Identification and Quantification of Microplastics in Effluents of Wastewater Treatment Plant by Differential Scanning Calorimetry (DSC)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling Sites

2.2. Sampling Method

2.3. Sample Processing

2.4. Thermal Analysis

3. Results

3.1. Concentration of Microplastics in the Samples

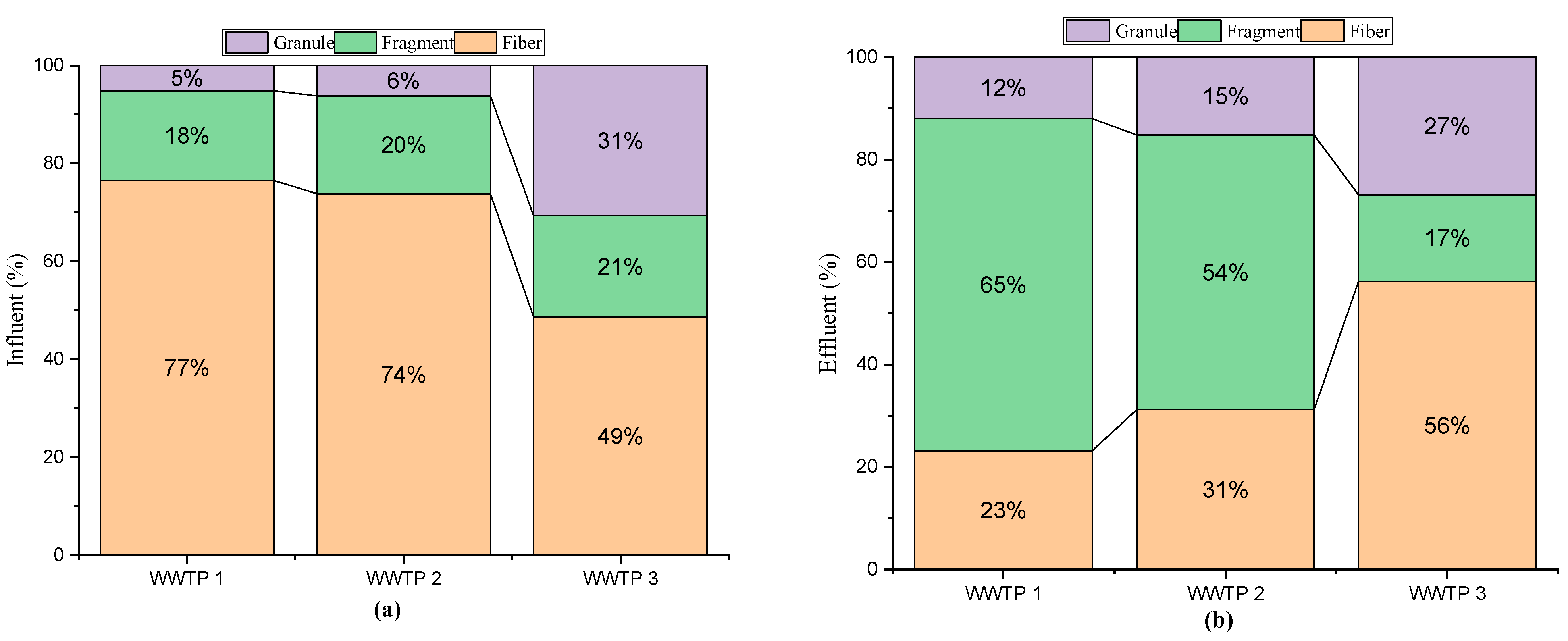

3.2. Classification of the Microplastics Presents in the Samples

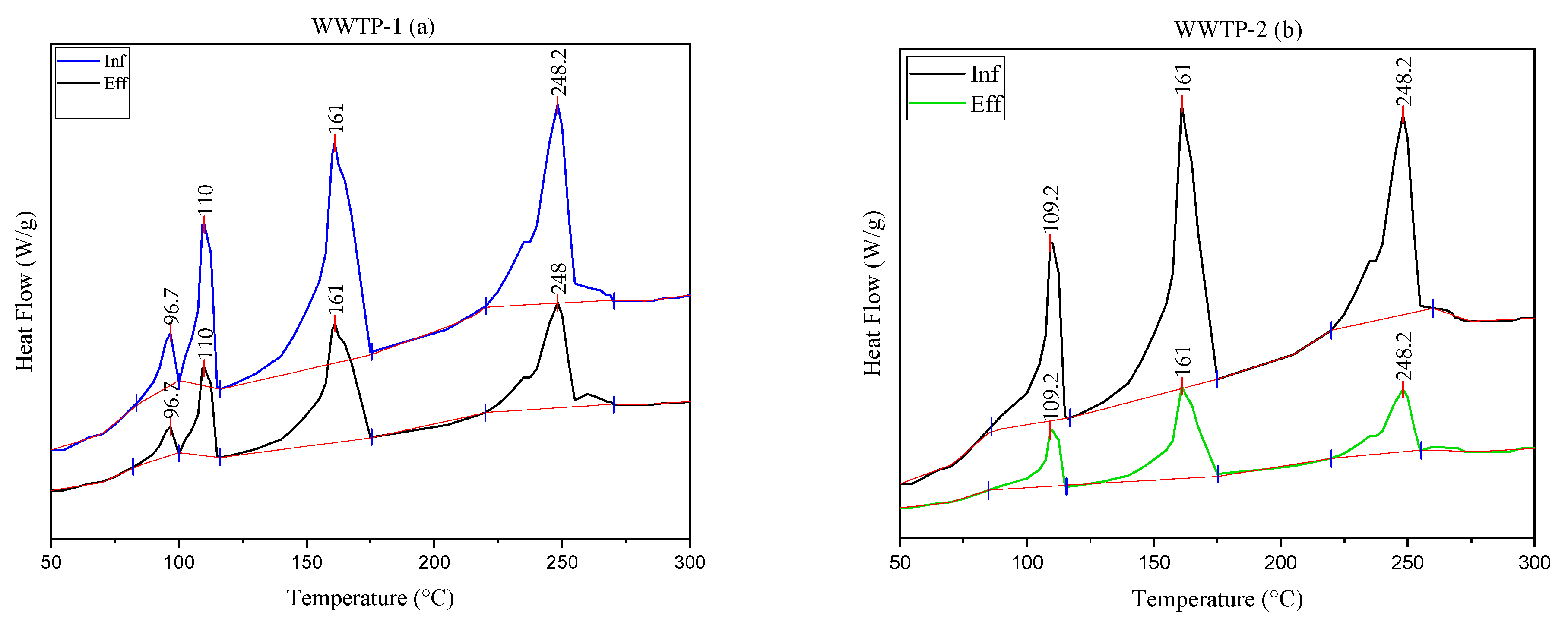

3.3. Identification of the Microplastics Present in the Samples

3.4. Determination of the Percentage Concentration of the Identified Plastics

3.5. Evaluation of the Effectiveness of WWTPs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Picó, Y.; Soursou, V.; Alfarhan, A.H.; El-Sheikh, M.A.; Barceló, D. First evidence of microplastics occurrence in mixed surface and treated wastewater from two major Saudi Arabian cities and assessment of their ecological risk. J. Hazard. Mater. 2021, 416, 125747. [Google Scholar] [CrossRef] [PubMed]

- Mallow, O.; Spacek, S.; Schwarzböck, T.; Fellner, J.; Rechberger, H. A new thermoanalytical method for the quantification of microplastics in industrial wastewater. Environ. Pollut. 2019, 259, 113862. [Google Scholar] [CrossRef] [PubMed]

- Hamidian, A.H.; Ozumchelouei, E.J.; Feizi, F.; Wu, C.; Zhang, Y.; Yang, M. A review on the characteristics of microplastics in wastewater treatment plants: A source for toxic chemicals. J. Clean. Prod. 2021, 295, 126480. [Google Scholar] [CrossRef]

