An Improved Emergy Analysis of the Environmental and Economic Benefits of Reclaimed Water Reuse System

Abstract

:1. Introduction

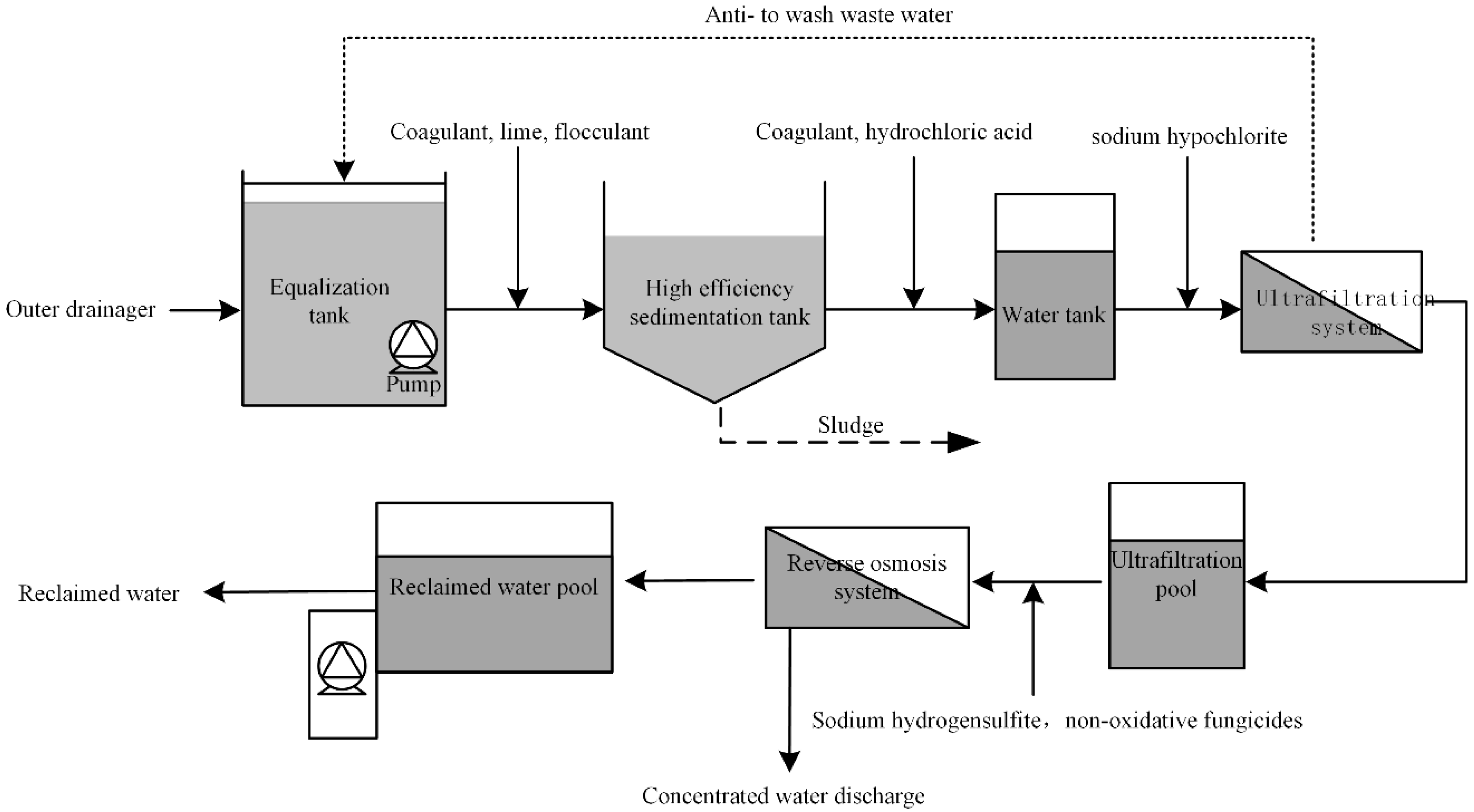

2. Study Site

3. Methods

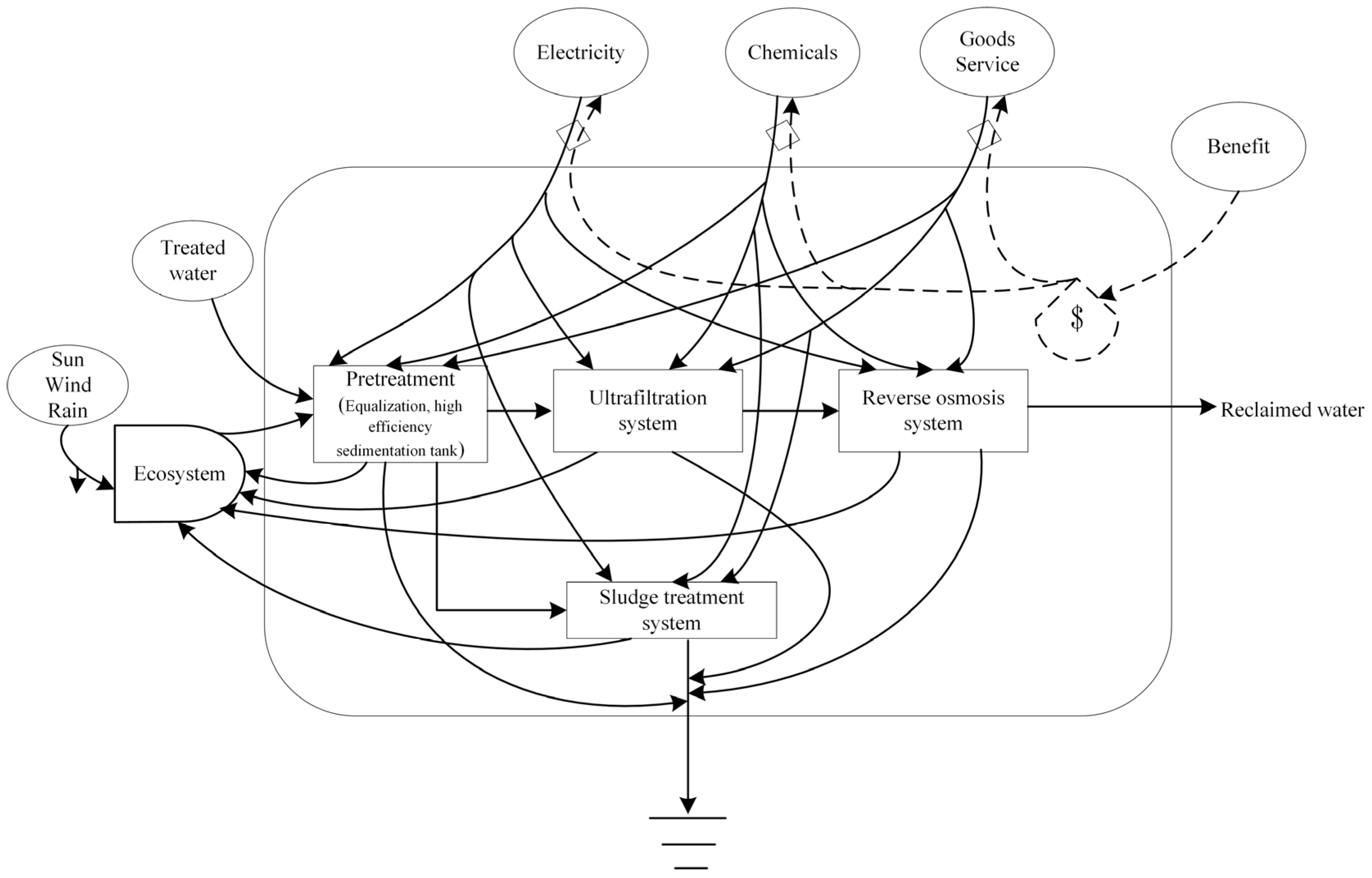

3.1. Emergy Analysis

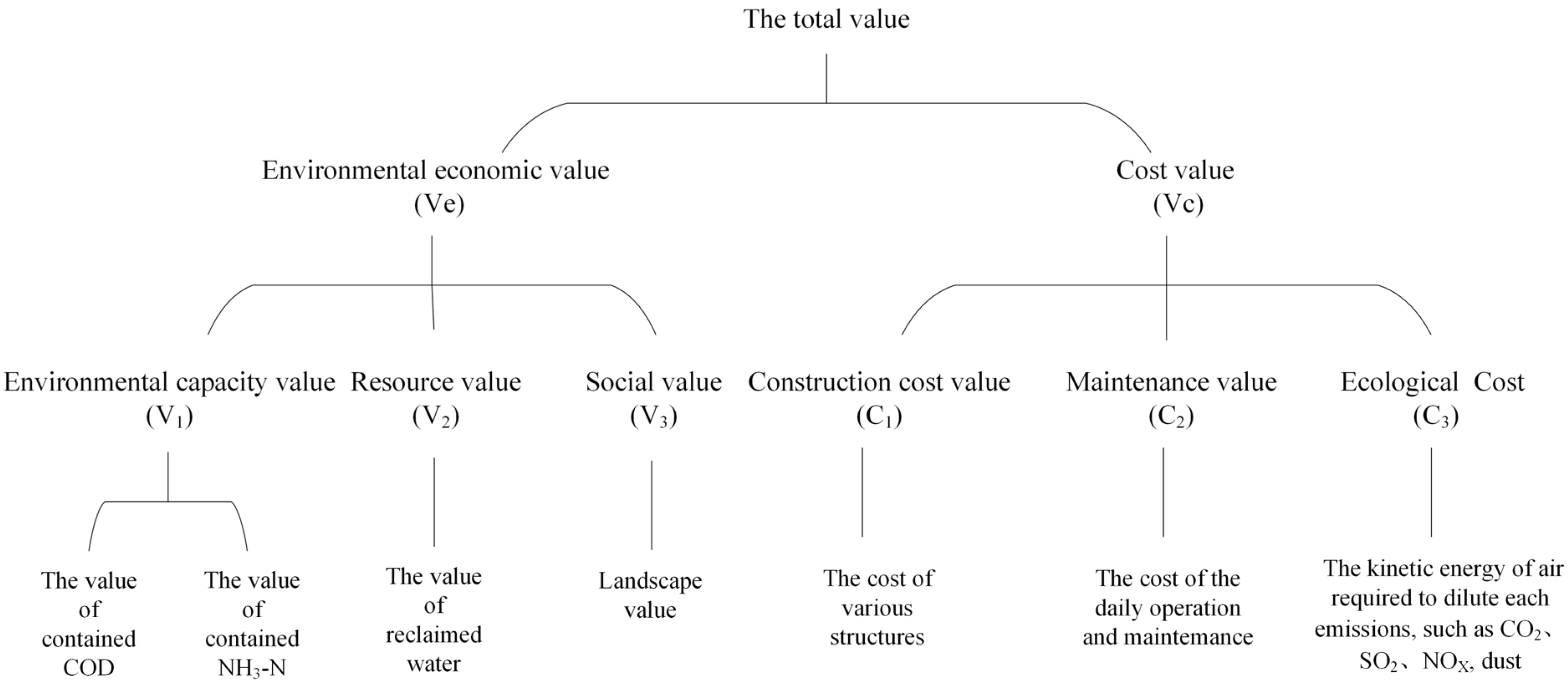

3.2. Improving the Assessment of Environmental Economic Value

4. Results and Discussion

4.1. Air Emission Impacts

4.2. The Emergy Flow of Plant A

4.3. The Environmental Performance of the Plant A

4.4. The Ve of Plant A

5. The Application Prospect of Reclaimed Water Reuse System in China

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Name | Accepted Concentrations | References |

|---|---|---|

| CO2 | 2000 mg/m3 | Indoor air quality standard (GB/T 18883-2002) |

| SO2 | 0.02 mg/m3 | Ambient air quality standards (GB 3095-2012) |

