Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles

Abstract

:1. Introduction

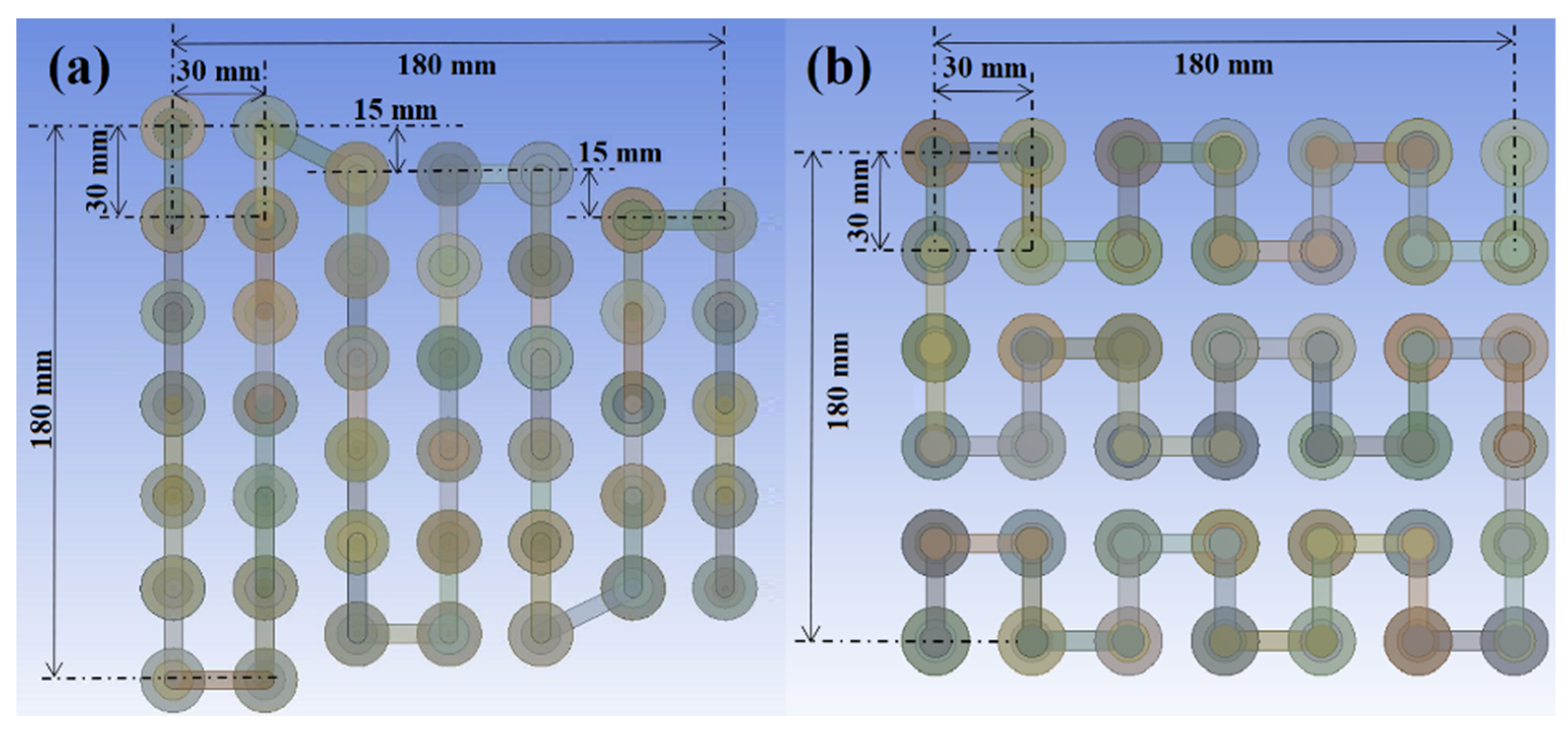

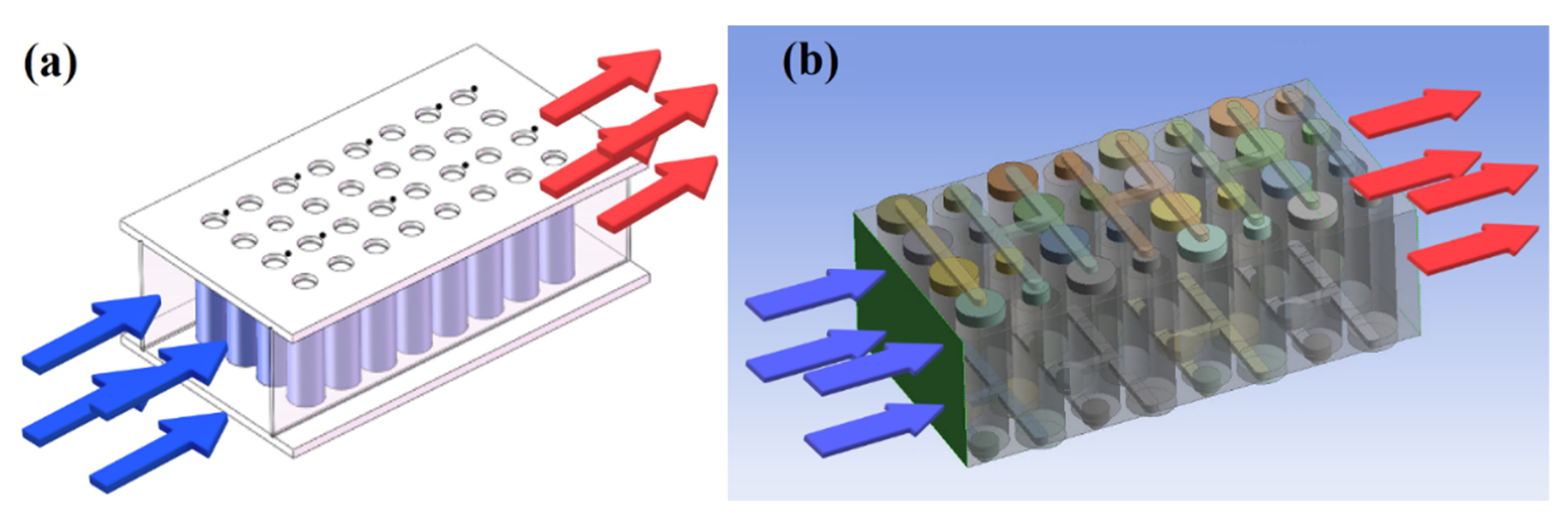

2. 3D Modeling and Cooling Performance Indicators

2.1. Major Parameters and 3D Modeling of the Li-Ion 21700 Cylindrical Battery Cell

2.2. Cooling Performance Indicators and Evaluation Criteria

3. Mathematical Models and Validations

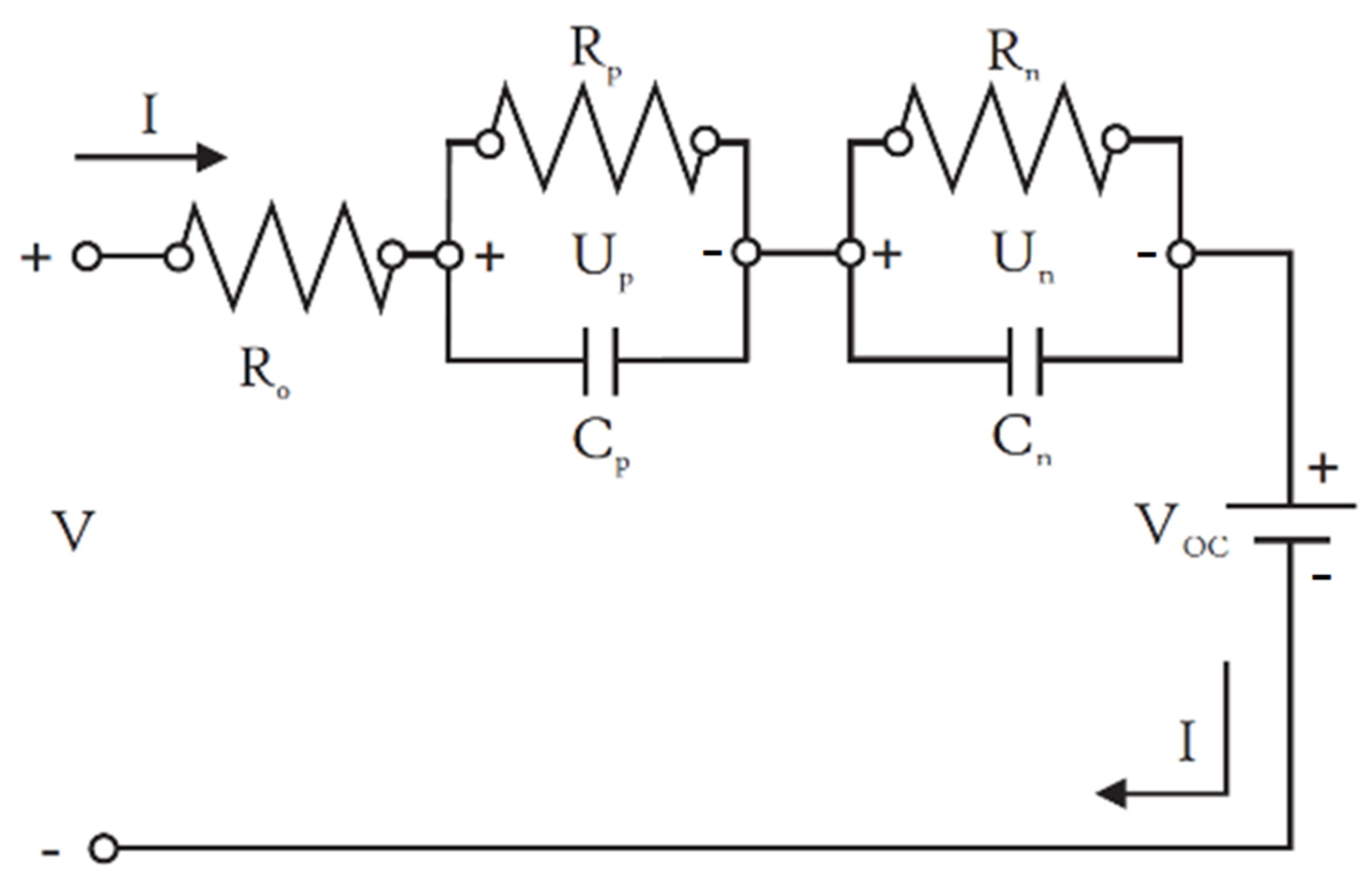

3.1. Battery Electrochemical Model

3.2. Thermodynamic Model

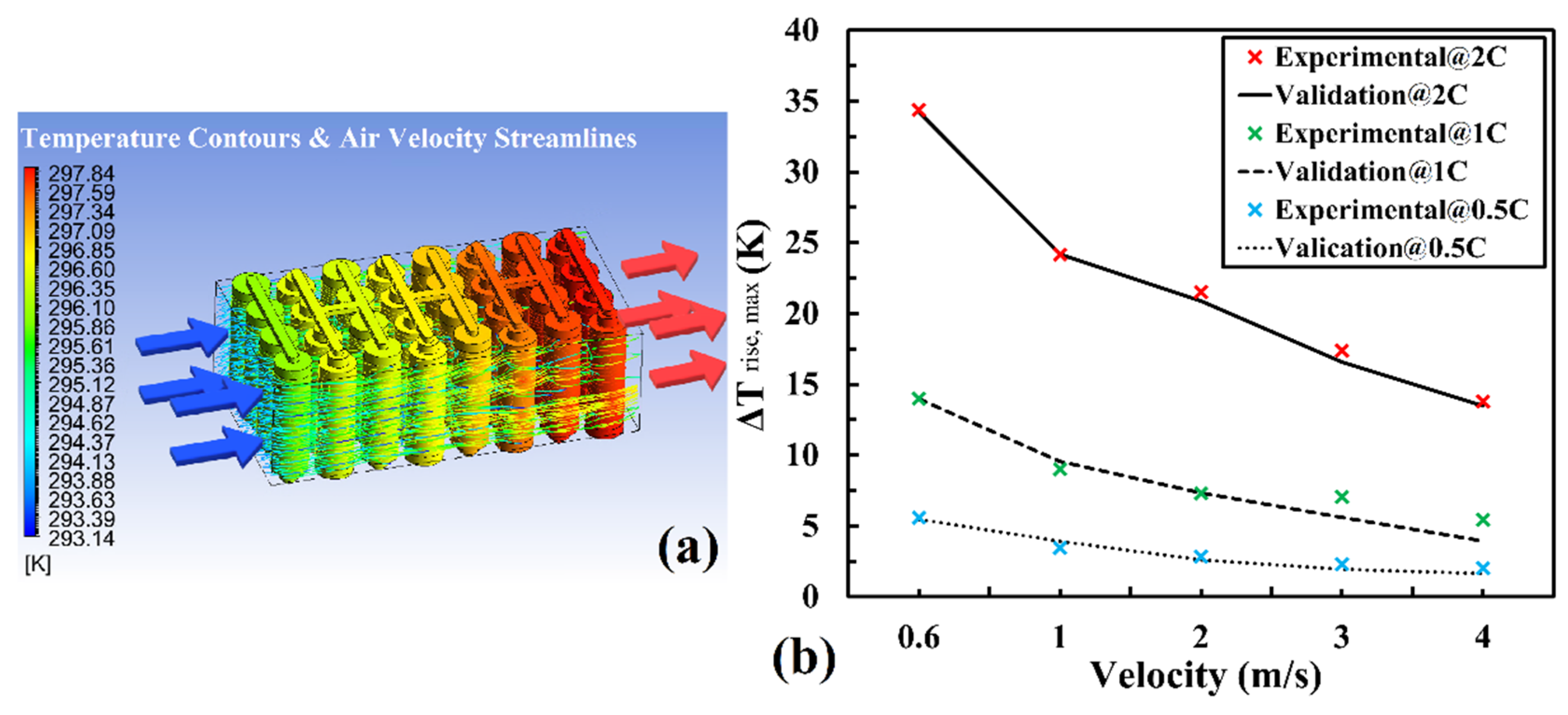

3.3. Mesh Independence Test and Model Validation

4. Results and Analysis

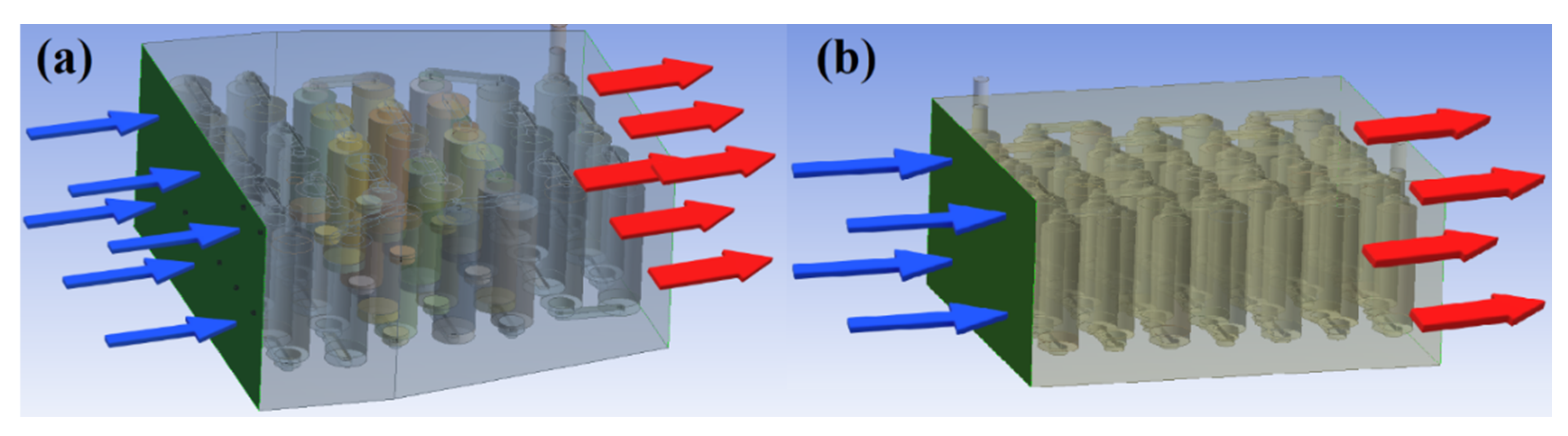

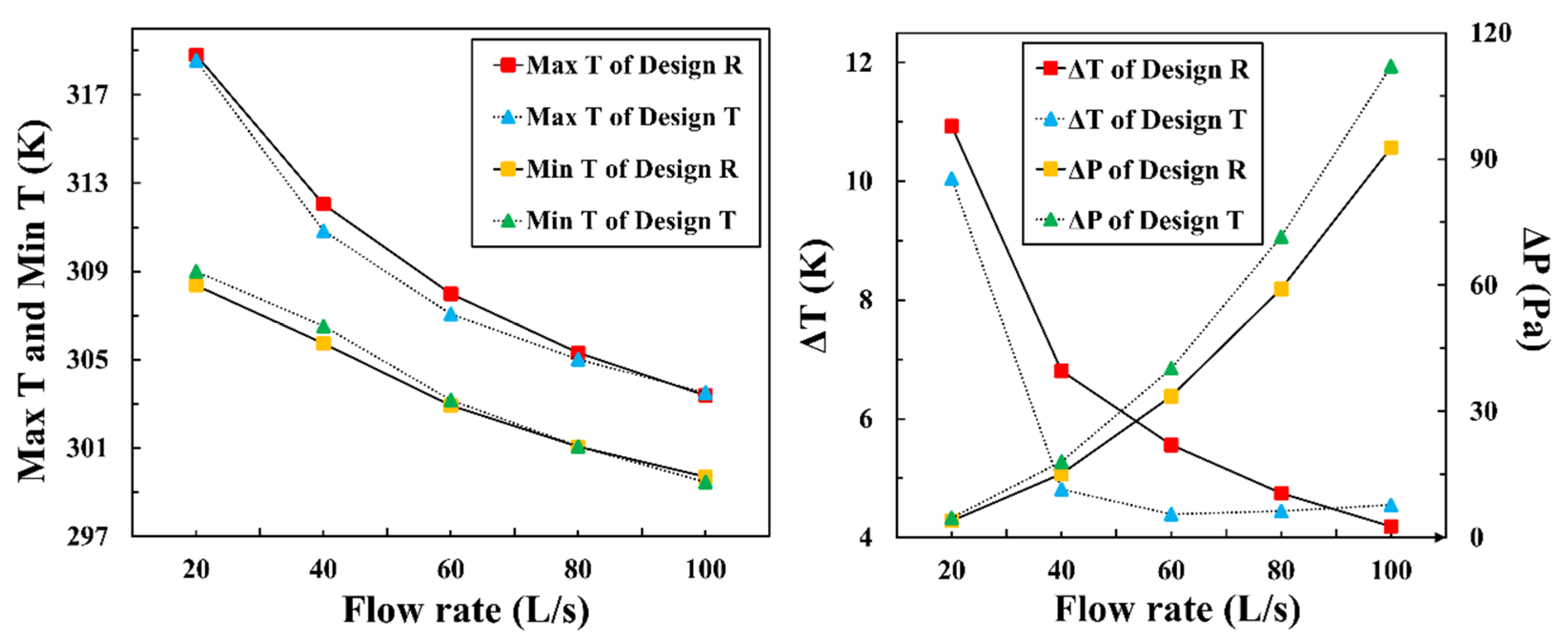

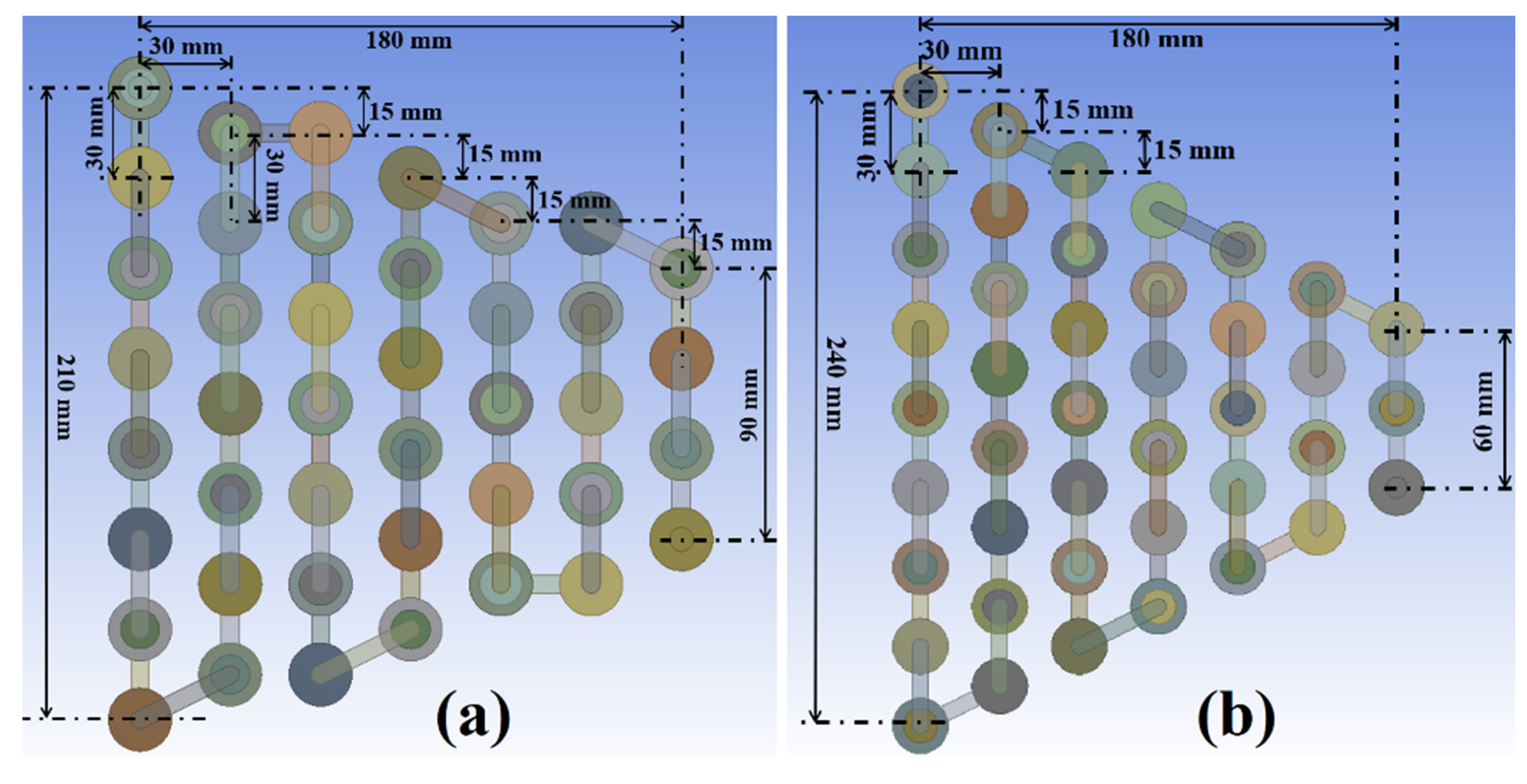

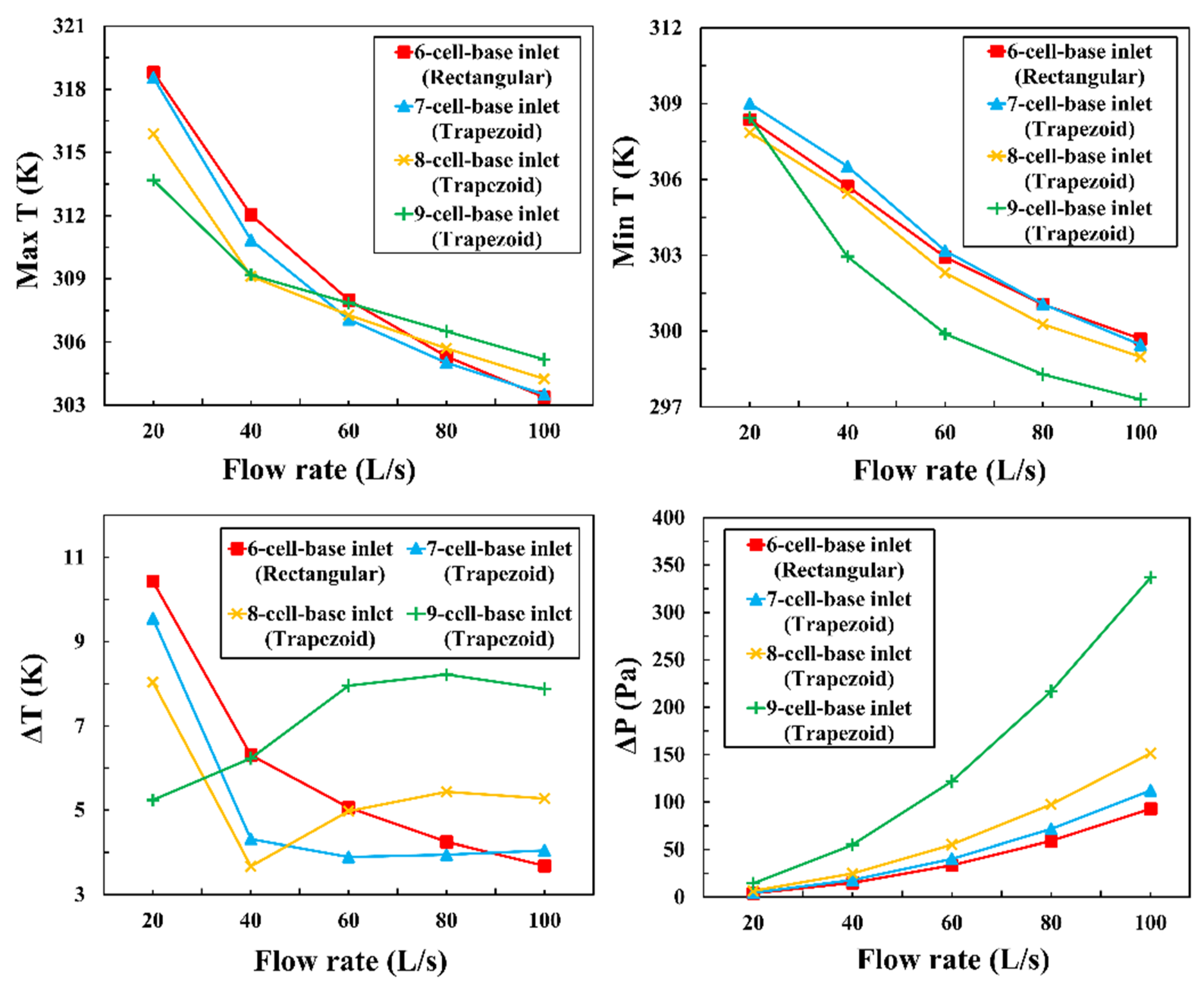

4.1. Comparison between Conventional Rectangular and Novel Trapezoid Designs

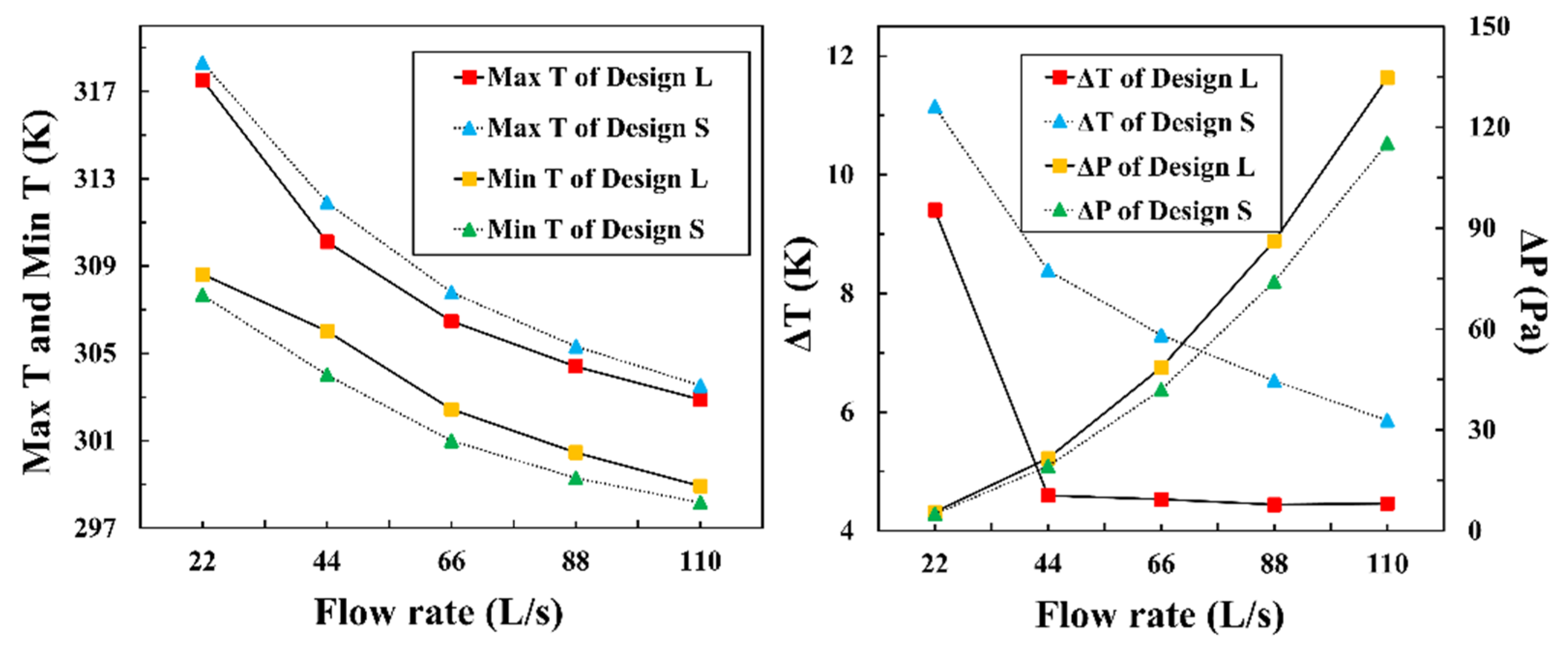

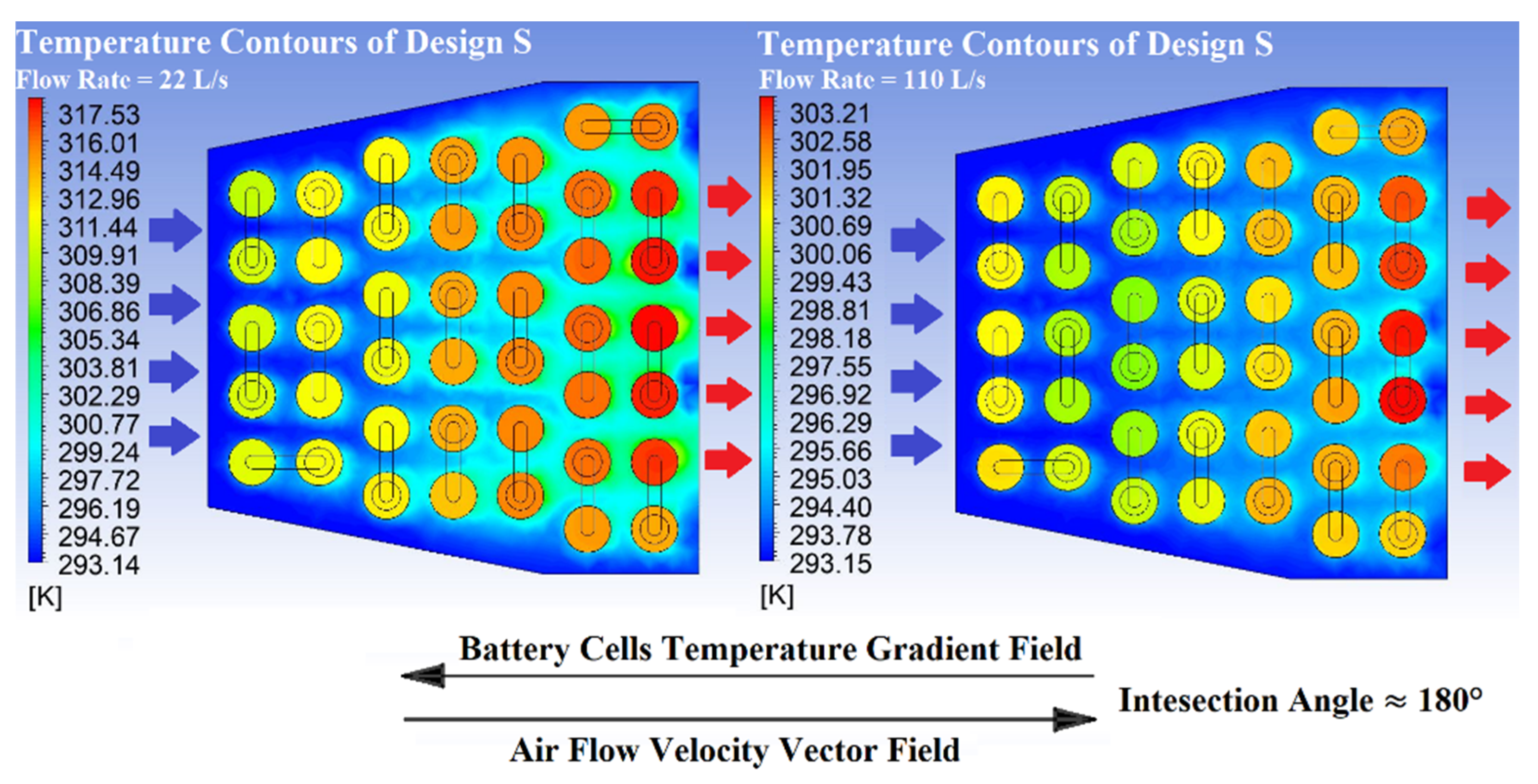

