Energy Consumption and CO2 Emissions Related to Wine Production: The Case Study of a Winery in Douro Wine Region-Portugal

Abstract

:1. Introduction

2. Methods

2.1. Energy to Water in Pumping Operation

2.2. Energy to Water in Clean Water Treatment Processes

2.3. Energy to Water in Wastewater Treatment Processes

2.4. CO2 Related Emissions

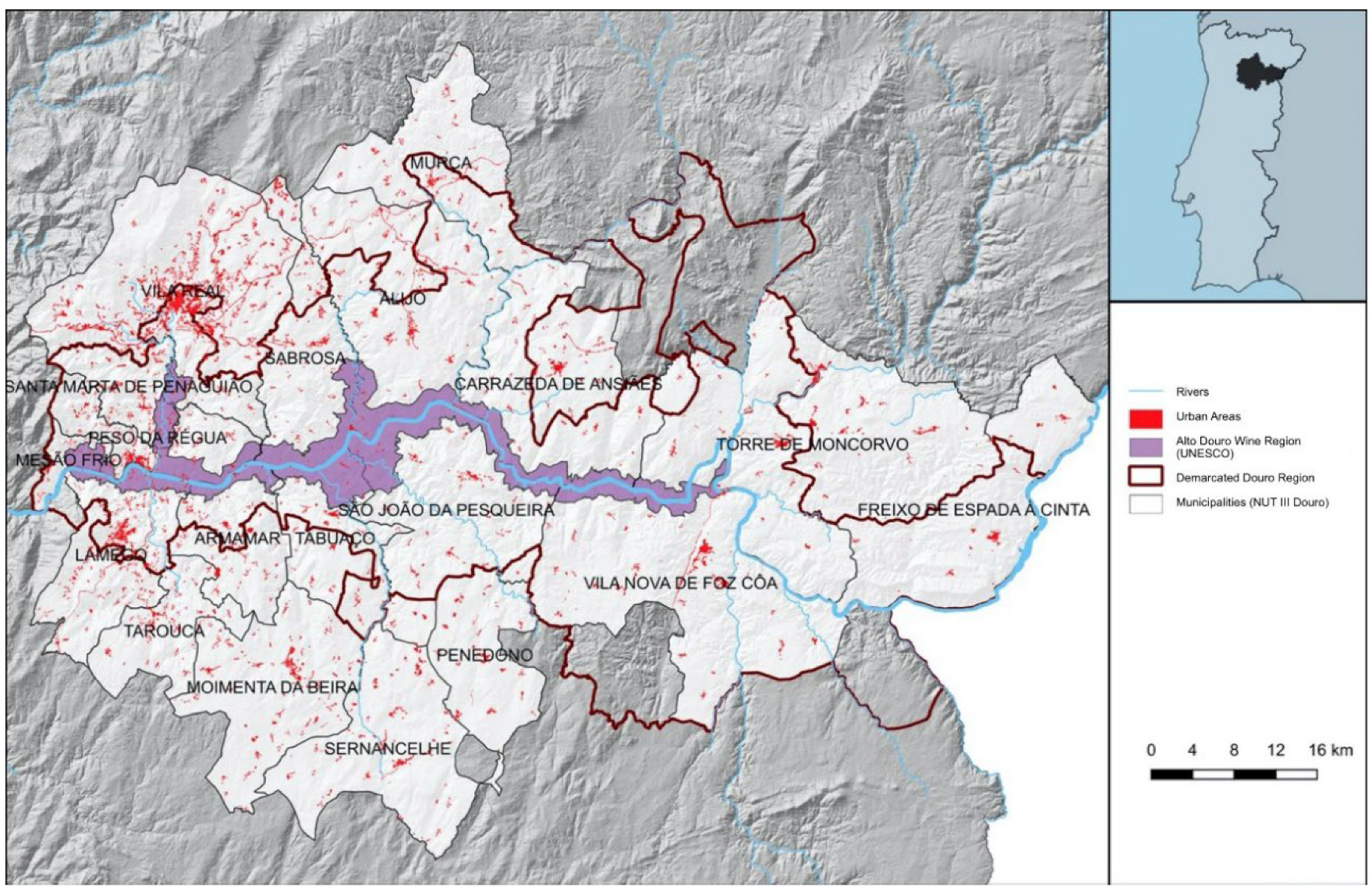

2.5. Study Area

2.6. Data Collection

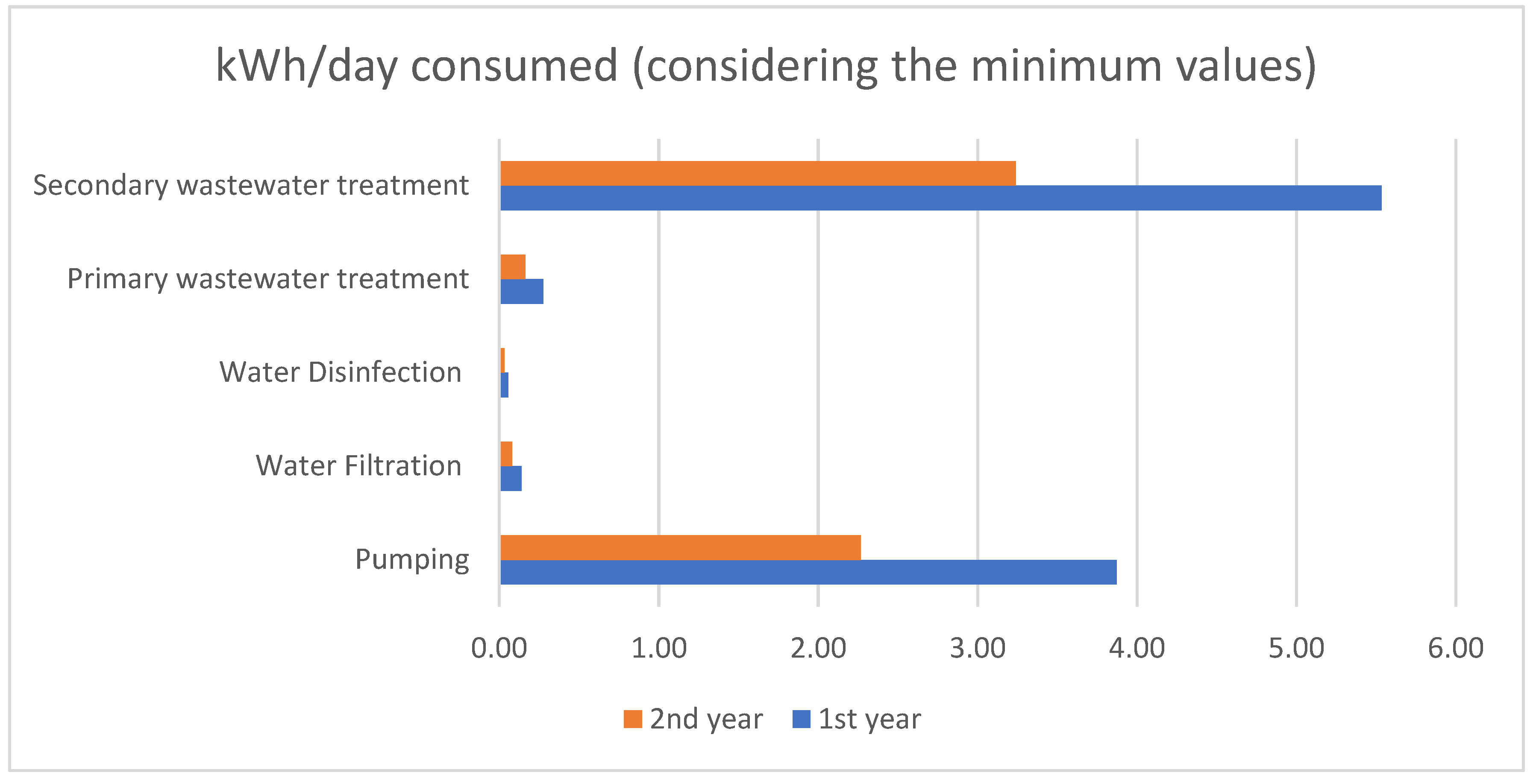

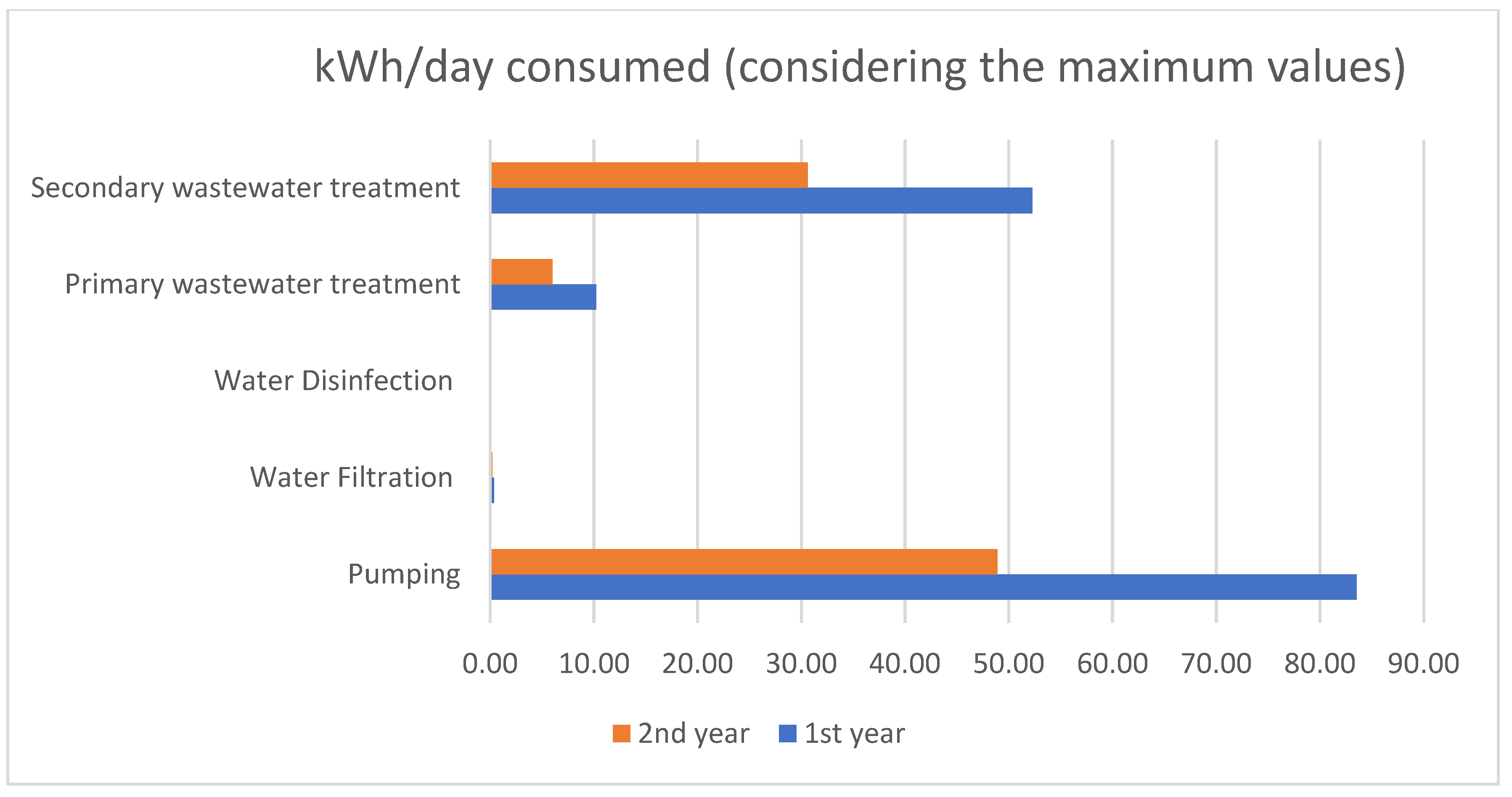

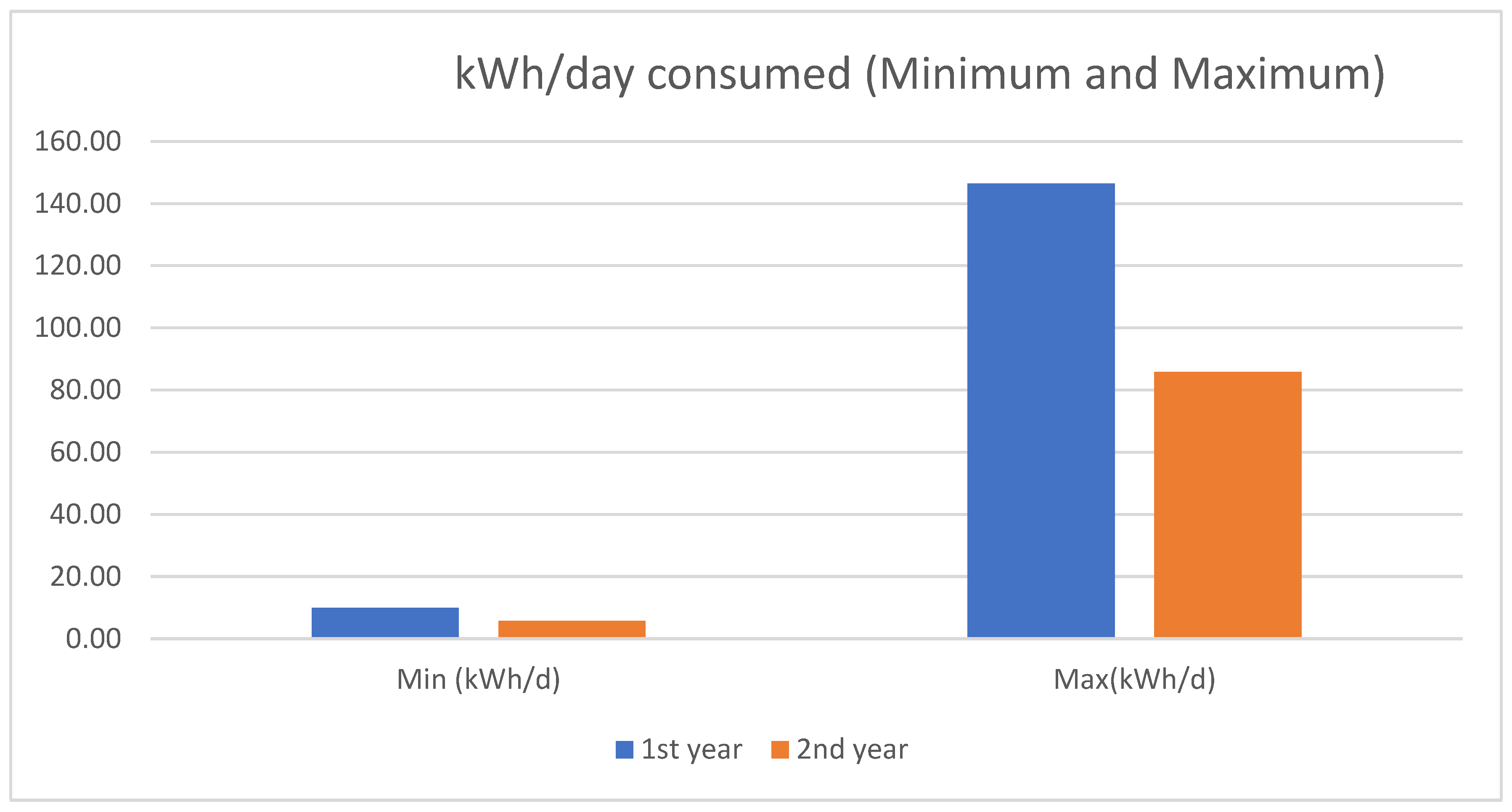

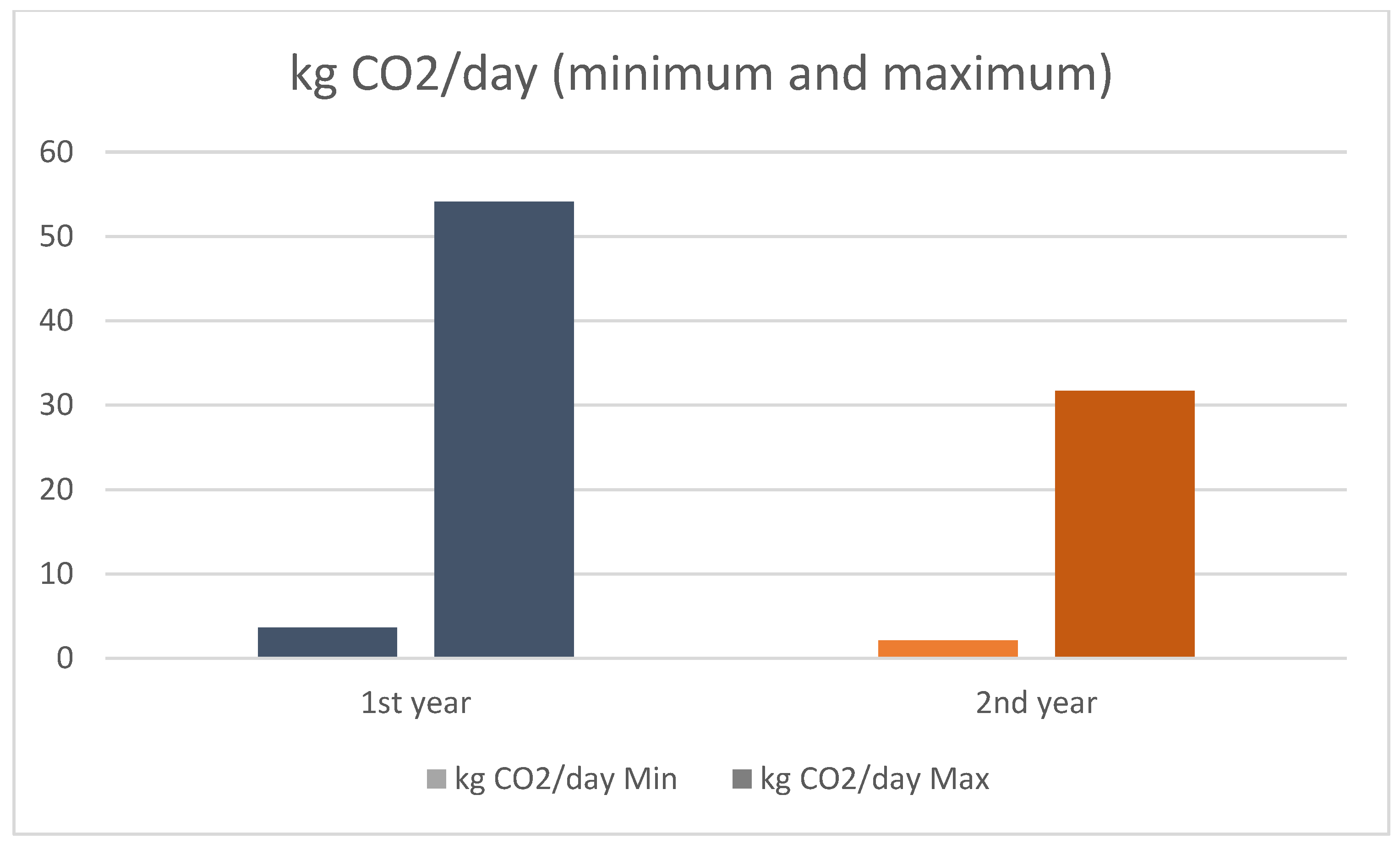

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Anderson, K.; Nelgen, S.; Pinilla, V. Global Wine Markets, 1860 to 2016: A Statistical