1. Introduction

As one of the widely used energy sources in industrial fields, compressed air is widely used in all walks of life because of its high speed, cleanliness, safety, low cost, and easy maintenance. However, due to the shortcomings of leakage and compressibility of air, the compressed air utilization rate is quite inefficient. Many scholars have studied compressed air energy saving.

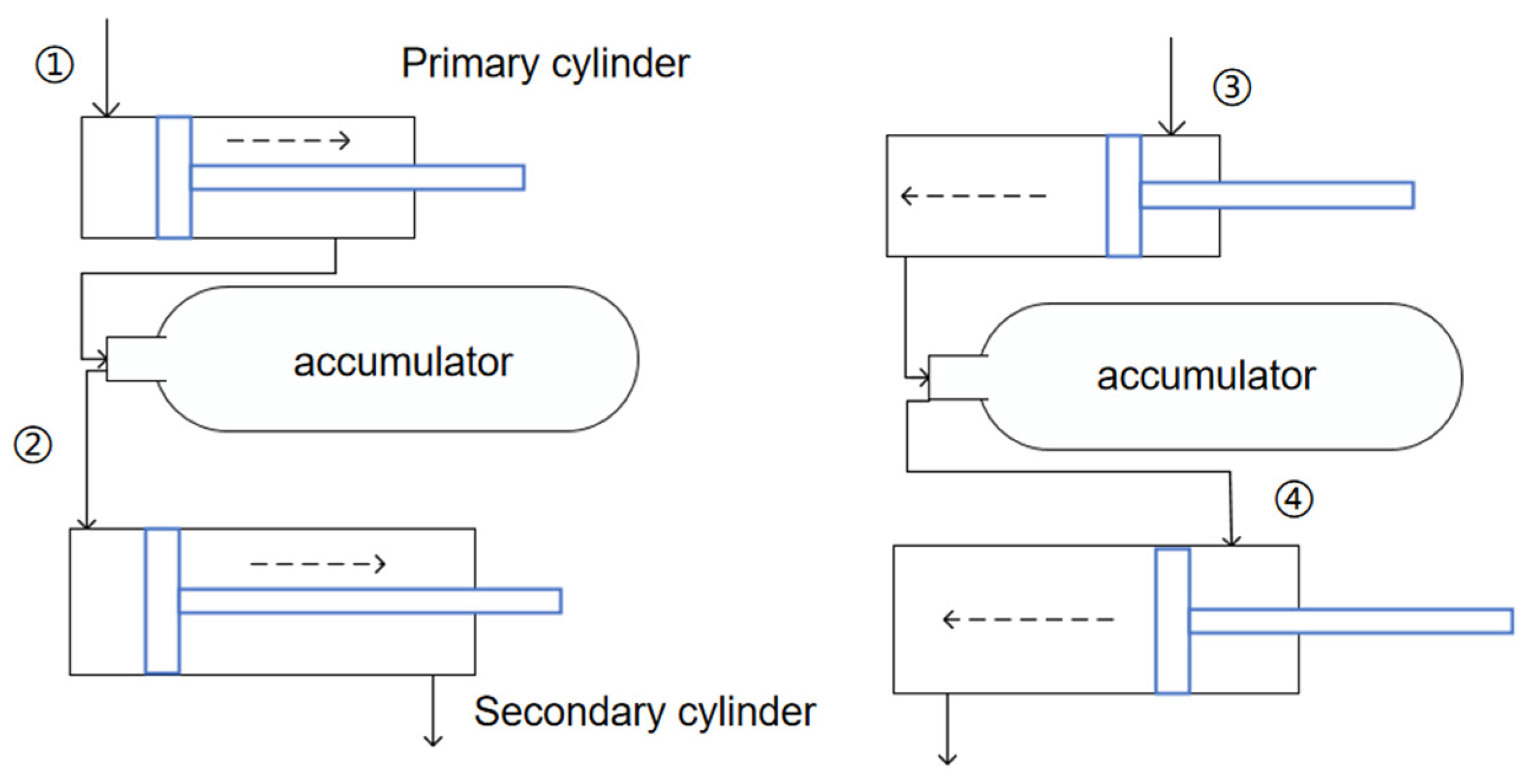

Exhausted air reuse is one of the most effective ways to save energy in pneumatic systems, which can save about 50% of compressed air consumption at most, and it is easy to operate [

1]. Yang et al. used a bypass valve to connect the cylinder inlet and exhaust chamber and delivered part of the compressed air in the cylinder exhaust chamber to the inlet chamber for reuse. This method saved about 12–28% energy. Due to the presence of the bypass valve, cylinder drive performance was also improved [

