1. Introduction

The coronavirus pandemic has disrupted the flow of goods in global food supply chains. The novelty of the disease, the unfamiliarity and the unpredictability of its mechanisms and directions of development surprised governments and economies, especially in the initial stages [

1]. This new challenge resulted in a number of decisions that significantly slowed down the processes and disturbed their stability and continuity [

2]. As a consequence, various spheres of the functioning of national economies have been impacted by a number of economic, social, and legal factors concerning the need to prevent the spread of the coronavirus. As the Organisation for Economic Co-operation and Development (OECD) points out, this is the largest public health crisis that has resulted in a severe economic crisis, with production in the affected countries halted, consumption and confidence collapsing, and stock markets reacting negatively to increased uncertainty [

3].

Carlsson-Szlezak et al. [

4] identify three probable channels of transmission of the health crisis to the economy in terms of demand and supply, such as the indirect hit to confidence—the wealth effect, the direct hit to consumer confidence, and the supply side shock—supply disruptions. The economic crisis caused by the coronavirus pandemic on supply is associated with a decline in labour supply, a decline in the use of production capacity, supply chain disruptions leading to shortages of parts and intermediate goods, while the demand suffers from expenditure and consumption reduction [

3]. Brodeur et al. [

5] emphasise that deep specialisation in the area of production and the increase in interdependence between entities, caused by numerous connections and feedback loops, will result in a cascading effect in the event of a collapse of supply chains. Disturbances in circular flows will also contribute to this. All the above proved true in the face of the coronavirus onset. The disruptions caused by the pandemic dramatically increased the volatility of supply and demand [

6].

According to Chenarides et al. [

7] the coronavirus pandemic has exposed a fundamental lack of resilience in the food supply chain. Although food production volumes are high, the pandemic could have a negative impact on food production levels, due to factors such as increased worker morbidity, supply chain disruptions and restrictive measures, as well as individual governments’ efforts to restrict food exports to meet national needs [

8]. In this context, it turned out that the greatest threat to food security is not the mere [

9] availability of food, but the problem of consumer access to it [

9]. It is emphasised that the coronavirus pandemic affects organisations in all parts of the food system, in particular in the sphere of cash flow and financial liquidity of producers [

10]. Demand-side disruptions (panic in purchasing, changing food purchasing patterns) forced supply chains to adapt by planning for disruptions that may occur on the supply side due to labour shortages or the [

11] availability of transport and delivery services [

11].

Logistics efficiency is crucial in managing the food supply chain during a crisis, as any disruption may have a negative impact on food quality, freshness, and safety, and may hinder access to markets and affordability [

12]. There are four main problems in the food industry and the food supply chain that emerged from the coronavirus pandemic: increase in the demand for functional food, supporting the protection of the immune system, increasing the importance of food safety, disclosing food security concerns due to restrictions in people’s mobility and the emergence of problems related to food sustainability [

13].

Food security has become one of the key challenges for the functioning of food supply chains in the era of the pandemic. Laborde et al. [

14] identify the four main pillars of food security affected by COVID-19, which are: availability (adequate food supply), access (ability to meet human food needs), utilisation (possible nutrient intake at a sufficient level) and stability (constancy of access to food).

In the face of dynamic, rapid changes in economic, social, technological, and political factors during the coronavirus pandemic, the possibility of ensuring the efficient activity of specific food supply chains at the operational level is an emerging question. In our research, we focused on the military food supply chain, which, due to its specific nature, is one of the least frequently analysed supply chains. The novelty of our research is the reference of the theoretical framework for the management of the food supply chain to the military sphere in peacetime, based on the example of the Armed Forces of the Republic of Poland.

In 2019, the potential of the Polish army was classified at 24th place in the world (PwrIndex: 0.4059) and spending on the Polish Armed Forces placed Poland in 19th place [

15]. At the end of 2021, the Polish Armed Forces numbered approximately 114,000 professional soldiers of which 45.8% were regular professional soldiers and 35.6% were non-commissioned officers. The land forces, consisting of about 48,000 professional soldiers, constitute the largest component of the Polish army. The armed reserve forces (around 12,000) and candidates for professional soldiers, numbering around 5000, are an important complement. Another important element is the Territorial Defence Forces the number of which at the end of 2021 exceeded 32,000.

Our research concerns the standard military unit MU1 (fictitious name) with an extended scope of tasks in the field of education and training of professional military personnel. The examined MU1 is a unit in the corps of land forces constituting the core of the Polish Armed Forces.

The COVID-19 pandemic caused organisational disruptions due to the need to group human resources according to their health status. It became necessary to identify the health condition and appropriate distribution of people in places that ensure isolation and, consequently, to define nutritional needs and ways of meeting these needs, taking into account formal limitations and safety restrictions. As a result of the change in nutritional standards and needs, the distribution of people in different places of stay made it necessary to reorganise the meal distribution system.

In addition, the pandemic situation forced a modification of the model ensuring the supply of meals to military units while maintaining safety rules. The conducted research indicates a contextual and situational approach to the development of the supply chain architecture in military units in crisis situations. In contrast to civilian food supply chains, military units that are part of the state’s military system are less reactive. It results from the general regulations concerning the food service in the field of safety in the area of physical and information flows.

Military units have become key organisations, the potential of which has been used to counteract the spread of the coronavirus. The range of tasks the military is required to perform during the COVID-19 crisis, and by far the most common use of the armed forces, has included supporting civilian health care efforts, social welfare, and assistance in emergency response logistics, including moving large amounts of critical medical supplies and staff to medical triage efforts (rapid construction of field hospitals, treatment bed provision, and patient offloading) [

16]. However, the potential of military units and the ability to carry out the tasks entrusted to them depend on the availability of resources, including food. Therefore, the military food supply chain is critical for the efficiency of the tasks performed by each military unit during a crisis, as in the case of the COVID-19 pandemic.

Based on the theory of supply chain management in relation to food flows, we have formulated four research questions:

RQ1. What is the resilience of the military food supply chain of the military unit?

