1. Introduction

The construction industry often drives a country’s socioeconomic development [

1]. Rising living standards, growing demand for construction projects, evolving consumer purchasing patterns, and natural population growth are contributing to the construction industry’s expansion. As a result of this development, the quantity of concrete produced throughout construction projects has increased considerably [

2]. Consequently, concrete waste has become a global environmental problem, including global warming, acid rain, air pollution, and climate change, that necessitates rapid action. Untreated concrete waste can potentially harm the environment. Therefore, concrete waste has been identified as a form of pollution that, if allowed to increase unchecked, has the potential to become a serious problem for any nation [

3]. As concrete waste has little or no monetary value, organizations in the construction industry may choose to dispose of it at landfills rather than recycling it. To effectively dispose of concrete waste, contractors and project owners may incur additional costs. In this situation, concrete waste treatment is no longer a matter of choice and has become an urgent need.

Concrete recycling, which involves converting unwanted concrete into recyclable aggregates, is one of the most effective concrete waste management solutions [

4]. Concrete recycling is imperative for reducing concrete waste as it can considerably reduce the negative environmental impacts of concrete waste [

2,

3,

5]. As a result of the multiple benefits of concrete recycling, several governments, particularly those in developed countries, have taken steps to make it a legal requirement in their jurisdictions. Despite this, the global concrete recycling rate is low, especially in developing nations [

5,

6]. According to one possible rationale, the use of recycled materials may be prohibited in countries with plentiful natural resources and a considerable number of landfills. Furthermore, the dynamism of construction operations has a major impact on the efficiency with which concrete recycling is carried out in construction projects [

7]. As a result, understanding the underlying success factors necessary for efficient concrete recycling in construction projects is crucial.

This study explores the success factors of concrete recycling in construction projects, using Malaysia as a case study. The objectives include (1) identifying the critical success factors for concrete recycling in construction projects, (2) comparing the critical success factors between large enterprises (LEs) and small–medium enterprises (SMEs), and (3) developing constructs that group the critical success factors. To achieve these objectives, first, a list of success factors was identified through semi-structured interviews with construction industry professionals from Malaysia and a systematic literature review of journal articles. This list was then incorporated into a questionnaire and disseminated to Malaysian construction industry professionals. The collected responses were analyzed using mean score ranking, normalization, agreement analysis, and factor analysis techniques. By meeting those objectives, the study hopes to present useful insights, including a list of critical success factors for concrete recycling. Whether there are statistically significant differences in criticality between LEs and SMEs is also noted. Finally, the study findings shed light on the critical success factors that determine the success of concrete recycling. These findings will make crucial contributions to the body of knowledge in the construction and environmental management domains and deepen existing understanding of the critical success factors for concrete recycling in both disciplines.

2. Literature Review

2.1. Concrete Recycling in Construction Projects

Construction and demolition waste generated by construction projects are some of the most demanding issues in developed and developing countries worldwide. Demolished concrete, bricks, masonry, wood, glass, insulation, roofing, wire, pipe, rock, and soil are some examples of construction and demolition wastes [

8]. Concrete waste accounts for roughly more than half of construction and demolition waste [

9]. Therefore, concrete waste takes up a lot of space in landfills and causes environmental issues. To address that concern, project management researchers and practitioners are looking into concrete recycling.

Concrete recycling provides many advantages to the industry, environment, and others. First, recycling concrete wastes as aggregates will reduce the consumption of natural resources and the use of landfill areas [

10]. Concrete recycling can also help prevent environmental harm caused by improper disposal, prolong the life of landfills, and conserve valuable natural resources [

11]. In addition, concrete recycling has several economic advantages, including the ability to sell specific recycled items and the removal of other waste from the site for free or at a reduced cost, as well as a decrease in materials going to landfill at a higher cost [

12]. As a result, it may boost contractors’ competitiveness by lowering production costs and improving their public image. Furthermore, studies suggest that the technical performance and environmental impact of recycled aggregate concrete are promising when compared to standard concrete [

13,

14,

15,

16]. Additionally, other potential benefits of concrete recycling include mitigating greenhouse gas and land-use change [

17].

2.2. Barriers to Concrete Recycling in Practice

While concrete cycling has undeniable benefits for the environment and other advantages, there are also challenges to overcome during its implementation. The construction environment is difficult to foresee; hence, concrete recycling can be challenging to manage in the real world. Each project has unique characteristics, projects must be completed on time, and there are financial limitations to consider [

18]. Owing to inadequate handling and a lack of supervisory attention on the workers’ side, construction activities might generate waste, including hazardous waste. Some core project team members are also more concerned with construction materials than waste management. Contractors who work on construction projects consider concrete recycling unimportant [

19]. Efforts to reduce concrete waste have been impeded owing to complacencies toward concrete recycling [

19].

In a cross-cultural study conducted in Australia, Hong Kong, and Japan, the most recognized barriers are lack of clients’ support, increase in management cost, and increase in documentation workloads, such as working documents, procedures, and tools [

20]. In the United States, the difficulties in concrete recycling are inadequate legislation and regulation regarding construction and demolition waste and a lack of systematic data reporting to measure the progress of construction and demolition waste recycling in general and concrete recycling in particular [

21]. For small construction projects, [

22] identified nine barriers in concrete recycling implementation that can be associated with facilities, workforce, quality, financial, technologies, and resources. Furthermore, contractors are not investing in concrete recycling equipment due to inadequate regulations that specify and control the use of recyclable materials [

23].

In addition, several academics have investigated the fundamental issues of concrete recycling in developing countries [

14,

15,

18]. First, the ambiguity surrounding leadership commitment and support for concrete recycling influences team members’ attitudes toward it in construction projects. As a result, fewer resources, labor, and time are available for concrete recycling activities. Second, it is also difficult to recycle concrete because there are no performance standards. The third impediment to continued growth is the construction industry’s unwillingness to change its longstanding working practices. Finally, the fourth issue for concrete recycling is the lack of economic incentives. In addition to that, another difficulty for concrete recycling is that it requires large storage spaces during the recycling process [

16]. In other words, another factor to consider is that concrete waste is bulky, difficult to compress, and requires more space to store throughout the recycling process.

2.3. Factors Affecting Concrete Recycling in Construction Projects

Academics and industry experts are now looking into various aspects of concrete recycling. A recent study revealed many critical factors influencing the adoption of concrete recycling practices. According to the Kuwaiti government, the purity of the recycled material, cost of collection and transportation, cost of sorting, cost of transformation into reusable material, cost of disposal of any residual material in landfills or incineration, and the requirement that recycled materials meet relevant specifications and standards all influence concrete recycling [

24]. According to data gathered from various sources and questionnaires of cement manufacturers, contractors, and project managers, the most important factors influencing concrete recycling in Thailand’s construction industry are cement quality, source of the law and regulations, standardization, price, and confidence [

25]. Further, it is proposed that the essential aspects to consider when deciding whether to recycle concrete waste are the market and site activities. In addition, there are only a few easily accessible recycling marketplaces, as well as significant industrial competition [

18,

26]. In addition to the elements previously identified to be influencing concrete recycling, the findings of this investigation indicate many other factors at work. As a result, these variables will need to be investigated further.

