Investigation on Characteristics and Prevention of Rockburst in a Deep Hard and Soft Compound Stratum Tunnel Excavated Using TBM

Abstract

:1. Introduction

2. Engineering Geology of the Research Area

2.1. Engineering Background

2.2. Formation Profile

2.3. Distribution of In Situ Stress

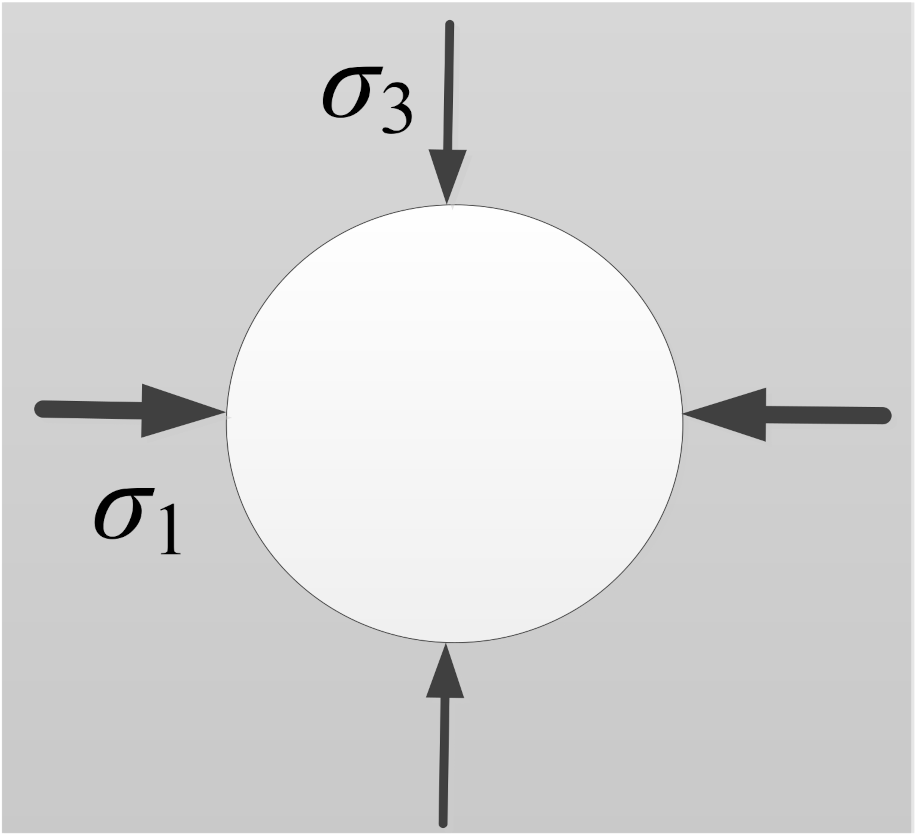

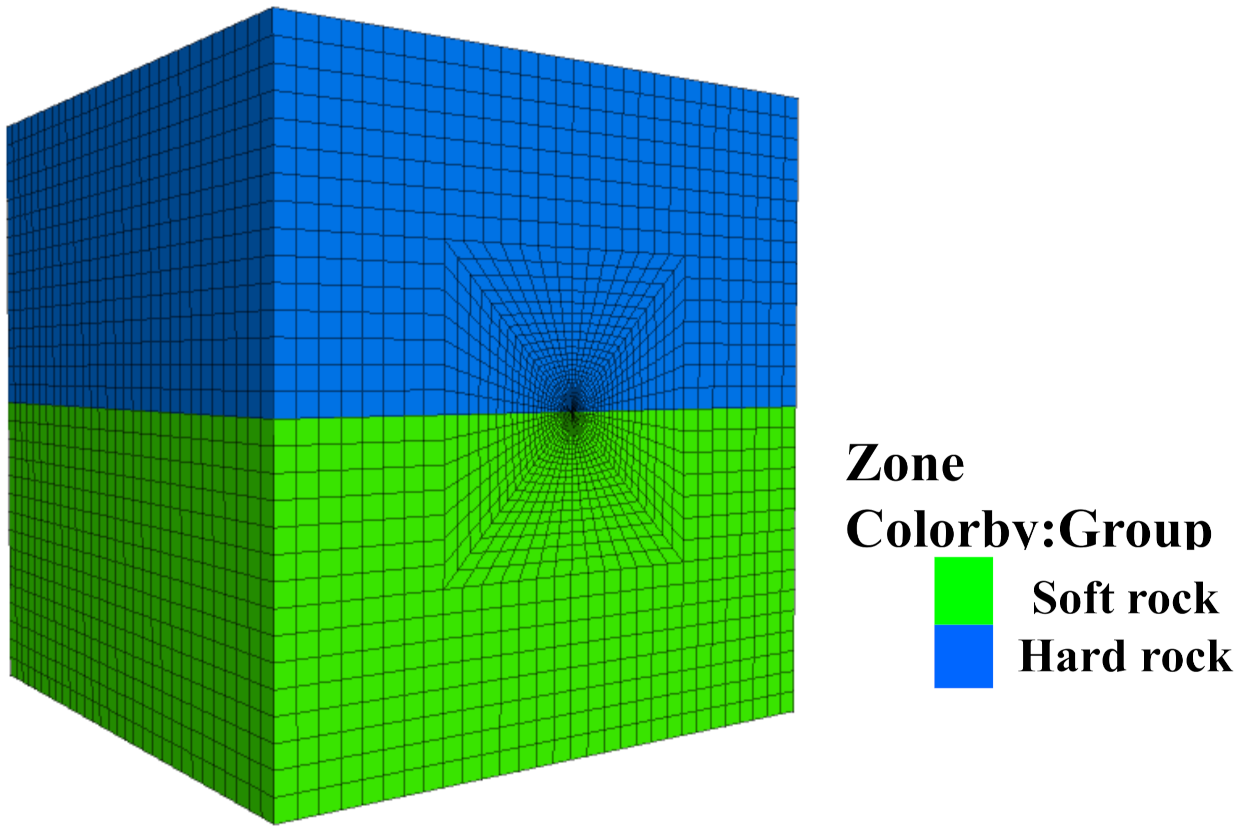

3. Tunnel Numerical Model Creation

3.1. Model Establishment

3.2. TBM Construction and Simulation Process

3.3. Constitutive Model Selection

4. Rockburst Energy Criterion Based on Rock Brittleness Index

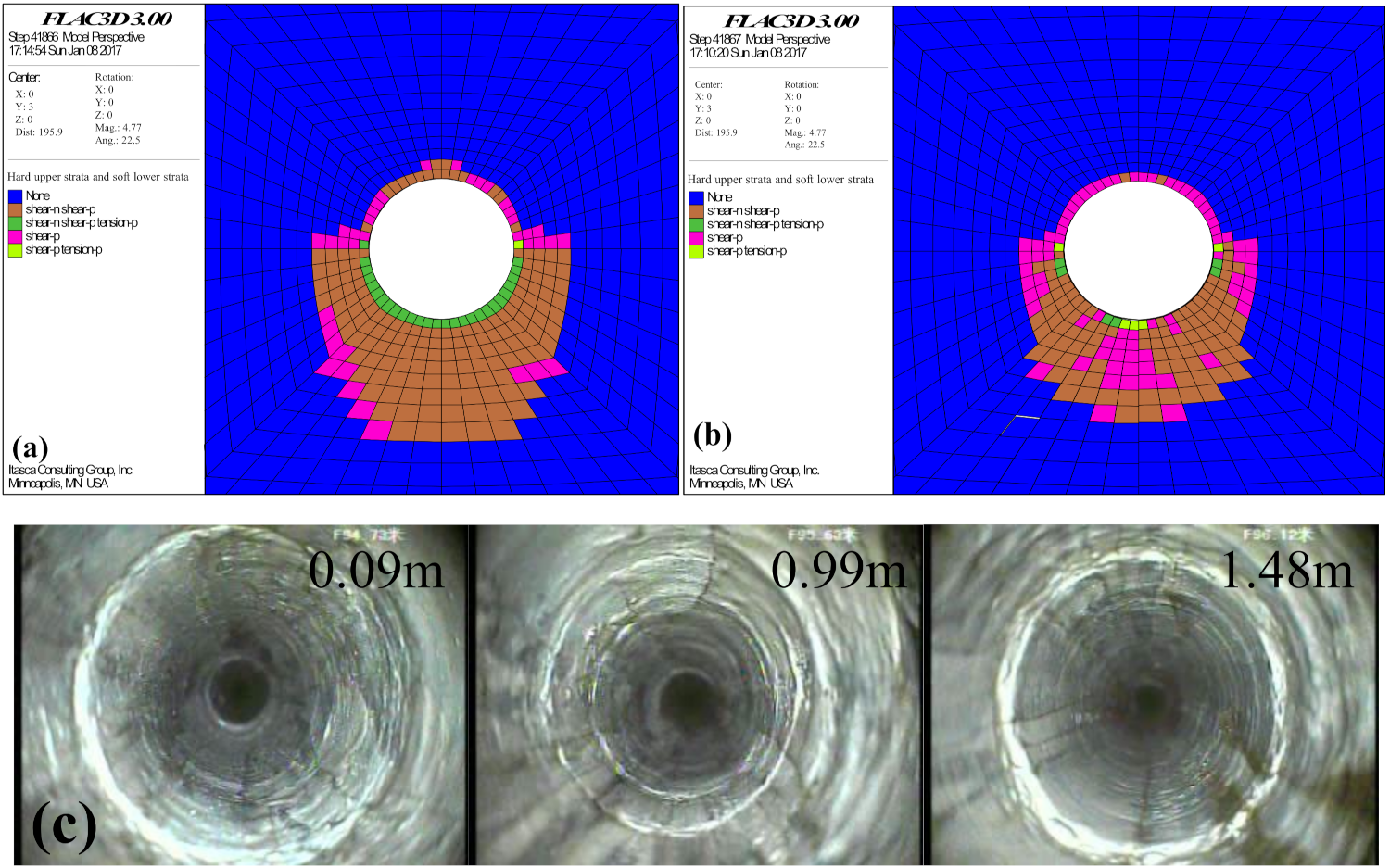

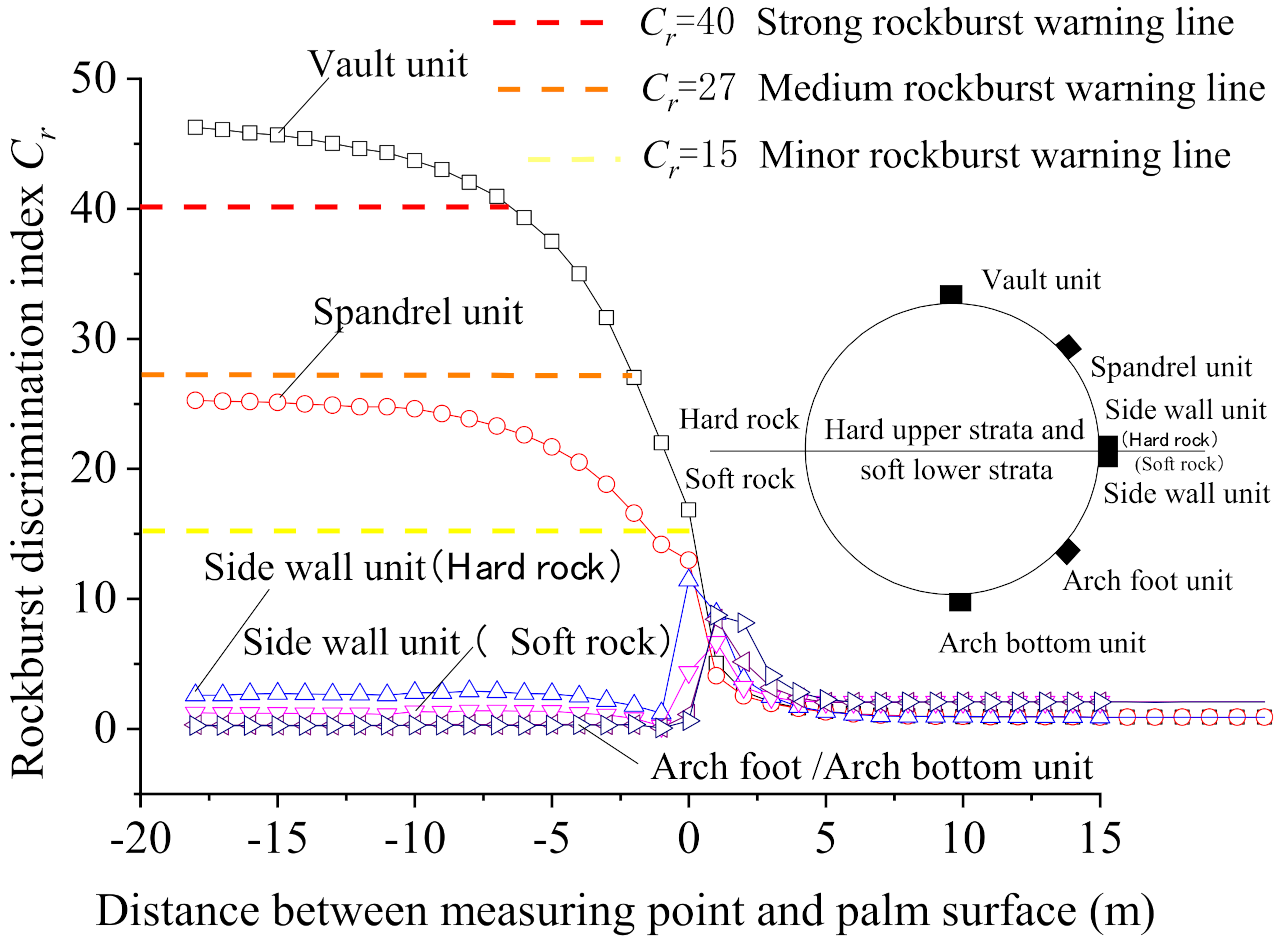

5. Simulation Results of Rockburst Feature

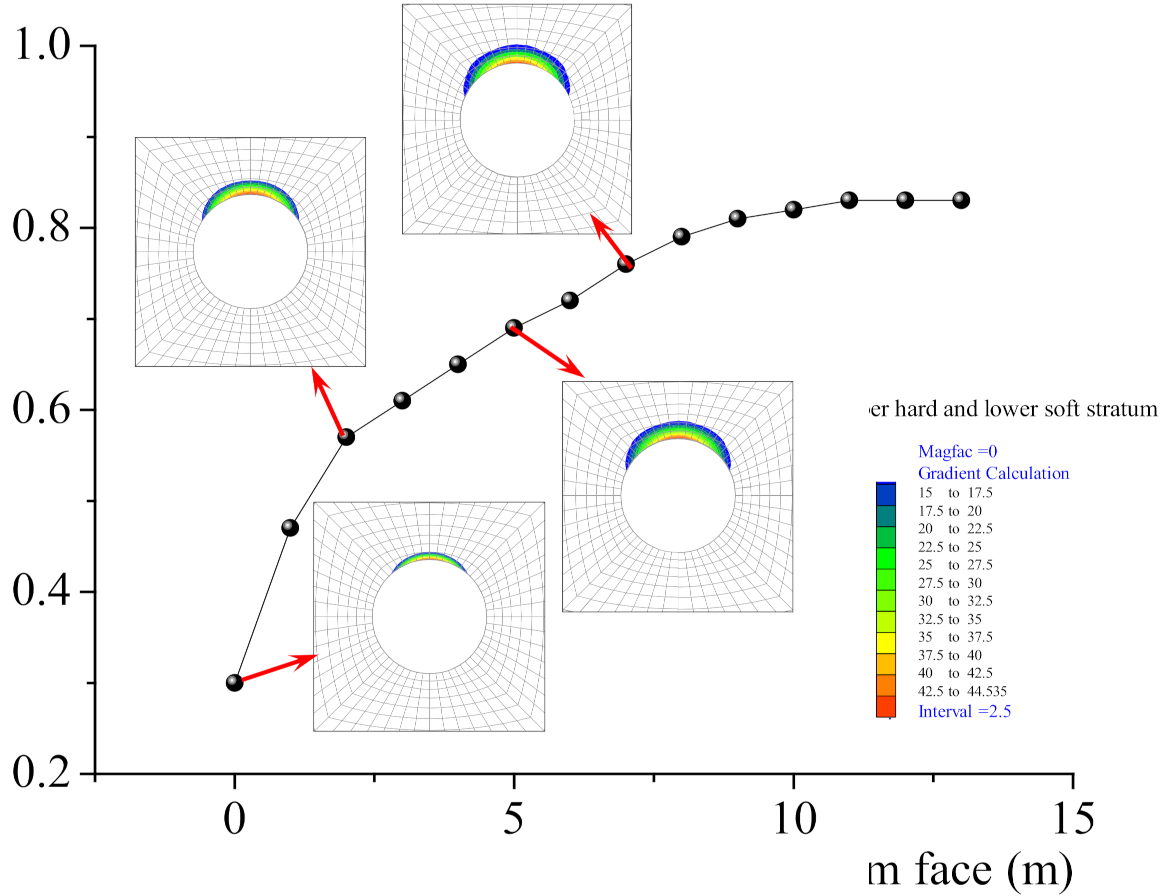