RQ2. Does the complexity of the military food supply chain increase in a pandemic situation?

RQ3. What types of factors are triggering disruptions to the internal military food supply chain caused by the COVID-19 pandemic?

RQ4. What actions are needed to restore capacity and restart the supply chain after disruptions?

In search of answers to the research questions posed, we have identified the critical factors determining the efficiency of military food chains. Our research has also shown various variants of model solutions for the internal military food supply chain in a typical military unit.

The article is composed of four other sections.

Section 1 contained the introduction.

Section 2 presents the theoretical aspects of military supply chains.

Section 3 describes the methodology used in our analysis, including case studies.

Section 4 elaborates on the results of the analysis.

Section 5 provides a discussion, the main theoretical and managerial implications, as well as conclusions, limitations, and future research perspectives.

2. Literature Review

The management of military food supply chains is a complex task that requires the involvement of many entities that should be prepared to operate in specific conditions. The main features specific to the military food supply chains include structure and relationships in the supply chain, the formal nature of relationships affecting the way processes are implemented, the needs of consumers (soldiers) and the nature of the product, varied depending on the tasks performed and operating conditions. Research on military supply chains, unlike research conducted in the civilian sphere, faces numerous limitations. One of them is the lack of access to open data enabling mathematical modelling related to uncertainty and disruptions as in the case of civil supply chains [

17,

18,

19]. Few studies concern food supply chains that are seen as weapons in terms of geopolitics and national security [

20,

21,

22,

23,

24].

In military food supply chains, there is a specific configuration of the system of connections, because the links are both military institutions and civil organisations. This has particular consequences for the nature of cooperation and the possibility of shaping partnership relations. A significant implication for North Atlantic Treaty Organization forces has been conducting operations in close cooperation with the civilian population [

25]. In accordance with NATO Standards, the success of its missions depends on NATO’s ability to organise, manage, and participate in these heterogeneous environments so that their collective capabilities and resources can be used effectively, efficiently and in a timely manner. This requires civil-military cooperation (CIMIC) and comprehensive coordination based on a common sense of purpose and resolve, mutual understanding, collaboration, and appropriate resourcing. Therefore, the aim is to establish a network and create mutual understanding between organisations, to foster cooperation during missions or operations, as well as develop mutual understanding and good working relations by military and non-military actors before any crisis through training, education, and other initiatives [

25]. Consequently, one of the basic criteria for selecting suppliers is the ability to quickly respond to the fulfilment of orders under conditions of mobilisation. The organisation of military food supply chains, as a component of the economic system, is based on three principles: (1) the use of local resources, (2) the use of regional infrastructure, resources, and services, while ensuring an appropriate level of quality, and (3) the principle of local supply to provide utilities and other support services (repairs, maintenance) [

26].

The military, while carrying out its tasks both in peacetime and during military operations, enters into various relations with the civilian environment and establishes cooperation with selected organisations. Civil-military interactions are “

a group of activities, founded on communication, planning and coordination, that NATO military bodies share and conduct with international and local non-military actors, both during NATO operations and in preparation for them, thereby mutually increasing the effectiveness and efficiency of their respective actions in response to crises” [

25] (p. 1.2). By contrast, civil-military cooperation means “

a joint function comprising a set of capabilities integral to supporting the achievement of mission objectives and enabling NATO commands to participate effectively in a broad spectrum of civil-military interaction with diverse non-military actors” [

25] (p. 2.1).

Such a wide range of tasks performed by the Armed Forces poses challenges for logistics activities, including those related to material security and food. When considering the concept of the supply chain in functional terms, the complexity of the processes carried out should be emphasised. The supply chain is assumed to be “

any combination of processes, functions, activities, relationships and pathways along which products, services, information and financial transactions move in and between enterprises” [

27] (p. 2). Tasks within the food supply and production processes include food purchasing, receipt, storage or distribution, preparation, cooking, service, and recovery of leftovers [

28]. The core functions of the Defence Logistics Agency include demand planning, inventory management, contracting and warehousing, and distribution [

29]. In particular, the task of military logistics is planning, preparation and use of means of supply (including the feeding system), as well as the implementation of specialised services in order to maintain the army in appropriate combat readiness within the country and to secure the operation of troops which perform tasks outside its borders [

30]. In the process of satisfying logistic requirements, an important element is the accumulation of appropriate stocks, both in terms of quantity and quality, which means the need to have reserves that would allow for the meeting of the current needs resulting from the operating principles of military units and institutions and to support society in crisis situations [

31].

Another specific feature of military food supply chains is the needs of recipients—soldiers performing their tasks in various conditions. In military supply chains, it is necessary to take into account additional requirements relating to the food product, its properties, form, packaging, etc., which must be adapted to the diverse and specific conditions of soldiers’ operations. In addition to combat operations, the military undertakes crisis response operations, including multi-functional operations that contribute to conflict prevention and resolution, for humanitarian purposes or crisis management in pursuit of the alliance’s declared goals [

25].

Ensuring operational readiness, maintaining the physical ability and mental fitness of soldiers at an optimal level requires adequate food, both in terms of quality and quantity, and adequate hydration [

32]. In times of peace, the needs of the army are secured using supply means resulting from current operations and the maintenance of supplies, taking into account the potential and resources of the Armed Forces. Safe food and water and attractively served, nutritious meals are critical to the health, well-being and working capacity of soldiers at home and during deployed operations [

28]. However, in deployed operations it is essential to equip soldiers with individual ration packs and approved bottled water to minimise the risk of food hazards [

28].

Due to the specificity of food products, the food supply chain is particularly susceptible to various disruptions. Chavez and Seow [

33] introduced the concept of product quality risk in the supply chain, defining it as a state of product quality in which it is influenced by direct and indirect materials from multi-tier suppliers, where a low-risk incident can have a cumulative effect across the network. In a multi-actor food supply chain, this cumulative effect can pose a serious threat to food safety. Considering the specificity of the food sector and the nature of consumer needs, aspects such as social responsibility, good agricultural practice (GAP), total quality management, and hazard analysis at critical control points (HACCP), are particularly vital in the management of modern food supply chains [

34]. These practices are critical to securing food safety and continuity of supply chains.