Prior studies have identified the factors affecting concrete recycling by interviewing industry specialists to improve concrete recycling implementation in practice [

17,

22]. The identified factors include the presence of recycling factories, availability of raw materials, quality of recycled concrete, cost of concrete recycling, concrete recycling standards, government support, laws and acts, client acceptance, proper planning, availability of skilled labor, and organizational management [

17]. Furthermore, SMEs face additional problems such as the high cost of renting concrete recycling equipment, its inadequacy for small construction projects, and a lack of providers for small-sized concrete recycling equipment [

22].

2.4. Positioning This Study

This subsection synthesizes the knowledge gaps that exist in the current literature to support the rationale for conducting the study. In summary, previous research has provided insights into concrete recycling regarding the affecting factors, benefits, and barriers in concrete recycling implementation. However, the present body of knowledge lacks information on success factors in practice. In other words, the critical success factors of concrete recycling in the construction industry have not been comprehensively explored. To address this gap, the critical success factors for concrete recycling among contractors are highlighted in this study.

3. Method

A questionnaire was used to collect quantitative data from a random sample to achieve the objectives of the study [

27]. Questionnaires are a prominent method for gathering data in construction management research. They are used to obtain professional viewpoints from the industry. Questionnaires can be distributed via email, normal mail, or other means of communication. In general, participants self-completed and conducted surveys, meaning that the respondents responded to and completed the survey themselves [

28]. In construction management research, surveys are utilized in the same manner as structured interviews, and the results are published. Respondents in self-completed surveys, as opposed to those who participate in internet surveys, must read the survey questions personally. Self-completed surveys provide a variety of advantages over structured interviews, including lower costs and faster delivery, better flexibility in the event of an interviewer’s absence, no interviewer variability, and greater convenience for respondents [

28]. Rather than using traditional methods, researchers used self-administered computerized questionnaires to investigate the underlying relationships among the critical success factors for concrete recycling in construction projects.

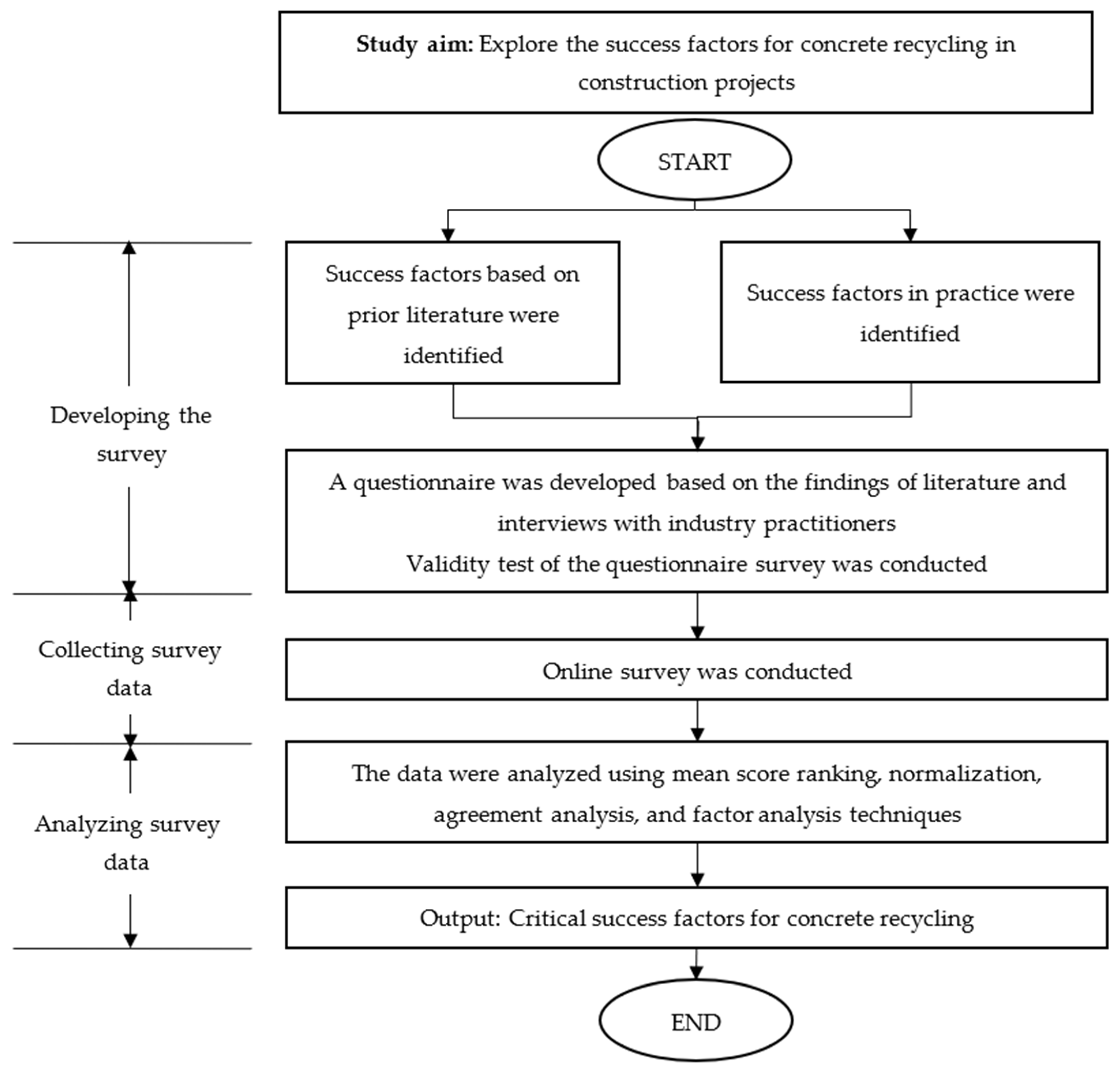

Figure 1 shows the study design diagram adapted from [

29].

3.1. Developing the Survey

In this study, the systematic literature review (SLR) technique was used to identify a list of potential success factors for concrete recycling in construction projects. Therefore, the research question for the SLR was “What are the success factors for concrete recycling in construction projects?”. Scopus was chosen as the preferred search engine because it has a larger database than other search engines and is frequently used for SLR [

30].

The search was conducted on 5 January 2020 and yielded 193 results. Keywords such as recycl*, concrete, construction, and project were used for the search. The search was limited to engineering, material science, environmental science, business management and accounting, economics, econometrics, financial markets, social sciences, and decision science. The purpose is to focus on the corpus of information associated with construction engineering and management. All selected articles were peer-reviewed publications from well-recognized construction engineering and management journals. Conference papers and thesis dissertations were excluded from this study due to their quality. Finally, the titles, abstracts, and conclusions of each manuscript were visually reviewed during the final stage to determine which publications should be included in the systematic review. Not all articles were related to concrete recycling in the construction industry. Thus, unrelated articles were excluded. Twenty-one articles were collected and analyzed. The complete search query is as follows:

TITLE-ABS-KEY (recycl*) AND (concrete) AND (construction) AND (project)) AND (LIMIT-TO (SRCTYPE “j”)) AND (LIMIT-TO (PUBSTAGE “final”)) AND (LIMIT-TO (SUBJAREA “ENGI”) OR LIMIT-TO (SUBJAREA “MATE”) OR LIMIT-TO (SUBJAREA “ENVI”) OR LIMIT-TO (SUBJAREA “BUSI”) OR LIMIT-TO (SUBJAREA “SOCI”) OR LIM-IT-TO (SUBJAREA “ECON”) OR LIMIT-TO (SUBJAREA “DECI”) AND (LIMIT-TO (LAGE AND “ECON”).

