5.1. Open Issues and Challenges

Despite the numerous advantages of blockchain technology for establishing sound traceability systems, specific challenges remain. This section provides a classification of the main challenges and open issues relevant to blockchain technology and its broader usage in SC traceability solutions.

Real life testing pilots: Several organizations are currently involved in real-world pilot studies for adopting blockchain in SC traceability. As far as these pilot initiatives are concerned, they exhibit the potential of blockchain traceability solutions. Still, they are not sufficient to prove the capabilities of blockchain to deliver real business value. Despite significant investments in blockchain, little is said about the technology’s full deployment. Most blockchain services are available on a limited-revenue basis and are managed at a pilot scale, usually within corporate boundaries. We believe that any architecture evaluation should be tested in a real-life scenario to ensure its performance in the context of SC traceability, taking into account different cost pools and operational requirements.

There is also a high barrier to technology and process adoption regarding real-life testing solutions. The integration of traceability technologies (including different devices) and processes, which do not exist in all SC networks, pose a significant barrier, especially in less technology-intensive SC industries. Blockchain is still in its infancy, and its penetration is limited in many sectors. Therefore, the technology’s lack of awareness and understanding may prevent certain SC participants from accepting blockchain-based SC traceability solutions. Implementing larger distributed systems will also prove difficult as system size and complexity must increase. Complex operational processes and interest-conflicting participants exist in real life SC scenarios. Therefore, the practicability and feasibility of blockchain-based traceability solutions should be verified across all SC participants taking into account end-to-end approaches.

Under the real application of blockchain solutions, the user feedback (i.e., involving all SC actors, both upstream and downstream of the SC) must be thoroughly collected and assessed. User input can be used for fine-tuning and optimizing the blockchain-based traceability workflow. In addition, designing and deploying information management systems across an entire SC is complex and costly. Incremental modification and augmentation to existing systems could provide a practical and cost-effective pathway to utilise blockchain technologies with legacy systems.

Evaluation and benchmarks: As observed in the literature, there is a lack of standardised benchmarks to compare different blockchain implementations, especially in light of different hardware, software setups, and transaction types. Most studies provide experimental results of the performance and scalability of their solutions in terms of transactions per second and the approximate cost in terms of gas fees. However, few papers provide a security analysis of their implementations, including the smart contract code. We believe that standardised cross-platform benchmarks are necessary so that authors discuss the real value of their works in practical scenarios and provide sound advancements in the state of the art. Moreover, real case studies are also necessary to understand the suitability of the different blockchain technologies/platforms according to the application context while measuring long term performance, managerial aspects, privacy and security, and other measurable features. For instance, according to latency and cost fees, novel public platforms such as Solana, Polkadot, Cardano, as well as Layer 2 solutions such as the Lightning Network (

https://lightning.network/, accessed on 15 December 2021), may fulfill the requirements for sustainable blockchain-based systems in the short to mid-term, but presently are unfeasible with, e.g., Ethereum due to increased gas fees.

Sustainability concerns: During our analysis, it was not easy to identify how blockchain-based traceability solutions bring economic, environmental, and social value. The sustainability perspective was always implied/inferred in all selected papers and not explicitly stated. For example, although some authors note significant benefits of the technology concerning the social dimension of sustainability, it is not clear how a company/sector can meet the expectations of various stakeholders concerning societal priorities (including its customers). The same holds for the economic dimension of sustainability, where real-life testing is needed for assessing the potential of blockchain technology to bring down operational costs and increase the overall SC surplus. This is particularly true because all the papers’ cost dimensions were concerned with blockchain-related costs (for example, gas fees, etc.) and not the SC economic benefits from adopting the blockchain technology in SC traceability. Future research is needed for uncovering how the technology can bring value in terms of increased environmental performance. Environmental-related concerns are significant, especially if we consider the massive energy requirements of current blockchain networks.

