The Role of Eco-Industrial Parks in Promoting Circular Economy in Russia: A Life Cycle Approach

Abstract

:1. Introduction

Eco-Industrial Parks in Russia

2. Materials and Methods

2.1. Study Area: Case Study Eco-Industrial Park

2.2. Life Cycle Assessment

2.2.1. Goal and Scope Definition

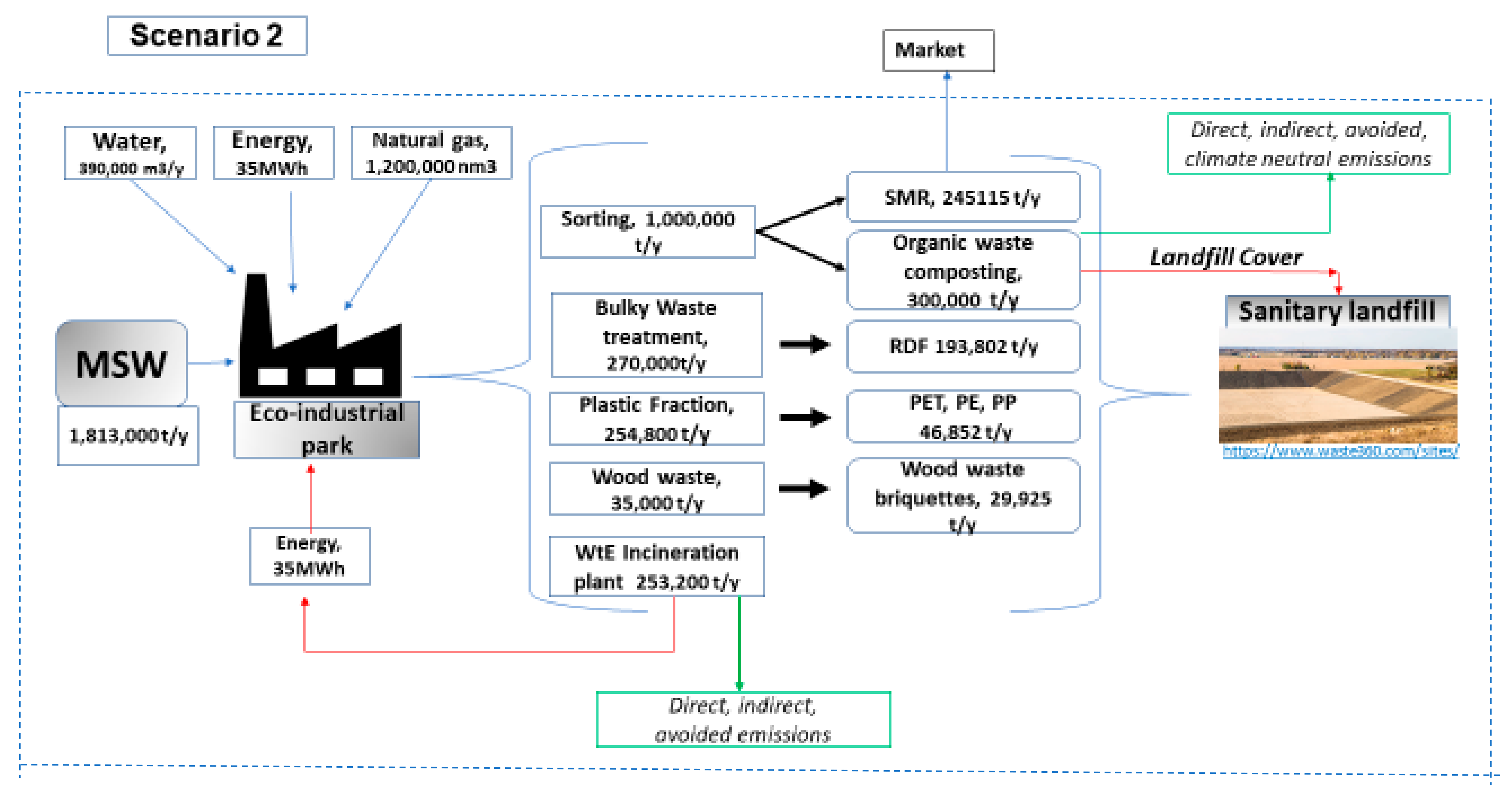

2.2.2. Scenarios

2.2.3. Life Cycle Inventory

2.2.4. Impact Assessment

- Global warming (kg CO2 eq);

- Ozone depletion (kg CFC-11 eq);

- Smog formation (kg O3 eq);

- Respiratory effects (kg PM2.5 eq);

- Acidification (kg SO2 eq);

- Eutrophication (kg N eq);

- Toxic carcinogenic and noncarcinogenic substances (CTUh);

- Fossil fuel depletion (MJ surplus);

- Ecotoxicity (CTUe).

