Abstract

The fast expansion of digital culture has fostered the creation of makerspaces such as fabrication laboratories (FabLabs) that, thanks to their flexibility and their use of open source tools, strengthen the sense of community and produce true transformations within those communities. Despite their relevance, few studies focus on the characterization of these environments. This paper presents the results of the FabLab Global Survey, aimed at understanding the characteristics of FabLabs through the visions of their managers, or “FabManagers”. The results show an enormous diversity of approaches within the FabLab movement that cannot be extrapolated to a single characteristic element, but that allow its global compression. Their properties reveal them as transforming elements that eliminate technological and cultural barriers, empowering user communities and optimizing learning processes regarding digital technology. FabLab activities allow not only economic and industrial development thanks to innovative projects, but also a digital technology approach for young students and the inclusion of minorities at risk, thus eliminating old cultural and social barriers.

1. Introduction

In the last decade, the processes of design, production and manufacturing have changed with the incursion of new technologies and strengthening concepts such as digital manufacturing, open innovation and Industry 4.0. This change has brought a new industrial revolution, where the popularization of knowledge and the productive elements and even the relationship between the user and manufacturing have changed. This change is also cultural and social since the user can achieve greater ease of access to information and the necessary technology and is no longer a mere consumer of products and services without the capacity to make actual decisions about them or the knowledge or technology to alter the industrial process or operation. Consumers can go on to become “prosumers”, a term coined in the early 1990s by Alvin Toffler in his book The Third Wave [1]—becoming producers and consumers of products without, in some cases, these being marketed or participating in the economy. This new democratization of industrial processes has been fueled by a proliferation of spaces and environments where users can acquire complex knowledge about digital technologies and modern manufacturing through social learning and the development of technologically advanced projects. The strong social interaction that occurs in these environments is conducive to learning and acquiring complex skills to carry out projects, in many cases solving the knowledge barrier and popularizing these digital manufacturing processes by providing a new tool for economic development and equal opportunities to achieve, finally, technological empowerment.

Within maker environments, the novelty of the movement and the significant expansion of FabLabs have aroused considerable interest in this type of collaborative initiative. Led by some standard features, including open technological knowledge and access to advanced technology and its strong international network structure, the FabLab is shown as a strong actor, with the ability to alter its environmental influence. Its effect depends on the properties of the laboratory, however, including the characteristics of the users who participate in it, and the attributes of FabLab that are included. Despite its strong social relevance, there is little information about the general properties of such environments in the literature.

Fabrication laboratories (FabLabs) are an integral part of “communities and spaces with more or less open to the public levels, with objectives and targets agreed by its members in which, through learning processes, production, prototyping, design, and manufacturing, both tangible and intangible assets, complex two-way exchanges of information are produced, knowledge, technology, skills and resources among users, users and society and between users and industry” that constitute the new wave of collaborative ecologies [2,3] into which elements such as makerspaces, hackerspaces, living-labs or co-workings also fall, highlighted by its origin and its capacity as an international organization.

A FabLab is a strong social space offering affordable and accessible manufactured tools and is sometimes conceived as an appropriate platform to begin the prototyping and development processes of any object [4]. They emerged in the 2000s at the Massachusetts Institute of Technology (MIT) from Professor Neil Gershenfeld’s subject [5,6], called “How to Make (Almost) Anything”. Thanks to the creation of this first FabLab, Professor Gershenfeld’s students could realize their designs, popularizing digital manufacturing and making the subject successful.

After this initial FabLab, fabrication laboratories were globally involved in a dramatic increase from 45 laboratories in 2010—a time that coincided with the popularization of digital production elements such as the 3D printer Rep-Rap—to over 1000 in just seven years. The first FabLabs, together with the creation of the FabLab in Boston, were established in Costa Rica, Ghana, India and Norway, with a strong interest in local development, but with notable differences in their main orientations.

Each FabLab is as different as their users’ interests or projects, but they share some characteristics that differentiate them from other similar ecologies. One of the primary and most common attributes of FabLabs involves rules from the “FabLab Charter”. These rules can be summarized in several ideas [7]: The FabLab must consider themselves a community resource and, consequently, leave some time in the week for public access. They must have a standard set of tools that give them the capacity to work and carry out projects and processes that allow projects to be shared between the different laboratories, giving them a network awareness that makes the laboratory an integral part of a larger network. They must respect the open source philosophy in their activities and projects and must consider the commercial initiatives carried out by their users as possible initiatives for incubation in a FabLab, but which must subsequently be developed as an external element.

An awareness of global integration allows FabLabs to exchange knowledge, promoting interconnections between different laboratories that make up the FabLab Network [7] thanks to elements such as the FabAcademy program and the various gurus therein formed. Other elements are the expansion of FabLabs, regional FabLabs networks and the involvement of the FabLab Foundation, regional and interregional FabLab meetings, creating documents and web portals of the laboratories, the development of collaborative projects between different FabLabs and, mainly, by creating a learning environment that fosters collaboration and interaction between users locally and internationally [8]. Thus, and through one of the critical aspects of the FabLab ideology, the learning and documentation of the projects carried out are prioritized, making them replicable in any other laboratory where it is possible to use the same instruments, generating a global knowledge environment in that ideas and projects transcend regional borders thanks to new technologies, receiving the support and improvements of a worldwide community and facilitating access to knowledge and complex techniques even for users without specific training.

It is necessary to note that, despite the importance of digital skills in today’s changing world and the existence of multiple elements that bring these skills to citizens, many non-experts see difficulties in accessing this maker culture, understood as an amateur and professional movement that includes the use of digital manufacturing technology and software with traditional manufacturing methods to create or customize objects [9]. Immersed in this maker culture and despite its popularity, FabLabs still have the problem that any advanced technology has for general users: the difficulty of use. Despite the growing popularity of this technology, users express a lack of skills and/or essential experience necessary for the design or use of the various techniques involved in digital manufacturing; there is a high level of complexity in the action and overall management required, for example, for the use of 3D design software or a favorite 3D printer that, despite interfaces and systems, have relatively simple operations. This lack of skills, many self-perceived by users, is a barrier for entry to digital manufacturing processes, the related technology and maker environments in general. This difficulty is usually solved only through actual access to the technology offered in these places or through the occasional workshops or training activities in the maker areas. The substantial impairment that requires access to this basic knowledge in digital manufacturing is overcome by working in the community, group learning and medium- and long-term project development to achieve the involvement of users in actions aimed for children and adults. In this respect, the projects in makerspaces in general, and the FabLab in particular, often act as transformations of the population in which they find themselves, working directly in their development, as a union or open to the community generation of non-expert users actively evolving learning, as demonstrated in FabLab Genk [9].

Innovation processes are also not beyond the capability of showing makerspaces to alter and improve the social and economic community in which are established directly. As an example, programs to promote development, such as ERUDITE, for the design and construction of services that improve the digital innovation in rural and urban environments, have been used in Slovenia; creation and tuning included two FabLabs (in Ptuj and Ribnica) with the aim of stimulating innovation and entrepreneurship by improving the economic and social conditions of nearby communities. These two laboratories were involved in the community–technical aspects of digital manufacturing through training, from primary school to university levels, in long-term programs adapted to local issues. The access of citizens to entrepreneurship was enhanced by generation communities working in the laboratories, and the process of co-creation next to the open innovation processes in the public sector was strengthened, improving transparency [10].

The participation of citizens in the programs developed in the FabLab also includes the realization of technologically advanced research projects through citizen science. In these programs, users become nodes of research in the development and use of many useful information devices, which is difficult to achieve otherwise. These programs, such as the Smart Citizen program conducted by FabLab Barcelona [11] or the MicroMascotas program mentored by César Laboratories in Etopía (FabLab Zaragoza) [12], include the massive participation of citizens, users and non-users of the FabLab; organizers, data collection tools and technological developments are made at very low cost, often by users themselves with open instructions. Through open calls, and thanks to the participation of various public entities, FabLabs realize incredible projects that are proposed, designed and led by citizens who, despite not having the means or the necessary knowledge, benefit from the participation of other users who perform tasks of high complexity. The Servet experimental stratosphere project, also developed in the Cesar laboratory in Etopía (FabLab Zaragoza), is a good demonstration of this [13]. This new wave of citizen involvement helps transform the cities from passive elements that are “product in, trash out” to living elements that generate knowledge, i.e., “data in, data out”. Here, the usual waste, technology and information are included in a fundamental element of sustainability that turns cities in the next model to FabCity, where information technologies redefine the use of the towns to obtain a new productive, economic and social dimension [11].

