Abstract

Cold bitumen emulsion mixtures (CBEMs) are made up of the same materials that are used in hot mixes. However, asphalt emulsion and water are used in such mixes. To date, many countries are still not using these mixes as a structure layer. This can be attributed mainly to their low resistance to rainfall, long curing time and low early strength. The addition of cementitious filler to CBEMs as a clean paving material is a potential technique to achieve superior mechanical qualities. The aim of this research is to compare improved CBEMs that might be used as a wearing surface to hot mix asphalt (HMA). These improvements were carried out through the use of a combination of cement and limestone, or a combination of ordinary Portland cement (OPC) and cement kiln dust (CKD). CBEMs were prepared according to Egyptian and British gradations using different percentages of ordinary Portland cement (OPC), CKD, and limestone. This may offer a new cold bitumen emulsion mixture to be used as a structural pavement layer in such countries. The main tests performed for the assessment of the mixes in this research are indirect tensile stiffness modulus, fatigue resistance, and resistance to rutting at different temperatures (20 °C, 45 °C, and 60 °C). The results show that adding OPC to CBEMs enhanced the results in terms of ITSM, rutting and fatigue resistance. However, significant improvements were made by binary filler made of CKD and OPC to the said mechanical properties in terms of both UK and Egyptian gradations. The ITSM values for both CBEMUK6 and CBEMEg6, which contain 80% OPC + 20% CKD, improved by around 8 and 9 times in comparison to CBEMUK1 and CBEMEg1, which contain 20% OPC + 80% L.S, respectively.

1. Introduction

Highway engineers and researchers are looking for innovative pavements to address growing environmental and economic challenges, and investigate new methods of pavement maintenance strategies [1,2,3]. The cold bitumen emulsion mixture (CBEM) is classified as cold mix asphalt. It is is the most well-known type of cold mix asphalt. It is a bituminous material that is made at room temperature. When cold mix asphalt is utilised instead of standard hot mix asphalt, there are several environmental and economic benefits. CBEMs are easy to make in general, and are ideal for low- to medium-traffic circumstances, rural places, and small-scale projects such as reinstatement. Furthermore, CBEMs emit negligible CO2 and other fume emissions, require little energy to manufacture, and are extremely safe to use [4,5]. Nevertheless, to date, there is no universally accepted mix design method for CBEMs.

There have been more than a few trials attempting to upgrade the mechanical properties of CBEMs. These have replaced conventional filler with different additives to solve the main disadvantage of cold mix asphalt, which is its weak strength in early life. This is the main reason for not using cold mix asphalt as a structure layer in road pavements (wearing surface, binder course, or bituminous base course), in comparison to HMA. The other disadvantages are the long curing time, and its inability to resist rainfall [6]. Several additives have been used to solve these shortcomings; the major ones are cement, fly ash, fibre, and chemical products.

Schmidt et al. [7] tried to develop the curing time by adding cement to the cold mix asphalt. The findings revealed that the mix cured faster, and the modulus of resilience of the treated mix was also rapidly improved. Li et al. [8] added cement to improve the fatigue life and increase the flexibility of asphalt concrete. Brown and Needham [9] reported that adding cement made emulsion charges more positive. Pouliot et al. [10] highlighted the hydration process between cement and the added emulsion. Song et al. [11] suggested using asphalt emulsion as a polymeric admixture. The experimental results show that increasing the polymer–cement ratio caused a reduction in the adhesiveness and compressive strength of the mortar, as well as improvements in water resistance and carbonation resistance. Thanaya et al. [12] used rapid-setting cement to accelerate the early strength and minimise the curing time. However, using cement only has a considerable CO2 impact, and cement is also considered a costly material. Thus, other trials have used cement with by-products or waste materials as supplementary materials [13,14,15].

Thanaya et al. [16] incorporated fly ash into cold bituminous emulsion mixtures. The experimental results show improvements in volumetric properties, creep under repeated load, and stiffness modulus compared to conventional CBEMs. Other trials have studied the effect of fly ash on cold mixes [17,18,19]. All of these researchers reported the effect of fly ash’s mechanical properties, such as stiffness modulus, creep stiffness, resilient modulus and resistance to water sensitivity.

