Multi-Criteria Assessment of the Economic and Environmental Sustainability Characteristics of Intermediate Wheatgrass Grown as a Dual-Purpose Grain and Forage Crop

Abstract

:1. Introduction

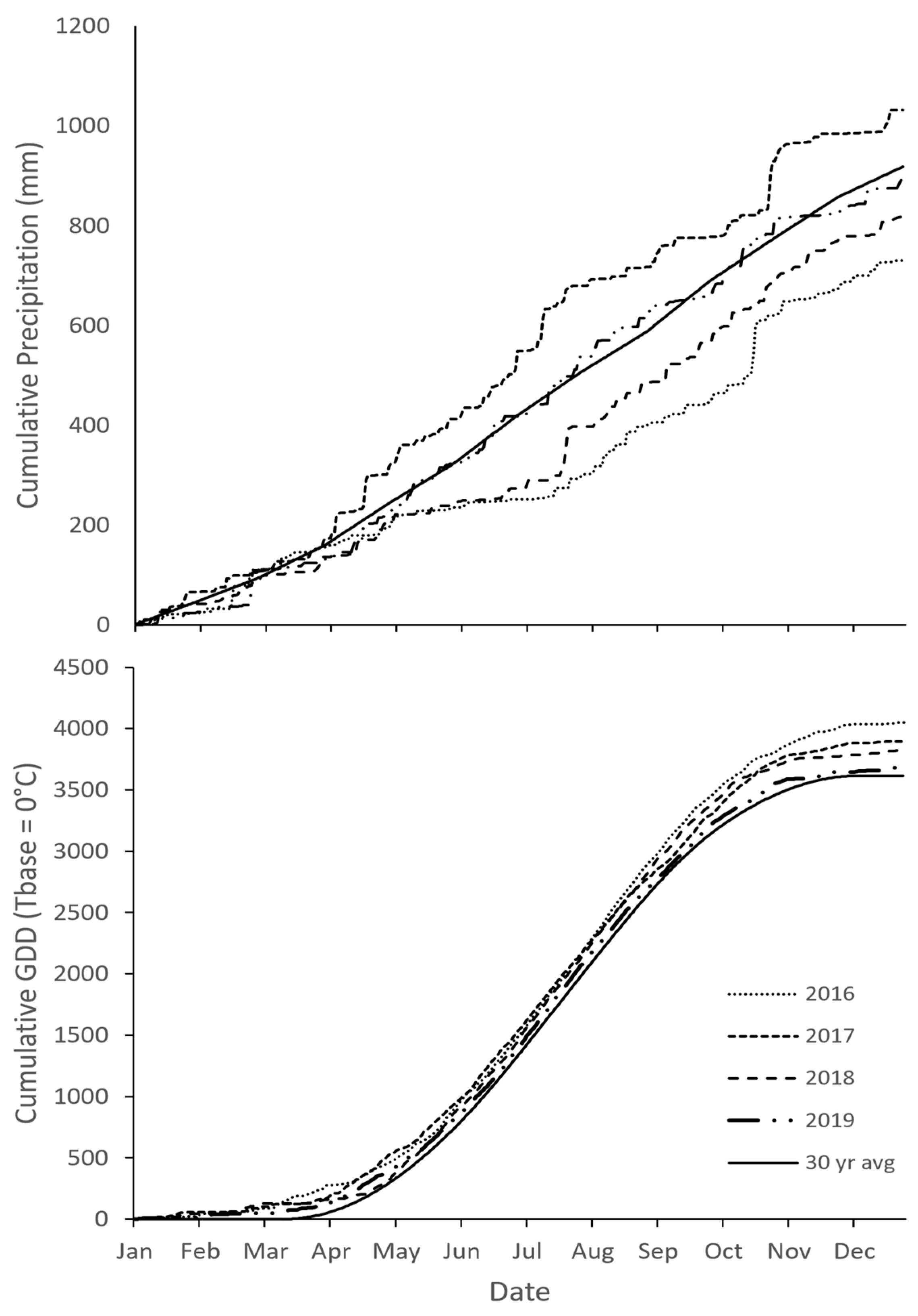

2. Materials and Methods

2.1. IWG and Wheat Systems

2.2. Corn–Soybean–Wheat Cropping System

2.3. System Boundaries, Assumptions, and Input Definitions

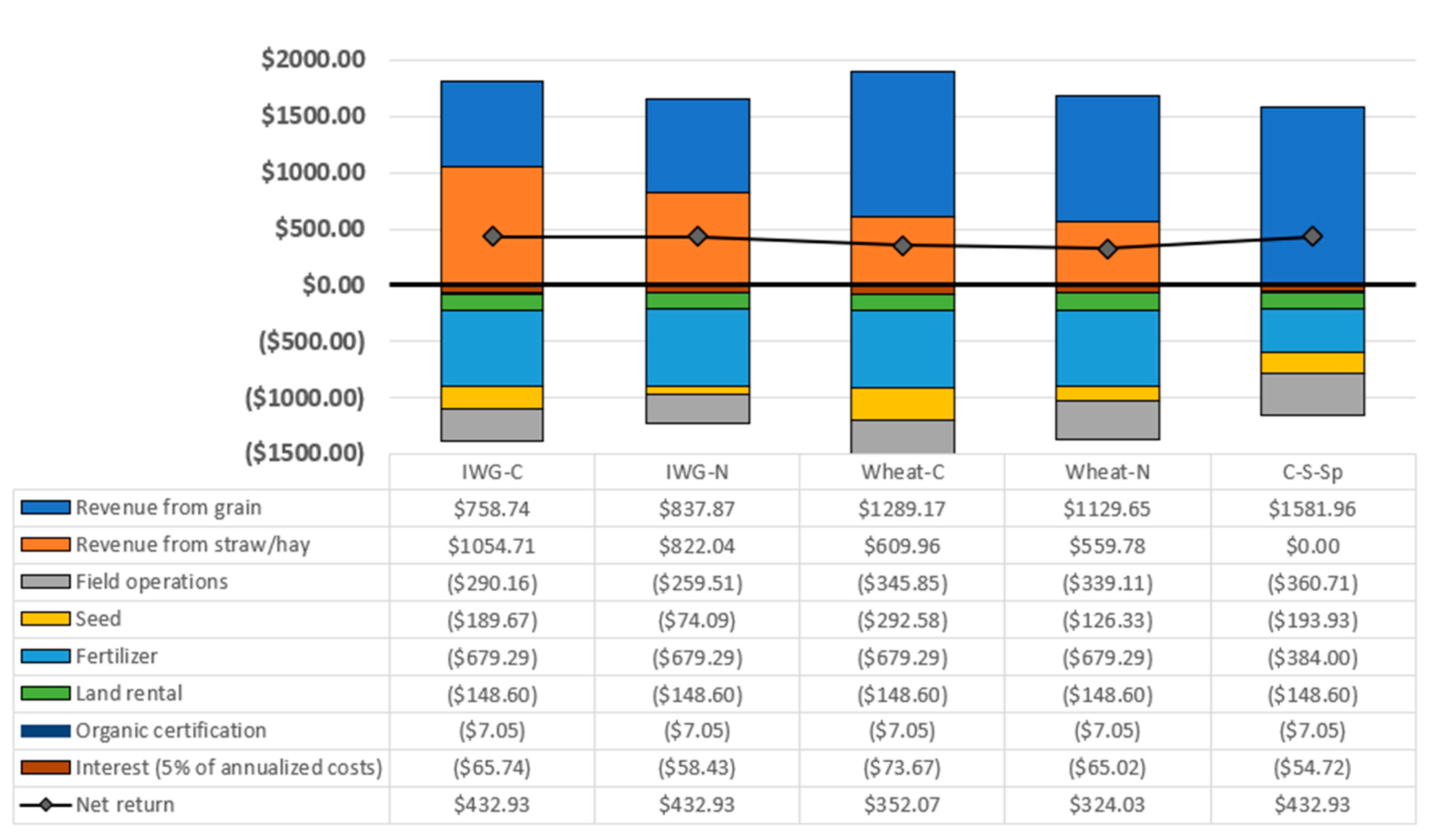

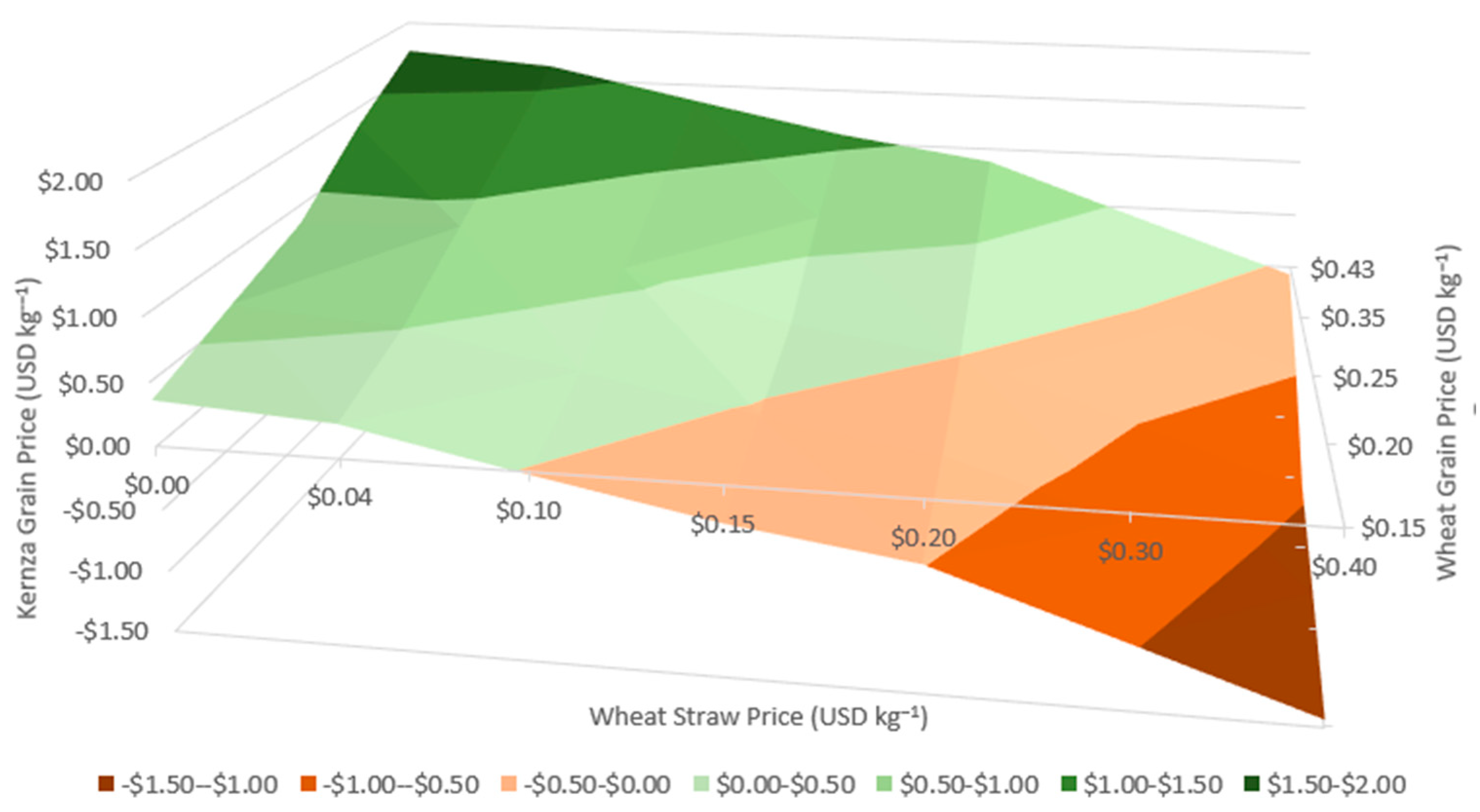

2.4. Enterprise Budgets

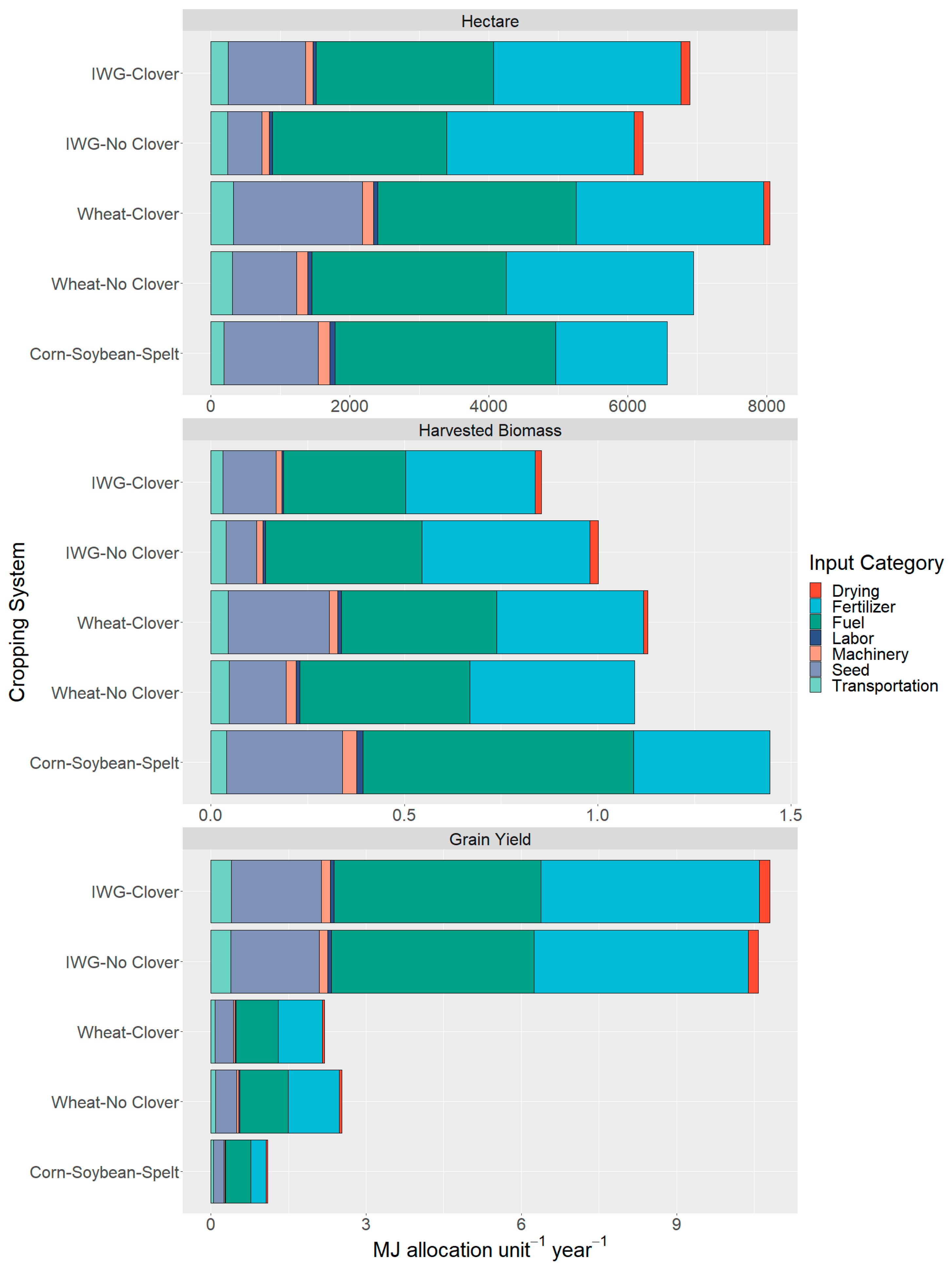

2.5. Energy Use and Greenhouse Gas Emissions

2.6. Emergy Evaluation

2.7. Statistical Analysis

3. Results and Discussion

3.1. Crop Yields and Economics

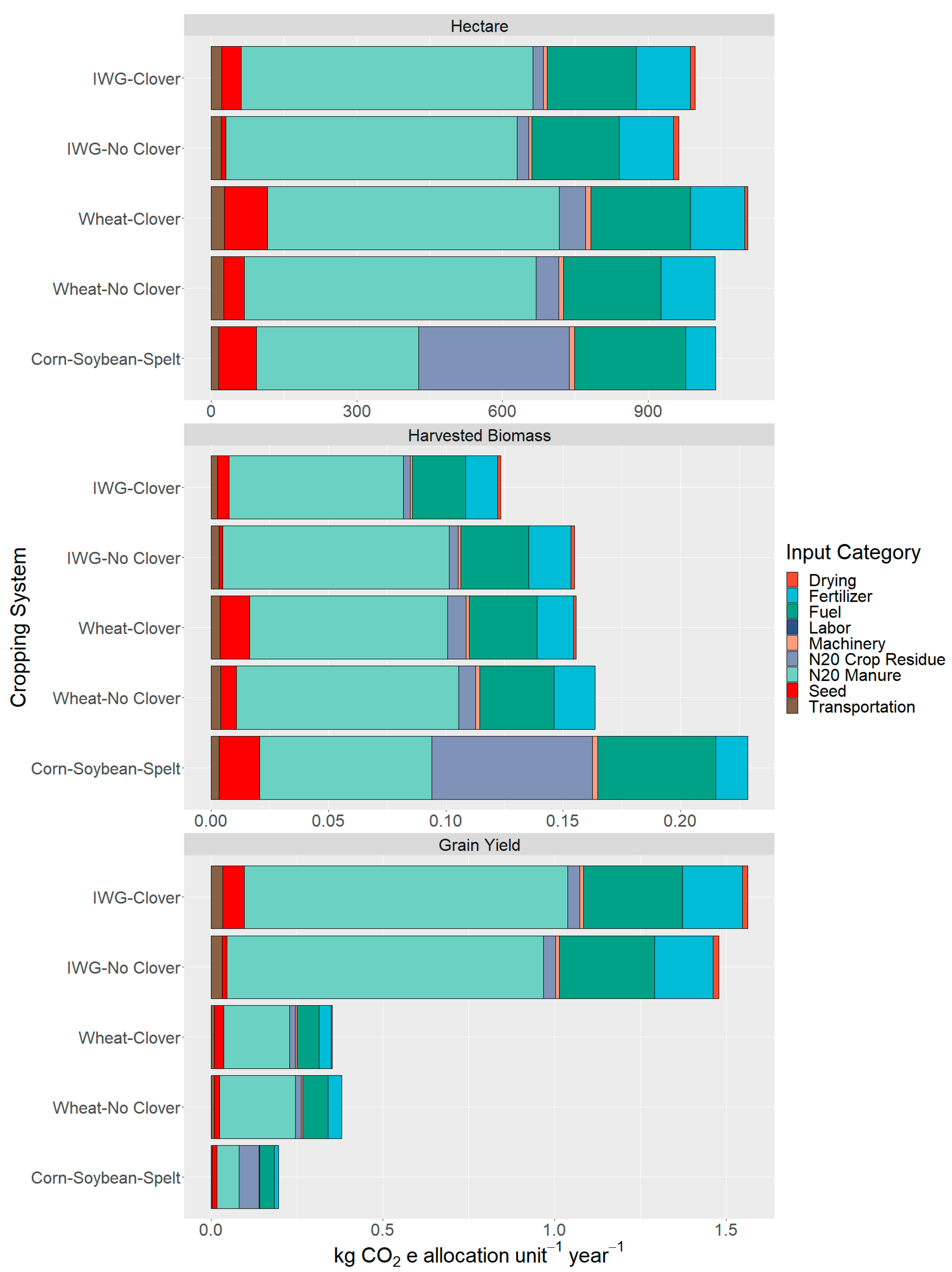

3.2. Energy Analysis

3.3. Greenhouse Gas Emissions

3.4. Emergy Evaluation

3.5. Comparison of Sustainability Indicators between Systems

3.6. Implications for Incorporating Intermediate Wheatgrass into Sustainable Cropping Systems

3.7. Limitations and Areas for Future Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bommarco, R.; Kleijn, D.; Potts, S.G. Ecological Intensification: Harnessing Ecosystem Services for Food Security. Trends Ecol. Evol. 2013, 28, 230–238. [Google Scholar] [CrossRef] [PubMed]