Therefore, one of the main challenges is to ensure supply chain resilience, which is the ability of the system to recover from disturbances and maintain its structural functions and controls, and to proactively avoid or even use such disturbances [

35]. Supply chain resilience (SCR) means the ability to “reduce the probabilities of a disruption, to reduce the consequences of those disruptions once they occur, and to reduce the time to recover normal performance” [

36] (p. 596). SCR is also the ability to “proactively plan and design the Supply Chain network for anticipating unexpected disruptive (negative) events, respond adaptively to disruptions while maintaining control over structure and function and transcending to a post-event robust state of operations, if possible, more favourable than the one prior to the event, thus gaining competitive advantage” [

37] (p. 921). Thus, restoring the capacity of the supply chain after disruptions requires a strategic approach based on building knowledge potential (constant measurement and evaluation of achievements and responding to deviations) and competences for adaptive, pro-innovative action.

3. Materials and Methods

In our research, we adopted a single case study method, showing the response of the military food supply chain in the military unit MU1 to a crisis caused by the COVID-19 pandemic.

The case study as an empirical research method can be exploratory, descriptive, or explanatory in nature and is used to study a contemporary phenomenon, as it focuses on the dynamics of a case in the context of real life [

38]. According to Darke et al. [

39] single cases allow for an in-depth investigation and rich description.

A single case study allows for a deeper understanding of the explored subject (due to the possibility of a richer description of the phenomenon), as well as for questioning the existing theoretical relations and exploring new ones (due to the possibility of conducting more insightful studies) [

40]. In addition, a single case allows for a more accurate understanding of the circumstances in which a phenomenon occurred and may be the basis for a generalisation for other cases by applying the findings of the study only to just another single case, but not to a whole class of cases [

41].

The starting point for conducting in-depth analyses using the single case study method is the selection of a research object—a system (case) representing the phenomenon under study. Creswell et al. [

42] define the case study as a qualitative approach where, over a defined period of time, a bounded system (case) or multiple bounded systems (cases) are explored through detailed, in-depth data collection covering various sources of information (e.g., observations, interviews, and audio-visual material) and reports containing a description of the case and case-based topics. In this stage, the research object was selected (a military unit). First, the functioning of the army in a pandemic situation was analysed in various aspects of logistics activities in the area of nutrition. Then, the focus was shifted to military units feeding soldiers on a continuous basis (24 h a day, seven days a week) while feeding at least two thousand soldiers a year. Another criterion for selecting the research object was conducting independent economic activity (in the form of an independent economic department), which is related to the possibility of partially independent decision-making in the field of food supply. The next criterion concerned the participation of soldiers in activities carrying the risk of coronavirus infection (participation in tasks performed outside the military unit). Finally, the choice was limited to a military unit with the ability to diversify the forms of nutrition in terms of preparing meals. Due to the information restrictions and the possibility of conducting participant observation resulting from the specificity of the military, a military unit which met all the adopted criteria was selected, and so it constituted the subject of an individual case that was then analysed.

In the next stage, as a result of in-depth partially structured interviews with specialists and entities, goals, tasks, and conditions for the management of the military food supply chain at the operational level were identified. This allowed for the implementation of the third stage, consisting of the development of supply chain maps under various conditions that occurred in connection with the implementation of tasks by soldiers in the unit and outside it in a pandemic situation. As a result of the analysis of the maps of processes implemented within the different variants of the supply chain, it was possible to identify disruptions and develop solutions that could be used to restore the supply chain’s ability to function efficiently.

The starting point for the development of the research procedure was the assumption that the scope and level of disruptions at the systemic and institutional levels that resulted from the coronavirus pandemic made it necessary to seek new solutions that would enable adequate responses and increase their resilience. According to Byrnes [

43], existing systems and processes of the supply chain are unable to cope with this level of unpredictability and disruption. It is therefore inevitable to consider new technology in supply chains and rethink different approaches. Aiming to seek new solutions must take into account the specificity of military food supply chains. The complexity and difficulty of managing food chains requires consideration of factors such as food quality, safety, and freshness over a limited period of time [

44]. Additionally, this complexity is escalated by the specific needs and conditions of the armed forces’ operations.

The following general objectives of the article were adopted: description of the essence and role of the food supply chain concept in the military, identification of the conditions for the efficient functioning of the food supply chain and in the event of a pandemic, sources of disruptions in the key processes implemented in the area of the internal food supply chain at the level of a military unit and presentation of proposals for the modification of the internal food supply chain for it to recover capacity and resume after a disruption.

3.1. Case Description

Our research was carried out in the MU1 military unit which, apart from standard tasks, implements the process of training and educating military personnel. Twenty-two military units of this type operate within the structures of the Polish Armed Forces. These units are military academies (5), training centres (11), non-commissioned officer schools (3), high schools (2), and language centres (1). They have a specific system of food supply to soldiers. Their specificity is related to the fact that, apart from professional soldiers and other workers, there are significant numbers of people within their area 24 h a day, 7 days a week throughout the year. The fact that that a full feeding system is implemented in these units is important from the point of view of the complexity of the supply chain architecture. In the analysed military unit, during the period of conducting the research on mass nutrition in a 24-h system, approximately 2200 people participated on average.

Pursuant to Polish legislation [

45], if the use of other forces and means is impossible or may prove insufficient, the Minister of National Defence may place at the disposal of the Chief Sanitary Inspector or the voivode subunits or units of the Armed Forces and delegate them to perform tasks related to the state of epidemic threat, a state of epidemic or a risk of spreading an infection or an infectious disease that may pose a threat to public health, in particular the occurrence of a particularly dangerous or highly contagious disease. In this case, subunits and units of the Armed Forces remain under the command of official superiors and perform the tasks specified by the Chief Sanitary Inspector or the voivode. In the discussed case, the main cause of disturbances in the military food supply chain was the delegation of soldiers and civilian personnel to perform tasks outside the military unit. As a result of infection with the COVID-19 virus, these people were then placed in isolation or quarantine on the premises of the military unit, which resulted in the need to change the current model of nutrition.

