A Comprehensive Risk-Assessment Method for Prefabricated Buildings Using EPC: A Case Study from China

Abstract

:1. Introduction

2. Literature Review

2.1. Implementation of Prefabricated Buildings in China

2.2. Implementation of EPC in Prefabricated Buildings

2.3. Risks Involved in Prefabricated Buildings

2.4. Risks Encountered in EPC

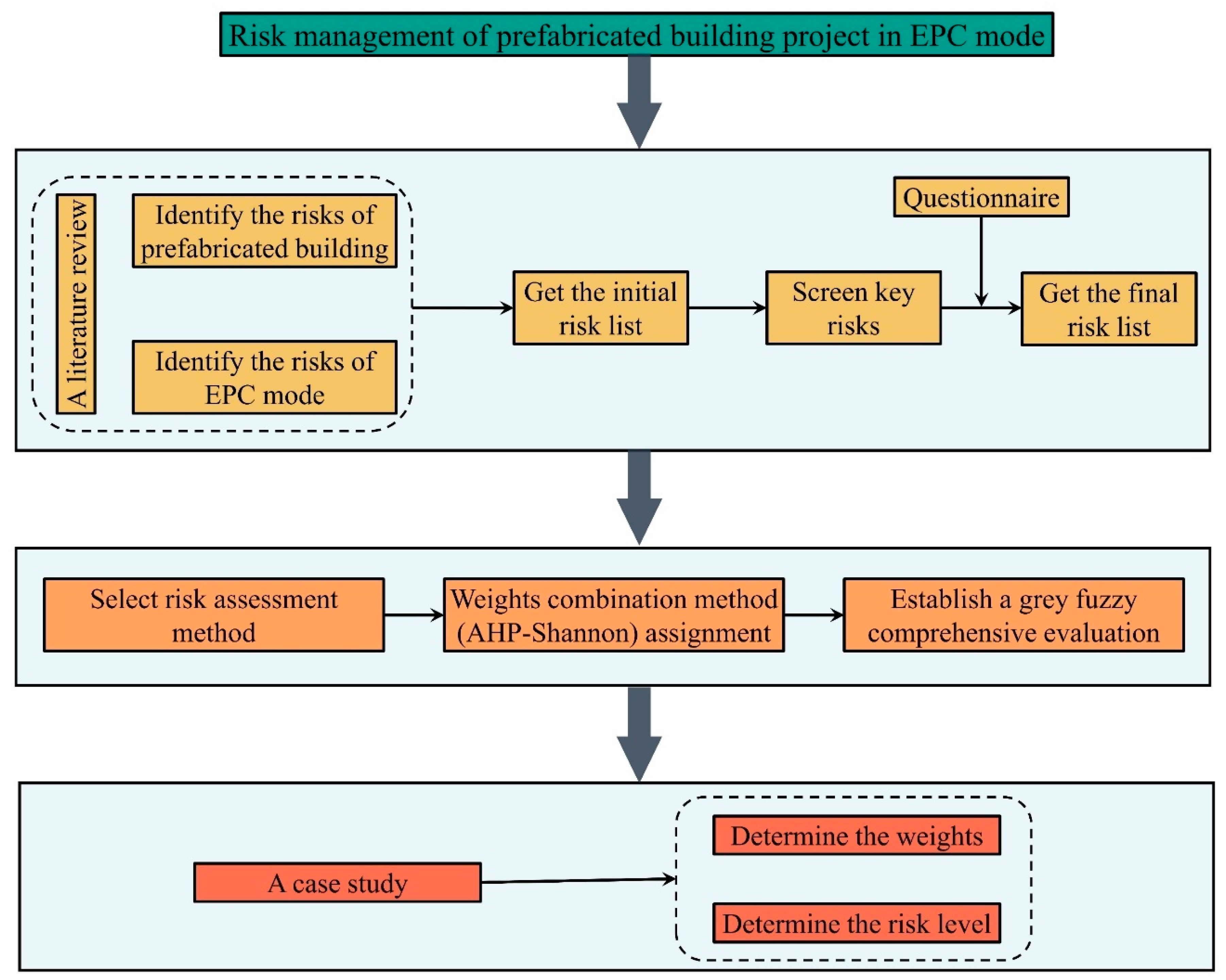

3. Methodology

- Task 1: Ascertain the risks of prefabricated building with EPC. Firstly, risk indicators were identified based on relevant literature. Secondly, questionnaires were sent to personnel with engineering-related experience to optimize these indicators. The details of Task 1 are presented in Section 4.1.

- Task 2: Establish a comprehensive risk-assessment method (AHP–EWM). Firstly, this study illustrated a method for determining weights, which considered both subjective (AHP) and objective (entropy) weight information. Secondly, a risk-assessment method was constructed based on the principles of grey–fuzzy comprehensive evaluation. Section 4.2 demonstrates the details of Task 2.

- Task 3: Based on the risk-assessment method obtained in Task 2, this study determined the combined weight of the indicator in Task 1 in a real project and used grey–fuzzy theory to assess its risk level. The details of Task 3 are presented in Section 5.