- Foley, J.A.; Ramankutty, N.; Brauman, K.A.; Cassidy, E.S.; Gerber, J.S.; Johnston, M.; Mueller, N.D.; O’Connell, C.; Ray, D.K.; West, P.C.; et al. Solutions for a Cultivated Planet. Nature 2011, 478, 337–342. [Google Scholar] [CrossRef] [Green Version]

- Asbjornsen, H.; Hernandez-Santana, V.; Liebman, M.; Bayala, J.; Chen, J.; Helmers, M.; Ong, C.K.; Schulte, L.A. Targeting Perennial Vegetation in Agricultural Landscapes for Enhancing Ecosystem Services. Renew. Agric. Food Syst. 2014, 29, 101–125. [Google Scholar] [CrossRef] [Green Version]

- Crews, T.E.; Carton, W.; Olsson, L. Is the Future of Agriculture Perennial? Imperatives and Opportunities to Reinvent Agriculture by Shifting from Annual Monocultures to Perennial Polycultures. Glob. Sustain. 2018, 1, e11. [Google Scholar] [CrossRef] [Green Version]

- Pimentel, D.; Cerasale, D.; Stanley, R.C.; Perlman, R.; Newman, E.M.; Brent, L.C.; Mullan, A.; Chang, D.T.-I. Annual vs. Perennial Grain Production. Agric. Ecosyst. Environ. 2012, 161, 1–9. [Google Scholar] [CrossRef]

- González-Paleo, L.; Vilela, A.E.; Ravetta, D.A. Back to Perennials: Does Selection Enhance Tradeoffs between Yield and Longevity? Ind. Crops Prod. 2016, 91, 272–278. [Google Scholar] [CrossRef]

- Vico, G.; Brunsell, N.A. Tradeoffs between Water Requirements and Yield Stability in Annual vs. Perennial Crops. Adv. Water Resour. 2018, 112, 189–202. [Google Scholar] [CrossRef]