| NOX | 0.04 mg/m3 | Ambient air quality standards (GB 3095-2012) |

| dust | 0.08 mg/m3 | Ambient air quality standards (GB 3095-2012) |

References

- Hartley, K.; Tortajada, C.; Biswas, A.K. A formal model concerning policy strategies to build public acceptance of potable water reuse. J. Environ. Manag. 2019, 250, 109505. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Lv, X.-T.; Wu, Q.-Y.; Zhang, D.-Y.; Zhou, Y.-T.; Peng, L.; Hu, H.-Y. Formation and control of disinfection byproducts and toxicity during reclaimed water chlorination: A review. J. Environ. Sci. 2017, 58, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Salgot, M.; Folch, M. Wastewater treatment and water reuse. Curr. Opin. Environ. Sci. Health 2018, 2, 64–74. [Google Scholar] [CrossRef]

- Racar, M.; Dolar, D.; Farkas, M.; Milcic, N.; Spehar, A.; Kosutic, K. Rendering plant wastewater reclamation by coagulation, sand filtration, and ultrafiltration. Chemosphere 2019, 227, 207–215. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, W.; Jiang, X.; Lu, D.; Zhang, Y.; Li, J. Analysis of the potential of reclaimed water utilization in typical inland cities in northwest China via system dynamics. J. Environ. Manag. 2020, 270, 110878. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Ngo, H.H.; Guo, W. A Critical Review on the End Uses of Recycled Water. Crit. Rev. Environ. Sci. Technol. 2013, 43, 1446–1516. [Google Scholar] [CrossRef]

- Lee, K.; Jepson, W. Drivers and barriers to urban water reuse: A systematic review. Water Secur. 2020, 11, 100073. [Google Scholar] [CrossRef]

- Lyu, S.; Chen, W.; Zhang, W.; Fan, Y.; Jiao, W. Wastewater reclamation and reuse in China: Opportunities and challenges. J. Environ. Sci. 2016, 39, 86–96. [Google Scholar] [CrossRef]

