Abstract

Waste management is currently a fast-growing environmental business and one of solutions to manage the huge amount of waste being generated on landfills is to use the disposed waste as an energy source. There is a major focus on energy forecasting, highlighting the importance of having reliable data on the volume and composition of municipal solid waste in landfills. However, the lack of historical data is forcing the development of machine-learning based models. This study contributes to this field by proposing a hybrid ANN-based model to forecast the total amount of landfill waste, different waste fraction and the potential for energy recovery. The proposed model includes an adaptive number of inputs adjusted to the relevant waste fraction and to the specific landfill. The obtained results substantiated that the proposed model allows for stable and accurate forecasting of recovered energy potential in cases where there is insufficient historical data. The experiments showed that the model with 12 inputs (meaning the forecast of the future value takes into account the last 12 months of data) was the most accurate in the energy forecasting task, with the lowest forecasting error in terms of mean absolute error −8.9878 gigawatt hours per year.

1. Introduction

Millions of tons of waste are generated worldwide every year, but only a small proportion is properly disposed of or recycled, reused or otherwise recovered as a resource. Population health, wildlife, soil, air, and marine ecosystems are still suffering from increasing waste production and improper waste management. Toxins in landfills have a negative impact on quality of life, and some waste has a decay time of more than 500 years. While many improvements have been made in this area, the high volumes of waste accumulated in landfills show that major challenges remain [1].

In recent years, the forecasting of municipal solid waste (MSW) has become a hot research area. A number of researchers have developed different forecasting methods, which are applied in different countries and regions; however, the methods developed share the common goal of ensuring accurate planning and sustainable management of mixed municipal waste generation [2]. Many socio-economic, demographic, or geographical factors have been used to determine which of these has the most significant relationship with MSW [3]. In general, the most commonly used indicators are population, income, type of population, age groups, employment, electricity consumption, consumer price index (CPI), gross domestic product (GDP) gross domestic spending on research and development (R&D) [4]. Some researches additionally include education [5], culture [6], territorial (regional) characteristics [7] or climate indicators [8]. For example, in the Czech Republic, studies on MSW at different spatial levels together with socio-economic and demographic indicators have shown that it is feasible to distinguish between spatial levels in order to better understand the amount and composition of waste accumulated, but this is not the case for the lower spatial levels (municipalities and districts) [9]. Some studies have shown that not only mentioned factors influence waste generation volumes, but regional division separating the Western, Central, Eastern, Northern and the Southern parts may be an influential factor [10]. Behavioral factors of recyclers (the waste bank, non-waste bank members or non-active recyclers) can also be used to identify the recycling activity and thus the total amount of waste [11]. However, to summarize, population and GDP have been considered as the most important variables influencing waste generation.

Various artificial intelligence (AI) techniques and methods such as data clustering, classification, dependency and logical relationships, and statistical algorithms have been applied to build predictive models [12]. In addition, there is a growing focus on waste management, landfills as a fuel source feasibility study, and scientific research on waste-to-energy challenges [13,14,15].

The forecasting of MSW properties such as amount, composition, including calorific values, is key information for ensuring successful waste management and optimization of activities. Unfortunately, such characteristics of MSW cannot be directly predicted and depends on many factors. Municipal waste varies from region to region because it depends on the lifestyle of the people living in the community. Different countries face different challenges, but this is often due to a lack of statistical information on MSW, so a variety of indicators such as demographic and socioeconomic factors, infrastructure, culture, location, climate, tourism, and many others are used employing with machine learning methods to identify the most informative and those that correlate well with MSW, such as composition, seasonality, etc. Several studies have been conducted to develop a forecasting model based on mentioned indicators in Canada [16], Turkey [17], China [7], Laos [3], Chile [18] and other.

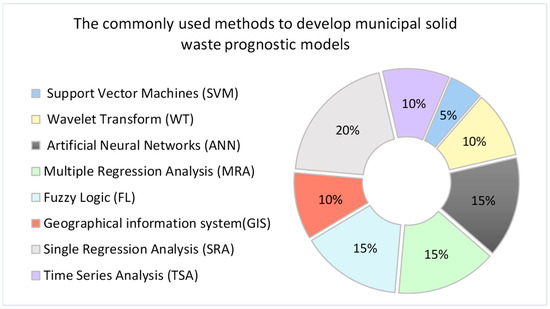

From an AI methods perspective, waste management models include expert systems [19], fuzzy logic [20], genetic [21], neuro-evolutional methods [22], artificial neural networks [8,23], Bayesian algorithms, regression models [24], and other methods [25]. The application of various methods for the development of forecasting models is presented in Figure 1 [26]. As can be seen, most of the studies have been carried out using the Singe Regression Analysis (SRA) approach, however, ANN, FL, and Multiple Regression Analysis (MRA) and are also quite commonly used.

Figure 1.

List of methods that are commonly used to develop waste forecasting models [26].

It can be noted that ANN-based models in the case of MSW management are used from different perspectives: ro analyze MSW related data [27] or capture disposal trend [28], to develop predictive models together with other machine learning (ML) or to optimization algorithms [29], deep learning approaches [30] for forecasting waste generation [31] and classification tasks based on image recognition [32].