- Hendrickson, J.R.; Berdahl, J.D.; Liebig, M.A.; Karn, J.F. Tiller Persistence of Eight Intermediate Wheatgrass Entries Grazed at Three Morphological Stages. Agron. J. 2005, 97, 1390–1395. [Google Scholar] [CrossRef] [Green Version]

- Crain, J.; DeHaan, L.; Poland, J. Genomic Prediction Enables Rapid Selection of High-Performing Genets in an Intermediate Wheatgrass Breeding Program. Plant Genome 2021, 14, e20080. [Google Scholar] [CrossRef]

- DeHaan, L.; Christians, M.; Crain, J.; Poland, J. Development and Evolution of an Intermediate Wheatgrass Domestication Program. Sustainability 2018, 10, 1499. [Google Scholar] [CrossRef] [Green Version]

- Culman, S.W.; Snapp, S.S.; Ollenburger, M.; Basso, B.; DeHaan, L.R. Soil and Water Quality Rapidly Responds to the Perennial Grain Kernza Wheatgrass. Agron. J. 2013, 105, 735–744. [Google Scholar] [CrossRef] [Green Version]

- Duchene, O.; Dumont, B.; Cattani, D.J.; Fagnant, L.; Schlautman, B.; DeHaan, L.R.; Barriball, S.; Jungers, J.M.; Picasso, V.D.; David, C.; et al. Process-Based Analysis of Thinopyrum intermedium Phenological Development Highlights the Importance of Dual Induction for Reproductive Growth and Agronomic Performance. Agric. Forest Meteorol. 2021, 301–302, 108341. [Google Scholar] [CrossRef]

