A Review of the Existing Potentials in Biodiesel Production in Iran

Abstract

1. Introduction

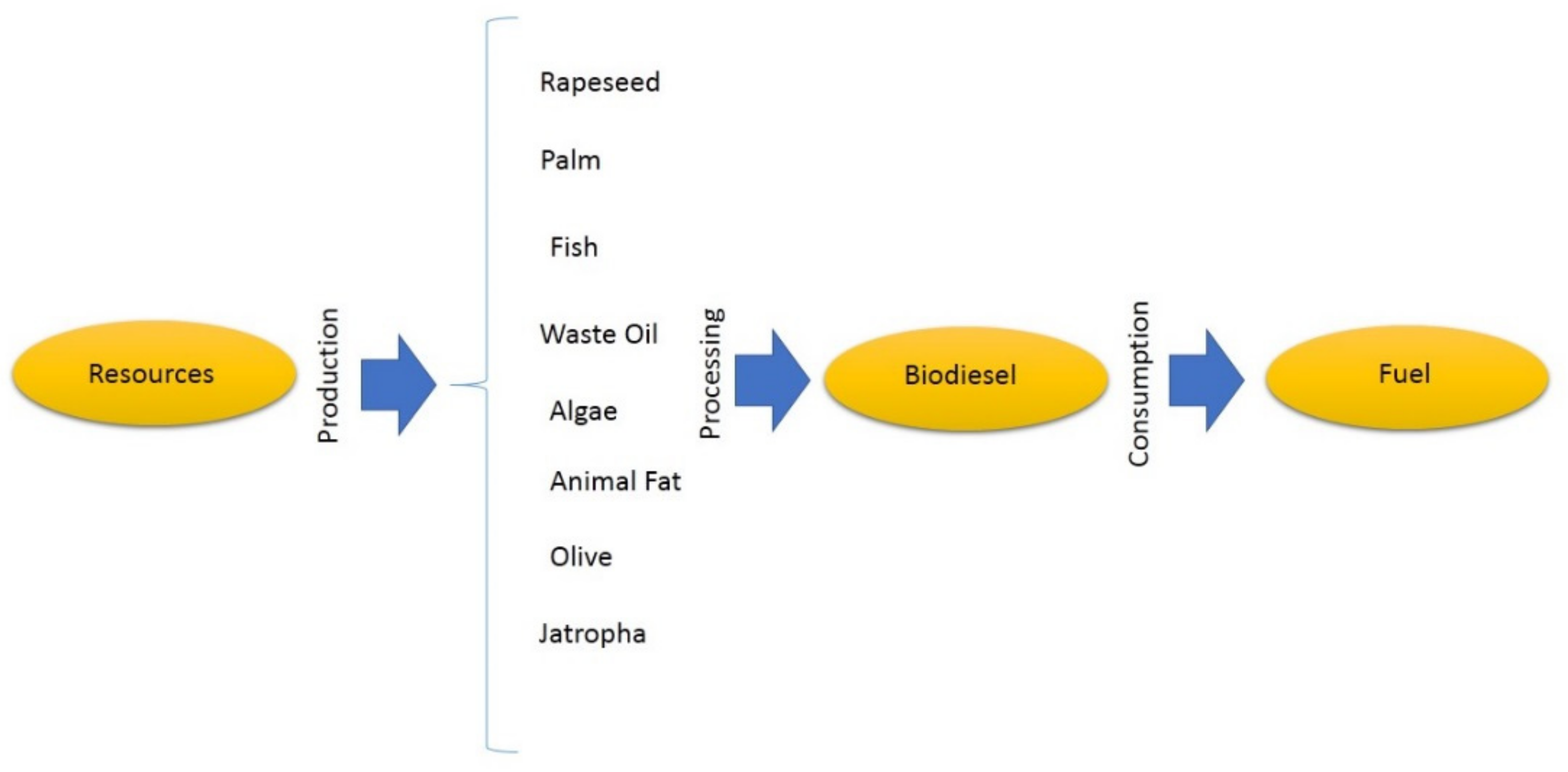

2. Production of Biodiesel

3. Production of Biodiesel in Iran

3.1. Production of Biodiesel from Rapeseed (Canola) Oil

3.2. Production of Biodiesel from Palm Oil

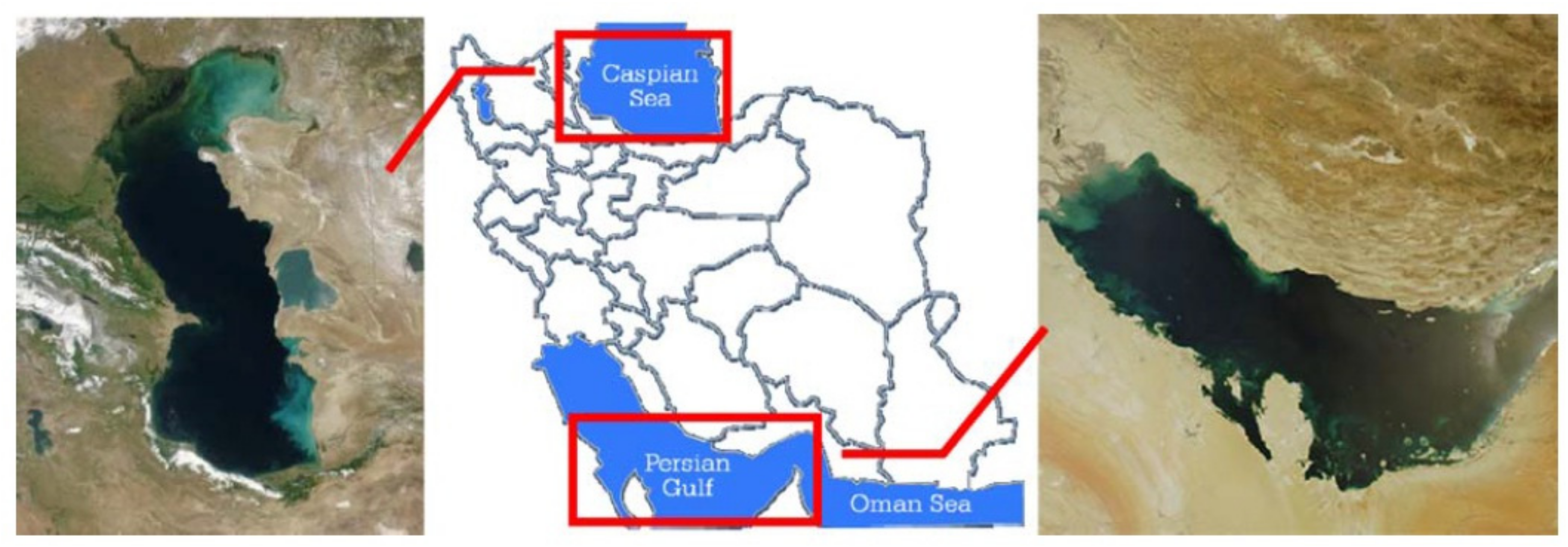

3.3. Production of Biodiesel from Fish oil

3.4. Production of Biodiesel from Waste Oil

3.5. Production of Biodiesel from Algae

3.6. Production of Biodiesel from Animal Fat

3.7. Production of Biodiesel from Olive Oil

3.8. Production of Biodiesel from Jatropha Oil

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nour, M.; Attia, A.M.A.; Nada, S.A. Improvement of CI engine combustion and performance running on ternary blends of higher alcohol (Pentanol and Octanol)/hydrous ethanol/diesel. Fuel 2019, 251, 10–22. [Google Scholar] [CrossRef]

- NS Energy Staff Writer, Top Ten Countries with the World’s Largest Oil Reserves, from Venezuela to Iraq, 4 November 2020. Available online: https://www.nsenergybusiness.com/features/newstop-ten-countries-with-worlds-largest-oil-reserves-5793487/ (accessed on 4 November 2020).

- Campbell, C.J. The Coming oil Crisis; Multi-Science Publishing Company: Brentwood, UK, 2004. [Google Scholar]

- Arrhenius, S. On the influence of carbonic acid in the air upon the temperature of the ground. London Edinburgh Dublin Philos. Mag. J. Sci. 1896, 41, 237–275. [Google Scholar] [CrossRef]

- Fleming, J.R. What role did G.S. calendar play in reviving the CO2 theory of global climate change? In Presidential Symposium on the History of the Atmospheric Sciences: People, Discoveries, and Technologies; American Meteorological Society: Boston, MA, USA, 2002. [Google Scholar]

- Spencer, W.R. Global warming, cold war, and the evolution of research plans. Hist. Stud. Phys. Biol. Sci. 1997, 7, 319–356. [Google Scholar]

- Spencer, W.R. The Discovery of Global Warming; Center for the History of Physics, American Institute of Physics: College Park, MD, USA, 2005. [Google Scholar]

- Nabi, M.N.; Rahman, M.M.; Akhter, M.S. Biodiesel from cotton seed oil and its effect on engine performance and exhaust emissions. Appl. Therm. Eng. 2009, 29, 2265–2670. [Google Scholar] [CrossRef]

- Raheman, H.; Phadatare, A.G. Diesel engine emissions and performance from blends of karanja methyl ester and diesel. Biomass Bioenergy 2004, 27, 393–397. [Google Scholar] [CrossRef]

- Shadidi, B.; Alizade, H.H.A.; Ghobadian, B. The effect of a novel hybrid nano-catalyst in diesel-biodiesel fuel blends on the energy balance of a diesel engine. Energy Equip. Syst. 2017, 5, 59–69. [Google Scholar]