2.2.5. Interpretation

3. Results and Discussion

3.1. Circular Economy in Russia

3.1.1. Administrative and Regulatory Barriers

3.1.2. Knowledge and Awareness Barriers

3.1.3. Financial Barriers

3.2. Eco-Industrial Parks and Circular Economy

3.3. Life Cycle Assessment Analysis

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Agamuthu, P. Circular economy: The way forward. Waste Manag. Res. 2018, 36, 481–482. [Google Scholar] [CrossRef] [PubMed]

- Škrinjarí, T. Empirical assessment of the circular economy of selected European countries. J. Clean. Prod. 2020, 255, 120246. [Google Scholar] [CrossRef]

- Rodriguez-Anton, J.M.; Rubio-Andrada, L.; Celemín-Pedroche, M.S.; Alonso-Almeida, M.D.M. Analysis of the relations between circular economy and sustainable development goals. Int. J. Sustain. Dev. World Ecol. 2019, 26, 708–720. [Google Scholar] [CrossRef]

- Bogoviz, A.V.; Bruno, S. Will the Circular Economy Be the Future of Russia’s Growth Model? In Exploring the Future of Russia’s Economy and Markets; Emerald Publishing Limited: Bingley, UK, 2018; pp. 125–141. [Google Scholar]

- Plastinina, I.; Teslyuk, L.; Dukmasova, N.; Pikalova, E. Implementation of circular economy principles in regional solid municipal waste management: The case of Sverdlovskaya Oblast (Russian Federation). Resources 2019, 8, 90. [Google Scholar] [CrossRef] [Green Version]

- Gadzhiev, N.G.; Murzak, N.A.; Mitenkova, A.E.; Skripkina, O.V.; Konovalenko, S.A. Problems of development of the circular economy as a factor in Russia’s sustainable development. South Russ. Ecol. Dev. 2020, 15, 155–164. [Google Scholar] [CrossRef]

- Kalchenko, O.; Evseeva, S.; Evseeva, O.; Plis, K. Circular economy for the energy transition in Saint Petersburg, Russia. E3S Web Conf. 2019, 110, 02030. [Google Scholar] [CrossRef]

- Wiesmeth, H.; Starodubets, N.V. The management of municipal solid waste in compliance with circular economy criteria: The case of Russia 1. Econ. Reg. 2020, 16, 725–738. [Google Scholar] [CrossRef]

- Ilyina, L.A.; Garanina, M.P.; Ilyina, T.A.; Maslova, O.P. Creation of the Circular Economy in Russia as a Means of Acceleration Transition to the Market Path of Development. In Circular Economy in Developed and Developing Countries: Perspective, Methods and Examples; Emerald Publishing Limited: Bingley, UK, 2020; pp. 157–164. [Google Scholar] [CrossRef]

- Kalioujny, B.; Ermushko, J.; Zhavoronok, A. Establishment of a strategy of circular economy increasing the well-being of society: Comparison of two national policies. SHS Web Conf. 2016, 28, 01050. [Google Scholar] [CrossRef]

- Dorokhina, E.Y. Industrial and eco-industrial parks as a means for the resolution of regional conflicts in the use of natural resources. Econ. Soc. Polit. Recreat. Geogr. 2018, 2, 113–118. [Google Scholar] [CrossRef]

- Li, W. Comprehensive evaluation research on circular economic performance of eco-industrial parks. Energy Procedia 2011, 5, 1682–1688. [Google Scholar] [CrossRef] [Green Version]

- Martín Gómez, A.M.; Aguayo González, F.; Marcos Bárcena, M. Smart eco-industrial parks: A circular economy implementation based on industrial metabolism. Resour. Conserv. Recycl. 2018, 135, 58–69. [Google Scholar] [CrossRef]