4. Implementation Risk Assessment

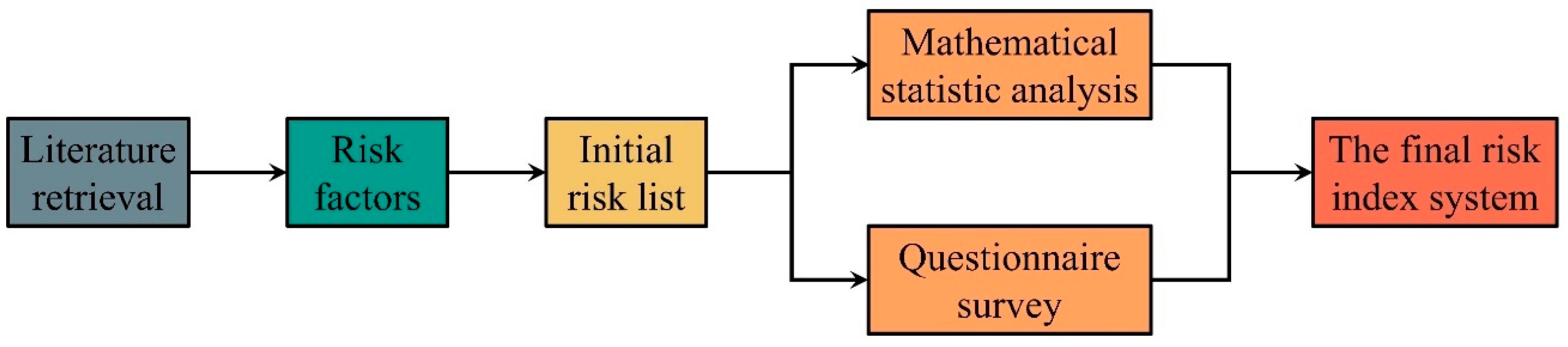

4.1. Risk-Assessment System

4.1.1. Risk Identification for Prefabricated Buildings with EPC

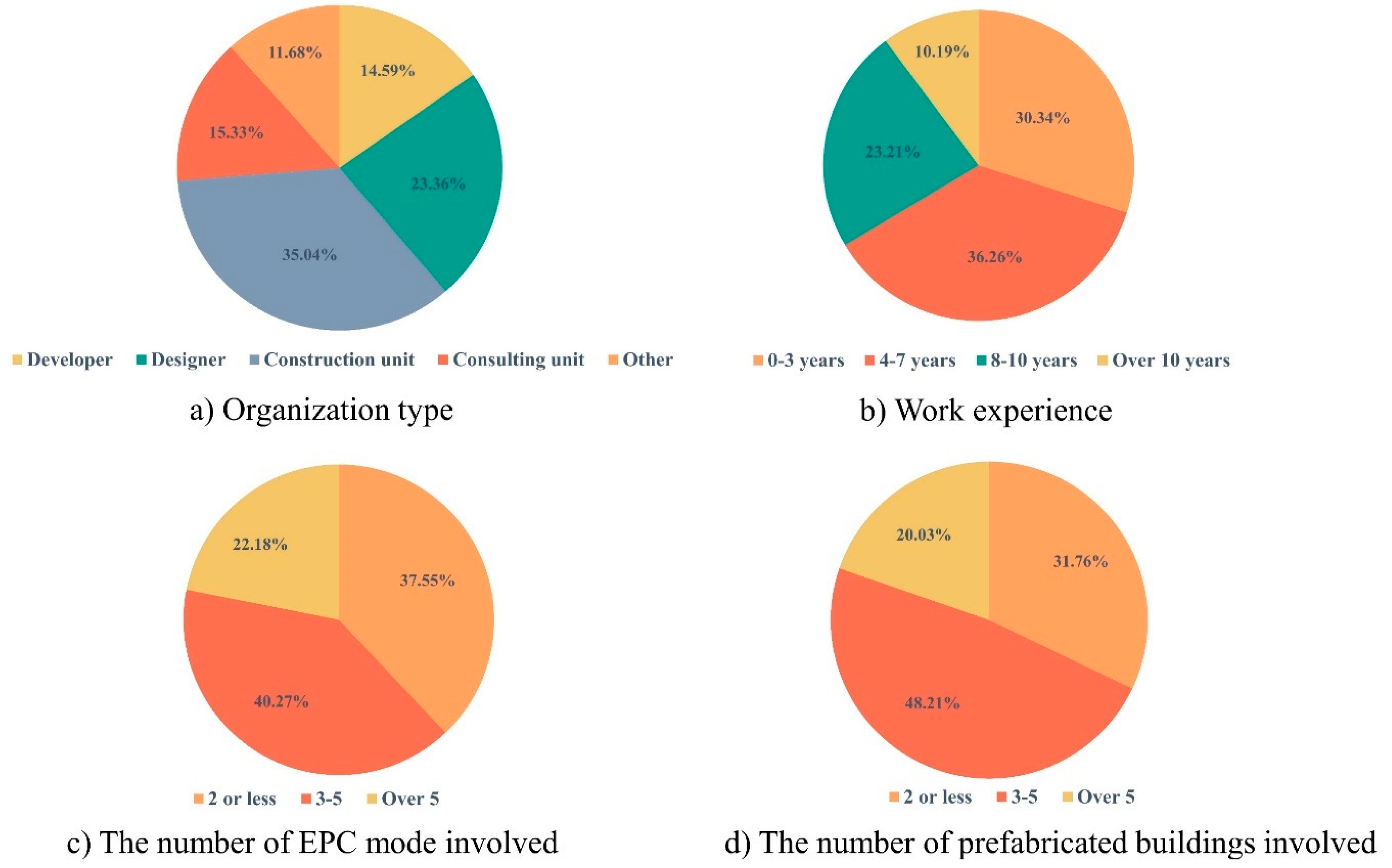

4.1.2. Finalization of Risks for Prefabricated Buildings with EPC

4.2. Risk-Assessment Method

4.2.1. AHP–Entropy Optimized Combination Weight

- Step 1: Build a hierarchical model.

- Step 2: Construct a judgment matrix.

- Step 3: Calculate the relative importance.

- Step 4: Perform a consistency check.

- Step 1: Normalize the judgment matrix and obtain the standard matrix P.

- Step 2: Calculate information entropy.

- Step 3: Calculate the indicator information entropy weight .