The same algorithms used to predict waste generation can be applied to a broader range of waste problems, such as forecasting the waste-to-energy (WtE) recovery, for the efficient use of energy resources for the regeneration of resources and for end-use applications [33,34,35].

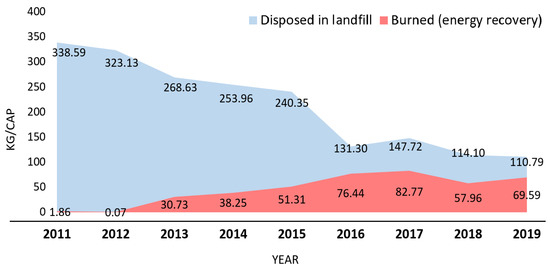

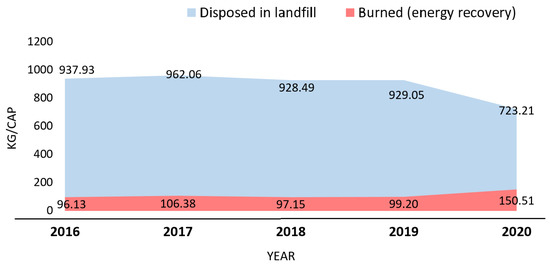

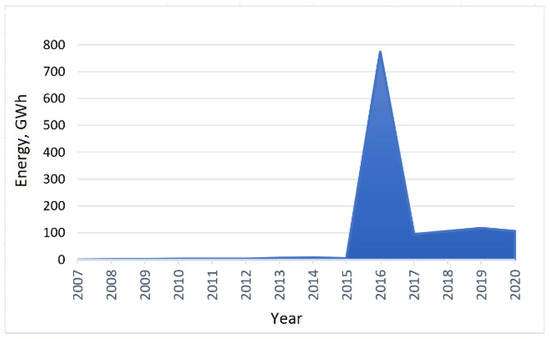

While landfills are the cheapest way to dispose of waste, they do not contribute to the value chain. Unmaintained landfills are harmful, and a major environmental concern is the release of methane gas, which significantly contributes to climate change. In the case of Lithuania, the geological survey has identified more than 800 geographical locations where mixed and municipal waste is stored, recycled, and otherwise treated in one way or another, which makes the issue of landfill site management, maintenance, and utilization of landfills of particular relevance to the country. Even though since 2016 there has been a significant decrease in the amount of MSW taken to landfill and an increase in the amount of energy produced by burning waste (see Figure 2), forecasting waste and its potential to be used as secondary raw materials is still a challenging task in the country and requires more detailed studies and experiments. Considering the total amount of energy generated, the country is also showing progress, although by 2020 only ~10% of all waste was used for energy production (since 2020, this number has reached 20.81%), ~55% recycled for other purposes and the rest was either exported, reused, or burned (Figure 3). This study attempts to provide a novel WtE forecasting solution based on the ANN method, by solving the problem of municipal waste landfills and to assess its potential as a source of renewable electricity. Socio-economic factors relevant to the Lithuanian municipality are included to address the waste forecasting tasks.

Figure 2.

Amount of MSW disposed in Lithuanian landfills and burned for energy recovery.

Figure 3.

Total amount of waste disposed in Lithuanian landfills and burned for energy recovery.

2. Materials and Methods

2.1. Model for Forecasting the Amount and Composition of MSW

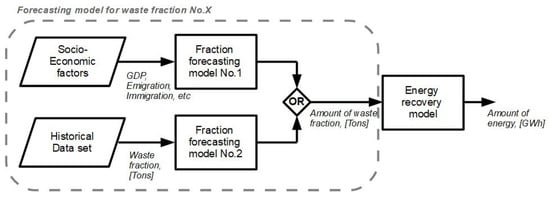

MSW collected in Lithuania is in mixed condition and is composed of more than 70 different fractions. Each waste fraction, such as paper or textiles, has its own identification code. Administrators of waste landfills have to register the total amount of MSW that is collected in landfill and monitor the composition of waste. An objective evaluation of the waste composition is difficult task that requires manual labor, especially when wastes are examined in landfills. Due this fact, not all waste fractions are correctly identified and registered in the set of historical data. Missing data can negatively affect the forecasting accuracy of energy recovery potential. We are proposing hybrid forecasting model that employs not only historical data of an individual fraction but also socio-economic factors when historical data is missing. The functional diagram of the proposed energy recovery concept is presented in the Figure 4. Proposed hybrid methods consist of 3 main models: (1) socio-economic factors based fore-casting model (see Figure 5), time series-based forecasting model (see Figure 6) and energy recovery model (see Figure 7). The first two models are used to forecast the amount of specific waste materials (individual fractions No. X) that can be used for energy recovery. The last model uses output of first models to forecast the potential amount of recovered energy. The number of individual fractions is forecasted using two different models, where the output for the energy recovery model is selected from the model that has a sufficient amount of input data.

Figure 4.

Functional diagram of proposed energy recovery model.

