The Coupled Thermal-Structural Resonance Reliability Sensitivity Analysis of Gear-Rotor System with Random Parameters

Abstract

1. Introduction

2. Thermal Theories and Numerical Simulation

2.1. Frictional Heat Generation

2.1.1. Average Contact Pressure

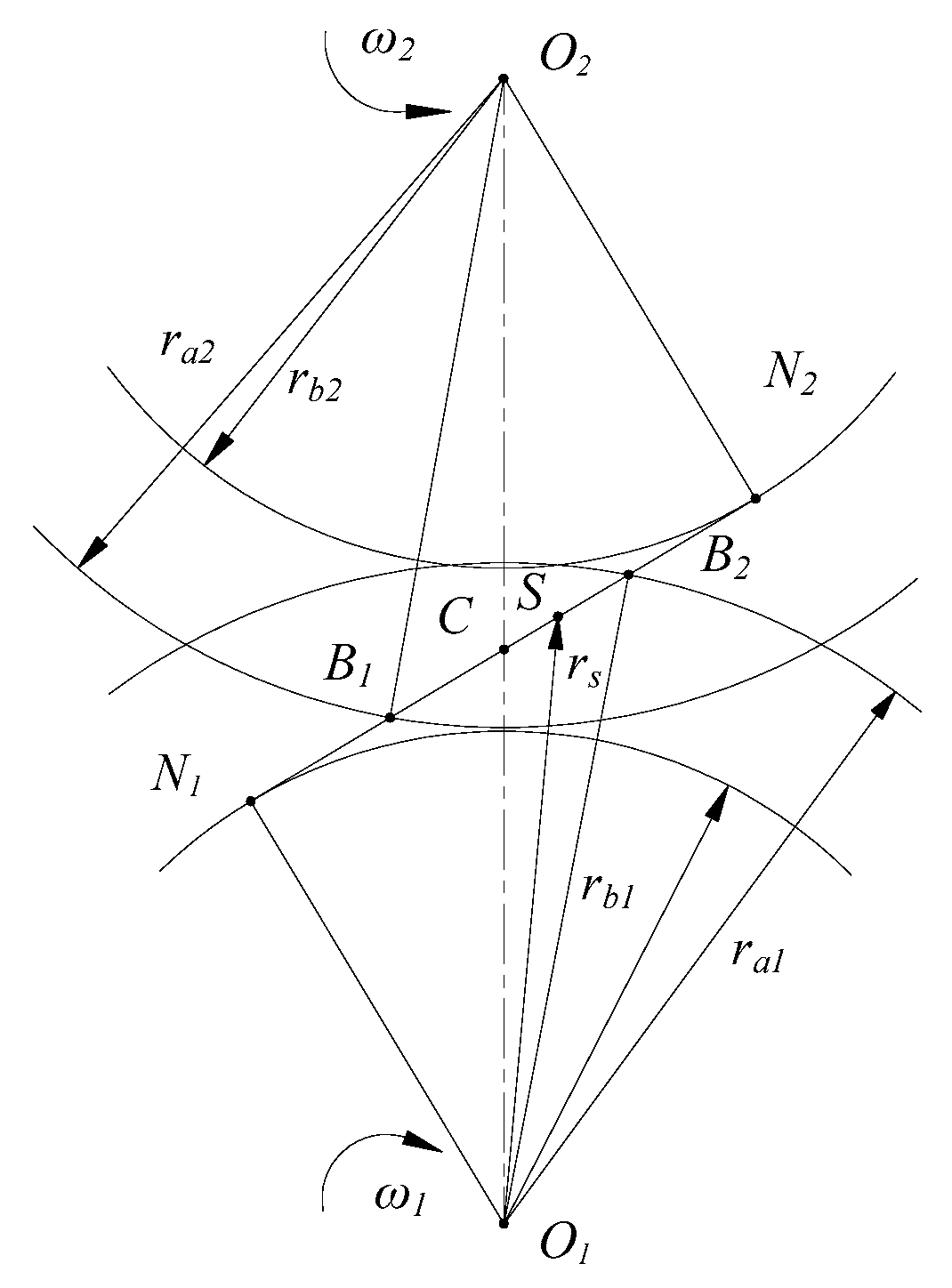

2.1.2. Relative Sliding Velocity

2.1.3. The Average Heat Generation on Meshing Surface

2.2. Convection Heat Transfer Coefficient

2.2.1. Meshing Surface Heat Transfer Coefficient

2.2.2. Convective Heat Transfer on Gear Flank

2.2.3. Heat Transfer Coefficient of the Root Surface, the Top Surface and the Non-Meshing Surface

2.2.4. Transmission Shaft Convection Heat Transfer Coefficient

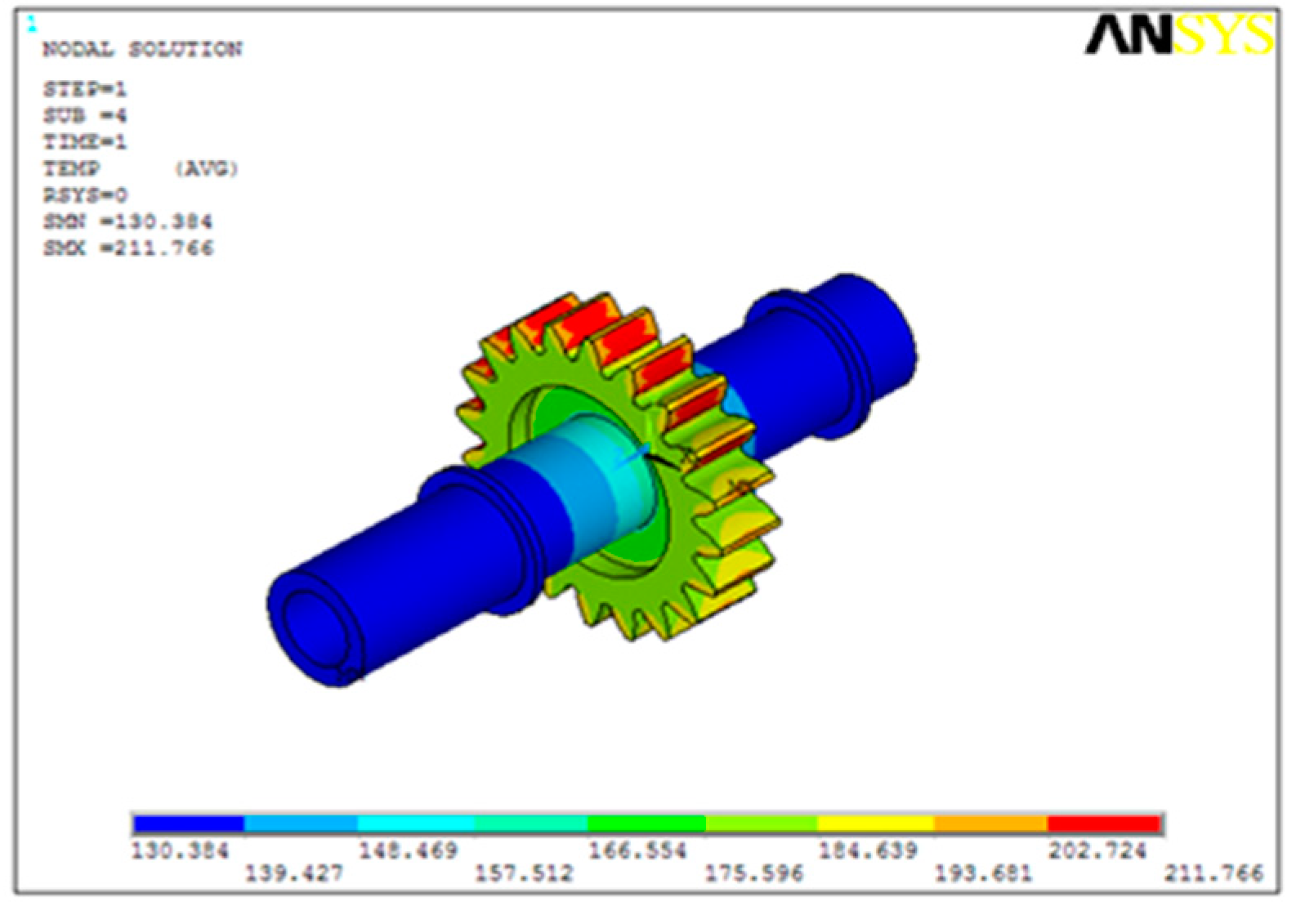

2.3. Finite Element Model and Numerical Simulation

2.3.1. Thermal Conduction Differential Equation

2.3.2. The Gear Boundary Conditions

3. The Proposed Reliability Analysis Method

3.1. Sparse Polynomial Chaos-Kriging (PC-Kriging)

3.2. The Adaptive DoE Strategy (Isomap-Clustering Strategy)

