Potential Contribution to Carbon Neutrality Strategy from Industrial Symbiosis: Evidence from a Local Coal-Aluminum-Electricity-Steel Industrial System

Abstract

:1. Introduction

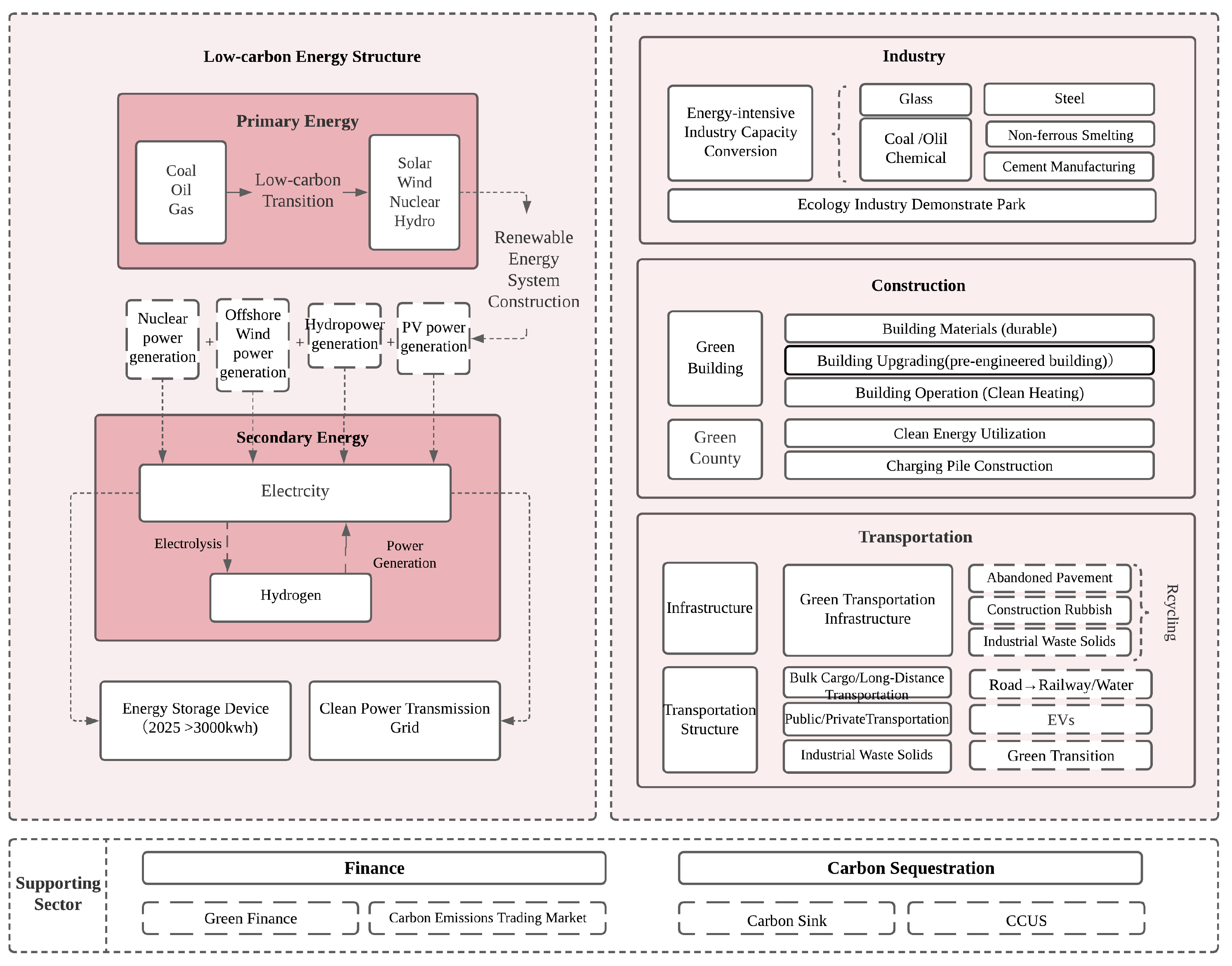

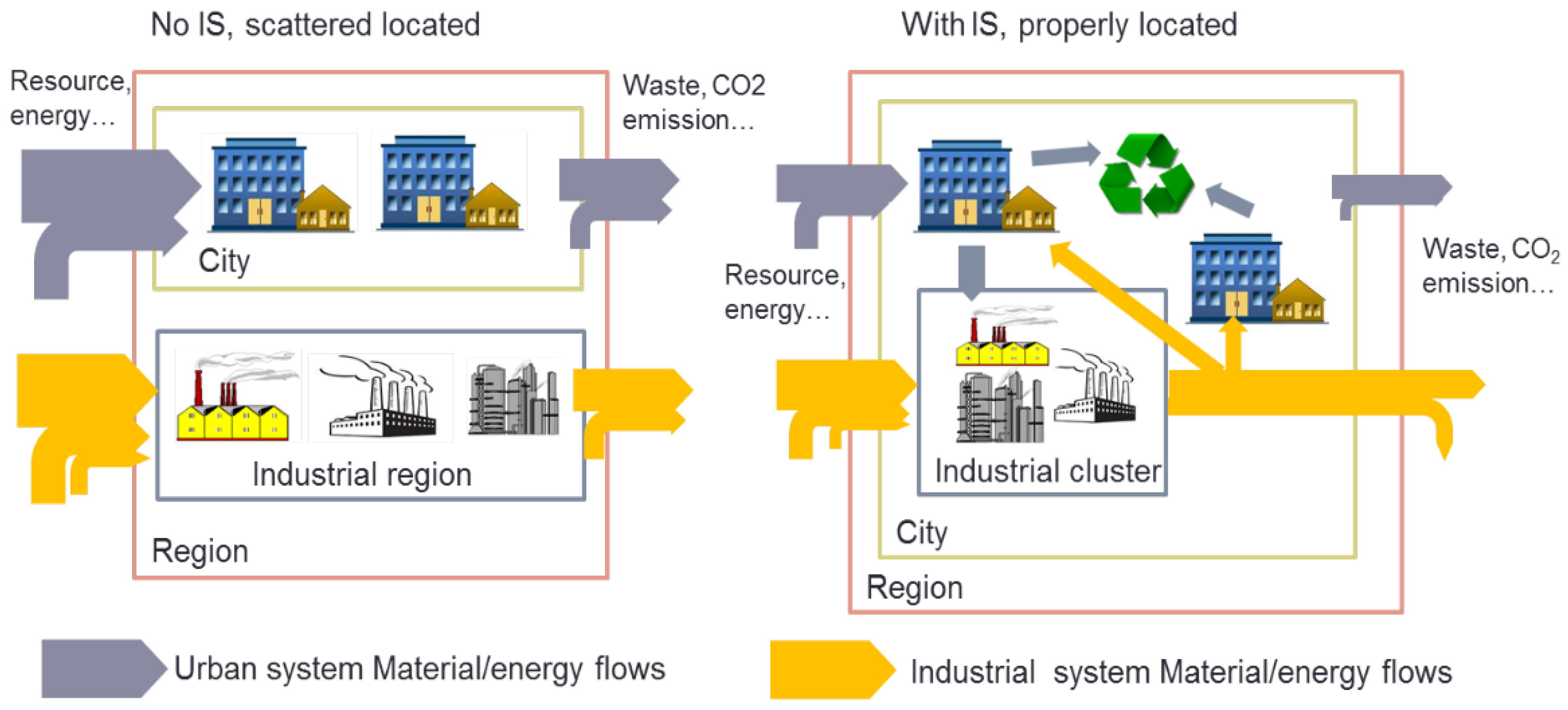

2. Carbon Neutrality Strategy and Industrial Symbiosis

3. Materials and Methods

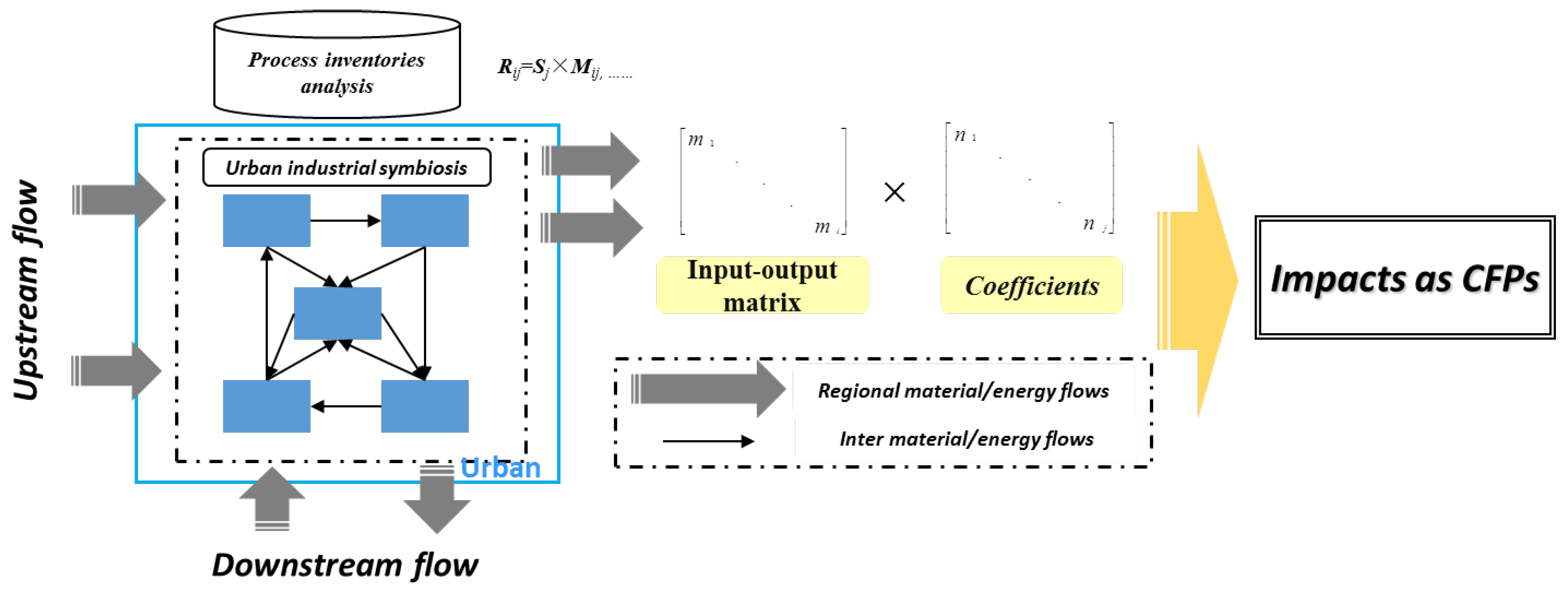

3.1. Model Integration Scheme