Bueno et al. [20] examined the influence of polypropylene fibre on the mechanical properties of cold mix asphalt. The results indicate that, by adding fibre to CBEMs, a small variation in mixture strength was caused, in addition to a reduction in the resilient moduli of mixtures, the Marshall Stability, and the dry density of the cold mix.

Portland cement has been broadly employed to substitute traditional limestone filler in CBEMs manufacturing to offer adequate early-age strength [21], overcome concerns about excessive air voids [22], high water sensitivity [23] and low early-age strength [21], and encourage the usage of such mixes. Filler, as one of the raw materials in the asphalt mixture, mainly fills the air voids and reduces the gap between aggregates [24]. It is useful for managing the mixture‘s performance [25,26]. As a result, proper filler selection and combination has been deemed a useful method for improving CBEMs’ performance.

The use of CKD as a partial OPC replacement material in the preparation of binary blended cement has not been fully established in the current body of literature, despite the existence of some studies on CBEMs’ production with OPC. In addition, the comparison of two different aggregate gradations from different climates has not been fully addressed in the previous studies. To date, the performance of the CBEMs is still inferior to conventional hot mix asphalt. So, researchers are working to develop CBEMs that have mechanical performances equal to or even better than the HMA. The aim of this study is to investigate whether OPC and CKD can be used to produce a novel CAEM that can be used as a sustainable pavement material. To explore the strength development of CAEM, a comprehensive set of laboratory experiments was conducted. In this research, six mixes of CBEMs with OPC and CKD, and CBEMs with OPC and limestone, are tested against Egyptian and British gradations. Firstly, an ITSM will be performed to determine the highest stiffness modulus of the different mixes. Then, the selected mixes for Egypt and Britain will be used to complete the wheel-track test at different temperatures, as well as a fatigue test. A comparison between the two types of hot mix asphalt (soft and hard) and the improved CBEMs was also performed. Moreover, the same aggregate type and gradation are used to prepare traditional hot mixture samples with 5% and 5.3% binder content, in order to match the requirements of AASHTO R12-85 2002 and BS EN 4987 2005 in Egypt and Britain, respectively.

2. Material and Testing

2.1. Materials

In this research, crushed granite aggregates were used. 4C and 14C dense- and close-graded surface course mixtures were selected because there are widely used in designing surface asphalt concrete mixtures in both countries. The difference between two gradations is shown in the design of the asphalt mixtures in both countries; the maximum nominal size in the British specifications (14 mm) is less than that in the Egyptian specifications (20 mm), which permits a larger surface area and fewer interstitial voids, and thus improves the compaction process.

The opposing charge on the granite aggregate surface attracts the positively charged cationic emulsifier. This achieves the best adherence between the aggregate and the emulsion.

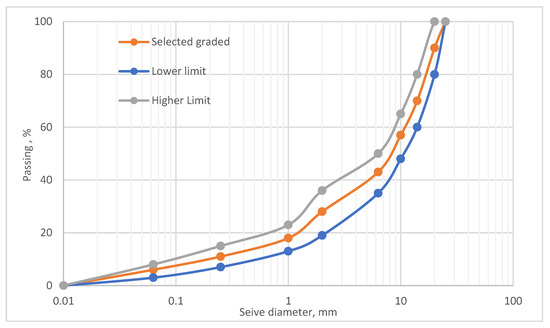

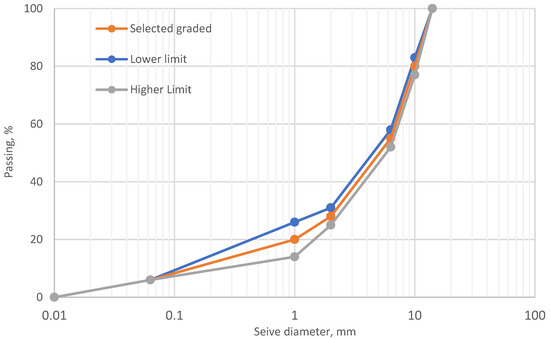

Figure 1 and Figure 2 show the particle size distributions of these gradations. The physical properties are given in Table 1. The different mixes of CBEMs with two types of filler (OPC with limestone or OPC with CKD) are illustrated in Table 2. The total percentage of filler used was 6% of the total aggregate weight. The bitumen binder 50–70 (CB3-50) was used to prepare the cold mix asphalt. The comparison between the cold mix asphalt and the hard hot mix asphalt, as well as the soft hot mix asphalt, was conducted using bituminous binder 61 and 143 pen grades. The properties of both the bituminous emulsion and the bitumen binder used in this study are shown in Table 3. The cold mix asphalt and hot mix asphalt specimens were mixed and compacted at laboratory temperatures of 20–25 °C and 160–170 °C, respectively.