2]. Seslija et al. put forward a new type of control mode using a bypass valve together with a PWM control, showing that 30% of energy was saved under the same working conditions in comparison to the traditional PWM control system. However, the tracking performance of the PWM bypass control system was slightly worse because it took more time to reach the required position influenced by gravity and load [

3]. Du et al. connected the cylinder inlet and exhaust chamber using an air compressor [

4]. By directly controlling the piston rod speed with a motor, 74% compressed air was saved on the premise of ensuring the smooth operation of the piston. However, the applicability and robustness of this method needed to be further verified [

5]. Li et al. collected the compressed air from the exhaust chamber through an air tank and then reused it after pressurization; the advantage was that the energy-saving efficiency was high, reaching more than 40%, but the disadvantage was that the back pressure was generated due to the air tank which reduced the piston speed by about 17% [

6]. Leszczynski et al. proposed an exhaust recovery energy storage and conversion system, which used an air tank to recover the exhausted air. When the air tank reached a certain pressure, it drove an indirect energy conversion device to generate power and store energy, which saved energy by 31% [

7]. Elija et al. put forward a control framework for exhausted air reuse, which saved energy up to 38% under different working conditions [

8].

In summary, to avoid complex control algorithms, exhaust energy saving often needs an effective energy storage element. However, as the core energy storage component of exhaust recovery, most of the existing air tanks are of rigid structure. Although they can realize high-pressure storage and long-term air storage, the tanks have heavy volume, poor portability, and they cannot store and discharge energy at a constant pressure, an inability that will increase the system instability during operation [

9]. In order to solve this problem, many scholars have studied the constant pressure energy storage device. James et al. proposed a new type of constant pressure hydraulic accumulator based on variable cross-sectional area pistons. The device solved the problem of system pressure change caused by the change of energy stored in the accumulator and reduced the design size of the accumulator. However, the problem with this device was that it was difficult to ensure that the design of the rolling diaphragm seal could meet the life requirements of cyclic use [

10]. Wang et al. designed an isobaric compressed air storage tank based on a special shaped cam conversion unit. The pressure fluctuation rate of the air storage device was about 2%, which reduced the energy consumption by about 18.7% compared with the traditional constant volume air storage device. However, the volume of the device was too large to be suitable for the exhaust recovery circuit [

11]. Cummins et al. presented a pneumatic strain energy accumulator using hyperelastic rubber material, which could store and discharge energy at certain constant pressure. The accumulator had high energy density and good portability, and it was successfully applied to pneumatic systems realizing exhaust energy saving [

12].

It can be seen that the application of elastic strain energy accumulator in exhaust energy saving for a pneumatic system has a good prospect [

13,

14]. Reference [

12] developed a model for applied systems that quantifies the compressed air savings directly attributable to the implementation of a compressed air recovery, storage and recycling device; they then experimentally verified the efficiency increase of an applied system using the storage device and compared that to the model predictions. However, reference [

12] has only done preliminary exploration and research, and there are still many unsolved problems. On the one hand, the energy storage value of the accumulator does not match the energy required by the secondary cylinder, resulting in a certain amount of residual air in the accumulator after the stroke, thus resulting in waste. On the other hand, this research is limited to a single working condition. This paper makes a more in-depth study on the exhaust energy-saving circuit driven by a similar accumulator. Given the above problems, based on the reference [

12], a constant pressure energy storage accumulator is designed and applied to the pneumatic circuit for exhaust recovery and energy saving based on the hyperelastic mechanical properties of rubber.

