Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain

Abstract

:1. Introduction

1.1. Objectives

1.2. A Brief Description of Pitahaya

1.3. Description of the Stakeholders and the Productive Process of the Pitahaya Sector in Palora Canton, Ecuador

2. Materials and Methods

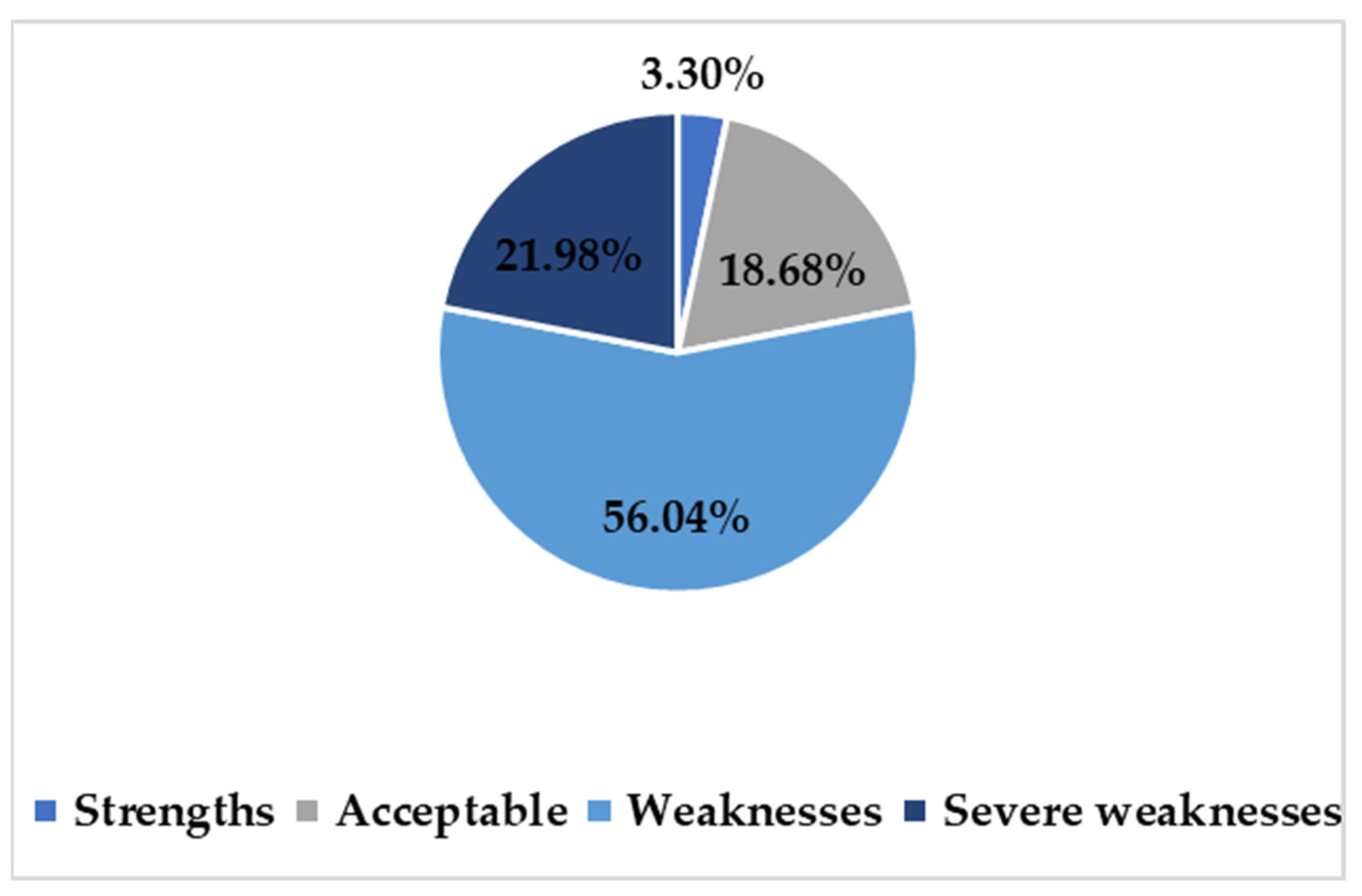

3. Results

4. Discussion

4.1. Comparative Analysis of the Application of the Circular Economy to Other Agri-Food Chains

4.2. Prospects for Improving CE in the Pitahaya Sector’s Agri-Food Chain in Ecuador

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- EC. Closing the Loop–An EU Action Plan for the Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic Social Committee the Committee of the Regions; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Ness, D. Sustainable urban infrastructure in China: Towards a Factor 10 improvement in resource productivity through integrated infrastructure systems. Int. J. Sustain. Dev. World Ecol. 2008, 15, 288–301. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Derkacz, A.J.; Dudziak, A.; Stoma, M. General Concept of Business Process Measures in the Circular Economy. Sustainability 2021, 13, 12675. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Bressanelli, G.; Saccani, N.; Perona, M. Investigating Business Potential and Users’ Acceptance of Circular Economy: A Survey and an Evaluation Model. Sustainability 2022, 14, 609. [Google Scholar] [CrossRef]

- Gamidullaeva, L.; Shmeleva, N.; Tolstykh, T.; Shmatko, A. An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development. Sustainability 2022, 14, 704. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Coghlan, C.; Proulx, P.; Salazar, K. A Food-Circular Economy-Women Nexus: Lessons from Guelph-Wellington. Sustainability 2022, 14, 192. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Golinska, P.; Kosacka, M.; Mierzwiak, R.; Werner-Lewandowska, K. Grey Decision Making as a tool for the classification of the sustainability level of remanufacturing companies. J. Clean. Prod. 2015, 105, 28–40. [Google Scholar] [CrossRef]