- Jungers, J.M.; DeHaan, L.H.; Mulla, D.J.; Sheaffer, C.C.; Wyse, D.L. Reduced Nitrate Leaching in a Perennial Grain Crop Compared to Maize in the Upper Midwest, USA. Agric. Ecosyst. Environ. 2019, 272, 63–73. [Google Scholar] [CrossRef]

- Jungers, J.M.; DeHaan, L.R.; Betts, K.J.; Sheaffer, C.C.; Wyse, D.L. Intermediate Wheatgrass Grain and Forage Yield Responses to Nitrogen Fertilization. Agron. J. 2017, 109, 462–472. [Google Scholar] [CrossRef] [Green Version]

- Law, E.P.; Wayman, S.; Pelzer, C.J.; DiTommaso, A.; Ryan, M.R. Intercropping Red Clover with Intermediate Wheatgrass Suppresses Weeds without Reducing Grain Yield. Agron. J. 2022, 114, 700–716. [Google Scholar] [CrossRef]

- Law, E.P.; Pelzer, C.J.; Wayman, S.; DiTommaso, A.; Ryan, M.R. Strip-Tillage Renovation of Intermediate Wheatgrass (Thinopyrum intermedium) for Maintaining Grain Yield in Mature Stands. Renew. Agric. Food Syst. 2021, 36, 321–327. [Google Scholar] [CrossRef]

- Pinto, P.; De Haan, L.; Picasso, V. Post-Harvest Management Practices Impact on Light Penetration and Kernza Intermediate Wheatgrass Yield Components. Agronomy 2021, 11, 442. [Google Scholar] [CrossRef]

- Muckey, E. Kernza® in Southern Minnesota: Assessing Local Viability of Intermediate Wheatgrass; University of Minnesota Extension: St. Paul, MN, USA, 2019; p. 33. Available online: https://conservancy.umn.edu/bitstream/handle/11299/202253/Kernza_Final_01272019.pdf?sequence=1 (accessed on 27 January 2022).