Compendium; University of Adelaide Press: Adelaide, Australia, 2017; p. 582. Available online: https://www.adelaide.edu.au/press/system/files/media/documents/2019-04/uap-global-wine-markets-ebook.pdf (accessed on 1 January 2022). [CrossRef]

- Matos, C.; Pirra, A. Water to wine in wineries in Portugal Douro Region: Comparative study between wineries with different sizes. Sci. Total Environ. 2020, 732, 139332. [Google Scholar] [CrossRef]

- Garn, J.; Jeff, D. Winery Water Conservation and Water Quality. In California Code of Sustainable Winegrowing Workbook, 3rd ed.; Sustainable Winegrowing Alliance, Wine Institute, and California Association of Winegrape Growers: San Francisco, CA, USA, 2012. [Google Scholar]

- Jourjon, F.; Racault, Y.; Rochard, J. Effluents Vinicoles: Gestion et Traitements; Féret: Bordeaux, France, 2001. [Google Scholar]

- Pirra, A. Manual de Boas Práticas Ambientais na Adega. In APHVIN-GHEVID (Associação Portuguesa da História da Vinha e do Vinho—Grupo de Estudos de História da Viticultura Duriense e do Vinho do Porto); IVV; Financiado pelo Instituto do Vinho do Douro e Porto: Régua, Portugal, 2008; p. 231. ISBN 978-972-98969-5-8. [Google Scholar]

- Asdrubali, F.; Baldinelli, G.; Scrucca, F. Comparative life cycle assessment of an innovative CSPair-cooled system and conventional condensers. Int. J. Life Cycle Assess 2015, 20, 1076–1088. [Google Scholar] [CrossRef]