- Lagrasta, F.P.; Pontrandolfo, P.; Scozzi, B. Circular Economy Business Models for the Tanzanian Coffee Sector: A Teaching Case Study. Sustainability 2021, 13, 13931. [Google Scholar] [CrossRef]

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Performance Measurement Systems for Circular Supply Chain Management: Current State of Development. Sustainability 2021, 13, 12082. [Google Scholar] [CrossRef]

- Castro, M.B.G.; Remmerswaal, J.A.M.; Brezet, J.C.; Reuter, M.A. Exergy losses during recycling and the resource efficiency of product systems. Resour. Conserv. Recycl. 2007, 52, 219–233. [Google Scholar] [CrossRef]

- Lamolinara, B.; Pérez-Martínez, A.; Guardado-Yordi, E.; Fiallos, C.G.; Diéguez-Santana, K.; Ruiz-Mercado, G.J. Anaerobic digestate management, environmental impacts, and techno-economic challenges. Waste Manag. 2022, 140, 14–30. [Google Scholar] [CrossRef] [PubMed]

- Martin-Gorriz, B.; Gallego-Elvira, B.; Martínez-Alvarez, V.; Maestre-Valero, J.F. Life cycle assessment of fruit and vegetable production in the Region of Murcia (south-east Spain) and evaluation of impact mitigation practices. J. Clean. Prod. 2020, 265, 121656. [Google Scholar] [CrossRef]

- Molina-Cedeño, C.S.; Pillco-Herrera, B.M.; Salazar-Muñoz, E.F.; Coronel-Espinoza, B.D.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Producción más limpia como estrategia ambiental preventiva en el proceso de elaboración de pasta de cacao. Un caso en la Amazonia Ecuatoriana. Ind. Data 2020, 23, 59–72. [Google Scholar] [CrossRef]

- Montero-Vega, F.S.; Molina-Cedeño, C.S.; Pillco-Herrera, B.M.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Evaluación del impacto ambiental de la construcción de una planta de tratamiento de aguas residuales. Caso río Pindo Chico, Puyo, Pastaza, Ecuador. Cienc. Ambient. Y Clima 2020, 3, 23–39. [Google Scholar] [CrossRef]