Organizational challenges: Various exploratory studies report on significant barriers to blockchain adoption in an organizational context, such as lack of specialised personnel, low organizational readiness and organizational culture [

102], and “resistance to change” attitude [

103]. Some SC participants may have difficulties addressing the technological uncertainties around blockchain, especially because they lack good organisational capabilities and a company culture receptive to new technologies. The wider adoption of blockchain across SC participants requires expertise, which is difficult for small and medium-size organisations to possess. In addition, small and medium-size organisations may be unaware of blockchain technology or may not have the necessary personnel to embrace the technology. Moreover, big SC players may have insufficient training capacities for educating non-specialised people. In general, open business culture and severe organisational transformation must adopt blockchain technology across SC participants.

Investment and operational costs: Building blockchain applications entails high costs. The cost to build blockchain-enabled solutions depends on various factors such as the project’s complexity, blockchain technology suitability analysis, and other technology and operational stacks. Blockchain implementation incurs various design, development, deployment, migration, and maintenance costs. For example, significant initial investment costs are incurred at the initial application stage, and the reuse of an existing blockchain network may be difficult due to the one-off characteristic of construction projects. There is a cost incurred for smart contract deployment, function calls in the smart contract, and each transaction initiated by the smart contract. These cost items could result in high operational costs if the contract is not programmed to keep cost-effectiveness in mind. Other costs include coding and testing, deployment on cloud platforms, moving the existing solution to the blockchain platform, maintaining new updates and testing that the app runs smoothly on every OS release, and third party costs (hosting, storage). Blockchain platforms also contribute to the cost of blockchain app development. A developer has to pay a certain fee to deploy a contract on the blockchain. Note that not all collaboration models in SC are based on a win-win philosophy. The prevalence of internal-only traceability systems across SC networks unavoidably gives rise to opportunistic behaviour. Experience has shown that the processing firms (upstream SC members) may bear the financial burden of implementing traceability. At the same time, gains are reaped by firms in the distribution businesses closer to the end customer (downstream SC members) [

104]. SC participants aspiring to adopt blockchain applications should view the benefits from a long-term perspective. Future work should evaluate the entire realization cost of the system, taking into account the system as a whole and under reasonable time frames.

Integrating blockchain with existing enterprise resource planning (ERP) systems necessitates substantial financial commitment. In general, updating business information systems and incorporating cutting-edge technology into a company’s arsenal necessitates significant long-term financial investments. On-boarding and maintenance expenses are also significant. Suppliers, third-party logistics providers, distributors, and manufacturers who participate in a SC network will be responsible for the cost of hosting a node (energy spent) inside a blockchain consortium. High costs will be incurred in the form of maintenance, data storage, and infrastructure improvements as a result of high volume transactions over broad SC networks, and SC members will be responsible for these expenses [

103].

Blockchain-related technological challenges: Despite being received as a panacea by many practitioners, the truth is that blockchain has several challenges that require further efforts to overcome. Concerning performance, aspects such as transaction latency, which affects scalability [

17,

105], are essential to ensure proper functioning of the blockchain solutions. Note that in the concrete scenario of ERP-related technologies and apps (gateways for the connection to the blockchain, diversity of protocols, standards, volume, and expected throughput, etc.), scalability may prove to be a big challenge for ERP/blockchain integration, given the massive quantity of transactions in current SC networks. The first step to maximise the performance of any SC traceability solution is to leverage a suitability assessment [

17]. Selecting the proper blockchain architecture (e.g., public blockchain, private blockchain, and their permission management) is crucial. However, it may condition several functional aspects, and thus, it needs to be performed carefully.

In addition to the blockchain platforms, development aspects are also critical. For example, the development and deployment of efficient and secure smart contracts [

106,

107], data management procedures (e.g., the use of hybrid approaches that enable decentralised storage to minimise on-chain data storage), and novel approaches that use Layer 2 blockchain solutions [

108] remain a challenge. Moreover, by minimising the number of transactions and data stored in the blockchain, we limit the impact of immutability when not desirable or illegal data is at stake [

109], as the information stored on the blockchain and decentralised storage systems such as IPFS cannot be easily deleted [

110,

111]. Finally, blockchain privacy and security issues should also be taken into account [

112].