Figure 1.

4C dense-graded surface course Egyptian gradation [27].

Figure 2.

14C close-graded surface course British gradation [28].

Table 1.

The physical properties of the aggregates used.

Table 2.

Mix types and percentages.

Table 3.

Bituminous emulsion and bitumen binder properties.

2.2. Sample Preparation

The Asphalt Institute Method (MS-14) was adopted by the Asphalt Institute [29] to prepare cold mix asphalt specimens. Only one change was made to this method—instead of the Marshall Test, an indirect tensile strength test was used. The procedural steps are summarised in Table 4.

Table 4.

Design mix procedures according to the Asphalt Institute [29]

2.3. Testing

To analyze the mechanical properties of the developed CBEMs, three types of fundamental tests were conducted (ITSM test, fatigue test, and wheel-tracking test) to explore the influences of both CKD and OPC, according to Egyptian and British gradations.

2.3.1. Indirect Tensile Stiffness Modulus (ITSM)

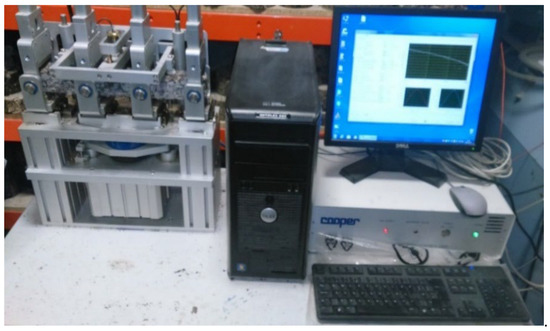

ITSM is a non-destructive test that determines the stiffness modulus of bituminous mixes, both hot and cold. The test was conducted following BS EN 12697-26 [30]. A steel load frame, a load cell with a pneumatic load actuator, a deformation measurement system, and a personal computer that records the electrical signals from the load actuator on five monitors make up the majority of the test equipment. Figure 3 depicts the test equipment within the refrigerated incubator, as well as the test specimen mounted on the loading platens and connected to the computer that measures deformation. The experiments were carried out at a constant temperature of 20 degrees Celsius. Table 5 depicts the test circumstances. The HYD 25 device from Cooper Research Technology was used to test ITSM for various specimens.

Figure 3.

Cooper Research Technology HYD 25 testing apparatus.

Table 5.

ITSM test conditions.

2.3.2. Fatigue Resistance

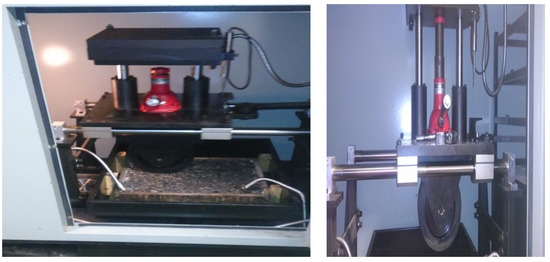

Fatigue damage occurs when an asphalt layer is subjected to a large number of bending force cycles [31]. The Cooper four-point bending test is used to measure the fatigue life of materials subjected to bending forces. The fatigue life is the number of cycles after which the stiffness is half of what it was at the start [32]. After the first 100 cycles of repeated loading, the specimen‘s initial stiffness will be determined automatically. The specimen is a prismatic beam that is loaded sinusoidally in either the controlled strain or the stress mode. The tests were carried out at a displacement-controlled temperature of 20 °C, with a strain level of 105 to 106 load repetitions (at 10 Hz), until the force required for the prescribed displacement was reduced to half its starting value. As illustrated in Figure 4, both graphical and tabular data were displayed on screen during testing, and the test data were saved to a disc in a Microsoft Excel TM-compatible format. Table 6 depicts the test circumstances. Fatigue resistance according to BS EN 12697-24 [33].

Figure 4.

Cooper four-point apparatus.

Table 6.

Four-point test conditions.