- Hidayaturrahman, H.; Lee, T.-G. A study on characteristics of microplastic in wastewater of South Korea: Identification, quantification, and fate of microplastics during treatment process. Mar. Pollut. Bull. 2019, 146, 696–702. [Google Scholar] [CrossRef]

- Expósito, N.; Rovira, J.; Sierra, J.; Folch, J.; Schuhmacher, M. Microplastics levels, size, morphology and composition in marine water, sediments and sand beaches. Case study of Tarragona coast (western Mediterranean). Sci. Total Environ. 2021, 786, 147453. [Google Scholar] [CrossRef]

- Bogdanowicz, A.; Zubrowska-Sudol, M.; Krasinski, A.; Sudol, M. Cross-Contamination as a Problem in Collection and Analysis of Environmental Samples Containing Microplastics—A Review. Sustainability 2021, 13, 12123. [Google Scholar] [CrossRef]

- Prajapati, S.; Beal, M.; Maley, J.; Brinkmann, M. Qualitative and quantitative analysis of microplastics and microfiber contamination in effluents of the City of Saskatoon wastewater treatment plant. Environ. Sci. Pollut. Res. 2021, 28, 32545–32553. [Google Scholar] [CrossRef]

- Yuan, F.; Zhao, H.; Sun, H.; Zhao, J.; Sun, Y. Abundance, morphology, and removal efficiency of microplastics in two wastewater treatment plants in Nanjing, China. Environ. Sci. Pollut. Res. 2020, 28, 9327–9337. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Q.; Ruan, Y.; Wu, R.; Chen, L.; Zhang, K.; Lam, K.S.P. Intra-day microplastic variations in wastewater: A case study of a sewage treatment plant in Hong Kong. Mar. Pollut. Bull. 2020, 160, 111535. [Google Scholar] [CrossRef]

- Uheida, A.; Mejía, H.G.; Abdel-Rehim, M.; Hamd, W.; Dutta, J. Visible light photocatalytic degradation of polypropylene microplastics in a continuous water flow system. J. Hazard. Mater. 2020, 406, 124299. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Lu, Y.; Zhang, Y.; Deng, Y.; Jiang, W.; Zhao, Y.; Geng, J.; Ding, L.; Ren, H.-Q. Uptake and Accumulation of Polystyrene Microplastics in Zebrafish (Danio rerio) and Toxic Effects in Liver. Environ. Sci. Technol. 2016, 50, 4054–4060. [Google Scholar] [CrossRef] [PubMed]

- Schirinzi, G.F.; Llorca, M.; Seró, R.; Moyano, E.; Barceló, D.; Abad, E.; Farré, M. Trace analysis of polystyrene microplastics in natural waters. Chemosphere 2019, 236, 124321. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Bai, X.; Ye, Z. Removal and generation of microplastics in wastewater treatment plants: A review. J. Clean. Prod. 2021, 291, 125982. [Google Scholar] [CrossRef]

- Habib, R.Z.; Al Kendi, R.; Thiemann, T. The Effect of Wastewater Treatment Plants on Retainment of Plastic Microparticles to Enhance Water Quality—A Review. J. Environ. Prot. 2021, 12, 161–195. [Google Scholar] [CrossRef]

- Taurino, R.; Pozzi, P.; Zanasi, T. Facile characterization of polymer fractions from waste electrical and electronic equipment (WEEE) for mechanical recycling. Waste Manag. 2010, 30, 2601–2607. [Google Scholar] [CrossRef]

- Okoffo, E.D.; O’Brien, S.; O’Brien, J.W.; Tscharke, B.J.; Thomas, K.V. Wastewater treatment plants as a source of plastics in the environment: A review of occurrence, methods for identification, quantification and fate. Environ. Sci. Water Res. Technol. 2019, 5, 1908–1931. [Google Scholar] [CrossRef]