4.2.2. Multilevel Grey Evaluation Method

5. Case Study

5.1. Background Information

5.2. Project Implementation Risk Assessment

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| First-Level | Second-Level | Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Expert 6 |

|---|---|---|---|---|---|---|---|

| Management risk U1 | Insufficient project management experience and ability U11 | 82 | 85 | 79 | 86 | 83 | 85 |

| Insufficient communication and coordination between various units U12 | 87 | 84 | 83 | 85 | 81 | 82 | |

| Unreasonable organization U13 | 84 | 81 | 87 | 84 | 84 | 82 | |

| Design risk U2 | Design changes U21 | 81 | 76 | 79 | 83 | 80 | 81 |

| Unreasonable component split U22 | 89 | 89 | 84 | 87 | 91 | 94 | |

| Insufficiently in-depth design U23 | 76 | 69 | 71 | 78 | 76 | 75 | |

| Immature standardized design techniques U24 | 84 | 83 | 80 | 88 | 79 | 82 | |

| Poor design coordination U25 | 84 | 83 | 90 | 85 | 83 | 87 | |

| Procurement risk U3 | Poor supplier credit and contract performance U31 | 81 | 83 | 84 | 81 | 86 | 85 |

| Quality defects of precast components U32 | 72 | 78 | 70 | 76 | 69 | 73 | |

| Incorrect transportation plan U33 | 78 | 79 | 81 | 81 | 83 | 85 | |

| Untimely delivery U34 | 80 | 85 | 82 | 81 | 81 | 78 | |

| Transport damage of precast components U35 | 90 | 85 | 93 | 89 | 92 | 91 | |

| Construction risk U4 | Unreasonable specialized construction plan U41 | 85 | 79 | 81 | 84 | 86 | 85 |

| Inadequate disclosure of technical quality and safety information U42 | 73 | 75 | 68 | 69 | 74 | 75 | |

| Immature hoisting technology U43 | 84 | 79 | 80 | 81 | 79 | 74 | |

| Inappropriate mechanical equipment selection U44 | 85 | 86 | 89 | 83 | 81 | 84 | |

| Improper site stacking and protection of components U45 | 78 | 81 | 73 | 75 | 82 | 79 | |

| Temporary support system with poor stability U46 | 81 | 72 | 70 | 79 | 75 | 72 | |

| Economic risk U5 | Inflation U51 | 87 | 85 | 83 | 81 | 84 | 83 |

| Rising prices U52 | 83 | 84 | 86 | 86 | 85 | 81 | |

| Insufficient developer credibility and payment ability U53 | 77 | 80 | 75 | 79 | 76 | 81 | |

| Interest rate fluctuations U54 | 87 | 85 | 86 | 90 | 87 | 89 | |

| Policy risk U6 | Unsound specifications U61 | 74 | 73 | 75 | 78 | 76 | 72 |

| Changes in industry-related laws and policies U62 | 80 | 79 | 78 | 79 | 76 | 81 | |

| Natural risk U7 | Adverse geological conditions U71 | 82 | 82 | 85 | 86 | 82 | 82 |

| Adverse weather conditions U72 | 83 | 78 | 80 | 83 | 83 | 85 |

| First-Level | Second-Level | Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Expert 6 |

|---|---|---|---|---|---|---|---|

| Management risk U1 | Insufficient project management experience and ability U11 | 2 | 2.5 | 2 | 1.5 | 2.5 | 1.5 |

| Insufficient communication and coordination between various units U12 | 1.5 | 1 | 1.5 | 2 | 1 | 1.5 | |

| Unreasonable organization U13 | 1 | 1.5 | 1 | 1.5 | 1.5 | 1 | |

| Design risk U2 | Design changes U21 | 1 | 1.5 | 1.5 | 2 | 1.5 | 2 |

| Unreasonable component split U22 | 2 | 2 | 2.5 | 2 | 2.5 | 2 | |

| Insufficiently in-depth design U23 | 3 | 3.5 | 3 | 3 | 3.5 | 3 | |

| Immature standardized design techniques U24 | 2.5 | 2 | 2.5 | 2 | 3 | 2.5 | |

| Poor design coordination U25 | 2 | 1.5 | 2 | 2 | 1.5 | 2 | |

| Procurement risk U3 | Poor supplier credit and contract performance U31 | 1.5 | 2 | 1.5 | 2 | 2 | 1.5 |

| Quality defects of precast components U32 | 3.5 | 3 | 4 | 3.5 | 3 | 3 | |

| Incorrect transportation plan U33 | 2 | 2.5 | 2 | 2 | 1.5 | 2 | |

| Untimely delivery U34 | 2 | 1.5 | 2 | 2 | 1.5 | 2 | |

| Transport damage of precast components U35 | 3 | 3.5 | 3 | 2.5 | 3 | 3 | |

| Construction risk U4 | Unreasonable specialized construction plan U41 | 2 | 2 | 2 | 2.5 | 2 | 2.5 |

| Inadequate disclosure of technical quality and safety information U42 | 2 | 3 | 2.5 | 2 | 2.5 | 3 | |

| Immature hoisting technology U43 | 2.5 | 2 | 2.5 | 3 | 3 | 2 | |

| Inappropriate mechanical equipment selection U44 | 3 | 2 | 2 | 1.5 | 2 | 2.5 | |

| Improper site stacking and protection of components U45 | 2.5 | 3 | 2.5 | 2 | 2.5 | 2 | |

| Temporary support system with poor stability U46 | 3.5 | 4 | 3.5 | 3.5 | 3 | 3.5 | |

| Economic risk U5 | Inflation U51 | 2 | 1.5 | 2 | 2 | 1.5 | 1.5 |

| Rising prices U52 | 2 | 2 | 1.5 | 1.5 | 1 | 1.5 | |

| Insufficient developer credibility and payment ability U53 | 2 | 1.5 | 1.5 | 1.5 | 2 | 1.5 | |

| Interest rate fluctuations U54 | 2 | 1 | 1.5 | 1 | 1 | 1 | |

| Policy risk U6 | Unsound specifications U61 | 2 | 1.5 | 1.5 | 2 | 1.5 | 1.5 |

| Changes in industry-related laws and policies U62 | 1 | 1 | 1.5 | 1 | 1.5 | 1 | |

| Natural risk U7 | Adverse geological conditions U71 | 1.5 | 2 | 1.5 | 1.5 | 2 | 2 |

| Adverse weather conditions U72 | 2 | 2 | 1.5 | 2 | 2 | 2 |

Appendix B

- 1.

- The subjective weights of first-level and second-level indicators determined by AHP were as follows:

- First-level indicators:

- Second-level indicators:

- 2.