In conjunction with the SLR, a two-step technique was used to ensure that the survey was acceptable and logically designed. First, fifteen semi-structured interviews were conducted with construction industry professionals to identify any missing success factors from the current body of knowledge. Construction project managers were interviewed because these individuals have hands-on experience at construction sites, unlike most other employees. The interview question used for the interview was “What are the success factors for concrete recycling in construction projects?”. After each interview, a summary was made and sent to the participants for validation purposes. The data received from the SLR and interviews were then combined to create a survey. The process of combining features with the same semantic substance made it feasible to create a total of 12 potential success factors for concrete recycling in construction projects (as listed in

Appendix A). Second, five university professors reviewed the drafted survey to ensure that the survey did not contain any misleading terminology or incorrect phrases. In addition, a second round of pilot testing with four construction project managers was conducted to identify and remove any additional or irrelevant success factors.

The survey results are organized into two sections. The first section collected individual background information to determine whether the respondents could engage in the study. In the second section, respondents were asked to rate the importance of each of the 12 success factors on a five-point Likert scale (1 = not critical, 2 = slightly critical, 3 = highly critical, 4 = critical, and 5 = extremely important). This scale was adopted owing to its short length and effectiveness in evaluating variables through questionnaire surveys [

29,

31]. The five-point Likert scale is also popular because of its ability to give clear results [

31,

32]. Finally, at the end of the twelfth success factor, respondents were allowed to add and rate any additional success factors linked to concrete recycling in construction projects that the respondents thought were important. This process ensures that all potential success factors are considered.

Appendix B shows the final form of the survey.

3.2. Collecting Survey Data

The study’s target population was construction industry professionals, including clients, consultants, and contractors, from Malaysia. Respondents were divided into SMEs or LEs as defined by the local government, which are as follows: SMEs are defined as having 5 to 50 full-time employees or an annual sales turnover between USD 50,000 and USD 1.25 million, whereas LEs have more than 50 full-time employees or an annual sales turnover larger than USD 1.25 million.

Due to the lack of a sampling frame, the sample used in this study was nonprobability [

33]. When a genuinely random sampling technique cannot be used to choose participants from the total population, nonprobability sampling can be employed to establish a representative sample [

34]. In this approach, participants may be selected for the research depending on their willingness to participate [

35]. As a result, the overall sample size was determined using the snowball sampling approach. It has also been used in previous construction management projects since it allows for the collecting and sharing of data and responses via referral or social networks [

31,

36].

The initial step in the data collection procedure is to contact industry professionals actively involved in construction project administration. Subsequently, the initial respondents were requested to send the survey to other potential respondents. The data collection commenced on 1 July 2020 and ended on 15 November 2020. At the end of the data collection, 89 valid responses were gathered and classified. The demographic background of the 89 respondents is illustrated in

Table 1.

The sample size ratio to the number of variables method was used to determine the sample size for the factor analysis. Reference [

37] recommended that the minimum ratio value should be 5.00. Accordingly, the sample size ratio to the number of variables is 89/12 = 7.42. Therefore, using the aforementioned rules of thumb, the sample size for this study is adequate. Furthermore, rather than representing the population, the objective of this study was to focus on the relative importance of the success factor. This objective has been set per prior works, such as those that identified the most critical elements affecting the adoption of construction innovations [

19,

38]. As a result, the sample size was deemed sufficient for this study.

3.3. Analyzing Survey Data

3.3.1. Reliability Test

To begin the data analysis, the study first determined the internal consistency of each of the 12 success variables using Cronbach’s alpha method. Cronbach’s alpha coefficients ranged from 0 to 1. When compared to other factors on the scale, high alpha values suggest that a collection of elements on the scale has a high degree of internal consistency and dependability. According to the data, the 12 success factors have internal consistency and reliability coefficients of 0.846, indicating that they are internally consistent and reliable for further analysis.

3.3.2. Mean Score Ranking Analysis

Statistical approaches such as descriptive means and standardization, rank agreement analysis, and factor analysis were used in tandem to analyze the data. To acquire the normalized values, the mean scores for each of the 12 success variables had to be determined using a similar technique. Only variables with a normalized value of 0.50 or higher were critical [

29,

39]. Other studies, such as the cost-effectiveness of optimization solutions for water distribution network rehabilitation, used the same data analysis technique [

39].

3.3.3. Agreement Analysis

The mean and normalized values of all respondent groups, including SMEs and LEs, were calculated and compared. The degree of agreement among various organizational sizes was investigated to identify areas of agreement or disagreement and the implications of these differences on the utilization of recycled concrete in construction projects. When comparing agreement levels between responder groups, the rank agreement factor (RAF) technique [

19] can be used to make quantitative comparisons. The RAF technique can calculate the average absolute difference in component rankings between the two groups. In this study, respondents from LEs and SMEs were grouped into groups one (

) and two (

), where N is the number of items (12 success factors), and k denotes the number of judgments. The null hypothesis is that “there is no good agreement in the ranking of success factors between LEs and SMEs”. Therefore, the alternate hypothesis is that “there is good agreement in the ranking of success factors between both groups”. The percentage agreement was calculated using Equations (1)–(5) to test the null hypothesis.

The mean value of the total ranks (R) is given by

The maximum rank agreement factor (RAFmax) is given by

The percentage disagreement (PD) is given by

The percentage agreement (PA) is given by

3.3.4. Factor Analysis

When studying many variables, factor analysis can identify the underlying variables that explain the same relationship pattern. The Kaiser–Meyer–Olkin (KMO) test and Bartlett’s test of sphericity were used to determine whether the data herein were eligible for factor analysis. The KMO uses a statistical approach to determine sample adequacy by evaluating the size of the partial correlation coefficients. On the other hand, Bartlett’s sphericity test assesses the link between a set of distinct variables [

40]. The data were suitable for factor analysis if Bartlett’s test results were statistically significant at

p < 0.05, and the KMO value was larger than 0.50. Factor extraction was required to be completed before the factor analysis could be completed in its entirety to discover relevant variables. As employed in probability theory, the eigenvalue is an expression that describes how much a variable contributes to the grouping of variables. Suppose that the importance of a variable is determined using this method. In this case, the variable may be used as a factor in the subsequent analysis. As a result, keeping variables with eigenvalues larger than one in most cases is typically preferable.