- Alabaeva, N.S.; Velitskaya, S.V.; Malahova, O.S.; Koroliova, C.P. Development of eco-industrial parks in Russia and abroad. J. Econ. Bus. 2019, 6, 19–22. [Google Scholar] [CrossRef]

- Al-Quradaghi, S.; Zheng, Q.P.; Elkamel, A. Generalized framework for the design of eco-industrial parks: Case study of end-of-life vehicles. Sustainability 2020, 12, 6612. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial ecology in a developing context. In Sustainable Development and Environmental Management; Springer: Dordrecht, The Netherlands, 2008; pp. 335–349. [Google Scholar] [CrossRef]

- Mousqué, F.; Boix, M.; Négny, S.; Montastruc, L.; Genty, L.; Domenech, S. Optimal On-Grid Hybrid Power System for Eco-Industrial Parks Planning and Influence of Geographical Position. In Proceedings of the 28th European Symposium on Computer Aided Process Engineering, Graz, Austria, 10–13 June 2018; Elsevier Masson SAS: Issy-les-Moulineaux, France, 2018; Volume 43, ISBN 9780444642356. [Google Scholar]

- Park, H.; Shah, I.H.; Gideon, T.N.; Lee, D.; Huong, T.T.; Park, Y.; Urjinkham, R. Eco-industrial park—A eco-innovation tool of circular economy transition in Korea. In Proceedings of the 2018 Circular Economy for Agro-Food Management, Ulsan, Korea, 13–15 June 2018. [Google Scholar]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Fang, C. Assessing environmental performance of eco-industrial development in industrial parks. Waste Manag. 2020, 107, 219–226. [Google Scholar] [CrossRef]

- Di Baldassarre, G.; Sivapalan, M.; Rusca, M.; Cudennec, C.; Garcia, M.; Kreibich, H.; Konar, M.; Mondino, E.; Mård, J.; Pande, S.; et al. Sociohydrology: Scientific Challenges in Addressing the Sustainable Development Goals. Water Resour. Res. 2019, 55, 6327–6355. [Google Scholar] [CrossRef] [Green Version]

- Bellantuono, N.; Carbonara, N.; Pontrandolfo, P. The organization of eco-industrial parks and their sustainable practices. J. Clean. Prod. 2017, 161, 362–375. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, H.; Guo, S. Evaluating the comprehensive benefit of eco-industrial parks by employing multi-criteria decision making approach for circular economy. J. Clean. Prod. 2017, 142, 2262–2276. [Google Scholar] [CrossRef]

- Tian, J.; Liu, W.; Lai, B.; Li, X.; Chen, L. Study of the performance of eco-industrial park development in China. J. Clean. Prod. 2014, 64, 486–494. [Google Scholar] [CrossRef]

- Wang, S.; Lu, C.; Gao, Y.; Wang, K.; Zhang, R. Life cycle assessment of reduction of environmental impacts via industrial symbiosis in an energy-intensive industrial park in China. J. Clean. Prod. 2019, 241, 118358. [Google Scholar] [CrossRef]

- Valenzuela-Venegas, G.; Salgado, J.C.; Díaz-Alvarado, F.A. Sustainability indicators for the assessment of eco-industrial parks: Classification and criteria for selection. J. Clean. Prod. 2016, 133, 99–116. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S. Indicators of sustainable development for industry: A General Framework. Process Saf. Environ. Prot. 2000, 78, 243–261. [Google Scholar] [CrossRef]

- Belaud, J.P.; Adoue, C.; Vialle, C.; Chorro, A.; Sablayrolles, C. A circular economy and industrial ecology toolbox for developing an eco-industrial park: Perspectives from French policy. Clean Technol. Environ. Policy 2019, 21, 967–985. [Google Scholar] [CrossRef] [Green Version]

- Erses Yay, A.S. Application of life cycle assessment (LCA) for municipal solid waste management: A case study of Sakarya. J. Clean. Prod. 2015, 94, 284–293. [Google Scholar] [CrossRef]

- Rajcoomar, A.; Ramjeawon, T. Life cycle assessment of municipal solid waste management scenarios on the small island of Mauritius. Waste Manag. Res. 2017, 35, 313–324. [Google Scholar] [CrossRef]