- The objective weights of first-level and second-level indicators determined by EWM were as follows:

- First-level indicators:

- Second-level indicators:

Next, the combined weights of the first-level and second-level indicators in the evaluation system could be obtained by Equation (11).- First-level indicators:

- Second-level indicators:

| Grey Number | Whitening Weight Function | |

|---|---|---|

| 1 | ||

| 2 | ||

| 3 | ||

| 4 | ||

| 5 |

References

- Jiang, L.; Li, Z.F.; Li, L.; Gao, Y.L. Constraints on the Promotion of Prefabricated Construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef] [Green Version]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.K.; Tan, J.J. A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Gan, X.L.; Chang, R.D.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Gan, X.L.; Chang, R.D.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134 Pt B, 482–494. [Google Scholar] [CrossRef] [Green Version]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Effect of stakeholder collaborative management on off-site construction cost performance. J. Clean. Prod. 2018, 184, 490–502. [Google Scholar] [CrossRef]

- Ji, Y.B.; Zhu, F.D.; Li, H.X.; Al-Hussein, M. Construction Industrialization in China: Current Profile and the Prediction. Appl. Sci. 2017, 7, 180. [Google Scholar] [CrossRef]

- Wang, Q.; Zeng, Y.E.; Wu, B.W. Exploring the relationship between urbanization, energy consumption, and CO2 emissions in different provinces of China. Renew. Sustain. Energy Rev. 2016, 54, 1563–1579. [Google Scholar] [CrossRef]

- Yuan, H. A SWOT analysis of successful construction waste management. J. Clean. Prod. 2013, 39, 1–8. [Google Scholar] [CrossRef]

- Ma, L.; Le, Y.; Li, H.; Jin, R.; Piroozfar, P.; Liu, M. Regional comparisons of contemporary construction industry concepts in the Chinese Context. Sustainability 2018, 10, 3831. [Google Scholar] [CrossRef] [Green Version]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Meng, Q.; Hu, X. Barriers to the development of prefabricated buildings in China: A news coverage analysis. Eng. Constr. Archit. Manag. 2020, 28, 2884–2903. [Google Scholar] [CrossRef]

- Wang, Z.L.; Shen, H.C.; Zuo, J. Risks in Prefabricated Buildings in China: Importance-Performance Analysis Approach. Sustainability 2019, 11, 3450. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Q. Key points of precast structure construction deep design. Constr. Technol. 2017, 46, 21–24. (In Chinese) [Google Scholar]

- Ye, H.W.; Zhou, C.; Wang, B. Promoting the Development of Assembly Building with EPC Mode. J. Eng. Manag. 2017, 31, 17–22. (In Chinese) [Google Scholar]

- Wang, T.; Tang, W.; Du, L.; Duffield, C.F.; Wei, Y. Relationships among Risk Management, Partnering, and Contractor Capability in International EPC Project Delivery. J. Manag. Eng. 2016, 32, 04016017. [Google Scholar] [CrossRef]

- Guo, Q.; Xu, Z.P.; Zhang, G.F.; Tu, T. Comparative analysis between the EPC contract mode and the traditional mode based on the transaction cost theory. In Proceedings of the 2010 IEEE 17th International Conference on Industrial Engineering and Engineering Management, Xiamen, China, 20–31 October 2010; pp. 91–195. [Google Scholar]

- Hale, D.R.; Shrestha, P.P.; Gibson, G.E.; Migliaccio, G.C. Empirical Comparison of Design/Build and Design/Bid/Build Project Delivery Methods. J. Constr. Eng. Manag. 2009, 135, 579–587. [Google Scholar] [CrossRef] [Green Version]

- Hussein, M.; Eltoukhy, A.E.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.P.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost-benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef] [Green Version]

- Wu, P.; Xu, Y.; Jin, R.; Lu, Q.; Madgwick, D.; Hancock, C.M. Perceptions towards risks involved in off-site construction in the integrated design & construction project delivery. J. Clean. Prod. 2019, 213, 899–914. [Google Scholar]

- Li, Z.D.; Shen, G.Q.; Xue, X.L. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef] [Green Version]

- Nawi, M.N.M.; Haron, A.T.; Hamid, Z.A.; Kamar, K.A.M.; Baharuddin, Y. Improving integrated practice through building information modeling integrated project delivery (BIM-IPD) for Malaysian industrialised building system (IBS) construction projects. Malays. Constr. Res. J. 2014, 15, 29–38. [Google Scholar]

- Osman, W.N.; Nawi, M.N.; Anuar, H.S.; Radzuan, K.; Osman, N.N. Readiness assessment for implementation of integrated project delivery (IPD) in industrialised building system (IBS) projects. J. Teknol. 2015, 77, 91–95. [Google Scholar] [CrossRef] [Green Version]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of offsite construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef] [Green Version]

- Bogus, S.M.; Migliaccio, G.C.; Jin, R. Study of the relationship between procurement duration and project performance in Design-Build Projects: Comparison between water/wastewater and transportation Sectors. J. Manag. Eng. 2013, 29, 382–391. [Google Scholar] [CrossRef]

- Mostafa, S.; Chileshe, N.; Zuo, J. A synergistic supply chain enhancing offsite manufacturing uptake in Australian house building. In Proceedings of the 30th Annual ARCOM Conference, Portsmouth, UK, 1–3 September 2014; pp. 1143–1152. [Google Scholar]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Nadim, W.; Goulding, J.S. Offsite production: A model for building down barriers. Eng. Constr. Archit. Manag. 2011, 18, 82–101. [Google Scholar] [CrossRef]

- Durdyev, S.; Ismail, S. Offsite Manufacturing in the Construction Industry for Productivity Improvement. Eng. Manag. J. 2019, 31, 35–46. [Google Scholar] [CrossRef]

- Rahimian, F.P.; Goulding, J.; Akintoye, A.; Kolo, S. Review of Motivations, Success Factors, and Barriers to the Adoption of Offsite Manufacturing in Nigeria. Procedia Eng. 2017, 196, 512–519. [Google Scholar] [CrossRef] [Green Version]