In accordance with the adopted methodological assumptions, the research object is a military unit MU1 which is a military economic unit providing continuous nutrition for soldiers accommodated in the unit or in facilities belonging to it. Pursuant to Polish legislation, the Armed Forces guard the sovereignty and independence of the Polish nation, its security and peace, and may take part in combating natural disasters and eliminating their consequences, in anti-terrorist and property protection activities, search operations and saving or protecting human health and life, clearing areas of military explosives and hazardous materials and their neutralisation, as well as in the implementation of tasks in the field of crisis management [

46].

The military unit MU1 carries out defence tasks and prepares military personnel. Due to information limitations, it has been anonymised. The analysed supply chain concerns mass nutrition implemented in relation to quantitatively significant groups the variability of which during the period of risk increases considerably. It is characterised by greater dynamics of changes depending on the orders issued in terms of soldiers’ location, as well as a consequence of the health condition and the resulting status by being subject to the appropriate isolation procedure. Any contaminated person who comes into contact with food or its packaging can cause a huge wave of contamination among actors along the entire supply chain. Important factors are the procedures related to the epidemic: quarantine, isolation, stay in a hospital or centre for people who do not require hospitalisation, convalescence, and recovery.

Although the organisation of material support for units and military institutions of the Polish Armed Forces during the COVID-19 pandemic was uninterrupted, there were local difficulties in satisfying nutritional needs due to the quantity, technical conditions, and production capacity of kitchen facilities. One of the reasons for such disruptions at the operational level could be the situations of delegating soldiers to perform tasks outside the unit, as well as the presence of soldiers and civilian personnel in quarantine or in isolation due to the coronavirus infection.

3.2. Data Analysis

In order to analyse the processes in the food supply chain in the military unit and identify dysfunctions and disruptions in the supply chain that may occur due to the threat of an epidemic, the process mapping method was used. It requires a detailed analysis of the system structure, its goals (outputs), as well as the identification of entities and their responsibility for processes and tasks performed [

47,

48]. As Biazzo [

49] emphasises, process mapping is based on building a model that shows the relationships between activities, people, data, and objects involved in achieving a specific result and is helpful in improving and re-designing business processes. When analysing the structure of supply chains, according to Lambert and Cooper [

50], it is necessary to take into account: (1) the structure of the supply chain network, (2) business processes, and (3) management variables as components of supply chain management. These elements should be treated as interrelated, creating a system of numerous interactions.

In this context, in the first stage, supply chain participants were identified, in particular the military unit (internal food chain, logistics division—administration, food receipt warehouse, storage, canteen and food laboratory), food suppliers/distributors, including suppliers who were also producers of food products, suppliers/distributors (e.g., wholesale companies, agricultural cooperatives or associations of food producers: farmers, gardeners, fruit growers), producers and suppliers of raw materials, food control units, the analytical laboratory, transport units, packaging suppliers, and units responsible for waste management. The following processes were distinguished: (1) preparatory (management) processes, including such activities as: needs planning, setting the conditions and requirements necessary to establish cooperation with external civilian suppliers of food and services, negotiations and setting the terms of the contract; (2) core processes—food production and delivery, food control and certification, meal preparation, contract performance, order picking, packaging, transport and food delivery; and (3) supporting processes—storage, testing food samples in the analytical laboratory and transferring food to the internal supply chain of a military unit for delivery for consumption, waste collection and control operations at the checkpoint.