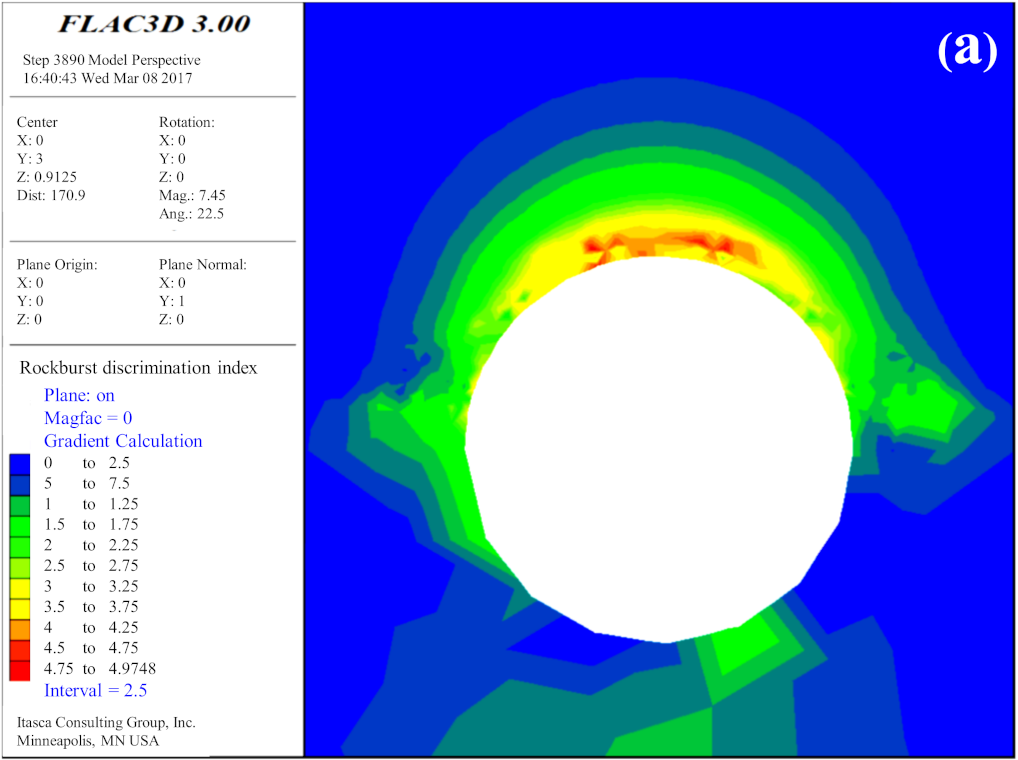

- (1)

- The hard rock part of the tunnel’s upper part with composite strata had rockburst risk under TBM excavation; however, the soft rock part had no rockburst risk due to large deformation and release of most of the energy.

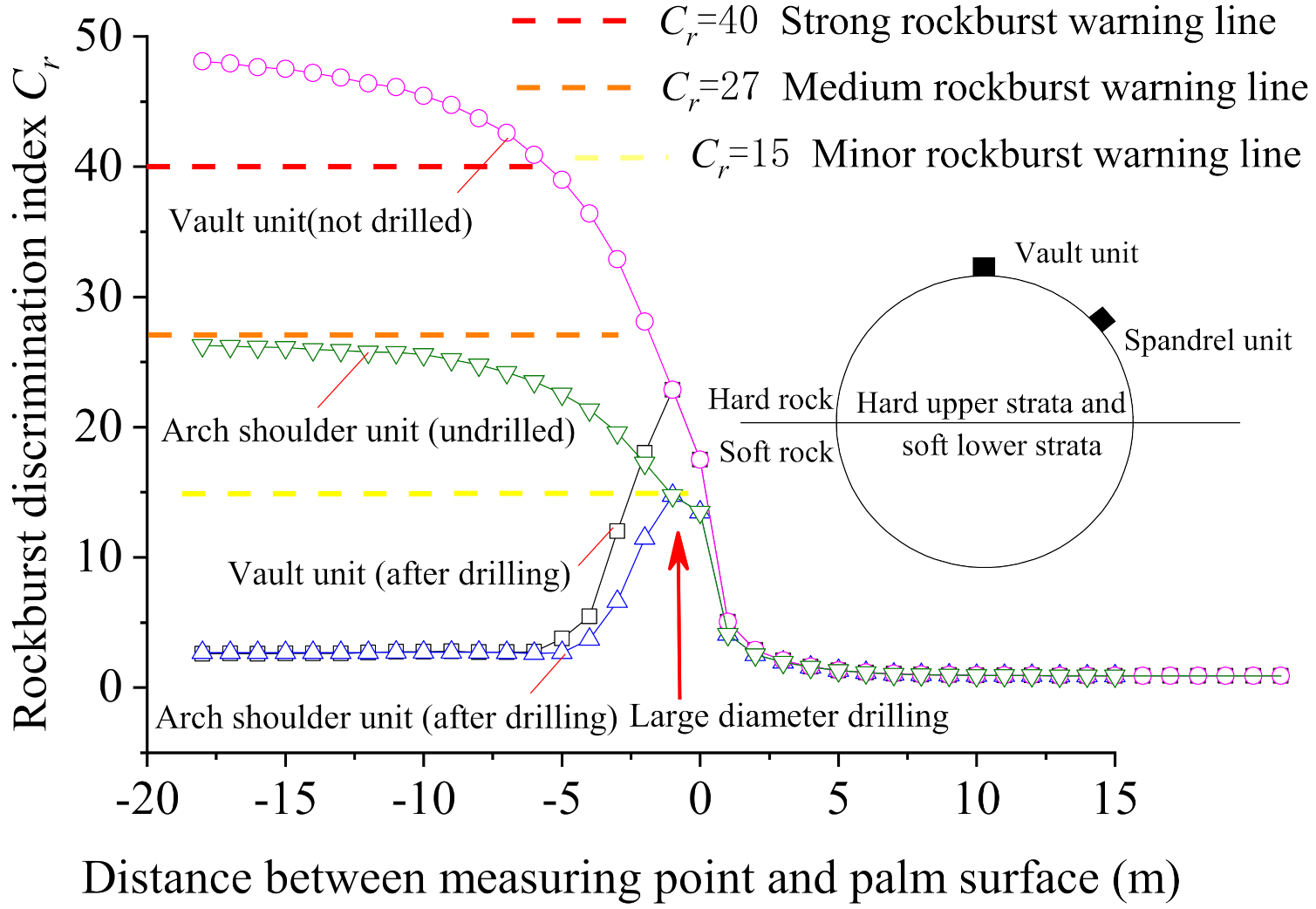

- (2)

- During excavation of the palm face up to a region situated before the measurement point, the Cr value of the surrounding rock changed according to the same law. In this situation, the palm face TBM excavation was maintained up to the monitoring section, and the Cr value of the surrounding rock at different locations in the hard rock part showed various change patterns, which were as follows: For surrounding rock at