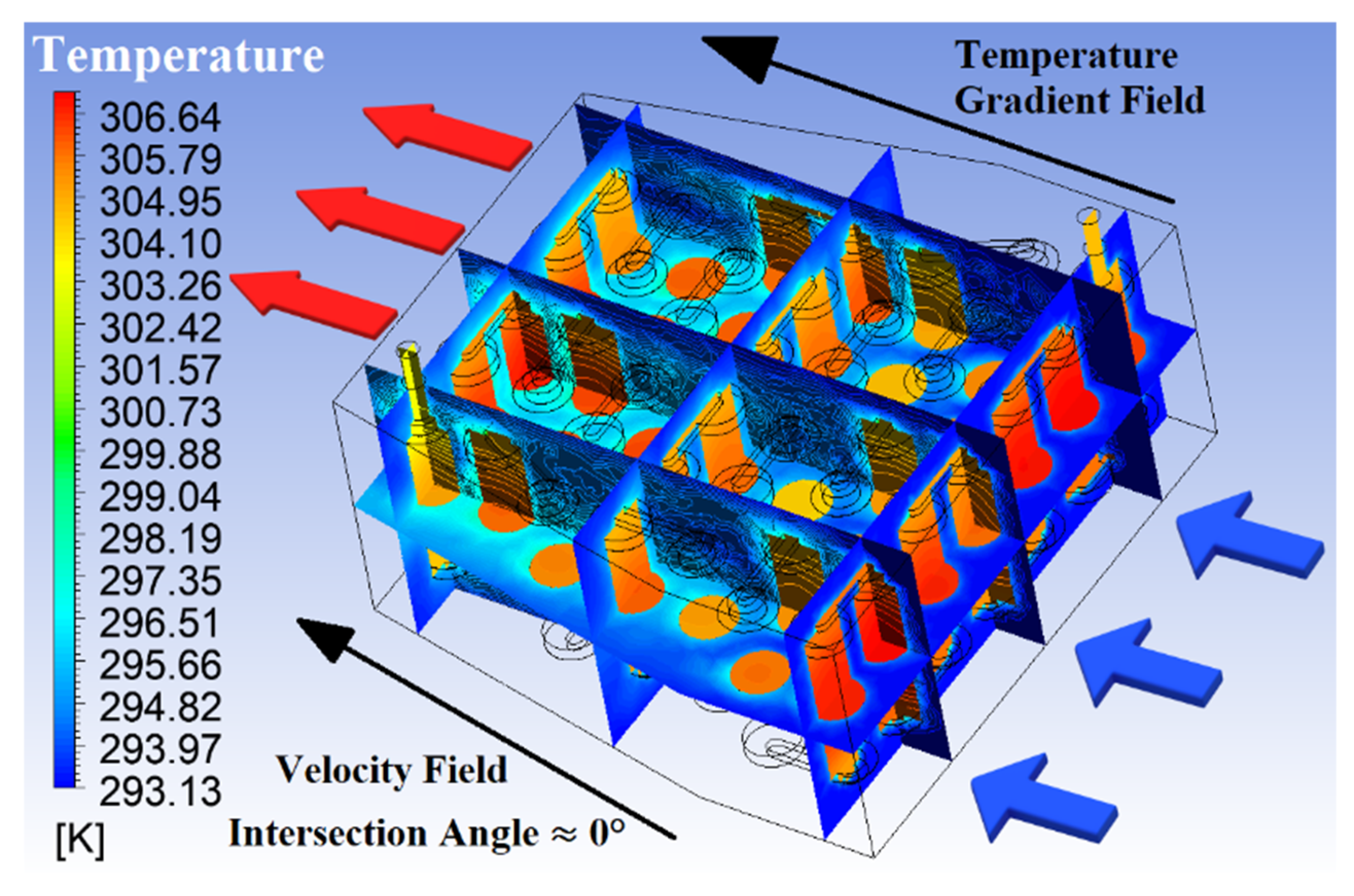

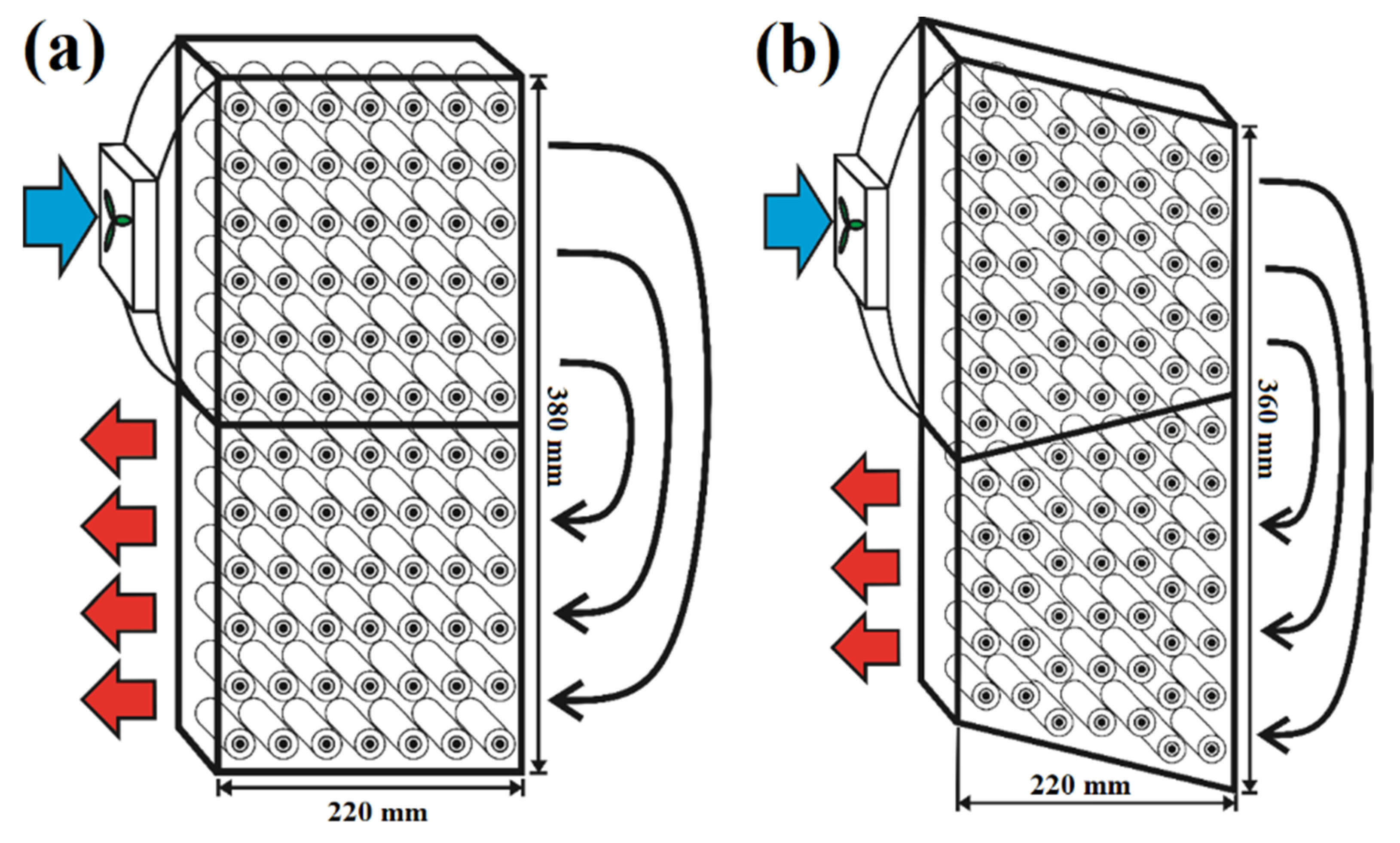

4.2. Cooling Effects of Air Flow Directions on Trapezoid Design

4.3. Trapezoid BTMS Design Optimization

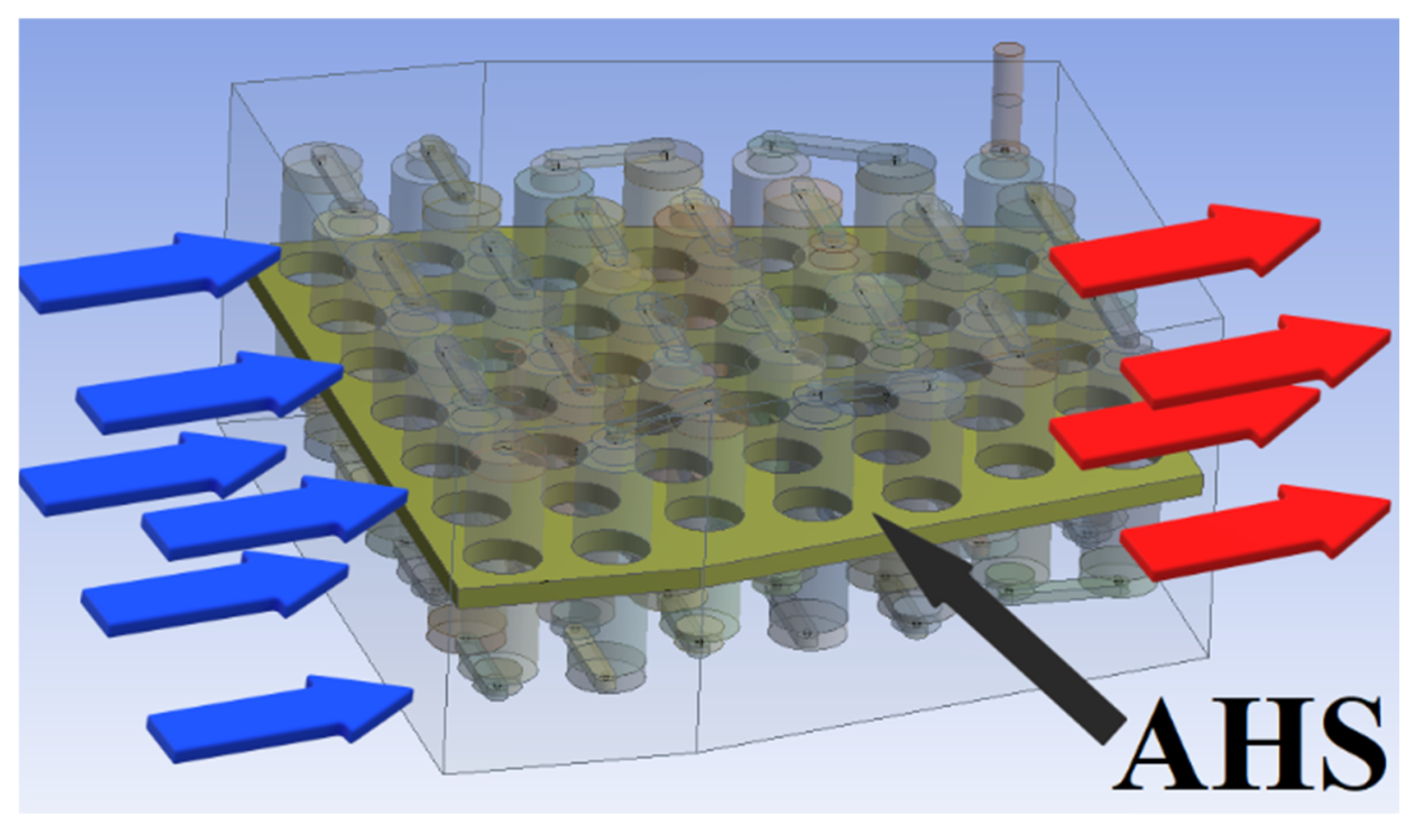

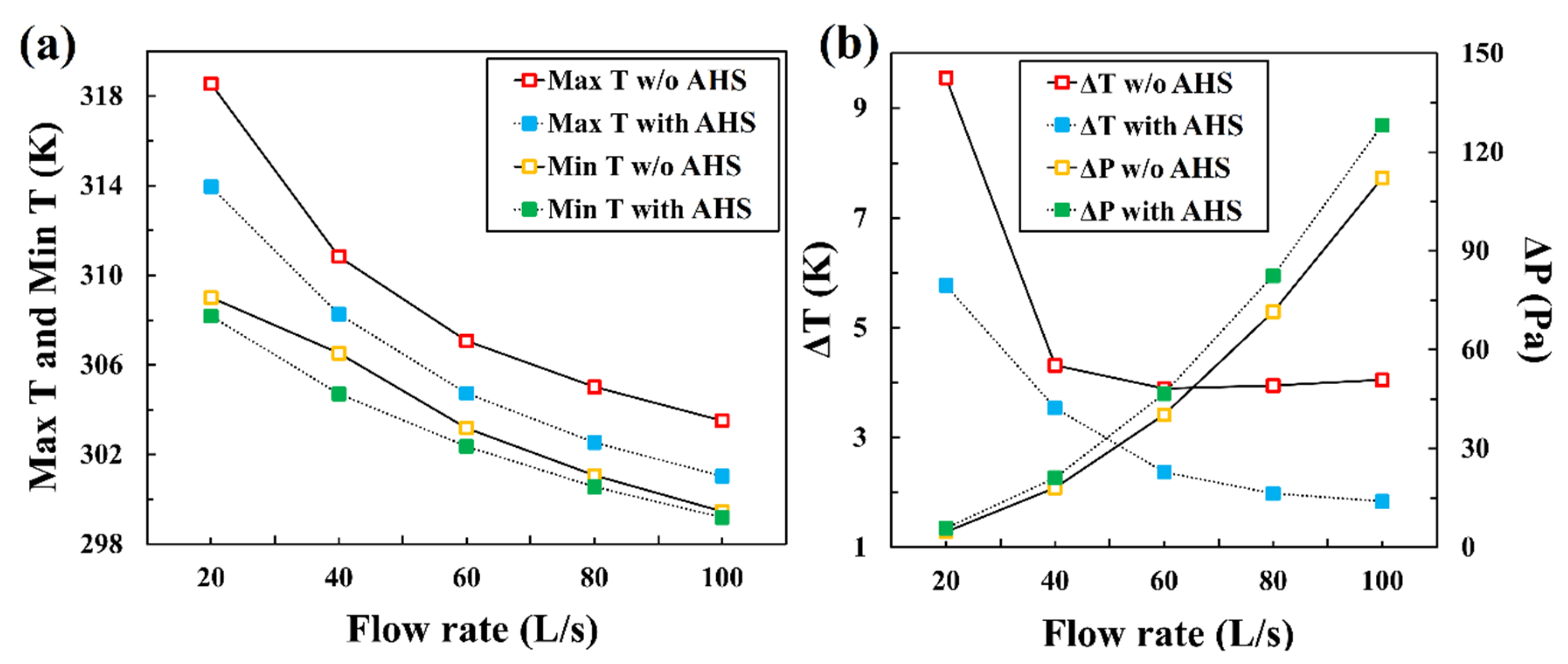

4.4. Cooling Effect of a Single-Layer AHS

5. Discussion

6. Conclusions

- The air flow direction has a dominant impact on the cooling performance of the trapezoid BTMS. Based on the FSP, the air flow velocity vector field should be consistent with the battery cells temperature gradient field to form a 0° intersection angle between two fields. A smaller synergy intersection angle usually leads to higher heat transfer coefficient. Since the high-temperature profile of the trapezoid design is on the long-base side and low-temperature profile is on the short-base side, the direction of the temperature gradient field is always from the long base to the short base if the boundary condition keeps constant. Thus, the