- Behrooznia, L.; Sharifi, M.; Hosseinzadeh-Bandbafha, H. Comparative life cycle environmental impacts of two scenarios for managing an organic fraction of municipal solid waste in Rasht-Iran. J. Clean. Prod. 2020, 268, 122217. [Google Scholar] [CrossRef]

- Alamu, S.O.; Wemida, A.; Tsegaye, T.; Oguntimein, G. Sustainability assessment of municipal solid waste in Baltimore USA. Sustainability 2021, 13, 1915. [Google Scholar] [CrossRef]

- Özer, B.; Yay, A.S.E. Comparative life cycle analysis of municipal waste management systems: Kırklareli/Turkey case study. Environ. Sci. Pollut. Res. 2021, 28, 63867–63877. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Tulokhonova, A.; Ulanova, O. Assessment of municipal solid waste management scenarios in Irkutsk (Russia) using a life cycle assessment-integrated waste management model. Waste Manag. Res. 2013, 31, 475–484. [Google Scholar] [CrossRef] [PubMed]

- Starostina, V.; Damgaard, A.; Rechberger, H.; Christensen, T.H. Waste management in the Irkutsk Region, Siberia, Russia: Environmental assessment of current practice focusing on landfilling. Waste Manag. Res. 2014, 32, 389–396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaazke, J.; Meneses, M.; Wilke, B.M.; Rotter, V.S. Environmental evaluation of waste treatment scenarios for the towns Khanty-Mansiysk and Surgut, Russia. Waste Manag. Res. 2013, 31, 315–326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vinitskaia, N.; Zaikova, A.; Deviatkin, I.; Bachina, O.; Horttanainen, M. Life cycle assessment of the existing and proposed municipal solid waste management system in Moscow, Russia. J. Clean. Prod. 2021, 328, 129407. [Google Scholar] [CrossRef]

- Yaroslavtsev, D.A.; Chekalin, V.S.; Liubarskaia, M.A. The Role of Information and Automation in Enhancing the Efficiency of the Functioning of Eco-industrial Parks in Russia. Adv. Econ. Bus. Manag. Res. 2019, 47, 933–937. [Google Scholar] [CrossRef]

- Smirnova, T. And again defining the concept of Eco-Techno Park. Waste Handl. 2020, 2, 30–32. [Google Scholar]

- Korotkovskaya, E.S.; Malinsky, I.G. Russian eco-technology parks as innovation element of the waste management system. In Economic Development in the 21st Century, Proceedings of the II International Scientific Conference, Minsk, Belarus, 28 February 2020; Belarus State University: Minsk, Belarus, 2020; pp. 165–167. [Google Scholar]

- Putinceva, N.; Kim, O.; Voronina, E.; Fugalevich, E.; Mikhailova, M.; Ushakova, E. Introduction of innovative technologies—A factor in the development of the waste management industry in Russia. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2020, 940, 012024. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- SimaPro SimaPro. Available online: http://www.pre-sustainability.com/simapro (accessed on 15 December 2019).

- Nordelöf, A.; Poulikidou, S.; Chordia, M.; Bitencourt de Oliveira, F.; Tivander, J.; Arvidsson, R. Methodological Approaches to End-Of-Life Modelling in Life Cycle Assessments of Lithium-Ion Batteries. Batteries 2019, 5, 51. [Google Scholar] [CrossRef] [Green Version]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