- Godiganur, S.; Murthy, C.H.S.; Reddy, R.P. 6BTA 5.9 G2-1Cummins engine performance and emission tests using methyl ester mahua (Madhuca indica) oil/diesel blends. Renew. Energy 2009, 34, 2172–2177. [Google Scholar] [CrossRef]

- Baiju, B.; Naik, M.K.; Das, L.M. A comparative evaluation of compression ignition engine characteristics using methyl and ethyl esters of Karanja oil. Renew. Energy 2009, 34, 1616–1621. [Google Scholar] [CrossRef]

- Shahid, E.M.; Jamal, Y. A review of biodiesel as vehicular fuel. Renew. Sustain. Energy Rev. 2008, 12, 2484–2494. [Google Scholar] [CrossRef]

- World Most Polluted Cities 2019. Available online: https://www.iqair.com/us/world-most-polluted-cities (accessed on 10 September 2020).

- Goodstein, D. Out of Gas: The End of the Age of Oil; Norton and Company: New York, NY, USA, 2004. [Google Scholar]

- Attanasi, E.D.; Root, D.H. The enigma of oil and gas field growth. AAPG Bull. 1994, 78, 321–332. [Google Scholar]

- Laherrere, J. World oil supply—What goes up must come down: When will it peak? Oil Gas J. 1999, 97, 57–64. [Google Scholar]

- Carlton, J. An electricity crunch may force the nation in to tough trade offs. Wall Street J. 2000, 10, A1. [Google Scholar]

- Meadows, D.H.; Meadows, D.L.; Randers, J. Beyond the Limits: Confronting Global Collapse Envisioning a Sustainable Future; Chelsea Green Publishing: Chelsea, VT, USA, 1992; p. 300. [Google Scholar]

- Weatherford, J. Savage Sand Civilization: Who Will Survive? Crown: New York, NY, USA, 1994; p. 310. [Google Scholar]

- Ghobadian, B. Liquid biofuels potential and outlook in Iran. Renew. Sustain. Energy Rev. 2012, 16, 4379–4388. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Kulchitskiy, A.R.; Nour, M.; El-Seesy, A.I.; Nada, S.A. The influence of castor biodiesel blending ratio on engine performance including the determined diesel particulate matters composition. Energy 2022, 239, 121951. [Google Scholar] [CrossRef]

- Ghobadian, B.; Najafi, G.; Rahimi, H.; Yusaf, T.F. Future of renewable energies in Iran. Renew. Sustain. Energy Rev. 2009, 13, 689–695. [Google Scholar] [CrossRef]

- Nour, M.; Sun, Z.; El-Seesy, A.I.; Li, X. Experimental evaluation of the performance and emissions of a direct-injection compression-ignition engine fueled with n-hexanol–diesel blends. Fuel 2021, 302, 121144. [Google Scholar] [CrossRef]

- Nour, M.; Nada, S.; Li, X. Experimental study on the combustion performance of a stationary CIDI engine fueled with 1-heptanol-diesel mixtures. Fuel 2022, 312, 122902. [Google Scholar] [CrossRef]

- Nour, M.; Elseesy, A.I.; Attia, A.; Li, X.; Nada, S. Adding n-butanol, n-heptanol, and n-octanol to improve vaporization, combustion, and emission characteristics of diesel/used frying oil biodiesel blends in DICI engine. Environ. Prog. Sustain. Energy. 2021, 40, 13549. [Google Scholar] [CrossRef]

