Barriers and Enablers for the Adoption of Sustainable Manufacturing by Manufacturing SMEs

Abstract

1. Introduction

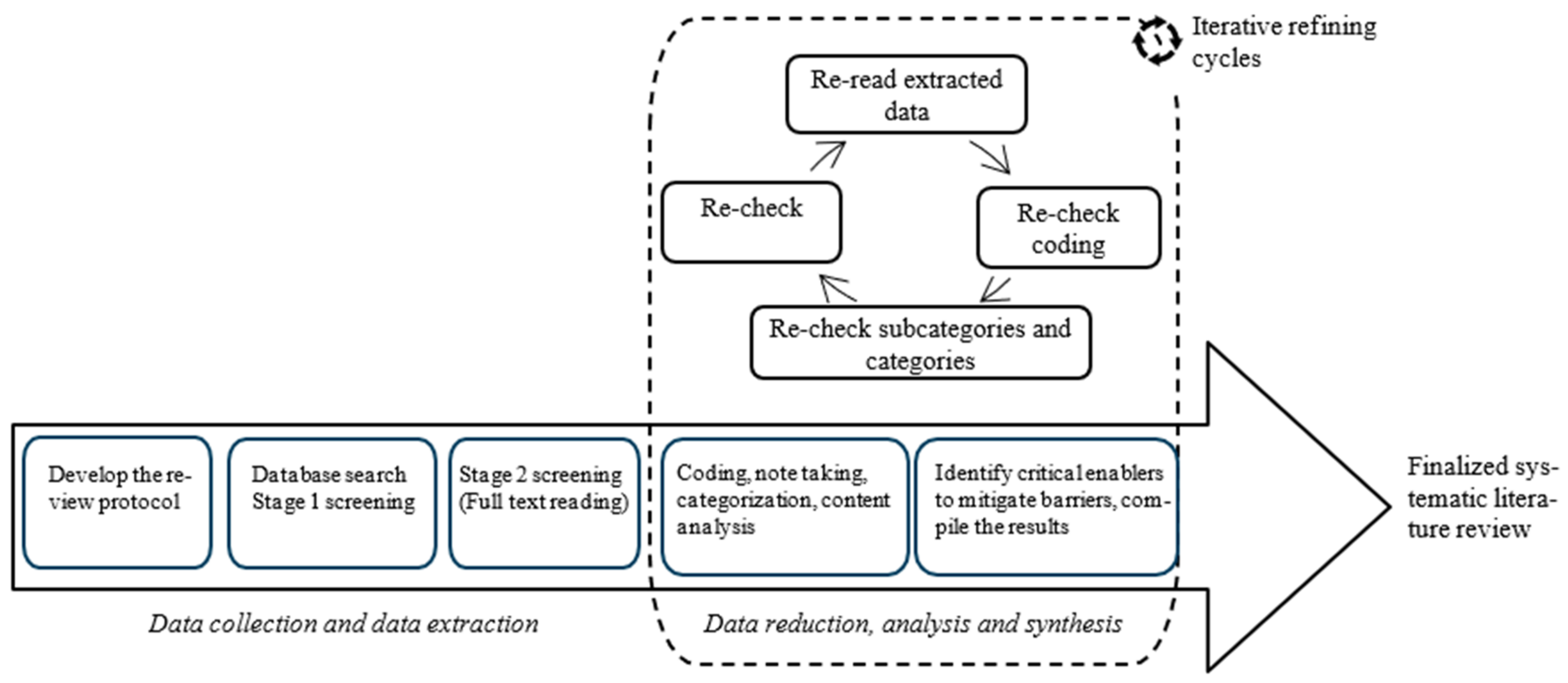

2. Theoretical Framework: Barriers, Enablers, and SMEs

3. Research Methodology

3.1. Data Collection and Extraction

3.2. Data Reduction, Analysis, and Synthesis

4. Results

4.1. Descriptive Analysis of the Systematic Literature Review Sample

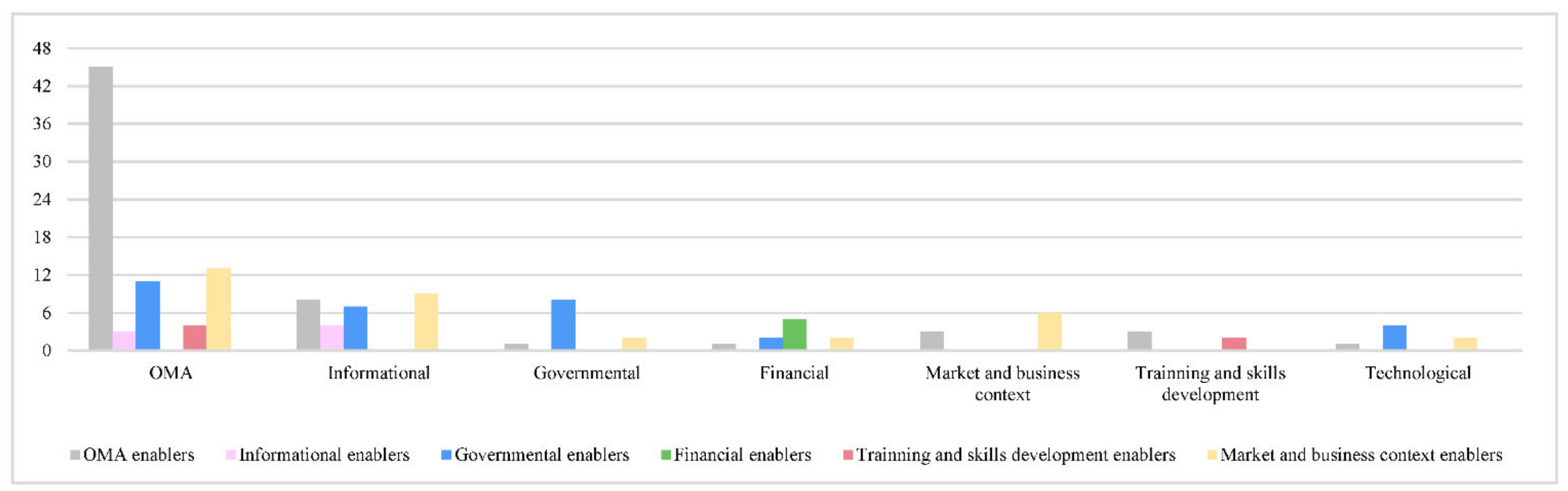

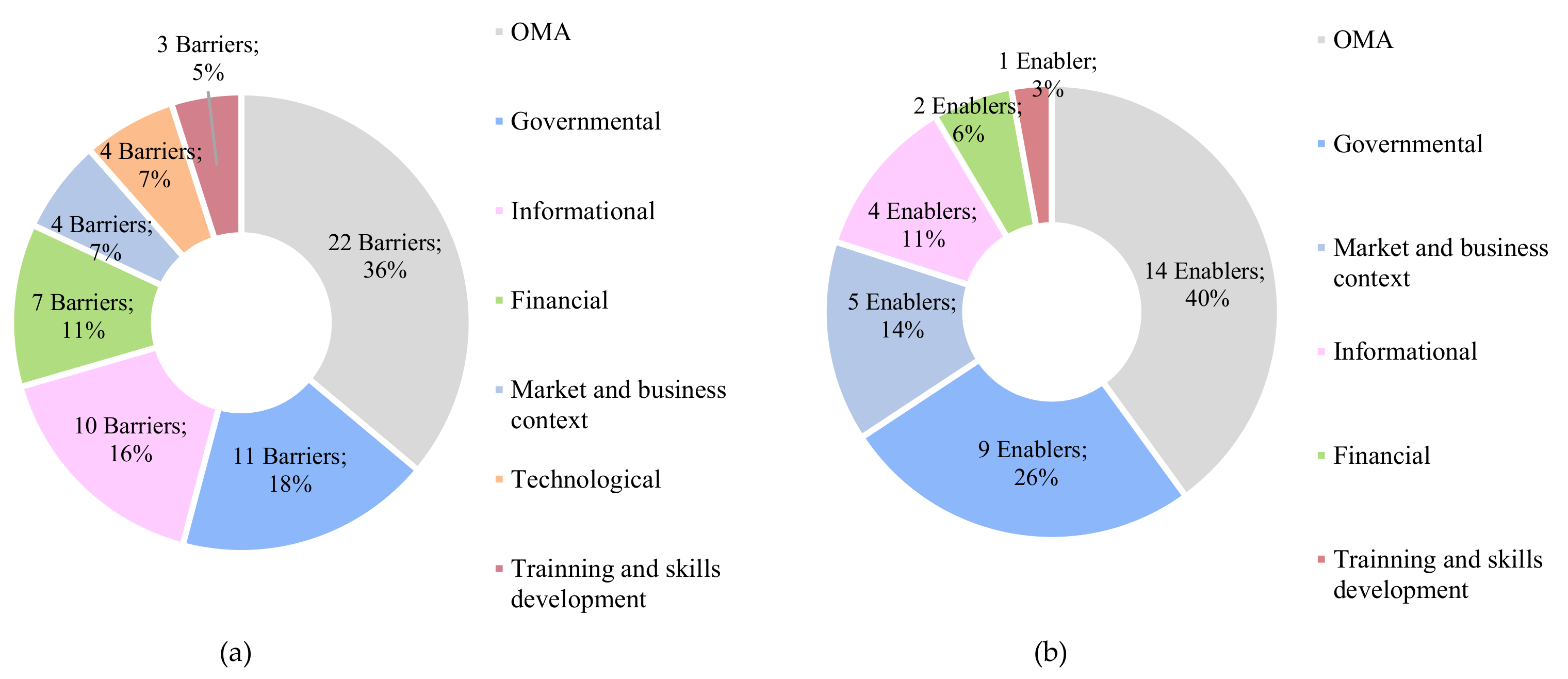

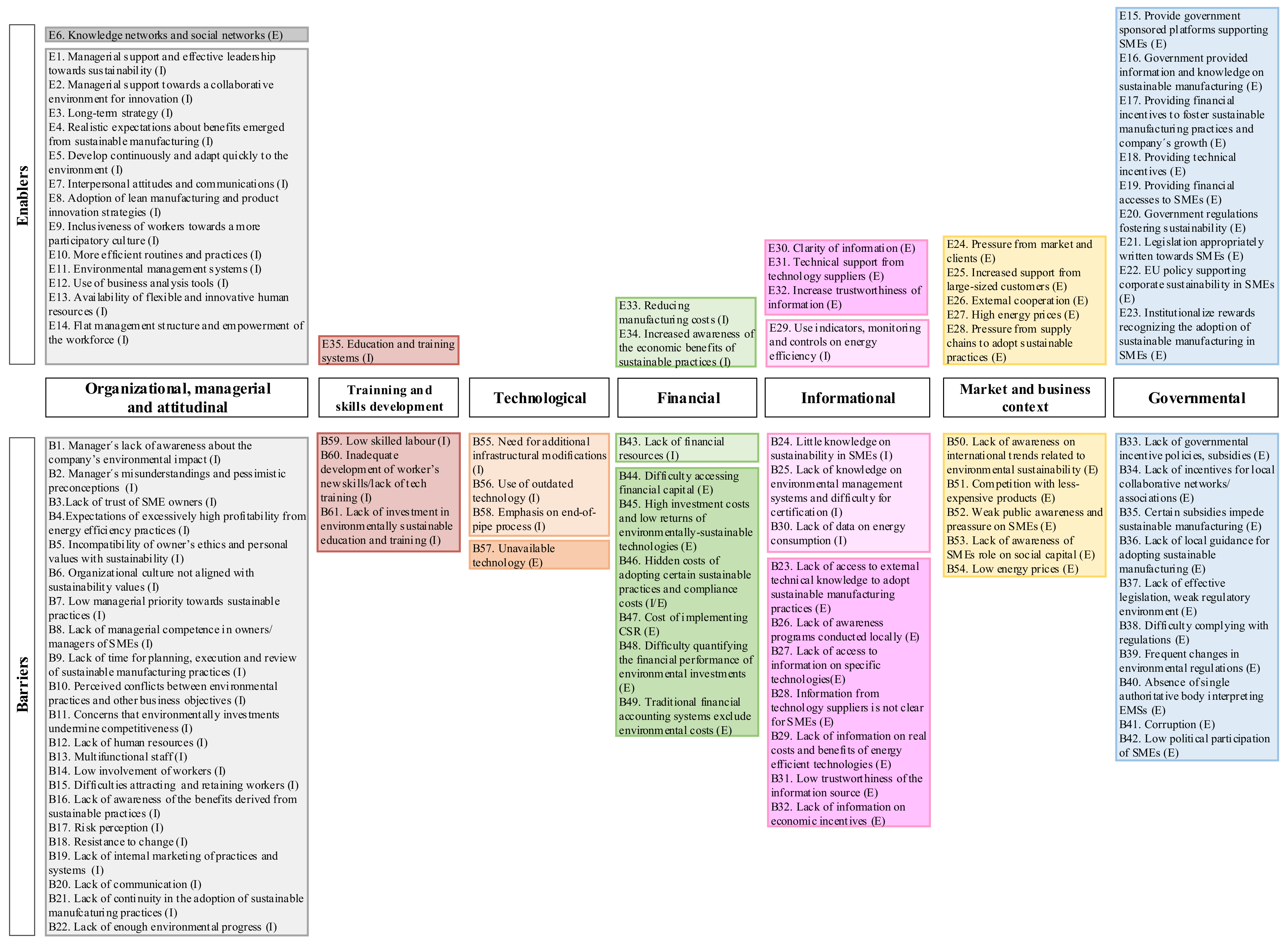

4.2. Barriers and Enablers for the Adoption of Sustainable Manufacturing

- (a)

- Organizational, managerial, and attitudinal aspects (OMA) (related to managerial skills, organizational culture and structure, and attitudes and beliefs).

- (b)

- Informational aspects (Inf) (related to information and knowledge).

- (c)

- Governmental aspects (Gov) (related to factors emerging from governmental policy).

- (d)

- Financial aspects (F) (related to aspects of economic or financial nature affecting the longevity of the enterprise).

- (e)

- Training and skills development aspects (TSD) (related to receiving or giving instruction, training programs in order to ensure human resources have the necessary skills and knowledge).

- (f)

- Market and business context aspects (M) (related to SMEs’ relations with suppliers, customers, and other stakeholders within the business context that prevent or facilitate the adoption of sustainable manufacturing).

- (g)

- Technological aspects (T) (related to the machinery, equipment, devices, and technology).