Socially, and despite the various programs that they develop, FabLabs embody many of the social stereotypes of the cultural environment in which they are included. Classically, despite great social advances in equality, technology has been dominated by males, in the so-called “gender gap”. Excluding natural gender equality and maintaining a strong differentiation is strengthened by social customs that make up the established roles, from the linguistic construction itself to the assumption of different cultural values. This classic “gender gap” seems also to be reflected in the distribution of users in FabLabs, where some studies show slightly higher female participation of 25% [14], far from equal participation. It is obviously not possible to generalize from these figures due to the diversity of FabLabs as cultural spaces and the variety of orientations, themes and projects which makes it impossible to extrapolate, as rightly noted by the authors of the study mentioned. The multiplicity of FabLab types scattered throughout the world promotes differences in the gender distribution of their users; countries such as Brazil have shown a greater elimination of differences in the participation of the genders, approaching parity [15]. Indeed, FabLabs reflect the differentiation that society sets, and despite the egalitarian mentality of these cultural environments, the existence of multiple programs for female empowerment and their inclusion in both the maker environment and in the FabLabs themselves, the ever-growing presence of women in FabLabs in technical roles and as FabLab managers and the impact on education and training programs open to egalitarian goals, laboratories are still far from achieving the equality pursued. An example of the type of program developed in the FabLab initiative is the Poderosas program in FabLab León [16], which aims to encourage female commitment to technology and digital manufacturing, improving self-confidence through exclusive programming activities for girls. These types of programs activate the curiosity of young users, enhancing their willingness to join higher education related to science and technology, where the male presence is classically predominant.

Despite all these efforts, the most significant gender differences among participating users in a FabLab can be found in laboratories dedicated to carrying out high-tech projects because, presumably, more cultural and economic factors limit access to resources themselves. These differences are probably due to the FabLab dependence on some institutions, where the difference is palpable, including variations due to the environment (industrial, artistic, academic, etc.) or the central themes of the laboratory (architecture, electronics, art, design, etc.) due to gender differences, since they are usually not at all limitations of access or use to users of any condition [17].

It can be argued, therefore, that FabLabs are not spaces that contribute to gender differences or discrimination, but even being influenced by their socio-economic background and cultural tradition, they constitute a hope, thanks to the widespread use of technology and the implementation of specific programs of empowerment and outstanding contributions to social equality in education, as well as their strong, open and participatory character [17].

In addition to the development of activities of inclusion and gender equality, several FabLabs are involved in programs aimed at social inclusion, equal opportunities or improving future opportunities for young people through training and skill development in technology and digital manufacturing. Some of these programs have strong support from foundations such as the Orange Foundation in “The Solidarity Program FabLab”, an international program aimed at young people between 12 and 25 years. This program, in which several countries in Europe, the Middle East and Africa participate, works with local authorities and a collaboration of FabManagers [18]. As an example, in addition to supporting 19 FabLabs in France, the 2015 program selected nine international social projects for further development [19]:

- Two projects in Spain: one proposed by the “Social Technology Foundation” in Barcelona, with the aim of creating objects for the sick, and another proposed by the association “Friends in Madrid”, which seeks the inclusion of young people with Asperger’s syndrome in digital creation in the FabLab.

- FabLab Trojmiastro in Poland included a project to improve access to digital technology in isolated rural settings.

- In Senegal, the “Ker Thiossane” association was supported by the Orange Foundation to improve the popularization of electronics among young people.

- In Cairo, the Egypt FabLab received support to create a network of mini-FabLab laboratories in five other cities.

The program also financed the creation of four new FabLabs, whose job was geared to solidarity and development as proposed by the “Old Market Alliance Hall” association in Slovakia, the “Jeunes et Sciences” association in the Tunisia project, FabLab Madagascar presented by the “SOS Village d’Enfants Madagascar” and the FabLab association in Mauritania presented by the “Mauritius Telecom Foundation”. In its 2018 edition, there were 61 projects in this program [20].

“The Solidarity FabLab Program” Challenge #Imake4MyCity, used digital technology in 2017 to offer participants aged between 12 and 25 years without formal qualifications in digital manufacturing the opportunity to show their creative potential. The challenge, endowed with three prizes of EUR 15,000 and in which more than 60 laboratories and associations were included, focused participants’ attention on the adaptation of inclusive sport under the title “Sport for All”, while in 2018, its focus was on creating a digital solution to reinvent the city of the future (Foundation Orange, 2017) [18].

The Orange Foundation also develops the “FabLabs Social” project in Spain within the “Solidarity FabLabs” program. The “FabLabs Social” program is a training program around digital fabrication aimed at improving the active and participatory social inclusion and employability of young people in vulnerable situations. “Breakers, Fabricate a New World” includes a program that aims to stimulate the learning of technological skills related to digital manufacturing, together with other transversal competences such as teamwork and social skills through a combination of digital innovation, the use of digital production in learning environments and social facilitation. The program is distributed in three annual calls and developed in FabLabs including FabLab Sevilla, FabLab Valencia, FabLab Leon, Tinkerers FabLab Castelldefels and Open Space MakeSpace Bilbao or Madrid, among other maker venues. This program has the support of Federation of Organizations with Projects and Flooring Assisted (FEPA) and BJ-Adaptations, as among its objectives it aims to include young people in care and guardianship who are disabled or problematic and at risk in the social sphere [18].

FabLab Bohol [21] is another case study, where the implementation of learning programs in the local population seeks the economic and social transformation of a rural area by improving the educational training of local entrepreneurs. These contextualized innovation programs are proposed as a solution to economic poverty and lack of industrialization in the rural regions and have a substantial impact on social and economic trends in the area.

It is clear that knowledge and training in new skills are powerful tools for economic and social development. Digital manufacturing in maker environments has a healthy positive relationship with education, as their conditions are ideal for acquiring skills in new technologies. There are numerous examples documented in the literature in which, through these learning environments, imagination, creativity and interaction between humans and technology [22,23,24,25] are improved, converting FabLabs into real laboratories for exploring and exceeding individual limits in creation, art, science and engineering [26,27,28]. By providing experience and knowledge, they also achieve improved self-esteem, motivation and, of course, fun [29]. Learning theories such as constructivism involve learning processes through direct experimental contact that are developed in the FabLab. Previous constructivist experiences include the constructionist Learning Laboratory, designed by Stager and Papert in the Maine Youth Centre with the idea of fostering an environment where knowledge is generated through the act of “doing” itself, showing the pillars of learning that take place in these collaborative environments even in challenging conditions [30].

In recent years, the scientific literature has offered particularly important evidence of the contribution of digital manufacturing to the development of new digital skills. This application of digital production, including immersion FabLabs in educational environments, is not limited to higher education, where knowledge of the target users could be closer than expected to develop such complex skills, but includes settings such as elementary schools or libraries. Digital manufacturing, and specifically the FabLab, provides the necessary characteristics for the profound transformation that the teaching–learning process should consist of in its openness to current and future society. This incursion into the training field both occurs in the official curriculum and is unofficially protected by carrying out exercise and recreational additional activities carried in embedded laboratories and their own educational institutions, such as from laboratories supported by public/private funds and externally to the educational institution, but within collaboration. These projects are of particular interest in the education of children which increases investment in technology, science, engineering, art and math (STEAM), and it is of great importance in preparing students for future society. In this way, the elements of digital manufacturing are part of school educational projects at early ages, as in the “Arcángel: D” project developed by the Arcángel Primary School with the collaboration of the FabLab Media Lab Prado [31] or MAkey Project with the aim of understanding the role of makerspaces in developing young children’s digital literacy and creativity [32,33,34,35].

The introduction of FabLabs in training programs also allows educational innovation. Some educational programs include innovative experiences such as using deliverable-based learning (DBL) in FabLab Faces in the Sorocaba Engineering School of São Paulo, Brazil, where students are encouraged to think about what final product they want from their job, learning in its design and constructing a path of knowledge that leads them to their ultimate goal. To strengthen social and economic development, they must be accompanied by a cultural event to be built for new generations in a way that relies on today’s adults. This cultural development implies the generalization of digital culture, but the educational objective collides head-on with the social reality in many regions. The addition of digital manufacturing activities and collaborations with FabLab educational programs contributes to the creation of a digital culture for the future and improved equal opportunities in society.

It is not only in purely educational environments that the elements of digital culture have a place. Typical librarian ideals are not so far from the collaborative ecology models close to the FabLab environment, especially if we consider factors such as free access to information, openness and freedom. This conventional approach seems to be reinforced by increasingly documented cases of FabLabs, makerspaces or hackerspaces linked to libraries. Since the opening of Fayetteville Free Library FabLab in 2010, by Lauren Britton [7], the number of these collaborations has increased rapidly, reaching 109 three years later, as identified in John Burke’s study [36]. In addition to this common ideology, the digital manufacturing environments share involvement in educational training with FabLabs by including experimental learning and communities of practice and improving self-efficacy through social education, even becoming elements of strong social transformation through the empowerment of the cities and individuals involved [37].