the sidewall of the tunnel, in the case of the face being excavated up to the monitoring section (the distance between the measuring point and the face was 0 m), the Cr value reached a maximum of 11.4, and then began to decrease and remained at a lower level. Throughout the entire TBM excavation process, the Cr value of the surrounding rock of the sidewall was always less than 15; thus, rockburst risk did not occur. Towards the surrounding rock at the vault and arch shoulder of the tunnel, in the case of excavation of the arch face up to the monitoring section, the Cr value of the surrounding rock at the vault increased to 16.8, causing a slight risk of rockburst. For a related case, the Cr value of the surrounding rock at the arch shoulder was 12.9; therefore, the possibility of rockburst did not occur. When the palm face was pushed through the monitoring section of 2 m, the Cr value of the surrounding rock at the arch shoulder exhibited an increment to 16.6, with a slight risk of rock explosion. When the Cr value of the surrounding rock of the vault increased to 27, a medium risk of rockburst occurred. Afterward, the palm face was pushed through the monitoring section of 7 m; the Cr value of the surrounding rock’s arch part exceeded 40 and gradually stabilized, and the risk of rockburst became strong. Similarly, the Cr value of the surrounding rock at the arch shoulder exhibited an increment to 24, and then gradually stabilized; the slight rockburst risk was continued.