- Quishpe-López, J.D.; Lliguicota-Guarquila, J.P.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. La producción más limpia, como estrategia de valorización (ecoeficiencia) del centro de faenamiento, Puyo, Pastaza, Ecuador. Rev. Científica De La UCSA 2020, 7, 59–71. [Google Scholar] [CrossRef]

- Soto-Cabrera, A.I.; Panimboza-Ojeda, A.P.; Ramones-Pinargote, A.; Pérez-Martínez, A.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Huella de carbono en el cultivo de la caña de azúcar. Evaluación agrícola de un caso de estudio de la amazonia ecuatoriana. Ingenio Magno 2020, 11, 22–32. [Google Scholar]

- Ramos-Ramos, T.P.; Guevara-Llerena, D.J.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Producción más limpia y ecoeficiencia en el procesado del cacao: Un caso de estudio en ecuador. Investig. Desarro. 2020, 20, 135–146. [Google Scholar] [CrossRef]

- Vilaplana, R.; Alba, P.; Valencia-Chamorro, S. Sodium bicarbonate salts for the control of postharvest black rot disease in yellow pitahaya (Selenicereus megalanthus). Crop Prot. 2018, 114, 90–96. [Google Scholar] [CrossRef]

- Bank, E.C. Foreign Trade. Available online: http://www.bce.fin.ec/index.php/c-exterior (accessed on 21 January 2022).

- Wichienchot, S.; Jatupornpipat, M.; Rastall, R.A. Oligosaccharides of pitaya (dragon fruit) flesh and their prebiotic properties. Food Chem. 2010, 120, 850–857. [Google Scholar] [CrossRef]

- MAG. MAG Mantiene Reuniones de Trabajo con Pequeños Productores de Pitahaya. Available online: https://www.agricultura.gob.ec/mag-mantiene-reuniones-de-trabajo-con-pequenos-productores-de-pitahaya/ (accessed on 21 January 2022).

- Alsarhan, L.M.; Alayyar, A.S.; Alqahtani, N.B.; Khdary, N.H. Circular Carbon Economy (CCE): A Way to Invest CO2 and Protect the Environment, a Review. Sustainability 2021, 13, 11625. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Dieguez-Santana, K.; Zabala-Velin, A.A.; Villarroel-Quijano, K.L.; Sarduy-Pereira, L.B. Evaluation of the Environmental Impact of the Pitahaya Crop, Cantón Palora, Ecuador. TecnoLógicas 2020, 23, 113–128. [Google Scholar] [CrossRef]

- Diéguez-Santana, K.; Rudi, G.R.; Urquiaga, A.J.A.; Muñoz, E.; Sablón-Cossio, N. An assessment tool for the evaluation of circular economy implementation. Acad. Rev. Latinoam. De Adm. 2021, 34, 316–328. [Google Scholar] [CrossRef]

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Kyriakopoulos, G.L.; Kapsalis, V.C.; Aravossis, K.G.; Zamparas, M.; Mitsikas, A. Evaluating Circular Economy under a Multi-Parametric Approach: A Technological Review. Sustainability 2019, 11, 6139. [Google Scholar] [CrossRef] [Green Version]

- Dora, M.; Biswas, S.; Choudhary, S.; Nayak, R.; Irani, Z. A system-wide interdisciplinary conceptual framework for food loss and waste mitigation strategies in the supply chain. Ind. Mark. Manag. 2021, 93, 492–508. [Google Scholar] [CrossRef]

- Vilariño, M.V.; Franco, C.; Quarrington, C. Food loss and Waste Reduction as an Integral Part of a Circular Economy. Front. Environ. Sci. 2017, 5, 21. [Google Scholar] [CrossRef] [Green Version]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Bravo, M.L.; Ruiz, M.; Sablón-Cossío, N. Prospects of the circular economy in an agrifood chain of fine organic aroma cocoa in the province of Manabí. Rev. Técnica De La Fac. De Ing. Univ. Del Zulia 2020, 37, 95–110. [Google Scholar]