Thus, and considering the development of culturally more distant regions from urban centers, and regions with less technological capacity, mobile laboratories are an interesting case. These laboratories represent the approach of digital technology to rural or remote environments. The first mobile FabLab was established in 2007 at the Center for Bits and Atoms (CBA) at MIT, followed by the laboratory used by the Council for Scientific and Industrial Research (CSIR) in South Africa in 2009 and MC2 STEM High School Cleveland Metropolitan School District in Ohio in 2010 [38]. One of the cases documented is the FryskLab, a mobile laboratory in Friesland (Netherlands) housed in an old bookmobile, which in 2012 was the first mobile FabLab in Europe [7], developed through an initiative of Bibliotheekservice Fryslan (BSF) (the Friesland Library Service). Its objective was to bring training and access to equipment and knowledge closer to regions that did not have a nearby laboratory, including training programs and the dissemination of digital manufacturing culture, even in primary and secondary education. Despite the limitation of space, it offers typical FabLab machines: 3D printers and scanners, laser and vinyl cutters, hardware such as Arduino boards and several open source portable computers. It is not the only mobile FabLab in Europe. In July 2018, there were 159 officially registered FabLabs in FabLabs.io. In France, we find the Nomad Lab, designed by ENSGSI School in 2012–2013 in order to remove the barriers to the creation and innovation of small and medium-sized enterprises in rural areas, improving their economic development [38].

The contribution of FabLab regional development is one of the inherent cultural and nature elements applicable to their integration in the regions where they are established. Thanks to FabLab’s own characteristics, which combine the use of digital manufacturing equipment with a high technological component, and the processes of social interaction and knowledge exchange, it is possible to confirm that FabLabs are suitable environments for generating open innovation processes. These processes, along with the facilitation of access to the skills and knowledge of digital manufacturing for non-expert users, democratize manufacturing previously reserved for highly industrial environments. FabLabs constitute a real opportunity for economic development and help in preventing social exclusion and unemployment, features especially relevant in developing countries, by promoting creativity and technological entrepreneurship from knowledge, addressing concepts of the collaborative economy. This situation has been taken advantage of by different regional governments in different parts of the world where, through actions that include the participation of FabLabs as facilitators, programs are carried out aimed at improving innovation and entrepreneurship for local development, constituting a new paradigm of technological inclusion through collaborative development [21,39].

Do all FabLab show the same properties, however? Do they all have the same characteristics and could they be implemented in the same way in any community or region? FabLabs are diverse in their features and conditions, but according to a standard general structure based on the FabLab Charter, they should have common aspects. Using the limited literature on the subject, this paper seeks to identify the main characteristics of the digital manufacturing laboratories linked to the FabLab movement and tries to characterize their main processes and activities in order to establish a basis for further development and research.

2. Materials and Methods

Considering the conception of the FabLab movement more deeply, we created an instrument to obtain information, developed as a questionnaire addressed to the managers of the various existing FabLabs. A focus group consisting of FabManagers and technologists helped identify the most relevant concepts related to the movement, allowing the following dimensions of interest or relevance to be defined:

- Descriptive aspect of basic characteristics;

- Perception dimension of digital manufacturing;

- Economic aspect;

- Social aspect;

- Dimension linked to innovation and technological development;

- Aspects related to documentation and knowledge sharing.

Based on these dimensions and validation by the Delphi method, we proceeded to design the questionnaire with the following general structure in which the different aspects are included:

- Part I: Description of FabLab;

- Block II: Innovation Processes and Documentation;

- Block III: Business Model Description;

- Block IV: Internal View.

After this initial process, we began implementation in November 2015. An online questionnaire was created to assess the laboratories, through the questionnaire platform of the University of Cantabria, based on the open source Lime Survey software [40]. The questionnaire was translated into French and English for international application, as alternative languages to Spanish.

Participants

To select sample sizes and obtain contact information, we used the www.fablabs.io (accessed on 1 March 2022) website. This website contains an updated list of registered FabLabs, organized by country, and it is possible to download a data file in JavaScript Object Notation (JSON) format light text for exchanging structured data which, once adequately converted, makes work through any data manager practical and straightforward.

The list of data included 516 laboratories on the date of receipt of questionnaire responses (December 2015), of which contact information of only 473 laboratories was available. Once the initial report was refined, 445 fabrication laboratories were finally contacted through email, informing them about the research and inviting them to participate through a direct link in their language (Spanish, English or French). Once the universe was defined, to determine the appropriate sample size, a confidence interval of 95% was established by setting the sample size needed for a margin of error of 10%. We consider 80 effective responses as an equal conservative ratio of 50%. In our case, after completion of the acceptance period units, representing 124 replies with the above values, a margin of error close to 7.5% was obtained, substantially below the 10% of our initial approach, as seen in Table 1.

Table 1.

Research data table.

The high participation in the questionnaire, superior to that of previous studies, allows us to propose an important general overview of the characteristics of this phenomenon. The descriptive analysis of the information generated through the FabLab Global Survey reveals a great diversity in the participating digital manufacturing spaces. The typology of their activities, the diversity of their users and business models, the ability to carry out projects and the other features queried account for this variety, but, above all, this variety allows us to access a significant amount of relevant information that is difficult to access in any other way and will permit subsequent studies.

As shown in Figure 1, laboratory participants in FabLab Global Survey come from all over the world, with the response obtained from European and Latin American FabLabs being especially significant.

Figure 1.

Distribution by country.

3. Results

The most notable results are discussed below, divided into their physical, social, economic and other distinctive features.

3.1. Expansion

One of the main characteristics of the FabLab movement is its fast expansion. The evolution of the number of laboratories registered in www.fablabs.io (accessed on 1 March 2022) shows a sharp growth curve from 3 registered FabLabs in 2003 to 678 registered FabLabs in mid-2016. Of those nearly 700 labs, more than 200 were registered in that last year. In July 2018, there were over 1300. This growth rate was also observed in the results of the questionnaire, by analyzing the start dates of the participants.

3.1.1. Start of Laboratory Activities

Since their birth in the early 2000s, the number of FabLabs has not stopped growing, although this growth was discreet at the beginning. These growth rates were endorsed in the questionnaire responses. Most of the laboratories that responded originate from the year 2010.

The diversity of fabrication laboratories is as wide as the number of laboratories in different continents. Laboratories generally do not behave as isolated cells, and their activities are committed to the environment in which they are included through the generation of various ecologies [2]. That is why one of the goals in developing this research instrument was to strengthen the primary and essential characteristics of the different laboratories in their environment, to achieve a general characterization, but with a different univocal classification according to exclusive intent features. There are many factors that determine these differentiating features, including financing, internal structure and process management, the involvement of own or external personnel, the interests developed by laboratory users, the objectives included in a lab’s creation or even the relations of the laboratories with other entities and communities. These are, therefore, aspects that make up the particular traits of each laboratory, influencing their activities and affecting their development.

3.1.2. Useful Surface

The variety of laboratories is also seen in their active surface areas, where answers ranged from 8500 m2 or 3200 m2 in some laboratories, in contrast to the smaller surface areas of modest laboratories, such as the 30 m2 indicated by FabLab Shibuya Tokyo or FabLab Lima in Peru. Sixty-three percent of laboratories participating in digital manufacturing reported possessing a smaller surface area than 250 m2.

Despite the apparent relationship, we can confirm the existence of a significant correlation between the available surface in a FabLab and annually available laboratory budget (rho = 0.459, p < 0.001). Similarly, we can say that there are significant correlations between the budget, the number of registered users (rho = 0.279, p < 0.05) and the number of current users (rho = 0.318, p < 0.01). Similarly, there are correlations between the physical area size of the FabLab, the number of registered users (rho = 0.243, p < 0.05) and the number of current users (rho = 0.284, p < 0.05), as shown in Table 2.

Table 2.

Correlation between surface area, budget and number of users.

3.1.3. Tools and Equipment

While the existence of laboratories has been commonly associated with the development of digital fabrication by popularizing typical tools such as 3D printers and laser cutters [41,42,43,44], it is no less valid that some of that equipment, when it is intensely used, reaches acquisition and maintenance costs that are not compatible with the budgets of some laboratories. In addition, although FabFoundation recommends a specific list of items for a FabLab, the reality seems to indicate that not all laboratories have the equipment suggested.