6. Borehole Pressure Relief Prevention of Rockburst

6.1. Pressure Relief Model of Borehole

6.2. Rockburst Treatment Effect of Borehole Pressure Relief

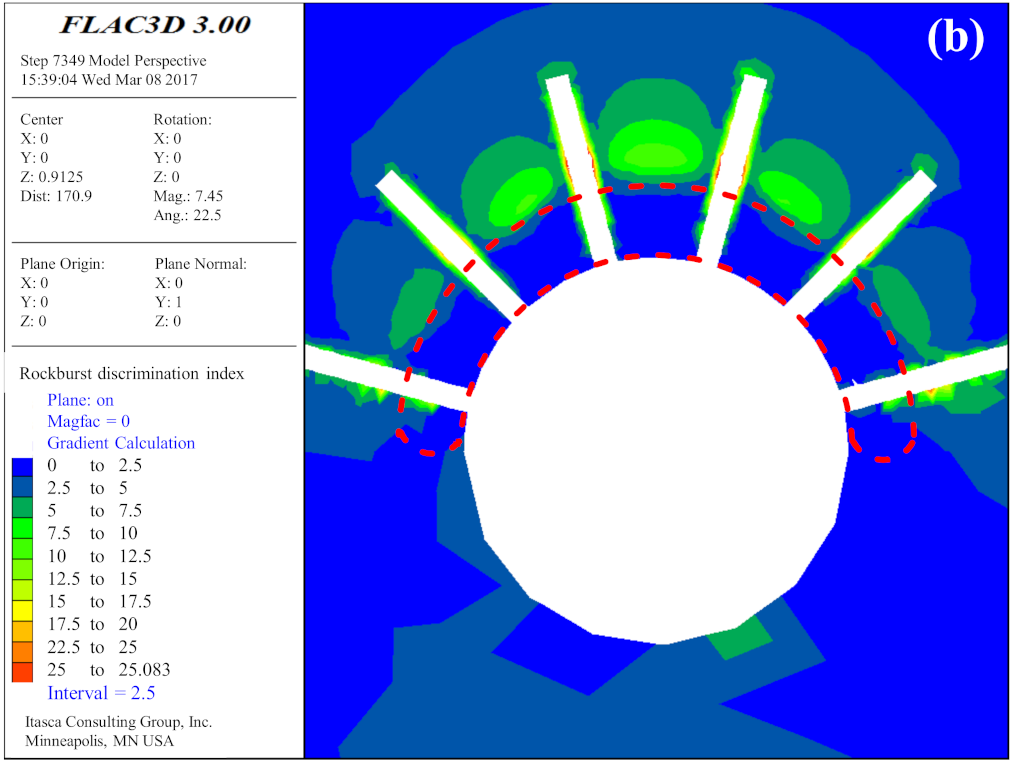

- (1)

- The Cr value of the tunnel surrounding the rock vault and arch shoulder immediately dropped below 3.0 after the borehole pressure relief; furthermore, the Cr value no longer increased as the TBM progressed compared with the non-implemented borehole pressure relief.

- (2)

- After pressure relief, the maximum value of Cr in surrounding rock exhibited a decrement to about 25 and was mainly located around the hole wall at the section of 1.5 m deep in the borehole. The main reason for this situation was the elastic state of the rock mass around the deeper section of the hole wall with a certain degree of stress concentration.

- (3)