- Cherchi, C.; Kesaano, M.; Badruzzaman, M.; Schwab, K.; Jacangelo, J.G. Municipal reclaimed water for multi-purpose applications in the power sector: A review. J. Environ. Manag. 2019, 236, 561–570. [Google Scholar] [CrossRef]

- Barker, Z.A.; Stillwell, A.S. Implications of Transitioning from De Facto to Engineered Water Reuse for Power Plant Cooling. Environ. Sci. Technol. 2016, 50, 5379–5388. [Google Scholar] [CrossRef]

- Kong, L.; Lau, K.K.-L.; Yuan, C.; Chen, Y.; Xu, Y.; Ren, C.; Ng, E.Y.Y. Regulation of outdoor thermal comfort by trees in Hong Kong. Sustain. Cities Soc. 2017, 31, 12–25. [Google Scholar] [CrossRef]

- Sun, S.; Xu, X.; Lao, Z.; Liu, W.; Li, Z.; Garcia, E.H.; He, L.; Zhu, J. Evaluating the impact of urban green space and landscape design parameters on thermal comfort in hot summer by numerical simulation. Build. Environ. 2017, 123, 277–288. [Google Scholar] [CrossRef]

- Pepper, I.L.; Gerba, C.P. Risk of infection from Legionella associated with spray irrigation of reclaimed water. Water Res. 2018, 139, 101–107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, W.-H.; Wang, Y.; Li, Z.; Wei, C.-Z.; Zhao, J.-C.; Sun, L.-Q. Effect of a strengthened ecological floating bed on the purification of urban landscape water supplied with reclaimed water. Sci. Total Environ. 2018, 622–623, 1630–1639. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Liu, S.; Smith, K.; Cui, Y.; Wang, Z. An overview on corrosion of iron and steel components in reclaimed water supply systems and the mechanisms involved. J. Clean. Prod. 2020, 276, 124079. [Google Scholar] [CrossRef]

- Gerrity, D.; Pecson, B.; Trussel, R.S.; Trussel, R.R. Potable reuse treatment trains throughout the world. J. Water Supply Res. Technol.—AQUA 2013, 62, 321–338. [Google Scholar] [CrossRef]

- Yuan, J.; Van Dyke, M.I.; Huck, P.M. Selection and evaluation of water pretreatment technologies for managed aquifer recharge (MAR) with reclaimed water. Chemosphere 2019, 236, 124886. [Google Scholar] [CrossRef]

- Szczuka, A. Emerging Technology Integration for Improving Water Reuse Treatment; Stanford University: Stanford, CA, USA, 2020. [Google Scholar]

- Adin, A. Slow granular filtration for water reuse. Water Sci. Technol. Water Supply 2003, 3, 123–130. [Google Scholar] [CrossRef]

- Sun, Y.; Angelotti, B.; Brooks, M.; Dowbiggin, B.; Evans, P.J.; Devins, B.; Wang, Z.-W. A pilot-scale investigation of disinfection by-product precursors and trace organic removal mechanisms in ozone-biologically activated carbon treatment for potable reuse. Chemosphere 2018, 210, 539–549. [Google Scholar] [CrossRef]

- Alturki, A.A.; Tadkaew, N.; McDonald, J.A.; Khan, S.; Price, W.E.; Nghiem, L.D. Combining MBR and NF/RO membrane filtration for the removal of trace organics in indirect potable water reuse applications. J. Membr. Sci. 2010, 365, 206–215. [Google Scholar] [CrossRef]

- Fujioka, T.; Khan, S.J.; McDonald, J.A.; Roux, A.; Poussade, Y.; Drewes, J.E.; Nghiem, L.D. N-nitrosamine rejection by reverse osmosis membranes: A full-scale study. Water Res. 2013, 47, 6141–6148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krzeminski, P.; Schwermer, C.; Wennberg, A.; Langford, K.; Vogelsang, C. Occurrence of UV filters, fragrances and organophosphate flame retardants in municipal WWTP effluents and their removal during membrane post-treatment. J. Hazard. Mater. 2017, 323, 166–176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoinkis, J.; Deowan, S.A.; Panten, V.; Figoli, A.; Huang, R.R.; Drioli, E. Membrane Bioreactor (MBR) Technology–a Promising Approach for Industrial Water Reuse. Procedia Eng. 2012, 33, 234–241. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.M.; Hu, Y.Y.; Ge, J.; Sun, J.; Wang, H.; Li, X. Advanced treatment of municipal reclaimed water for industrial water use in thermal power plant by multi-media filtration-activated carbon-membrane bioreactor combined technology. Technol. Water Treat. 2015, 41, 68–70+75. (In Chinese) [Google Scholar]

