Research on Spatial Planning of Petrochemical Industrial Parks from the Perspective of Symbiosis: Example of Yueyang Green Chemical Industry Park

Abstract

:1. Introduction

2. Theoretical Background

2.1. Industrial Symbiosis Theory

2.2. Symbiotic Industrial Park

2.3. Theory of Ecological Carrying Capacity

2.4. Theory of Sustainable Development

3. Materials and Methods

3.1. Studied District

3.2. Data Source and Processing

3.2.1. Source of Data

3.2.2. Determine Planning Principles

3.2.3. Analysis of the Status Quo of the Park

3.2.4. Design of Symbiotic Industrial Chain

3.2.5. Ecological Footprint and Ecological Carrying Capacity Estimation

3.2.6. Scale Prediction and Spatial Selection of Industrial Land

4. Results

4.1. Comprehensive Evaluation for the Resource Environment of Changling District under Symbiosis

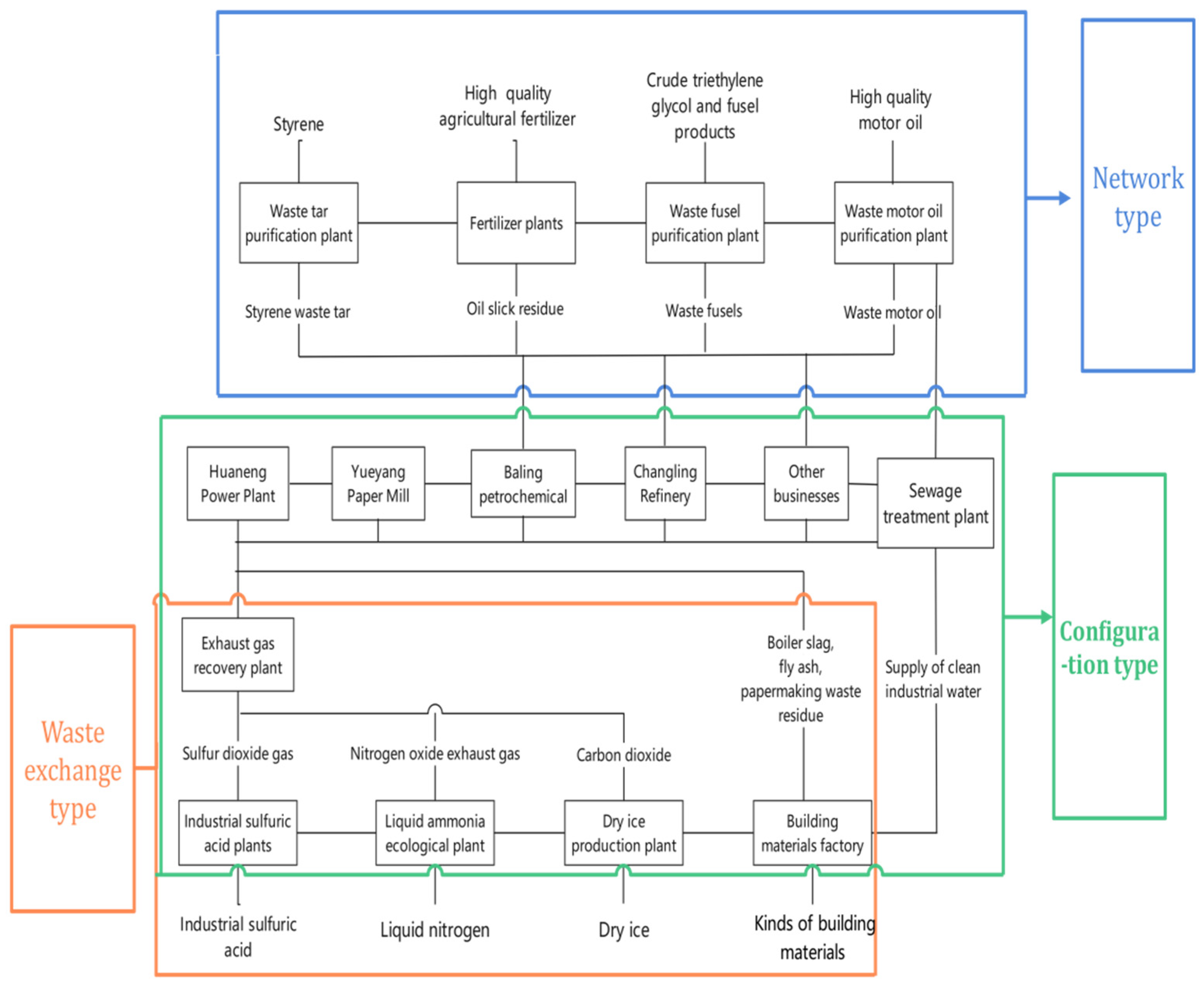

4.2. Design of the Symbiotic Industrial Network

4.3. Land-Use Scale Prediction Based on Ecological Carrying Capacity

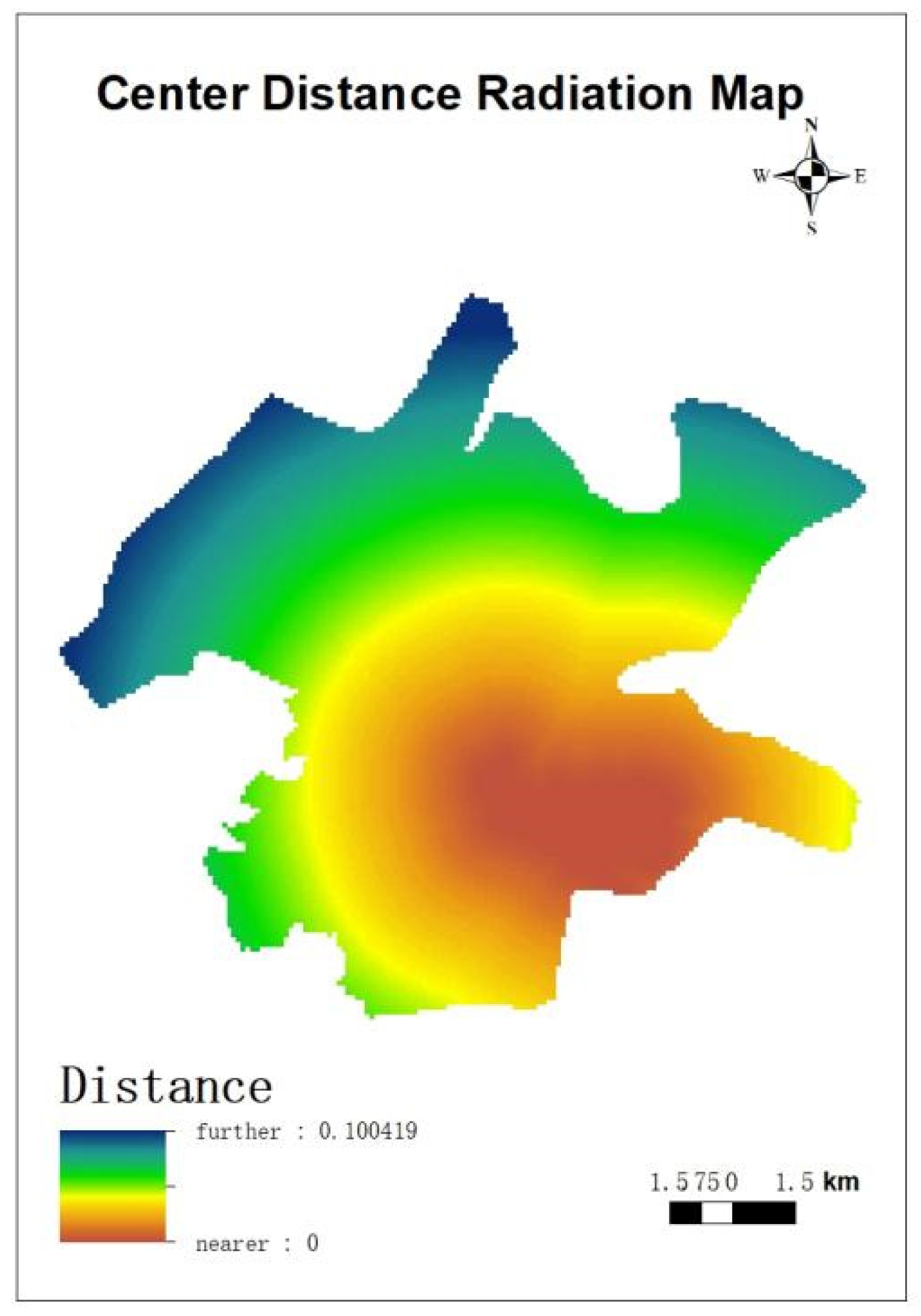