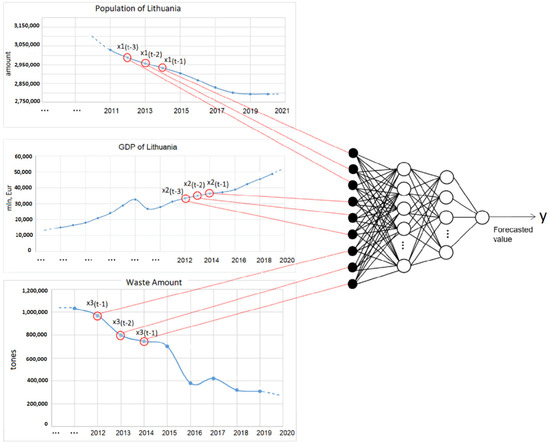

Figure 5.

The concept of the waste forecasting model, which is based-on socio-economic factors.

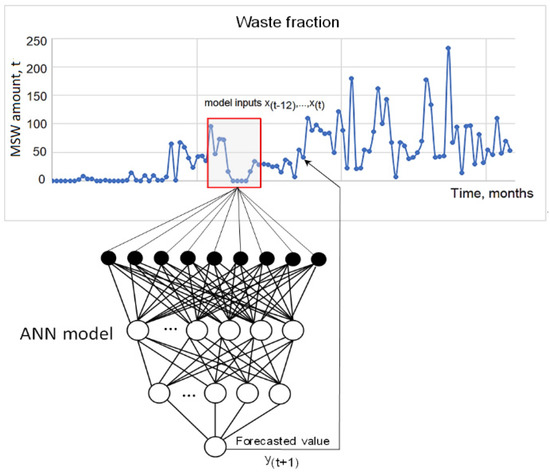

Figure 6.

Historical data-driven forecasting model of an individual waste fraction.

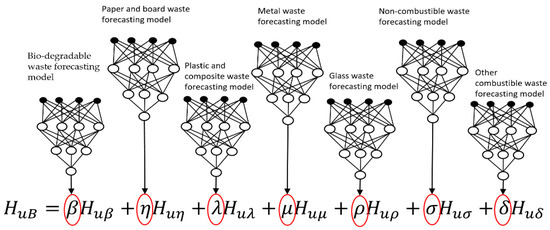

Figure 7.

The concept of the energy estimation model that can be potentially retrieved from the wastes.

The calculated correlation coefficients (Equation (1)) between the amount of landfill waste and socio-economic factors in the selected region show that the most significant factors are GDP, GDP per capita, immigration and population. The correlation coefficients for the two landfills in the country, namely Aukstrakiai and Takniskes, are presented in Table 1. The largest correlation has been observed between GDP, GDP per capita, population, emigration and immigration, while the smallest between employment indicators.

Table 1.

Correlation coefficients between the amount of landfill waste and socio-economic factors.

In cases where accurate forecasting cannot be achieved based on historical data, the dynamics of socio-economic factors that correlate with certain waste fraction are used for forecasting purposes. The two concepts of the model, one based on socio-economic factors and the other based on historical data, are illustrated in Figure 5 and Figure 6, respectively.

Feed-forward multi-layer perceptron ANN type [36] is selected in the research that has the structure of on one input layer, two hidden layers, and an output layer of neurons (Figure 5). ANNs are efficient data-driven modelling tool that is best for nonlinear systems dynamic modeling, forecasting and identification. The ANN’s generalization capabilities and flexible structure allows for the detection and classification of complex nonlinear behavior. The forecasting of the total volume, composition and energy recovery of waste is carried out using regression-based artificial neural network algorithms. The concept of the model for assessing the feasibility of recovering resources from landfills is based on the application of the best forecasting model. The size and complexity of the ANN structure is determined experimentally, taking into account the forecasting error of the model.

Model inputs are historical data on the most correlated socio-economic indicators and historical waste collection volumes for the selected region of the country. In order to obtain the output value representing the forecasted value of waste amount, the model must estimate the change in GDP , the change in the population and the change in waste amount in time intervals Thus, such an artificial neural network has 9 input signals and 1 output signal.

The proposed concept is applied not only for the forecasting of total amount of waste, but also for each waste fraction, such as paper, plastic, wood, textile, bio-waste and others that can be found in MSW. An independent forecasting ANN model is used for each fraction, where the outputs of the models are used to estimate the potential amount of energy that can be recovered from the waste.

Figure 6 shows the concept of forecasting model that is based on the historical data. The recorded amount of each fraction expressed in tons are used as the input to the model. The structure (e.g., the number of inputs) and complexity (e.g., the number of neurons in hidden layers) of the ANN-based model depends on forecasting error of the waste fraction.

The general concept of an energy potential estimation is shown in the Figure 6. Presented energy estimation method is limited to the 7 types of waste fractions but can be extended to any number required. This research uses 7 types of waste fractions expressed in tons, such as biologically degradable wastes β, paper wastes η, plastics and composites λ, metal wastes µ, glass wastes ρ, other not flammable wastes σ and δ.

The fit of the ANN based model was evaluated by calculating coefficient of determination and prediction error [37].