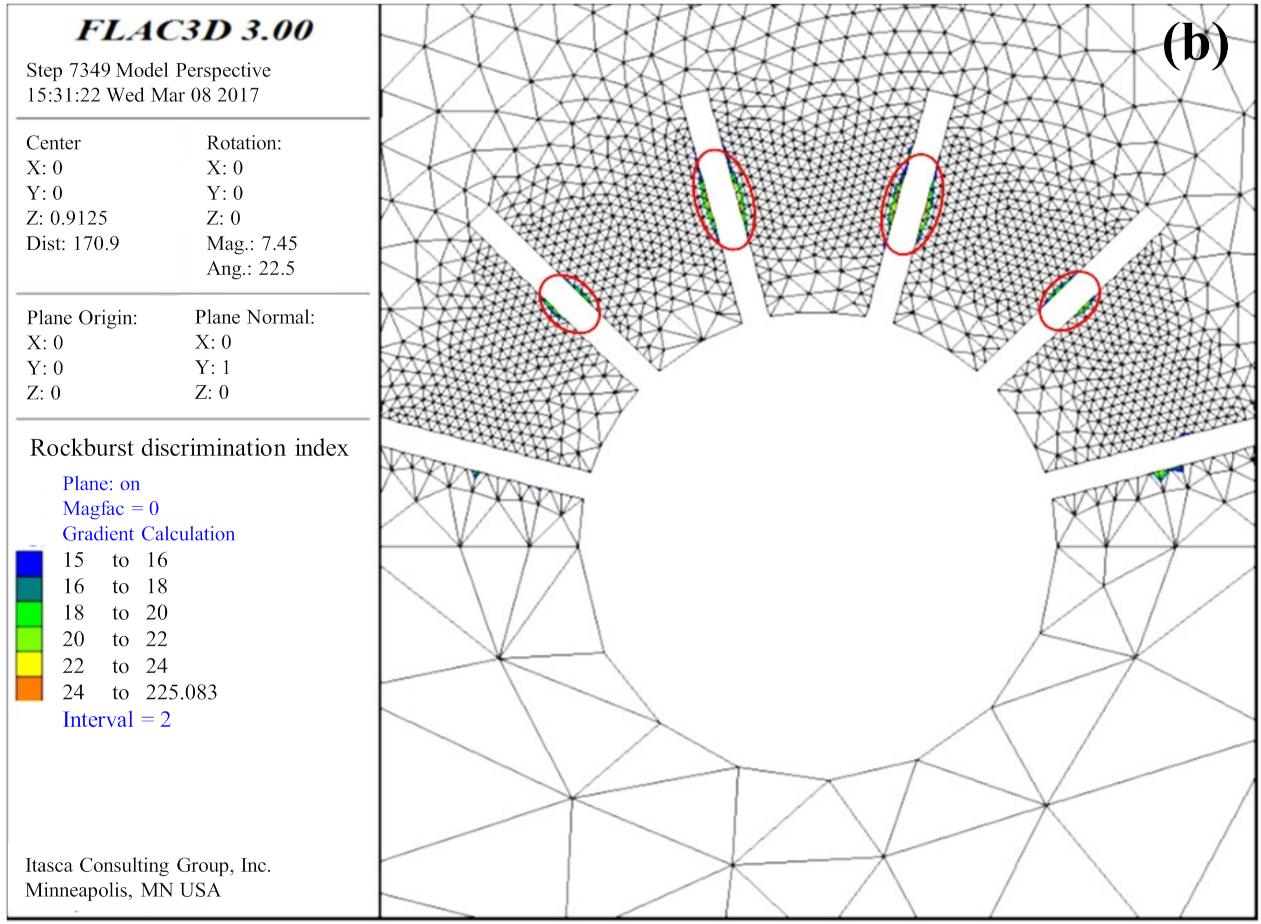

- After drilling and depressurizing the hard rock at the upper part of the tunnel that was 2 m behind the tunnel face, a certain depth of weakened zone was formed in the shallow region of surrounding rock; hence, the Cr value of the surrounding rock within the weakened zone decreased significantly. As shown in Figure 8b, in the area that the red dashed circle encloses, the Cr value of the surrounding rock in the weakened zone was considerably less than the rockburst threshold value of 15, and the rockburst risk was significantly reduced.

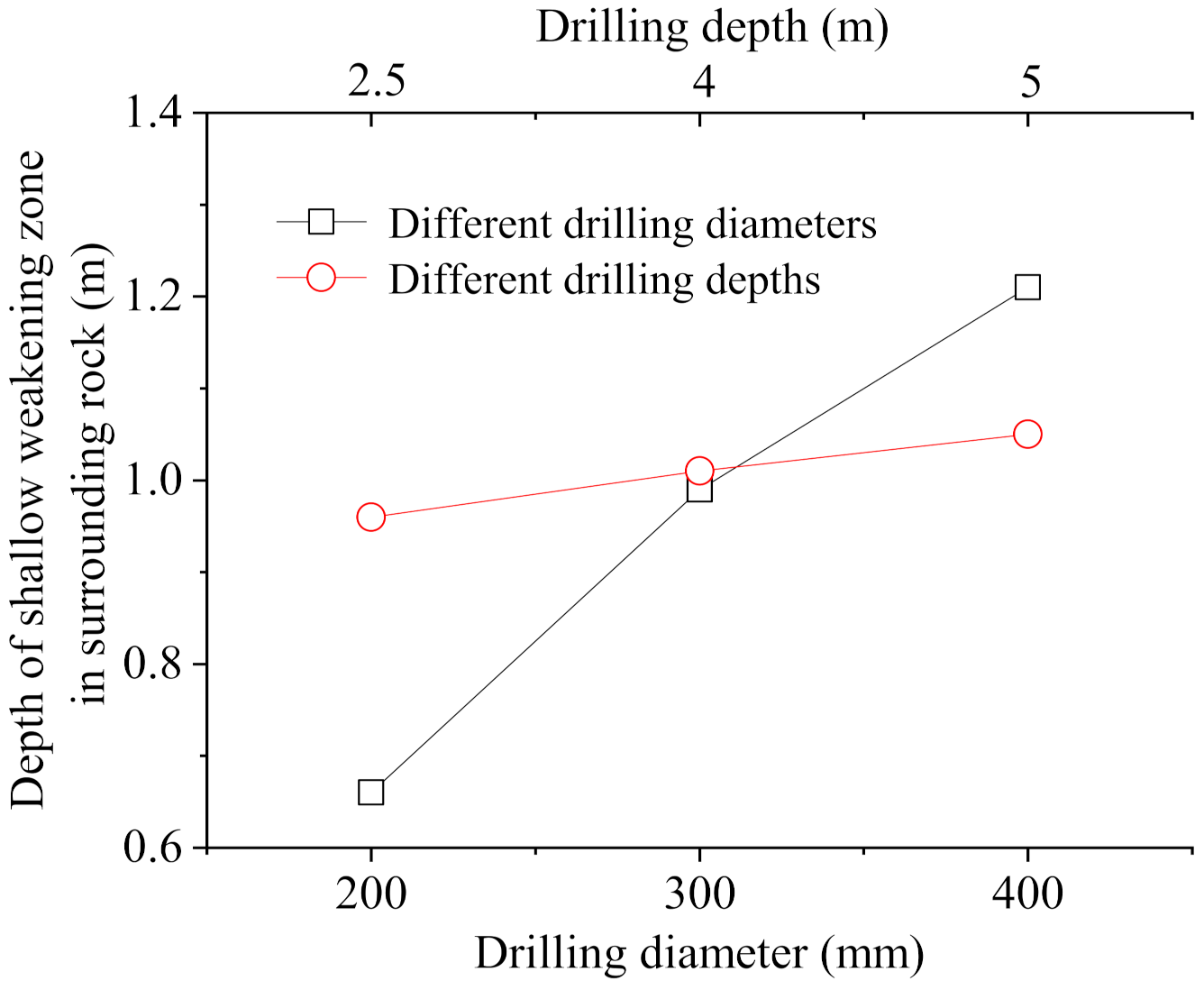

6.3. Influence of Borehole Parameters on Rockburst Prevention and Control Effect

7. Conclusions

- (1)

- The rockburst risk of the compound stratum tunnel excavated by TBM mainly occurred in the upper-hard rock part, while in the soft rock part, rockburst risk did not occur. After the excavation of the tunnel, the first slight rockburst risk occurred in the hard rock area of the tunnel vault. Subsequently, the rockburst intensity at the vault and arch shoulder positions increased progressively, resulting in the occurrence of a severe rockburst risk in the vault position at 7 m behind the working face, which indicated the hysteresis of strong rockburst.