In the fatigue test, prismatic specimens were employed, and their total length, width, and height were 400 mm, 50 mm, and 50 mm, respectively. For each mixture, three duplicated beam specimens were tested, and the average value was calculated.

2.3.3. Resistance to Rutting

Permanent deformation, mainly referring to rutting, is one of the main distress modes of asphalt pavement [34,35]. The deformation expected to occur in asphaltic materials under wheel loading is predicted using an autonomous wheel-tracking tester (HYCZ-5). The wheel-tracking equipment is shown in Figure 5. A Cooper roller compactor was used to make the slabs. The slab was 400 × 305 × 50 mm in size. Table 7 depicts the test circumstances. The test was carried out at various temperatures, including 20, 45, and 60 degrees Celsius, to evaluate the materials under various weather situations. The rut depth under load was measured in relation to the wheel load. Resistance to rutting at different temperatures was determined in accordance with BS EN 12697-22 [36].

Figure 5.

Wheel-tracking machine.

Table 7.

Wheel-track test conditions.

3. Results and Discussion

3.1. Indirect Tensile Stiffness Modulus

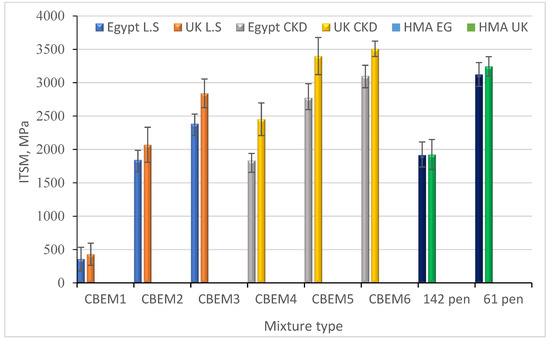

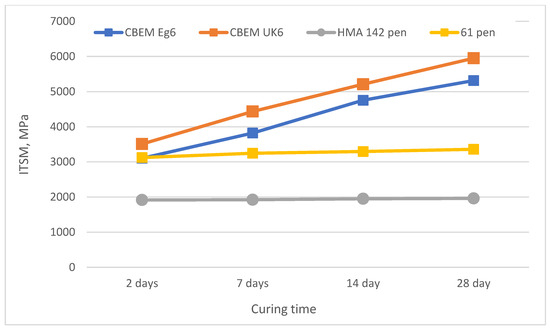

Following the BS EN 12697-26 specification [30], all specimens were tested firstly at an age of 2 days to assess the use of OPC with limestone and OPC with CKD as a filler at different percentages in CBEMs, according to Egyptian and British gradations. Accordingly, the best one—the one that gave highest ITSM for the different mixes—was chosen to complete the ITSM test at ages of 7, 14 and 28 days, and this ratio was used on the following tests, i.e., fatigue resistance and resistance to rutting.

For the mix of OPC with conventional limestone (LS), as shown in Figure 6 and Figure 7, it is obvious that the stiffness modulus for the British gradation is improved in comparison to that for the Egyptian gradation at different ages and mixes. This may be attributed to the difference in gradation, which may allow higher compaction in the British samples than in the Egyptian samples. A gradual increment is seen in ITSM, with the increased percentage of OPC in the mix at age 2 days under both Egyptian and British gradations. For the Egyptian gradation at 2 days, the ITSM for CBEM3 (80% OPC with 20% limestone) compares reasonably with soft HMA. However, under the British gradation, CBEM3 gives a higher value than soft HMA.

Figure 6.

ITSM of HMA and CBEMs for different mix types at 2 days.

Figure 7.

CBEM6 ITSM for the Egyptian and the British CBEMs at different ages.

For the mix of OPC with CKD at different ages, mixes and gradations, the stiffness modulus of the cold mix with CKD is higher than the stiffness modulus of the cold mix with limestone under both Egypt and British gradations. This indicates a significant improvement in the stiffness modulus resulting from the addition of CKD to the CBEMs. For both the British gradation and the Egyptian gradation, the ITSM values of CBEM at 2 and 7 days are higher than the ITSM values for soft and hard HMA. At different ages, the ITSM for CBEM6 under Egyptian and British gradations gave higher values than soft or hard HMA, with very little increment in stiffness modulus for the two types of HMA.

