Current Status and Review of Waste-to-Biogas Conversion for Selected European Countries and Worldwide

Abstract

1. Introduction

- Animal waste including animal manure, urine and wastewater from washing stables are all ideal raw materials for anaerobic digestion. The quantity of animal waste depends on the type of animal, its weight, physiological condition, feed composition and feeding methods [6]. However, animal manure has certain disadvantages, namely, it usually comes in large quantities and consequently has low dry-matter content, which results in low biogas yield per unit of processed raw material and high costs of raw material or digestate transportation. Additionally, animal waste may contain heavy metals and antibiotics, which have unfavourable effects on the process of anaerobic digestion or on the reuse of digestate [6,7]. The moisture content and the content of organic matter in the material significantly affect the quality of the final product, as they stimulate the growth of microorganisms [8]. However, it has been recently shown that the implementation of freeze concentration technology as an alternative way to recover nutrients from agro-industrial waste digestate makes it easier to transport animal waste due to volume reduction [9]. Traditional methods of drying materials with high moisture are cost intensive and have negative environmental effects. On the other hand, bio-drying is mostly suitable for municipal solid waste, waste from the pulp and paper industry, sewage sludge and green waste. In this auto-thermal process, waste is dried as a result of the thermal energy released during aerobic decomposition of the biodegradable fraction, while intensive aeration causes moisture removal [10].

- Garden and field waste represents another possible raw material for biogas production, boasting a high dry matter fraction, high yield of biogas per unit of fresh weight, low transportation costs and low production of liquid digestate. On the other hand, long retention times are needed for their digestion due to high levels of cellulose, hemicellulose and lignin. Furthermore, the carbon-to-nitrogen (C/N) ratio is high (usually above 50), which is unfavourable for the normal growth of microorganisms, and also increases the biogas plant or anaerobic digestion start-up delay [6]. Admixing additives to waste has been shown to increase the effectiveness of biostabilisation, resulting in shorter times and lower energy consumption to achieve the same results, namely, at least 7.5% of added digestate reduces the C/N ratio and consequently speeds up the process [11]. Residues in digestors are also difficult to remove when garden and field waste are processed [12,13]. Within this type of waste, maize has the highest biogas yield, followed by wheat and rice [6,14].

- Municipal waste is solid waste generated in people’s daily lives and it includes household waste, commercial waste and waste from cleaning. Organic waste is comprised of fractions of household waste, garden waste and similar organic waste. Impurities such as metal, glass, plastic and sand may seriously affect the operation of a biogas plant and must therefore be removed beforehand [6,14,19,20,21]. The aforementioned bio-drying process decreases the number of some pathogens or completely eliminates them, while for Escherichia coli (E. Coli), abundantly present in municipal solid waste, this effect is not entirely satisfactory. The biggest problem with drug resistant E. Coli is that it can spread outside the landfill area and may adversely affect people working in waste storage and processing [22].

- Food waste includes kitchen waste, food waste from restaurants, hotels, canteens, waste from the processing of fruit, vegetables, fat, flour, etc. In comparison with other types of waste, food waste has a high content of fat and salt as well as impurities, such as bones, utensils and other kitchenware parts, which may damage pumps, pipes and other equipment and must therefore be removed during the pretreatment phase [23,24,25]. As an example, large quantities of hot trub generated in breweries during beer production end up in landfills. Hot trub presents a valuable waste source for WtE processes but also contains E. Coli. Recent research has shown that hot trub can also be used in medicine as a sedative or in cosmetology, which could consequently reduce the amount deposited into landfills [26]. Still, the worst solution for disposing of sediments from breweries is to direct them into the municipal sewage system, which increases the costs of wastewater treatment and is irrational from an ecological and economic point of view [27].

- Municipal sludge includes various types of sludge and waste produced by municipal wastewater treatment plants and has a high water content, large volume and is unstable. Sludge from primary and secondary sedimentation processes is rich in organic matter, the digestion of which is simple and suitable for anaerobic treatment and has a similar potential for biogas production as animal manure.