velocity field should also be imposed along the direction of the temperature gradient field—from the long-base side to the short-base side, i.e., the inlet on the long-base side and the outlet on the short-base side for the trapezoid design.

- In this research, the optimal base angle of the trapezoid design is 78.69° (seven-cell-base inlet design). The optimal trapezoid design delivers 0.9 °C lower Max T and 1.17 °C lower ΔT than the rectangular one at 60 L/s flow rate. As a trapezoid layout battery pack design guideline, the optimal length ratio of the outlet to the inlet is suggested to be around 0.7.

- The multi-functional single-layer AHS can be used for both enhancing the battery pack strength and increasing the heat transfer coefficient. The Max T and ΔT values of the optimal trapezoid design with AHS are 4.6 K and 3.78 K lower than the design without AHS at 40 L/s flow rate.

- The novel trapezoid design could be implemented in commercial EV air-cooling BTMS applications by using thin-wall partitions. Theoretically, the modified trapezoid air-cooling BTMS could reduce the Max T and ΔT by 10.4% and 91.9% in addition to a space-saving of about 5.26%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| an, bn, …, fn (n = 0, 1, …, 5) | constant coefficients |

| A | battery surface area (m2) |

| C | capacitance (F) |

| Cp | specific heat capacity (J·kg−1⋅K−1) |

| I | battery current (A) |

| diffusion flux | |

| j | volumetric transfer current density (A·m−2) |

| k | thermal conductivity (W·m-1·K-1) |

| P, p | pressure (Pa) |

| Q | battery capacity (Ah) |

| q | heat generation rate (W·m−3) |

| R | resistance (Ω) |

| T | temperature (K) |

| V | battery voltage (V) |

| air flow velocity vector (m·s−1) | |

| Greek symbols | |

| ρ | mass density (kg·m−3) |

| σ | electrical conductivity (Siemens·m−1) |

| stress tensor | |

| ϕ | electric potential (V) |

| φ | electrode phase potential (V) |