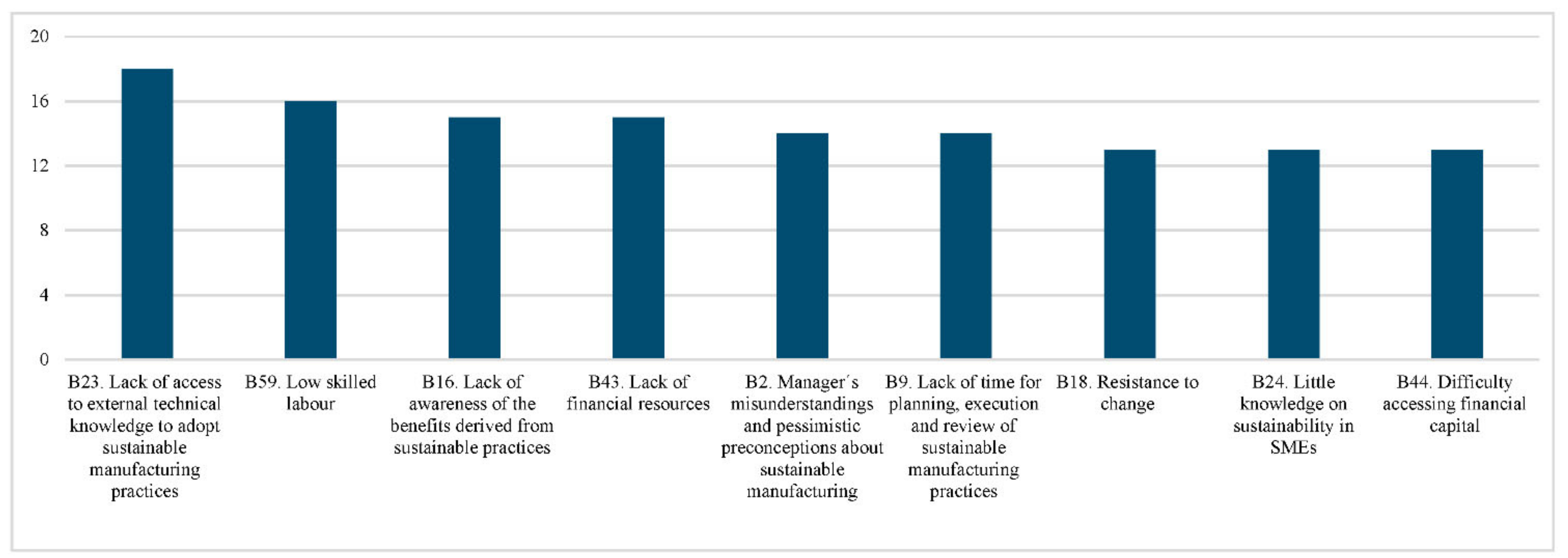

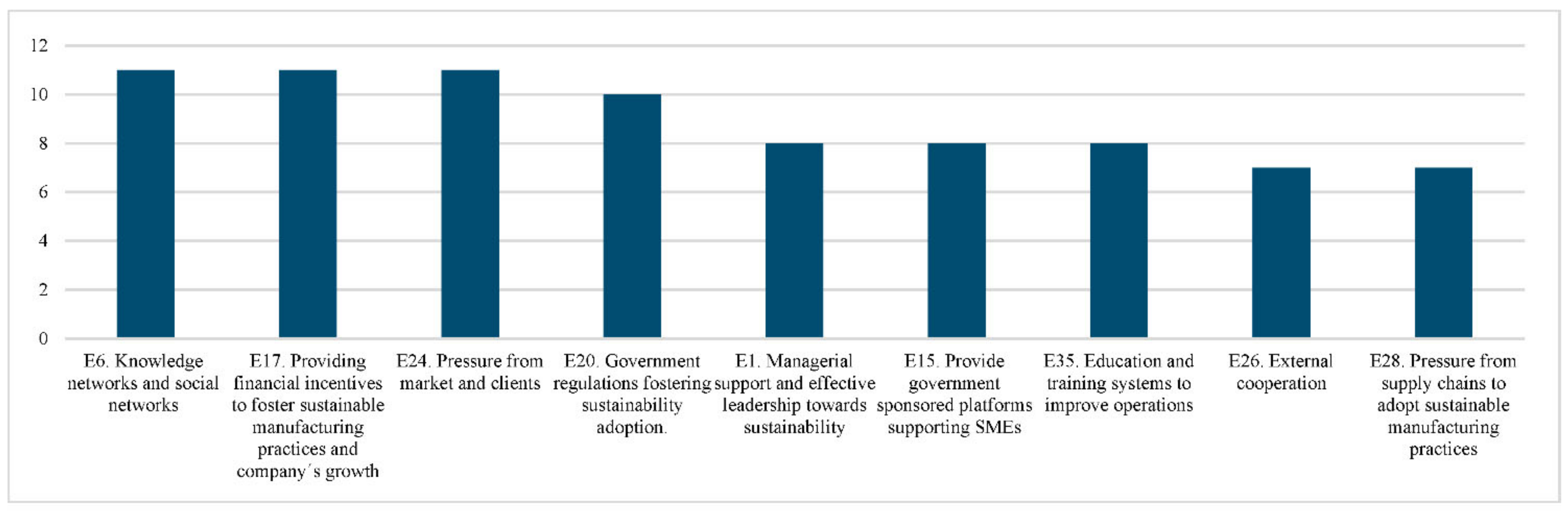

4.2.1. Barriers and Enablers per Category

4.2.2. Barriers and Enablers for Sustainable Manufacturing Lacking an Integrative Perspective

4.2.3. Internal and External Barriers and Enablers

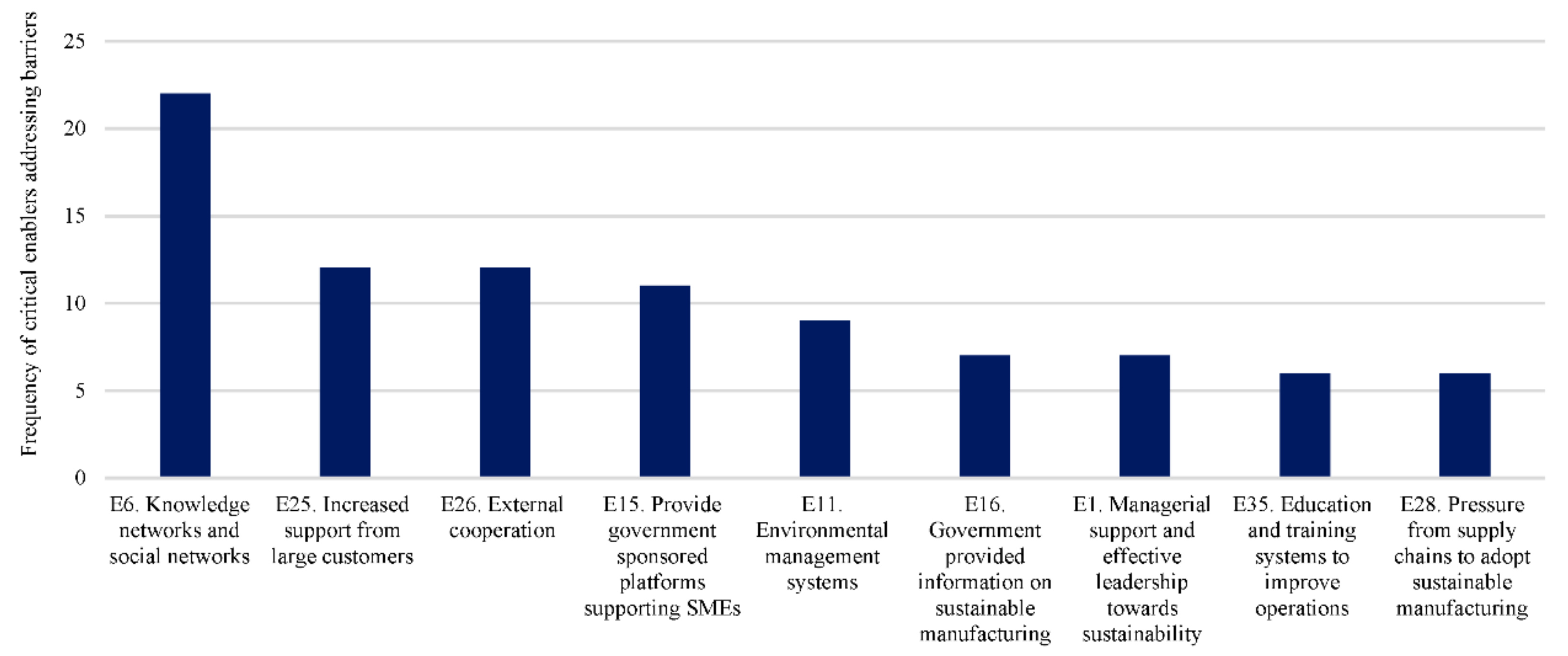

4.3. Mitigating Barriers through Enablers for Sustainable Manufacturing

5. Discussion

5.1. Barriers and Enablers for Sustainable Manufacturing in SMEs

5.2. Critical Enablers Addressing Identified Barriers

5.3. Limitations

6. Conclusions and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Barriers to Sustainable Manufacturing Adoption by Manufacturing SMEs | |||||

|---|---|---|---|---|---|

| Cat. | Subcategory | Origin | Description | References | Freq |

| Organizational, managerial, and attitudinal (OMA) | B1. Manager´s lack of awareness about the company’s environmental impact | I | Managers lack knowledge, understanding and awareness of environmental issues. | [21,23,64,70,71,81,83,84,85] | 9 |

| B2. Manager´s misunderstandings and pessimistic preconceptions about sustainable manufacturing | I | Pessimistic preconceptions of unmanageable time, and high-cost requirements to adopt sustainable manufacturing practices (e.g., costs, lack of commercial viability, lack of profitability, technical challenges). | [21,37,38,50,55,56,71,77,81,83,84,86,87,88] | 14 | |

| B3. Lack of trust of SME owners | I | SMEs’ owners’ resistance to share information about their companies. | [70,85] | 2 | |

| B4. Expectations of excessively high profitability from energy efficiency practices | I | Managers’ expectations of excessively high profitability from energy efficiency practices. | [56] | 1 | |

| B5. Incompatibility of owner’s ethics and personal values with sustainability | I | Lack of interest in sustainable manufacturing practices from SMEs’ owners. | [21,37,81,84,85,88] | 6 | |

| B6. Organizational culture not aligned with sustainability values | I | Underdeveloped culture involving sustainability values or principles. | [21,81,83,85,88] | 5 | |

| B7. Low managerial priority toward undertaken sustainable manufacturing practices | I | Higher priority given to production expansion or increasing market share over allocation of resources to sustainable technologies. | [22,23,24,36,37,83,85,86,87] | 9 | |

| B8. Lack of managerial competence in owners/managers of SMEs | I | Managers/owners of SMEs lack the basic managerial and technical capacity to implement sustainable manufacturing practices and to make of their enterprise a learning organization. | [22,24,77,79,86] | 5 | |

| B9. Lack of time for planning, execution and review of sustainable manufacturing practices | I | Lack of time of SMEs’ owners/managers and staff to engage in sustainability-related activities. | [21,23,24,37,39,65,78,79,81,82,85,86,87,89] | 14 | |

| B10. Perceived conflicts between environmental practices and other business objectives | I | Perceived trade-offs between environmental practices with other manufacturing performance objectives (e.g., quality, cost, delivery) regarding resources, energy usage, materials, and waste emissions. | [36,37,83,87] | 4 | |

| B11. Concerns that environmental investments undermine competitiveness | I | Additional costs from adopting environmental technologies might undermine the company’s competitiveness in the marketplace. | [22] | 1 | |