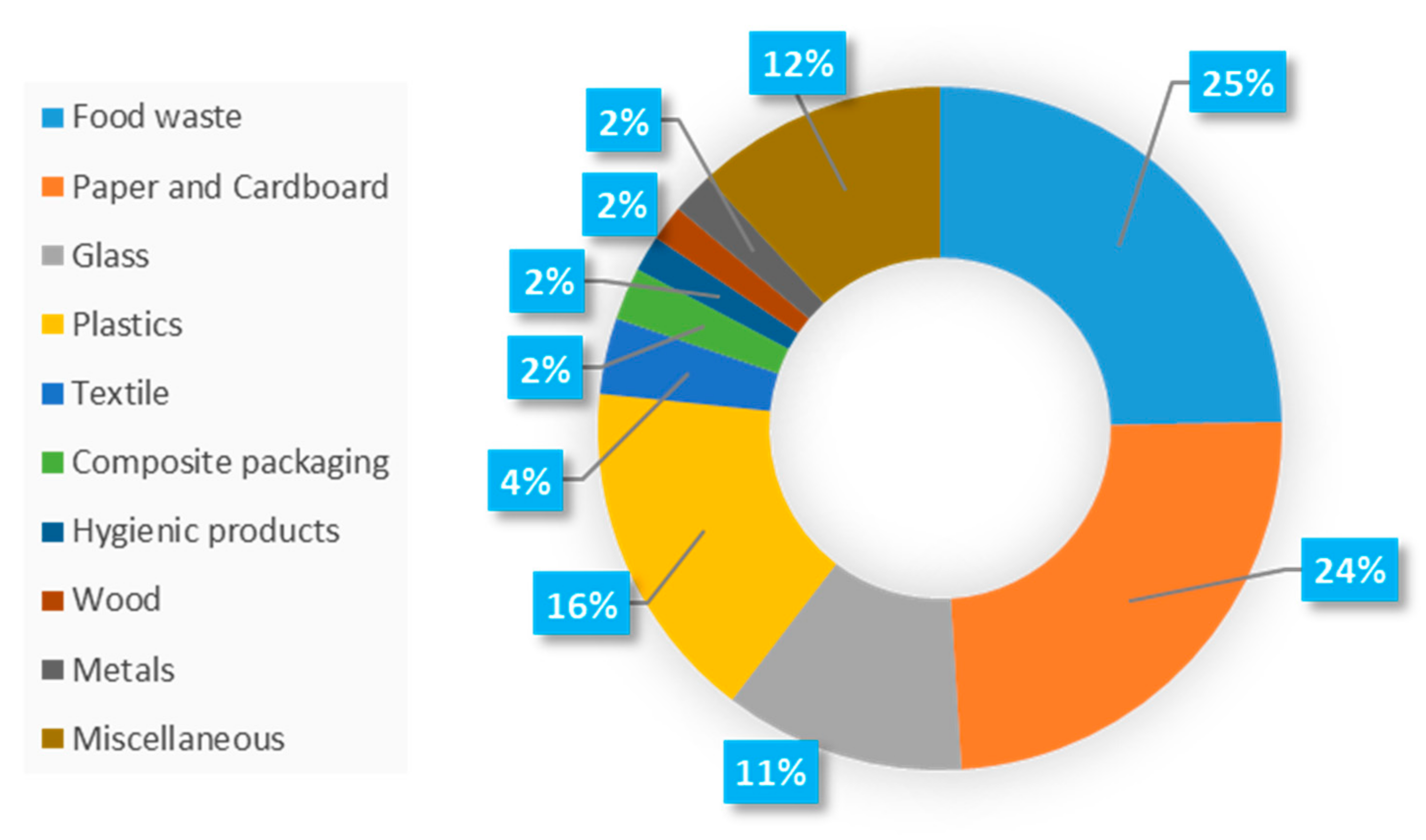

- Moscow Register of MSW. Territorial Scheme of Solid Waste Management in the City of Moscow; Department of Housing and Communal Services of Moscow: Moscow, Russia, 2019. [Google Scholar]

- Ratner, S.; Lazanyuk, I.; Revinova, S.; Gomonov, K. Barriers of consumer behavior for the development of the circular economy: Empirical evidence from Russia. Appl. Sci. 2021, 11, 46. [Google Scholar] [CrossRef]

- Larchenko, L.; Paranina, A.; Kulachinskaya, A.; Kuramshina, L. Opportunities and Challenges of Transitioning to a Circular Economy Model in Russian Regions. In Proceedings of the ICEPP 2021, Efficient Production and Processing; Vankov, Y., Ed.; Springer Nature: Cham, Switzerland, 2022; Volume 190, pp. 291–297. [Google Scholar]

- Bogoviz, A.V.; Revzon, O.A.; Poliakova, V.V.; Sumbatyan, S.L.; Morozova, N.G. Successful Manifestations of the Circular Economy in Modern Russia. In Circular Economy in Developed and Developing Countries: Perspective, Methods and Examples; Emerald Publishing Limited: Bingley, UK, 2021; pp. 149–156. [Google Scholar] [CrossRef]