- Asdrubali, F.; Cotana, F.; Presciutti, A.; Scrucca, F.; Bonamente, E. The Water Footprint of the Wine Industry: Implementation of an Assessment Methodology and Application to a Case Study. Sustainability 2015, 7, 12190–12208. [Google Scholar] [CrossRef] [Green Version]

- Herath, I.; Green, S.; Horne, D.; Singh, R.; McLaren, S.; Clothier, B. Water footprinting ofagricultural products: Evaluation of different protocols using a case study of New Zealand wine. J. Clean. Prod. 2013, 44, 159–167. [Google Scholar] [CrossRef]

- Herath, I.; Green, S.; Singh, R.; Horne, D.; van der Zijpp, S.; Clothier, B. Water footprinting ofagricultural products: A hydrological assessment for the water f ootprint of New Zealand’s wines. J. Clean. Prod. 2013, 44, 232–243. [Google Scholar] [CrossRef]

- Ene, S.A.; Teodosiu, C.; Robu, B.; Volf, I. Water footprint assessment in the winemakingindustry: A case study for a Romanian medium size production plant. J. Clean. Prod. 2013, 43, 122–135. [Google Scholar] [CrossRef]

- Aranda, S.; Scarpellini, I.; Scarpellini, S. Zabalza. Economic and environmental analysis of the wine bottle production in Spain by means of life cycle assessment. Int. J. Agric. Resour. Gov. Ecol. 2005, 4, 178–191. [Google Scholar] [CrossRef]

- Petti, L.; Ardente, F.; Bosco, S.; De Camillis, C.; Masotti, P.; Pattara, C.; Raggi, G. Tassielli State of the art of Life Cycle Assessment (LCA) in the wine industry. In Proceedings of the International Conference on Life Cycle Assessment in the Agri-food Sector, Bari, Italy, 22–24 September 2010. [Google Scholar]