4. Results

4.1. Results for Mean Score Ranking Analysis

Table 2 displays the means, standard deviations, and normalized values for each success factor, as well as their related standard deviations. However, the normalization values for ten success factors are less than 0.50, indicating that they are not statistically significant. The following are the top five success factors identified from the list of identified critical success factors: “availability of uniform standards for recycling concrete”, “adequate awareness among project stakeholders on concrete recycling”, “appropriate construction waste management plan”, “government policy to support concrete recycling”, and “good marketing strategy for concrete recycling”. The critical success factors that were least important were “availability of concrete recycling infrastructure” and “positive legislation toward concrete recycling”.

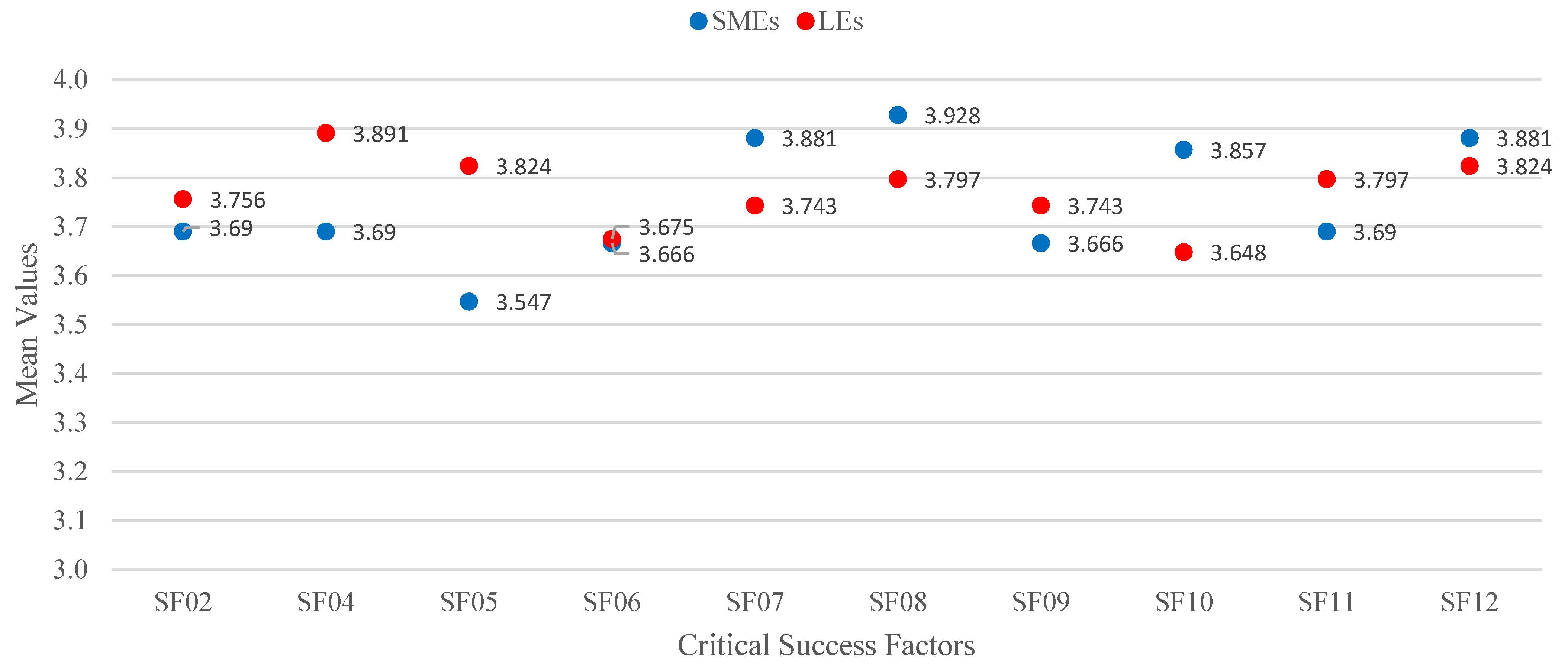

4.2. Results for Agreement Analysis

Table 3 shows the results of an agreement analysis between organizations of various sizes (SMEs and LEs) on the ten critical success factors for concrete recycling in construction projects: The critical success factor “availability of uniform standards for concrete” (SF08) is the most significant for SMEs, although it ranks fourth for LEs. Another aspect to consider is that while the LE rating for “appropriate construction waste management plan” (SF04) is the highest, it is only middlingly ranked for SMEs. Four success factors were ranked equally for SMEs and LEs: “good communication among employees” (SF11), “applications for recycled concrete in sub-industries” (SF02), “positive legislation towards concrete recycling” (SF09), and “availability of concrete recycling infrastructure” (SF06). Nonetheless, the level of agreement between the respondents from different organization sizes was only 22%. In other words, there is a minimal agreement between LEs and SMEs regarding the critical success factors for concrete recycling. According to the agreement analysis, despite several success factors being almost unanimously placed in the same order, the overall agreement was low.

Figure 2 displays the respondents’ agreements and disagreements.