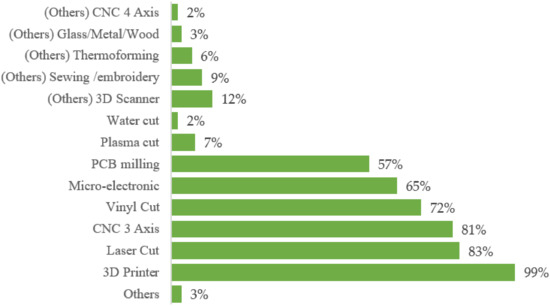

In our questionnaire, we used an item for the evaluation of the equipment present in the different participating laboratories without evaluating the concrete models or trademarks chosen. The results offered no surprises beyond logic; thanks to the increasingly accessible cost of digital manufacturing processes, all laboratories had 3D printers. A large majority also had laser cutters or CNC machines. These items have higher costs associated with consumables and the facilities required for their implementation and maintenance. The questionnaire also allowed providing other equipment that did not appear in the relationship initially indicated. Some laboratories indicated that they had 3D scanning elements (12% of laboratories) in their facilities and elements of sewing and embroidery (9% of the participating laboratories), as seen in Figure 2.

Figure 2.

Common tools in FabLabs.

3.1.4. Relevant Activities in the Laboratory

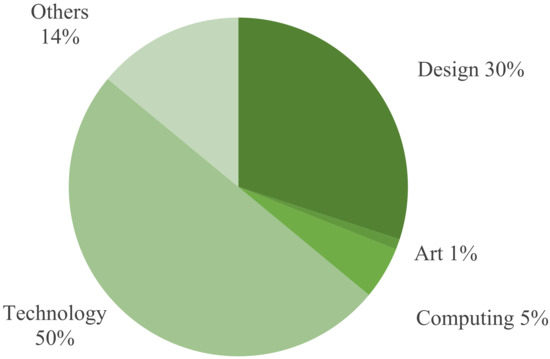

Fabrication laboratories present activities as diverse as the different interests of their users. In this sense, a community can develop different interests from another, based on the relevance or quantity of the activities developed. Through the FabLab Global Survey, it was intended to obtain information on the predominant interests in a general way. The option of indicating other interests not included in the range of options provided was also presented (Figure 3).

Figure 3.

Distribution of main interests in the FabLab.

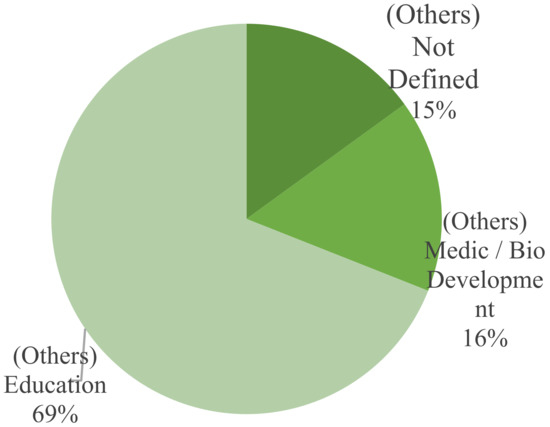

The main interests developed in FabLabs are activities related to technology (50% of the participating laboratories) and design (30%), although there is a growing interest in developing activities relating to education (9.6%) and medical/biological activities (2.24%) that were included in the Others section (Figure 4). Another aspect is the relevance of artistic activities recorded for 18% of the laboratories in a second preference.

Figure 4.

Distribution of relevant interests indicated in the “other” section.

3.1.5. Personnel

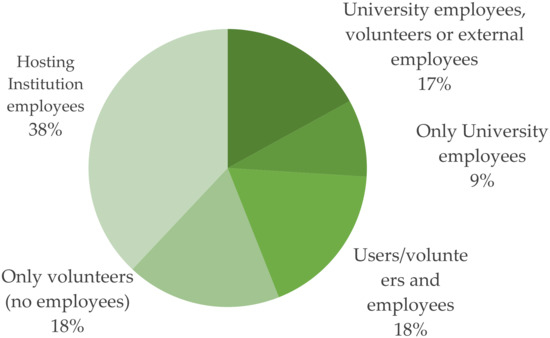

Another characteristic of some FabLabs is the presence of employees and professionals with specific dedication to the management of the equipment present in the laboratory. The presence of employees is not a constant feature in FabLabs, and labor dependency (e.g., salaried employees of external institution laboratory) was not a direct objective of this study. Thus, even though one of the main objectives in a FabLab is to train users to develop the necessary skills to carry out their own projects using the equipment available, we observed the presence of professional staff in charge of the facility in a large majority of laboratories. To obtain information concerning the types of employees present in the FabLabs, a specific multiple-choice question that allowed participants to indicate the number of employees and also select the type of employees was made available by offering the following as options: Employees of the Institution that Houses the FabLab, University Employees, FabLab Employees, Users and Volunteers.

The responses were grouped into seven main groups: laboratories whose employees solely depend on the university to which they belong or with which it maintains relations; FabLabs whose employees, in addition to the above, include external employees—not on the staff of the university; laboratories depending on users and volunteers; dependent employees of the institution that houses the laboratory; other types of personnel, foreign or belonging to a university; employees and volunteers or users (it should be noted that in some cases, laboratories participating in digital manufacturing correspond to mixed development centers in which, in addition to the dependence on an external entity, the participation of a university is added and open to the general public, which explains the variety in the composition of the laboratory personnel); and laboratories whose staff is independent of any institution.

In the latter group, it is interesting to note how 18% (as seen in Figure 5) of laboratories maintain their operations with users and volunteers, without the presence of specific employees, keeping a clear independence and assuming a spirit of working that is closer to the roots of FabLab movement in which support is from the laboratory users, based on suitable communication and documentation processes.

Figure 5.

Distribution of laboratories according to groups of personnel typologies.

Analyzing the information provided directly, it is interesting to note that only 36% (Table 3) of the laboratories have their own separate staff, i.e., FabLabs that have their own employees and/or users and volunteers, compared with 63% of laboratories with external institution dependent personnel.

Table 3.

Distribution by type of laboratory personnel.

3.1.6. Established Relationships with Other Communities and with External Entities

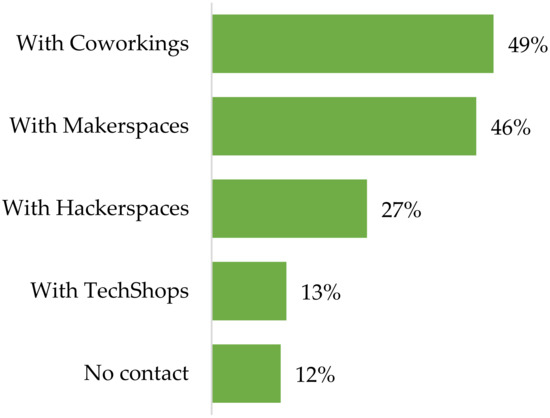

Digital fabrication laboratories, to be involved in the maker movement, dynamically and openly present activities that usually take advantage of their social characteristics for establishing relationships with other organizations and stakeholders in their environment. In this research, it was relevant to analyze the capacity of interrelationships between diverse communities of users with characteristics linked to digital manufacturing. We established a multiple-choice question for this, in which participating laboratories were allowed to indicate the communities with which they had maintained some type of collaborative relationship in the development of activities (Figure 6).

Figure 6.

Laboratories that have established relationships with a community.

The results obtained in this section show a high tendency to establish collaborative relationships with co-working spaces and makerspaces. It is also important to note a large number of laboratories (12%) that have not established any partnership with other entities, as seen in Figure 6.

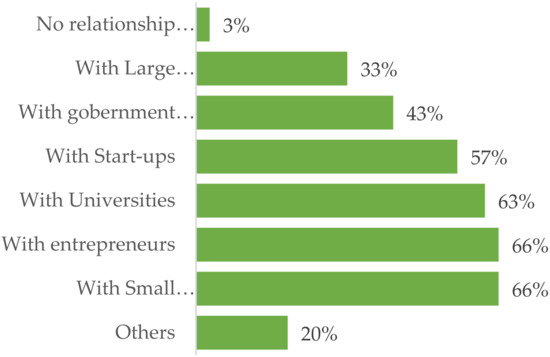

On the other hand, communities formed in digital manufacturing laboratories are also active in collaboration with other external development activities and projects of different entities. Proof of this is that only 3% of the responses claimed not to have established any kind of partnership with another entity, while 63% indicated having found some sort of relationship with universities, and 66% (Figure 7) indicated having formed partnerships with entrepreneurs and small companies.

Figure 7.

Laboratories that have established relationships with companies and other entities.

3.2. Social Aspect

Another intrinsic characteristic of digital fabrication laboratories, and mostly responsible for the activities that they develop, is the type of users. This was initially conditioned by the facilities and the activities carried out, also in planning the opening of the laboratory, and although sometimes not maintained after the initial idea, in others it is set as their own hallmark. As is clear from this study, a FabLab not only makes machines available, but also consists of the community of users who use them, the relationships and knowledge exchange that it develops through the implementation of projects and interaction with other laboratories.

