orientations: Impact on innovation capabilities and export performance. J. Int. Mark. 2011, 19, 36–58. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, L. Comparative analysis of spatial–temporal differences in sustainable development between the Yangtze River Economic Belt and the Yellow River Economic Belt. Environ. Dev. Sustain. 2022, 4, 1–16. [Google Scholar] [CrossRef]

- Chen, T.; Lu, H.; Chen, R.; Wu, L. The impact of marketization on sustainable economic growth—Evidence from West China. Sustainability 2021, 13, 3745. [Google Scholar] [CrossRef]

- Maignan, I.; Ferrell, O.C. Corporate social responsibility and marketing: An integrative framework. J. Acad. Mark. Sci. 2004, 32, 3–19. [Google Scholar] [CrossRef]

- Turker, D. Measuring corporate social responsibility: A scale development study. J. Bus. Ethics 2009, 85, 411–427. [Google Scholar] [CrossRef]

- Lievens, A.; Moenaert, R.K. New service teams as information-processing systems: Reducing innovative uncertainty. J. Serv. Res. 2000, 3, 46–65. [Google Scholar] [CrossRef]

- Jensen, R.; Szulanski, G. Stickiness and the adaptation of organizational practices in cross-border knowledge transfers. J. Int. Bus. Stud. 2004, 35, 508–523. [Google Scholar] [CrossRef]

- Zhou, K.Z.; Gao, G.Y.; Yang, Z.; Zhou, N. Developing strategic orientation in China: Antecedents and consequences of market and innovation orientations. J. Bus. Res. 2005, 58, 1049–1058. [Google Scholar] [CrossRef]

- Nwankpa, J.K.; Roumani, Y. IT capability and digital transformation: A firm performance perspective. In Proceedings of the Thirty Seventh International Conference on Information Systems, Dublin, Ireland, 16 November 2016; pp. 1–16. [Google Scholar]

| Variables | Frequency | % |

|---|---|---|

| Firm age | ||

| Under 10 | 126 | 23 |

| 10–20 | 147 | 26.8 |

| Over 20 | 275 | 50.2 |

| Firm size | ||

| Under 500 | 213 | 38.9 |

| 500–1000 | 133 | 24.3 |

| Over 1000 | 202 | 36.9 |

| Average annual sales | ||

| Less than 5 million | 171 | 31.2 |

| 5 million-10 million | 141 | 25.7 |

| More than 10 million | 236 | 43.1 |

| Ownership type | ||

| Private enterprise | 451 | 82.3 |

| Foreign-owned enterprise | 7 | 1.3 |

| State-owned enterprise | 75 | 13.7 |

| Joint venture | 15 | 2.7 |

| Industrial category | ||

| Mechanical equipment manufacturing | 56 | 10.2 |

| Pharmaceutical manufacturing | 19 | 3.5 |

| Electronic equipment manufacturing | 50 | 9.1 |

| Commodity manufacturing | 376 | 68.6 |

| Instrument manufacturing | 4 | 0.7 |

| Others | 43 | 7.8 |

| Constructs | Indicating Items | Factor Loading | CR | AVE | Cronbach’s α |

|---|---|---|---|---|---|

| FFE customer involvement | Firm always considers product reviews from customers during FFE innovation | 0.833 | 0.879 | 0.707 | 0.891 |

| Firm always conducts pilot tryouts with select customers during FFE innovation | 0.851 | ||||

| Firm’s FFE team is cross functional with customers | 0.839 | ||||

| FFE supplier involvement | Firm always considers product reviews from suppliers during FFE innovation | 0.967 | 0.977 | 0.934 | 0.988 |

| Firm’s FFE team is cross functional with suppliers | 0.968 | ||||

| Firm always shares FFE plans with suppliers | 0.964 | ||||

| CSR | Corporate environmental responsibility | 0.810 | 0.852 | 0.658 | 0.901 |

| Corporate employee responsibility | 0.818 | ||||

| Corporate philanthropic responsibility | 0.805 | ||||

| NPD performance | Firm’s product profits have increased over the last two years | 0.821 | 0.794 | 0.658 | 0.914 |

| Firm’s product market share has increased over the last two years | 0.801 | ||||

| Environmental uncertainties | Competitor uncertainty | 0.839 | 0.918 | 0.738 | 0.923 |