- Myoda, S.P. Treatment of Wastewaters for Water Reuse by a Catalytic Sonochemical Process; University of Delaware: Newark, DE, USA, 2002. [Google Scholar]

- Qiu, F.G. A Study on the Theory and Method of Health Risk Assessment for Wastewater Reclamation and Reuse. Ph.D. Thesis, Xi’an University of Architecture & Technology, Xi’an, China, 2004. [Google Scholar]

- Puckorius, P.; Kister, H.; Civan, F. Consider Recycled Water for Your Cooling Tower Makeup; CEP: New York, NY, USA, 2013. [Google Scholar]

- Walker, M.E.; Theregowda, R.B.; Safari, I.; Abbasian, J.; Arastoopour, H.; Dzombak, D.A.; Hsieh, M.-K.; Miller, D.C. Utilization of municipal wastewater for cooling in thermoelectric power plants: Evaluation of the combined cost of makeup water treatment and increased condenser fouling. Energy 2013, 60, 139–147. [Google Scholar] [CrossRef]

- Mu, H.; Feng, X.; Chu, K.H. Improved emergy indices for the evaluation of industrial systems incorporating waste management. Ecol. Eng. 2011, 37, 335–342. [Google Scholar] [CrossRef]

- Arden, S.; Ma, X. (Cissy); Brown, M. Holistic analysis of urban water systems in the Greater Cincinnati region: (2) resource use profiles by emergy accounting approach. Water Res. X 2019, 2, 100012. [Google Scholar] [CrossRef]

- Fang, D.; Chen, S.; Chen, B. Emergy analysis for the upper Mekong river intercepted by the Manwan hydropower construction. Renew. Sustain. Energy Rev. 2015, 51, 899–909. [Google Scholar] [CrossRef]

- Li, C.; Gillum, C.; Toupin, K.; Park, Y.H.; Donaldson, B. Environmental performance assessment of utility boiler energy conversion systems. Energy Convers. Manag. 2016, 120, 135–143. [Google Scholar] [CrossRef]

- Lee, J.M.; Braham, W. Right-Sizing Cities for Maximum Power: Urban Form Parameters for New York City and the Greater Philadelphia Region. Sustainability 2019, 11, 2352. [Google Scholar] [CrossRef] [Green Version]

- Zhong, S.; Geng, Y.; Qian, Y.; Chen, W.; Pan, H. Analyzing ecosystem services of freshwater lakes and their driving forces: The case of Erhai Lake, China. Environ. Sci. Pollut. Res. 2019, 26, 10219–10229. [Google Scholar] [CrossRef] [PubMed]

- Yazdani, S.; Salimipour, E.; Moghaddam, M.S. A comparison between a natural gas power plant and a municipal solid waste incineration power plant based on an emergy analysis. J. Clean. Prod. 2020, 274, 123158. [Google Scholar] [CrossRef] [PubMed]

- Zhan, C.; Zhao, R.; Hu, S. Emergy-based sustainability assessment of forest ecosystem with the aid of mountain eco-hydrological model in Huanjiang County, China. J. Clean. Prod. 2019, 251, 119638. [Google Scholar] [CrossRef]

- Yang, L.; Kong, F.-L.; Xi, M.; Li, Y.; Wang, S. Environmental economic value calculation and sustainability assessment for constructed rapid infiltration system based on emergy analysis. J. Clean. Prod. 2017, 167, 582–588. [Google Scholar] [CrossRef]

- Li, D.; Wang, R. Hybrid Emergy-LCA (HEML) based metabolic evaluation of urban residential areas: The case of Beijing, China. Ecol. Complex. 2009, 6, 484–493. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, S.; Wu, J.; Jiang, W. A sustainability analysis of a municipal sewage treatment ecosystem based on emergy. Ecol. Eng. 2010, 36, 685–696. [Google Scholar] [CrossRef]

- Song, Q.; Wang, Z.; Li, J. Sustainability evaluation of e-waste treatment based on emergy analysis and the LCA method: A case study of a trial project in Macau. Ecol. Indic. 2013, 30, 138–147. [Google Scholar] [CrossRef]

- Bastianoni, S.; Facchini, A.; Susani, L.; Tiezzi, E. Emergy as a function of exergy. Energy 2007, 32, 1158–1162. [Google Scholar] [CrossRef]

- Winfrey, B.K.; Tilley, D.R. An emergy-based treatment sustainability index for evaluating waste treatment systems. J. Clean. Prod. 2016, 112, 4485–4496. [Google Scholar] [CrossRef]

- Shen, W.B.; Zhao, T.; Liu, P.; Zhong, Y.H.; Zhang, H.T. Assessment of environment and economic values for constructed wetland and a case study. Res. Environ. Sci. 2005, 18, 70–73. (In Chinese) [Google Scholar]