3.2.1. Targeted Users, and Current Users

One of the fundamental aspects of creating a FabLab is planning the type of user to which the laboratory is directed. This affects not only the activities carried out, but also fundraising, project development and the ultimate goal of the laboratory.

Two multiple-choice questions were included in the questionnaire in which participants were allowed to choose between different types of users typically present in the FabLab (students, researchers, companies and general) and allowed an open response by providing other types of potential users already offered. Analyzing the target audience of the creation of a digital fabrication laboratory, it was possible to observe the active involvement of the FabLab general character of openness in that 15% of the participating laboratories provided laboratory services to the general public (Table 4). The initial involvement of laboratories with students is also noteworthy, as the inclusion of this category is evident in 75% of the participants.

Table 4.

Distribution by objective user typology.

Business activity also acquires remarkable values by being present in the selection of 42% of the participating laboratories, although, and as it was logical to expect, this was not among the exclusive objectives. An exclusive dedication to the student population, without including other user typologies, was important (9% of the participants) in the specific typology of manufacturing laboratories: those dedicated exclusively to training or the provision of services for the student community.

Only 51.6% of participating digital manufacturing laboratories currently include the user type originally planned, however. Laboratories exclusively dedicated to the public comprised 3% of the participants, while maintaining similar values, 71%, to those outlined about those established by this category within the chosen among others. Dedication to students exclusively, indicated by 10% of participants, seems to maintain the distribution between the values initially identified by the participants when planning users, reaching 62% of cases selected in this category.

For current users, business, again, is not an exclusive category, but is among regular users of the laboratories in 42% of situations, demonstrating a possible excess of optimism when considering the interaction of business planning for the creation of fabrication laboratories, as seen in Table 5.

Table 5.

Distribution by current user typology.

3.2.2. Registered Users and Regular Users

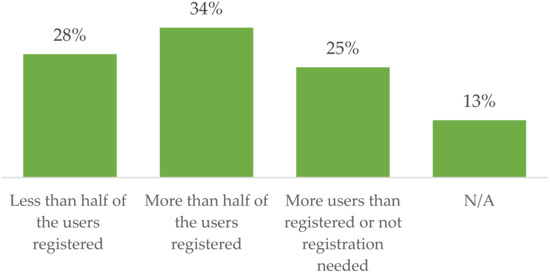

One of the usual difficulties in describing the business models used by digital manufacturing laboratories is mainly due to the different types of monetizing through possible membership and the existence of several organizational forms. From university-type laboratories, in which the manufacturing processes are produced for free to payment-for-use typologies, but for which there are no registered users, there is a wide range of different types. In our study, we analyzed the relationship between registered users and active users, considering those with a regular presence in the laboratory as active.

Analyzing the individualized information, the ratio of regular users to registered users for each laboratory was calculated and four large clusters were established: laboratories in which less than half of the users are registered, laboratories in which more than half of the users are registered, laboratories in which there are more regular users than registered users or in which registration is not needed and laboratories in which information was not available. The differences in everyday registered users may correspond to the effect of potential differences in methods of membership, different types of access, the impact of organizing various open events with free access or segmentation in customer type.

The two groups with a lower ratio of users to registered users demonstrate the difficulty for fabrication laboratories of maintaining an active link with all users. Despite this, bonding is usually high, social application has been proven and the theoretical development is demonstrated by noting that only 28% have less than 50% registered users (Figure 8).

Figure 8.

Usual over registered user ratio.

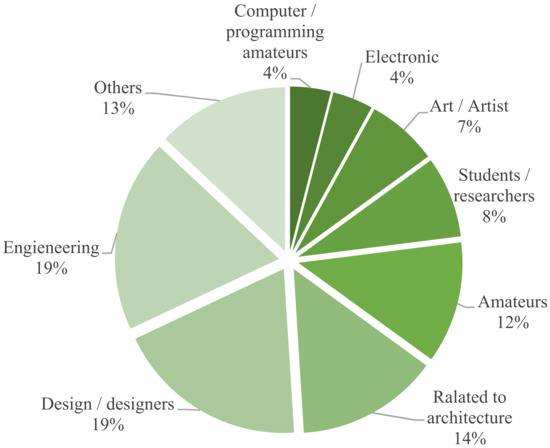

3.2.3. User Profile

Finally, for the evaluation of the user profile, we used a question of type ranking in which the participants had to order the different optional profiles provided according to the real users of the laboratory. Responses were grouped according to the first two profiles of the questionnaire. In this way, the majority of user profiles were engineers (19% of laboratories chose this option in first or second place) and designers (19%), followed by all those related to architecture (14%) and amateur users (13%). It is important to note that only 8% of laboratories reported students or researchers as their main users (Figure 9).

Figure 9.

User profile.

3.3. Economic Aspects

3.3.1. Economic Sustainability

Once the social reality of the FabLabs was demonstrated, the next aspect to be considered was the operating model and the characteristic typologies associated with the business model to guarantee sustainability. We understood economic sustainability as the ability of the laboratory to carry out its activities without interruption and continuously over time, without problems. It is an objective to be achieved from the adoption of a business model or, in some cases, insurance to be under the economic protection of an institution providing a particular service. As previously mentioned, one of the biggest difficulties that laboratories face is the costs of purchasing and maintaining equipment. Although basic equipment, such as a 3D printer, is a small investment and even, in some cases, built into the FabLab itself, this also includes other equipment such as laser cutters or CNC machines, which involve a high outlay, high maintenance costs for intensive use and even the adaptation of the facilities to their technical characteristics. All this, together with the common expenses and supplies, presents a difficulty for the development of FabLab activities.

In the section in question, we discuss the key economic issues associated with financing the activities of FabLabs, considering the diversity of budgets, the main source of income and business patterns and analyzing their characteristics as associated with the innovation and value proposition that a FabLab offers to its users and the community.

3.3.2. Annual Budget of Digital Manufacturing Laboratories

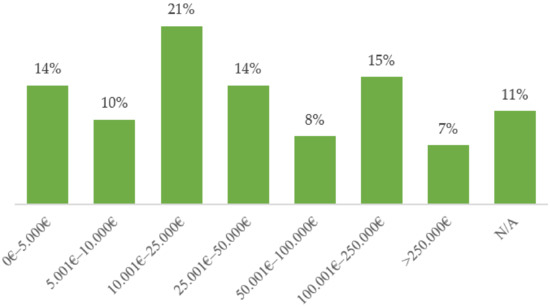

Budget is one of the conditioning factors of the activities developed in a FabLab. In our questionnaire, one of the open response questions was assigned to budget determination; although it was not mandatory, it did obtain a high response rate, enough to be considered in this study. The responses were grouped in significant quantity intervals for the analysis of the information related to the budget thus obtained, after adapting to a single type of currency applying the appropriate change.

It is interesting to note that 14% of the FabLabs had a meager annual budget, with amounts equal to or less than EUR 5000. Do not forget that for the development of the activities it is necessary to have a properly conditioned room and not only the equipment, but also the necessary consumables. On the other hand, it is also striking to note that 70% of laboratories have an annual budget of more than EUR 10,000 per year.

The diversity of budgets is obviously as varied as the laboratories themselves, but it is possible to group laboratories into budget ranges that include significant margins relative to the activities that can be developed in them. Based on this distribution, the most characteristic budget range was between EUR 10,001 and 25,000 per year (Figure 10).

Figure 10.

Distribution of laboratories in annual budget intervals.

3.3.3. Main Sources of Income

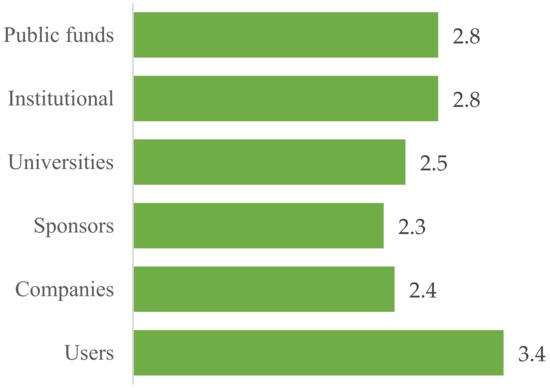

Once it is known what the typical budget of a laboratory is, it becomes important to identify the main source of that budget. The questionnaire provided options for respondents to rate on a five-point Likert scale. Research has demonstrated repeatedly that funding is rarely based on a single source, and so respondents were asked to indicate the relevance of a number of financing options in their annual budget.