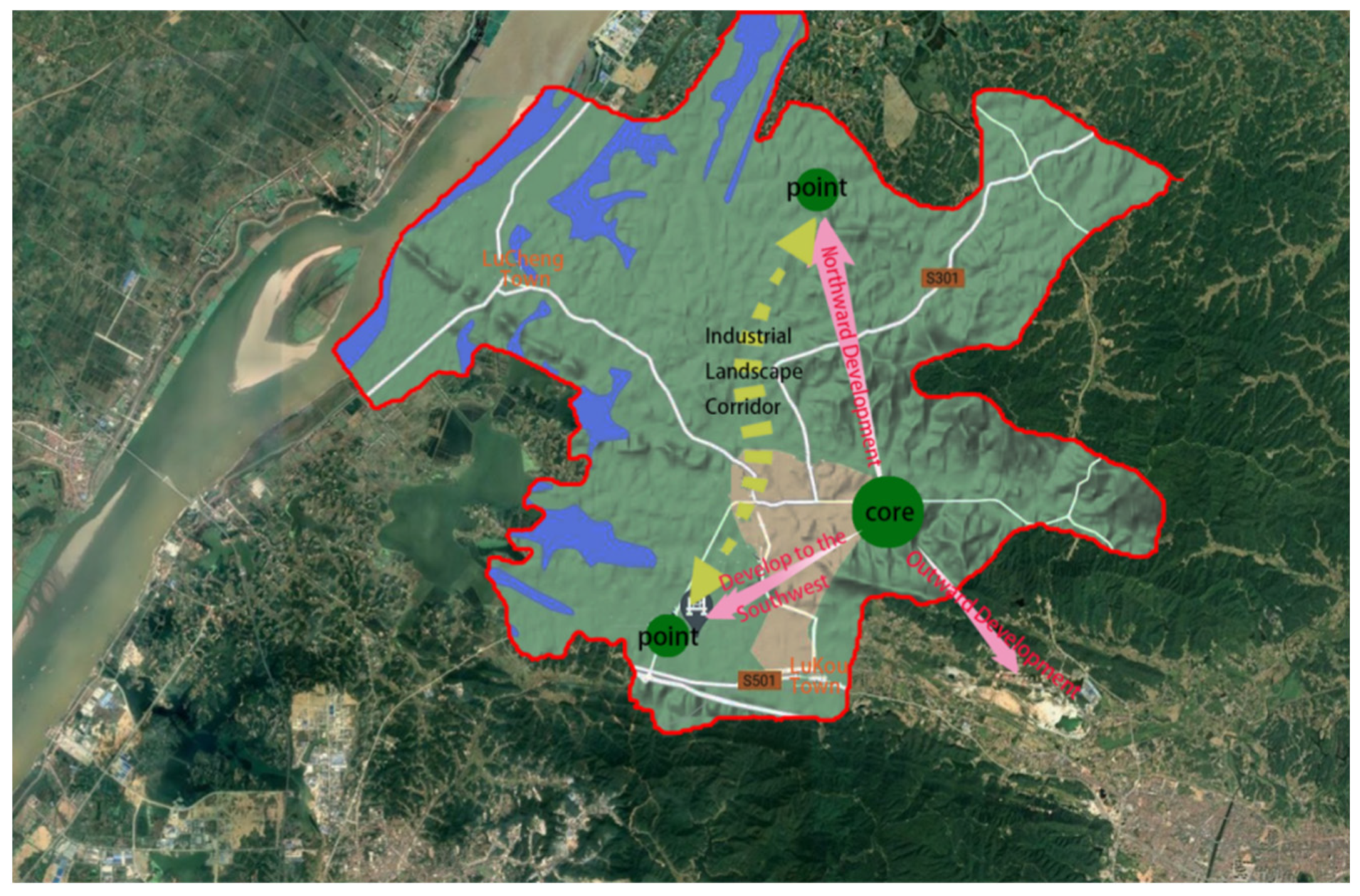

4.4. Spatial Site Selection and Layout of Ecoindustrial Park

5. Discussion

6. Conclusions and Political Implications

6.1. Conclusions

6.2. Policy Implications

6.2.1. Construction of an Appropriate Symbiotic Chain

6.2.2. Land-Use Elasticity Prediction

6.2.3. Intensive Planning of Public Facilities

6.3. Research Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ashton, W. Understanding the organization of industrial ecosystems. J. Ind. Ecol. 2008, 12, 34–51. [Google Scholar] [CrossRef]