4. Results

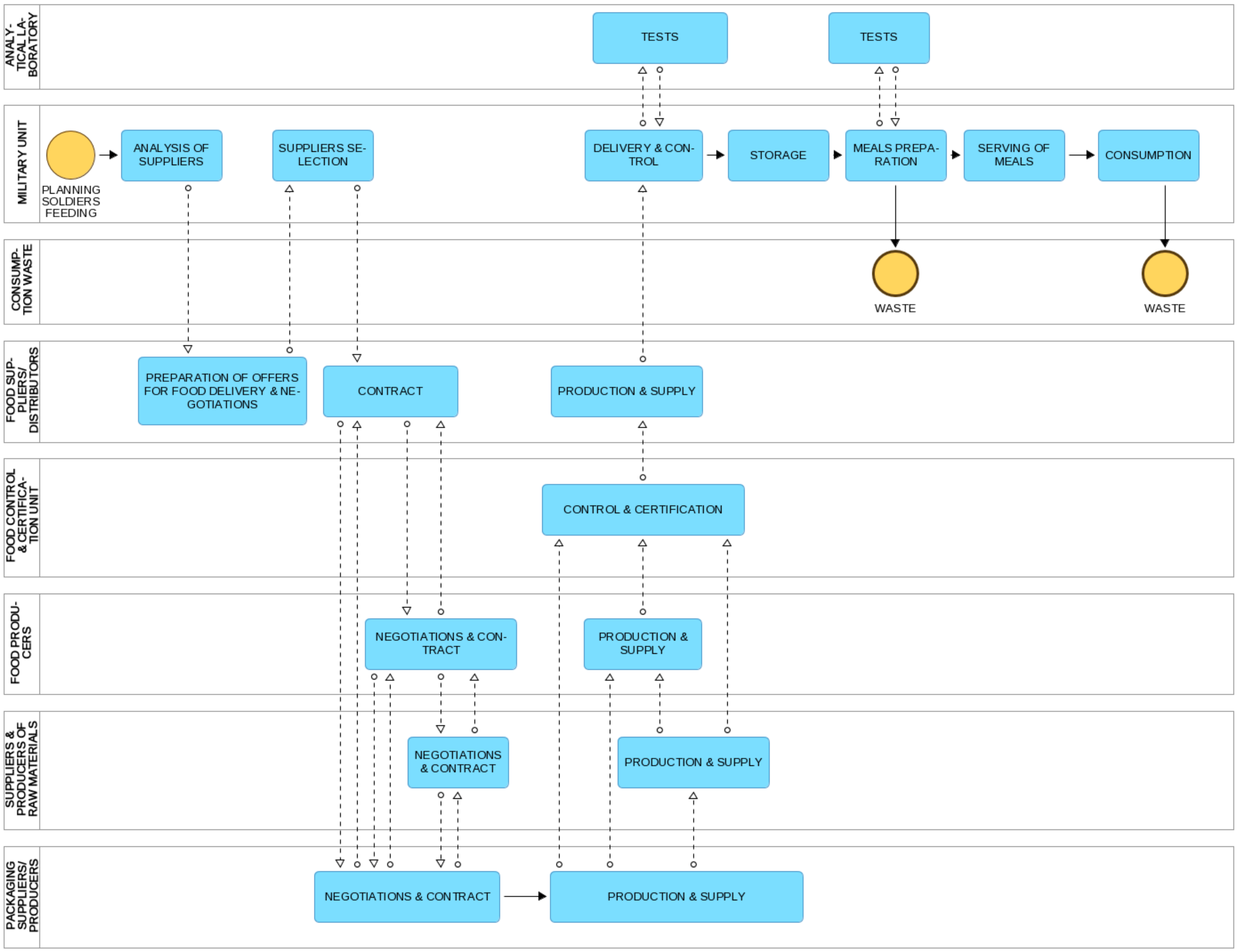

The starting point initiating the processes in the external food supply chain is the food demand plan prepared by the logistics division of the military unit, to which all decisions and actions regarding the subsequent stages of the food process are subordinated. The process ends with the collection of waste remaining after food preparation and consumption. The map of the processes in the general food supply chain in the military is shown in

Figure 1.

Moreover, it was assumed that the input data mean the need to carry out the process of delivering food to the military unit, taking into account specific requirements and rules in various system contexts, while the expected result (output) is ensuring food supplies meeting quantitative and qualitative requirements, in line with the needs of recipients (soldiers). Food is tested for compliance with safety requirements at the stage of food delivery and preparation. A specific role in ensuring the efficiency of the implemented processes is played by transport which is carried out practically at every stage. Transport services may be performed by entities executing particular essential tasks in the process or may be outsourced to external service providers.

The research carried out in the military unit MU1 showed that the supply chain presented in

Figure 1 was modified in response to the pandemic situation. Three more supply chains were developed in addition to the standard internal food supply chain. In the further part of the research, in order to identify the elements of supply chain management and management variables, we presented a description and analysis of the internal supply chain (process maps) for all available variants of nutrition. The results of our research revealed significant modifications to the architecture of the food supply chain.

In the MU1 military unit, four variants of the supply chain can be distinguished:

- 1.

Internal food supply chain carried out under standard conditions;

- 2.

Internal food supply chain in the sanitary regime;

- 3.

Internal food supply chain that includes the nutrition of quarantined/isolated soldiers in the area of the military unit;

- 4.

Food supply chain, including feeding soldiers in isolation in facilities outside the military unit.

As a result of this approach, process maps that illustrate the sequence of the main tasks and activities of the processes taking place in the area of food supply were developed (

Figure 2,

Figure 3,

Figure 4 and

Figure 5). All the basic cases that occurred in connection with the pandemic situation with regard to feeding soldiers in the military unit or accommodated in facilities belonging to the studied unit for isolation are described.

Variant 1. Internal food supply carried out under standard conditions.

In the traditional variant, the feeding of soldiers was carried out in the canteen according to the prepared menu. Consumption of food took place at tables, while meals were composed by soldiers themselves from the available menu. All persons involved in the preparation and serving of meals were subject to standard sanitary procedures. The following subsystems (organisational units) of the military unit were involved in the standard internal food supply chain: (1) logistics division responsible for planning nutritional needs, cooperation with suppliers, selecting suppliers, negotiating and concluding contracts and scheduling deliveries; (2) checkpoint that performs document checks of drivers and vehicles at the entrance to and exit from the military unit, as well as initial cargo inspection and forwarding documentation to the logistics division; (3) warehouse area responsible for unloading and verification of deliveries, informing the logistics division about the delivery status and forwarding for further storage in the canteen,; (4) canteen responsible for storage in the pantry, preparation of meals, serving meals, collecting dirty dishes and waste of non-consumed food in the “dirty” zone and washing dishes and equipment; and (5) food laboratory that performs food tests at various stages of the process.

A detailed map of the process implemented in the internal food supply chain is presented in

Figure 2.

Variant 2. Internal food supply chain in the sanitary regime.

This variant concerned the occurrence of a pandemic situation in its initial phase during which some soldiers ate meals in the canteen and some in the place of accommodation due to the risk of infection (

Figure 3). The pandemic situation caused the necessity to make changes at the entrance to the process in terms of input quality requirements resulting from the sanitary regime, such as strict adherence to phytosanitary regulations and the work schedule, serving and consuming meals subject to restrictive regulations and control, and introduction of changes in the organisation of space (maximum 50 people in the room and keeping a distance of 3 m between the tables) and the eating schedule. Ensuring food safety required the possibility of eating meals in small and permanent groups in separate rooms which were ventilated and disinfected after each group. In the absence of such a possibility, it was necessary to divide the consumption space in order to maintain the greatest physical distance (setting barriers—walls) separating the groups, disinfecting the space after each group, and airing it after each meal. They also had to be subjected to ozone treatment procedure every day once the serving and cleaning was finished. In the event of consumption in the canteen, it became necessary to maintain an appropriate sanitary regime regarding the distance between people waiting for a meal, by setting the requirement of keeping a distance of at least 2 m from each other. The canteen staff were also subject to special supervision and any disease symptoms were the basis for immediate intervention (removal from duties, quarantine, testing). Special sanitary restrictions were also introduced at the checkpoint, where each entry to the military unit and exit from the area was subject to controls taking into account additional COVID-19 procedures.