- Liubarskaia, M.A.; Putinceva, N.A. The Role of Secondary Resource Market in the Development of the Extended Producer Responsibility Mechanism in Russia. IOP Conf. Ser. Earth Environ. Sci. 2021, 938, 012014. [Google Scholar] [CrossRef]

- Abu Qdais, H.; Saadeh, O.; Al-Widyan, M.; Al-tal, R.; Abu-Dalo, M. Environmental sustainability features in large university campuses: Jordan University of Science and Technology (JUST) as a model of green university. Int. J. Sustain. High. Educ. 2019, 20, 214–228. [Google Scholar] [CrossRef]

- Qu, D.; Shevchenko, T.; Saidani, M.; Xia, Y.; Ladyka, Y. Transition towards a circular economy: The role of university assets in the implementation of a new model. Detritus 2021, 17, 3–14. [Google Scholar] [CrossRef]

- Salas, D.A.; Criollo, P.; Ramirez, A.D. The Role of Higher Education Institutions in the Implementation of Circular Economy in Latin America. Sustainability 2021, 13, 9805. [Google Scholar] [CrossRef]

- IFC. Waste in Russia: Garbage or Valuable Resource? Scenarios for Developing the Municipal Solid Waste Management Sector, International Finance Corporation, World Bank. 2014. Available online: https://documents1.worldbank.org/curated/pt/702251549554831489/pdf/Waste-in-Russia-Garbage-or-Valuable-Resource.pdf (accessed on 24 January 2022).

- Aranda-Usón, A.; Portillo-Tarragona, P.; María Marín, L.; Scarpellini, S. Financial Resources for the Circular Economy: A Perspective from Businesses. Sustainability 2019, 11, 888. [Google Scholar] [CrossRef] [Green Version]

- Pouikil, K. Concretising the role of extended producer responsibility in European Union waste law and policy through the lens of the circular economy. ERA Forum 2020, 20, 491–508. [Google Scholar] [CrossRef] [Green Version]

- Saha, I.; Tatiana, S.; Smirnova, T.S.; Vladimir, A.; Maryev, V.A. Implementation of Eco-Industrial Park for Effectual Establishment of Circular Economy in Russia. Nat. Environ. Pollut. Technol. 2021, 20, 2031–2040. [Google Scholar] [CrossRef]

- Vorotnikov, A.M.; Bajanov, I.N.; Lijin, D.H. Eco-Techno Parks: Development Prospects, Priority areas of implementation and features of Financing. Probl. Natioal Strateg. 2019, 55, 144–155. [Google Scholar]

- Bobylev, S.N.; Solovyeva, S.V. Circular economy and its indicators for Russia. Mir Novoi Ekon. = World New Econ. 2020, 14, 63–72. [Google Scholar] [CrossRef]

- Kurbatova, A.; Abu-Qdais, H.A. Using multi-criteria decision analysis to select waste to energy technology for a Mega city: The case of Moscow. Sustainability 2020, 12, 9828. [Google Scholar] [CrossRef]

- Abu Qdais, H.A.; Wuensh, C.; Dornack, C.; Nassour, A. The role of solid waste composting in mitigating climate change in Jordan. Waste Manag. Res. 2019, 37, 833–842. [Google Scholar] [CrossRef] [PubMed]

| Input | Output | |

|---|---|---|

| Solid waste quantity | 1,813,000 ton/year | 101,824 tons/year to landfill |

| Sorting | 1,000,000 ton/year | Material recovery from sorting 245,115 t/y. This includes

|

| Composting (25% food of waste) | 453,250 ton/year | 300,000 ton/year |

| From bulky to RDF | 270,000 ton/year | RDF, 193,802 t/y |

| WtE plant | 253,200 ton/year | Energy, 35 Mwh |

| Plastic fraction | 254,800 ton/year | PET, PE, PP 46,852 ton/year |

| Water | 390,000 m3 | |

| Electric Energy | 35 Mwh | |

| Natural gas | 1,200,000 nm3 |

| Waste Treatment Process | Main Characteristics and Assumptions |

|---|---|

| Incineration with energy recovery | Design capacity of 253,200 tons per year, where all the energy recovered will be used for the operation of the EIP and will produce 10% ash that will be landfilled. |

| Sorting and material recovery facility | Two lines of sorting with an annual capacity of 500,000 tons each. It is assumed that all the solid waste received is mixed and not being subjected for sorting at source. Collection and transportation to the EIP are excluded from the LCA analysis. |