- Alvarado, P.M.S.; Cossío, N.S.; Giler, M.A.B. Estudio de la cadena agroalimentaria del plátano en la provincia de Manabí. ECA Sinergia 2021, 12, 155–174. [Google Scholar] [CrossRef]

- Ortiz-Hernández, Y.D.; Carrillo-Salazar, J.A. Pitahaya (Hylocereus spp.): A short review. Comun. Sci. 2012, 3, 220–237. [Google Scholar] [CrossRef]

- Le Bellec, F.; Vaillant, F.; Imbert, E. Pitahaya (Hylocereus spp.): A new fruit crop, a market with a future. Fruits 2006, 61, 237–250. [Google Scholar] [CrossRef] [Green Version]

- Vásquez-Castillo, W.; Aguilar, K.; Vilaplana, R.; Viteri, P.; Viera, W.; Valencia-Chamorro, S.J.A.C. Calidad del fruto y pérdidas poscosecha de pitahaya amarilla (Selenicereus megalanthus Haw.) en Ecuador. Agron. Colomb. 2016, 34, S1081–S1083. [Google Scholar]

- Chemah, T.C.; Aminah, A.; Noriham, A.; Wan Aida, W.M. Determination of pitaya seeds as a natural antioxidant and source of essential fatty acids. Int. Food Res. J. 2010, 17, 1003–1010. [Google Scholar]

- Omidizadeh, A.; Yusof, R.M.; Ismail, A.; Roohinejad, S.; Nateghi, L.; Zuki, M.; Bakar, A. Cardioprotective compounds of red pitaya (Hylocereus polyrhizus) fruit. J. Food Agric. Environ. 2011, 9, 152–156. [Google Scholar] [CrossRef]

- Esquivel, P.; Araya, Y. Características del fruto de la pitahaya (Hylocereus sp.) y su potencial de uso en la industria alimentaria. Rev. Venez. De Cienc. Y Tecnol. De Aliment. 2012, 3, 113–129. [Google Scholar]

- Verona-Ruiz, A.; Urcia-Cerna, J.; Paucar-Menacho, L.M. Pitahaya (Hylocereus spp.): Cultivo, características fisicoquímicas, composición nutricional y compuestos bioactivos. Sci. Agropecu. 2020, 11, 439–453. [Google Scholar] [CrossRef]

- SENADI. SENADI Entrega el Certificado de Denominación de Origen por la Pitahaya Amazónica de Palora. Available online: https://www.derechosintelectuales.gob.ec/senadi-entrega-el-certificado-de-denominacion-de-origen-por-la-pitahaya-amazonica-de-palora/ (accessed on 10 November 2021).

- Vargas, Y.; Pico, J.; Díaz, A.; Sotomayor, D.; Burbano, A.; Caicedo, C.; Paredes, N.; Congo, C.; Tinoco, L.; Bastidas, S.; et al. Manual Técnico del Cultivo de Pitahaya; INIAP: Joya de los Sachas, Ecuador, 2020; p. 39. [Google Scholar]

- BCE. Exportaciones por Partidas Arancelarias. Frutas no Tradicionales. Pitahaya (Cereus spp.) Frescas. Available online: https://www.bce.fin.ec/ (accessed on 10 November 2021).

- El Universo. Ecuador Exportó Primer Contenedor de Pitahaya Hacia Europa. Available online: https://www.eluniverso.com/noticias/economia/ecuador-exporto-primer-contenedor-de-pitahaya-hacia-europa-nota/ (accessed on 10 November 2021).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- de Oliveira, C.T.; Luna, M.M.M.; Campos, L.M.S. Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics towards circular economy. J. Clean. Prod. 2019, 235, 562–573. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress Toward a Circular Economy in China. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- De Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.-H. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef] [PubMed]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Campos, L.M.S.; Cauchick-Miguel, P.A. Cleaner production as an antecedent for circular economy paradigm shift at the micro-level: Evidence from a home appliance manufacturer. J. Clean. Prod. 2018, 185, 740–748. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van Der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Riding, M.J.; Herbert, B.M.J.; Ricketts, L.; Dodd, I.; Ostle, N.; Semple, K.T. Harmonising conflicts between science, regulation, perception and environmental impact: The case of soil conditioners from bioenergy. Environ. Int. 2015, 75, 52–67. [Google Scholar] [CrossRef]