- Schindler, A.; Doedt, M.; Gezgin, Ş.; Menzel, J.; Schmölzer, S. Identification of polymers by means of DSC, TG, STA and computer-assisted database search. J. Therm. Anal. 2017, 129, 833–842. [Google Scholar] [CrossRef] [Green Version]

- Edo, C.; González-Pleiter, M.; Leganés, F.; Fernández-Piñas, F.; Rosal, R. Fate of microplastics in wastewater treatment plants and their environmental dispersion with effluent and sludge. Environ. Pollut. 2019, 259, 113837. [Google Scholar] [CrossRef]

- Bratovcic, A. Degradation of Micro- and Nano-Plastics by Photocatalytic Methods. J. Nanosci. Nanotechnol. Appl. 2017, 3, 1–9. [Google Scholar] [CrossRef]

- Franco, A.; Arellano, J.; Albendín, G.; Rodríguez-Barroso, R.; Zahedi, S.; Quiroga, J.; Coello, M. Mapping microplastics in Cadiz (Spain): Occurrence of microplastics in municipal and industrial wastewaters. J. Water Process Eng. 2020, 38, 101596. [Google Scholar] [CrossRef]

- Hernández-Fernández, J.; Lopez-Martinez, J.; Barceló, D. Quantification and elimination of substituted synthetic phenols and volatile organic compounds in the wastewater treatment plant during the production of industrial scale polypropylene. Chemosphere 2020, 263, 128027. [Google Scholar] [CrossRef] [PubMed]

- Sutton, R.; Mason, S.A.; Stanek, S.K.; Willis-Norton, E.; Wren, I.F.; Box, C. Microplastic contamination in the San Francisco Bay, California, USA. Mar. Pollut. Bull. 2016, 109, 230–235. [Google Scholar] [CrossRef] [PubMed]

- Ziajahromi, S.; Neale, P.A.; Silveira, I.T.; Chua, A.; Leusch, F.D. An audit of microplastic abundance throughout three Australian wastewater treatment plants. Chemosphere 2020, 263, 128294. [Google Scholar] [CrossRef]

- Habib, R.Z.; al Kindi, R.; Thiemann, T. The Effect of Wastewater Treatment Methods on the Retainment of Plastic Microparticles. In Wastewater Treatment; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Cristaldi, A.; Fiore, M.; Zuccarello, P.; Conti, G.O.; Grasso, A.; Nicolosi, I.; Copat, C.; Ferrante, M. Efficiency of Wastewater Treatment Plants (WWTPs) for Microplastic Removal: A Systematic Review. Int. J. Environ. Res. Public Health 2020, 17, 8014. [Google Scholar] [CrossRef]

- Alvim, C.B.; Bes-Piá, M.; Mendoza-Roca, J.-A. Separation and identification of microplastics from primary and secondary effluents and activated sludge from wastewater treatment plants. Chem. Eng. J. 2020, 402, 126293. [Google Scholar] [CrossRef]

- Bitter, H.; Lackner, S. First quantification of semi-crystalline microplastics in industrial wastewaters. Chemosphere 2020, 258, 127388. [Google Scholar] [CrossRef]

- Heo, N.W.; Hong, S.H.; Han, G.M.; Hong, S.; Lee, J.; Song, Y.K.; Jang, M.; Shim, W.J. Distribution of small plastic debris in cross-section and high strandline on Heungnam beach, South Korea. Ocean Sci. J. 2013, 48, 225–233. [Google Scholar] [CrossRef]

- Hidalgo-Ruz, V.; Thiel, M. Distribution and abundance of small plastic debris on beaches in the SE Pacific (Chile): A study supported by a citizen science project. Mar. Environ. Res. 2013, 87–88, 12–18. [Google Scholar] [CrossRef]

- Bank, M.S. Microplastic in the Environment: Pattern and Process; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Shim, W.J.; Hong, S.H.; Eo, S.E. Identification methods in microplastic analysis: A review. Anal. Methods 2016, 9, 1384–1391. [Google Scholar] [CrossRef]