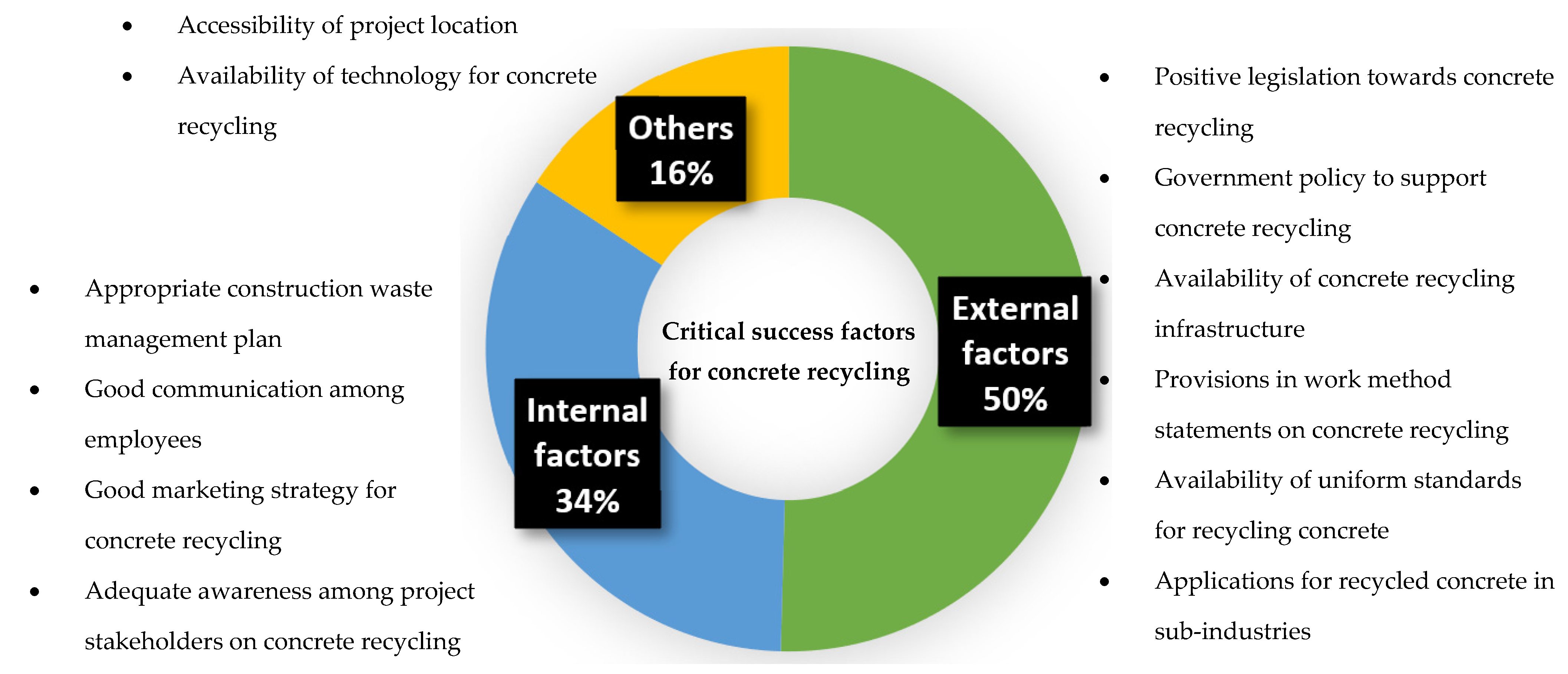

4.3. Results for Factor Analysis

The varimax rotation revealed two underlying groups that explained 55.825% of the overall variance in the data for the ten critical success factors (as listed in

Table 4). All ten critical success factors were successfully loaded into the two underlying components with factor loading values greater than 0.50 in both. Factor loadings refer to the link between an original variable and an extracted component, as assessed by the correlation coefficient. In most situations, statistically significant factor loadings greater than 0.5 are identified, and these loadings contribute to the group’s interpretation. If the material is not presented in this manner, it is dismissed as unimportant.

Figure 3 depicts the percentage contribution of each constituent to the overall success factors for concrete recycling.

5. Discussions

5.1. Group 1: External Factors

Group 1 comprises six critical success factors: positive legislation toward concrete recycling, government policy to support concrete recycling, availability of concrete recycling infrastructure, provisions in the work method statement on concrete recycling, availability of uniform standards for recycling concrete, and applications for recycled concrete in sub-industries. Therefore, this group is named external factors.

5.1.1. Positive Legislation toward Concrete Recycling

The advancement of legislation is projected to result in an improvement in human behavior over time. Concrete recycling as a waste management strategy and a source of raw materials for the market may become necessary in the future under regulation. For example, if concrete recycling is mandatory in the manufacture of precast concrete, the market will respond positively. This approach is an innovative way to increase demand, which is required for success [

31]. On the other hand, if concrete recycling is mandatory, with government inspections undertaken to ensure site compliance, all locations will have appropriate concrete waste management systems, and concrete recycling will only be seen as a necessary requirement rather than just an option. Market-based interest in concrete recycling will increase if a competitive offering of quality or price is established. As a result, firms will grow faster to fulfill demand, increasing the demand for recycled concrete. In view of this, the efficiency of the industry in collecting and recycling concrete waste is predicted to improve [

19]. The emphasis should be on developing smoothly, moving from newer approaches to more established ones. This will ensure that there is less resistance to change, less requirement for training, and a more rapid transition [

38].

5.1.2. Government Policy to Support Concrete Recycling

Actions deemed undesirable are subject to government scrutiny. The advantage of regulating projects as a policy intervention is that it ensures that all projects are held to high standards. In the instances where supply and demand are uncertain, regulation can help create more stable market conditions. Organizations that would ordinarily be excused from compliance would be unable to do so owing to the new regulations. Regulation, however, has some drawbacks. When it comes to obtaining compliance, regulators are frequently associated with a lack of flexibility, hindering the development of innovative methods. In addition, the cost of implementing regulations on their own can be excessively high, especially if no mechanisms to support them are in place. In the absence of supportive programs, regulations can raise prices while restricting the industry’s expansion [

17,

19].

5.1.3. Availability of Concrete Recycling Infrastructure

Concrete recycling can only be effective if performed in specialized separation and processing facilities [

17,

19]. Without these facilities, it would be impossible to carry out one-of-a-kind projects such as demonstrating alternate disposal methods or preparing landfills that sort materials. As a result, municipalities interested in concrete recycling must conduct a regional infrastructure study before proceeding. Existing recycling programs and separation facilities are the available options, as are limits and existing recycling programs. The distances between facilities, fees, and maximum capacity are vital details to consider. In addition, extensive cataloging of municipal constraints on forbidden materials, authorized disposal locations and methods, and any other policy or program governing construction, disposal, or repurposing are required. Finally, existing concrete recycling business opportunities must be identified. Surveys are required to identify whether there is widespread interest in concrete recycling, whether there are any common facilities or infrastructure in place, and whether there are any program components that have proven to be particularly beneficial. The United States Environmental Protection Agency’s “Municipal Solid Waste Recycling: A Guide for State and Local Governments” guides local governments through the process of evaluating waste recycling programs. This procedure can be altered to allow for concrete waste recycling.

5.1.4. Provisions in Work Method Statements on Concrete Recycling

Concrete recycling is frequently not related to a specific job and is part of basic site etiquette. Concrete recycling is commonly included in a contractor’s work method statement, allowing for more formal operation handling. Subcontractors and suppliers should be held to the same standards as principal contractors. A work process statement should be included as part of the overall agreement in the contract. It is believed that the formalization of concrete recycling will result in a more serious attitude toward the work and increased compliance and enforcement of legally necessary sanctions.

5.1.5. Availability of Uniform Standards for Concrete Recycling

Obtaining specified goals through concrete recycling requires clearance and faith in the usefulness of recycled materials. Regulations and certification requirements can aid in the development of trust and acceptance [

38]. Currently, there is no formal legislation or criteria for producing recycled concrete. Users may be hesitant to use the information accessible to them if there are no clearly defined standards or norms. In addition, the traditional method for selecting materials involves selecting natural, high-quality materials that have undergone extensive testing before being employed. On the other hand, recycled concrete has a bad reputation, making it difficult to accept or approve it as an environmentally responsible, high-quality construction material in the first place. As a result of this, recycled concrete for construction work has lost a considerable amount of trust, particularly for large-scale projects requiring tight quality control methods. Recycled concrete is rapidly gaining popularity in low-quality construction projects such as reclamation and sub-base, where it can help save money while maintaining or improving the quality of the completed product. In other words, even though recycled concrete is commonly available, people remain cautious about using it. It is crucial to recognize that the lack of standards and testing for the approval of recycled construction materials is a critical success factor in the recycling industry. As previously mentioned, forming national standards that define acceptable norms while avoiding misunderstandings is critical.