- Park, J.; Díaz-Posada, N.; Mejía-Dugand, S. Challenges in implementing the extended producer responsibility in an emerging economy: The end-of-life tire management in Colombia. J. Clean. Prod. 2018, 189, 754–762. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- Witjes, S.; Lozano, R. Towards a more Circular Economy: Proposing a framework linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Li, J.; Yu, K. A study on legislative and policy tools for promoting the circular economic model for waste management in China. J. Mater. Cycles Waste Manag. 2011, 13, 103–112. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef] [Green Version]

- EL Comercio. Lenín Moreno Amplia Estado de Excepción en Ecuador Por COVID-19. Available online: https://www.elcomercio.com/actualidad/politica/presidente-moreno-excepcion-pandemia.html (accessed on 14 February 2022).

- Raj, A.; Mukherjee, A.A.; de Sousa Jabbour, A.B.L.; Srivastava, S.K. Supply chain management during and post-COVID-19 pandemic: Mitigation strategies and practical lessons learned. J. Bus. Res. 2022, 142, 1125–1139. [Google Scholar] [CrossRef]

- Blazy, J.M.; Causeret, F.; Guyader, S. Immediate impacts of COVID-19 crisis on agricultural and food systems in the Caribbean. Agric. Syst. 2021, 190, 103106. [Google Scholar] [CrossRef]

- Barman, A.; Das, R.; De, P.K. Impact of COVID-19 in food supply chain: Disruptions and recovery strategy. Curr. Res. Behav. Sci. 2021, 2, 100017. [Google Scholar] [CrossRef]

- AGROCALIDAD. Manual de Procedimientos para la Certificación de Unidades de Producción en Buenas Prácticas Agropecuarias; Ministerio de Agricultura y Ganadería: Quito, Ecuador, 2020. [Google Scholar]

- Fernández-Ochoa, Á.; Leyva-Jiménez, F.J.; Pimentel-Moral, S.; del Carmen Villegas-Aguilar, M.; Alañón, M.E.; Segura-Carretero, A.; de la Luz Cádiz-Gurrea, M. Revalorisation of Agro-Industrial Wastes into High Value-Added Products. In Sustainable Bioconversion of Waste to Value Added Products; Inamuddin, K.A., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 229–245. [Google Scholar] [CrossRef]

- El-Chichakli, B.; Von Braun, J.; Lang, C.; Barben, D.; Philp, J. Policy: Five cornerstones of a global bioeconomy. Nature 2016, 535, 221–223. [Google Scholar] [CrossRef] [PubMed]

- Diéguez-Santana, K.; Casas-Ledón, Y.; Loureiro Salabarria, J.A.; Pérez-Martínez, A.; Arteaga-Pérez, L.E. A Life Cycle Assessment of Bread Production: A Cuban Case Study. J. Environ. Account. Manag. 2020, 8, 125–137. [Google Scholar] [CrossRef]

- Pleissner, D.; Lin, C.S.K. Valorisation of food waste in biotechnological processes. Sustain. Chem. Process. 2013, 1, 21. [Google Scholar] [CrossRef] [Green Version]

- Sridhar, A.; Ponnuchamy, M.; Kapoor, A.; Prabhakar, S. Valorization of food waste as adsorbents for toxic dye removal from contaminated waters: A review. J. Hazard. Mater. 2022, 424, 127432. [Google Scholar] [CrossRef]

- Diéguez-Santana, K.; Sarduy-Pereira, L.B.; Decker, M. Characterization and Quantification of Municipal Solid Waste in Fátima, Ecuadorian Amazon Parish. J. Environ. Treat. Tech. 2021, 9, 392–401. [Google Scholar] [CrossRef]