3.2.1. Dimensionality Reduction of with Isomap

3.2.2. k-Means Clustering Analysis

3.3. The Convergence Conditions of the Proposed Method

4. Application of the Proposed Method in Thermal Resonance Analysis

4.1. Natural Frequency of Gear Rotor Considering Temperature

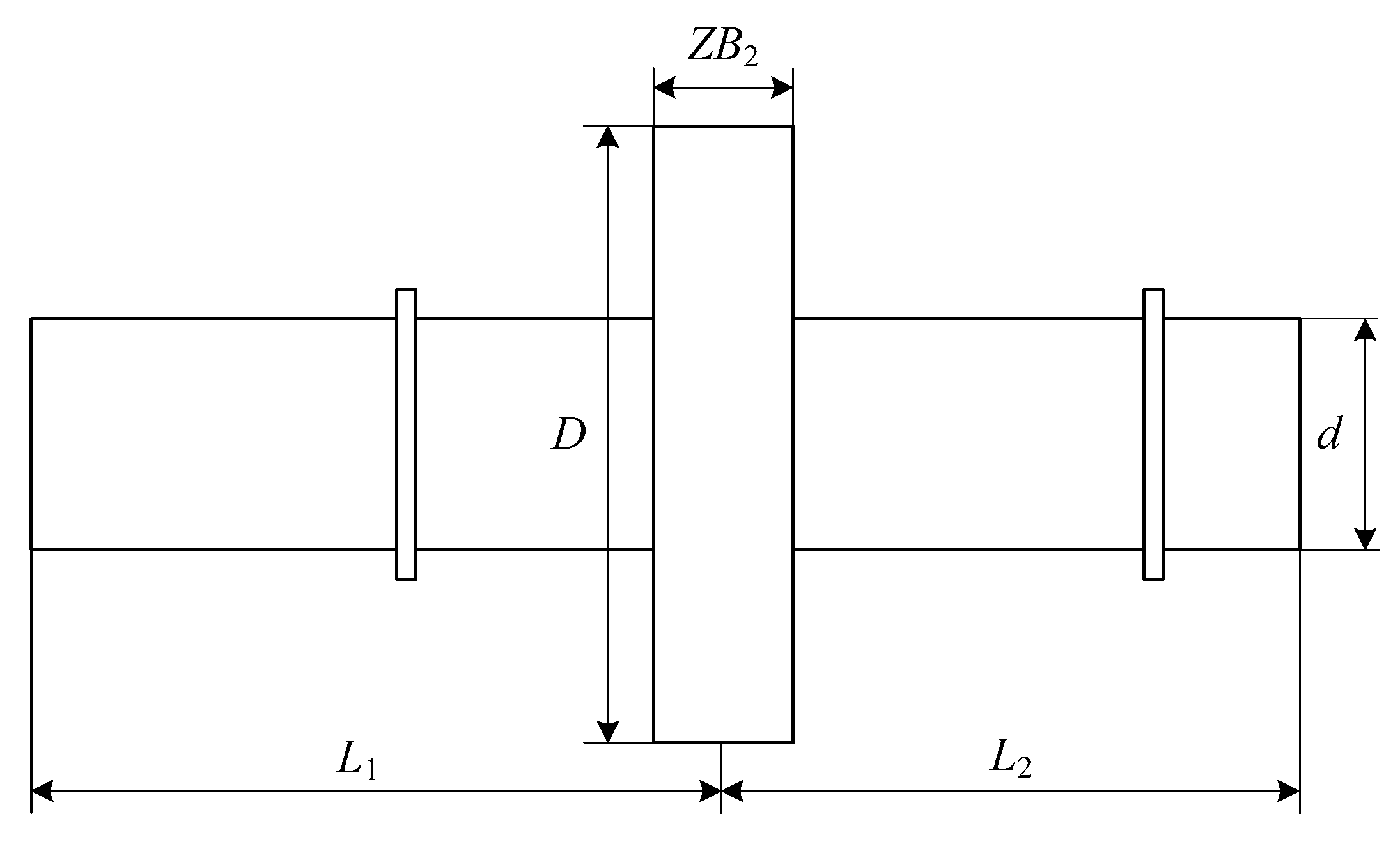

4.2. Resonance Failure Analysis of Gear-Rotor

4.3. Resonance Reliability Analysis of Gear Rotor

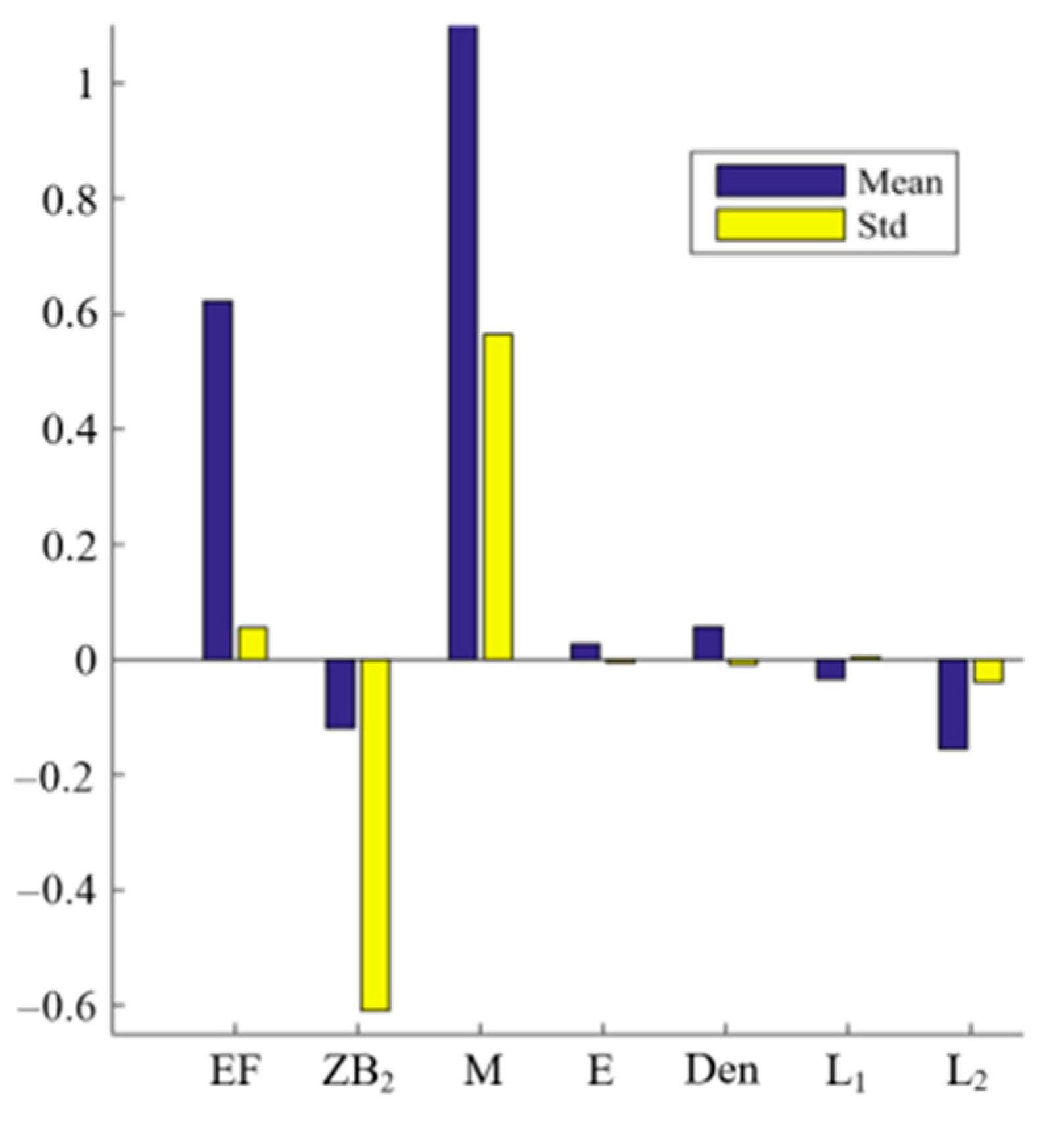

4.4. Resonance Reliability Sensitivity Analysis of Gear Rotor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, W.; Zhai, P.; Tian, J.; Luo, B. Thermal analysis of helical gear transmission system considering machining and installation error. Int. J. Mech. Sci. 2018, 149, 1–17. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, J.; Ma, Y. Resonance Reliability Sensitivity Analysis for Torsional Vibration of Gear-Rotor Systems with Random Parameters. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; Volume 14, pp. 121–131. [Google Scholar]