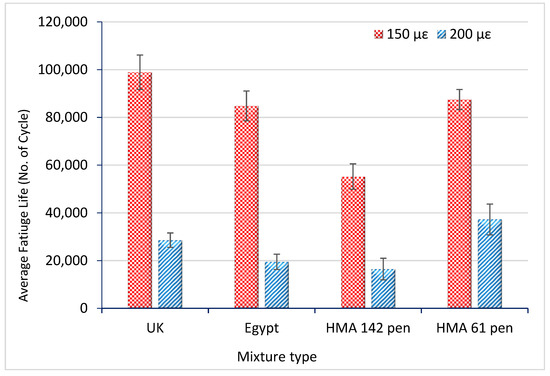

3.2. Fatigue Resistance

Fatigue tests were carried out in accordance with BS EN 12697-24 [33] at a frequency of 10 Hz and a temperature of 20 °C. Figure 8 depicts the results. Table 8 displays the fatigue connections determined for the two countries with different strains (150–200 m/m). The following is a definition of the fatigue–life relationship:

where Nf is the number of continuous strain applications until the specimen achieves half of its original stiffness, ε is the applied strain (µm/m), f1 and f2 are the regression constants, and E1 is the elastic modulus of the asphalt layers.

log Nf = f1 + log ε E1−f2

Figure 8.

Fatigue life for Egyptian and British CBEMs at 150 and 200 microstrain.

Table 8.

Fatigue relationship for Egyptian and British standards at 150 and 200 microstrain.

In the formula, y stands for log cycle, and x stands for log micro strain multiplied by the inverse of the modulus of elasticity (log microstrain× E1−1). The resulting coefficients of determination (R2) and significance of the F statistics demonstrate the model‘s reasonably high goodness-of-fit and relevance for prediction. This formula is compatible with most fatigue failure models that look like this (according to Mathew et al.) [37]:

Nf = f1 ε−f2 E1−f3

Figure 8 compares the average fatigue lives of the two countries, which correspond to 150 and 200 microstrains, respectively. The stiffness results were well-matched, indicating that the British gradation performed better than the Egyptian gradation.

It can be seen that both the CBEM UK6 and CBEM Eg6 had the highest fatigue lives, which are comparable to HMA 61 pen, with an improved performance for the CBEM UK6. The modified CBEM UK6 tolerated the highest number of cycles, and was ranked as the best mix with the longest fatigue life at the 150 strain level.

On the other hand, both the CBEM UK6 and CBEM Eg6 achieved better performances in comparison to HMA 141 pen at the 200 strain level.

These results illustrate the significant impact of OPC and CKD on the fatigue life behaviour of both CBEM UK6 and CBEM Eg6, compared to the HMA mixes.

This difference might be due to the stiffness of the said mixes, which depends on the strength of the secondary binder, so these results agree with the results presented in Figure 7. Both the CBEM UK6 and CBEM Eg6 mixes (80% OPC with 20% CKD) had a higher ITSM in comparison to both HMAs.

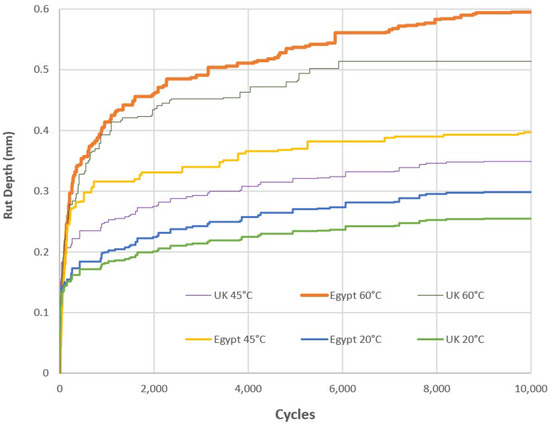

3.3. Resistance to Rutting

The rut evolutions of six slabs of CBEM6 mix (80% OPC with 20% CKD), as a function of the number of cycles, for both Egyptian and British gradations at the central position are displayed in Figure 9. The rutting resistance test was performed at several temperatures (20, 45, 60 °C) to assess the effect of temperature on the CBEMs in the two countries. This figure shows that, at different temperatures, for CBEMs, the rut depth under the wheel path changes slightly over time, in both the Egyptian gradation and the British gradation. So, replacing LS with both OPC and CKD enhanced the resistance to rutting of different CBEMs at different temperatures. As expected, the rut depth will increase when the temperature is increased. The rut depths at the end of the test for the Egyptian gradation were 0.2985, 0.349, and 0.595 mm, while those for the British gradations were 0.2555, 0.349, and 0.514 mm, at temperatures of 20, 45 and 60 °C, respectively. These values indicate that this mix can be used as a surface course for heavy loads in any weather (cold or hot).