- Wu, Z. Ecological Industrial Park Industrial Symbiosis Network Research; Dalian University of Technology: Dalian, China, 2002. [Google Scholar]

- Wang, Y.; Quan, H.; Ling, C.; Xu, H.; Wang, R.; Liu, S. Ecological agricultural park waste resource treatment and utilization research. Environ. Pollut. Control. Technol. Equip. 2002, 4, 60–64. [Google Scholar]

- Ren, Y.; Hu, G. Research on industrial chain Stability Mechanism—Is based on the perspective of parallel coupling in symbiosis theory. Comp. Econ. Soc. Syst. 2008, 2, 180–184. [Google Scholar]

- Lin, L.; Yan, S.; Zeng, H. Industrial agglomeration and human capital investment benefit—Comes from the micro-evidence of Chinese industrial enterprises. South. Econ. 2005, 2, 70–89. [Google Scholar]

- Liu, J.; Zang, L.; Ji, T. Discussion on Environmental Management in Industrial Parks in China. Environ. Sci. Technol. 2005, 2, 58–60, 117. [Google Scholar]

- Jones, S. Waste management in australia is an environmental crisis: What needs to change so adaptive governance can help? Sustainability 2020, 12, 9212. [Google Scholar] [CrossRef]

- Walter, C.S.; Contador, J.C.; Contador, J.L.; Fragomeni, M.A.; de Paula Monken, S.F.; Ana, F.R.; Martins de Souza, V.H. Implementing industry 4.0 through cleaner production and social stakeholders: Holistic and sustainable model. Sustainability 2021, 13, 12479. [Google Scholar]

- Rakic, S.; Pavlovic, M. A precondition of sustainability: Industry 4.0 readiness. Sustainability 2021, 13, 6641. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Long, H. Green development behavior and performance of industrial enterprises based on grounded theory study: Evidence from china. Sustainability 2019, 11, 4133. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.; Shang, J. Theory and method of ecological industrial park planning and construction. Econ. Geogr. 2004, 3, 399–402. [Google Scholar]

- Dang, L.; Li, L.; Li, W.; Chen, M. Definition, type and application of urban ecological sensitive area. J. East China Norm. Univ. Nat. Sci. Ed. 2004, 2, 97–103. [Google Scholar]

- Qin, C.; Wang, H.; Tian, Y.; Yao, Z. Research on the evaluation indicators of resource and environmental carrying capacity. China’s Popul. Resour. Environ. 2011, 21, 335–338. [Google Scholar]

- Jun, Y.; Zheng, Y. Exploration of Comprehensive Spatial Planning Preparation: A Case Study of Chongqing Urban and Rural Planning Reform Pilot. Planner 2009, 25, 90–93. [Google Scholar]

- Zhang, W.; Yu, J. Regional industrial ecological path selection based on industrial symbiosis network. Soc. Sci. 2008, 12, 47–50. [Google Scholar]

- Ayres, R.U.; Ayres, L.W. Industrial ecology: Toward closing the materials cycle. Resour. Conserv. Recycl. 1996, 21, 145–173. [Google Scholar] [CrossRef]

- Lambert, A.J.D.; Boons, F.A. Eco-industrial parks: Stimulating Sustainable Development in Mixed Industrial Parks. Technovation 2002, 22, 471–484. [Google Scholar] [CrossRef]

- Chertow, M.R.; Lombardi, D.R. Quantifying economic and environmental benefits of co-located firms. Environ. Sci. Technol. 2005, 39, 6535–6541. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lifset, R. Journal of Industrial Ecology at the School of Forestry & Environmental Studies; Yale University: New Haven, CT, USA, 1997. [Google Scholar]