- Mikkilä, M.; Utanun, P.; Luhas, J.; Horttanainen, M.; Linnanen, L. Sustainable Circular Bioeconomy—Feasibility of Recycled Nutrients for Biomass Production within a Pulp and Paper Integration in Indonesia, Southeast Asia. Sustainability 2021, 13, 10169. [Google Scholar] [CrossRef]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef] [PubMed]

- Hegde, S.; Trabold, T.A. Anaerobic Digestion of Food Waste with Unconventional Co-Substrates for Stable Biogas Production at High Organic Loading Rates. Sustainability 2019, 11, 3875. [Google Scholar] [CrossRef] [Green Version]

- Sridhar, A.; Kapoor, A.; Kumar, P.S.; Ponnuchamy, M.; Balasubramanian, S.; Prabhakar, S. Conversion of food waste to energy: A focus on sustainability and life cycle assessment. Fuel 2021, 302, 121069. [Google Scholar] [CrossRef]

- Byun, J.; Kwon, O.; Park, H.; Han, J. Food waste valorization to green energy vehicles: Sustainability assessment. Energy Environ. Sci. 2021, 14, 3651–3663. [Google Scholar] [CrossRef]

- Correddu, F.; Lunesu, M.F.; Buffa, G.; Atzori, A.S.; Nudda, A.; Battacone, G.; Pulina, G. Can Agro-Industrial By-Products Rich in Polyphenols be Advantageously Used in the Feeding and Nutrition of Dairy Small Ruminants? Animals 2020, 10, 131. [Google Scholar] [CrossRef] [Green Version]

- Giler, E.V.C.; Erazo, J.M.M.; Silva, R.A.V.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. La producción más limpia en el sector porcino: Una experiencia desde la Amazonía ecuatoriana. Anales Científicos 2019, 80, 76–91. [Google Scholar] [CrossRef]

- Castrica, M.; Tedesco, D.E.A.; Panseri, S.; Ferrazzi, G.; Ventura, V.; Frisio, D.G.; Balzaretti, C.M. Pet Food as the Most Concrete Strategy for Using Food Waste as Feedstuff within the European Context: A Feasibility Study. Sustainability 2018, 10, 2035. [Google Scholar] [CrossRef] [Green Version]

- Diéguez-Santana, K.; Sarduy-Pereira, L.B.; Casas-Ledón, Y.; Arteaga-Pérez, L.E. Cleaner Production Implementation in a Cocoa Processing Plant in Ecuadorian Amazon. J. Environ. Account. Manag. 2021, 9, 173–188. [Google Scholar] [CrossRef]

- Ishida, K.; Kishi, Y.; Oishi, K.; Hirooka, H.; Kumagai, H. Effects of feeding polyphenol-rich winery wastes on digestibility, nitrogen utilization, ruminal fermentation, antioxidant status and oxidative stress in wethers. Anim. Sci. J. 2015, 86, 260–269. [Google Scholar] [CrossRef]

- Mirzaei-Aghsaghali, A.; Maheri-Sis, N. Nutritive Value of Some Agroindustrial By-Products for ruminants—A Review. World J. Zool. 2008, 3, 40–46. [Google Scholar]

- Ilibay-Granda, C.G.; González-Morales, B.D.; Muñoz-Ganan, R.D.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Estrategia de producción más limpia para la destilería de alcohol artesanal “San Vicente”, Pastaza, Ecuador. Bistua Rev. De La Fac. De Cienc. Basicas 2021, 19, 24–30. [Google Scholar] [CrossRef]

- Cerda, A.; Artola, A.; Font, X.; Barrena, R.; Gea, T.; Sánchez, A. Composting of food wastes: Status and challenges. Bioresour. Technol. 2018, 248, 57–67. [Google Scholar] [CrossRef] [Green Version]

- Ghinea, C.; Leahu, A. Monitoring of Fruit and Vegetable Waste Composting Process: Relationship between Microorganisms and Physico-Chemical Parameters. Processes 2020, 8, 302. [Google Scholar] [CrossRef] [Green Version]