| B12. Lack of human resources | I | Limited personnel occupied with daily tasks and working alone on identification and implementation of sustainable manufacturing practices. | [23,65,77,79,83,85,86] | 7 | |

| B13. Multifunctional staff | I | Multifunctional staff often associated with interruptions in the adoption of sustainable manufacturing practices. | [21,81,86] | 3 | |

| B14. Low involvement of workers | I | Workers lack interest in sustainable manufacturing practices; thus, their involvement in such practices is low. Lack of accepting suggestions from employees. | [24,79,89] | 3 | |

| B15. Difficulties attracting and retaining workers | I | SMEs face a high turnover of staff and difficulties attracting new workers. | [21,77,81] | 3 | |

| B16. Lack of awareness of the benefits derived from sustainable manufacturing practices | I | Staff and managers lack interest and awareness of the economic and environmental benefits of sustainable manufacturing practices. | [21,23,37,38,39,56,70,71,77,81,82,83,84,85,89] | 15 | |

| B17. Risk perception | I | Overestimation of the investment risks, resulting from poor knowledge of energy efficiency technology. | [39,56,82,85] | 4 | |

| B18. Resistance to change | I | Management fears the risks of modifying current production processes and technologies and/or replacing them with new ones. Staff resistant to change to new practices. | [21,22,23,24,37,38,39,55,77,81,83,87,89] | 13 | |

| B19. Lack of internal marketing of practices and systems | I | Lack of internal marketing of practices and systems that promote among employees the sustainable objectives. | [21,81] | 2 | |

| B20. Lack of communication | I | Lack of communication vertically and horizontally in SMEs. | [55,79,81,89] | 4 | |

| B21. Lack of continuity in the adoption of sustainable manufacturing practices | I | Lack of a systemic approach toward the implementation of sustainable manufacturing. | [21,23,55,81] | 4 | |

| B22. Lack of enough environmental progress | I | Current environmental progress does not motivate the improvement. | [21,81] | 2 | |

| Informational (Inf) Tech’ | B23. Lack of access to external technical knowledge to adopt sustainable manufacturing practices | E | Insufficient offerings of external technical support to SMEs, lack of access to technical information, lack of available external knowledge for implementing sustainable manufacturing. Lack of metrics, benchmarks, and guidance for adopting sustainable manufacturing. | [21,22,24,37,55,56,65,70,71,77,81,83,84,85,87,88,89,90] | 18 |

| B24. Little knowledge on sustainability in SMEs | I | A lack of knowledge of sustainability concepts in SMEs. This due to the lack of, or limited access to, sustainability-related literature focused on SMEs. | [21,22,23,24,38,70,71,77,81,85,86,89,90] | 13 | |

| B25. Lack of knowledge on environmental management systems and difficulty for certification | I | SMEs are poorly informed about EMSs (EMASs and ISO 14001) and its benefits. High cost of certification/verification of EMSs. | [21,81] | 2 | |

| B26. Lack of awareness programs conducted locally | E | Lack of awareness programs about the importance of adopting sustainable manufacturing. | [23,37,65,77,89] | 5 | |

| B27. Lack of access to information on specific technologies | E | Information regarding sustainable technologies is not available to SMEs’ managers. This affects the perceived managerial complexity of new technology. | [56,86,89] | 3 | |