- Shadidi, B.; Alizade, H.H.A.; Najafi, G. Performance and exergy analysis of a diesel engine run on petrodiesel and biodiesel blends containing mixed CeO2 and MoO3 nanocatalyst. Biofuels 2020, 13, 1–7. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Nour, M.; El-Seesy, A.I.; Nada, S.A. The effect of castor oil methyl ester blending ratio on the environmental and the combustion characteristics of diesel engine under standard testing conditions. Sustain. Energy Technol. Assess. 2020, 42, 100843. [Google Scholar] [CrossRef]

- McDonnell, K.P.; Ward, S.M.; McNulty, P.B. Results of engine and vehicle testing of semi-refined rapeseed oil. In Proceedings of the 10th International Congress 1999, Cambria, Australia, 26–29 September 1999. [Google Scholar]

- Balat, M.; Balat, H. Progress in biodiesel processing. Appl. Energy 2010, 87, 1815–1835. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel—A Realistic Fuel Alternative for Diesel Engines; Springer-Verlag London Limited: London, UK, 2008. [Google Scholar]

- Lin, L.; Cunshan, Z.; Vittayapadung, S.; Xiangqian, S.; Mingdong, D. Opportunities and challenges for biodiesel fuel. Appl. Energy 2011, 88, 1020–1031. [Google Scholar] [CrossRef]

- Srivastava, A.; Prasad, R. Triglycerides-based diesel fuels. Renew. Sustain. Energy Rev. 2000, 4, 111–133. [Google Scholar] [CrossRef]

- Canakci, M.; Sanli, H. Biodiesel production from various feedstocks and their effects on the fuel properties. J. Ind. Microbiol. Biotechnol. 2010, 35, 431–441. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A. Handbook of Plant-Based Biofuels; Taylor & Francis Group: Oxfordshire, UK, 2008. [Google Scholar]

- Demirbas, A.H.; Demirbas, I. Importance of rural bioenergy for developing countries. Energy Convers. Manag. 2007, 48, 2386–2398. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Jun, Y.D.; Lee, K.B. Performance and emission study of preheated Jatropha oil on medium capacity diesel engine. Energy 2010, 35, 2484–2492. [Google Scholar] [CrossRef]

- Shahid, E.M.; Jamal, J. Production of biodiesel: A technical review. Renew. Sustain. Energy Rev. 2011, 15, 4732–4745. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B. Development of biodiesel: Current scenario. Renew. Sustain. Energy Rev. 2009, 13, 1646–1651. [Google Scholar] [CrossRef]

- Parawira, W. Biodiesel production from Jatropha curcas: A review. Sci. Res. Essays 2010, 5, 1796–1808. [Google Scholar]

- Jain, S.; Sharma, M.P. Biodiesel production from Jatropha curcas oil. Renew. Sustain. Energy Rev. 2010, 14, 3140–3147. [Google Scholar] [CrossRef]

- Rashid, U.; Anwar, F.; Moser, B.R.; Knothe, G. Moringa oleifera oil: A possible source of biodiesel. Bioresour. Technol. 2008, 99, 8175–8179. [Google Scholar] [CrossRef] [PubMed]

- Sharma, Y.C.; Singh, B.; Upadhyay, S.N. Advancements in development and characterization of biodiesel: A review. Fuel 2008, 87, 2355–2373. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef]

- Singh, S.P.; Singh, D. Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: A review. Renew. Sustain. Energy Rev. 2010, 14, 200–216. [Google Scholar] [CrossRef]

- Karmakar, A.; Karmakar, S.; Mukherjee, S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour. Technol. 2010, 101, 7201–7210. [Google Scholar] [CrossRef] [PubMed]

- Yusuf, N.N.A.N.; Kamarudin, S.K.; Yaakub, Z. Overview on the current trends in biodiesel production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. A comprehensive review of biodiesel as an alternative fuel for compression ignition engine. Renew. Sustain. Energy Rev. 2016, 57, 799–821. [Google Scholar] [CrossRef]

- Iranian Agricultural Statistics. Available online: https:/www.maj.ir/Index.aspx?page_=form&lang=1&PageID=11583&tempname=amar&sub=65&methodName=ShowModuleContent (accessed on 4 November 2020).

- Mirabdoli, M.; Zahedi, A.; Shayan Nezhad, A. Commercial optimization of biodiesel production from rapeseed oil as a clean fuel for thermal power plants. Modares Mech. Eng. 2011, 16, 135–142. (In Persian) [Google Scholar]

- Almasi, S.; Ghobadian, B.; Najafi, G. Optimasiton of biodiesel production process from Non-edible rapeseed using response surface method (RSM). Fuel Combust. 2018, 11, 1–18. (In Persian) [Google Scholar]

- Yazdanian, E.; Gholipour Zanjani, N.; Pirzaman, A.K. Effects of important parameters on biodiesel production using heterogeneous potassium carbonate/alumina catalyst and rapeseed oil. Fuel Combust. 2017, 10, 17–27. (In Persian) [Google Scholar]

- Hosseinzadeh Samani, B.; Ansari Samani, M.; Ebrahimi, R.; Esmaeili, Z.; Ansari Ardali, A. Energy, exergy, and environmental analysis and optimization of biodiesel production from rapeseed using ultrasonic waves. J. Renew. Energy Environ. 2020, 7, 51–61. [Google Scholar]

- Salehi, M.A.; Ahmadi, N. Optimization of biodiesel production from rapeseed using pulsed electric field method. J. Env. Sci. Tech. 2019, 20, 113–124. (In Persian) [Google Scholar]

- Hajar, M.; Vahabzadeh, F. Evaluation of artificial neural networks for modeling enzymatic biodiesel production from canola oil. In Proceedings of the 8th International Chemical Engineering Congress & Exhibition, Kish, Iran, 24–27 February 2014. [Google Scholar]

- Nayebzadeh, H.; Haghighi, M.; Saghatoleslami, N.; Alaei, S.; Yousefi, S. Texture/phase evolution during plasma treatment of microwave-combustion synthesized KOH/Ca12Al14O33-C nanocatalyst for reusability enhancement in conversion of canola oil to biodiesel. Renew. Energy 2019, 139, 28–39. [Google Scholar] [CrossRef]

- Khatibi, M.; Khorasheh, F.; Larimi, A. Biodiesel production via transesterification of canola oil in the presence of Na-K doped CaO derived from calcined eggshell. Renew. Energy 2021, 163, 1626–1636. [Google Scholar] [CrossRef]