As the threat of an epidemic increased, it was necessary to introduce dry regulations to ensure nutrition for quarantined or isolated soldiers. As a consequence, it was essential to create conditions for serving meals and eating in the place of accommodation. An additional challenge was the storage and collection of waste and used disposable dishes. According to sanitary requirements, waste should be marked as potentially contaminated and disposed of.

Variant 3. Internal food supply chain that includes the nutrition of quarantined or isolated soldiers in the area of the military unit.

Due to the quality and health requirements, nutrition with dry rations may be acceptable a short time. Therefore, in a situation where the quarantine or isolation lasted several weeks, it became necessary to introduce standard nutrition outside the canteen in the place of accommodation. This variant applied then to a situation where wholesome meals were delivered to quarantined soldiers in the take-away model (

Figure 4). The meals prepared in the canteen were packed in thermal packages containing individual portions intended for soldiers. Delivering food prepared in this way to the collection point at the quarantine point required the use of special transporters with waste containers. Then, it was necessary to collect, select and disinfect reusable containers while complying with appropriate safety rules. This resulted in the need to check the places where soldiers were lodged for appropriate equipment (kettles, refrigerators) and space necessary for eating meals. They had to be equipped with cutlery, cups, detergents, and disinfectants. Adequate space for consumption and safe collection of waste had to be secured. After preparing the portions intended for quarantined or isolated soldiers, there was no need to subject the food to further tests, because it had been closed in appropriate containers, limiting the influence of external factors. In addition, the process of preparing meals was appropriately adjusted to ensure food safety. In the case of soldiers who contracted COVID-19 and showed symptoms, it was necessary to adjust meals to the dietary needs appropriately during the course of the disease. In the case of people who were isolated due to illness, the feeding system depended on the physical condition of the sick. If they were in a good physical shape and could eat by themselves, a quarantine feeding system could be used. However, if this was not possible, it was necessary to use the help of medical staff to support the process or to transport sick soldiers to the hospital where the nutrition was taken over by the medical unit.

Variant 4. Food supply chain, including feeding soldiers in isolation in facilities outside the military unit.

A detailed complex situation was included in variant 4 under which the military unit carried out the feeding processes of soldiers in three ways: (1) a traditional manner for healthy soldiers; (2) in the accommodation place at the unit for potentially infected soldiers; and (3) outside the unit in the case of sick soldiers in the isolation facility (

Figure 5). Where it was possible to prepare meals in the isolation facility, appropriate products and staff had to be provided to prepare and deliver the meals. If this was not possible, meals had to be prepared on the premises of the military unit and delivered to the quarantine facility. This change affected the menu to ensure the meals and products that were to be prepared and transported were safe. Depending on the equipment of the places of isolation, it was also possible to use a mixed system where meals would be prepared partly in the area of the military unit and partly in the accommodation during isolation. In a crisis situation, food rations could also be used for feeding.

The need to transport food outside the military unit extended the process and resulted in increased involvement of the logistics department and the checkpoint. It required introducing changes in the functioning of the military unit in the sphere of planning and scheduling of transport units. As a consequence, it also affected the schedule of food preparation and the need to take into account the preparation of special meals and their delivery at the set time to soldiers accommodated outside the military unit. As a result, the working time of employees involved in the preparation and distribution of meals was extended.

5. Discussion

As a result of the analysis of the maps of processes implemented in the military food supply chain, it should be concluded that the pandemic situation affects the entire chain, both external and internal. The functioning of the military supply chain is largely determined by external civilian suppliers who supplement the military logistic potential in military and non-military operations within the framework of civil-military cooperation [

26]. However, the possibility of fully securing logistic activities requires readiness on the part of the civil sector to execute orders with special requirements relating to the ordered product itself, the appropriate quantity and quality of the order, as well as a positive result of the risk assessment, operational situation, and economic and legal conditions [

30].

The pandemic situation increased the complexity of the food supply chain architecture in the military unit MU1. It led to the development of new models of nutrition for soldiers and civilian workers. The implemented modifications prove the flexibility of the systems, which allows for an effective response to changes taking place in the environment as a result of any crisis. However, the complete adaptation of the systems took place with a certain time delay, which led to the emergence of the indicated dysfunctions in the area of management.

Our research empirically verified how the flexibility built into the overall military food supply chain (

Figure 1) affects the effectiveness of the response to disruptions caused by the COVID-19 pandemic. Using process mapping, we proved the limited flexibility of system solutions, which resulted in the launch of three new food supply chains. This is important when disruptions to the supply chain are dynamic and random in nature, such as the spread of the COVID-19 virus.

The pandemic situation increased the scope of requirements regarding relations with suppliers. For epidemic reasons, it was necessary to renegotiate the terms of contracts with suppliers and make quantitative and qualitative changes in orders and food deliveries. These changes were conditioned by the number of soldiers requiring a specific type of food, the necessity to include in the menu products providing nutritional value appropriate for the changed conditions and needs in terms of product range characteristics related to safety requirements (the possibility of disinfection, sufficiently long storage to eliminate the virus).

The packaging of supplied food, semi-finished products, raw materials and other food components should ensure their safety (including automatic elimination of the virus), the possibility of neutralising pathogens, but also the identification of the products themselves (composition) and their conditions of use (storage temperature, date shelf life). In addition to the food supply, for the proper functioning of the feeding system, it is necessary to provide properly packaged water, disposable dishes, detergents for washing dishes, cleaning and disinfecting furniture, appliances, surfaces, kitchen utensils, as well as waste bags and containers. Packaging must allow for proper transport, manipulation, storage, and protection of products, as well as allow for picking. Monitoring and tracing devices are also helpful, which means the transparency of the supply chain must be increased.