| ∇ | Del operator used as the partial derivative of a quantity with respect to all directions in the chosen coordinate system (m−1) |

| Subscripts | |

| a or + | anode |

| b | battery |

| c or - | cathode |

| i, n (=1, …, N) | arbitrary number |

| OC | open-circuit |

| Abbreviations | |

| AHS | aluminum heat spreader |

| BTMS | battery thermal management system |

| ECM | electric circuit model |

| EV | electric vehicle |

| FSP | field synergy principle |

| HEV | hybrid electric vehicle |

| Li-ion | Lithium-ion |

| Max | maximum |

| Min | minimum |

| MSMD | multi-scale multi-domain |

| OEM | original equipment manufacturer |

| SoC | state of charge |

References

- Zhang, B. The Effect of Aerosols to Climate Change and Society. J. Geosci. Environ. Prot. 2020, 8, 55. [Google Scholar] [CrossRef]

- Hu, X.; Chen, N.; Wu, N.; Yin, B. The Potential Impacts of Electric Vehicles on Urban Air Quality in Shanghai City. Sustainability 2021, 13, 496. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M. A Study of Variable Cell Spacings to the Heat Transfer Efficiency of Air-Cooling Battery Thermal Management System. Appl. Sci. 2021, 11, 11155. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M. Connecting battery technologies for electric vehicles from battery materials to management. iScience 2022, 25, 103744. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Wang, J.; Li, Y.; Liu, Q.; Li, W. Experimental Investigation of a Lithium Battery Cooling System. Sustainability 2019, 11, 5020. [Google Scholar] [CrossRef] [Green Version]

- Asef, P.; Milan, M.; Lapthorn, A.; Padmanaban, S. Future Trends and Aging Analysis of Battery Energy Storage Systems for Electric Vehicles. Sustainability 2021, 13, 13779. [Google Scholar] [CrossRef]

- Singh, L.K.; Gupta, A.K. Hybrid cooling-based lithium-ion battery thermal management for electric vehicles. Environ. Dev. Sustain. 2022, 24, 1–22. [Google Scholar] [CrossRef]