- (2)

- The rockburst area at the vault of the surrounding rock was the deepest, with a depth of about 0.88 m. The blast crater’s depth progressively decreased on both sides of the arch shoulder, forming a “V” shape.

- (3)

- After the hard rock part of the composite strata, the tunnel was relieved by drilling. A certain depth of weakening zone was formed in the shallow part of the surrounding rock, which significantly reduced the rockburst risk of the surrounding rock. Compared with the depth of the borehole, the diameter of the borehole has a more significant impact on the rockburst prevention effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hong, K.R. State-of-art and prospect of tunnels and underground works in China. Tunn. Constr. 2015, 35, 95–107. [Google Scholar]

- Liu, Q.S.; Huang, X.; Liu, J.P.; Pan, Y.U. Interaction and safety control between TBM and deep mixed ground. J. China Coal Soc. 2015, 40, 1213–1224. [Google Scholar] [CrossRef]

- Zhou, J.J.; Yang, Z.X. Discussion on key issues of TBM construction for long and deep tunnels. Rock Soil Mech. 2014, 35, 299–305. [Google Scholar] [CrossRef]

- Feng, Q.; Jin, J.C.; Zhang, S.; Liu, W.W.; Yang, X.X.; Li, W.T. Study on a damage model and uniaxial compression simulation method of frozen–thawed rock. Rock Mech. Rock Eng. 2021, 55, 187–211. [Google Scholar] [CrossRef]

- Qian, Q.H. Definition, mechanism, classification and quantitative forecast model for rockburst and pressure. Rock Soil Mech. 2014, 35, 1–6. [Google Scholar] [CrossRef]

- Ma, T.H.; Tang, C.A. Rockburst Analysis, Monitoring and Control; Dalian University of Technology Press: Dalian, China, 2014. [Google Scholar]

- Zhang, Z.T.; Chen, Z.; Chen, B.R.; Jiang, H.L.; Cui, H.; Gao, Z.L. TBM construction method in the large overburden and intensive rock burst zone. J. China Coal Soc. 2011, 36, 431–435. [Google Scholar] [CrossRef]

- Y, Y. Rockburst mechanism of deep buried high ground stress hard rock tunnel. Constr. Technol. 2013, 42, 237–239. [Google Scholar]

- Guo, J.Q.; Zhao, Q.; Wang, J.B.; Zhang, J. Rockburst prediction based on elastic strain energy. Chin. J. Rock Mech. Eng. 2015, 34, 1786–1795. [Google Scholar] [CrossRef]

- Wu, S.Y.; Zhou, J.F.; Chen, B.R.; Huang, M.B. Effect of excavation schemes of TBM on risk of rock burst of long tunnel at Jinping II Hydropower Station. Chin. J. Rock Mech. Eng. 2015, 34, 728–734. [Google Scholar] [CrossRef]

- Chen, B.R.; Feng, X.T.; Xiao, Y.X.; Ming, H.J.; Zhang, C.S.; Jing, H.; Chu, W. Acoustic emission test on damage evolution of surrounding rock in deep-buried tunnel during TBM excavation. Chin. J. Rock Mech. Eng. 2010, 29, 1562–1569. [Google Scholar]

- Jiang, B.Y.; Wang, L.G.; Gu, S.T.; Zhang, X.D.; Li, W.S. Study on rockburst mechanism of TBM excavation for deep tunnel based on energy principle. J. Min. Saf. Eng. 2017, 34, 1103–1109. [Google Scholar] [CrossRef]

- Fang, D.M.; Liu, N.; Zhang, C.Q.; Cu, W.J.; Chen, X.J. Rockburst risk control for large diameter TBM boring in high geostress region. Chin. J. Rock Mech. Eng. 2013, 32, 2100–2107. [Google Scholar]

- Li, L.P.; Jia, C.; Sun, Z.Z. Research status and development trend of major engineering disaster prevention and control technology in deep underground. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 2539–2556. [Google Scholar]

- Wang, Q.W.; Ju, N.P.; Du, L.L. Research on rockburst prediction and engineering measures of long and deep-lying tunnels. Hydrogeol. Eng. Geol. 2016, 43, 88–94. [Google Scholar]

- Liang, D.Z. Prevention and Control Measures for Rock Burst During Excavation of Underground Cavern Under High Geo-stress. Sichuan Water Power 2021, 40, 32–35. [Google Scholar]

- Zhang, J.J.; Fu, B.J. Rockburst and its criteria and control. Chin. J. Rock Mech. Eng. 2008, 27, 2034–2042. [Google Scholar]

- Lin, F. Study on Surrounding Rock Stability of TBM Construction Process for Long Distance Water Conveyance Tunnel; Zhejiang University of Technology: Hangzhou, China, 2013. [Google Scholar]

- Liu, H.; Liu, Q.S.; Tang, X.H.; Luo, C.Y.; Wan, W.K.; Chen, L. Identification of the interaction loads between TBM shield and surrounding rock. Rock Soil Mech. 2019, 40, 4946–4954. [Google Scholar]

- Huang, X.; Liu, Q.S.; Liu, K.D.; Kang, Y.S.; Liu, X.W. Laboratory study of deformation and failure of soft rock for deep ground tunnelling with TBM. Chin. J. Rock Mech. Eng. 2015, 34, 76–92. [Google Scholar] [CrossRef]

- Liu, L.P.; Wang, X.G.; Jia, Z.X.; Duan, Q.W.; Yu, H.Z.; Liu, B. Analysis of mechanism and characteristic of rockburst in drainage-hole of JinpingⅡ hydropower station. J. Cent. South Univ. (Sci. Technol.) 2011, 42, 3150–3156. [Google Scholar]

- Ramoni, M.; Anagnostou, G. The Interaction Between Shield, Ground and Tunnel Support in TBM Tunnelling through Squeezing Ground. Rock Mech. Rock Eng. 2011, 44, 37–61. [Google Scholar] [CrossRef]

- Hasanpour, R. Advance numerical simulation of tunnelling by using a double shield TBM. Comput. Geotech. 2014, 57, 37–52. [Google Scholar] [CrossRef]