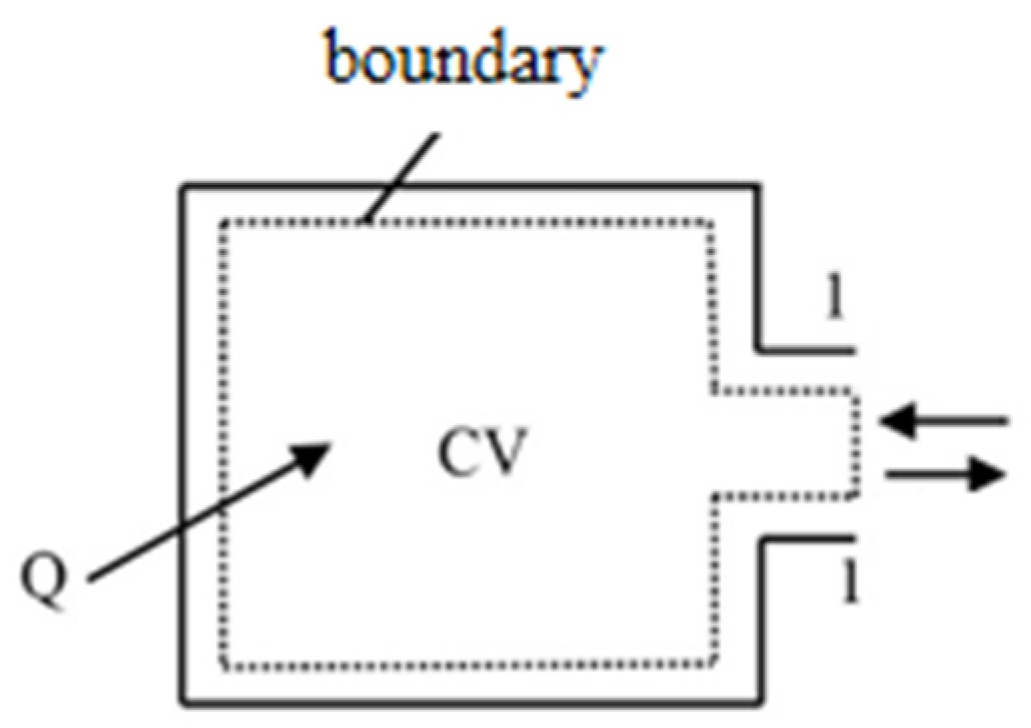

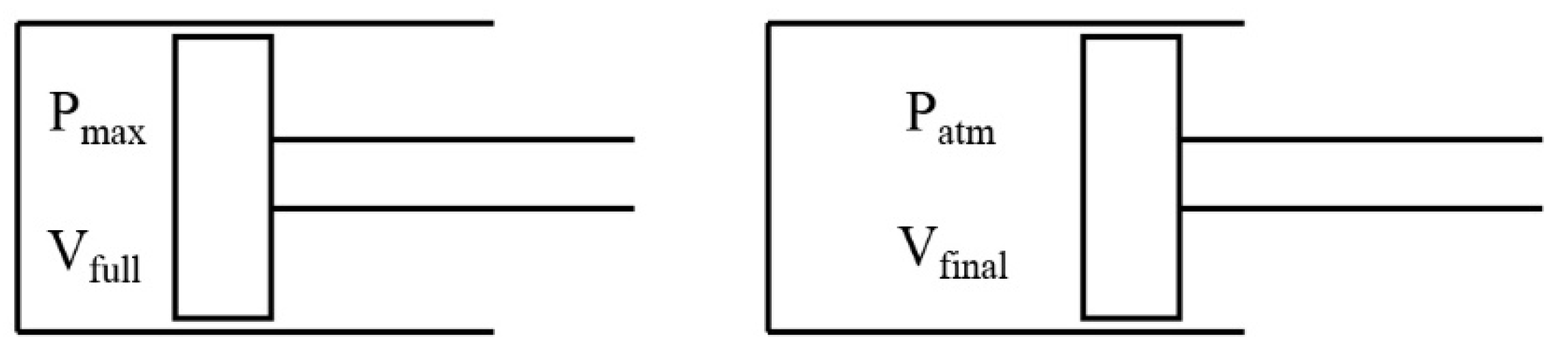

Section 2 of the paper describes the design process of a specific energy storage accumulator.

Section 3 illustrates the energy-saving circuit design and energy efficiency analysis modeling based on the accumulator. Then in

Section 4, the energy characteristics of the energy-saving circuit are verified by experiments, and the exhaust energy-saving characteristics of the pneumatic system under different working conditions are studied. Finally, conclusions are given.