It is reasonable to calculate correlation coefficients , those provide the strength of the linear relationship between two features. Pearson correlation coefficients values vary between −1 and 1, whereas if , then the variables have no relation; the closer the coefficient is to +1 or −1, the stronger the relationship. Signs indicate if the relationship is positive or negative, for example if , then two features have perfect positive relation:

where value variable samples, variables sample, —mean of values in variable, —mean of values in variable.

Mean absolute error (MSE) is a measure representing the average of the squared difference between the real and predicted values in the data set. RMSE is just the square root of the mean square error, the only difference that MSE measures the variance of the residuals, while RMSE standard deviation of residuals. Value of RMSE and MSE penalize large errors. In contrast, mean absolute error (MAE) is less biased for higher values and usually doesn’t penalize large errors. MAE is calculated according to the following formula:

where n—number of time point, —is the actual value at a given time period t, and is the predicted value.

The mean absolute percentage error (MAPE) is a measure of the accuracy of a forecasting system. MAPE is one of the most commonly used metrics to measure forecast accuracy, because it expresses accuracy as a percentage of the error:

where n—number of time point, —is the actual value at a given time period t, and is the predicted value.

2.2. Municipal Solid Waste to Energy

Mixed municipal wastes can be grouped into two groups, such as combustible and non-combustible fractions. Non-combustible fractions are converted into slags and ashes during the combustions process, while combustible wastes (or materials) are oxidized to gaseous materials. Not all waste is suitable for the thermal energy production as it may have high level of humidity or be insufficiently thermal to maintain combustion process (there is a need for additives, which helps to maintain proper combustion process). The minimal calorific value of the waste cannot be lower than . The waste that has lower colorific values does not maintain the proper combustion process without added fuel.

MSW contains a lot of fractions, which has high calorific values. For example, paper, textile, plastic, and wood wastes have high calorific values. Caloricity depends on the amount of the chemical elements which can be found in the wastes, such as coal (C), hydrogen (H), oxygen (O), water (W), nitrogen (N), and sulfur (S). Table 2 shows the ranges of calorific values (megajoule per kilogram (MJ/kg)) for all waste fractions selected for the study, as different sources give different values [38,39,40].

Table 2.

Caloricity of waste fraction MJ/kg.

The caloricity value of the individual waste fraction can be estimated using Equation (4), which takes into account chemical components of the waste fraction [41]. This value is the sum of the product of the calorific coefficients of the chemical components multiplied by the amount of the component in the waste [42].

where —caloricity of the wastes (MJ/kg); C—the amount of coal in the wastes %; H—the amount of hydrogen in the wastes %; N—the amount of nitrogen in the wastes %; O—the amount of oxygen in the wastes %; W—the amount of water in the wastes %; S—the amount of sulfur in the wastes %. Total caloricity of MSW is estimated taking into the account the amount of individual waste fraction (Equation (5)).

where —total caloricity of MSW (MJ/kg); —the caloricity of bio-wastes fraction (MJ/kg); —the amount of bio-wastes in MSW %; —the caloricity of paper wastes (MJ/kg); —the amount of paper fraction in the MSW %; —the caloricity of plastic and composites wastes (MJ/kg); —the amount of plastics and composites in MSW %; —the caloricity of metal wastes (MJ/kg); —the amount of metal wastes in MSW %; —the caloricity of glass wastes (MJ/kg); —the amount of glass wastes in MSW %; —the caloricity of other non-combustible wastes (MJ/kg); —the amount of other non-combustible wastes in MSW %; —the caloricity of other combustible wastes (MJ/kg); —the amount of other combustible wastes in MSW %. Due lack of data about the generated number of individual types of plastic waste, we assumed that the fractions such as plastic, plastic packages, composites and composite packages can be used as one fraction type, called “plastic and composites”. The average caloricity value of these fractions (see Table 2) is used in the Formula (5).

3. Results

3.1. Estimation of Raw Material Recovery Potential Based-on the MSW Trends

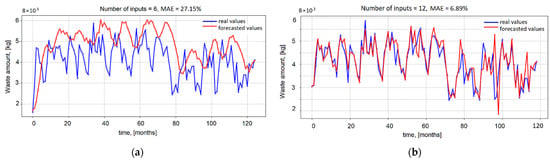

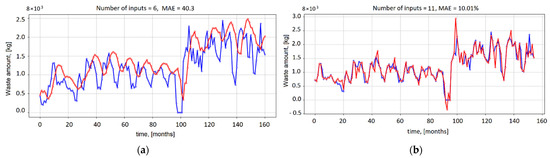

Figure 8 represent forecasting results of total amount of waste collected in Lapes landfill. The predicted waste value is obtained using a model different number of inputs in the range [6,7,8,9,10,11,12,13,14,15] (see Table 3). Performance indexes and correspond to evaluation results with testing data, and performance indexes and correspond to validation data set. The vertical axis shows the amount of waste in kilograms and the horizontal axis shows the time in months since 2007. The results in the Table 3 show that the best forecasting result varies considering two evaluation metrics: MAPE and Pearson correlation coefficient . The best accuracy result being achieved when the number of inputs equals 12 (,) and worst when the number of inputs equals 6.

Figure 8.

Total amount of wastes collected in the Lapes landfill: (a) the biggest forecasting error () and (b) the case of the smallest forecasting error (.