- Glover, J.D.; Reganold, J.P.; Bell, L.W.; Borevitz, J.; Brummer, E.C.; Buckler, E.S.; Cox, C.M.; Cox, T.S.; Crews, T.E.; Culman, S.W.; et al. Increased Food and Ecosystem Security via Perennial Grains. Science 2010, 328, 1638–1639. [Google Scholar] [CrossRef] [Green Version]

- Lanker, M.; Bell, M.; Picasso, V.D. Farmer Perspectives and Experiences Introducing the Novel Perennial Grain Kernza Intermediate Wheatgrass in the US Midwest. Renew. Agric. Food Syst. 2020, 35, 653–662. [Google Scholar] [CrossRef] [Green Version]

- Keene, C.L.; Law, E.P.; Jungers, J.M.; Stoltenberg, D.E. Herbicide Options for Use in Kernza Perennial Grain: IR-4 Update. In Proceedings of the North Central Weed Science Society Proceedings, Online, 30 November–3 December 2020; Virtual Meeting. Volume 75. [Google Scholar]

- Hunter, M.C.; Sheaffer, C.C.; Culman, S.W.; Lazarus, W.F.; Jungers, J.M. Effects of Defoliation and Row Spacing on Intermediate Wheatgrass II: Forage Yield and Economics. Agron. J. 2020, 112, 1862–1880. [Google Scholar] [CrossRef]

- Duchene, O.; Celette, F.; Ryan, M.R.; DeHaan, L.R.; Crews, T.E.; David, C. Integrating Multipurpose Perennial Grains Crops in Western European Farming Systems. Agric. Ecosyst. Environ. 2019, 284, 106591. [Google Scholar] [CrossRef]

- Ryan, M.R.; Crews, T.E.; Culman, S.W.; DeHaan, L.R.; Hayes, R.C.; Jungers, J.M.; Bakker, M.G. Managing for Multifunctionality in Perennial Grain Crops. BioScience 2018, 68, 294–304. [Google Scholar] [CrossRef] [PubMed]

- Bybee-Finley, K.A.; Ryan, M.R. Advancing Intercropping Research and Practices in Industrialized Agricultural Landscapes. Agriculture 2018, 8, 80. [Google Scholar] [CrossRef] [Green Version]

- Gaudin, A.C.M.; Westra, S.; Loucks, C.E.S.; Janovicek, K.; Martin, R.C.; Deen, W. Improving Resilience of Northern Field Crop Systems Using Inter-Seeded Red Clover: A Review. Agronomy 2013, 3, 148–180. [Google Scholar] [CrossRef] [Green Version]

- Favre, J.R.; Castiblanco, T.M.; Combs, D.K.; Wattiaux, M.A.; Picasso, V.D. Forage Nutritive Value and Predicted Fiber Digestibility of Kernza Intermediate Wheatgrass in Monoculture and in Mixture with Red Clover during the First Production Year. Anim. Feed Sci. Technol. 2019, 258, 114298. [Google Scholar] [CrossRef]

- Davis, A.S.; Hill, J.D.; Chase, C.A.; Johanns, A.M.; Liebman, M. Increasing Cropping System Diversity Balances Productivity, Profitability and Environmental Health. PLoS ONE 2012, 7, e47149. [Google Scholar] [CrossRef] [Green Version]

- Giuliano, S.; Ryan, M.R.; Véricel, G.; Rametti, G.; Perdrieux, F.; Justes, E.; Alletto, L. Low-Input Cropping Systems to Reduce Input Dependency and Environmental Impacts in Maize Production: A Multi-Criteria Assessment. Eur. J. Agron. 2016, 76, 160–175. [Google Scholar] [CrossRef]

- Vasileiadis, V.P.; Moonen, A.C.; Sattin, M.; Otto, S.; Pons, X.; Kudsk, P.; Veres, A.; Dorner, Z.; van der Weide, R.; Marraccini, E.; et al. Sustainability of European Maize-Based Cropping Systems: Economic, Environmental and Social Assessment of Current and Proposed Innovative IPM-Based Systems. Eur. J. Agron. 2013, 48, 1–11. [Google Scholar] [CrossRef]

- Maaz, T.; Wulfhorst, J.D.; McCracken, V.; Kirkegaard, J.; Huggins, D.R.; Roth, I.; Kaur, H.; Pan, W. Economic, Policy, and Social Trends and Challenges of Introducing Oilseed and Pulse Crops into Dryland Wheat Cropping Systems. Agric. Ecosyst. Environ. 2018, 253, 177–194. [Google Scholar] [CrossRef]

- Wayman, S.; Debray, V.; Parry, S.; David, C.; Ryan, M.R. Perspectives on Perennial Grain Crop Production among Organic and Conventional Farmers in France and the United States. Agriculture 2019, 9, 244. [Google Scholar] [CrossRef] [Green Version]

- Kletke, D. Enterprise Budgets. In Agricultural Policy Analysis Tools for Economic Development; Routledge: Milton Park, UK, 2019; pp. 189–211. ISBN 978-0-429-69380-9. [Google Scholar]

- Hoffman, E.; Cavigelli, M.A.; Camargo, G.; Ryan, M.; Ackroyd, V.J.; Richard, T.L.; Mirsky, S. Energy Use and Greenhouse Gas Emissions in Organic and Conventional Grain Crop Production: Accounting for Nutrient Inflows. Agric. Syst. 2018, 162, 89–96. [Google Scholar] [CrossRef]