- Hernández-Fernandez, J.; Rodríguez, E. Determination of phenolic antioxidants additives in industrial wastewater from polypropylene production using solid phase extraction with high-performance liquid chromatography. J. Chromatogr. A 2019, 1607, 460442. [Google Scholar] [CrossRef] [PubMed]

- He, S.; Jia, M.; Xiang, Y.; Song, B.; Xiong, W.; Cao, J.; Peng, H.; Yang, Y.; Wang, W.; Yang, Z.; et al. Biofilm on microplastics in aqueous environment: Physicochemical properties and environmental implications. J. Hazard. Mater. 2021, 424, 127286. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Fernández, J.; Rayón, E.; López, J.; Arrieta, M.P. Enhancing the Thermal Stability of Polypropylene by Blending with Low Amounts of Natural Antioxidants. Macromol. Mater. Eng. 2019, 304, 1900379. [Google Scholar] [CrossRef]

- Bitter, H.; Lackner, S. Fast and easy quantification of semi-crystalline microplastics in exemplary environmental matrices by differential scanning calorimetry (DSC). Chem. Eng. J. 2021, 423, 129941. [Google Scholar] [CrossRef]

- Majewsky, M.; Bitter, H.; Eiche, E.; Horn, H. Determination of microplastic polyethylene (PE) and polypropylene (PP) in environmental samples using thermal analysis (TGA-DSC). Sci. Total Environ. 2016, 568, 507–511. [Google Scholar] [CrossRef]

- Mansa, R.; Zou, S. Thermogravimetric analysis of microplastics: A mini review. Environ. Adv. 2021, 5, 100117. [Google Scholar] [CrossRef]

- Chialanza, M.R.; Sierra, I.; Parada, A.P.; Fornaro, L. Identification and quantitation of semi-crystalline microplastics using image analysis and differential scanning calorimetry. Environ. Sci. Pollut. Res. 2018, 25, 16767–16775. [Google Scholar] [CrossRef]

- Werme, C.; Codiga, D.; Libby, P.; Carroll; Charlestra, L.; Keay, K. 2020 Outfall Monitoring Overview; Massachusetts Water Resources Authority: Boston, MA, USA, 2021. [Google Scholar]

- Birocchi, P.; Dottori, M.; Costa, C.D.G.R.; Leite, J.R.B. Study of three domestic sewage submarine outfall plumes through the use of numerical modeling in the São Sebastião channel, São Paulo state, Brazil. Reg. Stud. Mar. Sci. 2021, 42, 101647. [Google Scholar] [CrossRef]

- Ziajahromi, S.; Neale, P.A.; Rintoul, L.; Leusch, F.D.L. Wastewater treatment plants as a pathway for microplastics: Development of a new approach to sample wastewater-based microplastics. Water Res. 2017, 112, 93–99. [Google Scholar] [CrossRef]

- Shabaka, S.H.; Ghobashy, M.; Marey, R.S. Identification of marine microplastics in Eastern Harbor, Mediterranean Coast of Egypt, using differential scanning calorimetry. Mar. Pollut. Bull. 2019, 142, 494–503. [Google Scholar] [CrossRef]

- Turan, N.B.; Erkan, H.S.; Engin, G.O. Microplastics in wastewater treatment plants: Occurrence, fate and identification. Process Saf. Environ. Prot. 2020, 146, 77–84. [Google Scholar] [CrossRef]

- Choong, W.S.; Hadibarata, T.; Yuniarto, A.; Tang, K.H.D.; Abdullah, F.; Syafrudin, M.; Al Farraj, D.A.; Al-Mohaimeed, A.M. Characterization of microplastics in the water and sediment of Baram River estuary, Borneo Island. Mar. Pollut. Bull. 2021, 172, 112880. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhang, J.; Liu, H.; Guo, X.; Zhang, X.; Yao, X.; Cao, Z.; Zhang, T. A review of the removal of microplastics in global wastewater treatment plants: Characteristics and mechanisms. Environ. Int. 2020, 146, 106277. [Google Scholar] [CrossRef] [PubMed]