5.1.6. Applications for Recycled Concrete in Sub-Industries

A wide strategy is likely to fall short of meeting the numerous specific quality standards observed in the construction industry. The prospect of investing in research and development becomes unappealing when the economy is facing a slump that affects everyone. As a result, raising the concept’s profile and enhancing the likelihood of securing funding are challenging jobs. A more appealing method would be to pool resources from numerous organizations for research and development goals, rather than just one. This might be accomplished by forming a sub-industry consortium of organizations with comparable levels of expertise and experience. Construction organizations, for example, may work together with research methods to improve recycling. As a result, newly discovered recycling technologies have become more segmented and tailored to the specific sub-industries in which they have been deployed.

5.2. Group 2: Internal Factors

Group 2 comprises four critical success factors: appropriate construction waste management plan, good communication among employees, good marketing strategy for concrete recycling, and adequate awareness among project stakeholders on concrete recycling. Therefore, this group is named internal factors.

5.2.1. Appropriate Construction Waste Management Plan

Waste management should be considered from the perspective of the planning process. Many variables might be set up, simulated, and altered in this manner before any financial consequences become apparent. This method is more cost-effective and faster in terms of production and distribution. When it comes to concrete waste, it is more beneficial to consider the first two higher levels in the hierarchy, “avoid” and “reduce”, earlier rather than later in the process. As the design specifies the materials to be used, potential waste can be minimized, and more efficient methods are used when available. Standard, modular, or prefabricated components could help reduce waste while also reducing construction costs. Another approach to consider is the specification of materials with higher recycling qualities and those that retain material homogeneity throughout and after a structure’s life span. The emphasis would be on waste prevention and reduction, followed by building the groundwork for easier and more successful recycling throughout the construction phase and implementing established routines and operational processes in the enterprises.

5.2.2. Good Communication among Employees

According to the study’s findings, although individuals engage in recycling practices, their supervisors do not convey these practices to their subordinates or employees. As a result, boosting employee communication is critical when discussing recycling processes. In addition, organizations may conduct seminars to demonstrate the recycling processes used by various people in their various communities.

5.2.3. Good Marketing Strategy for Concrete Recycling

To begin, construction organizations must first understand the nature of the recycling market to provide the most accurate assessment of the local conditions for concrete recycling. Local governments must access information on collectors, transporters, processors, brokers, and converters, and demand materials for construction projects to perform efficiently. All concrete recycling procedures should be meticulously documented to minimize legal liability. Concrete recycling information can be obtained from the following sources: local contractors, private landfill operations, brokers, for-profit organizations, and non-profit organizations that specialize in the resale of old construction materials. As different operators frequently cover large geographic areas, this research should be conducted at the regional rather than the national level.

5.2.4. Adequate Awareness among Project Stakeholders on Concrete Recycling

To make educated judgments about improving concrete waste disposal management, examining how communities involved in the construction industry, local governments, and citizens view and respond to this issue is also necessary. Everyone is invited to participate, from the construction industry to municipal governments to the public. Positive attitudes toward subordinates, disparities in attitudes between working groups, and a lack of training to emphasize the need for waste minimization have made it difficult for the industry to execute efficient waste management methods. Dealing with this issue has become even more challenging in recent years owing to the low cost of raw materials for construction projects. In contrast, providing players with the required knowledge about good practices and reinforcing vital messages through training programs can cultivate positive attitudes.

5.3. Implications

This study addresses a gap in the current body of information on concrete recycling in construction projects. This study has both theoretical and practical implications. First, it helps fill the knowledge gap with the critical success factors for concrete recycling in construction projects. A clear understanding of the critical success factors could significantly influence the implementation of concrete recycling in construction. Malaysia is a developing country; hence, scholars in the developing countries can use the list of the identified critical success factors for concrete recycling research. Next, the methodology derived from this study can also be used by other scholars to identify critical success factors in their respective countries. Finally, future work can make a comparison between not only LEs and SMEs but also urban and rural areas.

With respect to practical implications, industry practitioners could refer to the list of critical success factors when implementing concrete recycling in their construction projects. Furthermore, construction organizations could develop company policies based on these findings to encourage the industry to implement concrete recycling. The developed policies aim to ensure that all construction projects comply. Consequently, construction waste management in developing countries could be improved.

6. Conclusions and Future Directions

This study explores the success factors of concrete recycling among industry professionals. The objectives are (1) identifying the critical success factors for concrete recycling, (2) comparing the critical success factors between LEs and SMEs, and (3) grouping the critical success factors. The authors collected semi-structured interview data from 15 industry practitioners and systematically reviewed the existing literature associated with concrete recycling to accomplish these objectives, identifying 12 potential success factors. Subsequently, the criticality of the potential success factors was evaluated by 89 industry practitioners through questionnaires. Finally, the survey data were analyzed using mean ranking analysis, normalization, agreement analysis, and factor analysis techniques.

The analyses show ten critical success factors for concrete recycling out of the 12 potential success factors. External success factors comprise positive legislation for concrete recycling, government policy to support concrete recycling, availability of concrete recycling infrastructure, availability of uniform standards for concrete recycling, provisions in work method statements on concrete recycling, and applications for recycled concrete in sub-industries. Internal success factors for concrete recycling include appropriate construction waste management plans, good communication among employees, good marketing strategy for concrete recycling, and adequate awareness among project stakeholders on concrete recycling.

The results shed light on factors that could affect the success of concrete recycling. In addition to providing additional insights into concrete recycling, researchers and practitioners can benefit from this study in promoting concrete recycling. The key theoretical contribution of this study is that it provides a better understanding of the factors affecting concrete recycling. In most countries, reuse and recycling are still not common practices. Therefore, recycled construction waste has considerable potential to contribute to the market by helping countries cut down on landfill sites and reduce construction material expenses. Finally, the contractors in every construction industry should practice concrete recycling and provide appropriate training regarding the efficiency of concrete recycling.

Despite the relevance of these results, there are limitations to the study, which should be addressed in future endeavors. First, the results were derived from consolidating data from the three main construction project stakeholders (i.e., client, contractor, and consultant). Different stakeholders have different goals and definitions of success, including concrete recycling. Therefore, future works may consider a concurrent evaluation of the internal and external influences among clients, contractors, and consultants to identify symmetries and asymmetries on critical success factors for concrete recycling. The critical success factors were primarily interpreted within the context of Malaysia. The findings are very much tied to the local context from one country to another. Therefore, the findings should be applied to other countries with caution and appropriate adjustments. Thus, a wider scope of data collection across different countries and regions can provide opportunities for comparing and contrasting the findings, providing insights on the impact of applying and applicable reach of the results. However, the results of this study still provide valuable insights into the critical success factors for concrete recycling in construction projects. Future work can build roadmaps based on the study’s results while tailoring to local demands.

Author Contributions

Conceptualization, A.K.B. and R.A.R.; methodology, A.K.B. and R.A.R.; validation, R.A.R., S.A. and A.R.R.; formal analysis, A.K.B.; investigation, A.K.B.; resources, A.K.B., R.A.R. and S.A.; data curation, A.K.B.; writing—original draft preparation, A.K.B.; writing—review and editing, R.A.R., S.A. and A.R.R.; visualization, A.K.B.; supervision, R.A.R.; project administration, R.A.R.; funding acquisition, R.A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Ministry of Higher Education, Malaysia, through the Fundamental Research Grant Scheme (grant number: FRGS/1/2019/TK06/UMP/02/1). Also, the publication fee was funded by the Deanship of Scientific Research, Qassim University.