| B28. Information from technology suppliers is not clear for SMEs | E | Lack of information on costs and benefits of energy efficient technologies | [39,82] | 2 | |

| B29. Lack of information on real costs and benefits of energy efficient technologies | E | Lack of information and little knowledge of costs and benefits of energy efficient technologies. | [39,82,85] | 3 | |

| B30. Lack of data on energy consumption | I | Lack of data on energy consumption patterns and efficiency measures is common among SMEs. | [23,56] | 2 | |

| B31. Low trustworthiness of the information source | E | Quality of the available information on energy efficiency technologies. | [23,39,56,82] | 4 | |

| B32. Lack of information on economic incentives | E | Information regarding economic incentives is not available to managers. | [24,56] | 2 | |

| Governmental (Gov) | B33. Lack of governmental incentive policies; subsidies, taxes. | E | Lack of governmental subsidies and other types of incentives. Lack of access to information on economic incentives. | [22,23,24,69,70,77,84,89] | 8 |

| B34. Lack of incentives for local collaborative networks and associations | E | Lack of incentives for SMEs to build local collaborative networks. | [21,69,77,78,81] | 5 | |

| B35. Certain subsidies that impede sustainable manufacturing | E | Economic subsidies for business resource inputs may be a significant disincentive to environmental sustainability. | [55] | 1 | |

| B36. Lack of local guidance for adopting sustainable manufacturing | E | Lack of local guidance for adopting sustainable manufacturing/CSR. | [24,77,84,88,89,90] | 6 | |

| B37. Lack of effective legislation and a weak regulatory environment | E | Lenient environmental legislation and weakly enforced environmental legislation applicable to SMEs. | [21,22,24,55,65,69,77,81,83,84,89,90] | 12 | |

| B38. Difficulty complying with regulations | E | SMEs find it difficult to comply with regulations. SMEs perceive regulations as complex and challenging to understand. | [21,23,24,36,55,77,86] | 7 | |

| B39. Frequent changes in environmental regulations | E | Frequent changes in environmental regulations and lack of resources to track down the incoming environmental legislation. | [24,50,81] | 3 | |

| B40. Absence of a single authoritative body to interpret EMSs | E | Absence of a single authoritative body to interpret EMSs. | [21,81] | 2 | |

| B41. Corruption | E | Highly corrupt regulatory authorities and officials mostly in developing countries. Unfair competition due to corruption. | [79,84] | 2 | |

| B42. Low political participation of SMEs | E | SMEs have small or limited political participation. | [78] | 1 | |

| Financial (F) | B43. Lack of financial resources | I | Low availability of capital in SMEs. | [21,23,24,37,39,50,55,65,70,81,82,83,85,86,87] | 15 |

| B44. Difficulty accessing financial capital | E | Limited financing channels designed or available for SMEs. Lack of funds for environmentally related projects (e.g., capital devoted to energy efficiency investments). | [21,22,23,24,50,56,70,77,79,81,85,86,90] | 13 | |

| B45. High investment costs and low returns of environmentally sustainable technologies | E | The initial capital costs of adopting environmental technologies are often higher than those of conventional technologies. Low returns and longer payback periods for environmentally related investments. | [22,23,24,37,38,39,56,82,86,87] | 10 | |

| B46. Hidden costs of adopting certain sustainable manufacturing practices, and compliance cost for regulations. | I E | The aggregation of all the costs pre, during, or post the adoption of sustainable manufacturing practices (e.g., research on technologies available, disruption costs, training personnel on using new technology). | [39,79,82] | 3 | |

| B47. Cost of implementing CSR. | E | Social compliance cost (time, other types of costs) as a barrier to implementing CSR. | [24,86,88] | 3 | |

| B48. Difficulty quantifying the financial performance of environmental investments | E | Difficulty quantifying the financial performance of environmental investments. | [22] | 1 | |

| B49. Traditional financial accounting systems exclude environmental costs | E | Traditional financial accounting systems in SMEs fail to include environmental costs and liabilities. | [55,77] | 2 | |

| Market and business context (M) | B50. Lack of awareness of international trends related to environmental sustainability | E | Lack of awareness regarding international trends in legislation and markets about the importance of environmental aspects to business. | [83] | 1 |

| B51. Competition with less-expensive products | E | Competition with markets and less-expensive products excluding environmental or social considerations. | [71,83] | 2 | |

| B52. Weak public awareness and pressure on SMEs | E | Insufficient public pressure on SMEs toward more benign sustainable manufacturing practices. | [22,77] | 2 | |

| B53. Lack of awareness of SMEs role on social capital | E | Lack of awareness of media, academia, and politicians of SMEs adding to social capital. | [78] | 1 | |

| B54. Low energy prices | E | Low energy prices hindering proactive actions to reduce energy from SMEs. | [55,69] | 2 | |

| Technological (T) | B55. Need for additional infrastructural modifications | I | The adoption of new sustainable manufacturing practices related to infrastructure might result in problems with space, infrastructure, etc. | [22,23,38,85,89,90] | 6 |

| B56. Use of outdated technology | I | Technologies used by SMEs are outdated, and more sustainable and modern alternatives (equipment and substances) are unavailable. Lack of alternative substances to substitute the hazardous ones. | [24,37,55,77,89] | 5 | |

| B57. Unavailable technology | E | Technology suppliers not updated. Cleaner technologies suitable for the small-scale sector are limited. | [37,39,82,89] | 4 | |

| B58. Emphasis on end-of-pipe process | I | Emphasis on end-of-pipe process, as opposed to making changes in the processes. | [24,89] | 2 | |

| Training and skills development (TSD) | B59. Low skilled labour | I | Limited in-plant expertise. Shortage of skilled workers and core competency. | [21,22,23,24,36,56,65,70,77,79,81,83,85,86,87,90] | 16 |

| B60. Inadequate development of workers’ new skills, and lack of technical training | I | Inadequate development of workers’ new skills and capabilities. Lack of training programs on developing, performing and maintaining sustainable manufacturing practices. | [21,22,64,71,77,79,81,87,90] | 9 | |

| B61. Lack of investment in environmental education and training | I | SMEs often lack financial resources for education and training on environmental sustainability. | [21,22,23,70,81,86,90] | 7 | |

| Organizational, managerial, and attitudinal (OMA) | E1. Managerial support and effective leadership toward sustainability | I | Managerial support is pivotal to initiate and maintain sustainable manufacturing practices. Inspiring managers or personnel addressing sustainability issues could convert sustainable manufacturing adoption into an organizational priority. | [23,37,39,43,64,85,90,91] | 8 |

| E2. Managerial support toward a collaborative environment for innovation | I | A favorable environment for innovation by offering employees training on innovation and creative thinking; setting a reward system for employees’ innovation initiatives… | [67] | 1 | |

| E3. Long-term strategy | I | With the establishment of a long-term sustainability strategy, practices are more likely to succeed, as will be considered organizational priorities. | [37,39,43,85] | 4 | |

| E4. Realistic expectations about benefits emerged from sustainable manufacturing | I | Increased awareness about the expected benefits that may result from adopting sustainable manufacturing practices (e.g., cost savings, new markets, positive corporate image, improved environmental and social performance). | [37,39,43,65,91] | 5 | |

| E5. Develop continuously and quick adaption to the environment | I | Continuous and quick adaptation is an important competitive advantage for companies. By continuously improving SMEs expertise on environmental practices, SMEs can step ahead of their competition. | [65] | 1 | |

| E6. Knowledge networks and social networks | E | To participate, create and strengthen social networks with financiers, government bodies, suppliers’ associations, trade unions, stakeholders. Sustainability Partnership networks assist SMEs with gaining knowledge, pooling resources, and developing mutually beneficial sustainable projects. | [37,39,43,56,63,69,77,78,79,83,89] | 11 | |

| E7. Interpersonal attitudes and communications | I | The presence of good interpersonal attitudes and communications. | [56,64,85,89] | 4 | |

| E8. Adoption of lean manufacturing and product innovation strategies | I | Lean product innovation strategies enable SMEs to break into new markets and to thereby become more resilient to market changes. | [64] | 1 | |

| E9. Inclusiveness of workers toward a more participatory culture | I | The acknowledgment that all personnel within a company have valuable contributions. Employees share responsibility for sustainability and a common concern for the environment. | [37,39,43,64,90] | 5 | |

| E10. More efficient routines and practices | I | The problems with space and infrastructure from sustainable manufacturing practices might be solved by developing more efficient routines and practices. | [23] | 1 | |

| E11. Environmental management systems (EMAS and ISO 14001) | I | SMEs having ISO 14001 certification are likely to perform better on environmental activities. | [37,39,43,65] | 4 | |

| E12. Use of business analysis tools | I | Business analysis process tools (i.e., prioritization of environmental aspects; stakeholder analysis; SWOT analysis). | [83] | 1 | |

| E13. Availability of flexible and innovative human resources | I | To improve organizational and sustainability performance, while empowering personnel. | [64] | 1 | |

| E14. Flat management structure and empowerment of the workforce | I | Application of a flat management structure and the empowerment of the workforce to self-organize. | [64] | 1 | |

| Governmental (Gov) | E15. Provide government sponsored platforms supporting SMEs | E | Training, tutoring, consultation, awareness programs, and business-related incentives to foster sustainable manufacturing, attract customers and business partners. | [23,56,63,65,77,83,86,89] | 8 |

| E16. Government provided information and knowledge on sustainable manufacturing | E | Developing condensed knowledge about the adoption of sustainable manufacturing practices helps to overcome low awareness and lack of technical knowledge (e.g., “how to” guidance materials, case studies, webinars, workshops). | [23,64,69,86,89] | 5 | |

| E17. Providing financial incentives to foster sustainable manufacturing practices and the company´s growth | E | To provide financial incentives, such as subsidies, fewer taxes on raw materials, reduced import duties on environmental technologies. | [23,37,38,39,43,63,65,77,86,89,91] | 11 | |