3.2. Hybrid Approach for CFP Analysis

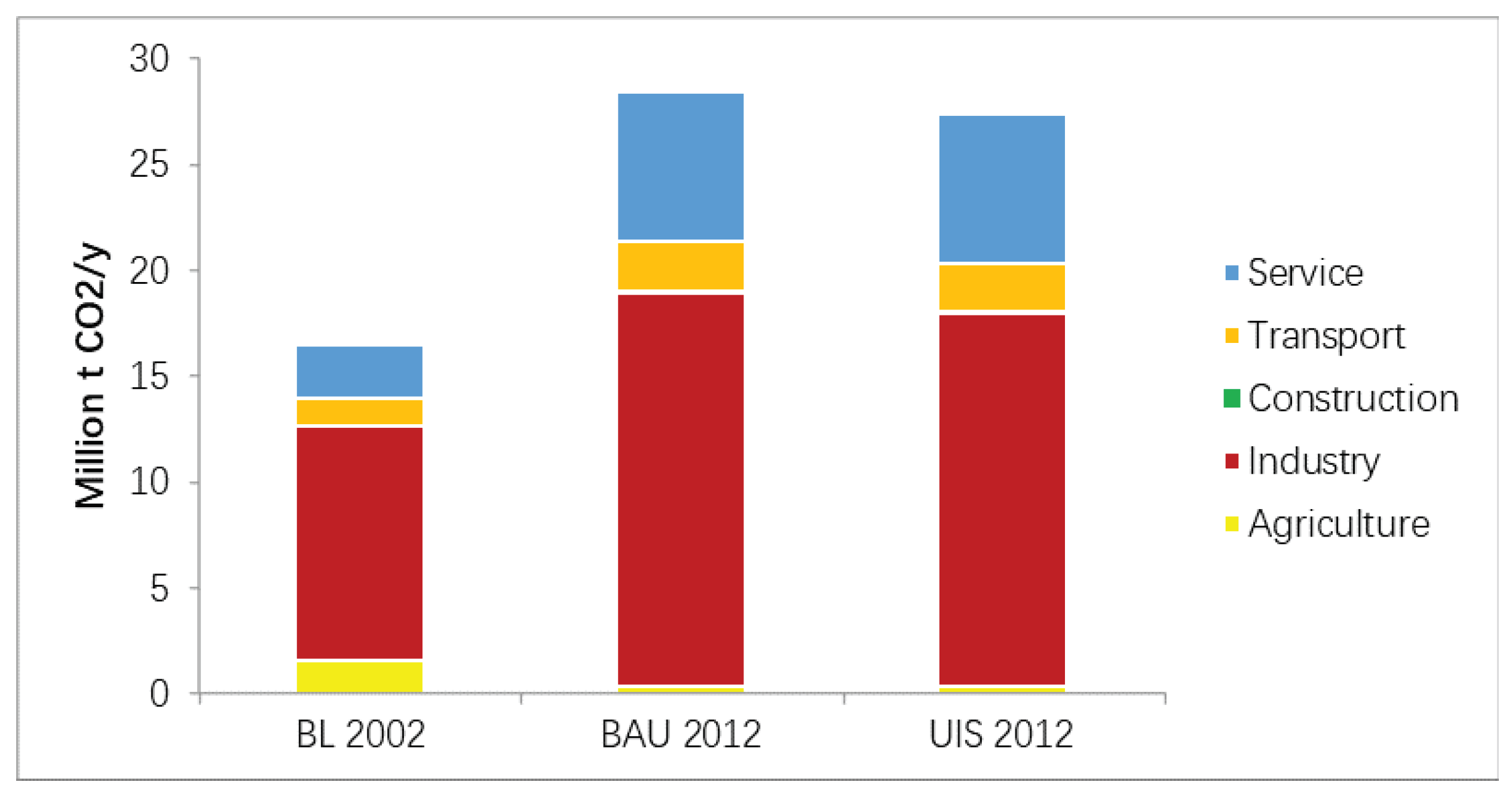

3.3. The Setting of Scenarios

- a.

- Baseline scenario in 2002, named BL 2002;

- b.

- Business-as-usual scenario in 2012: Regular technological development and economic growth by 2012, named BAU 2012;

- c.

- Urban Industry Symbiosis Scenario 2012: Considering multiple urban industry symbiosis programs based on local conditions, named UIS 2012.