- Yousefi, M.; Habibi, Z.; Brask, J.; Mohammadi, M.; Babaki, M. Preparation of highly reusable biocatalysts by immobilization of lipases on epoxy-functionalized silica for production of biodiesel from canola oil. Biochem. Eng. J. 2015, 101, 23–31. [Google Scholar]

- Abdolrahman Karim, A.H.; Tabasizadeh, M.; Farzad, A.; Rohani, A. Modeling and assessment the effective parameters of biodiesel production from date seed oil via conventional, microwave and Ultrasonic methods. Fuel Combust. 2018, 11, 29–46. (In Persian) [Google Scholar]

- Zare Sani, H.; Hassan Beigi, S.R.; Paqaleh, A.; Ghobadian, B.; Saberi Moghadam, M. Effect of moisture content, particle size and solvent type on oil extraction from mazafati date kernel and biodiesel production by ultrasound. J. Mech. Agric. Mach. Res. 2018, 7, 25–36. (In Persian) [Google Scholar]

- Foroutan, R.; Esmaeili, H.; Kosari Fard, M. Measuring the properties of the biodiesel produced from palm kernel oil and its combination with the commercial diesel fuel. J. Env. Sci. Tech. 2019, 21, 221–229. (In Persian) [Google Scholar]

- Zarein, M.; Khoshtaghaza, M.H.; Ghobadian, B.; Ameri Mahabadi, H. Prediction and optimization of palm biodiesel characteristics using permittivity properties and response surface methodology. Fuel Combust. 2018, 11, 15–27. (In Persian) [Google Scholar]

- Pourhoseini, S.H.; Namvar-Mahboub, M.; Hosseini, E.; Alimoradi, A. A comparative exploration of thermal, radiative and pollutant emission characteristics of oil burner flame using palm oil biodiesel diesel blend fuel and diesel fuel. Energy 2021, 217, 119338. [Google Scholar] [CrossRef]

- Shahedi, M.; Habibi, Z.; Yousefi, M.; Brask, J.; Mohammadi, M. Improvement of biodiesel production from palm oil by co-immobilization of Thermomyces lanuginosa lipase and Candida Antarctica lipase B: Optimization using response surface methodology. Int. J. Biol. Macromol. 2021, 170, 490–502. [Google Scholar] [CrossRef] [PubMed]

- Shahedi, M.; Yousefi, M.; Habibi, M.; Mohammadi, M.; As’habi, M.A. Co-immobilization of Rhizomucor miehei lipase and Candida antarctica lipase B and optimization of biocatalytic biodiesel production from palm oil using response surface methodology. Renew. Energy 2019, 141, 847–857. [Google Scholar] [CrossRef]

- Yahyaee, R.; Ghobadian, B.; Najafi, G. Waste fish oil biodiesel as a source of renewable fuel in Iran. Renew. Sustain. Energy Rev. 2013, 17, 312–319. [Google Scholar] [CrossRef]

- Zarein, M.; Khoshtaghaza, M.H.; Ghobadian, B.; Ameri Mahabadi, H.; Yahyaee, R. Prediction and Optimization of Fish Biodiesel Characteristics Using Permittivity Properties. J. Agr. Sci. Tech. 2019, 21, 309–322. [Google Scholar]

- Yari, N.; Mostafaei, M.; Naderloo, L.; Safieddin Ardebili, S.M. Biodiesel production from fish-waste oil by combining mechanical stirring and microwave. Fuel Combust. 2017, 10, 1–14. (In Persian) [Google Scholar]

- Khanjani, A.; Sobati, M.A. Performance and emission of a diesel engine using different water/waste fish oil (WFO) biodiesel/diesel emulsion fuels: Optimization of fuel formulation via response surface methodology (RSM). Fuel 2021, 288, 119662. [Google Scholar] [CrossRef]

- Zenouzi, A.; Ghobadian, B.; Tavakoli Hashjin, T.; Feyzollahnejad, M.; Bagherpour, H. Effect of the blends of diesel and biodiesel made from waste cooking oil on compression-ignition engine (CI) performance. Fuel Combust. 2008, 1, 54–59. (In Persian) [Google Scholar]

- Hajy Heidar, T.; Tahvildari, K. Efficient synthesis of biodiesel from waste cooking oil catalysed by Al2O3 impregnated with NaOH. J. Chem. Pet. Eng. 2015, 49, 143–151. [Google Scholar]

- Hasheminezhad, A.; Hashemi, S.J.; Tabatabaie, R. Evaluation of operative factors on conversion efficiency of biodiesel production from waste cooking oil. Iranica J. Energy Environ. 2018, 9, 100–104. [Google Scholar]

- Alavi, N.; Eslami, A.; Majlessi Nasr, M.; Masihi, N. Optimization of biodiesel production process from restaurant waste frying oils in the presence of homogeneous catalyst. J. Environ. Health Eng. 2019, 7, 83–93. (In Persian) [Google Scholar] [CrossRef][Green Version]

- Khoobbakht, G.; Karimi, M. Analysis of the parameters affecting on the performance and energy efficiency of biodiesel production from waste oil. J. Env. Sci. Tech. 2020, 22, 311–320. (In Persian) [Google Scholar]

- Shadidi, B.; Haji Agha Alizade, H.; Ghobadian, B. Feasibility of using biodiesel herbal fuel and nano cerium and molybdenum oxides as additive to diesel fuel in evaluating the energy balance of the diesel. J. Plant Res. 2018, 31, 348–358. (In Persian) [Google Scholar]

- Pirouzmand, M.; Mahdavi Anakhatoon, M.; Ghasemi, Z. One-step biodiesel production from waste cooking oils over metal incorporated MCM-41; positive effect of template. Fuel 2018, 216, 296–300. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Hosseinpour, S.; Tabatabaei, M.; Mojarab Soufiyan, M. Multi-objective exergetic and technical optimization of a piezoelectric ultrasonic reactor applied to synthesize biodiesel from waste cooking oil (WCO) using soft computing techniques. Fuel 2019, 235, 100–112. [Google Scholar] [CrossRef]

- Mohadesi, M.; Aghel, B.; Maleki, M.; Ansari, A. The use of KOH/Clinoptilolite catalyst in pilot of microreactor for biodiesel production from waste cooking oil. Fuel 2020, 263, 116659. [Google Scholar] [CrossRef]

- Helmi, M.; Tahvildari, K.; Hemmati, A.; Aberoomand azar, P.; Safekordi, A. Phosphomolybdic acid/graphene oxide as novel green catalyst using for biodiesel production from waste cooking oil via electrolysis method: Optimization using with response surface methodology (RSM). Fuel 2021, 287, 119528. [Google Scholar] [CrossRef]