- Camargo, G.G.T.; Ryan, M.R.; Richard, T.L. Energy Use and Greenhouse Gas Emissions from Crop Production Using the Farm Energy Analysis Tool. BioScience 2013, 63, 263–273. [Google Scholar] [CrossRef] [Green Version]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Hercher-Pasteur, J.; Loiseau, E.; Sinfort, C.; Hélias, A. Identifying the Resource Use and Circularity in Farm Systems: Focus on the Energy Analysis of Agroecosystems. Resour. Conserv. Recycl. 2021, 169, 105502. [Google Scholar] [CrossRef]

- Arguez, A.; Durre, I.; Applequist, S.; Vose, R.S.; Squires, M.F.; Yin, X.; Heim, R.R.; Owen, T.W. NOAA’s 1981–2010 U.S. Climate Normals: An Overview. Bull. Amer. Meteorol. 2012, 93, 1687–1697. [Google Scholar] [CrossRef]

- Caldwell, B.; Mohler, C.L.; Ketterings, Q.M.; DiTommaso, A. Yields and Profitability during and after Transition in Organic Grain Cropping Systems. Agron. J. 2014, 106, 871–880. [Google Scholar] [CrossRef] [Green Version]

- Nearing, M.A.; Xie, Y.; Liu, B.; Ye, Y. Natural and Anthropogenic Rates of Soil Erosion. Int. Soil Water Conserv. Res. 2017, 5, 77–84. [Google Scholar] [CrossRef]

- National Agricultural Statistics Service. Certified Organic Field Crops and Hay Harvested and Value of Sales: 2019; 2017 Census of Agriculture; United States Department of Agriculture: Washington, DC, USA, 2020; p. 125. [Google Scholar]

- Agricultural Marketing Service. Wolgemuth Hay Auction—New Holland, PA; USDA AMS Livestock, Poultry & Grain Market News: New Holland, PA, USA, 2021. Available online: https://mymarketnews.ams.usda.gov/viewReport/1716 (accessed on 27 January 2022).

- Ward, B.; Barker, F.J. Ohio Farm Custom Rates 2018; Ohio State University Extension: Columbus, OH, USA, 2018; Available online: https://farmoffice.osu.edu/sites/aglaw/files/site-library/farmmgtpdf/enterprisebudgets/Ohio%20Farm%20Custom%20Rates%20Final%202018.pdf (accessed on 27 January 2022).

- National Agricultural Statistics Service. Agricultural Land Values and Cash Rents. Final Estimates 2014–2018; United States Department of Agriculture: Washington, DC, USA, 2019; p. 18. [Google Scholar]

- Malcolm, G.M.; Camargo, G.G.T.; Ishler, V.A.; Richard, T.L.; Karsten, H.D. Energy and Greenhouse Gas Analysis of Northeast U.S. Dairy Cropping Systems. Agric. Ecosyst. Environ. 2015, 199, 407–417. [Google Scholar] [CrossRef]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006. [Google Scholar]

- Ortiz-Cañavate, J.; Hernanz, J.L. Energy for Biological Systems. In CIGR Handbook of Agricultural Engineering; Kitani, O., Jungbluth, T., Peart, R.M., Ramdani, D., Eds.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1999; pp. 13–42. [Google Scholar]

- Hanna, M. Fuel Required for Field Operations 2001. Available online: http://www.extension.iastate.edu/Publications/PM709.pdf (accessed on 27 January 2022).

- Lazarus, W.F. Machinery Cost Estimates 2021. Available online: https://drive.google.com/uc?export=download&id=0B3psjoooP5QxWWd3a2cwblJCTjQ (accessed on 27 January 2022).

- Ulgiati, S.; Brown, M.T. Monitoring Patterns of Sustainability in Natural and Man-Made Ecosystems. Ecol. Modell. 1998, 108, 23–36. [Google Scholar] [CrossRef]

- Ulgiati, S.; Brown, M.T.; Bastianoni, S.; Marchettini, N. Emergy-Based Indices and Ratios to Evaluate the Sustainable Use of Resources. Ecol. Eng. 1995, 5, 519–531. [Google Scholar] [CrossRef]

- Brown, M.T.; Ulgiati, S. Emergy Analysis and Environmental Accounting. In Encyclopedia of Energy; Oxford Academic Press: Oxford, UK, 2004; Volume 2, pp. 329–354. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2020. [Google Scholar]

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting Linear Mixed-Effects Models Using Lme4. J. Stat. Softw. 2015, 67, 1–48. [Google Scholar] [CrossRef]

- Lenth, R. Emmeans: Estimated Marginal Means, Aka Least-Squares Means; R Package Version 1.5.1; Github: San Francisco, CA, USA, 2020. [Google Scholar]

- Clark, I.; Jones, S.S.; Reganold, J.P.; Sanguinet, K.A.; Murphy, K.M. Agronomic Performance of Perennial Grain Genotypes in the Palouse Region of the Pacific Northwest, USA. Front. Sustain. Food Syst. 2019, 3, 39. [Google Scholar] [CrossRef]

- Fernandez, C.W.; Ehlke, N.; Sheaffer, C.C.; Jungers, J.M. Effects of Nitrogen Fertilization and Planting Density on Intermediate Wheatgrass Yield. Agron. J. 2020, 112, 4159–4170. [Google Scholar] [CrossRef]

- Hunter, M.C.; Sheaffer, C.C.; Culman, S.W.; Jungers, J.M. Effects of Defoliation and Row Spacing on Intermediate Wheatgrass I: Grain Production. Agron. J. 2020, 112, 1748–1763. [Google Scholar] [CrossRef]

- Pugliese, J.Y.; Culman, S.W.; Sprunger, C.D. Harvesting Forage of the Perennial Grain Crop Kernza (Thinopyrum intermedium) Increases Root Biomass and Soil Nitrogen Cycling. Plant Soil 2019, 437, 241–254. [Google Scholar] [CrossRef]

- Wayman, S.; Ryan, M.R.; Law, E.P.; DeHaan, L.R.; Culman, S.W. Developing Perennial Grain Cropping Systems and Market Opportunities in the Northeast; NESARE Project Report; Northeast SARE: South Burlington, VT, USA, 2021; Available online: https://projects.sare.org/project-reports/lne16-351/ (accessed on 27 January 2022).