Figure 9.

Slab rut depth evolution for CBEM 6 at different temperatures.

4. Conclusions

In this research, we conducted an experimental comparison of cold mix surface asphalt gradations in Egypt and Britain. OPC was mixed with either limestone or CKD at different percentages to be used as a filler in new CBEMs. Six cold mixes for each gradation were prepared during the test. ITSM, resistance to rutting at different temperatures (20, 45, and 60 °C) and fatigue resistance were the fundamental tests used in the comparison. The major conclusions of this research are as follows:

- (1)

- Ordinary Portland cement plays a significant role in improving the stiffness modulus of CBEMs, especially at high percentages (50% and 80% of total filler). This may be attributed to its providing a secondary cementitious binder, and the main role of cement in the hydration process. Increasing OPC from 20% to 80% improved the ITSM for both UK and Egypt gradations by around 8 and 9 times, respectively;

- (2)

- The best CKD percentage is 20%, which provides the highest ITSM when blended with 80% OPC. Reducing CKD from 80% to 20% improved the ITSM for both UK and Egypt gradations by 140% and 170%, respectively;

- (3)

- The results of rutting resistance also indicate that replacing LS with both OPC and CKD improved the performance at 20, 45 and 60 °C. It is noted that CBEM6 that have 80% OPC with 20% CKD achieved the highest rut resistance at 20 °C. Thus, the improved CBEM6 mix can be used as a structural layer in different climates, either in Egypt or in Britain;

- (4)

- The addition of OPC and CKD to CBEMs resulted in a substantial improvement in fatigue life for both British and Egyptian gradations at 150 and 200 microstrains;

- (5)

- This study showed that the British gradation (14C) gave improved results in all experimental tests compared to the Egyptian gradation (4C) commonly used in Egypt as a surface course. Accordingly, the British one may be a better gradation for Egyptian roads;

- (6)

- CBEMs with OPC and CKD as filler showed clearly improved mechanical properties, compared to CBEMs with OPC and limestone. Thus, this lab-scale trial should be expanded into the field.

Author Contributions

Conceptualization, T.A.-W. and A.D.; methodology, T.A.-W., A.D., H.A.N.; software, T.A.-W. and A.D.; validation, T.A.-W., A.D., H.K.S.; formal analysis, T.A.-W. and A.D.; investigation, T.A.-W., A.D., H.K.S.; resources, T.A.-W.and A.D.; data curation, T.A.-W., A.D., H.K.S.; writing—original draft preparation, T.A.-W. and A.D.; writing—review and editing, T.A.-W.and A.D.; visualization, T.A.-W.and A.D.; supervision, H.A.N. and A.D.; project administration, T.A.-W.and A.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to express their gratitude to Liverpool John Moores University staff for their assistance and support in this study effort.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Investigating the effect of corrective maintenance on the pavement life cycle and the optimal maintenance strategies. In Proceedings of the 19th COTA International Conference of Transportation Professionals: Transportation in China—Connecting the World, Nanjing, China, 6–8 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 811–822. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Investigating effective maintenance policies for urban networks of residential cities by using optimum and sensitivity analyses. Can. J. Civ. Eng. 2020, 47, 691–703. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Modelling the raveling propagation in hot and dry climate by using the statistical analysis concepts. In Proceedings of the 19th COTA International Conference of Transportation Professionals: Transportation in China—Connecting the World, Nanjing, China, 6–8 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 868–879. [Google Scholar] [CrossRef]

- Bouteiller, É.l. Asphalt emulsions for sustainable pavements. In Proceedings of the First International Conference on Pavement Preservation, Newport Beach, CA, USA, 13–15 April 2010. [Google Scholar]

- Wang, Z.; Sha, A. Micro hardness of interface between cement asphalt emulsion mastics and aggregates. Mater. Struct. 2010, 43, 453–461. [Google Scholar] [CrossRef]