3.4. Data Source

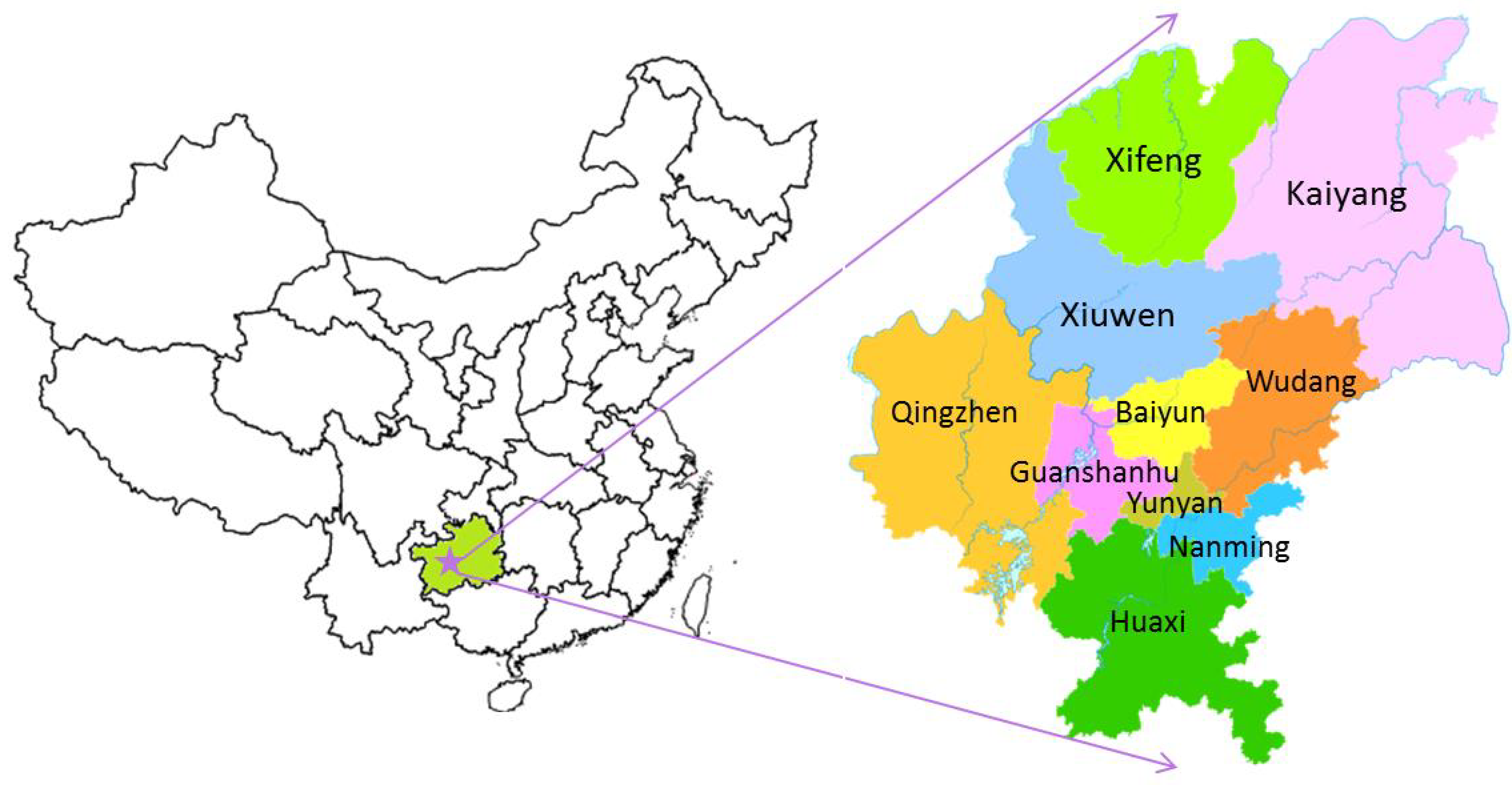

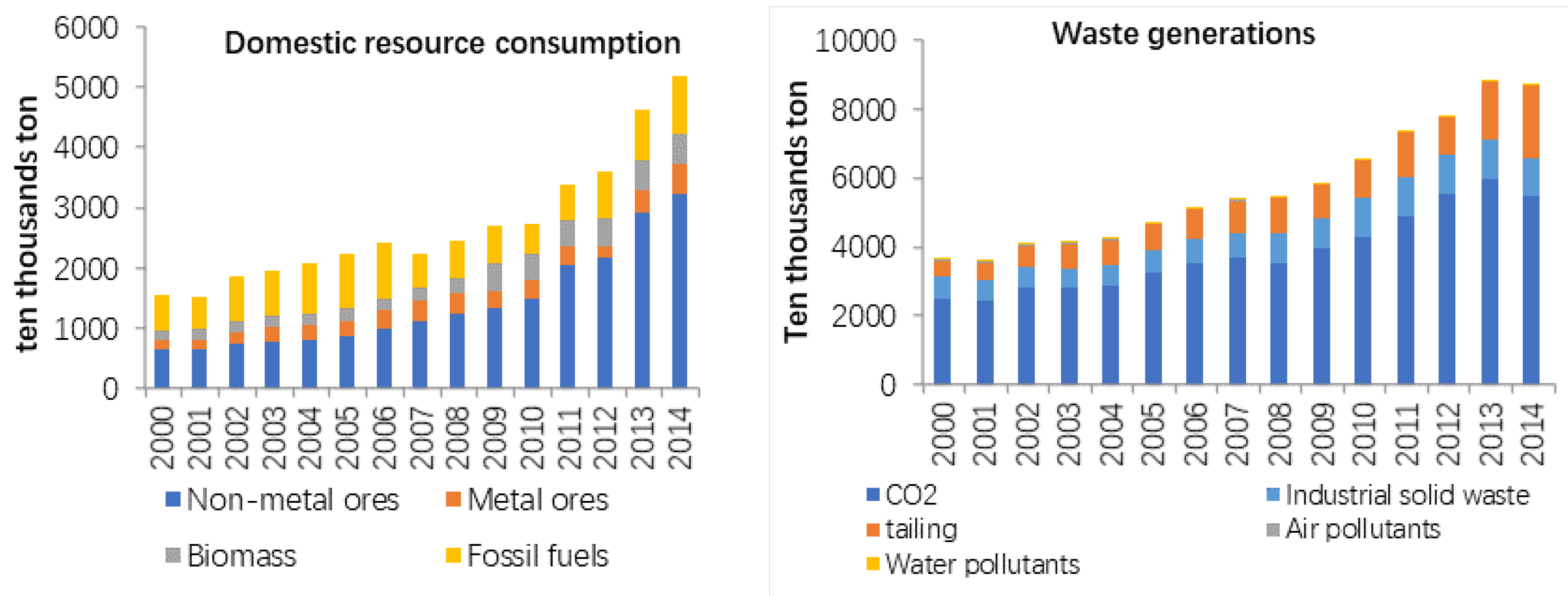

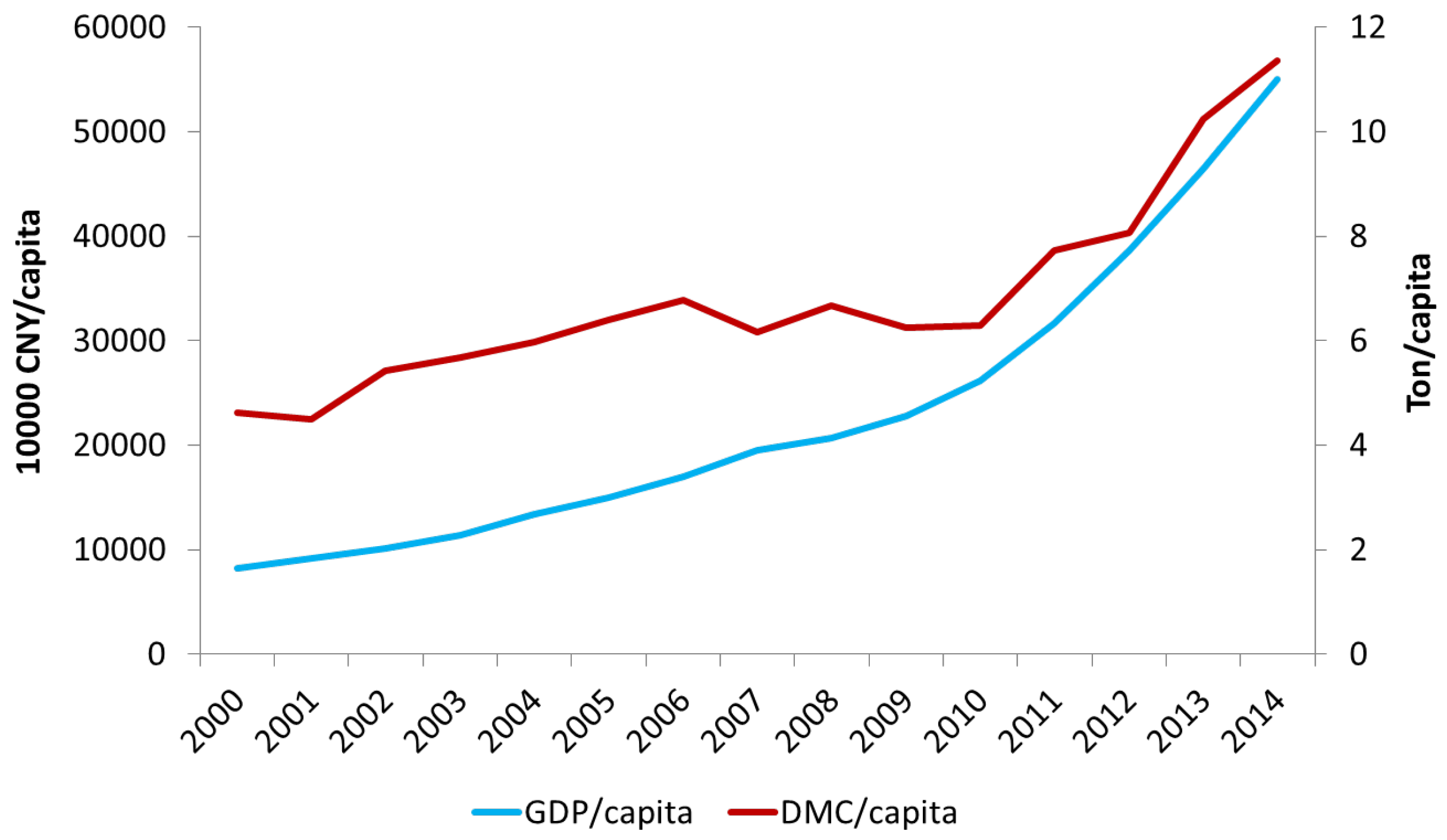

4. Introduction to the Case City

5. Results and Discussions

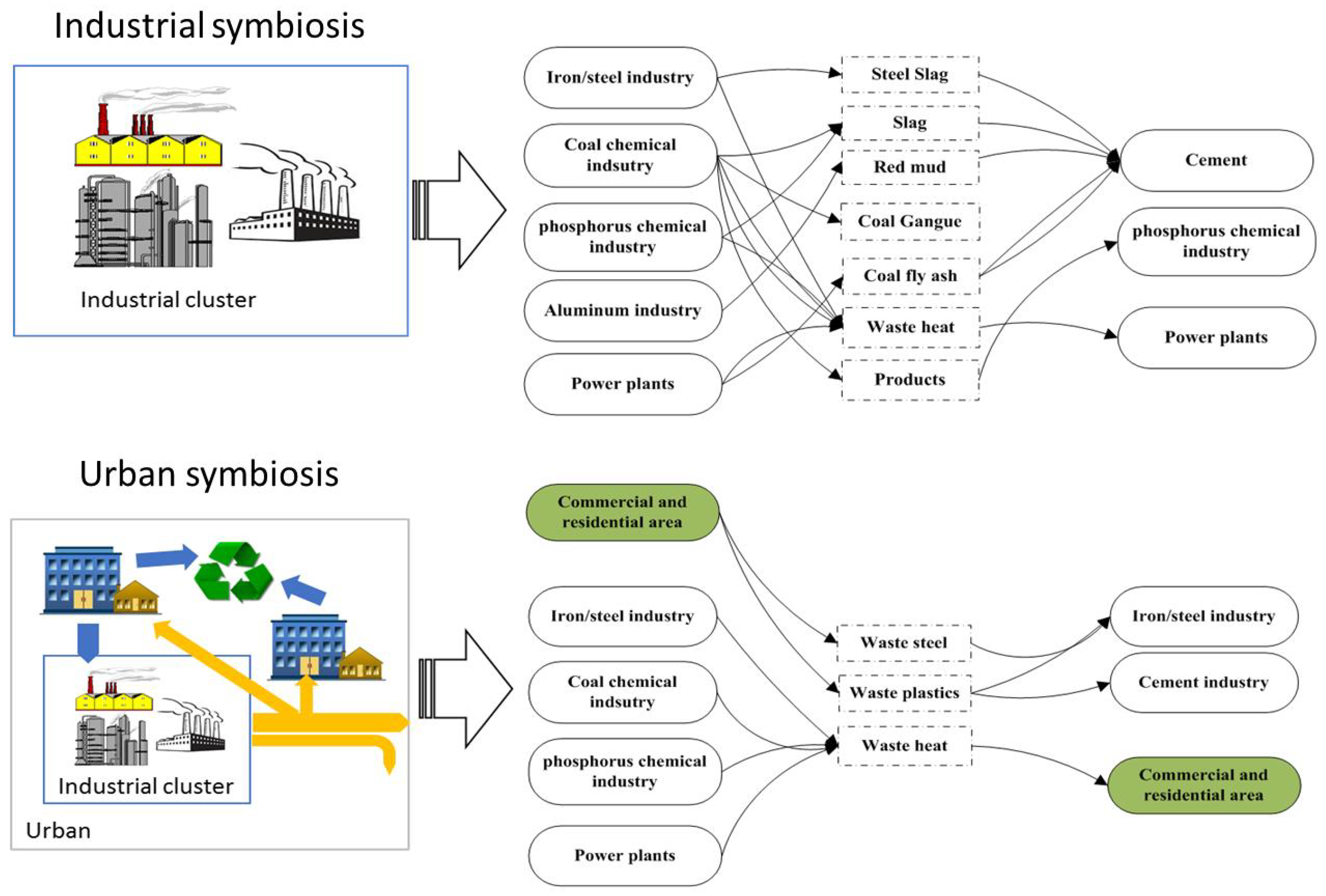

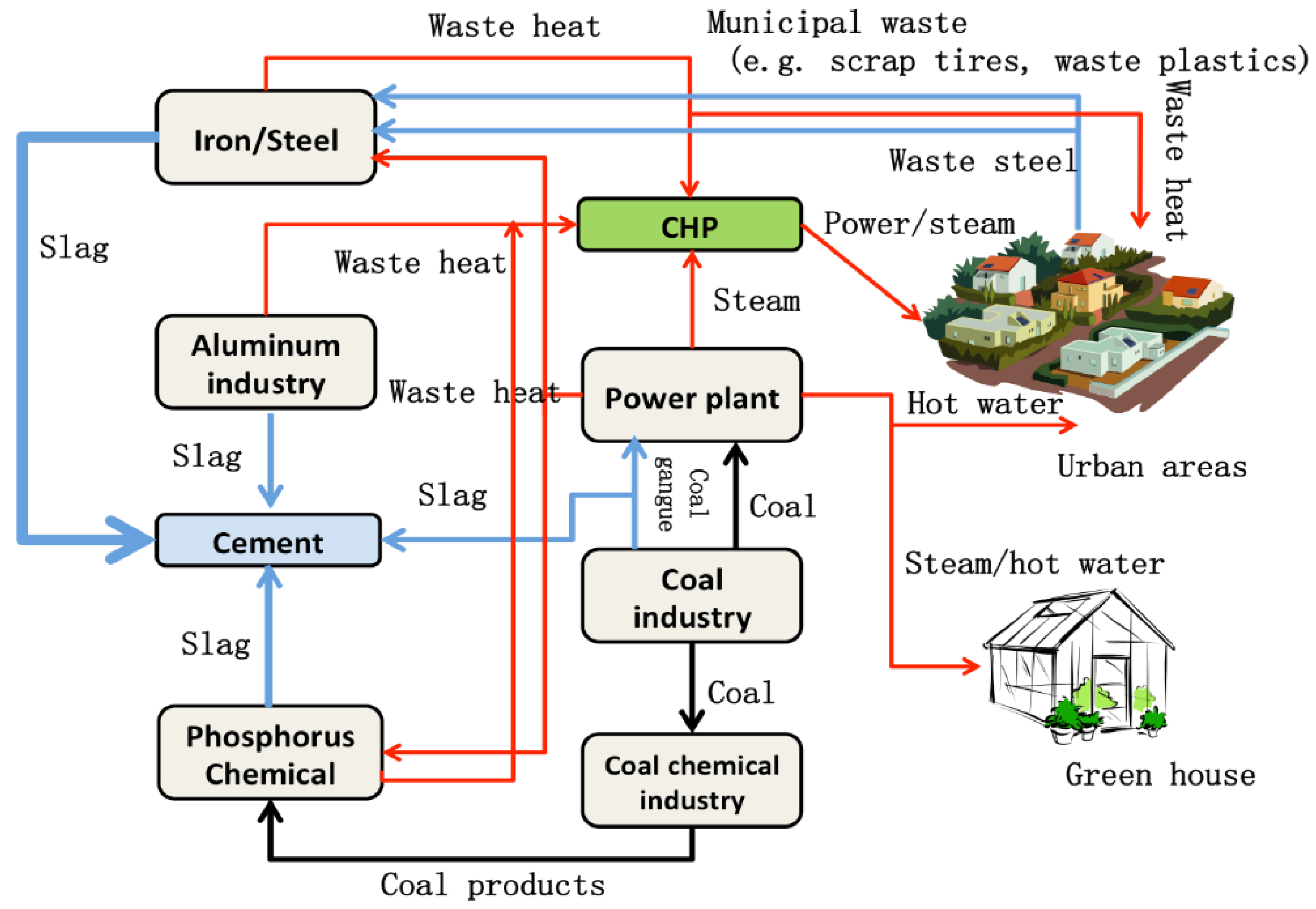

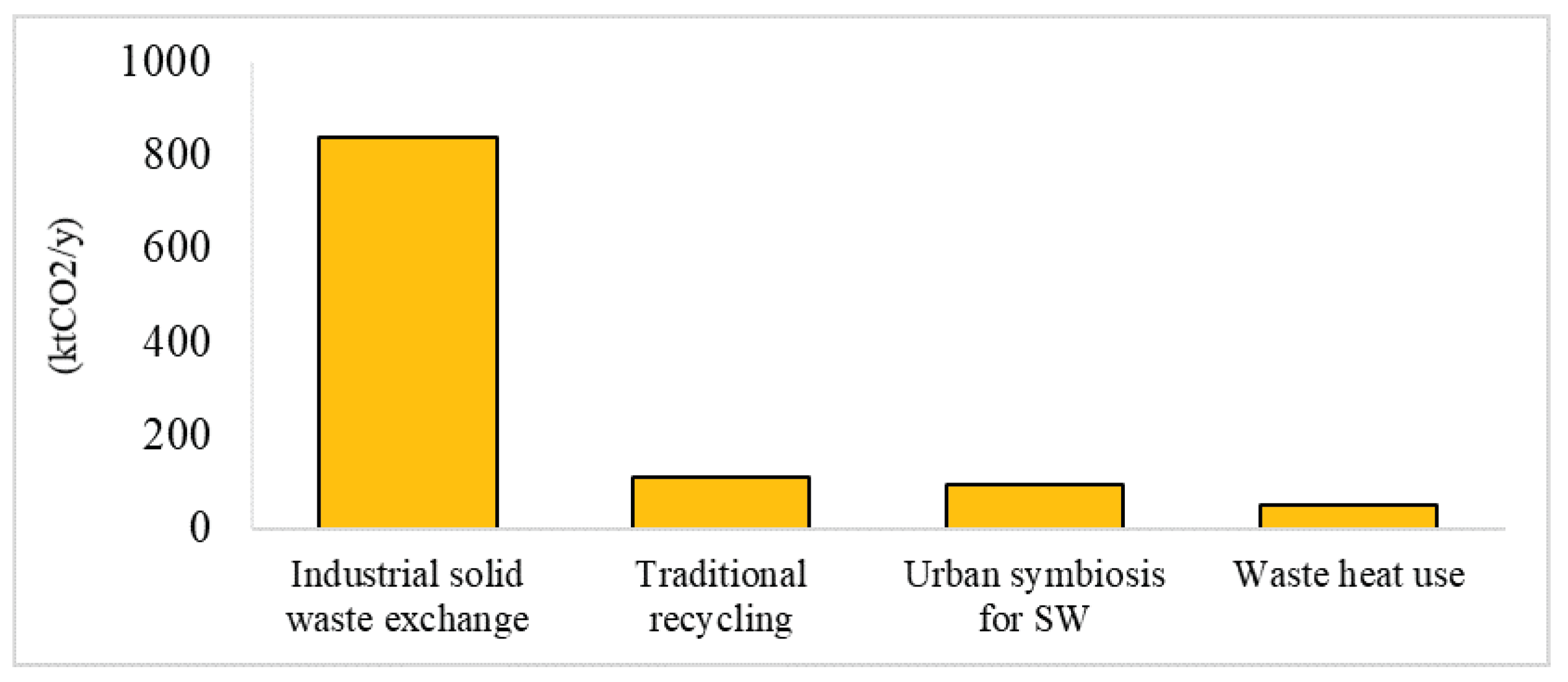

5.1. Design of Urban Industrial Symbiosis Scenarios

- a.

- Industrial solid waste exchanges: slag and coal gangue are recycled in the cement industry;

- b.

- Urban symbiosis for solid waste: urban municipal solid waste is recycled in the furnaces of iron and steel, and the cement industry replaces fossil fuels such as coke;

- c.

- Waste heat use: including the utilization of industrial waste heat and the provision of waste heat from industries to downtown areas (such as central heating systems for commercial and residential buildings) and the agricultural sector (such as from steam to greenhouses to produce high value-added agricultural products).