- Babaki, M.; Yousefi, M.; Habibi, Z.; Mohammadi, M. Process optimization for biodiesel production from waste cooking oil using multi-enzyme systems through response surface methodology. Renew. Energy 2017, 105, 465–472. [Google Scholar] [CrossRef]

- Fereidooni, L.; Mehrpooya, M. Experimental assessment of electrolysis method in production of biodiesel from waste cooking oil using zeolite/chitosan catalyst with a focus on waste biorefinery. Energy Convers. Manag. 2017, 147, 145–154. [Google Scholar] [CrossRef]

- Mohadesi, M.; Moradi, G.; Ghanbari, M.; Moradi, M.J. Investigating the effect of n-hexane as solvent on waste cooking oil conversion to biodiesel using CaO on a new support as catalyst. Measurement 2019, 135, 606–612. [Google Scholar] [CrossRef]

- Dehghani Soufi, M.; Ghobadian, B.; Mousavi, S.M.; Najafi, G.; Aubin, J. Valorization of waste cooking oil based biodiesel for biolubricant production in a vertical pulsed column: Energy efficient process approach. Energy 2019, 189, 116266. [Google Scholar] [CrossRef]

- Mehrasbi, M.R.; Mohammadi, J.; Peyda, M.; Mohammadi, M. Covalent immobilization of Candida antarctica lipase on core-shell magnetic nanoparticles for production of biodiesel from waste cooking oil. Renew. Energy 2017, 101, 593–602. [Google Scholar] [CrossRef]

- Mohadesi, M.; Aghel, A.; Maleki, M.; Ansari, A. Production of biodiesel from waste cooking oil using a homogeneous catalyst: Study of semi-industrial pilot of microreactor. Renew. Energy 2019, 136, 677–682. [Google Scholar] [CrossRef]

- Aghel, B.; Mohadesi, M.; Ansari, A.; Maleki, M. Pilot-scale production of biodiesel from waste cooking oil using kettle limescale as a heterogeneous catalyst. Renew. Energy 2019, 142, 207–214. [Google Scholar] [CrossRef]

- Badoei-dalfard, A.; Malekabadi, S.; Karami, Z.; Sargazi, G. Magnetic cross-linked enzyme aggregates of Km12 lipase: A stable nanobiocatalyst for biodiesel synthesis from waste cooking oil. Renew. Energy 2019, 141, 874–882. [Google Scholar] [CrossRef]

- Dehghani, S.; Haghighi, M. Sono-enhanced dispersion of CaO over Zr-Doped MCM-41 bifunctional nanocatalyst with various Si/Zr ratios for conversion of waste cooking oil to biodiesel. Renew. Energy 2020, 153, 801–812. [Google Scholar] [CrossRef]

- Mohammadshirazi, A.; Akram, A.; Rafiee, S.; Bagheri Kalhor, E. Energy and cost analyses of biodiesel production from waste cooking oil. Renew. Sustain. Energy Rev. 2014, 33, 44–49. [Google Scholar] [CrossRef]

- Ghobadian, B.; Rahimi, H.; Nikbakht, A.M.; Najafi, G.; Yusaf, T.F. Diesel engine performance and exhaust emission analysis using waste cooking biodiesel fuel with an artificial neural network. Renew. Energy 2009, 34, 976–982. [Google Scholar] [CrossRef]

- Janaun, J.; Ellis, N. Perspectives on biodiesel as a sustainable fuel. Renew. Sustain. Energy Rev. 2010, 14, 1312–1320. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae beats bioethanol. Trends Biotechnol. 2008, 26, 126–131. [Google Scholar] [CrossRef]

- Li, Y.; Horsman, M.; Wu, N.; Lan, C.Q.; Dubois-Calero, N. Biofuels from microalgae. Biotechnol. Prog. 2008, 24, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Lu, Y.; Gao, C.; Wu, Q. Alga-based biodiesel production and optimization using sugar cane as the feedstock. Energy Fuels 2009, 23, 4166–4173. [Google Scholar] [CrossRef]

- Singh, J.; Gu, S. Commercialization potential of microalgae for biofuels production. Renew. Sustain. Energy Rev. 2010, 14, 2596–2610. [Google Scholar] [CrossRef]

- Luiten, E.E.M.; Akkerman, I.; Koulman, A.; Kamermans, P.; Reith, H.; Barbosa, M.J.; Sipkema, D.; Wijffels, R. Realizing the promises of marine biotechnology. Biomol. Eng. 2003, 20, 429–439. [Google Scholar] [CrossRef]

- Najafi, G.; Ghobadian, B.; Yusaf, T. Algae as a sustainable energy source for biofuel production in Iran: A case study. Renew. Sustain. Energy Rev. 2011, 15, 3870–3876. [Google Scholar] [CrossRef]

- Shahi, T.; Zenouzi, A.; Beheshti, B.; Almasi, M. Comparison of four lipid extraction methods from microalgae dunaliella sp. for biodiesel production. Iran. J. Chem. Chem. Eng. 2020, 39, 371–378. [Google Scholar]

- Malekahmadi, F.; Khavarinezhad, R.; Soltani, N.; Najafi, F.; Nezhadsatari, T. Investigation of physiological properties of green algae in order to use them as biodiesel fuel. J. Plant Environ. Physiol. 2019, 53, 30–46. (In Persian) [Google Scholar]

- Raoufi, Z.; Mousavi Gargari, S.M.L. Optimization of oil extraction from Haematococcus pluvialis microalgae using response surface method and evaluation of its fatty acid profile in order to biodiesel production. Aquatic Physiol. Biotechnol. 2019, 7, 146–159. (In Persian) [Google Scholar]

- Beldaji, M.T.; Najafi, B.; Hejazi, M.A. Production of biodiesel from Chlorella Vulgaris microalgae and determination of some of its physical and chemical properties. J. Sci. 2010, 78, 99–110. (In Persian) [Google Scholar]

- Nematian, T.; Salehi, Z.; Shakeri, A. Conversion of bio-oil extracted from Chlorella vulgaris micro algae to biodiesel via modified superparamagnetic nano-biocatalyst. Renew. Energy 2020, 146, 1796–1804. [Google Scholar] [CrossRef]

- Valizadeh Derakhshan, M.; Nasernejad, B.; Dadvar, M.; Adabi, J.; Abbaspour, F. A novel pretreatment protocol for algal oil extraction for biodiesel production. In Proceedings of the 8th International Chemical Engineering Congress & Exhibition, Kish, Iran, 24–27 February 2014. [Google Scholar]