| E18. Providing technical incentives | E | Provision of technical development facilities for SMEs and emphasis on environmental technology development. | [38,63,77,83,89] | 5 | |

| E19. Providing financial accesses to SMEs | E | Developing financing channels for SMEs. | [23,89] | 2 | |

| E20. Government regulations fostering sustainability adoption | E | Law enforcement is important for effective implementation of policies and rules. Strict regulations could force SMEs to adopt sustainable manufacturing measures. | [37,38,39,43,63,65,85,86,89,91] | 10 | |

| E21. Legislation appropriately written toward SMEs | E | Legislation appropriately written will improve the understanding of law and its compliance. | [37,39,43,65,77,89] | 6 | |

| E22. EU policy supporting corporate sustainability in SMEs | E | EU support programmes and other policies offering directions and access to funding could improve SMEs corporate sustainability. | [67,85] | 2 | |

| E23. Institutionalize rewards recognizing the adoption of sustainable manufacturing in SMEs | E | Design governmental awards that recognize SMEs striving to improve sustainability performance. | [65] | 1 | |

| Market and business context (M) | E24. Pressure from market and clients | E | Pressure from market enables SMEs to satisfy customer requirements. Increasing market demand for environmentally friendly products. | [21,63,65,69,83,85,86,89,90,91] | 10 |

| E25. Increased support from large customers | E | Increased support from OEMs will require a cultural change in buyer-supplier relationships. It will help to improve sustainability performance and foster SMEs growth. | [65,89] | 2 | |

| E26. External cooperation | E | Collaboration with industrial associations helps SMEs to stay well informed and active in their field. Likewise, SMEs working along suppliers and customers to improve their sustainability performance. | [37,39,43,79,83,85,89] | 7 | |

| E27. High energy prices | E | SMEs are likely to reduce energy expenditure if energy prices are high. | [37,39,43] | 3 | |

| E28. Pressure from supply chains to adopt sustainable manufacturing practices | E | SMEs under strong pressure from supply chains will move toward sustainability, as motives for implementing sustainable manufacturing practices and policies are strongly influenced by pressure from supply chains. | [21,65,81,83,85,88,89] | 7 | |

| Informational (Inf) | E29. Use indicators, monitoring, and controls on energy efficiency | I | Keeping relevant data makes it possible to report on progress and results of energy efficiency practices. | [23,56] | 2 |

| E30. Clarity of information | E | Information about energy efficiency must be adequate to design and implement energy efficiency programs and monitor energy improvement measures. | [37,39,43] | 3 | |

| E31. Technical support from technology suppliers | E | Technical support from technology suppliers helps to overcome the risks associated with adopting new energy efficiency technologies, such as production disruptions due to installation. | [37,39,43] | 3 | |

| E32. Increase the trustworthiness of the information | E | Industrial associations or similar external stakeholders may increase the trustworthiness of information as these are regarded as a trustworthy source by companies. | [37,39,43,89] | 4 | |

| Financial (F) | E33. Reducing manufacturing costs | I | Cost reduction is vital to guarantee the continuity of the business. | [23,37,39,43,64,91] | 6 |

| E34. Increased awareness of the economic benefits of sustainable manufacturing practices | I | Awareness of the economic benefits of sustainable manufacturing practices. Implementing sustainable technology in manufacturing to attain economic benefits. | [37,39,43,89] | 4 | |

| Training and skills development (TSD) | E35. Education and training systems to improve operations | I | Education and training systems are decisive for improving industry practices and introducing sustainable manufacturing concepts and practices. Sensitization on sustainable manufacturing practices. | [37,39,43,64,69,77,83,89] | 8 |

| Technological (T) | (No enablers were identified) | ||||

References

- Jansson, J.; Nilsson, J.; Modig, F.; Hed Vall, G. Commitment to Sustainability in Small and Medium-Sized Enterprises: The Influence of Strategic Orientations and Management Values. Bus. Strategy Environ. 2017, 26, 69–83. [Google Scholar] [CrossRef]

- Ayyagari, M.; Demirgüç-Kunt, A.; Maksimovic, V. Small vs. Young Firms across the World: Contribution to Employment, Job Creation, and Growth; World Bank: Washington, DC, USA, 2011. [Google Scholar]

- Constantinos, C.; Yding Sørensen, S.; Larsen, P.B.; Alexopoulou, S. SMEs and the Environment in the European Union; European Commission: Paris, France, 2010. [Google Scholar]

- Hillary, R. Small and Medium-Sized Enterprises and the Environment: Business Imperatives; Greenleaf Publishing: Sheffield, UK, 2000. [Google Scholar]

- European Commission. SMEs, Resource Efficiency and Green Markets. Flash Eurobarometer 456; European Commission: Paris, France, 2017. [Google Scholar]

- Revell, A.; Stokes, D.; Chen, H. Small businesses and the environment: Turning over a new leaf? Bus. Strategy Environ. 2010, 19, 273–288. [Google Scholar] [CrossRef]

- Brundtland Commission. Report of the World Commission on Environment and Development: Our Common Future; Oxford University Press: Oxford, NY, USA, 1987. [Google Scholar]

- De Ron, A.J. Sustainable production: The ultimate result of a continuous improvement. Int. J. Prod. Econ. 1998, 56, 99–110. [Google Scholar] [CrossRef]

- Garetti, M.; Taisch, M. Sustainable manufacturing: Trends and research challenges. Prod. Plan. Control 2012, 23, 83–104. [Google Scholar] [CrossRef]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. Enablers and Barriers of Sustainable Manufacturing: Results from a Survey of Researchers and Industry Professionals. Procedia CIRP 2015, 29, 562–567. [Google Scholar] [CrossRef]

- U.S. Department of Commerce. Sustainable Manufacturing Initiatives (SMI): A true Public–Private Dialogue. International Trade Administration. 2010. Available online: https://www.oecd.org/sti/ind/45010349.pdf. (accessed on 15 August 2018).

- Moldavska, A.; Welo, T. The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. J. Clean. Prod. 2017, 166, 744–755. [Google Scholar] [CrossRef]

- Alayón, C.; Säfsten, K.; Johansson, G. Conceptual sustainable production principles in practice: Do they reflect what companies do? J. Clean. Prod. 2017, 141, 693–701. [Google Scholar] [CrossRef]

- Welsh, J.A.; White, J.F. A Small Business Is Not a Little Big Business. Harv. Bus. Rev. 1981, 59, 18–26. [Google Scholar]

- Jenkins, H. Small business champions for corporate social responsibility. J. Bus. Ethics 2006, 67, 241–256. [Google Scholar] [CrossRef]

- Avlonitis, G.J.; Salavou, H.E. Entrepreneurial orientation of SMEs, product innovativeness, and performance. J. Bus. Res. 2007, 60, 566–575. [Google Scholar] [CrossRef]

- Xie, X.M.; Zeng, S.X.; Tam, C.M. Overcoming barriers to innovation in SMEs in China: A perspective based cooperation network. Innov. Manag. Policy Pract. 2010, 12, 298–310. [Google Scholar] [CrossRef]

- Terziovski, M. Innovation practice and its performance implications in small and medium enterprises (SMEs) in the manufacturing sector: A resource-based view. Strateg. Manag. J. 2010, 31, 892–902. [Google Scholar] [CrossRef]

- Ghazilla, R.; Sakundarini, N.; Abdul-Rashid, S.H.; Ayub, N.S.; Olugu, E.U.; Musa, S.N. Drivers and barriers analysis for green manufacturing practices in Malaysian smes: A preliminary findings. Glob. Conf. Sustain. Manuf. Emerg. Potentials 2015, 26, 658–663. [Google Scholar] [CrossRef]

- Sudarsan, R.; Sriram, R.D.; Narayanan, A.; Sarkar, P.; Lee, J.H.; Lyons, K.W.; Kemmerer, S.J. Sustainable Manufacturing: Metrics, Standards, and Infrastructure-Workshop summary. In Proceedings of the 2010 IEEE International Conference on Automation Science and Engineering, Toronto, ON, Canada, 21–14 August 2010; pp. 144–149. [Google Scholar]

- Hillary, R. Environmental management systems and the smaller enterprise. J. Clean. Prod. 2004, 12, 561–569. [Google Scholar] [CrossRef]

- Shi, H.; Peng, S.Z.; Liu, Y.; Zhong, P. Barriers to the implementation of cleaner production in Chinese SMEs: Government, industry and expert stakeholders’ perspectives. J. Clean. Prod. 2008, 16, 842–852. [Google Scholar] [CrossRef]

- Henriques, J.; Catarino, J. Motivating towards energy efficiency in small and medium enterprises. J. Clean. Prod. 2016, 139, 42–50. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.; Leite, R.R.; Shibao, F.Y.; Lucato, W.C. Framework to overcome barriers in the implementation of cleaner production in small and medium-sized enterprises: Multiple case studies in Brazil. J. Clean. Prod. 2017, 142, 50–62. [Google Scholar] [CrossRef]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. An integrated approach for analysing the enablers and barriers of sustainable manufacturing. J. Clean. Prod. 2017, 142, 4412–4439. [Google Scholar] [CrossRef]

- Sorrell, S.; Schleich, J.; Scott, S.; O’Malley, E.; Trace, F.; Boede, U. Reducing Barriers to Energy Efficiency in Public and Private Organisation; Electronic Publication, Institute Fraunhofer ISI: Karlsruher, Germany, 2000; Available online: http://publica.fraunhofer.de/documents/N-5674.html (accessed on 15 August 2018).

- Sorrell, S.; Mallett, A.; Nye, S. Barriers to Industrial Energy Efficiency: A Literature Review; Working Paper no. 10/2011.; United Nations Industrial Development Organization: Vienna, Austria, 2011; Available online: http://sro.sussex.ac.uk/53957/1/WP102011_Barriers_to_Industrial_Energy_Efficiency_-_A_Literature_Review.pdf. (accessed on 15 August 2018).