- d.

- Traditional recycling: such as scrap steel recycling.

- (a)

- The substitution of steel-making waste (steel slag) for saved concrete raw material (such as the clinker), at the scale of 120 kt/y;

- (b)

- The substitution of cement material with phosphorus slag, at the scale of 500 kt/y;

- (c)

- The substitution of aluminum-making waste for concrete raw material, to save clinker and related resource and energy in producing clinker, at the scale of 400 kt/y;

- (d)

- Coal gangue resulting from power generation could be recycled and used to substitute cement raw materials, at the scale of 100 kt/y;

- (e)

- To recycle and use coal flying ash, to substitute cement raw materials, at the scale of 200 kt/y;

- (f)

- To recycle and reuse waste plastics, to substitute the fossil fuel consumption in the furnace of the steel plant, at the scale of 10 kt/y;

- (g)

- Waste heat recovery and provision to the steel and chemical plant, as substitute for the in-plant steam generation, so as to reduce fossil fuel consumption. The waste heat is also provided to CHP for the urban district central heating system, and the total scale is 300 t/y;

- (h)

- Recycling of steel scrap to save the raw material and energy consumption in the steel plant, at the scale of 100 kt/y.

5.2. Scenarios Analysis

6. Discussion

- a.

- As a final part of this section, research limitations and future concerns are discussed. From the perspective of urban CFP accounting methodology, uncertainty will be generated by using the provincial-level IOTs to present the interaction of sectors at the urban level. Hence, in the future, conducting an urban-level survey so that more detailed urban IO data could be compiled will significantly improve the current approach. Particular, in future studies, a sensitivity analysis on the coefficient matrix (in this study, we only borrowed the matrix from provincial IoTs, but it has the potential to use localized data to adjust and verify the coefficient matrix) will be helpful to test and verify the IOA.

- b.

- When tracing the urban CFPs, the trans-boundary issues (e.g., material and waste flows that go into and out of Guiyang) are not analyzed in depth at the current stage. As discussed in Section 2, one merit of urban industrial symbiosis is the optimization of the location of facilities and infrastructures, based on an optimized regional material and energy flow network. In this way, the regional supply chain can be improved from a broad viewpoint. A multi-regional input–output model (MRIO) is a powerful tool for investigating the impacts related to the trans-boundary flows. In our next stage of research, MRIO of the effects of urban industrial symbiosis on regional metabolism will be considered.