The majority of funding sources were valued with an average score of 3.4 out of 5 points and considered an important source of funding (ratings equal to or greater than 4) in 52% of cases. In addition, the source of financing is shown as the main funding (considered as the main funding source when the valuation of the rest of the options is low—scores equal to or less than 3) and the valuation of the financing from the users is high (scores equal to or greater than 4) in 18.8% of the cases and exclusive (considered exclusive when the rest of the options adopt the lowest possible value) in 7% of the cases, allowing the conclusion that the contribution of the users does not represent the only form of financing in most of the laboratories (Figure 11).

Figure 11.

Mean values of the relevance of the different sources of income.

Laboratories whose fundraising is based on public institutions, universities or public funds were about 26% of the participants (25.8%), and only 10.6% of these cases reported any of these funding sources as exclusive sources (valuing with minimal other funding sources).

The responses show that 1.18% of laboratories received their funding exclusively from private funds or sponsorship from private companies, and 27% of laboratories reported funding sources mostly associated with the contributions of their users, external companies or sponsors (scoring less than or equal to 3 points for the contribution of public entities, universities or institutions) (Table 6). Only 14.1% of the participating laboratories reported exclusive financing from private initiatives, understood as funding from companies, sponsors or their own users (values equal to or greater than 4 points) rather than financing of public or institutional origin from universities, institutions or public funds (valued, in this case, with the lowest possible score).

Table 6.

Sources of financing outstanding.

As noted, users are a significant source of funding for digital manufacturing in laboratories, being present as an essential factor in 52.9% of cases. Only 17.6% of participants declared funding from the contribution of public or private funds from universities, institutions, federal funds, direct funding or financing companies through sponsorship agreements without user involvement. Finally, the importance of funding sources from federal funds is evident, as 25.8% of cases were financed mainly from public funds, and the difficulty of maintaining laboratories based solely on funding from users is shown in that only 7% of participants were financed mainly by users.

3.3.4. Types of Institutions Housing the FabLab: Dependence and Independence of Institutions

The funding sources noted in the previous section show the dependence of most laboratories on institutions that provide appropriate stability. In this regard, the FabLab Global Survey included a question about the nature of the institutions that house the laboratories.

The decision to impose greater accuracy in determining the host institution among the possible entities in public or educational (universities, educational institutions, institutions dedicated to research or dependent on government or public institutions in general) was adopted based on the multiple examples of these relationships that can be seen in the different active FabLabs; however, to avoid making the mistake of not covering all possibilities, an open option was added to allow participants to indicate the type of entity that housed them. Most FabLabs were strongly dependent on host institutions (57% of the participating laboratories), leaving a significant 37% of laboratories with no direct relationship with any hosting institution and for which, therefore, matters relating to the space in which activities occur, supplies and equipment are a direct charge of the laboratory developing digital manufacturing.

In more detail, universities (no distinction between public universities or private universities) typically host the digital manufacturing laboratories, at 31%. Education entities, including universities of any type, non-university educational institutions and entities based on research, generally provide the framework for most FabLabs (52%). Only 3% of respondents said they relied on government institutions, showing, perhaps, the low involvement of non-public educational institutions in this kind of social movement. As envisaged in the development of the issue, some of the participating laboratories did not identify with the categories provided, and their responses were included in “Other.” These laboratories (2% of respondents) said they were hosted by non-governmental/non-profit organizations or private foundations (Table 7).

Table 7.

FabLab dependence.

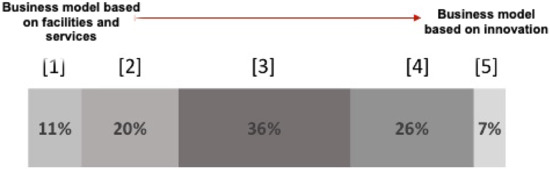

3.3.5. Business Model: Innovation vs. Service

Although the number of activities undertaken in FabLabs is varied, and a source of technological and educational innovation, the need for sizing was raised through a continuum. To do this, and based on the classical differentiation between the most basic business of the models, we proceeded to classify them into two different types: activities organized from the laboratory performing these acts as a service or activities purely innovative [45]. For this, a matter in which participants were invited to a position in a continuum divided into five positions whose ends were precisely the poles above was established. Thus, the participants could indicate, using the choice in the scale, their basic typology according to both parameters.

As shown in Figure 12, we found a balance between the two main types of general model (the average score was 2.97 points) with a slight tendency to business models based on innovation versus a service delivery model. In this respect, there was, importantly, a comparable number of FabLabs whose model was essentially the provision of service (31% of participants) versus participants whose model was essentially innovation (32% of participants).

Figure 12.

Business model.

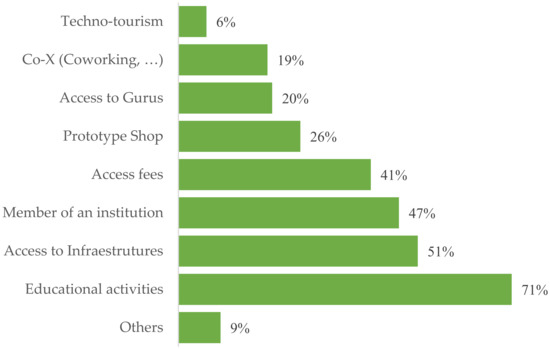

3.3.6. Business Model

Economic sustainability of FabLabs is one of the main problems in the maintenance and continuity of the laboratories. Some studies have classified their activities to establish patterns that fit with business models. In our case, and in order to identify the patterns shown by FabLabs, FabManagers could choose between the following typologies (Figure 13):

Figure 13.

Distribution of FabLabs depending on the type of business model.

- Techno-tourism. A business pattern characterized by the attendance of non-regular users who are traveling and visiting different communities and technology development centers.

- Co-X. Digital manufacturing laboratories combine their activities with the presence of collaborative work environments not directly related to the development of their activities, complementing or offering their services.

- Access to gurus. Knowledge is one of the main values in digital manufacturing laboratories. In this business pattern, the knowledge of experts becomes the main value proposition, and their expertise becomes the main contribution, providing consultancy or advisory services to users.

- Prototype shop. Technological capabilities coupled with strong experience and knowledge can be displayed as factors added to the prototype development service. In this particular pattern, digital fabrication laboratories provide their tangible and intangible resources for the development of basic models of temporary products by users or external customers.

- Access fees. A business pattern that bases its income on charging a recurring fee to its users for regular access to the laboratory and its services.

- Member of an institution. In this pattern, the FabLab is embedded within a larger institution to provide a service, which promotes all or most of its activities.

- Access to infrastructure and equipment. The technological capacity of laboratories is based on the existence of specific equipment for digital manufacturing. The business model based on access to infrastructure and equipment includes the possibility that both regular users and external users make use of these capabilities independently of the activities carried out in the laboratory. The central value proposition provided in this pattern resides in the equipment and infrastructure present in the FabLab and the services offered through its use.

- Educational activities. Since the beginning of the FabLab movement, the actions of FabLabs as digital manufacturing laboratories have been strongly linked to training and educational activities as sources of essential knowledge exchange. Through this pattern of business, laboratories focus their model on educational events or related educational activities carried out by other institutions or by the FabLab itself.

- Other. In this research, we tried to include and group the most common patterns, but we were aware that the variety of models of existing business could be as wide as the number of laboratories that exist, so participants were allowed to briefly describe their patterns.

3.3.7. Main Value Proposition Offered

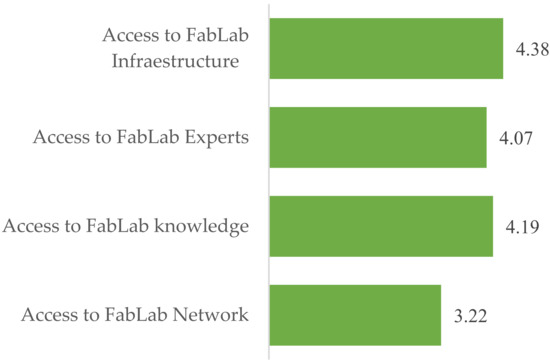

If the business model of a FabLab is trying to establish a pattern of income generation, the value proposition is the greatest asset that the laboratory offers to its participants. To develop this analysis, we considered the existence of several value propositions mentioned throughout the literature:

- Access to FabLab Network. Developing collaborative projects jointly with the laboratories that constitute the international FabLab Network provides, for each particular FabLab, access to a vast knowledge distributed in every corner of the planet and allows expansion of the project to infinite possibilities. Interaction with the FabLab Network can be via any FabLab Network node for information exchange or advice. In this case, the assessment of participants reduces the importance of access to the FabLab Network as a value proposition compared to other options presented in the questionnaire, since only 44% of the laboratories considered it an essential asset, with an average overall rating of 3.22 out of 5 points. The low consideration of the access to the FabLab Network by 33% of the laboratories is remarkable.