- Lai, Y.; Wu, W.; Chen, K.; Wang, S.; Xin, C. A compact and lightweight liquid-cooled thermal management solution for cylindrical lithium-ion power battery pack. Int. J. Heat Mass Transf. 2019, 144, 118581. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in battery thermal management systems for electric vehicles: A technical review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Numerical investigation on thermal characteristics of a liquid-cooled lithium-ion battery pack with cylindrical cell casings and a square duct. J. Energy Storage 2022, 48, 104041. [Google Scholar] [CrossRef]

- Murali, G.; Sravya, G.; Jaya, J.; Vamsi, V.N. A review on hybrid thermal management of battery packs and it’s cooling performance by enhanced PCM. Renew. Sustain. Energy Rev. 2021, 150, 111513. [Google Scholar] [CrossRef]

- Ikezoe, M.; Hirata, N.; Amemiya, C.; Miyamoto, T.; Watanabe, Y.; Hirai, T.; Sasaki, T. Development of High Capacity Lithium-Ion Battery for NISSAN LEAF; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012; Volume 1, p. 0664. ISSN 0148-7191. [Google Scholar]

- Nazari, A.; Farhad, S. Heat generation in lithium-ion batteries with different nominal capacities and chemistries. Appl. Therm. Eng. 2017, 125, 1501–1517. [Google Scholar] [CrossRef]

- Özsin, G.; Dermenci, K.B.; Turan, S. Thermokinetic and thermodynamics of Pechini derived Li 7 − 3x Al x La 3 Zr 2 O 12 (X = 0.0–0.2) xerogel decomposition under oxidative conditions. J. Therm. Anal. Calorim. 2021, 146, 1405–1420. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Jiang, J.-M.; Chung, Y.-H.; Chen, W.-C.; Shu, C.-M. Forced-air cooling system for large-scale lithium-ion battery modules during charge and discharge processes. J. Therm. Anal. Calorim. 2019, 135, 2891–2901. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, X.; Tao, W.; Shah, R. Effectiveness–thermal resistance method for heat exchanger design and analysis. Int. J. Heat Mass Transf. 2010, 53, 2877–2884. [Google Scholar] [CrossRef]

- Adam, A.Y.; Oumer, A.N.; Najafi, G.; Ishak, M.; Firdaus, M.; Aklilu, T.B. State of the art on flow and heat transfer performance of compact fin-and-tube heat exchangers. J. Therm. Anal. Calorim. 2020, 139, 2739–2768. [Google Scholar] [CrossRef]

- Duan, X.-Y.; Li, F.-B.; Ding, B.; Gong, L.; Xu, M.-H. Heat transfer characteristics and field synergy analysis of gas–liquid two-phase flow in micro-channels. J. Therm. Anal. Calorim. 2020, 141, 401–412. [Google Scholar] [CrossRef]

- Tao, W.-Q.; Guo, Z.-Y.; Wang, B.-X. Field synergy principle for enhancing convective heat transfer––its extension and numerical verifications. Int. J. Heat Mass Transf. 2002, 45, 3849–3856. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating air flow for Li-ion battery thermal management to improve temperature uniformity. J. Power Sources 2011, 196, 5685–5696. [Google Scholar] [CrossRef]

- Na, X.; Kang, H.; Wang, T.; Wang, Y. Reverse layered air flow for Li-ion battery thermal management. Appl. Therm. Eng. 2018, 143, 257–262. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Structure optimization of parallel air-cooled battery thermal management system with U-type flow for cooling efficiency improvement. Energy 2018, 145, 603–613. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J. Self-adapting J-type air-based battery thermal management system via model predictive control. Appl. Energy 2020, 263, 114640. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Huo, Y.; Liu, X.; Li, Y. Thermal management of cylindrical power battery module for extending the life of new energy electric vehicles. Appl. Therm. Eng. 2015, 85, 33–43. [Google Scholar] [CrossRef]

- Hong, S.; Zhang, X.; Chen, K.; Wang, S. Design of flow configuration for parallel air-cooled battery thermal management system with secondary vent. Int. J. Heat Mass Transf. 2018, 116, 1204–1212. [Google Scholar] [CrossRef]

- Zhang, J.; Kang, H.; Wu, K.; Li, J.; Wang, Y. The impact of enclosure and boundary conditions with a wedge-shaped path and air cooling for battery thermal management in electric vehicles. Int. J. Energy Res. 2018, 42, 4054–4069. [Google Scholar] [CrossRef]

- Tao, W.; He, Y.; Wang, Q.; Qu, Z.; Song, F. A unified analysis on enhancing single phase convective heat transfer with field synergy principle. Int. J. Heat Mass Transf. 2002, 45, 4871–4879. [Google Scholar] [CrossRef]

- Li, X.; He, F.; Ma, L. Thermal management of cylindrical batteries investigated using wind tunnel testing and computational fluid dynamics simulation. J. Power Sources 2013, 238, 395–402. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Yang, N.; Zhang, X.; Li, G.; Hua, D. Assessment of the forced air-cooling performance for cylindrical lithium-ion battery packs: A comparative analysis between aligned and staggered cell arrangements. Appl. Therm. Eng. 2015, 80, 55–65. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy. Appl. Therm. Eng. 2017, 123, 177–186. [Google Scholar] [CrossRef]

- Chen, K.; Chen, Y.; She, Y.; Song, M.; Wang, S.; Chen, L. Construction of effective symmetrical air-cooled system for battery thermal management. Appl. Therm. Eng. 2020, 166, 114679. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Design of the structure of battery pack in parallel air-cooled battery thermal management system for cooling efficiency improvement. Int. J. Heat Mass Transf. 2019, 132, 309–321. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Xu, X.; Wang, X. Numerical analysis and surrogate model optimization of air-cooled battery modules using double-layer heat spreading plates. Int. J. Heat Mass Transf. 2021, 176, 121380. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Yew, M.C.; Chong, W.T.; Yew, M.K.; Ng, T.C. Computational fluid dynamics simulation on open cell aluminium foams for Li-ion battery cooling system. Appl. Energy 2017, 204, 1489–1499. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Jing, Z.; Wang, C.; Zhou, G.; Zhao, W. Thermal performance of lithium-ion batteries applying forced air cooling with an improved aluminium foam heat sink design. Int. J. Heat Mass Transf. 2021, 167, 120827. [Google Scholar] [CrossRef]

- Fan, Y.; Bao, Y.; Ling, C.; Chu, Y.; Tan, X.; Yang, S. Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries. Appl. Therm. Eng. 2019, 155, 96–109. [Google Scholar] [CrossRef]

- Wang, H.; He, F.; Ma, L. Experimental and modeling study of controller-based thermal management of battery modules under dynamic loads. Int. J. Heat Mass Transf. 2016, 103, 154–164. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z. The numerical investigation of nanofluid based cylinder battery thermal management using lattice Boltzmann method. Int. J. Heat Mass Transf. 2015, 91, 374–384. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, X.; Ma, C.; Hao, D.; Chen, Y. Effects of the structure arrangement and spacing on the thermal characteristics of Li-ion battery pack at various discharge rates. Appl. Therm. Eng. 2020, 165, 114610. [Google Scholar] [CrossRef]

- Pesaran, A.A. Battery thermal models for hybrid vehicle simulations. J. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Zhao, C.; Cao, W.; Dong, T.; Jiang, F. Thermal behavior study of discharging/charging cylindrical lithium-ion battery module cooled by channeled liquid flow. Int. J. Heat Mass Transf. 2018, 120, 751–762. [Google Scholar] [CrossRef]

- Zhao, C.; Sousa, A.; Jiang, F. Minimization of thermal non-uniformity in lithium-ion battery pack cooled by channeled liquid flow. Int. J. Heat Mass Transf. 2019, 129, 660–670. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.-H.; Panchal, S.; Jee, S.-W.; Lee, M.-Y. Investigation on thermal performance of water-cooled Li-ion pouch cell and pack at high discharge rate with U-turn type microchannel cold plate. Int. J. Heat Mass Transf. 2020, 155, 119728. [Google Scholar] [CrossRef]

- Ye, Y.; Shi, Y.; Saw, L.H.; Tay, A.A. Performance assessment and optimization of a heat pipe thermal management system for fast charging lithium ion battery packs. Int. J. Heat Mass Transf. 2016, 92, 893–903. [Google Scholar] [CrossRef]

- Monika, K.; Chakraborty, C.; Roy, S.; Dinda, S.; Singh, S.A.; Datta, S.P. Parametric investigation to optimize the thermal management of pouch type lithium-ion batteries with mini-channel cold plates. Int. J. Heat Mass Transf. 2021, 164, 120568. [Google Scholar] [CrossRef]

- Saw, L.H.; Poon, H.M.; Thiam, H.S.; Cai, Z.; Chong, W.T.; Pambudi, N.A.; King, Y.J. Novel thermal management system using mist cooling for lithium-ion battery packs. Appl. Energy 2018, 223, 146–158. [Google Scholar] [CrossRef] [Green Version]