- Abbaspour Aghdam, F.; Arabian, D.; Khalilzadeh, R. Optimization of electrocoagulation for microalgae harvesting in biodiesel production. In Proceedings of the 8th International Chemical Engineering Congress & Exhibition, Kish, Iran, 24–27 February 2014. [Google Scholar]

- Najafi, B.; Torkian, M.; Hejazi, M.A.; Zamzamian, A.A. Effect of microalgae biodiesel on performance parameters and exhaust emissions from IDI diesel engine. Fuel Combust. 2011, 4, 29–42. (In Persian) [Google Scholar]

- Malakootian, M.; Hatami, B.; Dolatshahi, S.; Rajabzadeh, A. Survey of Solvent type and drying of biomass effects on lipidextraction from Nannochloropsis Oculata for biodiesel production. Iran. J. Health Environ. 2014, 7, 11–20. (In Persian) [Google Scholar]

- Ahmady asbchin, S.; Chaichi, M.J.; Mahmoudi, S. Effect of heavy metals on amount of biodiesel produced from microalgae Cyclotella Caspian Sea. In Proceedings of the 7th Seminar of Chemistry and Environment, Tehran, Iran, 26–27 August 2015. [Google Scholar]

- Forootan, M.; Hosseinzadeh Samani, B.; Lotfalian, A.; Rostami, S.; Esmaeili, Z.; Ansari Samani, M. Assessment of environmental impacts and energy of biodiesel production from chicken fat by life cycle assessment method. J. Renew. Energy Environ. 2019, 6, 25–33. [Google Scholar]

- Didar, Z.A. Comparative study of biodiesel production from beef bone marrow. J. Food Biosci. Technol. 2015, 5, 61–66. [Google Scholar]

- Keihani, M.; Esmaeili, H.; Rouhi, P. Biodiesel production from chicken fat using nano-calcium oxide catalyst and improving the fuel properties via blending with diesel. Phys. Chem. Res. 2018, 6, 521–529. [Google Scholar]

- Seffati, K.; Honarvar, B.; Esmaeili, H.; Esfandiari, N. Enhanced biodiesel production from chicken fat using CaO/CuFe2O4 nanocatalyst and its combination with diesel to improve fuel properties. Fuel 2019, 235, 1238–1244. [Google Scholar] [CrossRef]

- Karimi Alavijeh, M.; Asadi, N.; Yaghmaei, S. Simulation and economic study of biodiesel production from animal fat waste. J. Pet. Res. 2014, 84, 12–22. (In Persian) [Google Scholar]

- Ansari Ardali, M.; Sadr Ameli, S.M.; Ghobadian, B.; Shamloo, M.R.; Abadi, A. Production of biodiesel (biodiesel) from slaughterhouses for livestock and poultry. Sci. Energy Eng. Manag. 2015, 5, 24–31. (In Persian) [Google Scholar]

- Fayyazi, E.; Ghobadian, B.; Najafi, G.; Hosseinzadeh, B.; Mamat, R.; Hosseinzadeh, J. An ultrasound-assisted system for the optimization of biodiesel production from chicken fat oil using a genetic algorithm and response surface methodology. Ultrason. Sonochem. 2015, 26, 312–320. [Google Scholar] [CrossRef]

- Foroutan, R.; Mohammadi, R.; Ramavandi, B. Waste glass catalyst for biodiesel production from waste chicken fat: Optimization by RSM and ANNs and toxicity assessment. Fuel 2021, 291, 120151. [Google Scholar] [CrossRef]

- Abedi, S.; Tavakoli, O.; Abedi, S. Biofuel production from waste beef tallow oil using ultrasonic power. In Proceedings of the 8th International Chemical Engineering Congress & Exhibition, Kish, Iran, 24–27 February 2014. [Google Scholar]

- Che, F.; Sarantopoulos, I.; Tsoutsos, T.; Gekas, V. Exploring a promising feedstock for biodiesel production in Mediterranean countries: A study on free fatty acid esterification of olive pomace oil. Biomass Bioenergy 2011, 36, 427–431. [Google Scholar] [CrossRef]

- Enweremadu, C.C.; Mbarawa, M.M. Technical aspects of production and analysis of biodiesel from used cooking oil—A review. Renew. Sustain. Energy Rev. 2009, 13, 2205–2224. [Google Scholar] [CrossRef]

- De Graaff, J.; Eppink, L.A.J. Olive oil production and soil conservation in southern Spain, in relation to EU subsidy policies. Land Use Policy 1999, 16, 259–267. [Google Scholar] [CrossRef]

- Rajaeeifar, M.R.; Akram, A.; Ghobadian, B.; Rafiee, S.; Abdi, R. Energy and economic assessment of biodiesel production from olive pomace oil: A lifecycle approach. Iranian J. Biosyst. Eng. 2015, 46, 209–218. (In Persian) [Google Scholar]

- Rajaeeifar, M.R.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental impact assessment of olive pomace oil biodiesel production and consumption: A comparative lifecycle assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Nour, M.; Hassan, H.; Elfasakhany, A.; He, Z.; Mujtaba, M.A. Diesel-oxygenated fuels ternary blends with nano additives in compression ignition engine: A step towards cleaner combustion and green environment. Case Stud. Therm. Eng. 2021, 25, 100911. [Google Scholar] [CrossRef]

| Province | Area Under Cultivation (Hectare) | Rapeseed Production (Ton) |

|---|---|---|

| West Azarbayjan | 4530 | 5536 |

| East Azarbayjan | 4940 | 10,421 |

| Ardabil | 8050 | 18,383 |

| Isfahan | 560 | 1270 |

| Alborz | 459 | 1120 |

| Ilam | 10,389 | 21,679 |

| Bushehr | 400 | 554 |

| Tehran | 1070 | 2296 |

| Charmahal and Bakhtiari | 137 | 120 |

| South Khorasan | 61 | 64 |

| North Khorasan | 2910 | 3200 |

| Razavi Khorasan | 3611 | 8012 |

| Khuzestan | 23,200 | 49,318 |

| Zanjan | 860 | 1289 |

| Semnan | 470 | 1680 |

| Sistan and Baluchestan | 480 | 490 |

| Fars | 12,397 | 26,295 |

| Qazvin | 6000 | 9054 |

| Qom | 736 | 1900 |

| Kurdistan | 3400 | 6900 |

| Kerman | 1660 | 2918 |

| Kermanshah | 10,200 | 15,941 |

| Kohgiluyeh and Buyer-Ahmad Golestan | 1526 83,720 | 2057 168,000 |

| Gilan | 90 | 573 |

| Lorestan | 2020 | 3218 |

| Mazandaran | 18,550 | 26,582 |

| Markazi | 1100 | 2250 |

| Hormozgan | 1212 | 1400 |

| Hamedan | 4075 | 7080 |

| Yazd | 260 | 400 |

| Whole Country | 214,094 | 400,000 |

| Name of Researchers | Alcohol Type | Molar Ratio of Alcohol to Oil | Catalyst Used | Catalyst Amount | Reaction Conditions | Biodiesel Yield (%) |