Apart from scalability, lack of standardisation and interoperability frameworks could be significant barriers to successfully integrating ERP systems and blockchain-enabled applications, especially given the numerous ERP solutions on the market and the various blockchain architecture configurations and variants. ERP interactions, for example, are increasingly based on common data formats among SC trade partners. Unfortunately, although being organised, data created by blockchain-enabled apps are not fully covered by standardised frameworks [

105]. As a result, data translation between ERP software and blockchain platforms will be required in the coming years. Finally, interoperability across multiple blockchain networks is still a significant difficulty, but it is becoming an essential component of Web3. Interoperability across blockchain networks is essential because it allows data and value to be exchanged smoothly. In SC networks, where SC partners may be members of multiple blockchain networks, such communication is crucial [

113].

Addressing the “garbage in, garbage out” challenge: Like all computing systems, output quality is determined by the quality of input in any given blockchain application. Blockchain networks cannot guarantee the veracity of data that was not natively generated on-chain (for example, information coming from sources such as IoT devices across the SC). Apart from devices, humans may also input fraudulent data into the blockchain. For example, workers in the SC may create fake or incorrect data regarding traceability records, and unfortunately, blockchain is unable to detect intentionally and/or unintentionally corrupted data [

114]. In this case, and due to the immutability of blockchain technology, SC participants will end up with fraudulent data permanently written to the blockchain. The usage of solid identity management frameworks might be part of the solution, especially self-sovereign identity schemes; however, the veracity of traceability-related records is still undermined by human error. Therefore, future research should focus on the veracity and integrity of traceability-related data and especially on innovative ways to secure the source of generated information across vast SC networks.

Regulatory challenges of blockchain: Blockchain technology’s regulatory and legal approval is a cross-sectoral impediment to its broad deployment. The lack of a worldwide legislative framework, in particular, creates barriers to the global acceptance and use of blockchain technology. Data security, cyber-attacks, privacy compliance, and cross-border cooperation are emerging blockchain integration challenges. The difficulties surrounding smart contracts, such as usage, deployment, and enforcement, are significant. It is worth emphasising that the existing legal frameworks for recognising smart contracts worldwide are still in their infancy. It is uncertain if existing law schemes fully protect smart contracts. Because various parties (SC trade partners, government authorities, etc.) are engaged, ERP and blockchain integration poses major regulatory issues. Some regulations should be made on the governmental level to allow this technology in the food sector. Despite initial efforts toward standardisation of blockchain technology (e.g., ISO/TC 307 (

https://www.iso.org/committee/6266604.html, accessed on 15 December 2021), there is a long road ahead considering that legal constraints are also involved in the implementation of such a system.

Blockchain governance: Blockchain governance seems to be the biggest single challenge for the growth of distributed ledgers [

115]. Blockchain governance refers to the way disparate stakeholders within the same blockchain project achieve coordination, direction, and control [

116]. Not only does blockchain governance necessitate consensus among validating nodes, but it also necessitates consensus among network users. It should be noted that governance on the blockchain is fundamentally different from traditional contractual and relational governance [

117]. Practically, the debate over governance in the context of blockchain networks currently revolves around two pillars: centralised vs. decentralised and on-chain vs. off-chain. For example, public blockchain platforms like Ethereum are governed on a distributed basis in line with their autonomous and decentralised operation, leading to issues due to the lack of a central legal entity with formal responsibility for the system. During times of crisis, the risks of such a governance scheme can be amplified as the system’s developers try to agree on software code changes to address the problem [

115]. Off-chain governance mechanisms include public discussion and collectively agreed-upon updates. In contrast, on-chain governance mechanisms entail online voting (stakeholders vote using tokens to accept or reject a proposed change).