- Lindgren, J.; Lund, P.D. Effect of extreme temperatures on battery charging and performance of electric vehicles. J. Power Sources 2016, 328, 37–45. [Google Scholar] [CrossRef]

- Waldmann, T.; Wilka, M.; Kasper, M.; Fleischhammer, M.; Wohlfahrt-Mehrens, M. Temperature dependent ageing mechanisms in Lithium-ion batteries—A Post-Mortem study. J. Power Sources 2014, 262, 129–135. [Google Scholar] [CrossRef]

- Leng, F.; Tan, C.M.; Pecht, M. Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature. Sci. Rep. 2015, 5, 12967. [Google Scholar] [CrossRef] [Green Version]

- Sheng, L.; Su, L.; Zhang, H.; Li, K.; Fang, Y.; Ye, W.; Fang, Y. Numerical investigation on a lithium ion battery thermal management utilizing a serpentine-channel liquid cooling plate exchanger. Int. J. Heat Mass Transf. 2019, 141, 658–668. [Google Scholar] [CrossRef]

- Zou, D.; Ma, X.; Liu, X.; Zheng, P.; Hu, Y. Thermal performance enhancement of composite phase change materials (PCM) using graphene and carbon nanotubes as additives for the potential application in lithium-ion power battery. Int. J. Heat Mass Transf. 2018, 120, 33–41. [Google Scholar] [CrossRef]

- Yan, J.; Wang, Q.; Li, K.; Sun, J. Numerical study on the thermal performance of a composite board in battery thermal management system. Appl. Therm. Eng. 2016, 106, 131–140. [Google Scholar] [CrossRef]

- Shang, Z.; Qi, H.; Liu, X.; Ouyang, C.; Wang, Y. Structural optimization of lithium-ion battery for improving thermal performance based on a liquid cooling system. Int. J. Heat Mass Transf. 2019, 130, 33–41. [Google Scholar] [CrossRef]

- Choudhari, V.; Dhoble, A.; Panchal, S. Numerical analysis of different fin structures in phase change material module for battery thermal management system and its optimization. Int. J. Heat Mass Transf. 2020, 163, 120434. [Google Scholar] [CrossRef]

- Pan, M.; Zhong, Y. Experimental and numerical investigation of a thermal management system for a Li-ion battery pack using cutting copper fiber sintered skeleton/paraffin composite phase change materials. Int. J. Heat Mass Transf. 2018, 126, 531–543. [Google Scholar] [CrossRef]

- Tiedemann, W.; Newman, J. Mathematical modeling of the lead-acid cell. In Proceedings of the Symposium on Battery Design and Optimization; The Electrochemical Society: Princeton, NJ, USA, 1979; Volume 79. [Google Scholar]

- Lee, K.-J.; Smith, K.; Pesaran, A.; Kim, G.-H. Three dimensional thermal-, electrical-, and electrochemical-coupled model for cylindrical wound large format lithium-ion batteries. J. Power Sources 2013, 241, 20–32. [Google Scholar] [CrossRef]

- Chen, M.; Rincon-Mora, G.A. Accurate Electrical Battery Model Capable of Predicting Runtime and I–V Performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Pinto, A.M.; Oliveira, V.S.; Falcão, D.S.C. Direct Alcohol Fuel Cells for Portable Applications: Fundamentals, Engineering and Advances; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Barbir, F. PEM Fuel Cells: Theory and Practice; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Yang, Y.; Chen, L.; Yang, L.; Du, X. Numerical study of combined air and phase change cooling for lithium-ion battery during dynamic cycles. Int. J. Therm. Sci. 2021, 165, 106968. [Google Scholar] [CrossRef]

| Major Parameters | Values |

|---|---|

| Cell length (mm) | 70 |

| Cell diameter (mm) | 21 |

| Anode tab diameter (mm) | 21 |

| Anode tab height (mm) | 5 |

| Cathode tab diameter (mm) | 13 |

| Cathode tab height (mm) | 5 |

| Active material density (kg/m3) | 2092 |

| Active material Cp (Specific Heat) (J/kg-K) | 678 |

| Active material thermal Conductivity (W/m-K) | 18.2 |

| Active material electrical Conductivity (Siemens/m) | 3.541 × 107 |

| Passive material density (kg/m3) | 8978 |

| Passive material Cp (Specific Heat) (J/kg-K) | 381 |

| Passive material thermal Conductivity (W/m-K) | 387.6 |

| Passive material electrical Conductivity (Siemens/m) | 1 × 107 |

| Battery ECM Parameters | Values |

|---|---|

| Nominal Cell Capacity (Ah) | 4 |

| Specified C-Rate | 1 |

| Max Stop Voltage (V) | 4.3 |

| Min Stop Voltage (V) | 3 |

| Initial SoC | 1 |

| Reference Capacity (Ah) | 4 |

| a0 | 0.07446 |

| a1 | 0.1562 |

| a2 | 24.37 |

| b0 | 0.04669 |

| b1 | 0.3208 |

| b2 | 29.14 |

| c0 | 703.6 |

| c1 | −752.9 |

| c2 | 13.51 |

| d0 | 0.04984 |

| d1 | 6.603 |

| d2 | 155.2 |

| e0 | 4475 |

| e1 | −6056 |

| e2 | 27.12 |

| f0 | 3.685 |

| f1 | 0.2156 |

| f2 | −0.1178 |

| f3 | 0.3201 |

| f4 | −1.031 |

| f5 | 35 |

| Design No. | Inlet Velocity (m/s) | Inlet Dimension (m) | Volume Air Flow Rate (L/s) | Mass Air Flow Rate (g/s) | Outlet Dimension (m) |

|---|---|---|---|---|---|

| R-1 | 1 | 0.1 m × 0.2 m 6-cell-side inlet | 20 | 23.98 | 0.1 m × 0.2 m 6-cell-side outlet |

| R-2 | 2 | 40 | 47.96 | ||

| R-3 | 3 | 60 | 71.94 | ||

| R-4 | 4 | 80 | 95.92 | ||

| R-5 | 5 | 100 | 119.90 | ||

| T-1 | 0.91 | 0.1 m × 0.22 m 7-cell-base inlet | 20 | 23.98 | 0.1 m × 0.16 m 5-cell-base outlet |

| T-2 | 1.82 | 40 | 47.96 | ||

| T-3 | 2.73 | 60 | 71.94 | ||

| T-4 | 3.64 | 80 | 95.92 | ||

| T-5 | 4.55 | 100 | 119.90 |

| Design No. | Inlet Velocity (m/s) | Inlet Dimension | Volume Air Flow Rate (L/s) | Mass Air Flow Rate (g/s) | Outlet Dimension (m) |

|---|---|---|---|---|---|

| L-1 | 1 | 0.1 m × 0.22 m 7-cell-base inlet | 22 | 26.38 | 0.1 m × 0.16 m 5-cell-base outlet |

| L-2 | 2 | 44 | 52.76 | ||

| L-3 | 3 | 66 | 79.14 | ||

| L-4 | 4 | 88 | 105.52 | ||

| L-5 | 5 | 110 | 131.90 | ||

| S-1 | 1.375 | 0.1 m × 0.16 m 5-cell-base inlet | 22 | 26.38 | 0.1 m × 0.22 m 7-cell-base outlet |

| S-2 | 2.750 | 44 | 52.76 | ||

| S-3 | 4.125 | 66 | 79.14 | ||

| S-4 | 5.500 | 88 | 105.52 | ||

| S-5 | 6.875 | 110 | 131.90 |

| Design No. | Inlet Descriptions | Long Base Length (m) | Short Base Length (m) | Height (m) | Base Angle (°) | Ratio of Short Base (Outlet) to Long Base (Inlet) |

|---|---|---|---|---|---|---|

| 6 | 6-cell-side inlet (Rectangular) | 0.2000 | 0.2000 | 0.2200 | 90.00 | 1.00 |

| 7 | 7-cell-base inlet (Trapezoid) | 0.2200 | 0.1600 | 0.2200 | 78.69 | 0.73 |

| 8 | 8-cell-base inlet (Trapezoid) | 0.2500 | 0.1300 | 0.2200 | 74.75 | 0.52 |

| 9 | 9-cell-base inlet (Trapezoid) | 0.2935 | 0.0735 | 0.2200 | 63.44 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H.; Li, C. Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles. Sustainability 2022, 14, 4975. https://doi.org/10.3390/su14094975

Zhao G, Wang X, Negnevitsky M, Zhang H, Li C. Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles. Sustainability. 2022; 14(9):4975. https://doi.org/10.3390/su14094975

Chicago/Turabian StyleZhao, Gang, Xiaolin Wang, Michael Negnevitsky, Hengyun Zhang, and Chengjiang Li. 2022. "Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles" Sustainability 14, no. 9: 4975. https://doi.org/10.3390/su14094975

APA StyleZhao, G., Wang, X., Negnevitsky, M., Zhang, H., & Li, C. (2022). Performance Improvement of a Novel Trapezoid Air-Cooling Battery Thermal Management System for Electric Vehicles. Sustainability, 14(9), 4975. https://doi.org/10.3390/su14094975