- Costa, I.; Ferrao, P. A case study of industrial symbiosis development using a middle-out approach. J. Clean. Prod. 2010, 18, 984–992. [Google Scholar] [CrossRef]

- Branson, R. Re-constructing Kalundborg: The reality of bilateral symbiosis and other insights. J. Clean. Prod. 2016, 112, 4344–4352. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, C. A Comparative Study of the Industrial Symbiont Model based on Industrial Ecology. Sci. Sci. Technol. Manag. 2002, 2, 66–69. [Google Scholar]

- Miao, Z.; Peng, J. Research on Industrial Enterprise Ecosystem and Its Symbiotic Mechanism. Ecol. Econ. 2012, 7, 94–97, 104. [Google Scholar]

- Ehrenfeld, J.; Gertler, N. Industrial ecology in practice: The evolution of interdependence at kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef] [Green Version]

- Audra, J.; Potts, C. Choetaw eco-industrial Parks: An ecologieal approach to industrial land-use planning and design. Landsc. Uthan Plan. 1998, 42, 239–257. [Google Scholar]

- Park, H.S.; Rene, E.R.; Choi, S.M.; Chiu, A.S.F. Strategies for sustainable development of industrial park in Ulsan, South Korea—From spontaneous evolution to systematic expansion of industrial symbiosis. J. Environ. Manag. 2008, 87, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Geng, Y. Industrial and urban symbiosis in Japan: Analysis of the Eco-Town program1997–2006. J. Environ. Manag. 2009, 90, 1544–1556. [Google Scholar] [CrossRef]

- Yan, X.; Yuan, L. Industrial Symbiosis Research: Theory, Practice and Reflections. Mon. Theory Mag. 2009, 4, 155–157. [Google Scholar]

- Xue, Q.; Song, W.; Zhang, Y.L.; Fengyun, M. Research progress in ecological carrying capacity: Implications, assessment methods and current focus. J. Resour. Ecol. 2017, 8, 514. [Google Scholar]

- Fan, B.; Deng, F.; Ma, Q. A Review of the Sustainable Development Theory. Zhejiang Soc. Sci. Sec. 1998, 2, 42–58. [Google Scholar]

- Liu, G. Sustainable Development Strategy and Ecological Economic. In Proceedings of the third Symposium of China Society of Ecological Economics, Shanghai, China, 15 May 2021. [Google Scholar]

- Zhang, J. A Research Report of Yueyang Green Petrochemical Industrial Park. Anal. Enterp. 2009, 9, 66–68. [Google Scholar]

- Li, H. Analysis of Optimization of Planning and Control Index of Industrial Land from an Adaptive Perspective; South China University of Technology: Guangzhou, China, 2020; p. 116. [Google Scholar]

- Rural Social and Economic Investigation Department under National Bureau of Statistics. China Statistical Yearbook (Township) 2015–2020; China Statistics Press: Beijing, China, 2020.

- Sokka, L.; Lehtoranta, S.; Nissinen, A.; Melanen, M. Analyzing the Environmental Benefits of Industrial Symbiosis: Life Cycle Assessment Applied to a Finnish Forest Industry Complex. J. Ind. Ecol. 2011, 15, 137–155. [Google Scholar] [CrossRef]

- Li, B.; Xiang, P.; Hu, M.; Zhang, C.; Dong, L. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. J. Clean. Prod. 2017, 157, 267–277. [Google Scholar] [CrossRef]

- Jin, X.; Liu, Q. Evolution and Comment of Ecological Footprint Model for Natural Resources Accounting. J. Nat. Resour. 2017, 32, 163–176. [Google Scholar]

- Gao, Z.; Zeng, Q.; Tan, X.; Lei, J.; Zhang, Y. Calculation and Application of Equivalent Factor and Yield Factor in Ecological Footprint Model of “National Hectare”. J. Anhui Agric. Sci. 2010, 38, 7868–7871. [Google Scholar]

- Zang, S.; Zheng, R.; Sun, X. Quantitative Analysis of Sustainable Development of Resource-based Cities Based on Ecological Footprint Mode—A Case Study of Daqing, a Petroleum City in Heilongjiang Province. Sci. Geogr. Sin. 2006, 4, 420–424. [Google Scholar]