- Su, C.; Guo, F.; Shi, Q.; Zhang, Y. Reliability sensitivity estimation of rotor system with oil whip and resonance. Adv. Mech. Eng. 2017, 9, 168–180. [Google Scholar] [CrossRef]

- Zhou, J.; Zhu, S.; Qiu, Y.; Armaghani, D.J.; Zhou, A.; Yong, W. Predicting tunnel squeezing using support vector machine optimized by whale optimization algorithm. Acta Geotech. 2022, 17, 1343–1366. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Z. A Hybrid Model for Water Quality Prediction Based on an Artificial Neural Network, Wavelet Transform, and Long Short-Term Memory. Water 2022, 14, 610. [Google Scholar] [CrossRef]

- Liu, J.; Huang, Q.; Ulishney, C.; Dumitrescu, C.E. Comparison of Random Forest and Neural Network in Modeling the Performance and Emissions of a Natural Gas Spark Ignition Engine. J. Energy Resour. Technol. 2022, 144, 032310. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Gu, Y.; Lin, H.; Jie, B.; Zhang, Q.; Zhang, X. Adsorption property of fluoride in water by metal organic framework: Optimization of the process by response surface methodology technique. Surf. Interfaces 2022, 28, 101649. [Google Scholar] [CrossRef]

- Saeed, A.A.H.; Harun, N.Y.; Nasef, M.M.; Al-Fakih, A.; Ghaleb, A.A.S.; Afolabi, H.K. Removal of cadmium from aqueous solution by optimized rice husk biochar using response surface methodology. Ain Shams Eng. J. 2022, 13, 101516. [Google Scholar] [CrossRef]

- Wang, Z.; Shafieezadeh, A. Metamodel-based subset simulation adaptable to target computational capacities: The case for high-dimensional and rare event reliability analysis. Struct. Multidiscip. Optim. 2021, 64, 649–675. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.; Shafieezadeh, A. Value of Information Analysis via Active Learning and Knowledge Sharing in Error-Controlled Adaptive Kriging. IEEE Access 2020, 99, 51021–51034. [Google Scholar] [CrossRef]