7. Conclusions and Implications

- (1)

- Generalizing urban industrial symbiosis: it enables the optimization of the supply chain and the relationship of industries and areas, except for rural areas, by improving the life-cycle closing loops, hence offering an effective and efficient pathway for urban transition. The local stakeholders are encouraged to apply urban industrial symbiosis to regional planning. The academic field and local decision makers are urged to abandon the traditional sense of removing industries or end-of-pipe pollution control, and to make an effort to foster system innovation.

- (2)

- To support the generalization of urban industrial symbiosis, efficient technologies are the basis. National circular technologies and product inventories and standards, technical guidance for the planning of industrial parks while considering symbiosis, as well as quality standards for the input material as guidance for waste generators are all encouraged to be established and/or enhanced.

- (3)

- Carbon footprint analysis provides a powerful policy tool for dealing with emissions-related issues. However, it must be considered that the premise of CFP is still challenging, partly because of the lack of reliable city data. Therefore, the construction of related databases, e.g., a multi-regional input–output dataset and an urban-level inventory dataset, are highly recommended so as to provide a fundamental basis for CFPs such as the development of decision support tools.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFP | Carbon footprint |

| UIS | Urban industrial symbiosis |

| DMC | Domestic material consumption |

| GDP | Cross domestic production |

| CNY | Chinese yuan |

| kt | Thousand ton |

| GJ | Giga joules |

| tce | Ton coal equivalent. 1 tce = 29.27 GJ |

References

- Rodić, L.; Wilson, C.D. Resolving Governance Issues to Achieve Priority Sustainable Development Goals Related to Solid Waste Management in Developing Countries. Sustainability 2017, 9, 404. [Google Scholar] [CrossRef] [Green Version]

- Kharrazi, A.; Qin, H.; Zhang, Y. Urban Big Data and Sustainable Development Goals: Challenges and Opportunities. Sustainability 2016, 8, 1293. [Google Scholar] [CrossRef] [Green Version]

- Dong, L.; Fujita, T.; Dai, M.; Geng, Y.; Ren, J.; Fujii, M.; Wang, Y.; Ohnishi, S. Towards a preventative eco-industrial development: An industrial and urban symbiosis case in one typical industrial city in China. J. Clean. Prod. 2016, 114, 387–400. [Google Scholar] [CrossRef]

- Mattoni, B.; Gugliermetti, F.; Bisegna, F. A multilevel method to assess and design the renovation and integration of Smart Cities. Sustain. Cities Soc. 2015, 15, 105–119. [Google Scholar] [CrossRef]

- Dong, L.; Fujita, T.; Zhang, H.; Dai, M.; Fujii, M.; Ohnishi, S.; Geng, Y.; Liu, Z. Promoting low-carbon city through industrial symbiosis: A case in China by applying HPIMO model. Energy Policy 2013, 61, 864–873. [Google Scholar] [CrossRef]

- Dong, J.F.; Wang, Q.; Deng, C.; Wang, X.M.; Zhang, X.L. How to Move China toward a Green-Energy Economy: From a Sector Perspective. Sustainability 2016, 8, 337. [Google Scholar] [CrossRef] [Green Version]

- Wells, P.; Zapata, C. Renewable Eco-industrial Development. J. Ind. Ecol. 2012, 16, 665–668. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Ioppolo, G.; Morgante, A. Industrial Symbiosis, Networking and Innovation: The Potential Role of Innovation Poles. Sustainability 2017, 9, 169. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.; Yu, B. Eco-Industrial Parks from Strategic Niches to Development Mainstream: The Cases of China. Sustainability 2014, 6, 6325–6331. [Google Scholar] [CrossRef] [Green Version]

- Dong, L.; Gu, F.; Fujita, T.; Hayashi, Y.; Gao, J. Uncovering opportunity of low-carbon city promotion with industrial system innovation: Case study on industrial symbiosis projects in China. Energy Policy 2014, 65, 388–397. [Google Scholar] [CrossRef]

- Berkel, R.V.; Fujita, T.; Hashimoto, S.; Fujii, M. Quantitative Assessment of Urban and Industrial Symbiosis in Kawasaki, Japan. Environ. Sci. Technol. 2009, 43, 1271–1281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, L.; Dai, M.; Liang, H.; Zhang, N.; Mancheri, N.; Ren, J.; Dou, Y.; Hu, M. Material flows and resource productivity in China, South Korea and Japan from 1970 to 2008: A transitional perspective. J. Clean. Prod. 2017, 141, 1164–1177. [Google Scholar] [CrossRef]

- Lombardi, D.R.; Laybourn, P. Redefining Industrial Symbiosis. J. Ind. Ecol. 2012, 16, 28–37. [Google Scholar] [CrossRef]

- De Jong, M.; Joss, S.; Schraven, D.; Zhan, C.; Weijnen, M. Sustainable–smart–resilient–low carbon–eco–knowledge cities; making sense of a multitude of concepts promoting sustainable urbanization. J. Clean. Prod. 2015, 109, 25–38. [Google Scholar] [CrossRef] [Green Version]

- Dong, H.; Fujita, T.; Geng, Y.; Dong, L.; Ohnishi, S.; Sun, L.; Dou, Y.; Fujii, M. A review on eco-city evaluation methods and highlights for integration. Ecol. Indic. 2016, 60, 1184–1191. [Google Scholar] [CrossRef]

- Geng, Y.; Fujita, T.; Park, H.S.; Chiu, A.S.; Huisingh, D. Recent progress on innovative eco-industrial development. J. Clean. Prod. 2015, 114, 1–10. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2015, 114, 11–32. [Google Scholar] [CrossRef]

- Dong, L.; Liang, H. Spatial analysis on China’s regional air pollutants and CO2 emissions: Emission pattern and regional disparity. Atmos. Environ. 2014, 92, 280–291. [Google Scholar] [CrossRef]

- Chen, M.; Liu, W.; Tao, X. Evolution and assessment on China’s urbanization 1960–2010: Under-urbanization or over-urbanization? Habitat Int. 2013, 38, 25–33. [Google Scholar] [CrossRef]

- NBS. China Statistical Yearbook; National Bureau of Statistics: Beijing, China, 2011.