Standardisation and certification of the SC traceability process: SC traceability may greatly benefit when SC actors adopt shared standards for specific practices and methods. However, traceability is based on strong connections between different SC partners, which perform processes that affect the ownership, physical movement, position, or condition of traceable units (external traceability events). Traceability also relies upon appropriate tools for harvesting and managing the internal and external traceability events captured by technologies such as barcodes and RFID tags along with the SC. According to recent studies, the establishment of any traceability framework necessitates a well-organised and standardised framework involving all (internal and external) actors [

118]. Both external and internal traceability events will be handled with the EPCIS standard developed by GS1. For example, the GS1 Global Traceability Standard establishes a minimum set of traceability requirements for business processes to achieve full chain traceability regardless of technology. It lays out a common framework for creating a traceability system incorporating other GS1 standards like barcodes, data carriers, eCom, and EPCIS. Standardisation may apply not only to SC operations but also to traceability-related data and events handling. Note also that standardising internal and external traceability processes may require organisational changes. Uniform data definitions and authorities for creating, accessing, and changing data should be ensured by data governance. Data governance cannot be defined solely by the partners of a single blockchain initiative; it necessitates sector, if not industry-wide, agreement. Otherwise, suppliers will be required to adhere to various interface standards, rendering blockchain technology inefficient from an economic standpoint [

118].