- Musa, A.M.; Ishak, C.F.; Jaafar, N.M.; Karam, D.S. Carbon Dynamics of Fruit and Vegetable Wastes and Biodegradable Municipal Waste Compost-Amended Oxisol. Sustainability 2021, 13, 10869. [Google Scholar] [CrossRef]

- O’Connor, J.; Hoang, S.A.; Bradney, L.; Dutta, S.; Xiong, X.; Tsang, D.C.W.; Ramadass, K.; Vinu, A.; Kirkham, M.B.; Bolan, N.S. A review on the valorisation of food waste as a nutrient source and soil amendment. Environ. Pollut. 2021, 272, 115985. [Google Scholar] [CrossRef] [PubMed]

- Chiaraluce, G.; Bentivoglio, D.; Finco, A. Circular Economy for a Sustainable Agri-Food Supply Chain: A Review for Current Trends and Future Pathways. Sustainability 2021, 13, 9294. [Google Scholar] [CrossRef]

- Hernández-Alcántara, A.M.; Totosaus, A.; Pérez-Chabela, M.L. Evaluation of Agro-Industrial Co-Products as Source of Bioactive Compounds: Fiber, Antioxidants and Prebiotic. Acta Univ. Cibiniensis. Ser. E Food Technol. 2016, 20, 3–16. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, M.S.; Santos, M.C.; Moro, T.M.; Basto, G.J.; Andrade, R.M.; Gonçalves, É.C. Formulation and characterization of functional foods based on fruit and vegetable residue flour. J. Food Sci. Technol. 2015, 52, 822–830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diazvela, J.; Totosaus, A.; Pérez-Chabela, M. Integration of Agroindustrial Co-Products as Functional Food Ingredients: Cactus Pear (Ountia ficus indica) Flour and Pineapple (Ananas comosus) Peel Flour as Fiber Source in Cooked Sausages Inoculated with Lactic Acid Bacteria. J. Food Process. Preserv. 2015, 39, 2630–2638. [Google Scholar] [CrossRef]

- El Sohaimy, S. Functional foods and nutraceuticals-modern approach to food science. World Appl. Sci. J. 2012, 20, 691–708. [Google Scholar] [CrossRef]

- Rudra, S.G.; Nishad, J.; Jakhar, N.; Kaur, C. Food industry waste: Mine of nutraceuticals. Int. J. Sci. Environ. Technol. 2015, 4, 205–229. [Google Scholar]

- Galanakis, C.M. Emerging technologies for the production of nutraceuticals from agricultural by-products: A viewpoint of opportunities and challenges. Food Bioprod. Process. 2013, 91, 575–579. [Google Scholar] [CrossRef]

- Prakash, L.; Majeed, M. Natural Ingredients for Anti-Ageing Skin Care. Househ. Pers. Care Today 2009, 2, 44–46. [Google Scholar]

- Panzella, L. Natural Phenolic Compounds for Health, Food and Cosmetic Applications. Antioxidants 2020, 9, 427. [Google Scholar] [CrossRef] [PubMed]

| Item | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | Year 6 | Year 7 | Year 8 |

|---|---|---|---|---|---|---|---|---|

| Land preparation | 585 | - | - | - | - | - | - | - |

| Planting | 1253 | - | - | - | - | - | - | - |

| Trellising | 1180 | - | - | - | - | - | - | - |

| Weed control | 660 | 720 | 720 | 720 | 720 | 720 | 720 | 720 |

| Insect control | 140 | 540 | 1080 | 1080 | 1080 | 1080 | 1080 | 1080 |

| Disease control | 150 | 600 | 840 | 840 | 840 | 840 | 840 | 840 |

| Fertilization | 1340 | 2495 | 2960 | 2960 | 2960 | 2960 | 2960 | 2960 |

| Pruning | 480 | 585 | 585 | 585 | 585 | 585 | 585 | 585 |

| Harvesting | - | 75 | 750 | 750 | 750 | 750 | 750 | 750 |

| Total cost | 5788 | 5015 | 6935 | 6935 | 6935 | 6935 | 6935 | 6935 |

| No. | Criterion | Mean | SD | Min. | Median | Max. | Evaluation |

|---|---|---|---|---|---|---|---|

| 1 | Supply of materials/Raw materials | 1.66 | 0.16 | 1.42 | 1.72 | 1.83 | Low Level |