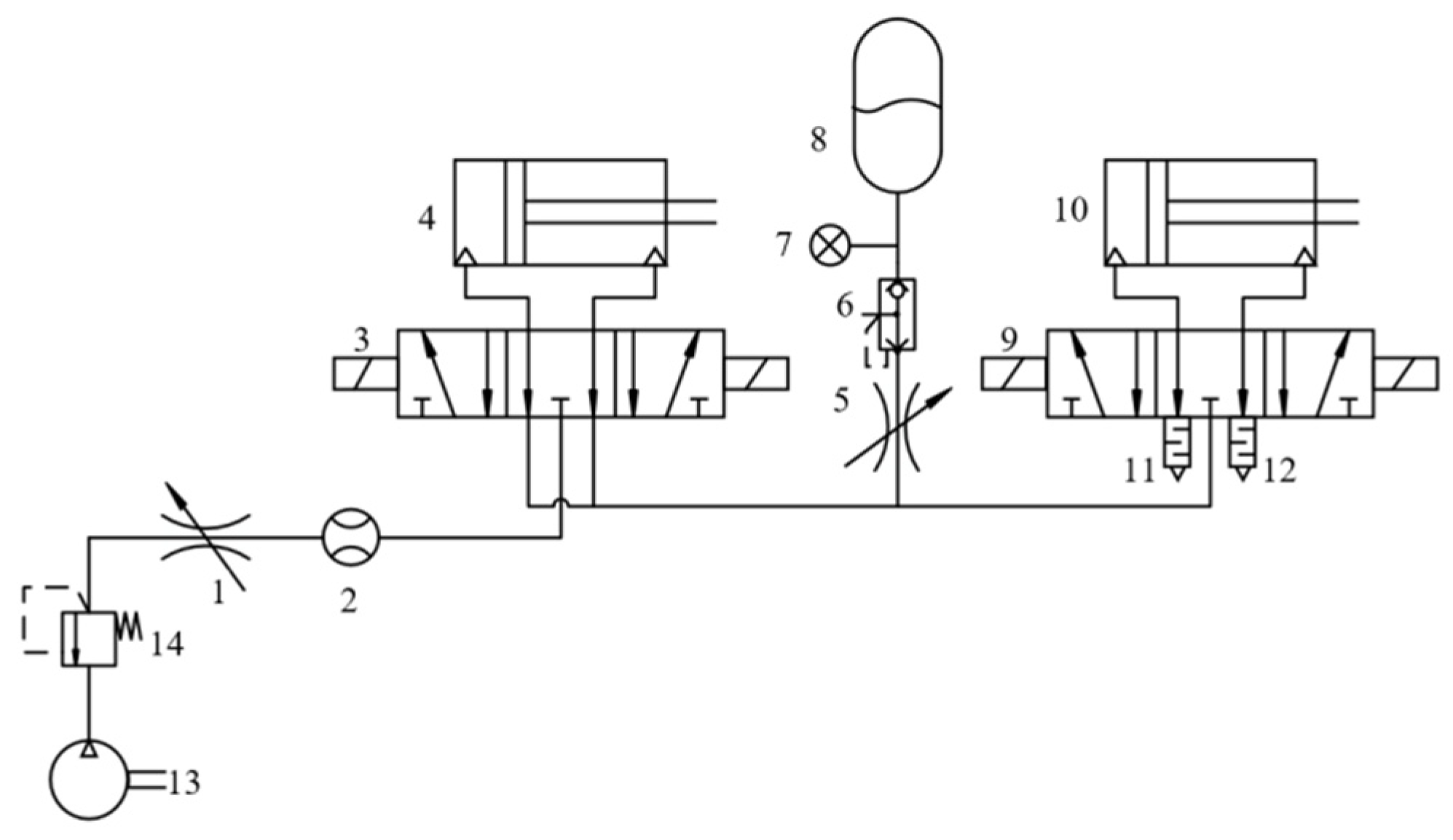

4. Energy-Saving Experiment Validation

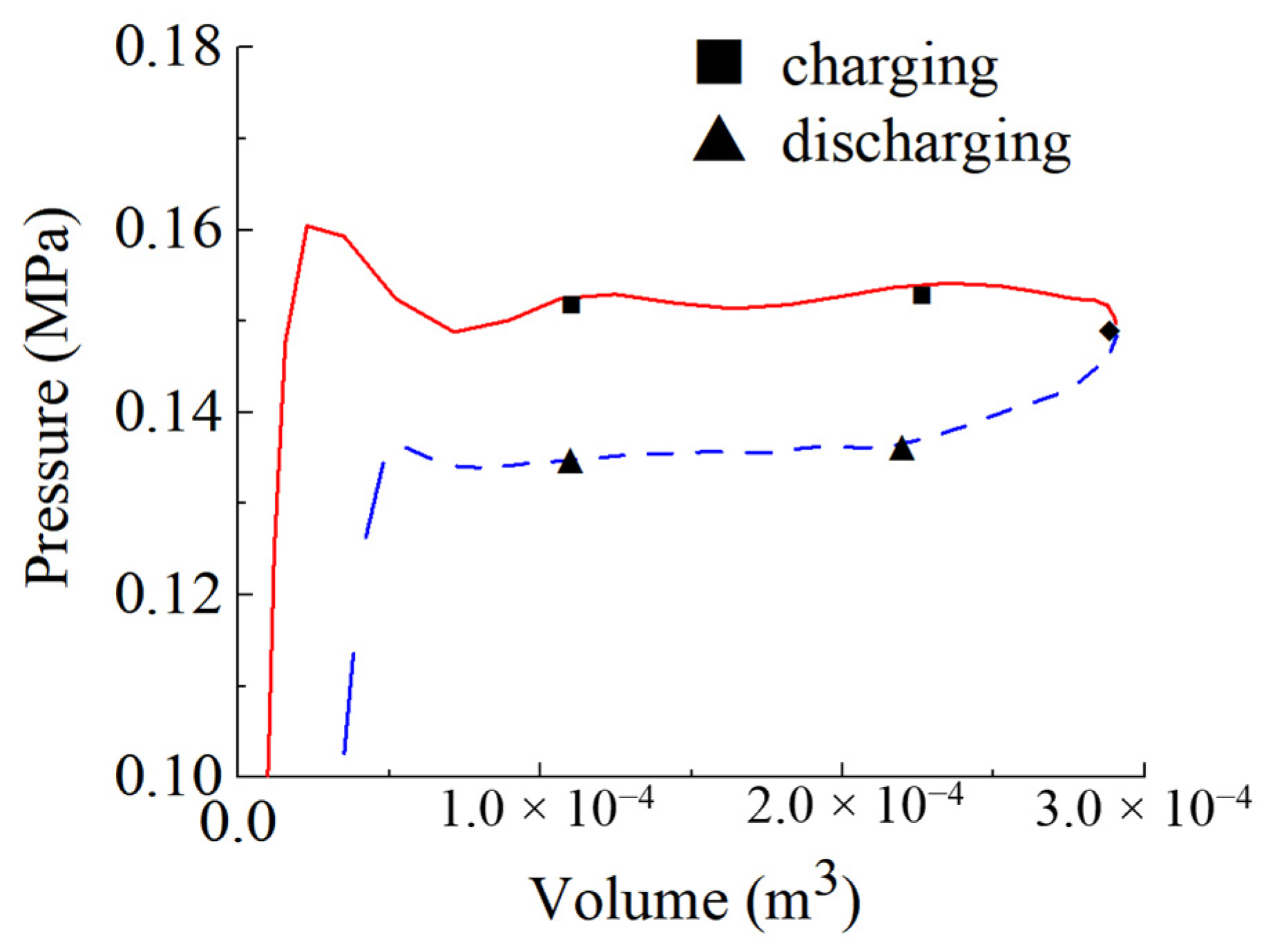

4.1. Energy-Saving Benchmark Setting

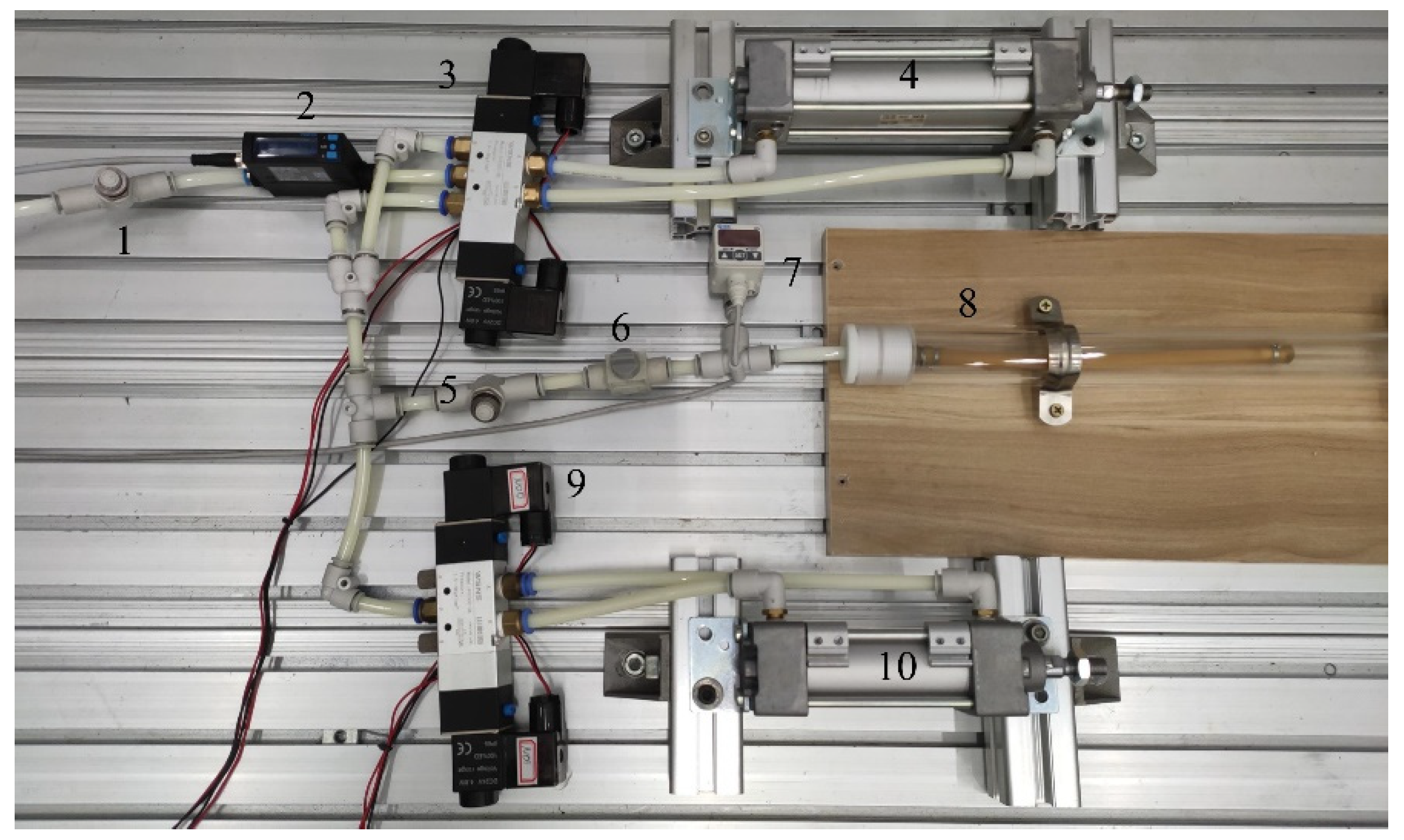

Section 3 of this paper illustrates the energy-saving circuit design and energy efficiency analysis modeling based on the accumulator. Then in this section, selecting the appropriate cylinder to help analyze the energy efficiency, the energy characteristics of the energy-saving circuit are verified by experiments, and the exhaust energy-saving characteristics of the pneumatic system under different working conditions are studied. The traditional pneumatic system is used as a benchmark to compare the energy-saving efficiency of the system with an energy accumulator. When verifying the energy-saving efficiency, there are three kinds of benchmarks: complete no regulation, partial regulation, and complete regulation. The pressure regulating valve is not used in the complete no regulation system, and the pressure regulating valve is used in one cylinder of the partially regulated system, which can partially reduce the compressed air waste. For the fully regulated system, both cylinders use pressure regulating valves, reducing the compressed air waste of the two cylinders. Meanwhile, the fully regulated system has equivalent force output with the system with a pneumatic strain energy accumulator. In conclusion, the fully regulated system is selected as the energy-saving benchmark, which determines the energy efficiency improvement due to the added strain energy accumulator.