1.1. Waste Management Issues

1.2. Environmental Issues

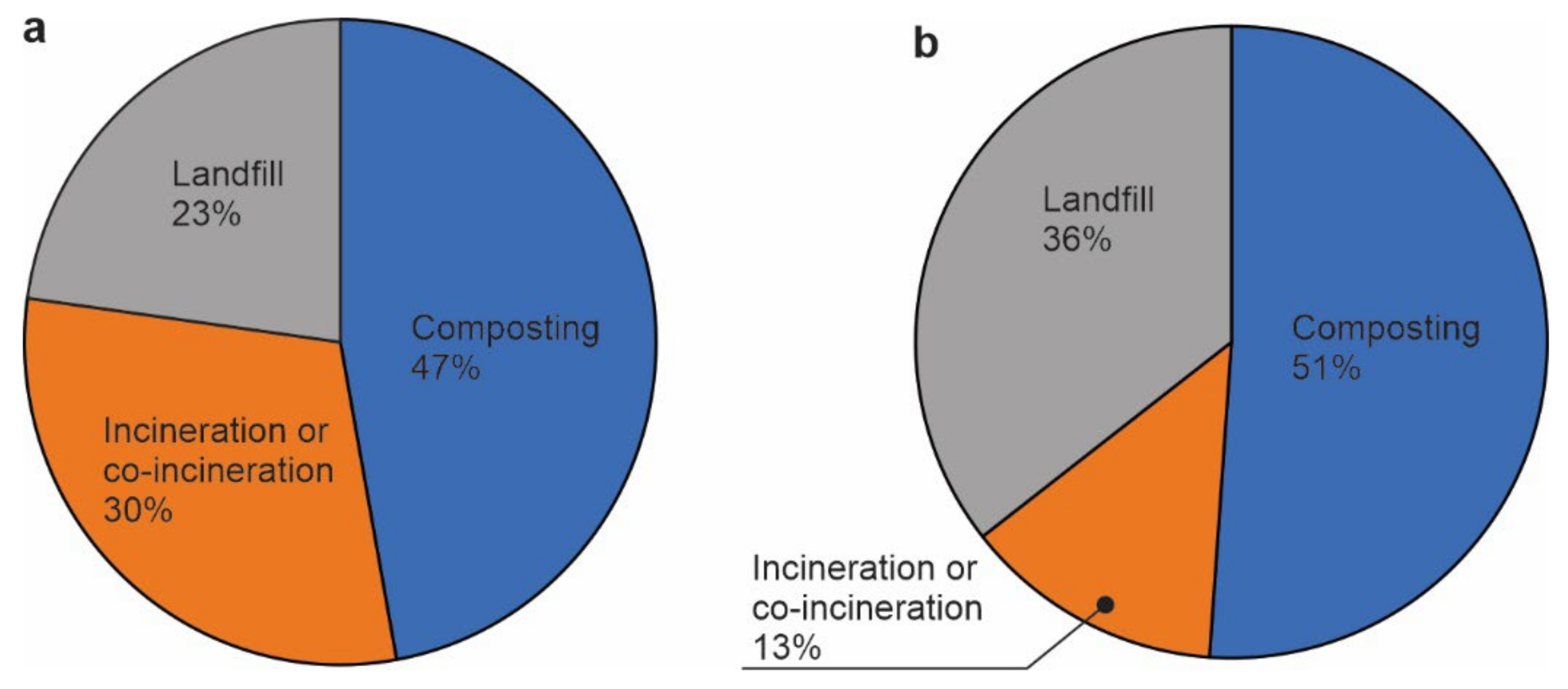

1.3. Problems Related to Waste Management Methods

1.4. Aim, Scope and Structure of the Review

2. Waste-to-Energy (WtE)

2.1. Biofuels

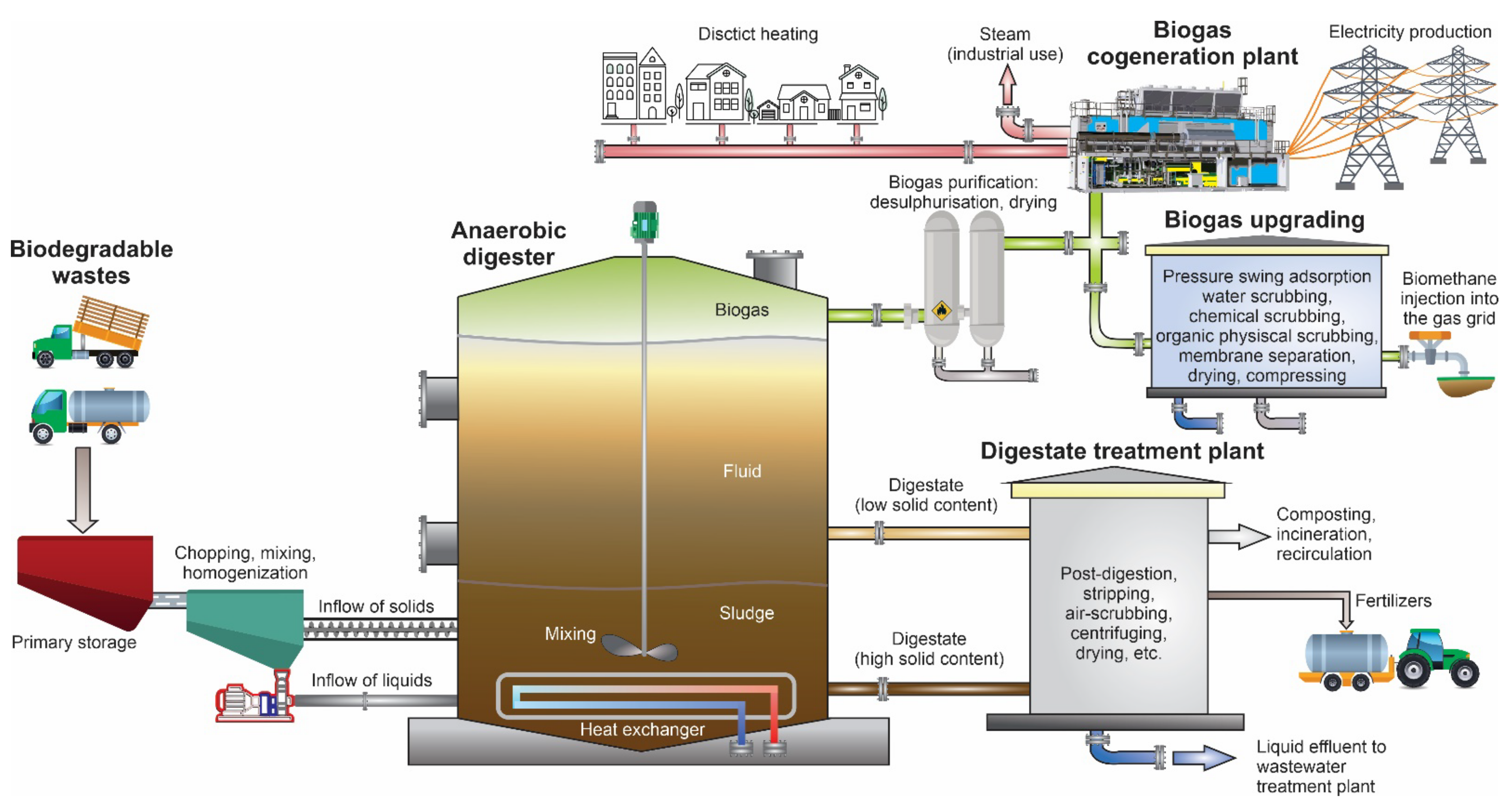

2.2. Anaerobic Digestion

- Hydrolysis;

- Acidogenesis;

- Acetogenesis;

- Methanogenesis.