- Li, J.R. The Study on Environmental and Economical Benefits of Integrated Urban Sewage Treatment Systems Based on Emergy. Bachelor’s Thesis, Sichuan Agricultural University, Sichuan, China, 2016. (In Chinese). [Google Scholar]

- Odum, H.T. Emergy of Global Processes. In Handbook of Emergy Evalution (Folio #2): A Compendium of Data for Emergy Computation Issued in a Series of Folios; Center for Environmental Policy Environmental Engineering Sciences, University of Florida: Gainesville, FL, USA, 2000; pp. 17–18. [Google Scholar]

- Zhou, J.; Jiang, M.; Chen, B.; Chen, G. Emergy evaluations for constructed wetland and conventional wastewater treatments. Commun. Nonlinear Sci. Numer. Simul. 2009, 14, 1781–1789. [Google Scholar] [CrossRef]

- Buranakarn, V. Evaluation of Recycling and Reuse of Building Materials Using the Emergy Analysis Method; University of Florida: Gainesville, FL, USA, 1998. [Google Scholar]

- Brown, M.T.; Bardi, E. Emergy of Ecosystems. In Handbook of Emergy Evaluation (Folio #3): A Compendium of Data for Emergy Computation Issued in a Series of Folios; Center for Environmental Policy Environmental Engineering Sciences, University of Florida: Gainesville, FL, USA, 2001; pp. 43–44. [Google Scholar]

- Zhang, X.; Jiang, W.; Deng, S.; Peng, K. Emergy evaluation of the sustainability of Chinese steel production during 1998–2004. J. Clean. Prod. 2009, 17, 1030–1038. [Google Scholar] [CrossRef]

- Yang, Z.; Jiang, M.; Chen, B.; Zhou, J.; Chen, G.; Li, S. Solar emergy evaluation for Chinese economy. Energy Policy 2010, 38, 875–886. [Google Scholar] [CrossRef]

- Grönlund, E.; Klang, A.; Falk, S.; Hanæus, J. Sustainability of sewage treatment with microalgae in cold climate, evaluated with eMergy and socio-ecological principles. Ecol. Eng. 2004, 22, 155–174. [Google Scholar] [CrossRef]

- Lan, S.F.; Qin, P.; Lu, H.F. Emergy Synthesis of Ecological Economic Systems; Chemical Industry Press: Beijing, China, 2002. (In Chinese) [Google Scholar]

- Zhang, X.H.; Jiang, W.J. The emergy analysis of municipal sewage treatment ecological systems. Acta Ecol. Sin. 2008, 28, 2300–2308. [Google Scholar]

- Arbault, D.; Rugani, B.; Tiruta-Barna, L.; Benetto, E. Emergy evaluation of water treatment processes. Ecol. Eng. 2013, 60, 172–182. [Google Scholar] [CrossRef]

- Odum, H.T. Emergy in ecosystems. In Ecosystem Theory and Application; Poluin, N., Ed.; John Wiley & Sons: New York, NY, USA, 1996; pp. 337–369. [Google Scholar]

- Vassallo, P.; Paoli, C.; Fabiano, M. Emergy required for the complete treatment of municipal wastewater. Ecol. Eng. 2009, 35, 687–694. [Google Scholar] [CrossRef]

- Shen, L.F.; Liu, W.X.; Zhang, J.X.; Li, Y.; Wang, Y.L. Reclaimed water reuse engineering on Wu-long-kou Sewage Treatment Plant in Zhengzhou City. Water Sew. Eng. 2007, 33, 50–52. (In Chinese) [Google Scholar]

- Lv, B.; Pu, G.B.; Yin, H.J.; Sun, B. Reclaimed wastewater reuse project of sewage treatment plant in Bishan county. China Water Wastewater 2010, 26, 125–128. (In Chinese) [Google Scholar]

- Application Report of QBDP. Application Report of Qingdao Baifa Seawater Desalination Plant Project. 2011. Available online: https://max.book118.com/html/2018/0626/5234300024001300.shtm (accessed on 26 June 2018). (In Chinese).