Table 3.

Forecasting results (testing and validation) of total waste amount for Lapes and Aukstrakiai landfills using varying number of inputs.

Figure 9 represent forecasting results of total amount of waste collected in Aukstrakiai landfill. In the case of Aukstrakiai landfill, forecasting model with 11 inputs demonstrated the best accuracy, where , however, correlation coefficient is obtained using 12 inputs. To forecast the total amount of waste, it is best to use a model with 11 inputs that evaluates the historical 11-month waste collection values. As in the case of Lapes landfill, the largest prediction error for Aukstrakiai landfill is obtained when the number of inputs is 6 ().

Figure 9.

Total amount of wastes collected in the Aukstrakiai landfill: (a) the biggest forecasting error (MAPE = 40.03%) and (b) the case of the smallest forecasting error (MAPE = 10.01%).

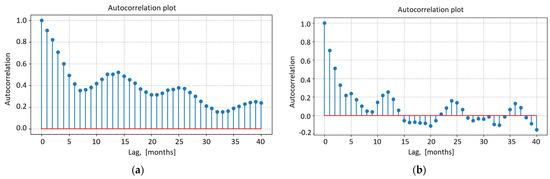

The predictability of the future amount of generated waste can be evaluated using autocorrelation function. Autocorrelation function is a mathematical representation of the similarity degree between a two-time series signal, where one is lagged version of itself over successive time intervals [43]. This function is similar to the correlation between two different time series, but autocorrelation uses the same time series twice, for example original form and lagged form. Autocorrelation measures the relationship between a variable’s current values and its past values (historical data). This function varies between positive 1 and negative 1, where +1 represents positive correlation, 0—represents no correlation and −1 demonstrates negative correlation. We used autocorrelation function to measure how much influence past amount values of MSW has for future amounts of MSW.

The autocorrelation function of the total MSW of Lapes landfill is shown in Figure 10 (right) and Aukstrakiai landfill (left). The timeline is represented on horizontal axis and the autocorrelation values are given on the vertical axis.

Figure 10.

The autocorrelation function of MSW collected in Aukstrakiai (a) and Lapes (b) lanfills.

Two autocorrelation functions demonstrate different nonlinear behavior in analyzed data. The autocorrelation estimated from Aukstrakiai landfill dataset shows high predictability potential because the lagged version of the dataset has high correlation values with original data set. However, the Lapes landfill dataset has more complex behavior because autocorrelation values are small and demonstrates low similarity between original dataset and lagged version of itself.

3.2. Accuracy of Energy Forecasting

We planned to divert high-calorific fractions to energy production by burning them. The potential of the energy recovery of the waste is evaluated using limited number of waste fractions. The limitation of waste fraction simplifies estimations and allows to make clear conclusions about proposed forecasting concept. This research includes “plastics and composites” (caloricity 20.6 MJ/kg), “glass wastes” (caloricity −0.1 MJ/kg), “textile” (caloricity 8.5 MJ/kg), “wood wastes” (caloricity 14.7 MJ/kg). The potential total caloricity Hcommon of selected waste fractions are estimated using Formula (5). The energy that can be potentially recovered from the MSW is estimated using Equation (6):

where ENER—the amount recovered energy (GWh/y), W—the number of combusted wastes (tonnes/y) ir —total caloricity of waste fractions (MJ/kg).

The potential amount of energy obtained by estimating real historical data is shown in Figure 11. The highest amount of energy 773.20 GWh/y was recovered in 2016, the lowest 0.25 GWh/y was recovered in 2007. The sudden increase in the amount of energy recovery in 2016 is due to the unprecedented collection increase in plastics and composites in waste.

Figure 11.

Estimated amount of energy based on real historical data.

Table 4 represents forecasted values of the recovered energy using 5 different forecasting models. The forecasted energy values are presented on the vertical axis (GWh/y) and the timeline is presented on the horizontal axis. Time axis begins from 2007 and ends with year 2020. The forecasted energy values of different models are shown with different color. Forecasted energy values is strongly correlated with estimated real energy values. All models predicted that the recovery of the energy is likely to strongly grow in 2016 due to increased collection of the plastics and composites fraction.

Table 4.

Forecasted energy values in Lithuania from 2007 to 2020.

The best forecasting results were achieved using models with 6 inputs (6 last months) for each waste fraction, such as model for “plastic and composites”, model for “paper wastes” and etc. The model with 6 inputs reached MAE = 7.936 GWh/y. The highest MAE value 16.69 GWh/y were reached using forecasting models with 10 inputs.

All experiments with the ANN model were implemented in Python and run on a PC (Dell Allienware) with NVidia GeForce GTX 980 M with 4 GB GDDR5 graphics and 4 GB of GDDR5 standard memory.