2.3. Biogas Purification after Anaerobic Digestion

2.4. Injection of Biomethane

3. Overview and Analysis of National Energy and Climate Plans for Selected EU Member States

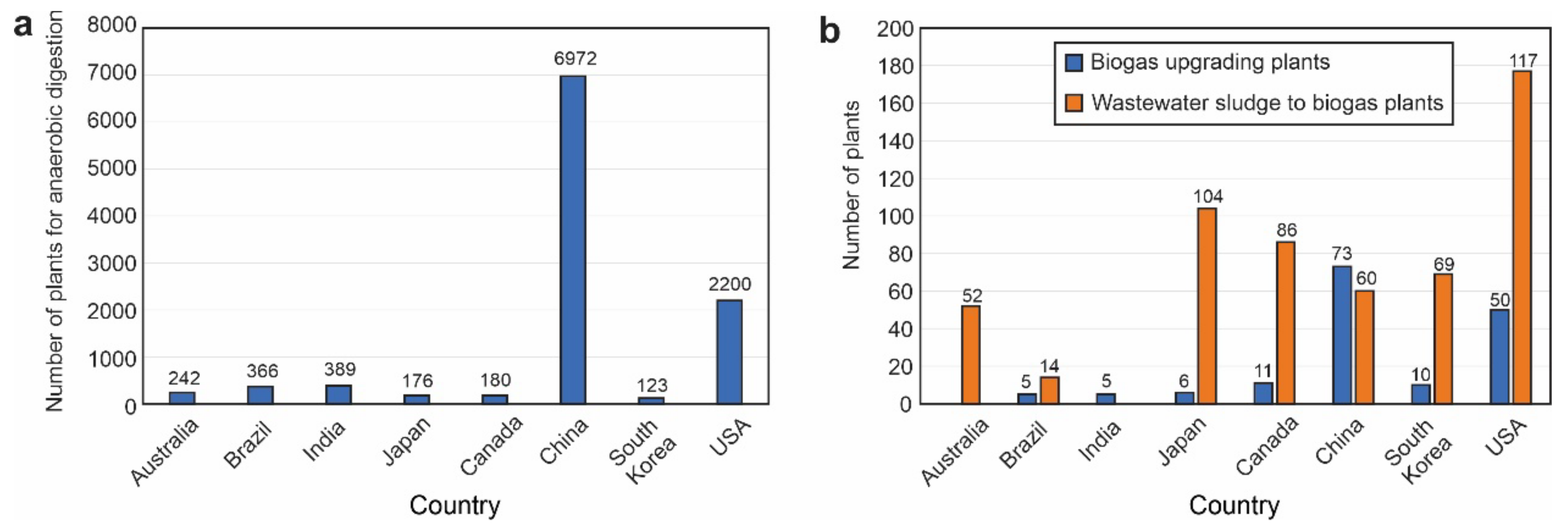

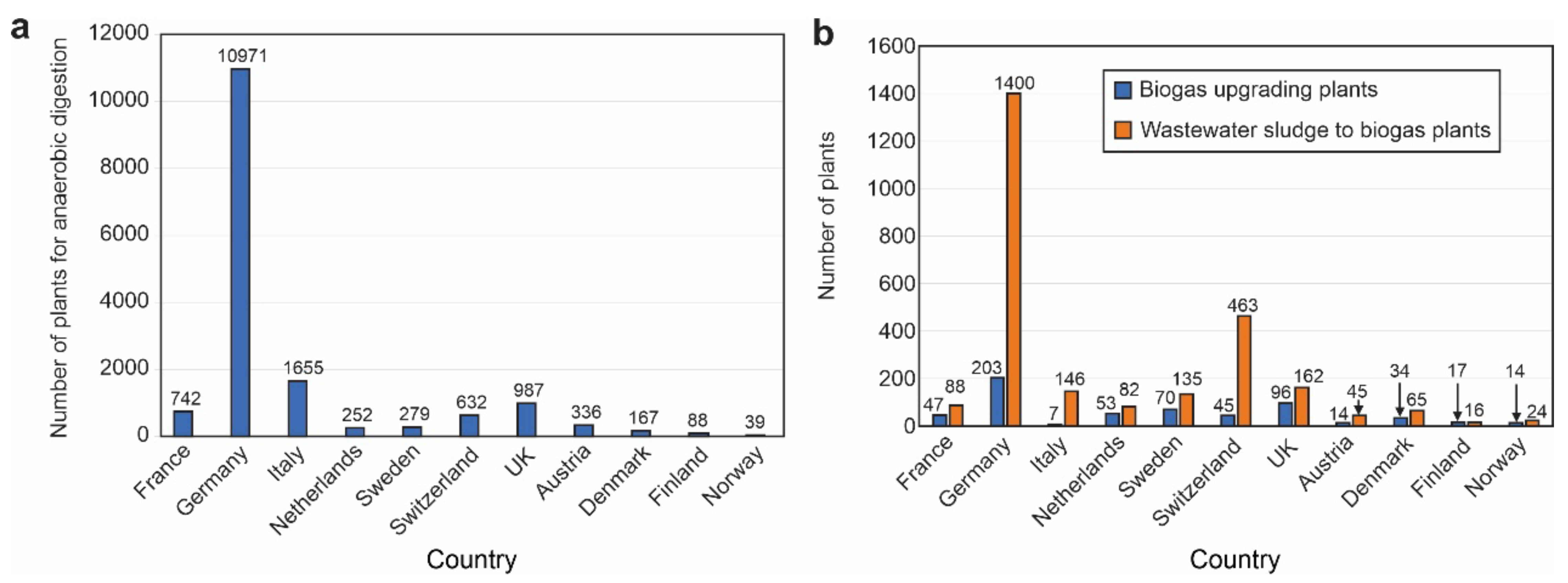

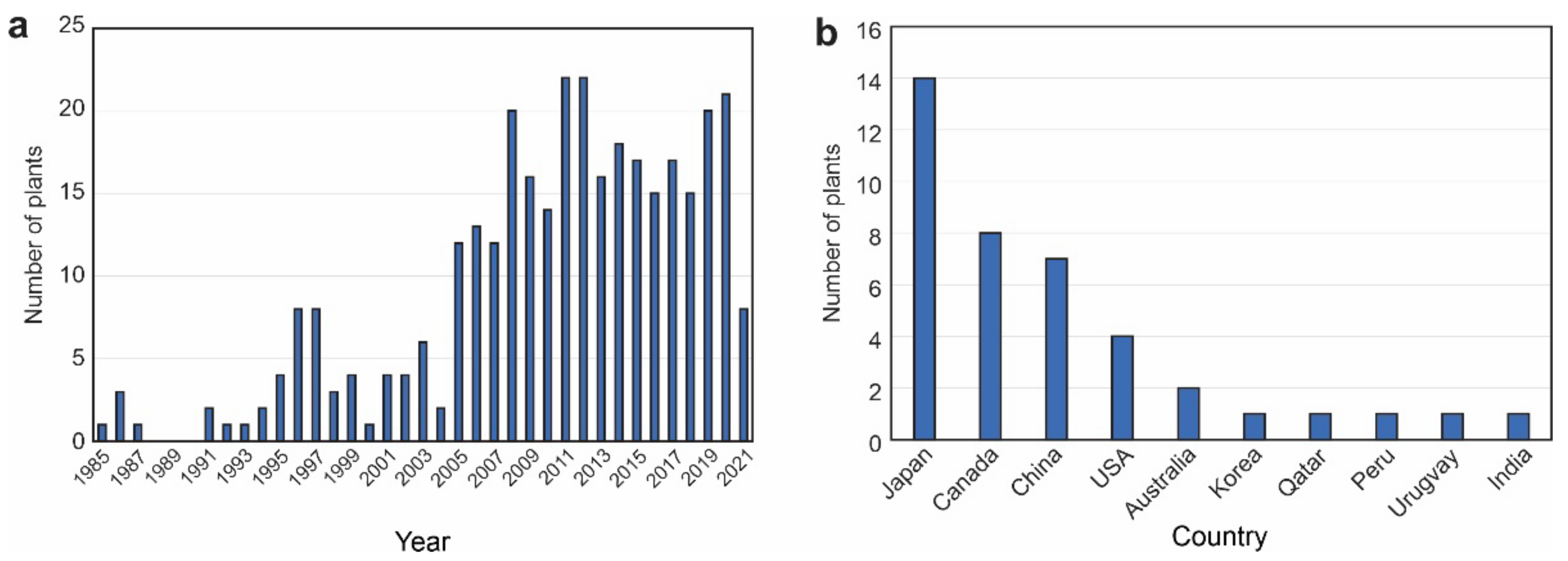

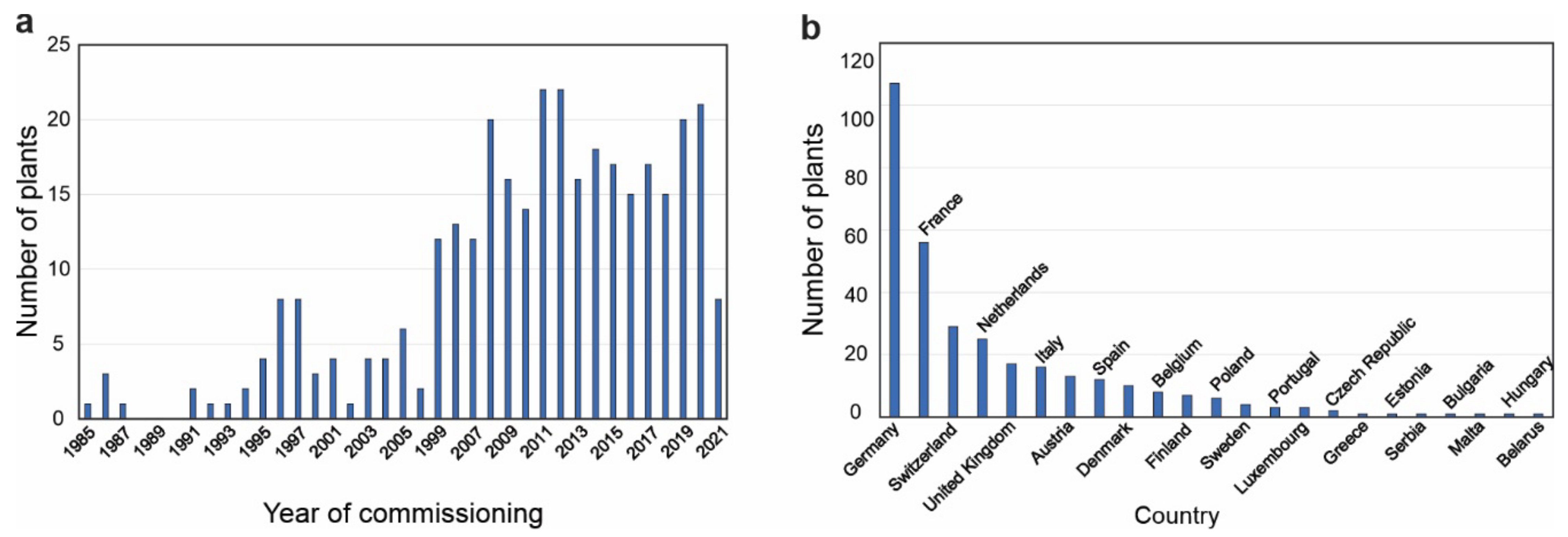

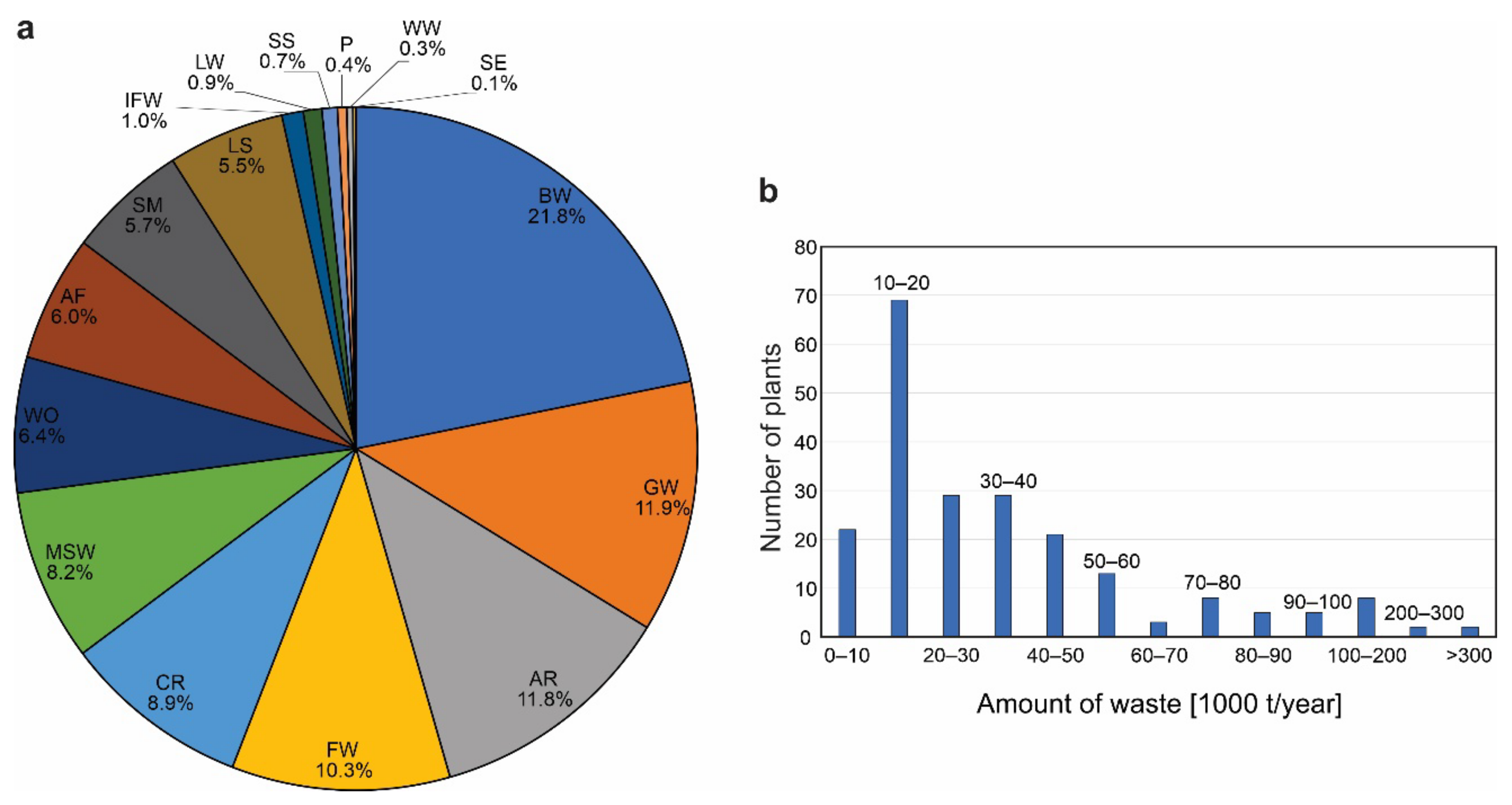

4. Analysis of Biogas Production from Waste around the World

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wilson, D.C.; Velis, C.A. Waste management—Still a global challenge in the 21st century: An evidence-based call for action. Waste Manag. Res. 2015, 33, 1049–1051. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018; ISBN 1-4648-1347-7. [Google Scholar]

- Dou, Z.; Toth, J.D. Global primary data on consumer food waste: Rate and characteristics—A review. Resour. Conserv. Recycl. 2020, 168, 105332. [Google Scholar] [CrossRef]