- Song, C.; Wang, Z.; Shafieezadeh, A.; Xiao, R. BUAK-AIS: Efficient Bayesian Updating with Active learning Kriging-based Adaptive Importance Sampling. Comput. Methods Appl. Mech. Eng. 2022, 391, 114578. [Google Scholar] [CrossRef]

- Xiao, X.; Li, Q.; Wang, Z. A novel adaptive importance sampling algorithm for Bayesian model updating. Struct. Saf. 2022, 97, 102230. [Google Scholar] [CrossRef]

- Wang, Z.; Shafieezadeh, A.; Xiao, X.; Wang, X.; Li, Q. Optimal monitoring location for tracking evolving risks to infrastructure systems: Theory and application to tunneling excavation risk. Reliab. Eng. Syst. Saf. 2022, 228, 108781. [Google Scholar] [CrossRef]

- Zhang, H.; Song, L.K.; Bai, G.C.; Li, X.Q. Active extremum Kriging-based multi-level linkage reliability analysis and its application in aeroengine mechanism systems. Aerosp. Sci. Technol. 2022, 131, 107968. [Google Scholar] [CrossRef]

- Li, X.Q.; Song, L.K.; Bai, G.C. Vectorial surrogate modeling approach for multi-failure correlated probabilistic evaluation of turbine rotor. Eng. Comput. 2021, 12, 1–20. [Google Scholar] [CrossRef]