4. Discussion

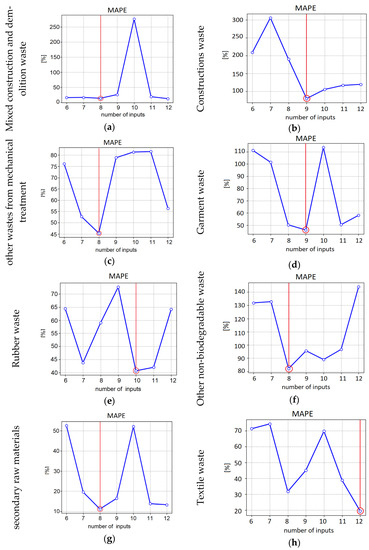

The accurate estimation and forecasting of energy recovery potential strongly depends on the correctness of the recorded data about collected MSW and its composition. Our research work has demonstrated that, in the case when there are missing, data in historical set socio-economic factors can be used for prediction of an amount of the waste and individual waste fraction. Additionally, our findings show that collection behavior of individual waste fractions varies from one landfill to another, and it differs between fractions (Figure 12). The amount and generation intensity of particular waste fraction depends on geographical location of the landfill and seasonality (national holidays etc.). We noticed that the usage of one type of the forecasting model with fixed amount of inputs gives lower forecasting accuracy than those with flexible number of inputs. The global optimum is obtained by calculating minimal value of performance measure MAPE.

Figure 12.

Forecasting MAPE value of the prediction model for different waste types (a) Mixed construction and demolition waste, (b) Construction waste, (c) other wastes from mechanical treatment, (d) Garment waste, (e) Ruber waste, (f) Other non-biodegradable waste, (g) secondary raw materials and (h) Textile waste at Lappe landfill using different number of inputs.

Accurate forecasting of MSW can also lead to a more accurate prediction of the percentage composition values of the landfill waste. To show the superiority of our method, the comparison table presented below includes forecasting results (waste fraction percentage values for Alytus Tankiskiu landfill) gained using different methods (Table 5). Actual values are acquired during the landfill drilling process, assessing the composition of the buckets. It can be observed that the autoregressive integrated moving average (ARIMA) model [44] produces large errors (in terms of MAE) when compared to the linear regression model and our proposed ANN model, which produces a significant smaller error, with a mean value of 3.368%. Using our model, the prognosis for the next year (2021–2022) is also provided.

Table 5.

Comparison of landfill composition values forecasted using different methods, including future forecasting for 2021–2022 years.

Upcoming research studies will involve development of ANN-based forecasting model that can automatically adapt to the complexity of the given data set (collection variability of individual waste fraction) by adjusting the right number of inputs.

5. Conclusions

In this study, a model based on artificial neural networks has been proposed, with several inputs adapted to the relevant waste fraction and to the specific landfill, taking into account the accuracy and the estimation range. The experimental results have shown that a model consisting of 12 inputs (months) is the most rational to forecast the total amount of waste in the Lapes landfill (). In the case Aukstrakiai landfill, the model with 11 inputs was the most accurate in terms of . In order to obtain the most accurate forecast possible, it is recommended to develop region-specific model for waste forecasting. For the prediction of waste composition, separate forecasting models were developed for each fraction of waste at different landfills. Different forecasting models demonstrated different results. Some models required less historical data, while others required more data to predict future values with confidence and accuracy. The minimum amount of data required for a rational forecasting of waste composition is the last 8 months of data.

Concerning the recovered energy forecasting task, it was found that the most accurate predictive model is the one with 12 inputs, being the model that takes into account the last 12 months of data to estimate the future value. The model of such a structure has achieved the highest forecasting results for the period from 2007 to 2020 compared to models with a smaller number of inputs. A total of 1225 GWh/y of energy could have been recovered during this period. The predictive values for the following years (both in terms of waste composition and energy recovery potential) will be verified by excavation and drilling of the landfill sites, which will allow the proposed hybrid model to be refined in accordance with the errors obtained.

Author Contributions

Conceptualization, V.R., A.P.-T. and L.E.; data preparation, V.R. and A.P.-T.; ANN based model development V.R. and A.P.-T.; experiments V.R. and A.P.-T., validation V.R. and A.P.-T.; writing—original draft preparation, V.R., A.P.-T. and L.E.; funding acquisition, L.E. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Lithuanian Business Support Agency (Grant agreement number 01.2.1-LVPA-V-835-03-0005).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, A.; Liu, X.; Chena, G.H. Municipal solid waste: Review of best practices in application of life cycle assessment and sus-tainable management techniques. Sci. Total Environ. 2020, 729, 138622. [Google Scholar] [CrossRef] [PubMed]

- Popli, K.; Park, C.; Han, S.-M.; Kim, S. Prediction of Solid Waste Generation Rates in Urban Region of Laos Using Socio-Demographic and Economic Parameters with a Multi Linear Regression Approach. Sustainability 2021, 13, 3038. [Google Scholar] [CrossRef]

- Paulauskaite-Taraseviciene, A.; Raudonis, V.; Sutiene, K. Forecasting municipal solid waste in Lithuania by incorporating socioeconomic and geographical factors. Waste Manag. 2022, 140, 31–39. [Google Scholar] [CrossRef]

- Vieira, V.H.A.D.M.; Matheus, D.R. The impact of socioeconomic factors on municipal solid waste generation in São Paulo, Brazil. Waste Manag. Res. J. Sustain. Circ. Econ. 2017, 36, 79–85. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mintz, K.K.; Henn, L.; Park, J.; Kurman, J. What predicts household waste management behaviors? Culture and type of behavior as moderators. Resour. Conserv. Recycl. 2019, 145, 11–18. [Google Scholar] [CrossRef]