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Roberts, S.J.F.; Ball, P.D. Developing a Library of Sustainable Manufacturing Practices. Procedia CIRP 2014, 15, 159–164. [Google Scholar] [CrossRef]

- Natarajan, G.; Wyrick, D. Environmental sustainability in Manufacturing SMEs in West Texas. In Proceedings of the 33rd Annual International Conference of the American Society for Engineering Management 2012, ASEM 2012—Agile Management: Embracing Change and Uncertainty in Engineering Management, Virginia Beach, VA, USA, 17–20 October 2012; pp. 856–861. [Google Scholar]

- Miras-Rodríguez, M.D.M.; Machuca, J.A.D.; Escobar-Pérez, B. Drivers that encourage environmental practices in manufacturing plants: A comparison of cultural environments. J. Clean. Prod. 2018, 179, 690–703. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Nordin, N.G.A.H.; Hassan, M. Drivers and barriers in sustainable manufacturing implementation in Malaysian manufacturing firms. In Proceedings of the IEEE Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 687–691. [Google Scholar]

- Alayón, C.; Sannö, A.; Säfsten, K.; Johansson, G. Sustainable production in surface treatment SMEs: An explorative study of challenges and enablers from the CEOs perspective. In Proceedings of the Global Cleaner Production and Sustainable Consumption- GCPSC Conference, Sitges, Barcelona, 1–4 November 2015. [Google Scholar]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. J. Purch. Supply Manag. 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Fernández-Viñé, M.B.; Gómez-Navarro, T.; Capuz-Rizo, S.F. Assessment of the public administration tools for the improvement of the eco-efficiency of Small and Medium Sized Enterprises. J. Clean. Prod. 2013, 47, 265–273. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Spallina, G.; Marchesani, F. Drivers for energy efficiency and their effect on barriers: Empirical evidence from Italian manufacturing enterprises. Energy Effic. 2017, 10, 855–869. [Google Scholar] [CrossRef]

- Millar, H.H.; Russell, S.N. The adoption of sustainable manufacturing practices in the Caribbean. Bus. Strategy Environ. 2011, 20, 512–526. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Abeelen, C.; Worrell, E.; Miggiano, F. Barriers and drivers for energy efficiency: Different perspectives from an exploratory study in the Netherlands. Energy Convers. Manag. 2015, 102, 26–38. [Google Scholar] [CrossRef]

- Merriam-Webster. Barrier In Merriam-Webster.com. Available online: https://www.merriam-webster.com/dictionary/barrier (accessed on 15 August 2018).

- Merriam-Webster. Enabler In Merriam-Webster.com. Available online: https://www.merriam-webster.com/dictionary/enabler (accessed on 15 August 2018).

- Lee, S.Y.; Klassen, R.D. Drivers and Enablers That Foster Environmental Management Capabilities in Small-and Medium-Sized Suppliers in Supply Chains. Prod. Oper. Manag. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Marchesani, F.; Spallina, G. Classification of drivers for industrial energy efficiency and their effect on the barriers affecting the investment decision-making process. Energy Effic. 2017, 10, 199–215. [Google Scholar] [CrossRef]

- Govindan, K.; Bouzon, M. From a literature review to a multi-perspective framework for reverse logistics barriers and drivers. J. Clean. Prod. 2018, 187, 318–337. [Google Scholar] [CrossRef]

- Ardic, O.P.; Mylenko, N.; Saltane, V. Small and Medium Enterprises: A Cross-Country Analysis with a New Data Set; The World Bank: Washington, DC, USA, 2011. [Google Scholar]

- OECD. OECD SME and Entrepreneurship Outlook 2005; OECD Publishing: Paris, France, 2005. [Google Scholar]

- European Commission. Commission Recommendation of 6 May 2003 Concerning the Definition of Micro, Small and Medium Sized Enterprise; European Commission: Paris, France, 2003; pp. 0036–0041. [Google Scholar]

- Ates, A.; Garengo, P.; Cocca, P.; Bititci, U. The development of SME managerial practice for effective performance management. J. Small Bus. Enterp. Dev. 2013, 20, 28–54. [Google Scholar] [CrossRef]

- Assarlind, M.; Gremyr, I. Critical factors for quality management initiatives in small-and medium-sized enterprises. Total Qual. Manag. Bus. Excell. 2014, 25, 397–411. [Google Scholar] [CrossRef][Green Version]

- Wielgórka, D. Environmental management in the aspect of sustainable development in micro-, small-, and medium-sized enterprises. Desalination Water Treat. 2016, 57, 982–992. [Google Scholar] [CrossRef]

- Jennings, P.; Beaver, G. The performance and competitive advantage of small firms: A management perspective. Int. Small Bus. J. 1997, 15, 63–75. [Google Scholar] [CrossRef]

- Cagliano, R.; Spina, G. A comparison of practice-performance models between small manufacturers and subconstractors. Int. J. Oprations Prod. Manag. 2002, 22, 1367–1388. [Google Scholar] [CrossRef]

- Jorgensen, A.L.; Knudsen, J.S. Sustainable competitiveness in global value chains: How do small Danish firms behave? Corp. Gov. Int. J. Bus. Soc. 2006, 6, 449–462. [Google Scholar] [CrossRef]

- Lozano, R. A Holistic Perspective on Corporate Sustainability Drivers. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 32–44. [Google Scholar] [CrossRef]

- Agwa-Ejon, J.; Fore, S. Challenges faced by SMEs in developing countries in implementing cleaner production (CP). Adv. Mater. Res. 2012, 367, 257–263. [Google Scholar] [CrossRef]

- Fresner, J.; Morea, F.; Krenn, C.; Aranda Uson, J.; Tomasi, F. Energy efficiency in small and medium enterprises: Lessons learned from 280 energy audits across Europe. J. Clean. Prod. 2017, 142, 1650–1660. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Chapter 39: Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D., Bryman, A.E., Eds.; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. [Google Scholar]

- Jesson, J.K.; Matheson, L.; Lacey, F.M. Doing Your Literature Review. Traditional and Systematic Techniques; Sage: London, UK, 2011. [Google Scholar]

- Thomé, A.M.T.; Scavarda, L.F.; Scavarda, A.J. Conducting systematic literature review in operations management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Hsieh, H.F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef] [PubMed]

- Miles, M.B.; Huberman, A.M.; Saldaña, J. Qualitative Data Analysis: An Expanded Sourcebook; SAGE Publications: Thousand Oaks, CA, SUA, 2019. [Google Scholar]

- Seuring, S.; Gold, S. Conducting content—Analysis based literature reviews in supply chain management. Supply Chain Manag. Int. J. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Coppa, M.; Sriramesh, K. Corporate social responsibility among SMEs in Italy. Public Relat. Rev. 2013, 39, 30–39. [Google Scholar] [CrossRef]

- Thomas, A.; Francis, M.; John, E.; Davies, A. Identifying the characteristics for achieving sustainable manufacturing companies. J. Manuf. Technol. Manag. 2012, 23, 426–440. [Google Scholar] [CrossRef]

- Agan, Y.; Acar, M.F.; Borodin, A. Drivers of environmental processes and their impact on performance: A study of Turkish SMEs. J. Clean. Prod. 2013, 51, 23–33. [Google Scholar] [CrossRef]

- Ashton, W.S.; Panero, M.A.; Izquierdo Cruz, C.; Hurtado Martin, M. Financing resource efficiency and cleaner production in Central America. Clean. Technol. Env. Policy 2018, 20, 53–63. [Google Scholar] [CrossRef]

- Tomšič, N.; Bojnec, Š.; Simčič, B. Corporate sustainability and economic performance in small and medium sized enterprises. J. Clean. Prod. 2015, 108, 603–612. [Google Scholar] [CrossRef]

- Williamson, D.; Lynch-Wood, G.; Ramsay, J. Drivers of Environmental Behaviour in Manufacturing SMEs and the Implications for CSR. J. Bus. Ethics 2006, 67, 317–330. [Google Scholar] [CrossRef]

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. The influence of energy prices on adoption of clean technologies and recycling: Evidence from European SMEs. Energy Econ. 2014, 46, 246–257. [Google Scholar] [CrossRef]

- De Barros, R.L.P.; De Paiva, M.D.F.F.; Sisinno, C.L.S. Cleaner production challenges in Brazilian SMEs. Ind. Environ. 2003, 26, 26–28. [Google Scholar]

- Jabbour, C.J.C.; Puppim-De-Oliveira, J.A. Barriers to environmental management in clusters of small businesses in Brazil and Japan: From a lack of knowledge to a decline in traditional knowledge. Int. J. Sustain. Dev. World Ecol. 2012, 19, 247–257. [Google Scholar] [CrossRef]

- Aloulou, W.; Fayolle, A. A Conceptual Approach of the Entrepreneurial Orientation Within the Small Business Context. J. Enterprising Cult. 2005, 13, 21–45. [Google Scholar] [CrossRef]

- Cagliano, R.; Blackmon, K.; Voss, C. Small firms under microscope: International differences in production/operations management practices and performance. Integr. Manuf. Syst. 2001, 12, 469–482. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Sustainable Manufacturing Performance Evaluation: Integrating Product and Process Metrics for Systems Level Assessment. Procedia Manuf. 2017, 8, 563–570. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Prioritizing Barriers to Green Manufacturing: Environmental, Social and Economic Perspectives. Procedia CIRP 2014, 47, 559–564. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S.; Herrmann, C. Comparison of Drivers and Barriers to Green Manufacturing: A Case of India and Germany. In 20th CIRP International Conference on Life Cycle Engineering; Springer: Sinagpore, 2013; pp. 723–728. [Google Scholar] [CrossRef]

- Ramjeawon, T. A case study of cleaner production opportunities in small and medium enterprises on the island of Mauritius. Electron. Green J. 2004, 1, 20. [Google Scholar] [CrossRef]