- Carballo-Penela, A.; García-Negro, M.C.; Doménech-Quesada, J.L. A methodological proposal for corporate carbon footprint and its application to a wine-producing company in Galicia, Spain. Sustainability 2009, 1, 302–318. [Google Scholar] [CrossRef] [Green Version]

- Gazulla, C.; Raugei, M.; Fullana, P. Taking a life cycle look at crianza wine production in Spain: Where are the bottlenecks? Int. J. Life Cycle Assess. 2010, 15, 330–337. [Google Scholar] [CrossRef]

- Bosco, S.; di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse gas emissions in the agricultural phase of wine production in the Maremma rural district in Tuscany, Italy. Ital. J. Agron. 2011, 6, 93–100. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T.; Feijoo, G. Environmental analysis of Ribeiro wine from a timeline perspective: Harvest year matters when reporting environmental impacts. J. Environ. Manag. 2012, 98, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Point, E.; Tyedmers, P.; Naugle, C. Life cycle environmental impacts of wine production and consumption in Nova Scotia, Canada. J. Clean. Prod. 2012, 27, 11–20. [Google Scholar] [CrossRef]

- Fusi, A.; Guidetti, R.; Benedetto, G. Delving into the environmental aspect of a Sardinian white wine: From partial to total life cycle assessment. Sci. Total Environ. 2014, 472, 989–1000. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iannone, R.; Miranda, S.; Riemma, S.; De Marco, I. Improving environmental performances in wine production by a life cycle assessment analysis. J. Clean. Prod. 2016, 111, 172–180. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Iribarren, D.; Moreira, M.T.; Feijoo, G. Joint life cycle assessment and data envelopment analysis of grape production for vinification in the Rías Baixas appellation (NW Spain). J. Clean. Prod. 2012, 27, 92–102. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Rugani, B.; Benetto, E. Tapping carbon footprint variations in the European wine sector. J. Clean. Prod. 2013, 43, 146–155. [Google Scholar] [CrossRef]

- Cholette, S.; Kumar, V. The energy and carbon intensity of wine distribution: A study of logistical options for delivering wine to consumers. J. Clean. Prod. 2009, 17, 1401–1413. [Google Scholar] [CrossRef]

- Amienyo, D.; Camilleri, C.; Azapagic, A. Environmental impacts of consumption of Australian red wine in the UK. J. Clean. Prod. 2014, 72, 110–119. [Google Scholar] [CrossRef]

- Bordiga, M. Valorization of Wine Making By-Products; Illustrated ed. Taylor Francis; CRC Press: Boca Raton, FL, USA, 2015; p. 383. ISBN 9781482255331. [Google Scholar]

- Martins, A.A.; Araújo, A.R.; Graça, A.; Caetano, N.; Mata, T.M. Towards sustainable wine: Comparison of two portuguese wines. J. Clean. Prod. 2018, 183, 662–676. [Google Scholar] [CrossRef]

- OIV. Guidelines for Sustainable Vitiviniculture: Production, Processing and Packaging of Products—Resolution CST 1/2008. 2008. Available online: http://www.oiv.int/public/medias/2089/cst-1-2008-en.pdf (accessed on 24 August 2021).

- Vinos de Chile. Sustainability Code of Chilean Wine Industry. 2012. Available online: http://www.sustentavid.org/en/imgmodulo/imagen_producto/26B.pdf (accessed on 1 January 2022).

- SWP. California Code of Sustainable Winegrowing Workbook Sustainable Winegrowing Program (SWP). 2016. Available online: http://www.sustainablewinegrowing.org/swpworkbook.php (accessed on 24 August 2021).

- ICV. Commitment to Sustainable Development. 2007. Available online: https://www.icv.fr/en/viticulture-oenology-consulting/grower-sustainable-development-vdd (accessed on 1 January 2022).

- VDD—Vignerons en Développement Durable. 2016. Available online: http://www.v-dd.com/en/ (accessed on 24 August 2021).

- Entwine. Entwine Australia & Environmental Management Systems 2013. Available online: http://www.wfa.org.au/assets/entwine/Entwine-and-EMS.pdf (accessed on 1 January 2022).

- CSWC. Sustainability Code of the Chilean Wine Industry. 2016. Available online: http://www.sustentavid.org/en/ (accessed on 1 January 2022).

- WASP. Wines of Alentejo Sustainability Programme. 2016. Available online: http://sustentabilidade.vinhosdoalentejo.pt/en (accessed on 24 August 2021).