- Pan, A.; Yu, L.; Yang, Q. Characteristics and Forecasting of Municipal Solid Waste Generation in China. Sustainability 2019, 11, 1433. [Google Scholar] [CrossRef] [Green Version]

- Vu, H.L.; Ng, K.T.W.; Bolingbroke, D. Time-lagged effects of weekly climatic and socio-economic factors on ANN municipal yard waste prediction models. Waste Manag. 2018, 84, 129–140. [Google Scholar] [CrossRef]

- Rosecký, M.; Šomplák, R.; Slavík, J.; Kalina, J.; Bulková, G.; Bednář, J. Predictive modelling as a tool for effective municipal waste management policy at different territorial levels. J. Environ. Manag. 2021, 291, 112584. [Google Scholar] [CrossRef]

- Wu, F.; Niu, D.; Dai, S.; Wu, B. New insights into regional differences of the predictions of municipal solid waste generation rates using artificial neural networks. Waste Manag. 2020, 107, 182–190. [Google Scholar] [CrossRef]

- Challcharoenwattana, A.; Pharino, C. Analysis of Socioeconomic and Behavioral Factors Influencing Participation in Community-Based Recycling Program: A Case of Peri-Urban Town in Thailand. Sustainability 2018, 10, 4500. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, M.; Talib, A.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial intelligence applications in solid waste man-agement: A systematic research review. Waste Manag. 2020, 109, 231–246. [Google Scholar] [CrossRef] [PubMed]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. Sustainable waste management: Waste to energy plant as an alternative to landfill. Energy Convers. Manag. 2017, 131, 18–31. [Google Scholar] [CrossRef]

- Istrate, I.-R.; Iribarren, D.; Gálvez-Martos, J.-L.; Dufour, J. Review of life-cycle environmental consequences of waste-to-energy solutions on the municipal solid waste management system. Resour. Conserv. Recycl. 2020, 157, 104778. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Michailidou, A.; Achillas, C. Multi-Criteria Decision Analysis towards promoting Waste-to-Energy Management Strategies: A critical review. Renew. Sustain. Energy Rev. 2020, 138, 110563. [Google Scholar] [CrossRef]

- Kannangara, M.; Dua, R.; Ahmadi, L.; Bensebaa, F. Modeling and prediction of regional municipal solid waste generation and diversion in Canada using machine learning approaches. Waste Manag. 2018, 74, 3–15. [Google Scholar] [CrossRef]

- Ceylan, Z. Estimation of municipal waste generation of Turkey using socio-economic indicators by Bayesian optimization tuned Gaussian process regression. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 38, 840–850. [Google Scholar] [CrossRef]

- Ponce, E.O.; Samarasinghe, S.; Torgerson, A. Model for assessing waste generation factors and forecasting waste generation using artificial neural networks: A case study of Chile. In Conference Proceedings of the Waste and Recycle, Fremantle, Australia, 21–24 September 2004; pp. 1–11. [Google Scholar]

- Ahuja, N.J.; Bahukhandi, K.D. Expert systems for Solid Waste Management: A Review. Int. Rev. Comput. Softw. 2012, 7, 1608–1613. [Google Scholar]

- Kokkinos, K.; Karayannis, V.; Lakioti, E.; Moustakas, K. Exploring social determinants of municipal solid waste management: Survey processing with fuzzy logic and self-organized maps. Environ. Sci. Pollut. Res. 2019, 26, 35288–35304. [Google Scholar] [CrossRef]

- Alberdi, E.; Urrutia, L.; Goti, A.; Oyarbide-Zubillaga, A. Modeling the Municipal Waste Collection Using Genetic Algorithms. Processes 2020, 8, 513. [Google Scholar] [CrossRef]

- Camero, A.; Toutouh, J.; Ferrer, J.; Alba, E. Waste generation prediction under uncertainty in smart cities through deep neuroevolution. Rev. Fac. Ing. Univ. Antioq. 2019, 93, 128–138. [Google Scholar] [CrossRef]

- Xu, A.; Chang, H.; Xu, Y.; Li, R.; Li, X.; Zhao, Y. Applying artificial neural networks (ANNs) to solve solid waste-related issues: A critical review. Waste Manag. 2021, 124, 385–402. [Google Scholar] [CrossRef] [PubMed]

- Araiza-Aguilar, J.; Rojas-Valencia, M.; Aguilar-Vera, R. Forecast generation model of municipal solid waste using multiple linear regression. Glob. J. Environ. Sci. Manag. 2020, 6, 1–14. [Google Scholar] [CrossRef]

- Cubillos, M.; Wulff, J.N.; Wøhlk, S. A multilevel Bayesian framework for predicting municipal waste generation rates. Waste Manag. 2021, 127, 90–100. [Google Scholar] [CrossRef]

- Kolekar, K.; Hazra, T.; Chakrabarty, S. A Review on Prediction of Municipal Solid Waste Generation Models. Procedia Environ. Sci. 2016, 35, 238–244. [Google Scholar] [CrossRef]