- Nageim, H.A.; Al-Busaltan, S.F.; Atherton, W.; Sharples, G. A comparative study for improving the mechanical properties of cold bituminous emulsion mixtures with cement and waste materials. Constr. Build. Mater. 2012, 36, 743. [Google Scholar] [CrossRef]

- Schmidt, R.J.; Santucci, L.E.; Coyne, L.D. Performance characteristics of cement-modified asphalt emulsion mixes. In Proceedings of the Association of Asphalt Paving Technologists Conference Proceeding (AAPT), Houston, TX, USA, 12–14 February 1973; pp. 300–319. Available online: https://trid.trb.org/view/35231 (accessed on 24 February 2022).

- Li, G.; Zhao, Y.; Pang, S.S.; Huang, W. Experimental Study of Cement-Asphalt Emulsion Composite. Cem. Concr. Res. 1998, 28, 635–641. [Google Scholar] [CrossRef]

- Brown, S.F.; Needham, D. A Study of cement modified bitumen emulsion mixtures. In Proceedings of the Association of Asphalt Paving Technologists Conference Proceeding (AAPT), Reno, NV, USA, 10–13 January 2000; Available online: https://trid.trb.org/view/675393 (accessed on 24 February 2022).

- Pouliot, N.; Marchand, J.; Pigeon, M. Hydration mechanisms, microstructure, and mechanical properties of mortars prepared with mixed binder cement slurry-asphalt emulsion. J. Mater. Civ. Eng. 2003, 15, 54–59. [Google Scholar] [CrossRef]

- Song, H.; Do, J.; Soh, Y. Feasibility study of asphalt-modified mortars using asphalt emulsion. Constr. Build. Mater. 2006, 20, 332–337. [Google Scholar] [CrossRef]

- Thanaya, I.N.A.; Zoorob, S.E.; Forth, J.P. A laboratory study on cold-mix, cold-lay emulsion mixtures. Proc. Inst. Civ. Eng.-Transp. Thomas Telford Ltd, February 2009, 162, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Wahed, T.; Al Nageim, H. Investigating the effects of cement and cement kiln dust as a filler on the mechanical properties of cold bituminous emulsion mixtures. Int. J. Civ. Eng. Technol. 2016, 7, 441–453. [Google Scholar]

- Shanbara, H.K.; Dulaimi, A.; Al-Mansoori, T.; Al-Busaltan, S.; Herez, M.; Sadique, M.; Abdel-Wahed, T. The future of eco-friendly cold mix asphalt. Renew. Sustain. Energy Rev. 2021, 149, 111318. [Google Scholar] [CrossRef]

- Abdel-Wahed, T.A.; Rashwan, N.K. Application of Cement Dust and OPC as Mineral Filler in the binder Hot Mix Asphalt. In Proceedings of the LJMU International Conference on; Asphalt, Pavement Engineering and Infrastructure, Liverpool, UK, 24–25 February 2016; Volume 15. [Google Scholar]

- Chelelgo, K.; C Abiero Gariy, Z.; Muse Shitote, S. Laboratory mix design of cold bitumen emulsion mixtures incorporating reclaimed asphalt and virgin aggregates. Buildings 2018, 8, 177. [Google Scholar] [CrossRef] [Green Version]

- Dulaimi, A.; Nageim, H.A.; Ruddock, F.; Seton, L. Laboratory Studies to Examine the Properties of a Novel Cold-Asphalt Concrete Binder Course Mixture Containing Binary Blended Cementitious Filler. J. Mater. Civ. Eng. 2017, 29, 04017139. [Google Scholar] [CrossRef]

- Dulaimi, A.; Nageim, H.A.; Ruddock, F.; Seton, L. Performance Analysis of a Cold Asphalt Concrete Binder Course Containing High-Calcium Fly Ash Utilizing Waste Material. J. Mater. Civ. Eng. 2017, 29, 04017048. [Google Scholar] [CrossRef]

- Al-Busaltan, S.; Nageim, H.A.; Atherton, W.; Sharples, G. Mechanical properties of an upgrading cold-mix asphalt using waste materials. J. Mater. Civ. Eng. 2012, 24, 1484–1491. [Google Scholar] [CrossRef]