- Access to FabLab knowledge. The FabLab is made up of a community of users, and as has been argued in previous sections, in reality, the FabLab is the community of users. This community of users is characterized by a common interest that acts as a unifying factor but in itself possesses a high level of knowledge in certain skills at a higher level than would be expected. This knowledge, which not only comes from formal education but also, on many occasions, has been forged in the course of the common activities of the laboratory itself, can be considered as another asset when its application to user projects is an aspect valued as such by the participants in the project and represents the most common intangible asset of digital fabrication laboratories, valued as highly important in 88% of the participating laboratories with an average rating of 4.19 out of 5 points.

- Access to the FabLab’s experts. In the FabLabs there are users with more advanced knowledge than the rest of the community who could be called experts, from the FabManagers themselves to other users whose training or job profiles allow a superior knowledge in some technical or technological aspects. Often, these experts’ knowledge, advice and collaboration become the true value proposition of the FabLab. Experts who have been trained through the Fab Academy Program, with some years of experience added to their previous knowledge of technological matters, are called Fab Gurus. Access to an expert who is part of FabLab as a value proposition obtained a high score of 4.07 out of 5 points and is considered a very important value proposition for 78% of the participating laboratories.

- Access to FabLab infrastructure. The equipment needed in manufacturing processes has high acquisition costs and is difficult to handle. Users can access this technologically advanced equipment at an affordable price per use. The learning curve for its utilization is mitigated by learning via Do It With Others (DIWO) processes, and training courses are regularly offered. The presence of complex equipment, which otherwise could involve disbursements of hundreds or thousands of dollars and would involve a steep learning process, implies a true value proposition in itself. Access to FabLab infrastructure received the highest mean score—4.38 out of 5 points—and was considered a highly relevant value proposition for 86% of the participating laboratories (Figure 14).

Figure 14. Average valuation of value propositions.

Figure 14. Average valuation of value propositions.

3.4. Distinctive Features

Once the physical, social and economic conditions laboratories are identified, we focus on their distinguishing characteristics, among which are the ability to promote entrepreneurship (through fast prototyping, level of innovation, collaboration with other entities, or due to independence in project development), the training offered and the public documentation of projects undertaken to conclude with their contribution to the community.

3.4.1. Entrepreneurship and Fast Prototyping

The FabLab can serve as a vivarium for business development, improving products and processes or generating prototypes that constitute the minimum viable product of a commercial initiative. Among the FabLab Global Survey participants, 22.9% had witnessed the creation of a new commercial initiative, stressing the importance of these processes.

The economic sustainability of these laboratories is, however, even today, an added difficulty for their own characteristics, causing many of them to depend in one way or another on the entity that hosts them. This kind of dependence could well place a limitation on the development of projects by establishing clear preferences in their choice, skewing the typology of their development or limiting the involvement of the laboratory in certain types of activities.

Answers provided by the participants show a high perception of the contribution of the FabLab as a factor in the development of entrepreneurial culture (73% of respondents rated their agreement with a 4 or 5 out of 5). A positive impact is noted on the contribution of the close ecologies to the FabLab, as positive factors in the development of entrepreneurial culture (73% of respondents rated their agreement with a 4 or 5 out of 5). The perception of fast prototyping as a contribution is also highly considered (90% of respondents rated it with 4 or above out of 5 as seen in Table 8), probably due to involvement in innovation processes.

Table 8.

Perception of the contribution of FabLabs.

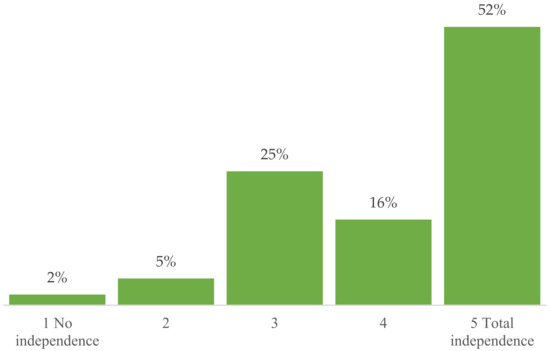

The FabLab Global Survey evaluated the perception of independence in carrying out different projects. The participants were asked to indicate the perceived independence of the realization of the FabLab projects on a 1 to 5 scale, with 1 meaning a null independence, and therefore a full dependence, and 5 meaning a complete independence. It is important to consider that while a large percentage of laboratories are dependent on institutions to ensure sustainability, 68% of laboratories indicated a high level of independence, and 52% of the participants indicated a level of absolute independence (Figure 15).

Figure 15.

Distribution of laboratories according to declared independence.

3.4.2. Development of Joint Projects with Other Institutions and Groups

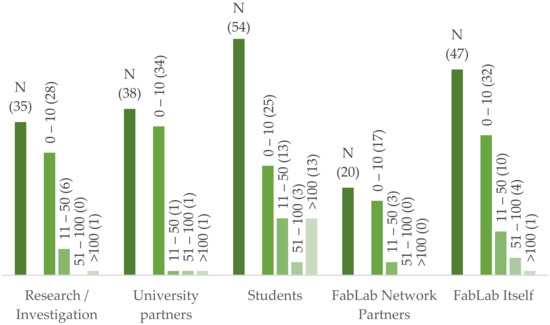

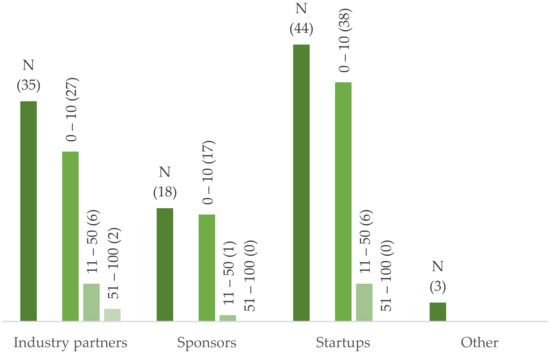

In the FabLab Global Survey, the participants were asked about the realization of joint projects with certain typical institutions in the FabLab environment. Among the participating laboratories, 43.5% had jointly carried out projects with external industries, although only 9.4% of the participants had carried out more than 10 projects. Twenty-four percent of participants reported having developed projects with sponsors, but only one participant carried out more than 10 projects. On the other hand, 45.9% of the participants indicated that they had carried out projects with research entities, although only 8.2% of the participants had completed more than 10 projects of this type. While 48.2% of the laboratories had carried out projects in collaboration with universities, only 1.18% of the laboratories developed more than 10 projects of this type. The projects carried out with students were the most common collaborative projects, present in 68.2% of the cases, where 34% of the participants exceeded 10 projects of this type and 15.3% had developed 100 projects. Only 24.7% of the laboratories had carried out joint projects with other laboratories in the FabLab Network, and only 3.5% had realized 10 projects (Figure 16 and Figure 17). Among the participating laboratories, 55.3% had developed projects jointly with startups, and 7% had developed 10 of these. As a reference, 62.4% of FabLabs had carried out projects without the need for external support, with 17.6% of participants exceeding 10 projects (Table 9).

Figure 16.

Distribution of number of projects developed.

Figure 17.

Distribution of number of projects developed (industrial section).

Table 9.

Distribution of FabLabs that have developed collaborative projects.

3.4.3. Level of Innovation, the Percentage of Innovation Projects Developed Jointly

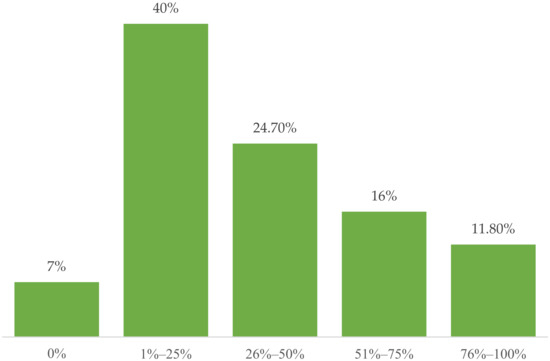

The projects developed in the environment of FabLabs are adjusted to multiple and different interests and objectives and, therefore, tend to be varied despite their common ground in digital manufacturing. One of the interests of this research was identifying the contribution of the projects carried out in the laboratories to innovation, for which an item was included in the FabLab Global Survey where participants were asked about the approximate percentage of projects carried out dedicated to innovation for research and development for industrial companies or small businesses. The results reveal that 27.8% of the laboratories had a high percentage of projects linked with innovation—more than 50% of the projects—with 11.8% of the cases considered as a very high level—more than 75% of the projects. By contrast, 40% of the laboratories reported a very low level of projects linked to innovation—less than 25% of projects dedicated to innovation. A meager 7% of the laboratories reported no projects linked to innovation (Figure 18).