- Mao, C.; Shen, Q.P.; Pan, W.; Ye, K.H. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Zhai, X.; Reed, R.; Mills, A. Factors impeding the offsite production of housing construction in China: An investigation of current practice. Constr. Manag. Econ. 2014, 32, 40–52. [Google Scholar] [CrossRef]

- Cao, X.Y.; Li, Z.F.; Liu, S. Study on factors that inhibit the promotion of SI housing system in China. Energy Build. 2015, 88, 384–394. [Google Scholar] [CrossRef]

- Luo, L.Z.; Mao, C.; Shen, L.Y.; Li, Z.D. Risk factors affecting practitioners’ attitudes toward the implementation of an industrialized building system A case study from China. Eng. Constr. Archit. Manag. 2015, 22, 622–643. [Google Scholar] [CrossRef]

- Wang, T.; Gao, S.; Li, X.; Ning, X. A meta-network-based risk evaluation and control method for industrialized building construction projects. J. Clean. Prod. 2018, 205, 552–564. [Google Scholar] [CrossRef]

- Pozin, M.A.A.; Nawi, M.N.M.; AzmanM, N.A.; Lee, A. Improving communication in managing industrialised building system (IBS) projects: Virtual environment. Malays. Constr. Res. J. 2017, 2, 1–13. [Google Scholar]

- Galloway, P. Design-Build/EPC contractor’s heightened Risk-changes in a changing world. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2009, 1, 7–15. [Google Scholar] [CrossRef]

- Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Exploring performance of the integrated project delivery process on complex building projects. Int. J. Proj. Manag. 2016, 34, 1089–1101. [Google Scholar] [CrossRef]

- Shen, W.; Choi, B.; Lee, S.; Tang, W.; Haas, C.T. How to Improve Interface Management Behaviors in EPC Projects: Roles of Formal Practices and Social Norms. J. Manag. Eng. 2018, 34, 04018032. [Google Scholar] [CrossRef]

- Yang, Y.; Tang, W.; Shen, W.; Wang, T. Enhancing Risk Management by Partnering in International EPC Projects: Perspective from Evolutionary Game in Chinese Construction Companies. Sustainability 2019, 11, 5332. [Google Scholar] [CrossRef] [Green Version]

- Votto, R.; Lee, H.L.; Berssaneti, F. Applying and Assessing Performance of Earned Duration Management Control Charts for EPC Project Duration Monitoring. J. Constr. Eng. Manag. 2020, 146, 04020001. [Google Scholar] [CrossRef]

- Aldhaheri, M.; Bakchan, A.; Sandhu, M.A. A structural equation model for enhancing effectiveness of engineering, procurement and construction (EPC) major projects. Eng. Constr. Archit. Manag. 2018, 25, 1226–1252. [Google Scholar] [CrossRef]

- Pekings, R.A. Sources of Changes in Design-Build Contracts for a Governmental Owner. J. Constr. Eng. Manag. 2011, 135, 588–593. [Google Scholar]

- Pal, R.; Wang, P.; Liang, X. The critical factors in managing relationships in international engineering, procurement, and construction (IEPC) projects of Chinese organizations. Int. J. Proj. Manag. 2017, 35, 1225–1237. [Google Scholar] [CrossRef]

- Gao, H.; Wang, Z.J. The general contractor’s risk prevention measures under EPC mode. J. Eng. Manag. 2016, 30, 114–119. (In Chinese) [Google Scholar]

- Shen, W.X.; Tang, W.Z.; Wang, S.L.; Duffield, C.F.; Hui, F.K.P.; You, R.C. Enhancing Trust-Based Interface Management in International Engineering-Procurement-Construction Projects. J. Constr. Eng. Manag. 2017, 143. [Google Scholar] [CrossRef]

- Shen, W.X.; Tang, W.Z.; Yu, W.Y.; Duffield, C.F.; Hui, F.K.P.; Wei, Y.P.; Fang, J. Causes of contractors’ claims in international engineering-procurement-construction projects. J. Civ. Eng. Manag. 2017, 23, 727–739. [Google Scholar] [CrossRef] [Green Version]

- Fallahnejad, M.H. Delay causes in Iran gas pipeline projects. Int. J. Proj. Manag. 2013, 31, 136–146. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, K. Top 225 international contractors in 2011 ENR report. J. Eng. Manag. 2011, 25, 584–590. (In Chinese) [Google Scholar]

- Fellows, R.; Liu, A. Research Methods for Construction, 3rd ed.; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Duan, S.X.; Xu, M. Research on procurement risk assessment of EPC engineering project based on structural equation model. Financ. Account. Mon. 2019, 852, 138–146. (In Chinese) [Google Scholar]

- Qi, B.K.; Zhu, Y.; Fan, W.Y. Risk factor identification method of the whole life cycle in prefabricated construction. J. Shenyang Jianzhu Univ. 2016, 18, 257–261. (In Chinese) [Google Scholar]

- Alanjari, P.; Razavialavi, S.; Abourizk, S. A simulation-based approach for material yard laydown planning. Autom. Constr. 2014, 40, 1–8. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Fard, M.M.; Terouhid, S.A.; Kibert, C.J.; Hakim, H. Safety concerns related to modular/prefabricated building construction. Int. J. Inj. Control. Saf. Promot. 2017, 24, 10–23. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Jiao, R.J.; Chen, L.; Wu, C. Green modular design for material efficiency: A leader-follower joint optimization model. J. Clean. Prod. 2013, 41, 187–201. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Luo, L.Z. SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong. Habitat Int. 2016, 57, 74–87. [Google Scholar] [CrossRef]

- Liu, B.; Huo, T.; Meng, J.; Gong, J.; Shen, Q.; Sun, T. Identification of Key Contractor Characteristic Factors That Affect Project Success under Different Project Delivery Systems: Empirical Analysis Based on a Group of Data from China. J. Manag. Eng. 2016, 32, 05015003. [Google Scholar] [CrossRef]

- Xia, M.M.; Zhao, L.; Qiao, Y.N.; Yuan, Z.M.; Cui, Y.L.; Zhao, L.M.; Li, J.L. Analysis of Factors Affecting the Quality of Precast Components Based on Structural Equation Modeling. Arab. J. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Identifying and Managing Critical Waste Factors for Lean Construction Projects. Eng. Manag. J. 2019, 32, 2–13. [Google Scholar] [CrossRef]