Institutional Review Board Statement

Ethical review and approval were waived for this study, due to the study involves anonymous data collection.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to some data being proprietary or confidential in nature. Therefore, the data may only be provided with restrictions (e.g., anonymized data).

Acknowledgments

The researchers would like to thank the Deanship of Scientific Research, Qassim University for funding the publication of this study. The authors are also grateful to the editors and the anonymous reviewers for their insightful comments, which helped improve this paper’s quality. Finally, this paper forms part of a large research project aimed at promoting concrete recycling implementation within a developing country, Malaysia, and therefore the authors acknowledge that this paper shares a similar background and methodology with other related papers published by the authors, but with different scopes and objectives.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Appendix A

Table A1.

List of potential success factors for concrete recycling in construction projects.

Table A1.

List of potential success factors for concrete recycling in construction projects.

| Code | Success Factors | Refs. |

|---|

| SF01 | Availability of technology for concrete recycling | [41,42,43,44] |

| SF02 | Applications for recycled concrete in sub-industries | [5,45] |

| SF03 | Accessibility of project location | [33,46,47] |

| SF04 | Appropriate construction waste management plan | [47] |

| SF05 | Good marketing strategy for concrete recycling | [48,49] |

| SF06 | Availability of concrete recycling infrastructure | [49] |

| SF07 | Government policy to support concrete recycling | [49] |

| SF08 | Availability of uniform standards for concrete recycling | [45,46,49,50,51,52,53,54] |

| SF09 | Positive legislation towards concrete recycling | [46,49] |

| SF10 | Provisions in work method statements on concrete recycling | [49] |

| SF11 | Good communication among employees | [47] |

| SF12 | Adequate awareness among project stakeholders on concrete recycling | [3,55] |

Appendix B. The Questionnaire Survey Used in This Study

Factors affecting concrete recycling implementation in construction projects in Malaysia.

Appendix B.1. Respondent’s Profile

Instruction: Please provide the following information.

Your type of organization:

- ○

Owner (e.g., government, developers)

- ○

Consultant

- ○

Contractor

- ○

Others: _____________

Your years of experience in the construction industry:

- ○

Less than 2 years

- ○

2–5 years

- ○

6–9 years

- ○

More than 10 years

Numbers of projects you have experienced:

- ○

1 project

- ○

2–5 projects

- ○

6–9 projects

- ○

More than 10 projects

Most of your construction projects are located at:

- ○

Northern Region (Perlis, Kedah, Penang, Perak)

- ○

East Coast Region (Kelantan, Terengganu, Pahang)

- ○

Central Region (Selangor, Kuala Lumpur, Putrajaya)

- ○

Southern Region (Negeri Sembilan, Melaka, Johor)

- ○

East Malaysia (Sabah, Sarawak, Labuan)

What is your company CIDB grade according to the tendering capacity?

- ○

Not applicable

- ○

G1—Not exceeding RM 200,000

- ○

G2—Not exceeding RM 500,000

- ○

G3—Not exceeding RM 1 Million

- ○

G4—Not exceeding RM 3 Million

- ○

G5—Not exceeding RM 5 Million

- ○

G6—Not exceeding RM 10 Million

- ○

G7—No Limit

Appendix B.2. Success Factors for Implementing Concrete Recycling in Malaysia

Table A2.

Please rate the criticality of the following success factors in implementing concrete recycling in Malaysia.

Table A2.

Please rate the criticality of the following success factors in implementing concrete recycling in Malaysia.

| Success Factor (In Random Order Using Online Survey Platform) | Criticality |

|---|

| Availability of Technology for Concrete Recycling | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Adequate awareness among project stakeholders on concrete recycling | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

Table A3.

Please indicate and rate any additional success factors in implementing concrete recycling in Malaysia.

Table A3.

Please indicate and rate any additional success factors in implementing concrete recycling in Malaysia.

| Additional Success Factor | Criticality |

|---|

| | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

References

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What gets measured, gets done: Development of a circular economy measurement scale for building industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef] [Green Version]

- Luangcharoenrat, C.; Intrachooto, S.; Peansupap, V.; Sutthinarakorn, W. Factors influencing construction waste generation in building construction: Thailand’s perspective. Sustainability 2019, 11, 3638. [Google Scholar] [CrossRef] [Green Version]

- Bakchan, A.; Faust, K.M.; Leite, F. Seven-dimensional automated construction waste quantification and management framework: Integration with project and site planning. Resour. Conserv. Recycl. 2019, 146, 462–474. [Google Scholar] [CrossRef]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Saadi, N.; Ismail, Z.; Alias, Z. A review of construction waste management and initiatives in Malaysia. J. Sustain. Sci. Manag. 2016, 11, 101–114. [Google Scholar]

- Zhang, C.; Hu, M.; Dong, L.; Gebremariam, A.; Miranda-Xicotencatl, B.; di Maio, F.; Tukker, A. Eco-efficiency assessment of technological innovations in high-grade concrete recycling. Resour. Conserv. Recycl. 2019, 149, 649–663. [Google Scholar] [CrossRef]

- Coventry, S. The Reclaimed and Recycled Construction Materials Handbook; Construction Industry Research and Information Association: London, UK, 1999. [Google Scholar]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef] [Green Version]

- Heath, J.C.; Nelson, B. Recycling Spent Sandblasting Grit and Similar Wastes as Aggregate in Asphaltic Concrete; Tech Data Sheet; Naval Facilities Engineering Service Center Port: Hueneme, CA, USA, 1998; pp. 93043–94370. [Google Scholar]

- Carneiro, A.P.; Cassa, J.C.; DeBrum, I.A.; Vieira, A.M.; Costa, A.D.B.; Sampaio, T.S. Construction waste characterization for production of recycled aggregate—Salvador/Brazil. Waste Manag. Ser. 2000, 1, 825–835. [Google Scholar]

- Snook, K.; Turner, A.; Ridout, R. Recycling Waste from the Construction Site; Chartered Institute of Building: Bracknell, UK, 1995. [Google Scholar]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Attitudinal and behavioural approaches to improving waste management on construction projects in Australia: Benefits and limitations. Int. J. Constr. Manag. 2015, 15, 137–147. [Google Scholar] [CrossRef]

- Uğural, M.N.; Giritli, H.; Urbański, M. Determinants of the turnover intention of construction professionals: A mediation analysis. Sustainability 2020, 12, 954. [Google Scholar] [CrossRef] [Green Version]

- Teo, M.M.M.; Loosemore, M. A theory of waste behaviour in the construction industry. Constr. Manag. Econ. 2001, 19, 741–751. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Badraddin, A.K.; Rahman, R.A.; Zakaria, Z.; Hasan, M. Factors Affecting Concrete Recycling Adoption in the Construction Projects. In Proceedings of the International Conference of Sustainable Earth Resources Engineering 2020, Gambang, Malaysia, 6–7 April 2020; IOP Publishing: Bristol, UK, 2020; Volume 641, p. 012018. [Google Scholar]