Figure 18.

Percentage of projects related to innovation.

The communities that emerge within a FabLab often share the point of view of one of the key roles present in their daily lives: the FabManager. The FabManager is, along with the rest of the technical staff, the soul of the laboratory. They know the function of all available material—some of the machinery has even been created by them or with their essential collaboration—and participate in all processes that are taking place in the laboratory, in most cases being a fundamental part of them. It is thus interesting to hear their opinion of aspects such as the contribution of the FabLab to entrepreneurship development, the process of project documentation or the training of users.

3.4.4. Documentation

Another important aspect to consider in this section involves the internal processes associated with public FabLab project documentation. As suggested by the FabLab Charter [2,8,40], a FabLab has a responsibility to disseminate the knowledge generated in the projects through its public documentation. Project documentation is an added difficulty in development since it involves time and resources, rarely available in digital manufacturing laboratories. This feature is not exclusive to FabLabs, as it is shared with the culture of the maker movement.

Documentation seems to be perceived as an obstacle and represents a serious difficulty in the development of projects; however, a common platform for the documentation process has not been established (although some joint initiatives from within the network of FabLabs have been developed and there are some attempts to standardize the documentation process), and relatively few laboratories make the public documentation process a priority using an online platform. Several items were included in FabLab Global Survey concerning the documentation process, from the items designed to assess the perception of documentation to items that were intended to determine who is ultimately responsible for the documentation process and items that evaluate the actual percentage of documented projects. Most of the participants expressed the great importance of project documentation as one of the main benefits of FabLab (68% of participants) and also the difficulty that it represents (53% participants), as seen in Table 10.

Table 10.

Distribution according to the degree of agreement with the statements regarding the documentation.

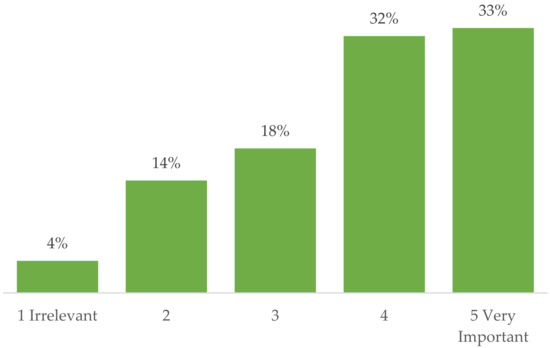

When asked about the importance of documentation in their own FabLab in particular, 65% of participants reported a high or very high importance and 18% admitted a relatively low importance. Although 68% of respondents considered the public documentation of projects as one of the great strengths of the FabLab, 51% recognized it as one of its great difficulties (Figure 19).

Figure 19.

Evaluation of the importance of the documentation processes for the FabLab.

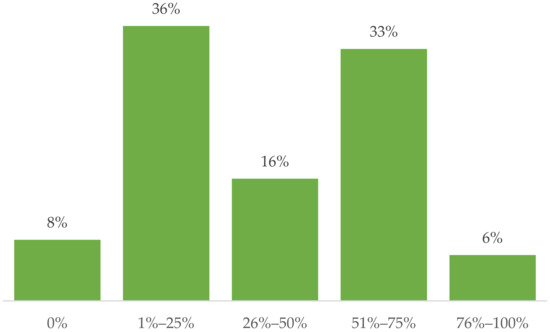

If we focus on the actual percentage of publicly documented projects, 39% of the laboratories showed a high rate of documented projects (more than 50% of the projects documented) while only 6% assumed a very high rate (more than 75% of projects). The difficulty associated with project documentation seems to be the reason for the high number of laboratories with a low rate of documented projects, demonstrated by 36% of participants having more than 25% of projects documented and 8% of laboratories without any projects documented. It is interesting to note that 35% of the participating laboratories that indicated public documentation of projects was important had a documentation rate lower than 50% (Figure 20).

Figure 20.

Distribution by percentage ranges of documented projects.

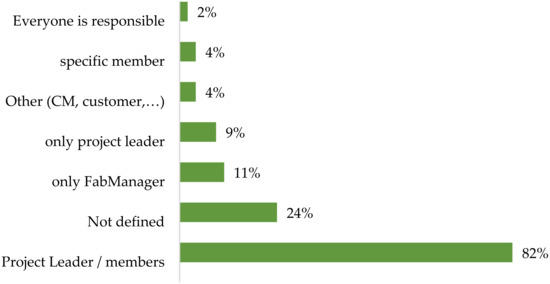

An item was included to identify who was responsible for project documentation. Participants noted the person responsible for documenting from a multiple choice offered. Twenty-four percent of respondents indicated that there was no fixed role in charge of documentation, and 82% reported any of the project members as usually responsible for documentation, with the project leader being responsible for 9% of cases. Four percent of the participants indicated that there was a specific user or member in the laboratory responsible for project documentation, and 11% identified the Fab Manager as responsible for such documentation. Two percent of respondents indicated that all members and users of the laboratory were responsible for the documentation process equally, and in 4% of cases, that responsibility fell on other actors such as a community manager or the client themselves (Figure 21).

Figure 21.

Responsibility for project documentation.

3.4.5. Education

Knowledge sharing is one of the main advantages of FabLabs. In the FabLab Global Survey, items were included to evaluate perceptions about FabLab contributions to training in new digital fabrication technologies, including the 3D design and open hardware platforms. The results revealed certain differences in processes associated with training each of the above aspects. For open hardware development platforms, the majority opinion was that the FabLab provides adequate training (74%) in these technologies and, although values are subtly lower, the perception of training in additive manufacturing and 3D technology training (69% and 61%, respectively, as seen in Table 11) was similar. We must not forget that, although the open hardware platforms and the communities associated with their use have democratized and simplified previously unthinkable processes for the ordinary user, they require high knowledge of aspects as diverse as electronics or programming projects.

Table 11.

Perception of FabLab training.

3.4.6. FabLab Contribution to Users and the Community

Digital fabrication laboratories provide a framework for social relationships where there is an exchange of knowledge about technological aspects. This exchange of knowledge takes shape through the FabLab activities. These activities were divided into four main processes that try to include, in a generic way, the most common aspects of the interaction and implementation of value proposals.

A FabLab Global Survey item aimed to obtain information about the real contribution that FabLab makes to its users through a question in which the participants evaluated different proposals from 1 to 5 and in which it was possible to add new options in case those suggested do not apply.

In our survey, the possible contributions are as follows:

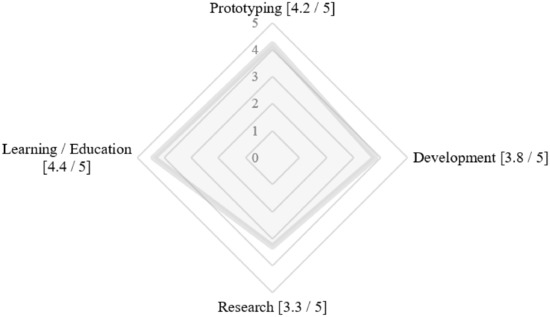

- Education and learning. FabLabs are a true learning community where their users, regardless of the existence of a guru or not, learn by doing and watching what others do. They learn to overcome their difficulties with the support of the community, interact in finding solutions and discover aspects that otherwise would have required a complex journey through regulated education. It is an informal, competitive and dynamic learning-centered interest and is based on project learning. FabLab’s contribution of education and learning to its users was valued very highly by the participants—a score of 4.4 out of 5 points—and was considered of very high relevance in 87% of the cases. Only 4% of cases considered this contribution as low in importance (Figure 22).

Figure 22. Average valuation of the main contributions of a FabLab.

Figure 22. Average valuation of the main contributions of a FabLab. - Research. Open innovation processes include research elements set out in FabLabs. In some cases, this research is conducted jointly with other entities to become a true development laboratory. This type of activity was evaluated as of intermediate importance by participants—obtaining a value of 3 out of 5 points—and considered relevant in the possible contributions of the laboratory in 44% of cases. Twenty-four percent of participants felt that FabLab did not contribute to these processes for its users.

- Development. In this section, we distinguish the application of processes to product development as part of the non-specific standard innovation process and included in the dynamics of the existing systems in FabLab. In this respect, 65% of FabManagers considered the contribution FabLab makes to their development processes (3.8 points out of 5) as being of high importance.

- Prototyping. The innovation processes carried out in FabLabs emphasize the application of technology, and they own digital manufacturing processes to develop new projects or products that meet diverse needs. This development takes place through prototyping and knowledge sharing. Eighty-one percent of laboratories assigned high scores (4.2 out of 5 points on average) for the FabLab contribution to their users in prototyping, describing its importance as very high.

4. Discussion