- Liu, C.; Yang, S.; Cui, Y.; Yang, Y. An improved risk assessment method based on a comprehensive weighting algorithm in railway signaling safety analysis. Saf. Sci. 2020, 128, 104768. [Google Scholar] [CrossRef]

- Karasan, A.; Ilbahar, E.; Kahraman, C. A novel pythagorean fuzzy AHP and its application to landfill site selection problem. Soft Comput. 2019, 23, 10953–10968. [Google Scholar] [CrossRef]

- Chang, T.; Deng, X.; Hwang, B.G. Investigating political risk paths in international high-speed railway projects: The case of Chinese international contractors. Sustainability 2019, 11, 4157. [Google Scholar] [CrossRef] [Green Version]

- Cho, T.; Lee, J.B.; Kim, S.S. Probabilistic risk assessment for the construction phases of a PSC box girder railway bridge system with six sigma methodology. KSCE J. Civ. Eng. 2011, 15, 119–130. [Google Scholar] [CrossRef]

- Liu, X.T.; Rao, S.S. Vibration Analysis in the Presence of Uncertainties Using Universal Grey System Theory. J. Vib. Acoust. Trans. Asme 2018, 140, 031009. [Google Scholar] [CrossRef]

- Han, L.F.; Tang, W.Y.; Liu, Y.M.; Wang, J.; Fu, C.F. Evaluation of measurement uncertainty based on grey system theory for small samples from an unknown distribution. Sci. China Technol. Sci. 2013, 56, 1517–1524. [Google Scholar] [CrossRef]

- Feng, S.X.; Lei, H.Y.; Wan, Y.F.; Jin, H.Y.; Han, J. Influencing factors and control measures of excavation on adjacent bridge foundation based on analytic hierarchy process and finite element method. Front. Struct. Civ. Eng. 2021, 15, 461–477. [Google Scholar] [CrossRef]

- Lee, D.; Lee, D.; Lee, M.; Kim, M.; Kim, T. Analytic Hierarchy Process-Based Construction Material Selection for Performance Improvement of Building Construction: The Case of a Concrete System Form. Materials 2020, 13, 1738. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.H.; Gong, Z.R. Integrated linguistic entropy weight method and multi-objective programming model for supplier selection and order allocation in a circular economy: A case study. J. Clean. Prod. 2020, 227, 122597. [Google Scholar] [CrossRef]

- Wang, C.Y.; Xu, M.; Olsson, G.; Liu, Y. Characterizing of water-energy-emission nexus of coal-fired power industry using entropy weighting method. Resour. Conserv. Recycl. 2020, 161, 104991. [Google Scholar] [CrossRef]

- Eskander, R.F.A. Risk assessment influencing factors for Arabian construction projects using analytic hierarchy process. Alex. Eng. J. 2018, 57, 4207–4218. [Google Scholar] [CrossRef]

- Yan, M.; Zhao, F.; Tian, J.; Li, C.; Guo, N. Introduction of construction organization management and technology system of assembly concrete structure. Eng. Qual. 2014, 32, 13–18. (In Chinese) [Google Scholar]

- Jiang, W.; Huang, Z.; Peng, Y.; Fang, Y.; Cao, Y. Factors affecting prefabricated construction promotion in China: A structural equation modeling approach. PLoS ONE 2020, 15, e0227787. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Risk Description | Resource |

|---|---|

| Lack of government incentives, directives, and promotion; inadequate policies and regulations | [22,30,31,32,33,34] |

| Immature development leading to a lack of market acceptance | [1,2,3,4] |

| Lack of knowledge and expertise and low levels of skilled labor | [3,4,22] |

| Higher initial investment | [20,21,22] |

| Inappropriate design codes and standards for prefabricated buildings | [32] |

| Dependence on traditional construction methods | [30,32,33] |

| Lack of a quality-monitoring mechanism | [34] |

| Poor cooperation between internal and external stakeholders | [3,4,5,6,35] |

| Risk Description | Resource |

|---|---|

| Uncertain circumstances; complex economic and political environment | [37,38,39,40] |

| The strengths of EPC contractors are mainly in construction, whereas their capability gaps are usually related to engineering and procurement | [39,40] |

| Rising price of materials and equipment | [16,41,42] |

| Exchange rate fluctuation | [40,42] |

| Complicated interfaces and concurrent engineering, procurement, and construction make it more challenging | [38,42,43,44] |

| Some factors contribute to delays | [51] |

| Number | Risk Indicator | Description | References |

|---|---|---|---|

| 1 | Inflation | The effects of price level and currency purchasing power decline | [39,40,54] |

| 2 | Quality defects of precast components | Including size deviation, insufficient strength, and reserved embedded parts; specifications do not meet the requirements | [55] |

| 3 | Design changes | Owner’s requirements, insufficient design capabilities, or distortion of survey data leading to design modifications | [6,14] |

| 4 | Adverse weather conditions | Floods, rainstorms, typhoons, and other natural disasters | [46] |

| 5 | Interest rate fluctuations | The effects of a change in interest rates caused by policy changes | [40,41,42,47,48] |

| 6 | Adverse geological conditions | Earthquakes, landslides, karsts, seepage deformation, and other undesirable geological phenomena | [47] |

| 7 | Poor design coordination | Insufficient coordination between electromechanical, pipeline, and other major systems, as well as between procurement and construction | [14,33,34] |

| 8 | Unreasonable component split | Precast component split does not meet the design, construction, and other requirements | [48] |

| 9 | Insufficiently in-depth design | The design does not provide sufficiently in-depth details for the components to meet the requirements of the specification standards, construction technology, and conflict with other professions | [14,20] |

| 10 | Immature hoisting technology | Construction personnel involved in the hoisting and connection technology are not skilled | [1,2,3,4] |

| 11 | Transport damage of precast components | Damage caused by the lack of scientific protection | [21] |

| 12 | Unreasonable organization | The responsibilities of each department are not clear and the power division is not equal | [3,4,5,31,32,33,34] |