- Wieme, R.A.; Carpenter-Boggs, L.A.; Crowder, D.W.; Murphy, K.M.; Reganold, J.P. Agronomic and Economic Performance of Organic Forage, Quinoa, and Grain Crop Rotations in the Palouse Region of the Pacific Northwest, USA. Agric. Syst. 2020, 177, 102709. [Google Scholar] [CrossRef]

- Gaudin, A.C.M.; Tolhurst, T.N.; Ker, A.P.; Janovicek, K.; Tortora, C.; Martin, R.C.; Deen, W. Increasing Crop Diversity Mitigates Weather Variations and Improves Yield Stability. PLoS ONE 2015, 10, e0113261. [Google Scholar] [CrossRef] [Green Version]

- Bell, L.W.; Byrne (nee Flugge), F.; Ewing, M.A.; Wade, L.J. A Preliminary Whole-Farm Economic Analysis of Perennial Wheat in an Australian Dryland Farming System. Agric. Syst. 2008, 96, 166–174. [Google Scholar] [CrossRef]

- Cox, W.; Hanchar, J.J.; Cherney, J.; Sorrells, M. Economic Responses of Maize, Soybean, and Wheat in Three Rotations under Conventional and Organic Systems. Agronomy 2019, 9, 424. [Google Scholar] [CrossRef] [Green Version]

- Adigun, O.D. Evaluating the Economic Effects of Using Broiler Litter as an Alternative Fertilizer for a Corn-Wheat-Soybean Cropping Sequence in South Carolina. 2020. Available online: https://tigerprints.clemson.edu/cgi/viewcontent.cgi?article=4267&context=all_theses (accessed on 27 January 2022).

- Li, S.; Jensen, E.S.; Liu, N.; Zhang, Y.; Dimitrova Mårtensson, L.-M. Species Interactions and Nitrogen Use during Early Intercropping of Intermediate Wheatgrass with a White Clover Service Crop. Agronomy 2021, 11, 388. [Google Scholar] [CrossRef]

- Tautges, N.E.; Jungers, J.M.; DeHaan, L.R.; Wyse, D.L.; Sheaffer, C.C. Maintaining Grain Yields of the Perennial Cereal Intermediate Wheatgrass in Monoculture v. Bi-Culture with Alfalfa in the Upper Midwestern USA. J. Agric. Sci. 2018, 156, 758–773. [Google Scholar] [CrossRef]

- Piringer, G.; Steinberg, L.J. Reevaluation of Energy Use in Wheat Production in the United States. J. Ind. Ecol. 2006, 10, 149–167. [Google Scholar] [CrossRef]

- Kramer, K.J.; Moll, H.C.; Nonhebel, S. Total Greenhouse Gas Emissions Related to the Dutch Crop Production System. Agric. Ecosyst. Environ. 1999, 72, 9–16. [Google Scholar] [CrossRef]

- Biswas, W.K.; Graham, J.; Kelly, K.; John, M.B. Global Warming Contributions from Wheat, Sheep Meat and Wool Production in Victoria, Australia—A Life Cycle Assessment. J. Clean. Prod. 2010, 18, 1386–1392. [Google Scholar] [CrossRef]

- Martin, J.F.; Diemont, S.A.W.; Powell, E.; Stanton, M.; Levy-Tacher, S. Emergy Evaluation of the Performance and Sustainability of Three Agricultural Systems with Different Scales and Management. Agric. Ecosyst. Environ. 2006, 115, 128–140. [Google Scholar] [CrossRef]

- Wang, X.; Chen, Y.; Sui, P.; Gao, W.; Qin, F.; Zhang, J.; Wu, X. Emergy Analysis of Grain Production Systems on Large-Scale Farms in the North China Plain Based on LCA. Agric. Syst. 2014, 128, 66–78. [Google Scholar] [CrossRef]

- Brown, M.T.; Brandt-Williams, S.L.; Tilley, D.; Ulgiati, S. Emergy Synthesis: An Introduction. In Emergy Synthesis: Theory and Applications of the Emergy Methodology; University of Florida: Gainesville, FL, USA, 2000; pp. 1–14. [Google Scholar]

- Ghaley, B.B.; Kehli, N.; Mentler, A. Emergy Synthesis of Conventional Fodder Maize (Zea mays L.) Production in Denmark. Ecol. Indic. 2018, 87, 144–151. [Google Scholar] [CrossRef]

- Coppola, F.; Haugaard-Nielsen, H.; Bastianoni, S.; Østergård, H. Sustainability Assessment of Wheat Production Using Emergy. In Proceedings of the Cultivating the Future Based on Science. Proceedings of the Second Scientific Research Conference of the International Society of Organic Agriculture Research; International Society of Organic Agriculture Research: Modena, Italy, 2008. [Google Scholar]

- Kuczuk, A. Cost-, Cumulative Energy- and Emergy Aspects of Conventional and Organic Winter Wheat (Triticum aestivum L.) Cultivation. JAS 2016, 8, 140. [Google Scholar] [CrossRef]

- Battaglia, M.; Thomason, W.; Fike, J.H.; Evanylo, G.K.; von Cossel, M.; Babur, E.; Iqbal, Y.; Diatta, A.A. The Broad Impacts of Corn Stover and Wheat Straw Removal for Biofuel Production on Crop Productivity, Soil Health and Greenhouse Gas Emissions: A Review. GCB Bioenergy 2021, 13, 45–57. [Google Scholar] [CrossRef]

| Field Operation | Equipment Used | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|

| Primary tillage | Moldboard plow | Aug 16 | - | - | - |

| Fall fertilizer application | Drop spreader | Aug 30 | Sep 13 | Sep 13 | - |

| Secondary tillage and planting | Disk harrow, cultipacker, grain drill | Aug 31 | Sep 14 | Sep 14 | - |

| Frost seeding red clover | None (broadcast by hand) | - | Mar 29 | Mar 22 | Mar 19 1 |

| Spring fertilizer application | None (broadcast by hand) | - | Apr 19 | Apr 20 | Apr 25 |

| Wheat grain and straw harvest | Plot combine, flail chopper | - | Jul 19 | Jul 11 | Jul 15 |

| IWG grain and forage harvest | Plot combine, flail chopper | - | Aug 9 | Aug 15 | Aug 23 |