|---|---|---|---|---|---|---|

| Mirabdoli et al. [51] | Methanol | 1:6 | NaOH | 0/31% wt | 59.95 °C for 1 h | 78.65 |

| Almasi et al. [52] | Methanol | 1:4.87 | KOH | 0/1 mol | 55 °C | 89.26 |

| Yazdanian et al. [53] | Methanol | 1:15 | K2CO3/Al2O3 | 1% wt | 65 °C for 2 h | 99 |

| Hosseinzadeh Samani et al. [54] | Methanol | 1:6 | KOH | 1% wt | 60 °C for 9 min | 93 |

| Salehi et al. [55] | Methanol | 1:4.75 | NaOH | 0/1 mol | 50 °C | - |

| Hajar et al. [56] | Methanol | 1:3 | Novozym 435 | 5% wt | 38 °C | 86 |

| Nayebzadeh et al. [57] | Methanol | - | KOH/Ca12Al14O33-C | 4% wt | Microwave, 270 w for 30 min | - |

| Khatibi et al. [58] | Methanol | 1:9 | Na-K/CaO | 3% wt | 50 °C for 3 h | 97.6 |

| Yousefi et al. [59] | Methanol | 1:9 | Silica-exposy | - | 50 °C | 98 |

| Province | Area under Cultivation (Hectare) |

|---|---|

| Isfahan | 367 |

| Ilam | 93 |

| Bushehr | 33,969 |

| South Khorasan | 1532 |

| Khuzestan | 41,085 |

| Semnan | 123 |

| Sistan and Baluchestan | 57,108 |

| Fars | 28,752 |

| Kerman | 58,855 |

| Kermanshah | 726 |

| Kohgiluyeh and Buyer-Ahmad | 246 |

| Hormozgan | 35,567 |

| Yazd | 1921 |

| Whole Country | 260,209 |

| Name of Researchers | Alcohol Type | Molar Ratio of Alcohol to Oil | Catalyst Used | Catalyst Amount | Reaction Conditions | Biodiesel Yield (%) |

|---|---|---|---|---|---|---|

| Abdolrahman Karim et al. [60] | Methanol | 1:9 | H2SO4 | 1% wt | 56 °C | 97.75 |

| ZareSani et al. [61] | Methanol | 1:6 | KOH | 1% wt | 45 °C | 88.1 |

| Foroutan et al. [62] | Methanol | - | KOH | - | 60 °C for 1 h | - |

| Zarein et al. [63] | Methanol | - | KOH | 2% wt | 45 °C for 1 h | 91.1 |

| Pourhoseini et al. [64] | Methanol | - | Fe3O4 | - | 70 °C for 4 h | - |

| Shahedi et al. [65] | t-butanol | 1:2.3 | Novozym 435 | 0/02% w/w | 47 °C | 94 |

| Shahedi et al. [66] | t-butanol | 1:5.9 | Novozym 435 | - | 35.6 °C | 78.3 |

| Province | Production (Ton) |

|---|---|

| West Azarbayjan | 6812 |

| East Azarbayjan | 15,425 |

| Ardabil | 9655 |

| Isfahan | 10,220 |

| Alborz | 2500 |

| Ilam | 10,098 |

| Bushehr | 22,267 |

| Tehran | 6772 |

| Charmahal and Bakhtiari | 22,115 |

| South Khorasan | 1495 |

| North Khorasan | 2250 |

| Razavi Khorasan | 12,290 |

| Khuzestan | 80,938 |

| Zanjan | 17,218 |

| Semnan | 1262 |

| Sistan and Baluchestan | 15,944 |

| Fars | 10,601 |

| Qazvin | 3998 |

| Qom | 1714 |

| Kurdistan | 10,638 |

| Kerman | 5816 |

| Kermanshah | 21,590 |

| Kohgiluyeh and Buyer-Ahmad Golestan | 16,960 19,870 |

| Gilan | 50,684 |

| Lorestan | 23,980 |

| Mazandaran | 80,824 |

| Markazi | 6348 |

| Hormozgan | 29,069 |

| Hamedan | 6301 |

| Yazd | 1076 |

| Whole Country | 526,730 |

| Description | Production (1000 Ton) |

|---|---|

| Fishing in southern waters | 720/2 |

| Fishing in northern waters | 35/5 |

| Aquaculture | 526/7 |

| Whole Country | 1282/4 |

| Name of Researchers | Alcohol Type | Molar Ratio of Alcohol to Oil | Catalyst Used | Catalyst Amount | Reaction Conditions | Biodiesel Yield (%) |

|---|---|---|---|---|---|---|

| Yahyaei et al. [67] | Methanol | 1:4 | KOH | 1% wt | 60 °C for 2 h | 91 |

| Zarein et al. [68] | Methanol | - | H2SO4 | 1% wt | 60 °C for 1 h | 90.8 |

| Yari et al. [69] | Methanol | 1:5.33 | KOH | 1% wt | Microwave time 0/5 min and reaction time 24.61 min | 92.62 |

| Khanjani et al. [70] | Methanol | 1:6 | KOH | 1% wt | 55 °C for 2 h | - |

| Province | Area Under Cultivation (Hectare) | Sugarcane Production (Ton) |

|---|---|---|

| West Azarbayjan | 40 | 1873 |

| East Azarbayjan | 26,984 | 1,164,474 |

| Ardabil | 2431 | 93,708 |

| Isfahan | 1287 | 51,058 |

| Ilam | 285 | 15,100 |

| Charmahal and Bakhtiari | 1022 | 45,851 |

| South Khorasan | 700 | 29,923 |

| North Khorasan | 1610 | 76,850 |

| Razavi Khorasan | 11,799 | 650,530 |

| Khuzestan | 11,268 | 625,759 |

| Semnan | 1603 | 72,225 |

| Fars | 2700 | 126,879 |

| Qazvin | 479 | 16,760 |

| Kurdistan | 750 | 32,935 |

| Kerman | 193 | 7870 |

| Kermanshah | 6301 | 305,790 |

| Golestan | 908 | 44,583 |

| Lorestan | 3899 | 178,128 |

| Markazi | 310 | 16,462 |

| Hamedan | 5512 | 277,117 |

| Whole Country | 80,081 | 3,383,875 |

| Name of Researchers | Alcohol Type | Molar Ratio of Alcohol to Oil | Catalyst Used | Catalyst Amount | Reaction Conditions | Biodiesel Yield (%) |