| 2 | Design | 1.99 | 0.15 | 1.85 | 1.93 | 2.2 | Low Level |

| 3 | Manufacturing | 2.57 | 0.13 | 2.4 | 2.6 | 2.75 | Medium Level |

| 4 | Business cycle | 2.44 | 0.14 | 2.3 | 2.45 | 2.6 | Medium Level |

| 5 | Distribution and sales (chain) | 1.72 | 0.17 | 1.45 | 1.75 | 1.9 | Low Level |

| 6 | Consumption and use (reuse of products) | 2.23 | 0.15 | 2 | 2.2 | 2.4 | Low Level |

| 7 | 4R | 2.13 | 0.12 | 2 | 2.1 | 2.3 | Low Level |

| 8 | Remanufacturing | 1.69 | 0.19 | 1.4 | 1.75 | 1.9 | Low Level |

| 9 | Sustainability | 2.78 | 0.11 | 2.65 | 2.75 | 2.95 | Medium Level |

| No. | Criterion | Cocoa Chain, Mexico | Organic Cocoa, Manabí, Ecuador | Coconut Chain, Manabí | Banana Chain, Manabí | Pitahaya, Ecuador |

|---|---|---|---|---|---|---|

| Reference | [31] | [37] | [31] | [38] | This work | |

| 1 | Source or supply | 2.54 | 2.06 | 1.09 | 2.63 | 1.72 |

| 2 | Design | 2.25 | 2.69 | 1.40 | 2.88 | 1.93 |

| 3 | Manufacturing | 2.80 | 1.30 | 1.81 | 2.83 | 2.60 |

| 4 | Business cycle | 3.50 | 2.00 | 2.39 | 2.68 | 2.45 |

| 5 | Distribution and sales | 3.23 | 2.98 | 1.39 | 2.72 | 1.75 |

| 6 | Consumption and use | 3.22 | 1.19 | 1.46 | 2.66 | 2.20 |

| 7 | 4R | 2.94 | 1.64 | 1.30 | 2.69 | 2.10 |

| 8 | Remanufacturing | 2.80 | 1.00 | 1.01 | 2.93 | 1.75 |

| 9 | Sustainability | 3.50 | 4.03 | 2.21 | 2.94 | 2.75 |

| - | Total (9 indicators) | 2.98 | 2.10 | 1.56 | 2.77 | 2.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diéguez-Santana, K.; Sarduy-Pereira, L.B.; Sablón-Cossío, N.; Bautista-Santos, H.; Sánchez-Galván, F.; Ruíz Cedeño, S.d.M. Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain. Sustainability 2022, 14, 2950. https://doi.org/10.3390/su14052950

Diéguez-Santana K, Sarduy-Pereira LB, Sablón-Cossío N, Bautista-Santos H, Sánchez-Galván F, Ruíz Cedeño SdM. Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain. Sustainability. 2022; 14(5):2950. https://doi.org/10.3390/su14052950

Chicago/Turabian StyleDiéguez-Santana, Karel, Liliana B. Sarduy-Pereira, Neyfe Sablón-Cossío, Horacio Bautista-Santos, Fabiola Sánchez-Galván, and Sebastiana del Monserrate Ruíz Cedeño. 2022. "Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain" Sustainability 14, no. 5: 2950. https://doi.org/10.3390/su14052950

APA StyleDiéguez-Santana, K., Sarduy-Pereira, L. B., Sablón-Cossío, N., Bautista-Santos, H., Sánchez-Galván, F., & Ruíz Cedeño, S. d. M. (2022). Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain. Sustainability, 14(5), 2950. https://doi.org/10.3390/su14052950