Our research showed that functioning of the internal food supply chain depends on the ability to ensure adequate conditions for appropriate handling of food, including transport, storage, preparation, serving, consumption, and selection, as well as storage and neutralization of waste and leftovers. Not only food products and their packaging must be protected. Protection must also be provided for places and working tools, storage, transport and waste disposal sites, and all persons who handle food and physical goods in contact with food. An important element has become the proper protection and cleaning of reusable packaging (containers, transporters) and proper maintenance of transport/loading surfaces, storage, production and serving areas and places where meals are consumed. Waste logistics has also become particularly problematic. During the pandemic, it has been necessary to change the organisation of zones, segregate and store waste, date containers with waste and keep them for a period that guarantees the absence of the virus (to limit its spread), create additional divisions of waste zones (by date and type) and designate waste shipment routes from different origins.

The safety (ensured by using masks or gloves) and physical condition of employees are particularly important factors determining the quality and continuity of the food supply chain. In a pandemic, security is based on limiting the spread of the virus and providing human resources to carry out tasks. The need to introduce control systems (temperature measurement) and disinfection concerns people who prepare food (and have contact with food before and during the process of its preparation), serve food (including changing the conditions of serving food to eliminating direct contact), consume food (schedule and zones), and carry out cleaning activities. It became necessary to divide teams into smaller fixed groups and create conditions that minimise contact between them. In many cases, this resulted in the extension of the time of the procedures performed. In the event of an illness or suspected infection of one worker, the entire group is subjected to epidemic procedures. Rigorous procedures for separating groups performing regular tasks from each other are beneficial for organisational and sanitary reasons, but have negative social consequences, making it difficult to build a friendly atmosphere at work and cooperate.

In addition, our research revealed that the pandemic situation may cause dysfunctions at the stage of food consumption. Serving meals in groups of many people and freedom of movement are elements that also foster creating and maintaining interpersonal relationships and they constitute an important element of organisational culture. The pandemic forced the creation of conditions for separation in this area. The creation of physical barriers, the re-planning and reorganisation of the spatial system for the consumption of meals by soldiers, as well as changes in the schedule of their daily activities in order to limit personal contacts and allow for maintaining social distance contributed to changes in the functioning of the individual’s nutrition system.

6. Conclusions

Dysfunctions in the food supply chain in the result of the coronavirus epidemic require a systemic approach, developing procedures and good practices that will fully support building resilience. Queiroz et al. [

51] propose to categorise the SC resilience actions in the context of pandemic disruptions, using four main categories, namely: systems (structures, resources, capacities, interactions (responses, coordination)), process (distribution, transportation, procurement, production, resources allocation, flexibility), control (inventory control, sourcing control, manufacturing control, resilience as KPI in optimisation models) and recovery (manufacturing production, human labour, transportation network, suppliers, production flexibility).

Resistance is proactive and means the capacity of a system to absorb disturbance and reorganise while undergoing changes in order to maintain the same function, structure, identity, and feedback [

52]. Ali et al. [

53] identify five basic resilience abilities and their elements: the ability to anticipate (situation awareness, robustness, increasing visibility building security, knowledge management—pre-disruption), to adapt (increasing flexibility, building redundancy), to respond (collaboration, agility), to recover (contingency planning, market position), and to learn (knowledge management—post-disruption, building social capital).

Any disruptions are a prerequisite for learning, continuous improvement, strengthening resilience and sustainable development in the supply chain, building a supply chain management culture based on such elements as knowledge management, innovation, leadership, and disruptive environment awareness [

54].

To increase the flexibility of supply chains, [

55] suggests following six practical principles, namely: (1) ensuring continuity by providing partners with data on changes in supply and demand so that they can react quickly; (2) developing relationships based on cooperation with suppliers and customers (design or redesign of processes, components and products, preparation of backup plans); (3) designing products so that they initially have common parts and processes and are differentiated towards the end of the production process (deferment strategy); (4) storage of a small inventory of components that cause bottlenecks; (5) building a reliable logistics system that allows for quick regrouping in response to unexpected needs; and (6) creating a team dedicated to developing contingency plans in the event of crises.

Flexible, agile response to disruptions is especially important to the resilience of the supply chain. Tendall et al. [

56] define the resilience of the food system in the context of more participatory structures in relation to the whole system, highlighting the importance of the time dimension and the multi-level nature of the food system (from individuals, through national food systems to global value chain networks). Thus, in military institutions characterised by a bureaucratic and centralised management style, there are barriers to an agile approach. Planning of supplies and expenses in military units is carried out one year in advance (VII-IX of the previous year). This results in the system being rather rigid. Due to the pandemic situation, consent was given to make changes in the budgets of units and purchase additional amounts of disinfectants, personal protective equipment (especially for handling food preparation and dispensing) and disposable packaging, cutlery, cups, and napkins. This made it possible to react faster to threats and ensure food safety.

An indispensable task is to develop a quality management system that covers the key threats to food safety and the methods of their control, the purpose of which is to ensure consistent compliance with key quality parameters (internal and external stakeholder requirements) at all stages of supply chain relations [

57]. Due to the increasing importance of proactive risk management in terms of quality, safety, origin, and responsible sourcing of materials in the food supply chain, the reputation of suppliers, producers and distributors is becoming a key risk factor that requires comprehensive assessment [

58]. The search for partners with appropriate food safety certificates, including Food Defence and Food Fraud, is therefore crucial. Due to the lockdown, restrictions on movement, including border crossing, it became necessary to seek national and local partners, which increased the emphasis on creating a short supply chain. In short, with regard to food supply chains, thanks to direct interactions between producers and consumers, it is possible to achieve benefits, such as mutual knowledge and respect, trust, solidarity and compromise between the producer and the consumer, recognition of the quality of the food product and production conditions, ethics and values, (re)connections with traditions and identities, collective civic engagement in the local food system, the intensity and direction of information flows, and the balance of power between actors [

59]. Direct (face-to-face) contacts between producers and consumers foster interaction and sharing of information about the origin of the product and its production process, so that consumers can make their own value judgments [

60].

Among the main measures to minimise the impact of the COVID-19 pandemic on the logistics of food value chains, the Food and Agriculture Organization of the United Nations (FAO) recommends, inter alia, ensuring the priority of consumer and employee health in food value chains and food safety and integrity (safety measures recommended by the World Health Organization), as well as the use of information technology (IT) for the maintenance of logistics (IT applications and social media as innovative ways to coordinate the supply of fresh produce from the farm to the consumers, innovative logistics and transport methods for direct deliveries to the public) [

12].