- Mintenig, S.; Int-Veen, I.; Löder, M.; Primpke, S.; Gerdts, G. Identification of microplastic in effluents of waste water treatment plants using focal plane array-based micro-Fourier-transform infrared imaging. Water Res. 2017, 108, 365–372. [Google Scholar] [CrossRef] [PubMed]

- Mahon, A.M.; O’Connell, B.; Healy, M.; O’Connor, I.; Officer, R.; Nash, R.; Morrison, L. Microplastics in Sewage Sludge: Effects of Treatment. Environ. Sci. Technol. 2016, 51, 810–818. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, M.N.; Gondal, M.A.; Redhwi, H.H. Identification of different type of polymers in plastics waste. J. Environ. Sci. Health Part A 2008, 43, 1303–1310. [Google Scholar] [CrossRef]

| Plant | Sample | Influent | Sample | Effluent | ||

|---|---|---|---|---|---|---|

| Concentration | Volume | Concentration | Volume | |||

| (MP/L) | L | (MP/L) | L | |||

| WWTP-1 | A1-1 | 7 | 50 | A1-2 | 3.62 | 35 |

| A2-1 | 10 | 45 | A2-2 | 4.18 | 30 | |

| A3-1 | 8.5 | 97 | A3-2 | 3.67 | 82 | |

| WWTP-2 | B1-1 | 7.1 | 35 | B1-2 | 0.41 | 20 |

| B2-1 | 9.12 | 55 | B2-2 | 0.28 | 40 | |

| B3-1 | 8.5 | 82 | B3-2 | 0.82 | 67 | |

| WWTP-3 | C1-1 | 6.8 | 50 | C1-2 | 0.46 | 35 |

| C2-1 | 8.5 | 65 | C2-2 | 0.37 | 50 | |

| C3-1 | 8 | 98 | C3-2 | 0.51 | 83 | |

| Plant | Sample | Influent | Sample | Effluent | ||||

|---|---|---|---|---|---|---|---|---|

| 10–1000 μm | 1000–5000 μm | Concentration | 10–1000 μm | 1000–5000 μm | Concentration | |||

| (MP/L) * | (MP/L) | (MP/L) | (MP/L) | (MP/L) | (MP/L) | |||

| WWTP-1 | A1-1 | 2.2 | 4.8 | 7 | A1-2 | 3.58 | 0.036 | 3.62 |

| A2-1 | 3.7 | 6.3 | 10 | A2-2 | 4.1 | 0.075 | 4.18 | |

| A3-1 | 2.95 | 5.55 | 8.5 | A3-2 | 3.64 | 0.033 | 3.67 | |

| WWTP-2 | B1-1 | 1.2 | 5.9 | 7.1 | B1-2 | 0.41 | 0 | 0.41 |

| B2-1 | 2.3 | 6.82 | 9.12 | B2-2 | 0.28 | 0 | 0.28 | |

| B3-1 | 1.95 | 6.56 | 8.5 | B3-2 | 0.82 | 0 | 0.82 | |

| WWTP-3 | C1-1 | 1.6 | 5.2 | 6.8 | C1-2 | 0.45 | 0.004 | 0.46 |

| C2-1 | 2.57 | 5.9 | 8.5 | C2-2 | 0.37 | 0.004 | 0.37 | |

| C3-1 | 2.29 | 5.75 | 8 | C3-2 | 0.51 | 0 | 0.51 | |

| Material | Abbreviation | Formula | Density | Tm | Onset Temperature | Sources |

|---|---|---|---|---|---|---|

| g/cm3 | °C | °C | ||||

| Low density polyethylene | LDPE | (C2H4)n | 0.910–0.925 | 118 | 110 | Personal care products (such as body and facial scrubs), packaging films food and water bottles |