- Li, X.Q.; Song, L.K.; Bai, G.C. Recent advances in reliability analysis of aeroengine rotor system: A review. Int. J. Struct. Integrity. 2022, 13, 1–29. [Google Scholar] [CrossRef]

- Bucher, C.; Most, T. A comparison of approximate response functions in structural reliability analysis. Probabilistic Eng. Mech. 2008, 23, 154–163. [Google Scholar] [CrossRef]

- Schoebi, R.; Sudret, B.; Wiart, J. Polynomial-Chaos-Based Kriging. Int. J. Uncertain. Quantif. 2015, 5, 171–193. [Google Scholar] [CrossRef]

- Handschuh, R.F. Thermal Behavior of Spiral Bevel Gears. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 1993. [Google Scholar]

- Shi, Y.; Yao, Y.-P.; Fei, J.-Y. Analysis of bulk temperature field and flash temperature for locomotive traction gear. Appl. Therm. Eng. 2016, 99, 528–536. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, W.; Chen, Y.; Wang, T.; Li, G.; Ball, A.D. Investigation into the meshing friction heat generation and transient thermal characteristics of spiral bevel gears. Appl. Therm. Eng. 2017, 119, 245–253. [Google Scholar] [CrossRef]

- Dewinter, A.; Blok, H. Fling-Off Cooling of Gear Teeth. J. Eng. Ind. 1974, 96, 60–72. [Google Scholar] [CrossRef]

- Long, H.; Lord, A.A.; Gethin, D.T.; Roylance, B.J. Operating temperatures of oil-lubricated medium-speed gears: Numerical models and experimental results. Proc. Inst. Mech. Eng. Part Gs J. Aerosp. Eng. 2003, 217, 87–106. [Google Scholar] [CrossRef]

- Van Heijningen, G.J.J.; Blok, H. Continuous as Against Intermittent Fling-Off Cooling of Gear Teeth. J. Lubr. Technol. 1974, 96, 529–538. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Prediction of the Bulk Temperature in Spur Gears Based on Finite Element Temperature Analysis. ASLE Trans. 1979, 22, 25–36. [Google Scholar] [CrossRef]

- Hartnett, J.P.; Deland, E.C. The Influence of Prandtl Number on the Heat Transfer from Rotating Nonisothermal Disks and Cones. J. Heat Transf. 1961, 83, 95–96. [Google Scholar] [CrossRef]

- Popiel, C.; Bogusławski, L. Local heat-transfer coefficients on the rotating disk in still air. Int. J. Heat Mass Transf. 1975, 18, 167–170. [Google Scholar] [CrossRef]

- Dorfman, L.A.; Kemmer, N. Hydrodynamic Resistance and the Heat Loss of Rotating Solids; Oliver & Boyd: Edinburgh, UK, 1963. [Google Scholar]

- Fernandes, C.M.; Rocha, D.M.; Martins, R.C.; Magalhães, L.; Seabra, J.H. Finite element method model to predict bulk and flash temperatures on polymer gears. Tribol. Int. 2018, 120, 255–268. [Google Scholar] [CrossRef]

- Anderson, J.T.; Saunders, O.A. Convection from an isolated heated horizontal cylinder rotating about its axis. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1953, 217, 555–562. [Google Scholar]

- Becker, K.M. Measurements of convective heat transfer from a horizontal cylinder rotating in a tank of water. Int. J. Heat Mass Transf. 1963, 6, 1053–1062. [Google Scholar] [CrossRef]

- Seghir-Ouali, S.; Saury, D.; Harmand, S.; Phillipart, O.; Laloy, D. Convective heat transfer inside a rotating cylinder with an axial air flow. Int. J. Therm. Sci. 2006, 45, 1166–1178. [Google Scholar] [CrossRef]

- Luo, B.; Li, W. Influence factors on bulk temperature field of gear. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 953–964. [Google Scholar] [CrossRef]

- Efron, B.; Hastie, T.; Johnstone, I.; Tibshirani, R. Least angle regression. Ann. Stat. 2004, 32, 407–499. [Google Scholar] [CrossRef]