- OECD. Stat, Stat Technology, 2020. Amount of Waste among OECD Databases. 2020. Available online: https://data.oecd.org/ (accessed on 8 February 2020).

- Dobers, G.M. Acceptance of biogas plants taking into account space and place. Energy Policy 2019, 135, 110987. [Google Scholar] [CrossRef]

- Deng, L.; Liu, Y.; Wang, W. Biogas Technology, 1st ed.; Springer: Singapore, 2020. [Google Scholar]

- Marchtinez, J.; Dabert, P.; Barrington, S.; Burton, C. Livestock waste treatment systems for environmental quality, food safety, and sustainability. Bioresour. Technol. 2009, 100, 5527–5536. [Google Scholar] [CrossRef] [PubMed]

- Malinowski, M.; Wolny-Koładka, K. Microbiological and Energetic Assessment of the Effects of the Biodrying of Fuel Produced from Waste. Ecol. Chem. Eng. S 2017, 24, 551–564. [Google Scholar] [CrossRef][Green Version]

- Alfano, B.; Barretta, L.; Del Giudice, A.; De Vito, S.; Di Francia, G.; Esposito, E.; Formisano, F.; Massera, E.; Miglietta, M.L.; Polichetti, T. A Review of Low-Cost Particulate Matter Sensors from the Depvelopers’ Perspectives. Sensors 2021, 20, 6819. [Google Scholar] [CrossRef]

- Wolny-Koładka, K.; Malinowski, M.; Zdaniewicz, M. Energy-related and microbiological evaluation of the effects of bulking agents on the brewery hot trub biodrying. Food Bioprod. Process. 2021, 127, 398–407. [Google Scholar] [CrossRef]

- Malinowski, M.; Famielec, S.; Wolny-Koładka, K.; Sikora, J.; Gliniak, M.; Baran, D.; Sobol, Z.; Salamon, J. Impact of digestate addition on the biostabilization of undersized fraction from municipal solid waste. Sci. Total Environ. 2021, 770, 145375. [Google Scholar] [CrossRef]

- Gupta, P.; Singh, R.S.; Sachan, A.; Vidyarthi, A.S.; Gupta, A. Study on biogas production by anaerobic digestion of garden-waste. Fuel 2012, 95, 495–498. [Google Scholar] [CrossRef]

- Perin, J.K.H.; Borth, P.L.B.; Torrecilhas, A.R.; da Cunha, L.S.; Kuroda, E.K.; Fernandes, F. Optimization of methane production parameters during anaerobic co-digestion of food waste and garden waste. J. Clean. Prod. 2020, 272, 123130. [Google Scholar] [CrossRef]

- Hamer, G. Solid waste treatment and disposal: Effects on public health and environmental safety. Biotechnol. Adv. 2003, 22, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Lup, D.T.; Stroe, A.M.; Chezan, P.M.; Pica, E.M. The Importance of Waste Incineration. Stud. Univ. Babeș-Bolyai Ambient. 2018, 63, 43–48. [Google Scholar] [CrossRef]