| 13 | Improper site stacking and protection of components | Failure to provide essential protection for components and unreasonable stacking methods and areas | [56,57] |

| 14 | Temporary support system with poor stability | The hoisting support system is not firm and displays insufficient strength and poor safety | [52,55] |

| 15 | Inappropriate mechanical equipment selection | The main parameters such as lifting weight, height, and moment of mechanical equipment can not meet the requirements | [58] |

| 16 | Untimely delivery | When raw materials are in short supply, equipment malfunctions or inventory turnover is untimely, supplies often fail to be delivered on time | [39,44] |

| 17 | Rising prices | An increase in the price of labor, materials, and equipment caused by supply and demand | [16,39,47] |

| 18 | Immature standardized design techniques | The designers do not adopt the standardized methods of prefabricated building | [7,12,13] |

| 19 | Poor supplier credit and contract performance | The supplier’s capital, debt, production capacity, and business reputation are damaged | [38,39,40] |

| 20 | Insufficient developer credibility and payment ability | The developer breaches the contract and project funds can not be in place on time | [38,41] |

| 21 | Tax rate fluctuations | Changes caused by national macroeconomic regulation and control | [17,39] |

| 22 | Unsound specifications | Conflicts in all aspects of assembly construction and a lack of a unified standard system | [1,2] |

| 23 | Insufficient communication and coordination between various units | Lack of communication between design units, component manufacturers, contractors, and other participating units | [3,4,5,6] |

| 24 | Insufficient project management experience and ability | The general contractor and subcontractors lack experience in prefabricated building project management | [1,2,3,4] |

| 25 | Changes in industry-related laws and policies | The relevant laws and policies are changed during the process of construction | [22,38] |

| 26 | Unreasonable specialized construction plan | Specialized schemes are not appropriate for prefabricated buildings | [33] |

| 27 | Incorrect transportation plan | Mainly includes unreasonable transportation routes and protective measures | [54,59] |

| 28 | Inadequate disclosure of technical quality and safety information | The communication of technical information between professional personnel and the first line of the operation personnel is not comprehensive | [60] |

| 29 | Inadequacy of competent purchasing staff | The purchasing staff are not familiar with the market environment and have insufficient experience | [40,41,47] |

| 30 | Supplier designated by developers | The developer appoints suppliers to the general contractor during the procurement process of the project | [39,59] |

| Cronbach’s α Coefficient | Reliability |

|---|---|

| Cronbach’s α coefficient < 0.3 | Unreliable |

| 0.3 ≤ Cronbach’s α coefficient < 0.4 | Barely reliable |

| 0.4 ≤ Cronbach’s α coefficient < 0.5 | Reliable |

| 0.5 ≤ Cronbach’s α coefficient < 0.7 | Reliable (most common) |

| 0.7 ≤ Cronbach’s α coefficient < 0.9 | Reliable (second most common) |

| 0.9 ≤ Cronbach’s α coefficient | Perfectly reliable |

| Risk Indicator | Survey Results | Calculation Results | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | μ | σ | δ | R | |

| Inflation | 0 | 9 | 30 | 65 | 33 | 3.89 | 0.84 | 0.22 | 77.81 |

| Quality defects of precast components | 0 | 1 | 49 | 50 | 37 | 3.90 | 0.80 | 0.21 | 77.96 |

| Design changes | 0 | 1 | 59 | 44 | 33 | 3.80 | 0.81 | 0.21 | 75.91 |

| Adverse weather conditions | 0 | 5 | 18 | 81 | 33 | 4.04 | 0.72 | 0.18 | 80.73 |

| Interest rate fluctuations | 0 | 10 | 45 | 50 | 32 | 3.76 | 0.89 | 0.24 | 75.18 |

| Adverse geological conditions | 0 | 2 | 45 | 59 | 31 | 3.87 | 0.77 | 0.20 | 77.37 |

| Poor design coordination | 0 | 2 | 52 | 48 | 35 | 3.85 | 0.82 | 0.21 | 76.93 |

| Unreasonable component split | 0 | 3 | 50 | 60 | 24 | 3.77 | 0.76 | 0.20 | 75.33 |

| Insufficiently in-depth design | 0 | 4 | 58 | 40 | 35 | 3.77 | 0.86 | 0.23 | 75.47 |

| Immature hoisting technology | 0 | 0 | 60 | 47 | 30 | 3.78 | 0.78 | 0.21 | 75.62 |

| Transport damage of precast components | 0 | 3 | 35 | 79 | 20 | 3.85 | 0.68 | 0.18 | 76.93 |

| Unreasonable organization | 0 | 6 | 53 | 46 | 32 | 3.76 | 0.86 | 0.23 | 75.18 |

| Improper site stacking and protection of components | 0 | 5 | 50 | 46 | 36 | 3.82 | 0.86 | 0.23 | 76.50 |

| Temporary support system with poor stability | 0 | 0 | 43 | 48 | 46 | 4.02 | 0.81 | 0.20 | 80.44 |

| Inappropriate mechanical equipment selection | 0 | 1 | 3 | 52 | 47 | 4.06 | 0.80 | 0.20 | 81.17 |

| Rising prices | 0 | 8 | 36 | 60 | 33 | 3.86 | 0.85 | 0.22 | 77.23 |

| Untimely delivery | 0 | 2 | 52 | 54 | 29 | 3.80 | 0.78 | 0.21 | 76.06 |

| Immature standardized design techniques | 0 | 11 | 13 | 68 | 45 | 4.07 | 0.86 | 0.21 | 81.46 |

| Poor supplier credit and contract performance | 0 | 10 | 46 | 48 | 33 | 3.76 | 0.90 | 0.24 | 75.18 |

| Insufficient developer credibility and payment ability | 0 | 3 | 47 | 48 | 39 | 3.90 | 0.84 | 0.22 | 77.96 |