| Emergy Indicator | Abbreviation | Equation 1 |

|---|---|---|

| Specific Emergy | - | (R + N + F)/mass of product |

| Emergy Yield Ratio | EYR | (R + N + F)/F |

| Environmental Loading Ratio | ELR | (F + N)/R |

| Emergy Sustainability Index | ESI | EYR/ELR |

| Factor | Level | Grain Yield | Crop Biomass | Red Clover Biomass 1 | Forage Yield 2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| kg ha−1 | |||||||||

| Grain Crop | IWG | 478 | b 3 | 5486 | a | 1413 | a | 6438 | a |

| Wheat | 2807 | a | 3828 | b | 411 | b | 4024 | b | |

| Intercrop | Red clover | 1224 | 4675 | 911 | 5597 | a | |||

| No clover | 1097 | 4537 | NA | 4675 | b | ||||

| Year | 2017 | 2039 | a | 5324 | a | 632 | b | 5653 | a |

| 2018 | 728 | c | 3463 | b | 1600 | a | 4230 | b | |

| 2019 | 1033 | b | 5271 | a | 502 | b | 5541 | a | |

| Grain Crop x Year | |||||||||

| IWG | 2017 | 1212 | a | 5541 | b | 809 | b | 5943 | b |

| 2018 | 202 | c | 3866 | b | 3004 | a | 5597 | b | |

| 2019 | 441 | b | 7785 | a | 425 | b | 8022 | a | |

| Wheat | 2017 | 3429 | A | 5167 | A | 456 | A | 5378 | A |

| 2018 | 2644 | A | 3072 | B | 196 | A | 3165 | B | |

| 2019 | 2416 | A | 3533 | B | 580 | A | 3866 | B | |

| Effect | p-value | ||||||||

| Grain Crop | <0.001 | 0.0208 | <0.001 | 0.0051 | |||||

| Intercrop | 0.2533 | 0.6854 | NA | 0.0017 | |||||

| Year | <0.001 | <0.001 | <0.001 | <0.001 | |||||

| Grain Crop x Intercrop | 0.7529 | 0.8853 | NA | 0.1680 | |||||

| Grain Crop x Year | <0.001 | <0.001 | <0.001 | <0.001 | |||||

| Intercrop x Year | 0.0965 | 0.4079 | NA | 0.0416 | |||||

| Crop x Intercrop x Year | 0.8084 | 0.4954 | NA | 0.4971 | |||||

| Sustainability Indicator | IWG-C | IWG-N | Wheat-C | Wheat-N | C-S-Sp |

|---|---|---|---|---|---|

| Specific emergy (seJ g−1) | 3.67 × 109 | 3.50 × 109 | 1.09 × 109 | 1.24 × 109 | 5.82 × 108 |

| Emergy yield (Y) | 7.03 × 1015 | 6.84 × 1015 | 1.03 × 1015 | 1.02 × 1016 | 9.30 × 1015 |

| Renewable fraction (R) | 4.70 × 1015 | 4.70 × 1015 | 4.70 × 1015 | 4.70 × 1015 | 4.70 × 1015 |

| Nonrenewable local fraction (N) | 7.62 × 1014 | 7.62 × 1014 | 2.82 × 1015 | 2.82 × 1015 | 2.82 × 1015 |

| Purchased fraction (F) | 1.56 × 1015 | 1.40 × 1015 | 2.74 × 1015 | 2.64 × 1015 | 1.78 × 1015 |

| EYR (Y/F) | 4.50 | 4.88 | 3.74 | 3.84 | 5.23 |

| ELR (N + F/R) | 0.49 | 0.46 | 1.18 | 1.16 | 0.98 |

| ESI (EYR/ELR) | 9.11 | 10.60 | 3.17 | 3.31 | 5.36 |

| Sustainability Indicator | IWG-C | IWG-N | Wheat-C | Wheat-N |

|---|---|---|---|---|

| Specific emergy (seJ g−1) | 3.16 × 108 | 3.90 × 108 | 7.78 × 108 | 8.44 × 108 |

| Emergy yield (Y) | 7.14 × 1015 | 6.87 × 1015 | 1.03 × 1016 | 1.02 × 1016 |

| Renewable fraction (R) | 4.70 × 1015 | 4.70 × 1015 | 4.70 × 1015 | 4.70 × 1015 |

| Nonrenewable local fraction (N) | 7.62 × 1014 | 7.62 × 1014 | 2.82 × 1015 | 2.82 × 1015 |

| Purchased fraction (F) | 1.64 × 1015 | 1.40 × 1015 | 2.75 × 1015 | 2.65 × 1015 |

| EYR (Y/F) | 4.37 | 4.90 | 3.74 | 3.84 |

| ELR (N + F/R) | 0.51 | 0.46 | 1.18 | 1.16 |

| ESI (EYR/ELR) | 8.56 | 10.65 | 3.16 | 3.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Law, E.P.; Wayman, S.; Pelzer, C.J.; Culman, S.W.; Gómez, M.I.; DiTommaso, A.; Ryan, M.R. Multi-Criteria Assessment of the Economic and Environmental Sustainability Characteristics of Intermediate Wheatgrass Grown as a Dual-Purpose Grain and Forage Crop. Sustainability 2022, 14, 3548. https://doi.org/10.3390/su14063548

Law EP, Wayman S, Pelzer CJ, Culman SW, Gómez MI, DiTommaso A, Ryan MR. Multi-Criteria Assessment of the Economic and Environmental Sustainability Characteristics of Intermediate Wheatgrass Grown as a Dual-Purpose Grain and Forage Crop. Sustainability. 2022; 14(6):3548. https://doi.org/10.3390/su14063548

Chicago/Turabian StyleLaw, Eugene P., Sandra Wayman, Christopher J. Pelzer, Steven W. Culman, Miguel I. Gómez, Antonio DiTommaso, and Matthew R. Ryan. 2022. "Multi-Criteria Assessment of the Economic and Environmental Sustainability Characteristics of Intermediate Wheatgrass Grown as a Dual-Purpose Grain and Forage Crop" Sustainability 14, no. 6: 3548. https://doi.org/10.3390/su14063548

APA StyleLaw, E. P., Wayman, S., Pelzer, C. J., Culman, S. W., Gómez, M. I., DiTommaso, A., & Ryan, M. R. (2022). Multi-Criteria Assessment of the Economic and Environmental Sustainability Characteristics of Intermediate Wheatgrass Grown as a Dual-Purpose Grain and Forage Crop. Sustainability, 14(6), 3548. https://doi.org/10.3390/su14063548