- Bueno, B.d.S.; Silva WRd Lima DCd Minnete, E. Engineering properties of fiber reinforced cold asphalt mixes. J. Environ. Eng. 2003, 129, 952–955. [Google Scholar] [CrossRef]

- Al Nageim, H.; Dulaimi, A.; Ruddock, F.; Seton, L. Development of a new cementitious filler for use in fast-curing cold binder course in pavement application. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016; pp. 167–180. [Google Scholar]

- Dulaimi, A.; Al Nageim, H.; Ruddock, F.; Seton, L. Microanalysis of Alkali-Activated Binary Blended Cementitious Filler in a Novel Cold Binder Course Mixture. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016. [Google Scholar]

- Dulaimi, A.; Al Nageim, H.; Ruddock, F.; Seton, L. Assessment the Performance of Cold Bituminous Emulsion Mixtures with Cement and Supplementary Cementitious Material for Binder Course Mixture. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016. [Google Scholar]

- Dulaimi, A.; Shanbara, H.K.; Jafer, H.; Sadique, M. An evaluation of the performance of hot mix asphalt containing calcium carbide residue as a filler. Constr. Build. Mater. 2020, 261, 119918. [Google Scholar] [CrossRef]

- Lu, D.; Wang, Y.; Leng, Z.; Zhong, J. Influence of ternary blended cementitious fillers in a cold mix asphalt mixture. J. Clean. Prod. 2021, 318, 128421. [Google Scholar] [CrossRef]

- Mignini, C.; Cardone, F.; Graziani, A. Using fine aggregate matrix mortars to predict the curing behaviour of cement bitumen treated materials produced with different cements. Constr. Build. Mater. 2021, 268, 121201. [Google Scholar] [CrossRef]

- Ministry of Housing, Utilities and Urban Development, National Center for Housing and Building Research. The Egyptian Code for the Fundamentals of the Design and Requirements for the Implementation of Urban and Rural Road Works; Code No. 104/4—2020; ECP—2020; National Center for Housing and Building Research: Giza, Egypt, 2020.

- BS EN 13108; European Committee for Standardization. Part 1. Bituminous Mixtures Materials Specification-Asphalt Concrete. British Standards Institution: London, UK, 2013.

- Asphalt Institute. Asphalt Cold Mix Manual, Manual Series No. 14(MS-14), 3rd ed.; Asphalt Institute: Lexington, KY, USA, 1997. [Google Scholar]

- BS EN 12697; European Committee for Standardization. Part 26. Bituminous Mixtures-Test Methods for Hot Mix Asphalt- Stiffness. British Standards Institution: London, UK, 2012.

- Mohamed, A.S.; Xiao, F.; Hettiarachchi, C.; Abdel-Wahed, T. Bond Strength in Dry Condition of Reclaimed Asphalt Modified by Crumb Rubber Modified Binder. J. Adhes. 2022; in press. [Google Scholar] [CrossRef]

- Pramesti, F.P.; Molenaar, A.A.A.; Van de Ven, M.F.C. The Prediction of Fatigue Life based on Four Point Bending Test. Procedia Eng. 2013, 54, 851–862. [Google Scholar] [CrossRef] [Green Version]

- BS EN 12697; European Committee for Standardization. Part 24. Bituminous Mixtures-Test Methods for Hot Mix Asphalt- Resistance to Fatigue. British Standard Institution: London, UK, 2012.

- Moussa, G.S.; Abdel-Raheem, A.; Abdel-Wahed, T. Effect of Nanoclay Particles on the Performance of High-Density Polyethylene-Modified Asphalt Concrete Mixture. Polymers 2021, 13, 434. [Google Scholar] [CrossRef]

- Tavassoti, P.; Solaimanian, M.; Chen, X. Characterization of fatigue performance of cold mix recycled asphalt mixtures through uniaxial tension–compression testing. Constr. Build. Mater. 2022, 329, 127155. [Google Scholar] [CrossRef]

- BS EN 12697-22; European Committee for Standardization. Part 22. Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Wheel Tracking Test Methods for Hot Mix Asphalt. British Standard Institution: London, UK, 2012.

- Mathew, T.; Krishna, R. Introduction to Transportation Engineering; National Programme on Technology Enhanced Learning: Delhi, India, 2009; Chapter 27; pp. 1–8. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).