- Azarmi, S.L.; Oladipo, A.A.; Roozbeh, V.; Alipour, H. Comparative Modelling and Artificial Neural Network Inspired Pre-diction of Waste Generation Rates of Hospitality Industry: The Case of North Cyprus. Sustainability 2018, 10, 2965. [Google Scholar] [CrossRef] [Green Version]

- Vu, H.L.; Ng, K.T.W.; Richter, A.; Kabir, G. The use of a recurrent neural network model with separated time-series and lagged daily inputs for waste disposal rates modeling during COVID-19. Sustain. Cities Soc. 2021, 75, 103339. [Google Scholar] [CrossRef]

- Abbsi, M.; Hanandeh, A.E. Forecasting municipal solid waste generation using artificial intelligence modelling approaches. Waste Manag. 2016, 56, 13–22. [Google Scholar] [CrossRef]

- Lin, K.; Zhao, Y.; Kuo, J.H.; Deng, H.; Cui, F.; Zhang, Z.; Zhang, M.; Zhao, C.; Gao, X.; Zhou, T.; et al. Toward smarter management and recovery of municipal solid waste: A critical review on deep learning approaches. J. Clean. Prod. 2022, 346, 130943. [Google Scholar] [CrossRef]

- Huang, L.; Cai, T.; Zhu, Y.; Zhu, Y.; Wang, W.; Sun, K. LSTM-Based Forecasting for Urban Construction Waste Generation. Sustainability 2020, 12, 8555. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Q.; Zhang, X.; Bao, Q.; Su, J.; Liu, X. Waste image classification based on transfer learning and convolutional neural network. Waste Manag. 2021, 135, 150–157. [Google Scholar] [CrossRef] [PubMed]

- Singh, M. Forecasting of waste-to-energy system: A case study of Faridabad, India. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 42, 319–328. [Google Scholar] [CrossRef]

- Bagheri, M.; Esfilar, R.; Golchi, M.S.; Kennedy, C.A. A comparative data mining approach for the prediction of energy recovery potential from various municipal solid waste. Renew. Sustain. Energy Rev. 2019, 116, 109423. [Google Scholar] [CrossRef]

- Muawad, S.A.; Wedaa, S.A.; Abuelnuor, A.A.; Elemam, A.E.; Ali, A.M.; Aldin, A.S.; Osman, I.I. Waste- to- Energy Production of Alternative Energy Source Using Landfill Technology. In Proceedings of the International Conference on Computer, Control, Electrical, and Electronics Engineering (ICCCEEE), Khartoum, Sudan, 21–23 September 2019. [Google Scholar]

- Maynard, M. Neural Networks: Introduction to Artificial Neurons, Backpropagation and Multilayer Feedforward Neural Networks with Real-World Applications; Independently published; 2020; p. 42. ISBN 9798642783528. [Google Scholar]

- Botchkarev, A. Performance Metrics (Error Measures) in Machine Learning Regression, Forecasting and Prognostics: Properties and Typology, Interdisciplinary Journal of Information, Knowledge, and Management. arXiv 2019, arXiv:1809.03006. [Google Scholar]

- Menikpura, S.N.M.; Basnayake, B.F.A. New applications of ‘Hess Law’ and comparisons with models for determining calorific values of municipal solid wastes in the Sri Lankan context. Renew. Energy 2009, 34, 1587–1594. [Google Scholar] [CrossRef]

- Environmental Protection Encouragement Agency. Neue Ersatzbrennstoff-Anlagen—Kein Ersatz für Intelligentes Stoffstrommanagement; Independently Published: Norderstedt, Germany, 2007. [Google Scholar]

- Boer, E.; Boer, J.; Jager, J. Deliverable Report: Environmental Sustainability Criteria and Indicators for Waste Management The Use of Life Cycle Assessment Tool for the Development of Integrated Waste Management Strategies for Cities and Regions with Rapid Growing Economies; European Commission: Darmstadt, Germany, 2005. [Google Scholar]

- Cerbe, G.; Hoffmann, H.-J. Einführung in die Thermodynamik, 10th ed.; Carl Hanser Verlag: Munich/Vienna, Germany, 1994. [Google Scholar]

- Valaviciene, I. The Impact of Seasonal Variation of Municipal Waste Generation on Waste Management System Indicator. Ph.D. Thesis, Technological Sciences, Environmental Engineering and Landscape Management, Kaunas University of Technology, Kaunas, Lithuania, 2013; p. 109. [Google Scholar]

- Leap, J.N. An Investigation of the Effects of Correlation, Autocorrelation, and Sample Size in Classifier Fusion; Theses and Dissertations. 4023, BiblioScholar; Air Force Institute of Technology, Air Force University: Dayton, OH, USA, 2012; p. 122. ISBN 10:1288326947. [Google Scholar]

- Kiaulytė, A.; Denafas, G. Feasibility Assessment for Resource Recovery at Alytus Regional Landfill; Environmental Engineering; Kaunas University of Technology, Faculty of Chemical Technology, Kaunas University of Technology: Kaunas, Lithuania, 2015; pp. 1–60. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).