- Vallero, D.A. Thermal Waste Treatment, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Gómez-Brandón, M.; Podmirseg, S.M. Biological waste treatment. Waste Manag. Res. J. Sustain. Circ. Econ. 2013, 31, 773–774. [Google Scholar] [CrossRef] [PubMed]

- Rada, E.C. Biological Treatment of Solid Waste, 1st ed.; Apple Academic Press: Waretown, NJ, USA, 2015. [Google Scholar]

- Singh, A. Managing the uncertainty problems of municipal solid waste disposal. J. Environ. Manag. 2019, 240, 259–265. [Google Scholar] [CrossRef]

- Rao, M.N.; Sultana, R.; Kota, S.H. Chapter 2—Municipal Solid Waste BT—Solid and Hazardous Waste Management, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Salomone, R.; Saija, G.; Mondello, G.; Giannetto, A.; Fasulo, S.; Savastano, D. Environmental impact of food waste bioconversion by insects: Application of Life Cycle Assessment to process using Hermetia Illucens. J. Clean. Prod. 2017, 140, 890–905. [Google Scholar] [CrossRef]

- Wolny-Koładka, K.; Zdaniewicz, M. Antibiotic Resistance of Escherichia coli Isolated from Processing of Brewery Waste with the Addition of Bulking Agents. Sustainability 2021, 13, 10174. [Google Scholar] [CrossRef]

- Read, Q.D.; Brown, S.; Cuéllar, A.D.; Finn, S.M.; Gephart, J.A.; Marchston, L.T.; Meyer, E.; Weitz, K.A.; Muth, M. Assessing the environmental impacts of halving food loss and waste along the food supply chain. Sci. Total Environ. 2020, 712, 136255. [Google Scholar] [CrossRef]

- Cattaneo, A.; Federighi, G.; Vaz, S. The environmental impact of reducing food loss and waste: A critical assessment. Food Policy 2020, 98, 101890. [Google Scholar] [CrossRef]

- García-Herrero, L.; De Menna, F.; Vittuari, M. Food waste at school. The environmental and cost impact of a canteen meal. Waste Manag. 2019, 100, 249–258. [Google Scholar] [CrossRef]

- González-Morales, S.; Pérez-Labrada, F.; García-Enciso, E.L.; Leija-Marchtínez, P.; Medrano-Macías, J.; Dávila-Rangel, I.E.; Juárez-Maldonado, A.; Rivas-Marchtínez, E.N.; Benavides-Mendoza, A. Rheological and Microbiological Characteristics of Hops and Hot Trub Particles Formed during Beer Production. Molecules 2021, 22, 558. [Google Scholar] [CrossRef]

- Zhukova, V.; Corte-Leon, P.; Blanco, J.M.; Ipatov, M.; Gonzalez, J.; Zhukov, A. The Application Potential of Hop Sediments from Beer Production for Composting. Chemosensors 2021, 9, 100. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change. The Paris Agreement. 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 10 January 2022).

- UK Government. Un Climate Change Conference UK 2021 in Partnership with Italy, 2021. COP26: The Glasgow Climate Pact. Available online: https://ukcop26.org/ (accessed on 10 January 2022).

- Cudjoe, D.; Acquah, P.M. Environmental impact analysis of municipal solid waste incineration in African countries. Chemosphere 2021, 265, 129186. [Google Scholar] [CrossRef] [PubMed]

- Istrate, I.-R.; Galvez-Marchtos, J.-L.; Dufour, J. The impact of incineration phase-out on municipal solid waste landfilling and life cycle environmental performance: Case study of Madrid, Spain. Sci. Total Environ. 2021, 755, 142537. [Google Scholar] [CrossRef] [PubMed]

- Xiaoli, C.; Ziyang, L.; Shimaoka, T.; Nakayama, H.; Ying, Z.; Xiaoyan, C.; Komiya, T.; Ishizaki, T.; Youcai, Z. Characteristics of environmental factors and their effects on CH4 and CO2 emissions from a closed landfill: An ecological case study of Shanghai. Waste Manag. 2010, 30, 446–451. [Google Scholar] [CrossRef]

- Adamcová, D.; Radziemska, M.; Ridošková, A.; Barton, S.; Pelcová, P.; Elbl, J.; Kynický, J.; Brtnický, M.; Vaverková, M.D. Environmental assessment of the effects of a municipal landfill on the content and distribution of heavy metals in Tanacetum vulgare L. Chemosphere 2017, 185, 1011–1018. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Gu, K.; Yu, Q.; Sun, Y.; Wang, Y.; Xin, M.; Bian, R.; Wang, H.; Zhang, D. Leaching behavior and environmental risk assessment of toxic metals in municipal solid waste incineration fly ash exposed to mature landfill leachate environment. Waste Manag. 2021, 120, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Hoornweg, D.; Bhada-Tata, P.; Kennedy, C. Peak Waste: When Is It Likely to Occur? J. Ind. Ecol. 2014, 19, 117–128. [Google Scholar] [CrossRef]

- Nagendran, R. Waste—A Handbook for Management, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Makisha, N.; Semenova, D. Production of biogas at wastewater treatment plants and its further application. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2018; Volume 144, p. 4016. [Google Scholar] [CrossRef]