The mathematical model of energy-saving circuit has been established; because the energy-saving efficiency is expressed in the form of ratio, it can be expressed indirectly by comparing the air consumption of the system.

4.2. Experimental Condition Design

The selected cylinder models from SMC Company are MDBL32-150Z, MDBL32-100Z, and MDBL32-50Z. Different displacement ratios are obtained by combining different cylinders. When the supply pressure is 0.3 MPa, different cylinder combinations and strokes are shown in

Table 1.

In

Table 1, I to VI are the combination ratio codes of primary and secondary cylinders with different stroke ratios;

x represents the stroke number of the primary cylinder and

y represents the stroke number of the secondary cylinder. In the combination of I, III, and V, the pneumatic strain energy accumulator recovers the compressed air discharged from the operation of the larger stroke cylinder to supply air to the smaller stroke cylinder. In this case, the operation stroke of the primary cylinder is greater than that of the secondary cylinder. In the combination of II, IV, and VI, the pneumatic strain energy accumulator recovers the compressed air discharged from the operation of the smaller stroke cylinder to supply air to the larger stroke cylinder. In this case, the primary cylinder operates multiple strokes, and the operation stroke of the secondary cylinder is greater than or equal to that of the primary cylinder.

In the energy-saving system, after the primary and secondary cylinders complete one stroke respectively, there is no residual air in type V and VI combined pneumatic strain energy accumulator; that is, the exhausted air from the recovered primary cylinder is just enough to supply the complete stroke for the secondary cylinder. This situation is an ideal case for exhaust recovery and energy saving with a strain energy accumulator. For types I, II, III, and IV, there is residual air in the pneumatic strain energy accumulator. Although this part of the air is recovered, it cannot be fully utilized. In order to fully recover the air discharged from the operation of the primary cylinder during the next operation, this part of residual air needs to be discharged through the quick exhaust valve installed at the air inlet of the accumulator, which will cause second energy waste.

4.3. Energy-Saving Efficiency Analysis

For the above energy-saving system, first run 20 cycles to weaken the influence of rubber airbag Mullins effect [

16]. Then run 10 complete cycles to determine the air consumption of the whole energy-saving system through the amount of air entering the primary cylinder. The air consumption of primary and secondary cylinders under the benchmark system is shown in

Table 2 and

Table 3, which are measured under the air supply pressure of 0.158 MPa and 0.113 MPa for a complete stroke. According to

Table 1, the average air consumption with various types of systems (with different cylinder combinations) is shown in

Table 4.