5.2. Key Findings

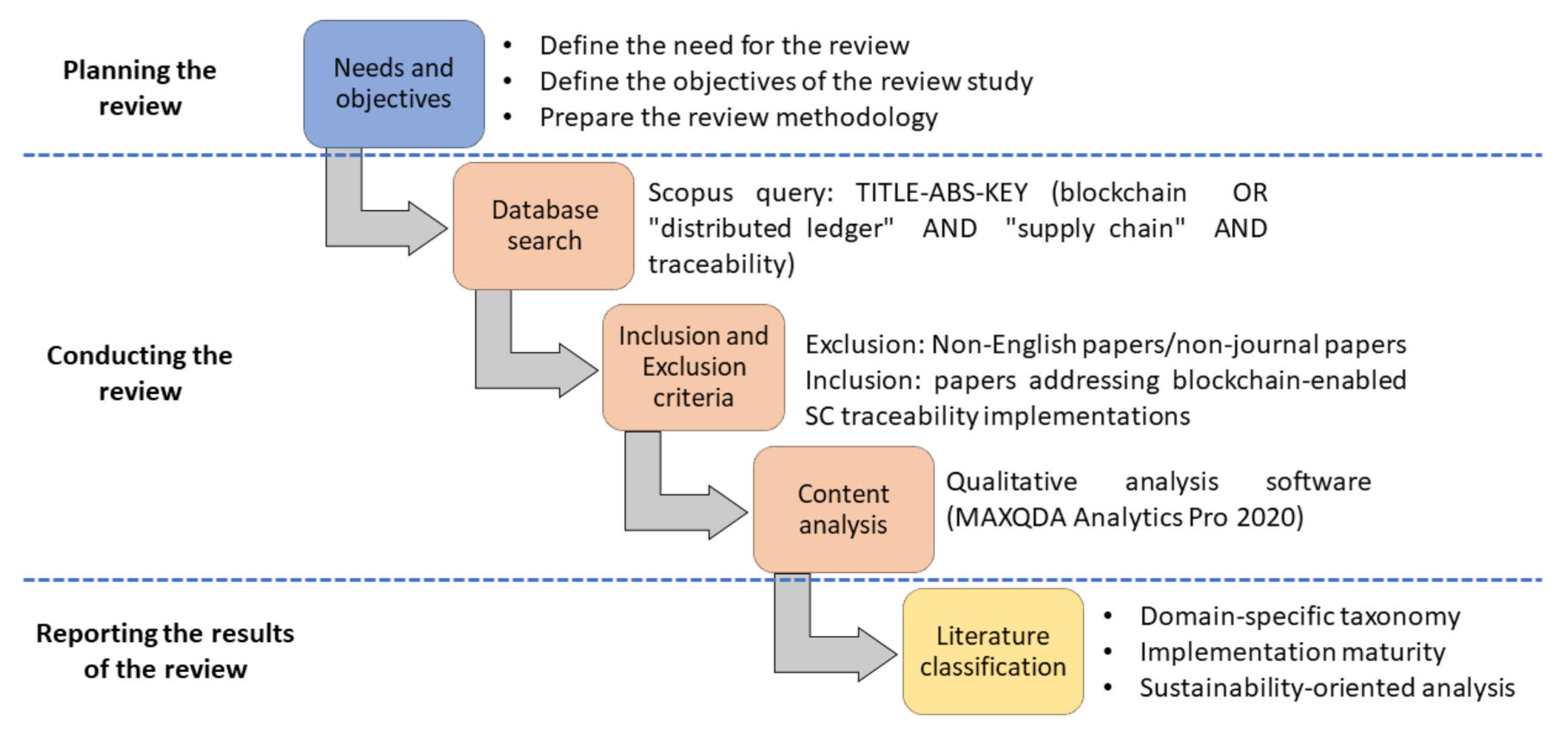

In what follows, we provide a summary of the main findings of our study in accordance with the various research questions initially posed.