| Composting | All the biodegradable organic fraction is separated and subjected to composting. The amount of the solid waste that will be subjected to composting is 453,250 tons per year (25% of the generated waste) to produce 300,000 tons per year of finished compost. All the produced compost is assumed to be used as a final cover of the landfill that is located within the EIP boundaries. |

| Landfilling | It is assumed that all the residual waste, after separation and energy recovery, will be directed to the sanitary landfill. The estimated landfilled waste is about 101,824 tons/year and assumed to be inert; it will not be subjected to biodegradation. |

| Impact Category | Unit | Landfilling (S1) | Landfill Eco-Industrial Park (S2) | Percent Reduction/Increase |

|---|---|---|---|---|

| Global warming | kg CO2 eq | 9.05 × 108 | 3.70 × 108 | 59% |

| Eutrophication | kg N eq | 2,475,291 | 460,371.03 | 81% |

| Acidification | kg SO2 eq | 249,148.17 | 184,625.32 | 26% |

| Smog | kg O3 eq | 3,920,057.9 | 3,227,569.2 | 18% |

| Ozone Depletion | kg CFC-11 eq | 6.9706184 | 1.2806006 | 81% |

| Carcinogenic | CTUh | 3.7935234 | 0.26318803 | 92% |

| Non carcinogenic | CTUh | 7.3697049 | 0.2988090 | 96% |

| Ecotoxicity | CTUe | 1.64 × 108 | 5,372,424.5 | 96% |

| Fossil fuel depletion | MJ surplus | 60,254,697 | 52,659,851 | 13% |

| Respiratory effects | kg PM2.5 eq | 26,690.386 | 40,035.7 | +33% |

| Impact Category | Unit | Emissions from EIP (Scenario 2) | Emission with 10% Conversion from Landfill | Emission with 20% Conversion from Landfill | Decrease in the Impact Category for 10% Diversion | Decrease in the Impact Category for 20% Diversion |

|---|---|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | −16.721524 | −21.146866 | −25.572208 | 26.50% | 53% |

| Global warming | kg CO2 eq | 26,045,152 | −90,906,690 | −2.08 × 108 | 249% | 698% |

| Smog | kg O3 eq | −14,728,371 | −19,733,735 | −24,739,099 | 33% | 68% |

| Acidification | kg SO2 eq | −1,486,174.7 | −1,909,028.5 | −2,331,882.3 | 28.50% | 57% |

| Eutrophication | kg N eq | 340,068.98 | 263,239.19 | 186,409.4 | 22.60% | 45% |

| Carcinogenic | CTUh | −14.434815 | −17.961323 | −21.487831 | 24% | 49% |

| Non carcinogenic | CTUh | −44.415678 | −55.6601 | −66.904522 | 25% | 50.6% |

| Respiratory effects | kg PM2.5 eq | −291,183.18 | −368,841.4 | −446,499.62 | 26.7% | 53% |

| Ecotoxicity | CTUe | −2.52 × 108 | −3.13 × 108 | −3.74 × 108 | 24% | 49% |

| Fossil fuel depletion | MJ surplus | −5.15 × 108 | −6.46 × 108 | −7.77 × 108 | 25% | 51% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu-Qdais, H.A.; Kurbatova, A.I. The Role of Eco-Industrial Parks in Promoting Circular Economy in Russia: A Life Cycle Approach. Sustainability 2022, 14, 3893. https://doi.org/10.3390/su14073893

Abu-Qdais HA, Kurbatova AI. The Role of Eco-Industrial Parks in Promoting Circular Economy in Russia: A Life Cycle Approach. Sustainability. 2022; 14(7):3893. https://doi.org/10.3390/su14073893

Chicago/Turabian StyleAbu-Qdais, Hani A., and Anna I. Kurbatova. 2022. "The Role of Eco-Industrial Parks in Promoting Circular Economy in Russia: A Life Cycle Approach" Sustainability 14, no. 7: 3893. https://doi.org/10.3390/su14073893

APA StyleAbu-Qdais, H. A., & Kurbatova, A. I. (2022). The Role of Eco-Industrial Parks in Promoting Circular Economy in Russia: A Life Cycle Approach. Sustainability, 14(7), 3893. https://doi.org/10.3390/su14073893