| Polypropylene | PP | (C3H6)n | 0.83–0.92 | 164 | 161 | Synthetic textile fibers, water pipes, food and medicine containers |

| Polyethylene terephthalate | PET | (C10H8O4)n | 0.96–1.45 | 248.5 | 248.2 | Bottles and synthetic textile fibers |

| Polystyrene | PS | (C8H8)n | 1.04–1.1 | 104.4 | 96.7 | Disposable plastic plates and cutlery, sound insulation material for hollow floors |

| Material | Plant 1 | Plant 2 | Plant 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Influent | Effluent | Influent | Effluent | Influent | Effluent | |||||||

| Area mJ | % | Area mJ | % | Area mJ | % | Area mJ | % | Area mJ | % | Area mJ | % | |

| PS | 2.256 | 4% | 1.228 | 4% | - | - | - | - | 2.303 | 5% | 1.563 | 7% |

| PE-LD | 7.443 | 14% | 4.046 | 15% | 10.011 | 20% | 3.006 | 19% | 7.499 | 16% | 4.154 | 18% |

| PP | 23.138 | 45% | 12.408 | 45% | 24.188 | 48% | 7.880 | 50% | 19.842 | 41% | 10.843 | 46% |

| PET | 19.041 | 37% | 9.983 | 36% | 16.321 | 32% | 4.957 | 31% | 18.358 | 38% | 7.155 | 30% |

| Total | 51.878 | 100% | 27.665 | 100% | 50.520 | 100% | 15.842 | 100% | 48.001 | 100% | 23.715 | 100% |

| Plant | Sample | Influent | Effluent | Total Removal (%) |

|---|---|---|---|---|

| MP/L | MP/L | |||

| WWTP-1 | A1 | 7.00 | 3.62 | 48.3 |

| A2 | 10.00 | 4.18 | 58.2 | |

| A3 | 8.50 | 3.67 | 56.8 | |

| WWTP-2 | B1 | 7.10 | 0.41 | 94.16 |

| B2 | 9.12 | 0.28 | 96.9 | |

| B3 | 8.51 | 0.82 | 90.4 | |

| WWTP-3 | C1 | 6.80 | 0.46 | 93.3 |

| C2 | 8.47 | 0.37 | 95.6 | |

| C3 | 8.04 | 0.51 | 93.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández Fernández, J.; Cano, H.; Guerra, Y.; Puello Polo, E.; Ríos-Rojas, J.F.; Vivas-Reyes, R.; Oviedo, J. Identification and Quantification of Microplastics in Effluents of Wastewater Treatment Plant by Differential Scanning Calorimetry (DSC). Sustainability 2022, 14, 4920. https://doi.org/10.3390/su14094920

Hernández Fernández J, Cano H, Guerra Y, Puello Polo E, Ríos-Rojas JF, Vivas-Reyes R, Oviedo J. Identification and Quantification of Microplastics in Effluents of Wastewater Treatment Plant by Differential Scanning Calorimetry (DSC). Sustainability. 2022; 14(9):4920. https://doi.org/10.3390/su14094920

Chicago/Turabian StyleHernández Fernández, Joaquín, Heidis Cano, Yoleima Guerra, Esneyder Puello Polo, John Fredy Ríos-Rojas, Ricardo Vivas-Reyes, and Juan Oviedo. 2022. "Identification and Quantification of Microplastics in Effluents of Wastewater Treatment Plant by Differential Scanning Calorimetry (DSC)" Sustainability 14, no. 9: 4920. https://doi.org/10.3390/su14094920

APA StyleHernández Fernández, J., Cano, H., Guerra, Y., Puello Polo, E., Ríos-Rojas, J. F., Vivas-Reyes, R., & Oviedo, J. (2022). Identification and Quantification of Microplastics in Effluents of Wastewater Treatment Plant by Differential Scanning Calorimetry (DSC). Sustainability, 14(9), 4920. https://doi.org/10.3390/su14094920