- Cheng, J.L.; Yang, S.Q.; Du, L.K.; Wen, S.; Zhang, J.Y. Three-dimensional numerical simulation on interaction between double-shield TBM and surrounding rock mass in composite ground. Chin. J. Rock Mech. Eng. 2016, 35, 511–523. [Google Scholar] [CrossRef]

- Meng, Q.B.; Han, L.J.; Qiao, W.G. Elastic-plastic analysis of the very weakly cemented surrounding rock considering characteristics of strain softening and expansion. J. China Univ. Min. Technol. 2018, 47, 760–767. [Google Scholar]

- Jiang, B.Y.; Tan, Y.L.; Wang, L.G.; Gu, S.T.; Dai, H.B. Development and numerical implementation of elastoplastic damage constitutive model for rock based on Mogi-Coulomb criterion. J. China Univ. Min. Technol. 2019, 48, 784–792. [Google Scholar] [CrossRef]

- Gao, Y.H.; Feng, X.T.; Zhang, X.W.; Zhou, Y.Y.; Zhang, Y. Generalized crack damage stress thresholds of hard rocks under true triaxial compression. Acta Geotech. 2020, 15, 565–580. [Google Scholar] [CrossRef]

- Shang, Y.J.; Zhang, J.J.; Fu, B.J. Analyses of three parameters for strain mode rockburst and expression of rockburst potential. Chin. J. Rock Mech. Eng. 2013, 32, 1520–1527. [Google Scholar]

- Tao, Z.Y. Rockburst and its criterion in highly geostressen zone. People’s Yangtze River 1987, 5, 32. [Google Scholar] [CrossRef]

- Chen, B.R.; Feng, X.T.; Zeng, X.H.; Xiao, Y.X.; Zhang, Z.T.; Ming, H.J.; Feng, G.L. Real-time microseismic monitoring and its characteristic analysis during TBM tunnelling in deep-buried tunnel. Chin. J. Rock Mech. Eng. 2011, 30, 275–283. [Google Scholar]

- Hou, J.; Zhang, C.S.; Shan, Z.G. Rockburst characteristics and the control measures in the deep diversion tunnel of Jinping II hydropower station. Chin. J. Undergr. Space Eng. 2011, 7, 1251–1257. [Google Scholar]

- Li, W.S.; Jiang, B.Y.; Gu, S.T.; Yang, X.X.; Faiz, U.A.S. Experimental study on the shear behaviour of grout-infilled specimens and micromechanical properties of grout-rock interface. J. Cent. South Univ. 2021, 2021, 1–14. [Google Scholar]

- Jiang, B.Y. Evolution and Control Mechanism of Rockburst Induced by TBM Excavation in Deep Mixed Ground Tunnel; China University of Mining and Technology: Xuzhou, China, 2017. [Google Scholar]

- Liao, Q.L.; Zeng, Q.B.; Liu, T.; Lu, S.B.; Hou, Z.S. Automatic model generation of complex geologic body with FLAC3D based on ANSYS platform. Chin. J. Rock Mech. Eng. 2005, 24, 1010–1013. [Google Scholar]

| Lithology | Elastic Modulus (GPa) | Poisson Ratio | The Angle of Internal Friction (°) | Cohesive Forces (MPa) | Uniaxial Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Gneiss | 7.5 | 0.27 | 38 | 5.5 | 78 | 4.7 |

| Marl | 1.5 | 0.35 | 24 | 1.0 | 12 | 1.2 |

| Lithology | η | β | |

|---|---|---|---|

| Gneiss | 0.014 | 5 | 0.8 |

| Marl | 0.004 | 1 | 0.6 |

| Rockburst Criterion | Country/ Regional Engineering | Rockburst Discriminant | Rockburst Intensity Classification | |||

|---|---|---|---|---|---|---|

| No Rockburst | Minor Rockburst | Medium Rockburst | Strong Rockburst | |||

| E. Hoek method | South Africa | <0.34 | 0.34~0.42 | 0.42~0.56 | >0.70 | |

| Russenes criterion | Norway | <0.2 | 0.2~0.3 | 0.3~0.55 | >0.55 | |

| Turchaninov criterion | Xibin Block Mine, Kola Peninsula | <0.3 | 0.3~0.5 | 0.5~0.8 | >0.8 | |

| Elastic energy index criterion | Polish coal mine | <2 | 2.0~4.9 | ≥5.0 | ||

| Erlang Mountain highway tunnel criterion | China | 0.3 | 0.3~0.5 | 0.5~0.7 | >0.7 | |

| Zhenyu Tao rockburst criterion | China | >14.5 | 14.5~5.5 | 5.5~2.5 | <2.5 | |

| Rockburst potential criterion | China | <1.7 | 1.7~3.3 | 3.3~9.7 | >9.7 | |

| Cr Indicator Value | <15.0 | 15.0~27.0 | 27.0~40.0 | >40.0 |

|---|---|---|---|---|

| Rockburst intensity | No rockburst | Minor rockburst | Medium rockburst | Strong rockburst |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Ding, M.; Li, W.; Gu, S.; Ji, H. Investigation on Characteristics and Prevention of Rockburst in a Deep Hard and Soft Compound Stratum Tunnel Excavated Using TBM. Sustainability 2022, 14, 3190. https://doi.org/10.3390/su14063190

Jiang B, Ding M, Li W, Gu S, Ji H. Investigation on Characteristics and Prevention of Rockburst in a Deep Hard and Soft Compound Stratum Tunnel Excavated Using TBM. Sustainability. 2022; 14(6):3190. https://doi.org/10.3390/su14063190

Chicago/Turabian StyleJiang, Bangyou, Mingjun Ding, Wenshuai Li, Shitan Gu, and Hongguang Ji. 2022. "Investigation on Characteristics and Prevention of Rockburst in a Deep Hard and Soft Compound Stratum Tunnel Excavated Using TBM" Sustainability 14, no. 6: 3190. https://doi.org/10.3390/su14063190

APA StyleJiang, B., Ding, M., Li, W., Gu, S., & Ji, H. (2022). Investigation on Characteristics and Prevention of Rockburst in a Deep Hard and Soft Compound Stratum Tunnel Excavated Using TBM. Sustainability, 14(6), 3190. https://doi.org/10.3390/su14063190