This part studies the efficiency of energy loss with the pneumatic strain energy accumulator; the air consumption can be used as an indirect expression of energy loss, and its ratio is consistent. Based on Formula (9), the energy-saving efficiency of the system under different working conditions can be calculated according to the data from

Table 2,

Table 3 and

Table 4. The energy-saving efficiency of the energy-saving circuit based on the combination of different cylinder stroke ratios in

Table 1 is shown in

Table 5. The residual air ratio means the percentage of residual air in the accumulator compared to the total recovered air from the primary cylinder after finishing the motion stroke of the secondary cylinder.

From

Table 5, it can be seen that the energy-saving efficiency in systems I, III, and V is lower than that of types II, IV, and VI. This is because the primary cylinder with a large stroke needs to overcome the backpressure for a long time and consume more compressed air. At the same time, when the energy-saving device recovers the compressed air discharged to supply air to the smaller stroke secondary cylinder, the work done by the expansion energy will cause the secondary cylinder to run additional strokes. Under the condition of recovering the same energy, the smaller stroke secondary cylinder will run more stroke, while for the large stroke secondary cylinder, the work done by the expansion energy is not enough to make it run a completed stroke.

Comparing the systems VI, IV, and II, with three smaller stroke preliminary cylinders and larger stroke secondary cylinders, it can be seen that the energy-saving efficiency of system VI increases significantly because the air recovered by pneumatic strain energy accumulator is fully utilized. However, for systems IV and II, the energy recovered by the accumulator is not fully utilized after the corresponding stroke is completed. The remaining compressed air is discharged into the atmosphere through the quick exhaust valve, resulting in compressed air re-waste. From the above analysis, it can be seen that when the pneumatic strain energy accumulator is applied to the pneumatic system for exhausted air recovery and energy saving, the ideal circuit combination is that the compressed air recovered by the accumulator from the upstream pneumatic actuator is fully supplied to the downstream pneumatic actuator as much as possible. This result further illustrates the design and calculation necessity for the accumulator size in

Section 2.2, which was neglected in reference [

12].