Therefore, decision-making tools supporting the management of disruptions in the supply chain are of key importance. The use of innovative information and communication tools is essential for knowledge management and increasing transparency in the supply chain. According to [

61] (p. 18) “transparency of a netchain is the extent to which all the netchain’s stakeholders have a shared understanding of, and access to, the product-related information that they request, without loss, noise, delay and distortion”. In order to improve quality, quality assurance, certification, reporting, and transparency in the supply chain, it is necessary to ensure business functions by designing and generating quality and its guarantees, optimising business processes, in particular logistics processes and restoring processes that are necessary in the event of a disaster. A more efficient use of communication based on transparent information within the framework of integrated communication systems is also required [

62]. However, this requires relationship management and the development of coordination mechanisms in the supply chain, so that it is possible to flexibly and quickly respond to changes in the needs of participants and consumers, while ensuring food safety. Controlling an outbreak of an epidemic requires prompt response, adherence to certain control protocols and the availability of supplies along with the necessary human resources to be used during the containment activities [

63].

The pursuit of coordination focuses activities on the following areas: synchronisation of logistics activities, exchange of information, adjustment of incentives (stimulation of members’ behaviour and interaction with other partners) and learning together to increase each partner’s capacity (continuous improvement) [

64].

Kumar et al. [

65] emphasise that a resilient supply chain should also take into account social wellbeing (job security) and health and safety practices appropriate to the state during and after the COVID-19 pandemic, which means the need to develop sustainable and resilient supply chains in the economic, social, and environmental areas. The environmental and ecological aspect has gained importance during the pandemic due to the challenges related to waste management. Due to sanitary reasons, there has been an increase in the use of disposable plastic dishes, personal protective equipment, and disinfectants in the food supply chain. In addition, food waste may occur, which forces the search for organisational and technological solutions towards reasonable waste management. Therefore, extensive waste management activities aimed at sustainable development and circular economy are necessary. These include investments in safety equipment and physical infrastructure for sorting, collection and recycling, development of automation and innovation in existing and emerging technologies, such as the introduction of artificial intelligence for collecting and segregation, design of environmentally friendly products such as bioplastics and the reduction of food waste, reuse of food, utilisation of food waste and recycling of nutrients (by composting) [

66]. The case of COVID-19 shows a wide scope for implementing the principles of the circular economy concept, providing credible solutions, including design and product policy factors, such as repair ability, reusability and remanufacturing potential, offering significant resilience (stock availability) and competitiveness [

67].

In conclusion, it should be emphasised that restoring the capacity and restarting the food supply chain after disruptions is a complex, multi-faceted task that requires multi-directional actions in the areas of management processes (organisation, information system supporting decision-making processes, procedures) and logistics (transport, storage, food serving, waste collection), manufacturing and technology (production, food processing), and relationships (partnership, trust, responsibility for safety, communication). The need to take into account the specificity of military supply chains makes it crucial to identify barriers and limitations that slow down or even prevent flexible and quick responses to changes resulting from the development of a pandemic situation. In particular, this concerns restrictive law in the field of supplier selection and contracting procedures, the possibility of changing them, and the exchange of critical information in relations with civil suppliers. The issue of the functioning of military food supply chains is minimally developed in the literature on the subject. This also applies to the new situation that has arisen in connection with the coronavirus pandemic, which results from its novelty and continuous nature. In a final conclusion, it should be emphasised that with the current knowledge about the course and consequences of the coronavirus pandemic, it is not possible to identify all disruptions in food supply chains and their consequences. The conducted analyses concerned Polish military units that carry out nutrition processes for soldiers. However, due to the adopted level of generality and simplification of the described processes, it can be concluded that the formulated inferences and proposed solutions are universal and transnational in nature.

The analysis of the crisis situation and its consequences for the functioning of military food supply chains, based on the example of Poland, can be treated as a model solution. In individual countries affected by the pandemic, the supply systems of individual military units were subject to similar factors, which forced the creation of new solutions. These solutions in particular stages of the pandemic have, to date, assumed the form illustrated in the example of the Polish military unit. As practice shows, military logistics differs from civil logistics and solutions proven feasible in civil supply chains may be difficult to apply to military systems. Thus, the proposed solutions constitute a model procedure with a certain level of generalisation assumed, taking into account the specific conditions and the needs of the army. It results not only from the willingness to present a universal solution, but it is also a consequence of information protection. The sphere of military activity is a very sensitive area in the activities of each state, and allied relations. Therefore, the conducted case study analysis is qualitative.

The conducted research leads to the conclusion that the pandemic undoubtedly caused the need to revise the existing solutions used in the food supply chain (external and internal) in order to ensure the continuity of the feeding processes. As a consequence, it will be necessary to introduce legislative changes as regards the adaptation of military supply chains to the new conditions ensuring their resilience. These changes should concern the shortening of chains and, consequently, their reorganisation. Moreover, it is necessary to increase the reactivity and adaptability of supply chains and adapt civil-military cooperation to dynamically changing conditions, which translates, inter alia, to shortening the time needed for planning needs by the military unit and negotiating and concluding contracts with civil suppliers.

The considerations undertaken in the article made it possible to answer the formulated research questions and achieve the research goals. Regardless of the limitations, the presented analyses, conclusions, and proposed recommendations may be useful in a practical, managerial, and scientific dimensions and constitute a starting point for broader, in-depth research. According to the authors, the challenges for further research are certainly issues related to the possibilities of technological and informational support for processes implemented in the food supply chain. Research to ensure the resilience of military supply chains should be directed at reviewing domestic food supply chains, as well as those operating in international military operations.

In the long-term perspective, the environmental consequences of changes in the area of waste management, increased use of disposable utensils, detectors, disinfectants, and personal protective equipment may also be important. In this context, the importance of the concepts of a sustainable supply chain and circular economy should be particularly emphasised.