- Fan, W. Historical Evolution of China’s Industrialization; Wuhan University: Hubei, China, 2013; pp. 65–75. [Google Scholar]

| Year | Land Type | Arable Land | Grassland | Forest Land | Water Area | |

|---|---|---|---|---|---|---|

| 2015 | Ecological Footprint Demand per capita | Area per capita (hm2/cap) | 0.0513 | 0.0017 | 0.0778 | 0.0459 |

| Equivalent Factor | 4.72 | 1.13 | 0.19 | 3.02 | ||

| Equivalent Area (hm2/cap) | 0.2421 | 0.0019 | 0.0148 | 0.1386 | ||

| Ecological Carrying Capacity | Area per capita (hm2/cap) | 0.0451 | 0.0015 | 0.0685 | 0.0404 | |

| Equivalent Factor | 4.72 | 1.13 | 0.19 | 3.02 | ||

| Yield Factor | 3.4633 | 0.0052 | 2.2694 | 7.1128 | ||

| Equivalent Area (hm2/cap) | 0.738 | 0.0001 | 0.0295 | 0.8676 | ||

| Ecological Surplus | 1.2377 | |||||

| 2016 | Ecological Footprint Demand per capita | Area per capita (hm2/cap) | 0.0507 | 0.0017 | 0.0779 | 0.0454 |

| Equivalent Factor | 4.39 | 1.44 | 0.18 | 3.22 | ||

| Equivalent Area (hm2/cap) | 0.2226 | 0.0024 | 0.014 | 0.1462 | ||

| Ecological Carrying Capacity | Area per capita (hm2/cap) | 0.0446 | 0.0015 | 0.0686 | 0.034 | |

| Equivalent Factor | 4.39 | 1.44 | 0.18 | 3.22 | ||

| Yield Factor | 3.2273 | 0.0053 | 2.4752 | 7.7436 | ||

| Equivalent Area (hm2/cap) | 0.6321 | 0.0001 | 0.0305 | 0.9962 | ||

| Ecological Surplus | 1.2737 | |||||

| 2020 | Ecological Footprint Demand per capita | Area per capita (hm2/cap) | 0.0388 | 0.0005 | 0.0894 | 0.0374 |

| Equivalent Factor | 5.61 | 1.52 | 0.21 | 3.55 | ||

| Equivalent Area (hm2/cap) | 0.2177 | 0.0008 | 0.0188 | 0.0330 | ||

| Ecological Carrying Capacity | Area per capita (hm2/cap) | 0.0341 | 0.0004 | 0.0788 | 0.0329 | |

| Equivalentfactor | 5.61 | 1.52 | 0.21 | 3.55 | ||

| Yield factor | 4.4373 | 0.0023 | 3.4968 | 9.8642 | ||

| Equivalent Area (hm2/cap) | 0.8500 | 0.0000 | 0.0578 | 1.1525 | ||

| Ecological Surplus | 1.6903 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Yuan, X.; Yang, S.; Abudu, K.; Qin, K. Research on Spatial Planning of Petrochemical Industrial Parks from the Perspective of Symbiosis: Example of Yueyang Green Chemical Industry Park. Sustainability 2022, 14, 4580. https://doi.org/10.3390/su14084580

Wang M, Yuan X, Yang S, Abudu K, Qin K. Research on Spatial Planning of Petrochemical Industrial Parks from the Perspective of Symbiosis: Example of Yueyang Green Chemical Industry Park. Sustainability. 2022; 14(8):4580. https://doi.org/10.3390/su14084580

Chicago/Turabian StyleWang, Min, Xiaohan Yuan, Shuqi Yang, Kahaer Abudu, and Kongtao Qin. 2022. "Research on Spatial Planning of Petrochemical Industrial Parks from the Perspective of Symbiosis: Example of Yueyang Green Chemical Industry Park" Sustainability 14, no. 8: 4580. https://doi.org/10.3390/su14084580

APA StyleWang, M., Yuan, X., Yang, S., Abudu, K., & Qin, K. (2022). Research on Spatial Planning of Petrochemical Industrial Parks from the Perspective of Symbiosis: Example of Yueyang Green Chemical Industry Park. Sustainability, 14(8), 4580. https://doi.org/10.3390/su14084580