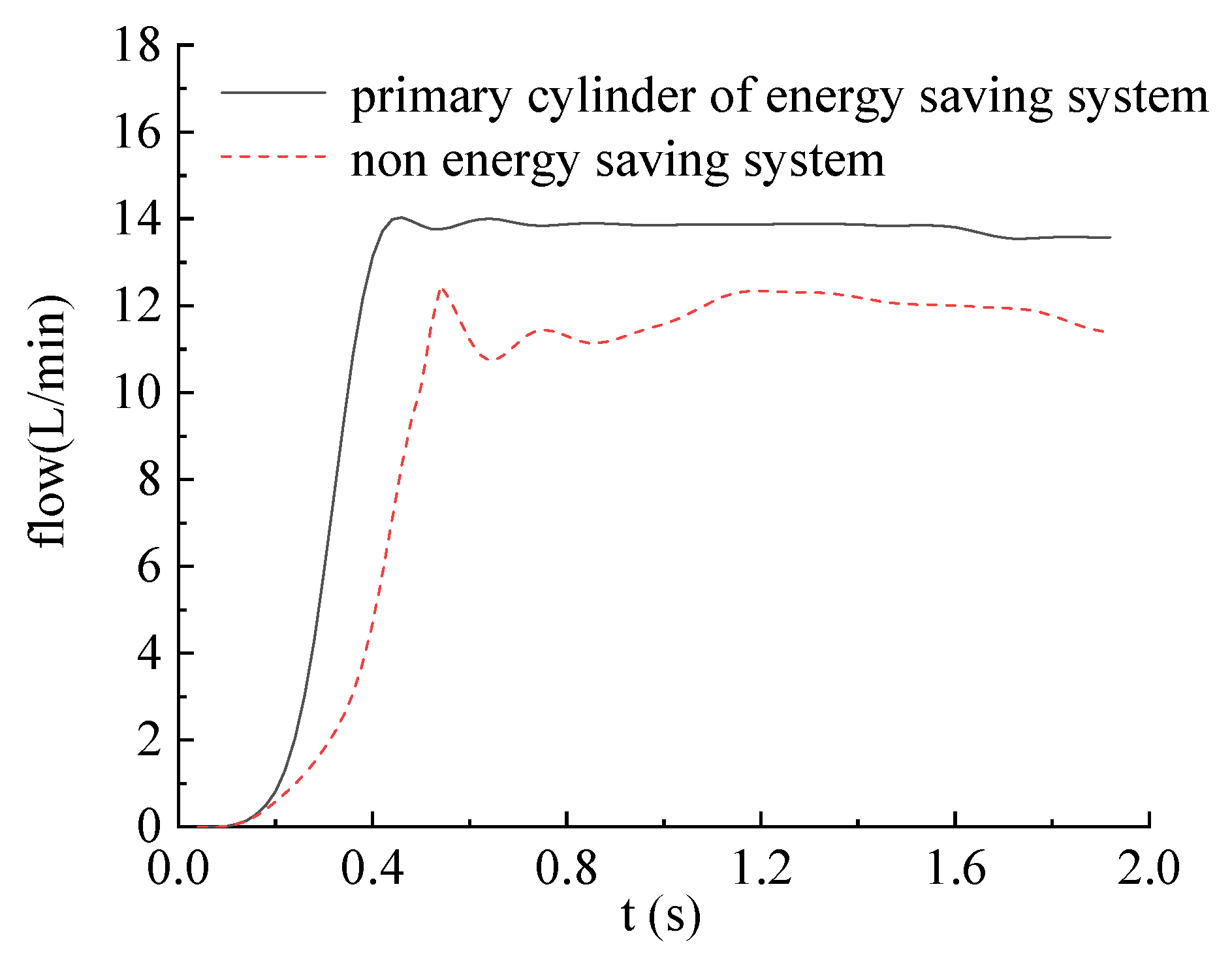

4.4. System Operation Stability Analysis

Although the additional pneumatic accumulator will improve the energy efficiency of a pneumatic system, when the pneumatic strain energy accumulator is connected to the exhaust end of the cylinder for compressed air recovery, it will inevitably produce back pressure, which will affect the cylinder running speed and motion stability. In order to study the stability characteristics of pneumatic system, the concept of volatility is introduced. By comparing the volatility of the system, the effect of pneumatic strain energy accumulator on the operation stability of the system is studied. This section analyzes the change of airflow into the cylinder when the main cylinder of the two systems extends the stroke and then estimates the influence of pneumatic strain energy accumulator on the system operation stability, which was neglected in the reference [

12]. The fluctuation rate of intake airflow of a primary cylinder of the energy-saving system and reference system is shown in

Table 6. The change of intake flow of the primary cylinder with a stroke of 200 mm under the operation of the two systems is shown in

Figure 9.

It can be seen from

Table 6 and

Figure 9 that under the air supply pressure of 0.3 MPa, the inlet flow fluctuation rate of the primary cylinder of different combinations of energy-saving systems is significantly lower than that of the primary cylinder of non-energy-saving systems, indicating that the application of pneumatic strain energy accumulator to the exhaust end can not only improve the stability of cylinder operation but also play a buffer role.

It is worth noting that to ensure that the two systems have equivalent output force, the energy-saving system with a strain energy accumulator needs higher air supply pressure, which makes the air compressor need to produce higher pressure compressed air, so it needs to consume more power. Moreover, although the accumulator can provide stable expansion pressure and contraction pressure, the acquisition of this pressure needs a time process. That is to say, at the end of the accumulator deflating stage, there may be too low of a pressure to drive the movement of the secondary cylinder. Therefore, a certain size redundancy should be considered in the accumulator design.

5. Conclusions

In this paper, an energy-saving circuit with exhaust recovery based on a strain energy accumulator with constant pressure energy storage and discharge is proposed, and the system energy-saving efficiency model is established. Firstly, the size of the airbag and rigid shield and the maximum energy storage capacity of the device are determined. Then the loop energy-saving mathematical model is established using air consumption. Finally, a test bed is built to verify the energy-saving efficiency. The main conclusions are as follows:

- (1)

Due to the additional strain energy accumulator, under given different stroke ratio and air supply pressure, the energy-saving system can recover the compressed air discharged from the primary cylinder to supply air to the secondary cylinder, which improves energy efficiency. The variation range of energy-saving efficiency is 21.1–54.1%, respectively. Results show that applying a pneumatic strain energy accumulator to an exhaust recovery system for compressed air energy saving has a good energy-saving effect.

- (2)

Residual air in the accumulator has a negative impact on energy-saving efficiency. In practical application, the recovered pressure energy of the pneumatic strain energy accumulator and the pressure energy consumed by secondary components should be matched as much as possible to reduce the generation of residual air.

- (3)

Under the air supply pressure of 0.3 MPa, the inlet flow fluctuation rates of the primary cylinder of the energy-saving system with different cylinder combinations are 2.45%, 2.66%, 2.25%, and 1.91%, respectively, while the inlet flow fluctuation rates of the primary cylinder of the benchmark system are 6.78%, 5.37%, 5.53%, and 4.69%, respectively. It is concluded that applying a pneumatic strain energy accumulator for exhaust recovery and energy saving can improve the stability of cylinder operation.

The research of this paper has a good energy-saving effect for traditional pneumatic systems. However, the accumulator is not ready for practical application. The next step will be to arrange case studies with a real system to see the actual energy savings. Furthermore, the existing accumulator only produces a low supply pressure, about 0.1 MPa; research in the future needs to use better hyperelastic materials or structures to achieve new accumulators.