- Spence, L.J.; Schmidpeter, R. SMEs, Social Capital and the Common Good. J. Bus. Ethics 2003, 45, 93–108. [Google Scholar] [CrossRef]

- Shah, S.F.H.; Nazir, T.; Zaman, K.; Shabir, M. Factors affecting the growth of enterprises: A survey of the literature from the perspective of small- and medium-sized enterprises. J. Enterp. Transform. 2013, 3, 53–75. [Google Scholar] [CrossRef]

- Murillo-Luna, J.L.; Garcés-Ayerbe, C.; Rivera-Torres, P. Barriers to the adoption of proactive environmental strategies. J. Clean. Prod. 2011, 19, 1417–1425. [Google Scholar] [CrossRef]

- Balzarova, M.A.; Castka, P. Underlying mechanisms in the maintenance of ISO 14001 environmental management system. J. Clean. Prod. 2008, 16, 1949–1957. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Worrell, E.; Pugliese, G. Empirical investigation of energy efficiency barriers in Italian manufacturing SMEs. Energy 2013, 49, 444–458. [Google Scholar] [CrossRef]

- Seidel, M.; Seidel, R.; Tedford, D.; Cross, R.; Wait, L.; Hämmerle, E. Overcoming barriers to implementing environmentally benign manufacturing practices: Strategic tools for SMEs. Environ. Qual. Manag. 2009, 18, 37–55. [Google Scholar] [CrossRef]

- Hasan, M.N. Measuring and understanding the engagement of Bangladeshi SMEs with sustainable and socially responsible business practices: An ISO 26000 perspective. Soc. Responsib. J. 2016, 12, 584–610. [Google Scholar] [CrossRef]

- Seidel-Sterzik, H.; McLaren, S.; Garnevska, E. Effective life cycle management in SMEs: Use of a sector-based approach to overcome barriers. Sustainability 2018, 10, 359. [Google Scholar] [CrossRef]

- Gombault, M.; Versteege, S. Cleaner production in SMEs through a partnership with (local) authorities: Successes from the Netherlands. J. Clean. Prod. 1999, 7, 249–261. [Google Scholar] [CrossRef]

- Hitchens, D.; Clausen, J.; Trainor, M.; Keil, M.; Thankappan, S. Competitiveness, environmental performance and management of SMEs. Greener Manag. Int. 2003, 44, 45–57. [Google Scholar] [CrossRef]

- Hsu, J.L.; Cheng, M.C. What Prompts Small and Medium Enterprises to Engage in Corporate Social Responsibility? A Study from Taiwan. Corp. Soc. Responsib. Environ. Manag. 2012, 19, 288–305. [Google Scholar] [CrossRef]

- Frijns, J.; Van Vliet, B. Small-scale industry and cleaner production strategies. World Dev. 1999, 27, 967–983. [Google Scholar] [CrossRef]

- Aboelmaged, M. The drivers of sustainable manufacturing practices in Egyptian SMEs and their impact on competitive capabilities: A PLS-SEM model. J. Clean. Prod. 2018, 175, 207–221. [Google Scholar] [CrossRef]

- Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of drivers for integrated lean-green manufacturing for Indian manufacturing SMEs. J. Clean. Prod. 2018, 171, 675–689. [Google Scholar] [CrossRef]

| Search Terms | Where | Number of Hits |

|---|---|---|

| (SME* OR "small and medium sized enterprise*" OR "small compan*" OR "small enterprise*") AND (Sustainab* OR respons* OR environmental* OR social* OR economic* OR green* OR clean* OR benign) AND (enabl* OR barrier* OR challeng* OR "critical factor*" OR facilitator* OR driver* OR hinder* OR obstacle*) AND (manufactur* OR product* OR assemb* OR operation*) | Scopus (Title, abstract, keywords) | 2545 |

| Barriers | Enablers | |

|---|---|---|

| Most frequently mentioned | Lack of access to external technical knowledge to adopt sustainable manufacturing practices (B23); low skilled labor (B59); lack of awareness of the benefits derived from sustainable manufacturing practices (B16); lack of financial resources (B43); manager´s misunderstandings and pessimistic preconceptions (B2); lack of time for planning, execution and review of sustainable manufacturing practices (B9); little knowledge on sustainability in SMEs (B24); difficulties accessing financial capital (B44); resistance to change (B18), lack of effective legislation and/or weak regulatory environment (B37); high investment costs and low returns of environmentally technologies (B45). | Knowledge networks and social networks (E6); provision of financial incentives to foster sustainable manufacturing (E17); pressure from market and clients (E24); government regulations fostering sustainability adoption (E20). |

| Least frequently mentioned | Concerns that environmental investments undermine competitiveness (B11); certain subsidies impeding sustainable manufacturing (B35); low political participation of SMEs (B42); difficulty quantifying the financial performance of environmental investments (B48); lack of awareness on international trends related to environmental sustainability (B50); lack of awareness of SMEs role on social capital (B53). | Managerial support toward collaborative environment for innovation (E2); develop continuously and quick adaptation (E5); adoption of lean manufacturing (E8); more efficient routines and practices (E10), use of business analysis tools (E12); availability of flexible and innovative human resources (E13); flat management structure and empowerment of workforce (E14); institutionalize rewards recognizing adoption of sustainable manufacturing in SMEs (E23). |

| Cat. | Barriers | Enablers Mitigating Specific Barriers |

|---|---|---|

| Organizational, managerial and attitudinal (OMA) | B1. Manager´s lack of awareness about the company’s environmental sustainability impact (I) | ◊E12. Use of business analysis tools (I/OMA) |

| ◊E16. Government provided information on sustainable manufacturing (E/Gov) | ||

| ◊E11. Environmental management systems (I/OMA) | ||

| E15. Provide government sponsored platforms supporting SMEs (E/Gov) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| E26. External cooperation (E/M) | ||

| B2. Manager´s misunderstandings and pessimistic preconceptions (I) | ◊E4. Realistic expectations about benefits emerged from sustainable manufacturing (I/OMA) | |

| E30. Clarity of information (E/Inf) | ||

| E15. Provide government sponsored platforms supporting SMEs (E/Gov) | ||

| E28. Pressure from supply chains to adopt sustainable manufacturing Practices (E/M) | ||

| B3. Lack of trust of SME owners (I) | E6. Knowledge networks and social networks (E/OMA) | |

| B4. Expectations of excessively high profitability from energy efficiency practices (I) | ◊E4. Realistic expectations about benefits emerged from sustainable manufacturing (I/OMA) | |

| E30. Clarity of information (E/Inf) | ||

| B5. Incompatibility of owner’s ethics and personal values with sustainability (I) | ◊E1. Managerial support and effective leadership toward sustainability (I/OMA) | |

| B6. Organizational culture not aligned with sustainability values (I) | E1. Managerial support and effective leadership toward sustainability (I/OMA) | |

| E14. Flat management structure and empowerment of workforce (I/OMA) | ||

| E11. Environmental management systems (I/OMA) | ||

| B7. Low managerial priority toward sustainable manufacturing practices (I) | ◊E1. Managerial support and effective leadership toward sustainability (I/OMA) | |

| ◊E12. Use of business analysis tools (I/OMA) | ||

| E15. Provide government sponsored platforms supporting SMEs (E/Gov) | ||

| E28. Pressure from supply chains to adopt sustainable manufacturing practices(E/M) | ||

| E24. Pressure from market and clients (E/M) | ||

| E23. Institutionalize rewards recognizing the adoption of sustainable manufacturing in SMEs (E/Gov) | ||

| B8. Lack of managerial competence in owners/managers of SMEs (I) | E15. Provide government sponsored platforms supporting SMEs (E/Gov) | |

| E16. Government provided information on sustainable manufacturing (E/Gov) | ||

| E35. Education and training systems to improve operations (I/TSD) | ||

| E11. Environmental management systems (I/OMA) | ||

| E26. External cooperation (E/M) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| B9. Lack of time for planning, execution and review of sustainable practices (I) | E13. Availability of flexible and innovative human resources (I/OMA) | |

| B10. Perceived conflicts between environmental practices and other business objectives (I) | ◊E12. Use of business analysis tools (I/OMA) | |

| E1. Managerial support and effective leadership toward sustainability (I/OMA) | ||

| B11. Concerns that environmental investments undermine competitiveness (I) | ◊E4. Realistic expectations about benefits emerged from sustainable manufacturing (I/OMA) | |

| ◊E12. Use of business analysis tools (I/OMA) | ||

| E8. Adoption of lean manufacturing and product innovation strategies (I/OMA) | ||

| E26. External cooperation (E/M) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| B12. Lack of human resources (I) | ◊E13. Availability of flexible and innovative human resources (I/OMA) | |

| E6. Knowledge networks and social networks (E/OMA) | ||

| B13. Multifunctional staff (I) | ◊E13. Availability of flexible and innovative human resources (I/OMA) | |

| B14. Low involvement of workers (I) | E9. Inclusiveness of workers toward a more participatory culture (I/OMA) | |

| B15. Difficulties attracting and retaining workers (I) | E9. Inclusiveness of workers toward a more participatory culture (I/OMA) | |

| E14. Flat management structure and empowerment of workforce (I/OMA) | ||

| E35. Education and training systems to improve operations (I/TSD) | ||

| E7. Interpersonal attitudes and communications (I/OMA) | ||

| E11. Environmental management systems (I/OMA) | ||

| B16. Lack of awareness of the benefits derived from sustainable manufacturing practices (I) | ◊E35. Education and training systems to improve operations (I/TSD) | |

| ◊E11. Environmental management systems (I/OMA) | ||

| ◊E6. Knowledge networks and social networks (E/OMA) | ||

| E15. Provide government sponsored platforms supporting SMEs (E/Gov) | ||

| E16. Government provided information on sustainable manufacturing (E/Gov) | ||

| E28. Pressure from supply chains to adopt sustainable manufacturing Practices (E/M) | ||