- Kareem, W.A.; Asa, O.A.; Lawal, M.O. Resources conservation and waste management practices in construction industry. Arab. J. Bus. Manag. Rev. 2015, 4, 20. [Google Scholar] [CrossRef] [Green Version]

- Badraddin, A.K.; Rahman, R.A.; Almutairi, S.; Esa, M. Main Challenges to Concrete Recycling in Practice. Sustainability 2021, 13, 11077. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, L.; Le, K.N. Cross-cultural comparison of concrete recycling decision-making and implementation in construction industry. Waste Manag. 2010, 30, 291–297. [Google Scholar] [CrossRef]

- Jin, R.; Chen, Q. Overview of concrete recycling legislation and practice in the United States. J. Constr. Eng. Manag. 2019, 145, 05019004. [Google Scholar] [CrossRef]

- Darof, A.C.; Rahman, R.A.; Zakaria, Z.; Yusof, N.A. Barriers for Implementing Concrete Recycling in Small Construction Projects. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 641, p. 012010. [Google Scholar]

- Kawano, H. Barriers for sustainable use of concrete materials. In Concrete Technology for a Sustainable Development in the 21st Century; E&FN Spon: London, UK, 2000; pp. 288–293. [Google Scholar]

- Kartam, N.; Al-Mutairi, N.; Al-Ghusain, I.; Al-Humoud, J. Environmental management of construction and demolition waste in Kuwait. Waste Manag. 2004, 24, 1049–1059. [Google Scholar] [CrossRef]

- Duangmanee, V.; Tuprakay, S.; Kongsong, W.; Prasittisopin, L.; Charoenrien, S. Influencing Factors in Production and Use of Recycle Concrete Aggregates (RCA) in Thailand. J. Inform. Technol. Manag. Innov. 2018, 5, 203–215. [Google Scholar]

- Chinda, T. Investigation of factors affecting a construction waste recycling decision. Civ. Eng. Environ. Syst. 2016, 33, 214–226. [Google Scholar] [CrossRef]

- Krosnick, J.A. Questionnaire design. In The Palgrave Handbook of Survey Research; Palgrave Macmillan: Cham, Switzerland, 2018; pp. 439–455. [Google Scholar]

- Bryman, A.; Bell, E. Business Research Methods; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Radzi, A.R.; Rahman, R.A.; Doh, S.I.; Esa, M. Construction Readiness for Highway Projects: Key Decision Criteria. J. Constr. Eng. Manag. 2022, 148, 04021196. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, web of science, and Google scholar: Strengths and weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef]

- King, S.S.; Rahman, R.A.; Fauzi, M.A.; Haron, A.T. Critical analysis of pandemic impact on AEC organizations: The COVID-19 case. J. Eng. Des. Technol. 2022, 20, 358–383. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, L.; Wu, Y. Green strategy for gaining competitive advantage in housing development: A China study. J. Clean. Prod. 2011, 19, 157–167. [Google Scholar] [CrossRef]

- Zhao, X.; Hwang, B.G.; Low, S.P.; Wu, P. Reducing hindrances to enterprise risk management implementation in construction firms. J. Constr. Eng. Manag. 2015, 141, 04014083. [Google Scholar] [CrossRef]

- Patton, M.Q. Qualitative Research and Evaluation Components; SAGE Publishing, Inc.: Thousand Oaks, CA, USA, 2001. [Google Scholar]

- Wilkins, J.R. Construction workers’ perceptions of health and safety training programmes. Constr. Manag. Econ. 2011, 29, 1017–1026. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major barriers to off-site construction: The developer’s perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- DiStefano, C.; Zhu, M.; Mindrila, D. Understanding and using factor scores: Considerations for the applied researcher. Pract. Assess. Res. Eval. 2009, 14, 20. [Google Scholar]

- Al-Mohammad, M.S.; Haron, A.T.; Aloko, M.N.; Rahman, R.A. Factors affecting BIM implementation in post-conflict low-income economies: The case of Afghanistan. J. Eng. Des. Technol. 2021, in press. [Google Scholar]

- Farouk, A.M.; Rahman, R.A.; Romali, N.S. Economic analysis of rehabilitation approaches for water distribution networks: Comparative study between Egypt and Malaysia. J. Eng. Des. Technol. 2021, in press. [Google Scholar]

- Kaiser, H.F. An index of factorial simplicity. Psychometrika 1974, 39, 31–36. [Google Scholar] [CrossRef]

- Chini, A.R. General issues of construction materials recycling in USA. In Portugal SB07. Sustainable Construction, Materials and Practices; IOS Press: Amsterdam, The Netherlands, 2007; pp. 848–855. [Google Scholar]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X. Critical success factors for public–private partnerships in infrastructure development. J. Constr. Eng. Manag. 2005, 131, 3–14. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Analysis of the implementation of effective waste management practices in construction projects and sites. Resour. Conserv. Recycl. 2014, 93, 99–111. [Google Scholar] [CrossRef] [Green Version]

- Adabre, M.A.; Chan, A.P. Critical success factors (CSFs) for sustainable affordable housing. Build. Environ. 2019, 156, 203–214. [Google Scholar] [CrossRef]

- Xiao, J.; Ding, T. Research on recycled concrete and its utilization in building structures in China. Front. Struct. Civ. Eng. 2013, 7, 215–226. [Google Scholar] [CrossRef]

- Crawford, R.H.; Mathur, D.; Gerritsen, R. Barriers to improving the environmental performance of construction waste management in remote communities. Procedia Eng. 2017, 196, 830–837. [Google Scholar] [CrossRef]

- Díaz, M.; Almendro-Candel, M.B.; Blanco, D.; Jordan, M.M. Aggregate Recycling in Construction: Analysis of the Gaps between the Chilean and Spanish Realities. Buildings 2019, 9, 154. [Google Scholar] [CrossRef] [Green Version]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization in construction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef] [PubMed]

- Gálvez-Martos, J.L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef] [Green Version]

- Koskela, S.; Mattila, T.; Antikainen, R.; Mäenpää, I. Identifying key sectors and measures for a transition towards a low resource economy. Resources 2013, 2, 151–166. [Google Scholar] [CrossRef]

- Khalaf, F.M.; DeVenny, A.S. Properties of new and recycled clay brick aggregates for use in concrete. J. Mater. Civ. Eng. 2005, 17, 456–464. [Google Scholar] [CrossRef]

- Kaming, P.F.; Marliansyah, J. Implementation of Life Cycle Costing: A Case of Hostel Building in Kediri, Eastern Jawa, Indonesia. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bach, Switzerland, 2016; Volume 845, pp. 326–331. [Google Scholar]

- Lockrey, S.; Nguyen, H.; Crossin, E.; Verghese, K. Recycling the construction and demolition waste in Vietnam: Opportunities and challenges in practice. J. Clean. Prod. 2016, 133, 757–766. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).