- Al-Jayyousi, O.R. Greywater reuse: Towards sustainable water management. Desalination 2003, 156, 181–192. [Google Scholar] [CrossRef]

- Qi, H.; Zeng, S.; Shi, L.; Dong, X. What the reclaimed water use can change: From a perspective of inter-provincial virtual water network. J. Environ. Manag. 2021, 287, 112350. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; She, Z.; Chiu, Y.-H.; Qin, S.; Zhang, L. Assessment and improvement analysis of economic production, water pollution, and sewage treatment efficiency in China. Socio-Econ. Plan. Sci. 2021, 74, 100956. [Google Scholar] [CrossRef]

- Sear, D.; Newson, M. Environmental change in river channels: A neglected element. Towards geomorphological typologies, standards and monitoring. Sci. Total Environ. 2003, 310, 17–23. [Google Scholar] [CrossRef]

- van Roon, M. Water localisation and reclamation: Steps towards low impact urban design and development. J. Environ. Manag. 2007, 83, 437–447. [Google Scholar] [CrossRef] [PubMed]

| Item | pH | Turbidity (NTU) | COD (mg/L) | NH3-N (mg/L) | SS (mg/L) | Conductivity (mg/L) | Fecal Coliforms (MPN/L) |

|---|---|---|---|---|---|---|---|

| Influent | 6.0–9.0 | - | 45 | 3 | 10 | 5600 | 1000 |

| Effluent | 7.0–7.5 | <3 | <2 | No detection | 0 | <100 | - |

| Remove (t/y) | - | - | 313.9 | 15 | - | - | - |

| The reuse of urban recycling water–Water quality standard for industrial uses (GB/T19923-2005) | 6.5–8.5 | ≤5 | ≤60 | ≤10 | - | - | ≤2000 |

| Standards for drinking water quality (GB5749-2006) | 6.5–8.5 | - | <3 | <0.5 | - | - | - |

| Emergy Index | Traditional Emergy Analysis | Improved Emergy Analysis |

|---|---|---|

| Local renewable resources (R) | Re + Rs | Re + Rs |

| Local nonrenewable resources (N) | N | N |

| Purchased resources from main economy (F) | FN + FR | FN + FR |

| Total emergy (U) | R + N + F | R + N + F + Es |

| Emergy yield ratio (EYR) | U/F | U/F |

| Environmental loading ratio (ELR) | (FN + N)/(FR + R) | (FN + N + Es)/(FR + R) |

| Emergy sustainability index (ESI) | EYR/ELR | EYR/ELR |

| Note | Item | Raw Data | Renewable Factor | UEV (sej/unit) | References | Solar Emergy (sej/y) |

|---|---|---|---|---|---|---|

| Local renewable resources | ||||||

| Environment (Re) | ||||||

| 1 | Rain (J) | 8.75 × 1010 | 1.00 | 2.31 × 104 | [46] | 2.02 × 1015 |

| 2 | Sunlight (J) | 1.15 × 1012 | 1.00 | 1.00 | [46] | 1.15 × 1012 |

| 3 | Wind (J) | 5.22 × 1010 | 1.00 | 1.86 × 103 | [46] | 9.69 × 1013 |

| 4 | Earth cycle (J) | 3.87 × 1010 | 1.00 | 4.40 × 104 | [46] | 1.70 × 1015 |

| Sewage works effluent (Rs) | ||||||

| 5 | Outer drainage (J) | 6.63 × 1013 | 1.00 | 4.36 × 106 | [47] | 2.89 × 1020 |

| Total R (Re + Rs) | 2.89 × 1020 | |||||

| Total N | 0 | |||||

| Purchased resources from main economy (F) | ||||||

| 6 | Fiberglass/fiber reinforced plastic (g) | 1.55 × 105 | 0.00 | 7.40 × 109 | [48] | 1.15 × 1015 |

| 7 | Brick and cement (g) | 1.25 × 108 | 0.00 | 2.30 × 109 | [49] | 2.89 × 1017 |

| 8 | Steel (g) | 2.77 × 106 | 0.00 | 3.21 × 109 | [50] | 8.91 × 1015 |

| 9 | Sand (g) | 1.02 × 108 | 0.00 | 1.27 × 109 | [47] | 1.29 × 1017 |

| 10 | Machinery (g) | 2.58 × 106 | 0.00 | 8.53 × 109 | [49] | 2.20 × 1016 |

| 11 | Materials expenses (USD) | 4.66 × 103 | 0.05 | 7.46 × 1012 | [51] | 3.48 × 1016 |

| 12 | Labor (USD) | 7.14 × 104 | 0.90 | 7.46 × 1012 | [51] | 5.33 × 1017 |

| 13 | Tax (USD) | 8.12 × 104 | 0.05 | 7.46 × 1012 | [51] | 6.06 × 1017 |

| 14 | Poly aluminum chloride (g) | 3.16 × 109 | 0.00 | 3.37 × 109 | [52] | 1.07 × 1019 |

| 15 | Polyacrylamide (g) | 1.60 × 107 | 0.00 | 3.37 × 109 | [52] | 5.39 × 1016 |

| 16 | Hydrated lime (t) | 2.49 × 103 | 0.00 | 1.27 × 1015 | [53] | 3.16 × 1018 |