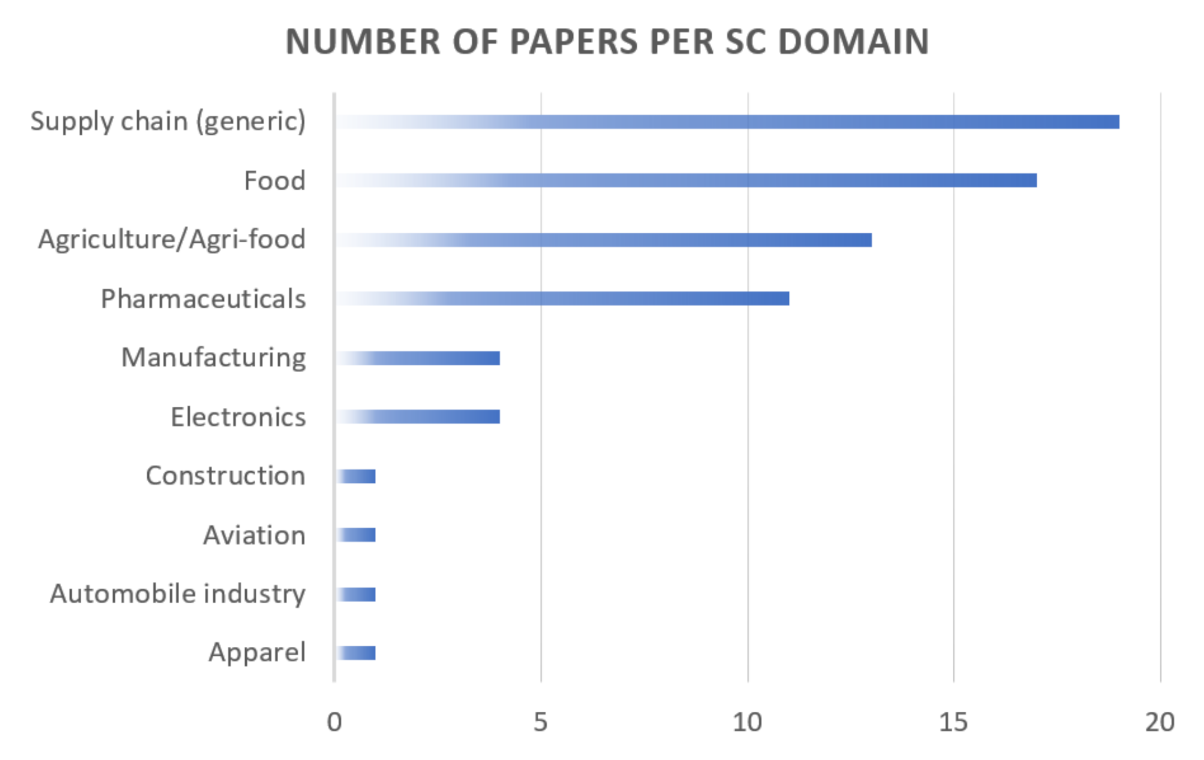

RQ1: The available blockchain-enabled SC traceability implementations encompass various SC domains, such as generic, food, agriculture/agri-food, pharmaceuticals, manufacturing, electronics, apparel, aviation, automobile, industry, and construction. However, most retrieved blockchain implementations fall within the agricultural and food supply domain. These two sectors are of paramount importance in terms of increased visibility, transparency, and security and have attracted most of the attention from the scientific community. Other domains, like pharmaceuticals, have also received considerable attention during recent years. The list of traceable products includes, among others, agricultural products (crops, soybeans, buckwheat, wine, grains, wheat, flour, cotton, etc.), food (eggs, beef, dairy products, fish and seafood, bread, etc.), medical supplies (vaccines, drugs), electronics (electronic parts/devices, e-products, integrated circuits, mobile phones, etc.), and other products (steel, aircraft spare parts, airbags, precast concrete products, wind turbine blades, and automotive parts). All authors adopted architecture development and system design/testing methods concerning the methodologies applied. In addition, many authors used simulation as their main testing methodology. Finally, for many authors, cost-benefit analysis was applied as security analysis (mostly informal security analysis). Given the analysed literature, no specific differences were found topic-wise; thus, the maturity of blockchain implementations is a global challenge to overcome, paired with the integration, adoption, and benchmark-related challenges discussed in

Section 5.1.

RQ2: As previously discussed in

Section 4.2, most implementations do not include advanced and functional interfaces. The latter, paired with the lack of benchmarks and thorough testing under real conditions through use case scenarios, increases the difficulty of assessing the quality of proposed solutions. Concerning the underlying blockchain technologies used, Ethereum blockchain is the most used, followed by Hyperledger. Due to its design and industry-oriented functionality, Hyperldeger implementations presented more maturity on average than the rest of the technologies. Nevertheless, novel blockchain technologies (e.g., Layer 2 solutions as well as blockchain networks with more scalable consensus mechanisms such as Cardano (

https://cardano.org/, accessed on 15 December 2021), Polkadot (

https://polkadot.network/, accessed on 15 December 2021), or Solana (

https://solana.com/, accessed on 15 December 2021), are emerging, which may change the paradigm in the years to come. In this regard, a strategy that enables cross-chain integration and testing is a desirable feature to consider.

RQ3: The challenges surrounding blockchain regarding its adoption and regulation, and the inherent technological issues, pose a serious overhead. Current literature lacks a systematic way to evaluate the sustainability perspective of their solutions, as authors mainly focus on the performance of the technology. Thus, a de facto evaluation and discussion of the different sustainability aspects is necessary. This is a crucial step for the advancement of the state of the art since it will: (1) improve benchmarking, (2) identify the pain points of this research field, and (3) provide a fruitful ground for discussion towards the rest of blockchain-related challenges discussed in

Section 5.1.

RQ4: Enhancing the maturity of implementations and the quality of their evaluations is a complex task. From a comparison-wise perspective, each problem may require different blockchain platforms to be solved, which hinders direct comparisons in the literature. In terms of maturity, many platforms offer ready-to-use attractive solutions for most developers; thus, they are leveraged for research articles to prove functionality. However, these experiments are not enough to provide a holistic view of how a system would perform in real-life SC scenarios. Lack of regulations, standards, and a clear roadmap of “how-to” impede researchers and practitioners from developing and testing sound blockchain-based solutions. Therefore, we believe that all these aspects need to evolve together in parallel, offering a solid paradigm for the transition and adoption of blockchain.