- Martins, A.R.; Araújo, A.; Morgado, A.; Graça, N.; Caetano, S.; Mata, T.M. Sustainability Assessment of two Portuguese wines. In Proceedings of the 22nd International Sustainable Development Research Society Conference, School of Science and Technology, Universidade Nova de Lisboa, Lisbon, Portugal, 13–15 July 2016; pp. 213–224. [Google Scholar]

- UNEP. Guidelines for Social Life Cycle Assessment of Products, 2011; United Nations Environment Programme (UNEP) and Society of Environmental Toxicology and Chemistry (SETAC): Paris, France, 2009. [Google Scholar]

- Zamagni, A.; Pesonen, H.; Swarr, T. From LCA to Life Cycle Sustainability Assessment: Concept, practice and future directions. Int. J. Life Cycle Assess. 2013, 18, 1637–1641. [Google Scholar] [CrossRef] [Green Version]

- Guinée, J.B. Chapter 3-Life Cycle Sustainability Assessment: What Is It and What Are Its Challenges. In Taking Stock in Industrial Ecology; Clift, R., Druckman, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Petti, L.; Arzoumanidis, I.; Benedetto, G.; Bosco, S.; Cellura, M.; Camillis, C.D.; Fantin, V.; Masotti, P.; Pattara, C.; Raggi, A.; et al. Life cycle assessment in the wine sector. In Life Cycle Assessment in the Agri-Food Sector; Notarnicola, B., Salomone, R., Petti, L., Renzulli, P., Roma, R., Cerutti, A., Eds.; Springer: Cham, Switzerland, 2015; pp. 123–184. [Google Scholar]

- Mattsson, B.; Sonesson, U. Environmentally-Friendly Food Processing; Technology and Nutrition; Woodhead Publishing Series in Food Science: Swaston, UK, 2003; ISBN 978-1-85573-677-1. [Google Scholar]

- Galitsky, C.; Worrell, E.; Radspieler, A.; Healy, P.; Zechiel, S. BEST Winery Guidebook: Benchmarking and Energy and Water Savings Tool for the Wine Industry; LBNL-3184; Lawrence Berkeley National Laboratory: Berkley, CA, USA, 2005. [Google Scholar]

- Christ, K.L.; Burritt, R.L. Critical environmental concerns in wine pro duction: An integrative review. J. Clean. Prod. 2013, 53, 232–242. [Google Scholar] [CrossRef]

- Duarte, E.; Martins, M.; Ghira, J.; Carvalho, E.; Spranger, I.; Costa, S.; Leandro, M.; et Duarte, J. An integrated approach for assessing the environmental impacts of wineries in Portugal. In Actes du 2éme Congrès International sur le Traitement des Effluents Vinicoles; Cemagref: Bordeaux, France, 1998; pp. 61–69. [Google Scholar]

- Pirra, A. Tratamento de Efluentes Vinícolas da região demarcada do Douro. Tese de Doutoramento na Área científica de Ciências Agrárias Ciências Agronómicas, Universidade de Trás-os-Montes e Alto Douro, Vila Real, Portugal; p. 296.

- Quinteiro, P.; Dias, A.C.; Pina, L.; Neto, B.; Riddoutt, B.G.; Arroja, L. Addressing the freshwater use of a portuguese wine (Vinho Verde) using different LCA methods. J. Clean. Prod. 2014, 68, 46–55. [Google Scholar] [CrossRef]

- Plappally, A.K.; Lienhard, V.J.H. Energy requirements for water production, treatment, end use, reclamation and disposal. Renew. Sustain. Energy Rev. 2012, 16, 4818–4848. [Google Scholar] [CrossRef]

- Reardon, D.; Newell, P. Recycling conserves both water and energy. In Proceedings of the Water Energy Sustainability Symposium, New Orleans, LA, USA, 29 September–3 October 2012; Water Environment Federation. [Google Scholar] [CrossRef]

- Ahlfeld, D.P.; Laverty, M.M. Analytical solutions for minimization of energy use for groundwater pumping. Water Resour. Res. 2011, 47. [Google Scholar] [CrossRef]

- GEI/Navigant (2009). Embedded energy in water studies: Study2: Water agency and function component study and embedded energy—water load profiles-FInal Work Plan. [Online] California Institute for Energy and Environment. Available online: http://uc-ciee.org/library/7/340/79/nested (accessed on 10 December 2021).