| Industrial policy uncertainty | 0.868 | ||||

| Market demand uncertainty | 0.866 | ||||

| Industrial technology uncertainty | 0.862 |

| Variables | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| 1. FFE customer involvement | 1 | ||||

| 2. FFE supplier involvement | 0.227 ** | 1 | |||

| 3. CSR engagement | 0.573 ** | 0.246 ** | 1 | ||

| 4. NPD performance | 0.508 ** | 0.314 ** | 0.743 ** | 1 | |

| 5. Environmental uncertainties | 0.377 ** | 0.310 ** | 0.453 ** | 0.468 ** | 1 |

| Mean | 3.844 | 3.420 | 3.748 | 3.519 | 3.472 |

| SD | 0.733 | 1.647 | 0.692 | 0.803 | 0.831 |

| Category | χ2 | χ2/df | CFI | GFI | NFI | IFI | RMSEA |

|---|---|---|---|---|---|---|---|

| Values | 63.401 | 1.668 | 0.996 | 0.980 | 0.990 | 0.996 | 0.035 |

| Recommended values | >0 | <3 | >0.9 | >0.9 | >0.9 | >0.9 | <0.06 |

| Hypotheses | Path Coefficient | C.R. | S.E. |

|---|---|---|---|

| Hypothesis 1a | 0.033 | 0.604 | 0.054 |

| Hypothesis 1b | 0.044 ** | 2.947 | 0.15 |

| Hypothesis 2a | 0.605 *** | 13.889 | 0.044 |

| Hypothesis 2b | 0.043 ** | 2.877 | 0.015 |

| Hypothesis 3 | 0.852 *** | 14.741 | 0.058 |

| Variables | Point Estimate | Bias-Corrected 95% CI | Percentile 95% CI | ||

|---|---|---|---|---|---|

| Lower | Upper | Lower | Upper | ||

| Total Effects | |||||

| FFE customer involvement–CSR–NPD | 0.600 | 0.463 | 0.730 | 0.464 | 0.735 |

| FFE supplier involvement–CSR–NPD | 0.096 | 0.053 | 0.153 | 0.051 | 0.142 |

| Indirect Effects | |||||

| FFE customer involvement–CSR–NPD | 0.539 | 0.425 | 0.678 | 0.421 | 0.673 |

| FFE supplier involvement–CSR–NPD | 0.040 | 0.009 | 0.079 | 0.010 | 0.081 |

| Direct Effects | |||||

| FFE customer involvement–CSR–NPD | 0.060 | −0.057 | 0.185 | −0.062 | 0.182 |

| FFE supplier involvement–CSR–NPD | 0.057 | 0.013 | 0.106 | 0.011 | 0.106 |

| Moderating Effects | Path Coefficient | C.R. | S.E. |

|---|---|---|---|

| CSR’s moderating effect on hypothesis 1a | 0.231 | 3.897 | 0.032 |

| CSR’s moderating effect on hypothesis 1b | 0.127 | 1.982 | 0.074 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Hu, H.; Wang, Y. Fuzzy Front-End Vertical External Involvement, Corporate Social Responsibility and Firms’ New Product Development Performance in the VUCA Age: From an Organizational Learning Perspective. Sustainability 2023, 15, 280. https://doi.org/10.3390/su15010280

Huang J, Hu H, Wang Y. Fuzzy Front-End Vertical External Involvement, Corporate Social Responsibility and Firms’ New Product Development Performance in the VUCA Age: From an Organizational Learning Perspective. Sustainability. 2023; 15(1):280. https://doi.org/10.3390/su15010280

Chicago/Turabian StyleHuang, Jiaxu, Haiqing Hu, and Yong Wang. 2023. "Fuzzy Front-End Vertical External Involvement, Corporate Social Responsibility and Firms’ New Product Development Performance in the VUCA Age: From an Organizational Learning Perspective" Sustainability 15, no. 1: 280. https://doi.org/10.3390/su15010280

APA StyleHuang, J., Hu, H., & Wang, Y. (2023). Fuzzy Front-End Vertical External Involvement, Corporate Social Responsibility and Firms’ New Product Development Performance in the VUCA Age: From an Organizational Learning Perspective. Sustainability, 15(1), 280. https://doi.org/10.3390/su15010280