| 17 | Ethylenediaminetetraacetic acid (USD) | 1.17 × 104 | 0.00 | 7.46 × 1012 | [51] | 8.69 × 1016 |

| 18 | Hydrochloric acid (kg) | 2.27 × 105 | 0.00 | 2.01 × 1012 | [54] | 4.56 × 1017 |

| 19 | Sodium hypochlorite (g) | 3.69 × 108 | 0.00 | 3.29 × 109 | [55] | 1.21 × 1018 |

| 20 | Scale inhibitor (USD) | 6.56 × 104 | 0.00 | 7.46 × 1012 | [51] | 4.89 × 1017 |

| 21 | Sodium hydrogensulfite (USD) | 1.30 × 104 | 0.00 | 7.46 × 1012 | [51] | 9.71 × 1016 |

| 22 | Non-oxidizing fungicides (USD) | 4.25 × 101 | 0.00 | 7.46 × 1012 | [51] | 3.17 × 1014 |

| 23 | Sodium hydroxide (g) | 1.21 × 108 | 0.00 | 1.86 × 109 | [55] | 2.25 × 1017 |

| 24 | Activated carbon (t) | 2.55 × 102 | 0.00 | 1.98 × 1016 | [55] | 5.05 × 1018 |

| 25 | Filter membranes (USD) | 4.31 × 106 | 0.00 | 6.70 × 109 | [51] | 2.89 × 1016 |

| 26 | Electricity (kw·h) | 2.63 × 107 | 0.05 | 7.95 × 1011 | [56] | 2.09 × 1019 |

| 27 | Maintenances (USD) | 1.78× 106 | 0.05 | 7.46 × 1012 | [51] | 1.33 × 1019 |

| Renewable fraction of purchased resources (FR) | 5.14 × 1018 | |||||

| Nonrenewable fraction of purchased resources (FN) | 5.22 × 1019 | |||||

| Total F (FR + FN) | 5.73× 1019 | |||||

| Ecological services needed to dilute emissions to an acceptable level (Es) | ||||||

| 28 | CO2 (J) | 6.49 × 1013 | 0.00 | 1.86 × 103 | [45] | 1.26 × 1017 |

| 29 | SO2 (J) | 8.38× 1013 | 0.00 | 1.86 × 103 | [45] | 1.56 × 1017 |

| 30 | NOx (J) | 9.60 × 1014 | 0.00 | 1.86 × 103 | [45] | 1.78 × 1018 |

| 31 | Dust (J) | 3.47 × 1012 | 0.00 | 1.86 × 103 | [45] | 6.43 × 1015 |

| Total Es | 1.78 × 1018 | |||||

| Total U | 3.48 × 1020 | |||||

| Output | ||||||

| 32 | Reclaimed water (m3) | 7.30× 106 | 4.76 × 1013 | 3.48 × 1020 | ||

| Scenario | EYR | ELR | ESI | Method | Reference |

|---|---|---|---|---|---|

| A | 55.41 | 2.99 | 18.55 | Traditional emergy analysis | [58] |

| B | 142.8 | 0.005 | 28560 | Traditional emergy analysis | [59] |

| C | 1.01 | 5.46 | 0.19 | Traditional emergy analysis | [60] |

| D | 6.04 | 0.196 | 30.79 | Traditional emergy analysis | This study |

| 6.07 | 0.202 | 30.01 | Improved emergy analysis |

| Note | Ve | Vc | Vb | η | ||||

|---|---|---|---|---|---|---|---|---|

| V1 | V2 | V3 | C1 | C2 | C3 | 2.93 × 1020 | 1:4.96 | |

| Value (sej/y) | 4.08 × 1018 a | 3.48 × 1020 | 0 | 1.62 × 1018 | 5.57 × 1019 | 2.10 × 1016 | ||

| Total | 3.52 × 1020 | 5.91 × 1019 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Wang, L. An Improved Emergy Analysis of the Environmental and Economic Benefits of Reclaimed Water Reuse System. Sustainability 2022, 14, 5050. https://doi.org/10.3390/su14095050

Yang L, Wang L. An Improved Emergy Analysis of the Environmental and Economic Benefits of Reclaimed Water Reuse System. Sustainability. 2022; 14(9):5050. https://doi.org/10.3390/su14095050

Chicago/Turabian StyleYang, Ling, and Lin Wang. 2022. "An Improved Emergy Analysis of the Environmental and Economic Benefits of Reclaimed Water Reuse System" Sustainability 14, no. 9: 5050. https://doi.org/10.3390/su14095050

APA StyleYang, L., & Wang, L. (2022). An Improved Emergy Analysis of the Environmental and Economic Benefits of Reclaimed Water Reuse System. Sustainability, 14(9), 5050. https://doi.org/10.3390/su14095050