| Tax rate fluctuations | 0 | 1 | 79 | 51 | 6 | 3.45 | 0.59 | 0.27 | 69.05 |

| Unsound specifications | 0 | 0 | 63 | 44 | 30 | 3.76 | 0.79 | 0.21 | 75.18 |

| Insufficient communication and coordination between various units | 5 | 6 | 13 | 68 | 45 | 4.04 | 0.96 | 0.24 | 80.73 |

| Insufficient project management experience and ability | 0 | 3 | 24 | 76 | 34 | 4.03 | 0.71 | 0.18 | 80.58 |

| Changes in industry-related laws and policies | 0 | 15 | 31 | 63 | 28 | 3.76 | 0.90 | 0.24 | 75.13 |

| Unreasonable specialized construction plan | 0 | 2 | 43 | 40 | 52 | 4.04 | 0.87 | 0.21 | 80.73 |

| Incorrect transportation plan | 0 | 2 | 42 | 50 | 43 | 3.98 | 0.82 | 0.21 | 79.56 |

| Inadequate disclosure of technical quality and safety information | 0 | 5 | 12 | 80 | 40 | 4.13 | 0.71 | 0.17 | 82.63 |

| Inadequacy of component purchasing staff | 3 | 13 | 31 | 69 | 21 | 3.67 | 0.92 | 0.26 | 73.43 |

| Supplier designated by developers | 4 | 42 | 52 | 32 | 7 | 2.97 | 0.93 | 0.31 | 59.42 |

| First-Level | Second-Level |

|---|---|

| Management risk U1 | Insufficient project management experience and ability U11 |

| Insufficient communication and coordination between various units U12 | |

| Unreasonable organization U13 | |

| Design risk U2 | Design changes U21 |

| Unreasonable component split U22 | |

| Insufficiently in-depth design U23 | |

| Immature standardized design techniques U24 | |

| Poor design coordination U25 | |

| Procurement risk U3 | Poor supplier credit and contract performance U31 |

| Quality defects of precast components U32 | |

| Incorrect transportation plan U33 | |

| Untimely delivery U34 | |

| Transport damage of precast components U35 | |

| Construction risk U4 | Unreasonable specialized construction plan U41 |

| Inadequate disclosure of technical quality and safety information U42 | |

| Immature hoisting technology U43 | |

| Inappropriate mechanical equipment selection U44 | |

| Improper site stacking and protection of components U45 | |

| Temporary support system with poor stability U46 | |

| Economic risk U5 | Inflation U51 |

| Rising prices U52 | |

| Insufficient developer credibility and payment ability U53 | |

| Interest rate fluctuations U54 | |

| Policy risk U6 | Unsound specifications U61 |

| Changes in industry-related laws and policies U62 | |

| Natural risk U7 | Adverse geological conditions U71 |

| Adverse weather conditions U72 |

| Rank | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 0 | 0.52 | 0.89 | 1.12 | 1.26 | 1.36 | 1.41 | 1.46 |

| Criteria | Level |

|---|---|

| [90,100] | Absolutely important |

| [80,89] | Important |

| [70,79] | Generally important |

| [60,69] | Unimportant |

| Under 60 | Extremely unimportant |

| Risk Level | First-Level Indicators | Weight | Second-Level Indicators | Interlayer Weight |

|---|---|---|---|---|

| 3.3203 | Management risk U1 | 0.0864 | Insufficient project management experience and ability U11 | 0.5451 |

| Insufficient communication and coordination between various units U12 | 0.2894 | |||

| Unreasonable organization U13 | 0.1655 | |||

| Design risk U2 | 0.2298 | Design changes U21 | 0.0805 | |

| Unreasonable component split U22 | 0.2071 | |||

| Insufficiently in-depth design U23 | 0.3420 | |||

| Immature standardized design techniques U24 | 0.2333 | |||

| Poor design coordination U25 | 0.1371 | |||

| Procurement risk U3 | 0.0885 | Poor supplier credit and contract performance U31 | 0.0576 | |

| Quality defects of precast components U32 | 0.5480 | |||

| Incorrect transportation plan U33 | 0.1277 | |||

| Untimely delivery U34 | 0.0961 | |||

| Transport damage of precast components U35 | 0.1706 | |||

| Construction risk U4 | 0.4814 | Unreasonable specialized construction plan U41 | 0.0877 | |

| Inadequate disclosure of technical quality and safety information U42 | 0.0962 | |||

| Immature hoisting technology U43 | 0.0633 | |||

| Inappropriate mechanical equipment selection U44 | 0.0619 | |||

| Improper site stacking and protection of components U45 | 0.1953 | |||

| Temporary support system with poor stability U46 | 0.4956 | |||

| Economic risk U5 | 0.0318 | Inflation U51 | 0.2233 | |

| Rising prices U52 | 0.1793 | |||

| Insufficient developer credibility and payment ability U53 | 0.4748 | |||

| Interest rate fluctuations U54 | 0.1226 | |||

| Policy risk U6 | 0.0251 | Unsound specifications U61 | 0.6853 | |

| Changes in industry-related laws and policies U62 | 0.3147 | |||

| Natural risk U7 | 0.0570 | Adverse geological conditions U71 | 0.4140 | |

| Adverse weather conditions U72 | 0.5960 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, M.; Zhao, L.; Zhao, L. A Comprehensive Risk-Assessment Method for Prefabricated Buildings Using EPC: A Case Study from China. Sustainability 2022, 14, 1910. https://doi.org/10.3390/su14031910

Xia M, Zhao L, Zhao L. A Comprehensive Risk-Assessment Method for Prefabricated Buildings Using EPC: A Case Study from China. Sustainability. 2022; 14(3):1910. https://doi.org/10.3390/su14031910

Chicago/Turabian StyleXia, Manman, Lemeng Zhao, and Li Zhao. 2022. "A Comprehensive Risk-Assessment Method for Prefabricated Buildings Using EPC: A Case Study from China" Sustainability 14, no. 3: 1910. https://doi.org/10.3390/su14031910

APA StyleXia, M., Zhao, L., & Zhao, L. (2022). A Comprehensive Risk-Assessment Method for Prefabricated Buildings Using EPC: A Case Study from China. Sustainability, 14(3), 1910. https://doi.org/10.3390/su14031910