| B17. Risk perception (I) | E30. Clarity of information (E/Inf) | |

| E15. Provide government sponsored platforms supporting SMEs (E/Gov) | ||

| E16. Government provided information on sustainable manufacturing (E/Gov) | ||

| E25. Increased support from large customers (E/M) | ||

| B18. Resistance to change (I) | ◊E2. Managerial support for collaborative environment for innovation (I/OMA) | |

| ◊E5. Develop continuously/adapt to the environment (I/OMA) | ||

| E11. Environmental management systems (I/OMA) | ||

| E8. Adoption of lean manufacturing and product innovation strategies (I/OMA) | ||

| E28. Pressure from supply chains to adopt sustainable manufacturing practices (E/M) | ||

| E25. Increased support from large customers (E/M) | ||

| B19. Lack of internal marketing of practices and systems (I) | E35. Education and training systems to improve operations (I/TSD) | |

| E11. Environmental management systems (I/OMA) | ||

| B20. Lack or poor communication (I) | ◊E7. Interpersonal attitudes and communications (I/OMA) | |

| E11. Environmental management systems (I/OMA) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| B21. Lack of continuity in the adoption of sustainable manufacturing practices (I) | ◊E11. Environmental management systems (I/OMA) | |

| ◊E3. Long-term strategy (I/OMA) | ||

| ◊E25. Increased support from large customers (E/M) | ||

| ◊E1. Managerial support and effective leadership toward sustainability (I/OMA) | ||

| E28. Pressure from supply chains to adopt sustainable manufacturing (E/M) | ||

| E5. Develop continuously/adapt to the environment(I/OMA) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| B22. Lack of enough environmental progress (I) | ◊E4. Realistic expectations about benefits emerged from sustainable manufacturing (I/OMA) | |

| E6. Knowledge networks and social networks (E/OMA) | ||

| E25. Increased support from large customers (E/M) | ||

| Informational (Inf) | B23. Lack of access to external technical knowledge to adopt sustainable manufacturing practices (E) | ◊E16. Government provided information on sustainable manufacturing (E/Gov) |

| ◊E15. Provide government sponsored platforms supporting SMEs (E/Gov) | ||

| ◊E31. Technical support from technology suppliers (E/Inf) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| E26. External cooperation (E/M) | ||

| E25. Increased support from large customers (E/M) | ||

| B24. Little knowledge on sustainability in SMEs (I) | ◊E15. Provide government sponsored platforms supporting SMEs (E/Gov) | |

| ◊E16. Government provided information on sustainable manufacturing (E/Gov) | ||

| E6. Knowledge networks and social networks (E/OMA) | ||

| E25. Increased support from large customers (E/M) | ||

| E26. External cooperation (E/M) | ||

| B25. Lack of knowledge on environmental systems and difficulty for certification (I) | E15. Provide government sponsored platforms supporting SMEs (E/Gov) | |

| E6. Knowledge networks and social networks (E/OMA) | ||

| E25. Increased support from large customers (E/M) | ||

| E26. External cooperation (E/M) | ||

| B26. Lack of awareness programs conducted locally (E) | ◊E6. Knowledge networks and social networks (E/OMA) | |

| ◊E26. External cooperation (E/M) | ||

| E15. Provide government sponsored platforms supporting SMEs (E Gov) | ||

| B27. Lack of access to information specific technologies (E) | E6. Knowledge networks and social networks (E/OMA) | |

| E26. External cooperation (E/M) | ||

| B28. Information from technology suppliers is not clear for SMEs (E) | ◊E30. Clarity of information (E/Inf) | |

| E6. Knowledge networks and social networks (E/OMA) | ||

| E26. External cooperation (E/M) | ||

| B29. Lack of information on real costs and benefits of energy efficient technologies (E) | E32. Increase trustworthiness information(E/Inf) | |

| E6. Knowledge networks and social networks (E/OMA) | ||

| B30. Lack of data on energy consumption | ◊E29. Use indicators, monitoring and controls on energy efficiency | |

| B31. Low trustworthiness of the information source (E) | ◊E32. Increase trustworthiness information (E/Inf) | |

| B32. Lack of information on economic incentives (E) | ◊E17. Provide financial incentives to foster sustainable manufacturing practices and company´s growth (E Gov) | |

| E26. External cooperation (E/M) | ||

| Governmental (G) | B33. Lack of governmental incentive policies, subsidies (E) | ◊E18. Provide technical incentives (E/Gov) |

| ◊E17. Provide financial incentives to foster sustainable manufacturing practices and company´s growth (E/Gov) | ||

| B34. Lack of incentives for local collaborative networks/associations (E) | ◊E6. Knowledge networks and social networks (E/OMA) | |

| ◊E26. External cooperation (E/M) | ||

| B35. Certain subsidies that impede sustainable manufacturing (E) | ◊E17. Provide financial incentives to foster sustainable manufacturing practices and company´s growth (E/Gov) | |

| B36. Lack of local guidance for adopting sustainable manufacturing (E) | ◊E15. Provide government sponsored platforms supporting SMEs (E/Gov) | |

| ◊E16. Government provided information on sustainable manufacturing (E/Gov) | ||

| E25. Increased support from large customers (E/M) | ||

| B37. Lack of effective legislation, weak regulatory environment (E) | ◊E20. Government regulations fostering sustainability adoption (E/Gov) | |

| B38. Difficulty complying with regulations (E) | ◊E21. Legislation appropriately written toward SMEs (E/Gov) | |

| B39. Frequent changes in environmental regulations (E) | - | |

| B40. Absence of single authoritative body interpreting EMSs (E) | - | |

| B41. Corruption (E) | - | |

| B42. Low political participation of SMEs (E) | E22. EU policy supporting corporate sustainability in SMEs (E/Gov) | |

| Financial (F) | B43. Lack of financial resources (I) | ◊E33. Reducing manufacturing costs (I/F) |

| E19. Provide financial accesses to SMEs (E/Gov) | ||

| B44. Difficulty accessing financial capital (E) | ◊E19. Provide financial accesses to SMEs (E/Gov) | |

| B45. High investment costs and low returns of environmentally-sustainable technologies (E) | E6. Knowledge networks and social networks (E/OMA) | |

| E25. Increased support from large customers (E/M) | ||

| B46. Hidden costs of adopting certain sustainable manufacturing practices and compliance costs (I/E) | ◊E34. Increased awareness of the economic benefits of sustainable manufacturing practices (I/F) | |

| ◊E33. Reducing manufacturing costs (I/F) | ||

| E25. Increased support from large customers (E/M) | ||

| B47. Cost of implementing CSR (E) | ◊E34. Increased awareness of the economic benefits of sustainable manufacturing practices (I/F) | |

| ◊E33. Reducing manufacturing costs (I/F) | ||

| B48. Difficulty quantifying the financial performance of environmental investments (E) | - | |

| B49. Traditional financial accountings systems exclude environmental costs (E) | - | |

| Market and business context (M) | B50. Lack of awareness of international trends related to environmental sustainability (E) | E6. Knowledge networks and social networks (E/OMA) |

| E24. Pressure from market and clients (E/M) | ||

| E25. Increased support from large customers (E/M) | ||

| E26. External cooperation (E/M) | ||

| B51. Competition with less-expensive products (E) | E8. Adoption of lean manufacturing and product innovation strategies (I/OMA) | |

| E25. Increased support from large customers (E/M) | ||

| B52. Weak public awareness and pressure on SMEs (E) | ◊E24. Pressure from market and clients (E/M) | |

| B53. Lack of awareness of SMEs role on social capital (E) | ◊E6. Knowledge networks and social networks (E/OMA) | |

| B54. Low energy prices (E) | ◊E27. High energy prices (E/M) | |

| Technological (T) | B55. Need for additional infrastructural modifications (I) | ◊E10. More efficient routines and practices (I/OMA) |

| B56. Use of outdated technology (I) | ◊E18. Provide technical incentives (E/Gov) | |

| B57. Unavailable technology (E) | ◊E18. Provide technical incentives (E/Gov) | |

| B58. Emphasis on end-of-pipe process (I) | E20. Government regulations fostering sustainability adoption (E/Gov) | |

| E17. Provide financial incentives to foster sustainable manufacturing practices and company´s growth (E Gov) | ||

| E24. Pressure from market and clients (E/M) | ||

| E28. Pressure from supply chains to adopt sustainable manufacturing practices (E/M) | ||

| Training and skill development (TSD) | B59. Low skilled labor (I) | ◊E35. Education and training systems to improve operations (I/TSD) |

| E6. Knowledge networks and social networks (E/OMA) | ||

| B60. Inadequate development of worker’s new skills/lack of tech training (I) | ◊E35. Education and training systems to improve operations (I/TSD) | |

| E6. Knowledge networks and social networks (E/OMA) | ||

| B61. Lack of investment in environmentally sustainable education and training (I) | E1. Managerial support and effective leadership toward sustainability (I/OMA) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alayón, C.L.; Säfsten, K.; Johansson, G. Barriers and Enablers for the Adoption of Sustainable Manufacturing by Manufacturing SMEs. Sustainability 2022, 14, 2364. https://doi.org/10.3390/su14042364

Alayón CL, Säfsten K, Johansson G. Barriers and Enablers for the Adoption of Sustainable Manufacturing by Manufacturing SMEs. Sustainability. 2022; 14(4):2364. https://doi.org/10.3390/su14042364

Chicago/Turabian StyleAlayón, Claudia Lood, Kristina Säfsten, and Glenn Johansson. 2022. "Barriers and Enablers for the Adoption of Sustainable Manufacturing by Manufacturing SMEs" Sustainability 14, no. 4: 2364. https://doi.org/10.3390/su14042364

APA StyleAlayón, C. L., Säfsten, K., & Johansson, G. (2022). Barriers and Enablers for the Adoption of Sustainable Manufacturing by Manufacturing SMEs. Sustainability, 14(4), 2364. https://doi.org/10.3390/su14042364