- UN. World Urbanization Prospects the 2011 Revision; United Nations, Department of Economic and Social Affairs, Population Division: New York, NY, USA, 2012. [Google Scholar]

- Courtonne, J.Y.; Alapetite, J.; Longaretti, P.Y.; Dupré, D.; Prados, E. Downscaling material flow analysis: The case of the cereal supply chain in France. Ecol. Econ. 2015, 118, 67–80. [Google Scholar] [CrossRef]

- Yu, C.; Dijkema, G.P.; De Jong, M.; Shi, H. From an eco-industrial park towards an eco-city: A case study in Suzhou, China. J. Clean. Prod. 2015, 102, 264–274. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Fujita, T.; Ohnishi, S.; Li, H.; Fujii, M.; Dong, H. Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J. Clean. Prod. 2013, 59, 226–238. [Google Scholar] [CrossRef]

- Takiguchi, H.; Takemoto, K. Japanese 3R Policies Based on Material Flow Analysis. J. Ind. Ecol. 2008, 12, 792–798. [Google Scholar] [CrossRef]

- Oh, D.-S.; Kim, K.-B.; Jeong, S.-Y. Eco-Industrial Park Design: A Daedeok Technovalley case study. Habitat Int. 2005, 29, 269–284. [Google Scholar] [CrossRef]

- Krausmann, F.; Gingrich, S.; Nourbakhch-Sabet, R. The Metabolic Transition in Japan. J. Ind. Ecol. 2011, 15, 877–892. [Google Scholar] [CrossRef]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Geng, Y. Industrial and urban symbiosis in Japan: Analysis of the Eco-Town program 1997–2006. J. Environ. Manag. 2009, 90, 1544–1556. [Google Scholar] [CrossRef]

- Park, H.-S.; Won, J.-Y. Ulsan Eco-industrial Park: Challenges and Opportunities. J. Ind. Ecol. 2007, 11, 11–13. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Peters, G.P. Carbon Footprint of Nations: A Global, Trade-Linked Analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef] [Green Version]

- Leontief, W. Quantitative input-output relations in the economic system. Rev. Econ. Stat. 1936, 18, 105–125. [Google Scholar] [CrossRef] [Green Version]

- Giljum, S.; Hubacek, K. Conceptual foundations and applications of physical input-output tables. In Handbook of Input-Output Economics in Industrial Ecology; Springer: Dordrecht, The Netherlands, 2009; pp. 1–75. [Google Scholar]

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G.; et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 2015, 524, 335–338. [Google Scholar] [CrossRef] [Green Version]

- Baldini, C.; Gardoni, D.; Guarino, M. A critical review of the recent evolution of Life Cycle Assessment applied to milk production. J. Clean. Prod. 2017, 140 Pt 2, 421–435. [Google Scholar] [CrossRef]

- Heinonen, J.; Jalas, M.; Juntunen, J.K.; Ala-Mantila, S.; Junnila, S. Situated lifestyles: I. How lifestyles change along with the level of urbanization and what the greenhouse gas implications are—A study of Finland. Environ. Res. Lett. 2013, 8, 025003. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Yang, J.; Zhou, X.; Liu, Y. The ecological footprint evaluation of low carbon campuses based on life cycle assessment: A case study of Tianjin, China. J. Clean. Prod. 2017, 144, 266–278. [Google Scholar] [CrossRef]

- Mi, Z.; Zhang, Y.; Guan, D.; Shan, Y.; Liu, Z.; Cong, R.; Yuan, X.C.; Wei, Y.M. Consumption-based emission accounting for Chinese cities. Appl. Energy 2016, 184, 1073–1081. [Google Scholar] [CrossRef] [Green Version]

- Wiedmann, T. Editorial: Carbon Footprint and Input-Output Analysis—An Introduction. Econ. Syst. Res. 2009, 21, 175–186. [Google Scholar] [CrossRef]

| Intermediate Output | Final Demand | Total Outputs | |

|---|---|---|---|

| Intermediate Input | AX | Y | X |

| Value Added | |||

| Total Outputs |

| Synergies of Symbiotic Network | Process Data | |

|---|---|---|

| Substitution of steel-making waste for concrete raw material (120 kt/y) | Resource-saving of clinker 120 kt/year reduction of CO emission by 66 kt/year. Slag reduction of 120 kt/y. | |

| Substitute cement material with phosphorus slag (500 kt/y) | Clinker-saving 500 kt/year and reduction of CO emission by 275 kt/year. Slag-reduction of 500 kt/y. | |

| waste regeneration of industry | Substitution of aluminum-making waste for concrete raw material (400 kt/y) | Clinker-saving of 400 kt/year and reduction of CO emission by 220 kt/y. Slag-reduction of 400 kt/y. |

| Coal gangue regenerated by power generation (100 kt/y) | Save 30 ktce/y of fossil fuel. Reduce CO emission by 78 kt/y. Reduce solid waste by 100 kt/y. | |

| Coal flying ash recycling (200 kt/y) | Material-saving of concrete and reduction of CO by 200 kt/y. Ash reduction of 200 kt/y. | |

| Urban symbiosis for SW | Waste plastics regenerated (10 kt/y) | Waste plastic at 1 t is equal to 1.2 t of coke. CO emission-reduction of 31.2 kt/y. |

| Waste heat use | Heat reclamation (300 t/y) | Fossil-fuel saving of 18,864 tce and CO emission-reduction of 49,046 t/y. |

| Conventional recycle | Waste steel recycling and reuse (100 kt/y) | Save raw material 2.5 t and energy 12.25 GJ/t steel. Reduce CO emission by 108.8 kt/y. |

| Carbon Intensity (tCO/10,000 Yuan) | ||

|---|---|---|

| 2002 | 2012 | |

| A (Agricultural sector) | 1.50 | 0.24 |

| B (Industries) | 2.89 | 1.20 |

| C (Construction and building sector) | 0.59 | 0.05 |

| D (Transport sector) | 2.09 | 0.63 |

| E (Commercial and residential sector) | 0.65 | 0.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huan, J.; Han, L. Potential Contribution to Carbon Neutrality Strategy from Industrial Symbiosis: Evidence from a Local Coal-Aluminum-Electricity-Steel Industrial System. Sustainability 2022, 14, 2487. https://doi.org/10.3390/su14052487

Huan J, Han L. Potential Contribution to Carbon Neutrality Strategy from Industrial Symbiosis: Evidence from a Local Coal-Aluminum-Electricity-Steel Industrial System. Sustainability. 2022; 14(5):2487. https://doi.org/10.3390/su14052487

Chicago/Turabian StyleHuan, Jiajia, and Ling Han. 2022. "Potential Contribution to Carbon Neutrality Strategy from Industrial Symbiosis: Evidence from a Local Coal-Aluminum-Electricity-Steel Industrial System" Sustainability 14, no. 5: 2487. https://doi.org/10.3390/su14052487

APA StyleHuan, J., & Han, L. (2022). Potential Contribution to Carbon Neutrality Strategy from Industrial Symbiosis: Evidence from a Local Coal-Aluminum-Electricity-Steel Industrial System. Sustainability, 14(5), 2487. https://doi.org/10.3390/su14052487