- Maas, C. Greenhouse Gas and Energy Co-Benefits of Water Conservation; Research report; POLIS: Victoria, BC, Canada, 2009; pp. 1–33. [Google Scholar]

- Maas, C. Ontario’s Water-Energy Nexus: Will We Find Ourselves in Hot Water… or Tap into Opportunity? Research report; POLIS: Victoria, BC, Canada, 2010; pp. 1–20. [Google Scholar]

- Arpke, A.; Hutzler, N. Domestic water use in the United States. J. Ind. Ecol. 2006, 10, 169–184. [Google Scholar] [CrossRef]

- Kenway, S.J.; Priestley, A.; Cook, S.; Seo, S.; Inman, M.; Gregory, A. Energy Use in the Provision and Consumption of Urban Water in Australia and New Zealand. CSIRO: Water for a Healthy Country National Research Flagship; Water Service Association of Australia: Sydney, Australia, 2008. [Google Scholar]

- WEF. Energy Conservation in Water and Waste Water Facilities, 1st ed.; WEF Press, McGraw Hill: New York, NY, USA, 2010. [Google Scholar]

- Mizuta, K.; Shimada, M. Benchmarking energy consumption in municipal wastewater treatment plants in Japan. Water Sci. Technol. 2010, 62, 2256–2262. [Google Scholar] [CrossRef]

- Yang, L.; Zeng, S.; Chen, J.; He, M.; Yang, W. Operational energy performance assessment system of municipal waste water treatment plants. Water Sci. Technol. 2010, 62, 1361–1370. [Google Scholar] [CrossRef]

- Radcliffe, J.C. Water Recycling in Australia, Australian Academy of Technological Sciences and Engineering, Melbourne. 2004. Available online: https://www.atse.org.au/Documents/Publications/Reports/Water/ATSE%20Water%20Recycling%20in%20Australia%202004.pdf (accessed on 10 December 2021).

- Kneppers, B.; Birchfield, D.; Lawton, M. Energy-Water Relationships in Reticulated Water Infrastructure Systems; WA7090/2; Research report; Beacon Pathway Limited: Rotorua, New Zealand, 2009; pp. 1–31. [Google Scholar]

- Matos, S.; Pereira, E.V.; Amorim, I.; Bentes, A.; Briga-Sá, A. Wastewater and greywater reuse on irrigation in centralized and decentralized systems—An integrated approach on water quality, energy consumption and CO2 emissions. Sci. Total Environ. 2014, 493, 463–471. [Google Scholar] [CrossRef]

- Matos, C.; Bentes, I.; Pereira, S.; Faria, D.; Briga-Sá, A. Energy consumption, CO2 emissions and costs related to baths water consumption depending on the temperature and the use of flow reducing valves. Sci. Total Environ. 2019, 646, 280–289. [Google Scholar] [CrossRef]

- WRF. Knowledge Portals and Energy Management: Energy Efficiency & Treatment FAQs Water Research Foundation, Colorado. 2013. Available online: http://www.waterrf.org/knowledge/energy-management/efficiency-treatment/Pages/faqs.aspx (accessed on 9 March 2021).

- Rothausen, S.; Conway, D. Greenhouse-gas emissions from energy use in the water sector. Nat. Clim. Chang. 2011, 1, 210–219. Available online: www.nature.com/natureology (accessed on 9 March 2021). [CrossRef]

- Silva-Afonso, A.; Rodrigues, F.; Pimentel-Rodrigues, C. “Water efficiency in buildings: Assessment of its impact on energy efficiency and reducing GHG emissions”—Recent Researches in Energy & Environment. In Proceedings of the 6th IASME/WSEAS International Conference on Energy & Environment—EE’11, Cambridge, UK, 23–25 February 2011; WSEAS Press: Cambridge, UK, 2011; pp. 191–195, ISSN 1792-8230/ISBN 978-960-474-274-5. [Google Scholar]

| Where | Energy Consumption | Reference |

|---|---|---|

| California | 0.14–0.69 kWh/m3 | [48] |

| Canada | 0.25–3.02 kWh/m3 | [49,50] |

| Canada | Flow rate of 100–950 m3/d consumed 0.84–3.02 kw h/m3 Flow rate of 1000–10,000 m3/d consumed 0.25–1.11 kw h/m3 | [50] |

| m3 Water/Day | |

|---|---|

| 1st year | 27.66 |

| 2nd year | 16.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matos, C.; Pirra, A. Energy Consumption and CO2 Emissions Related to Wine Production: The Case Study of a Winery in Douro Wine Region-Portugal. Sustainability 2022, 14, 4317. https://doi.org/10.3390/su14074317

Matos C, Pirra A. Energy Consumption and CO2 Emissions Related to Wine Production: The Case Study of a Winery in Douro Wine Region-Portugal. Sustainability. 2022; 14(7):4317. https://doi.org/10.3390/su14074317

Chicago/Turabian StyleMatos, Cristina, and António Pirra. 2022. "Energy Consumption and CO2 Emissions Related to Wine Production: The Case Study of a Winery in Douro Wine Region-Portugal" Sustainability 14, no. 7: 4317. https://doi.org/10.3390/su14074317

APA StyleMatos, C., & Pirra, A. (2022). Energy Consumption and CO2 Emissions Related to Wine Production: The Case Study of a Winery in Douro Wine Region-Portugal. Sustainability, 14(7), 4317. https://doi.org/10.3390/su14074317