|---|---|---|---|---|---|---|

| Zenuzi et al. [71] | Methanol | 1:9 | KOH | 1% wt | - | - |

| Hajy Heidar and Tahvildari [72] | Methanol | 1:6 | NaOH/Al2O3 | 1.5% wt | 70 °C for 3 h | 92.5 |

| Hasheminezhad et al. [73] | Methanol | 1:15 | KOH | 1% wt | 60 °C | 95.81 |

| Alavi et al. [74] | Methanol | 1:6 | NaOH | 1% wt | 65 °C for 70 min | 89.48 |

| Khoobbakht and karimi [75] | Methanol | 1:6 | KOH | - | 60 °C for 1 h | 95 |

| Shadidi et al. [76] | Methanol | 1:6 | KOH | 1% wt | 60 °C for 1 h | 96.81 |

| Pirouzmand et al. [77] | Methanol | 1:8 | MCM-41 | - | 50 °C | 92 |

| Aghbashlo et al. [78] | Methanol | 1:8 | KOH | 1% wt | Ultrasonic reactor (F = 1.7 MH) | 96.5 |

| Mohadesi et al. [79] | Methanol | 1:2.25 | KOH/Clinoptilolite | 8.1% wt | 65 °C | 97.45 |

| Helmi et al. [80] | Methanol | 1:6 | Phosphomolybdic acid/graphene oxide | 0/5% wt | electrolysis method (V = 60, T = 24 h) | 90.39 |

| Babaki et al. [81] | t-butanul | 1:3 | Rhizomucor miehei (RML) Candida antarctica (CALB) | 22.5% wt | 50 °C | 91.5 |

| Fereidooni and Mehrpooya [82] | Methanol | 1:7 | KOH/zeolite/chitosan | 2% wt | electrolysis method (V = 40) | 93 |

| Mohadesi et al. [83] | n-hexane | 1:14.75 | CaO/scoria | 1% wt | 59.7 °C | 97.7 |

| Dehghani Soufi et al. [84] | Methanol | 1:4 | K2CO3 | 1% wt | Vertical pulsed column (F = 3.6 Hz) | 83.3 |

| Name of Researchers | Animal Fat Type | Alcohol Type | Molar Ratio of Alcohol to Fat | Catalyst Used | Catalyst Amount | Reaction Conditions | Biodiesel Yield (%) |

|---|---|---|---|---|---|---|---|

| Didar [110] | Beef | Methanol | 1:6 | NaOH | 1% wt | 78 °C for 2 h | - |

| Keihani et al. [111] | Chicken | Methanol | 1:9 | CaO Nanocatalyst | 1% wt | 65 °C for 5 h | 94.4 |

| Seffati et al. [112] | Chicken fat | Methanol | 1:15 | CaO/CuFe2O4 | 3% wt | 70 °C for 4 h | 94.52 |

| Karimi Alavijeh et al. [113] | Beef tallow | Methanol | 1:6 | H2SO4 | 8% wt | - | 95 |

| Ansari Ardali et al. [114] | Chicken fat | Methanol | 1:6 | KOH | 1.25% wt | 60 °C for 1 h | 93 |

| Fayyazi et al. [115] | Chicken fat | Methanol | 1:7 | KOH | 1% wt | Ultrasonic waves for 9 min | 94.8 |

| Foroutan et al. [116] | Chicken fat | Methanol | 1:14.5 | Na2SiO3 | 5% wt | 70 °C for 132 min | 98.77 |

| Abedi et al. [117] | Beef tallow | Methanol | 1:6 | KOH | 1% wt | Ultrasonic amplitude of 60% and 9 min at 45 °C | - |

| Province | Area Under Cultivation (Hectare) | Olive Production (Ton) |

|---|---|---|

| Ardabil | 529 | 170 |

| Isfahan | 986 | 935 |

| Ilam | 621 | 878 |

| Bushehr | 80 | 70 |

| Tehran | 1230 | 913 |

| South Khorasan | 32 | 21 |

| North Khorasan | 200 | 17 |

| Khuzestan | 1959 | 2591 |

| Zanjan | 20,156 | 45,010 |

| Semnan | 4352 | 12,253 |

| Sistan and Baluchestan | 423 | 339 |

| Fars | 9440 | 25,433 |

| Qazvin | 9520 | 26,800 |

| Qom | 621 | 412 |

| Kerman | 3279 | 4390 |

| Kermanshah | 1001 | 3740 |

| Kohgiluyeh and Buyer-Ahmad Golestan | 851 7137 | 353 11,004 |

| Gilan | 9151 | 17,550 |

| Lorestan | 595 | 2189 |

| Mazandaran | 844 | 167 |

| Markazi | 819 | 285 |

| Hormozgan | 89 | 92 |

| Yazd | 2364 | 2340 |

| Whole Country | 77,382 | 158,378 |

| Main Areas | Average Rainfall (mm) (2020) | Average 11 Years | Average 50 Years |

|---|---|---|---|

| Caspian Sea | 279/9 | 273/7 | 255/1 |

| Persian Gulf and Oman Sea | 332/1 | 242/3 | 287/2 |

| West | 217/4 | 220/3 | 208/7 |

| Central Plateau | 126/8 | 101/4 | 114/7 |

| East | 86/2 | 60/1 | 76/1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shadidi, B.; Najafi, G.; Zolfigol, M.A. A Review of the Existing Potentials in Biodiesel Production in Iran. Sustainability 2022, 14, 3284. https://doi.org/10.3390/su14063284

Shadidi B, Najafi G, Zolfigol MA. A Review of the Existing Potentials in Biodiesel Production in Iran. Sustainability. 2022; 14(6):3284. https://doi.org/10.3390/su14063284

Chicago/Turabian StyleShadidi, Behdad, Gholamhassan Najafi, and Mohammad Ali Zolfigol. 2022. "A Review of the Existing Potentials in Biodiesel Production in Iran" Sustainability 14, no. 6: 3284. https://doi.org/10.3390/su14063284

APA StyleShadidi, B., Najafi, G., & Zolfigol, M. A. (2022). A Review of the Existing Potentials in Biodiesel Production in Iran. Sustainability, 14(6), 3284. https://doi.org/10.3390/su14063284