- Arnold, T.W. Uninformative Parameters and Model Selection Using Akaike’s Information Criterion. J. Wildl. Manag. 2011, 74, 1175–1178. [Google Scholar] [CrossRef]

- Tenebaum, J.B. A global geometric framework for nonlinear dimensionality reduction. Science 2000, 290, 2319–2323. [Google Scholar] [CrossRef] [PubMed]

- Macqueen, J. Some Methods for Classification and Analysis of MultiVariate Observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability, Berkeley, CA, USA, 21 June–18 July 1965 and 27 December 1965–7 January 1966. [Google Scholar]

- Saxena, A.; Chouksey, M.; Parey, A. Measurement of FRFs of coupled geared rotor system and the development of an accurate finite element model. Mech. Mach. Theory 2018, 123, 66–75. [Google Scholar] [CrossRef]

- Concli, F.; Cortese, L.; Vidoni, R.; Nalli, F.; Carabin, G. A mixed FEM and lumped-parameter dynamic model for evaluating the modal properties of planetary gearboxes. J. Mech. Sci. Technol. 2018, 32, 3047–3056. [Google Scholar] [CrossRef]

| Basic Parameters | Driving Gears | Driven Gears |

|---|---|---|

| Module | 3 | 3 |

| Number of teeth | 34 | 20 |

| pressure angle (°) | 25 | 25 |

| Face width (mm) | 15 | 14.5 |

| Addendum coefficient | 1 | 1 |

| Coefficient of clearance | 0.25 | 0.25 |

| Modification coefficient | 0 | 0 |

| Radius of gear spoke (mm) | 40 | 20 |

| Gear spoke width (mm) | 6 | 5 |

| Order i | ||||

|---|---|---|---|---|

| 1 | 4263 | 4181 | −82 | −1.92% |

| 2 | 5722 | 5665 | −57 | −1.00% |

| 3 | 5722 | 5665 | −57 | −1.00% |

| 4 | 6182 | 6123 | −59 | −0.95% |

| 5 | 6184 | 6125 | −59 | −0.95% |

| 6 | 8357 | 8333 | −24 | −0.29% |

| EF (Hz) | ZB2 (mm) | M (mm) | E (MPa) | Den (kg/m3) | L1 (mm) | L2 (mm) | |

|---|---|---|---|---|---|---|---|

| Means | 4533.33 | 14.5 | 3 | 2.1 × 105 | 7860 | 14 | 40 |

| Std | 45.3 | 0.29 | 0.0375 | 6.3 × 103 | 78.6 | 0.7 | 2 |

| Parameter | EF | ZB2 | M | E | Den | L1 | L2 |

|---|---|---|---|---|---|---|---|

| Mean | 0.6224 | −0.1189 | 1.1297 | 0.0276 | 0.0570 | −0.0335 | −0.1553 |

| Std | 0.0554 | −0.6090 | 0.5645 | −0.0047 | −0.0081 | 0.0049 | −0.0389 |

| Factor | 0.2241 | 0.2226 | 0.4530 | 0.0100 | 0.0207 | 0.0121 | 0.0574 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Sun, Z.; Zhang, S.; Wang, J. The Coupled Thermal-Structural Resonance Reliability Sensitivity Analysis of Gear-Rotor System with Random Parameters. Sustainability 2023, 15, 255. https://doi.org/10.3390/su15010255

Yu Z, Sun Z, Zhang S, Wang J. The Coupled Thermal-Structural Resonance Reliability Sensitivity Analysis of Gear-Rotor System with Random Parameters. Sustainability. 2023; 15(1):255. https://doi.org/10.3390/su15010255

Chicago/Turabian StyleYu, Zhenliang, Zhili Sun, Shengnan Zhang, and Jian Wang. 2023. "The Coupled Thermal-Structural Resonance Reliability Sensitivity Analysis of Gear-Rotor System with Random Parameters" Sustainability 15, no. 1: 255. https://doi.org/10.3390/su15010255

APA StyleYu, Z., Sun, Z., Zhang, S., & Wang, J. (2023). The Coupled Thermal-Structural Resonance Reliability Sensitivity Analysis of Gear-Rotor System with Random Parameters. Sustainability, 15(1), 255. https://doi.org/10.3390/su15010255