- Cinar, S.O.; Nsair, A.; Wieczorek, N.; Kuchta, K. Long-Term Assessment of Temperature Management in an Industrial Scale Biogas Plant. Sustainability 2022, 14, 612. [Google Scholar] [CrossRef]

- Khademi, F.; Samaei, M.R.; Shahsavani, A.; Azizi, K.; Mohammadpour, A.; Derakhshan, Z.; Giannakis, S.; Rodriguez-Chueca, J.; Bilal, M. Investigation of the Presence Volatile Organic Compounds (BTEX) in the Ambient Air and Biogases Produced by a Shiraz Landfill in Southern Iran. Sustainability 2022, 14, 1040. [Google Scholar] [CrossRef]

- Sauve, G.; Van Acker, K. The environmental impacts of municipal solid waste landfills in Europe: A life cycle assessment of proper reference cases to support decision making. J. Environ. Manag. 2020, 261, 110216. [Google Scholar] [CrossRef] [PubMed]

- Randazzo, A.; Asensio-Ramos, M.; Melián, G.; Venturi, S.; Padrón, E.; Hernández, P.; Pérez, N.; Tassi, F. Volatile organic compounds (VOCs) in solid waste landfill cover soil: Chemical and isotopic composition vs. degradation processes. Sci. Total Environ. 2020, 726, 138326. [Google Scholar] [CrossRef] [PubMed]

- Mattiello, A.; Chiodini, P.; Bianco, E.; Forgione, N.; Flammia, I.; Gallo, C.; Pizzuti, R.; Panico, S. Health effects associated with the disposal of solid waste in landfills and incinerators in populations living in surrounding areas: A systematic review. Int. J. Public Health 2013, 58, 725–735. [Google Scholar] [CrossRef]

- Wolny-Koładka, K.; Malinowski, M.; Żukowski, W. Impact of Calcium Oxide on Hygienization and Self-Heating Prevention of Biologically Contaminated Polymer Materials. Materials 2020, 13, 4012. [Google Scholar] [CrossRef]

- Flores, R.M.; Feratero, V.J.; Cobaria Soneja, S.K.; Rodelas Gonzales, R.P.A.; Burog, E.; Alvarez, C.J.B.; Bagus, D. A Case Study about the Improper Waste Disposal in Barangay Mojon Tampoy; A Research Paper Presented to the Faculty of De La Salle Lipa Senior High School; De La Salle Lipa: Lipa, Philippines, 2017. [Google Scholar]

- Gopal, L.C.; Govindarajan, M.; Kavipriya, M.; Mahboob, S.; Al-Ghanim, K.A.; Virik, P.; Ahmed, Z.; Al-Mulahim, N.; Senthilkumaran, V.; Shankar, V. Optimization strategies for improved biogas production by recycling of waste through response surface methodology and artificial neural network: Sustainable energy perspective research. J. King Saud Univ. Sci. 2020, 33, 101241. [Google Scholar] [CrossRef]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew. Energy 2020, 168, 438–447. [Google Scholar] [CrossRef]

- Begum, S.; Anupoju, G.R.; Eshtiaghi, N. Anaerobic co-digestion of food waste and cardboard in different mixing ratios: Impact of ultrasound pre-treatment on soluble organic matter and biogas generation potential at varying food to inoculum ratios. Biochem. Eng. J. 2020, 166, 107853. [Google Scholar] [CrossRef]

- Mateus, S.; Carvalheira, M.; Cassidy, J.; Freitas, E.; Oehmen, A.; Reis, M.A. Two-stage anaerobic digestion system treating different seasonal fruit pulp wastes: Impact on biogas and hydrogen production and total energy recovery potential. Biomass Bioenergy 2020, 141, 105694. [Google Scholar] [CrossRef]

- Pozzo, A.D.; Guglielmi, D.; Antonioni, G.; Tugnoli, A. Sustainability analysis of dry treatment technologies for acid gas removal in waste-to-energy plants. J. Clean. Prod. 2017, 162, 1061–1074. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strat. Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Gustafsson, M.; Anderberg, S. Dimensions and characteristics of biogas policies—Modelling the European policy landscape. Renew. Sustain. Energy Rev. 2020, 135, 110200. [Google Scholar] [CrossRef]

- Brémond, U.; Bertrandias, A.; Steyer, J.-P.; Bernet, N.; Carrere, H. A vision of European biogas sector development towards 2030: Trends and challenges. J. Clean. Prod. 2020, 287, 125065. [Google Scholar] [CrossRef]

- Lundmark, R.; Anderson, S.; Hjort, A.; Lönnqvist, T.; Ryding, S.-O.; Söderholm, P. Establishing local biogas transport systems: Policy incentives and actor networks in Swedish regions. Biomass Bioenergy 2021, 145, 105953. [Google Scholar] [CrossRef]

- Wang, K.; Nakakubo, T. Comparative assessment of waste disposal systems and technologies with regard to greenhouse gas emissions: A case study of municipal solid waste treatment options in China. J. Clean. Prod. 2020, 260, 120827. [Google Scholar] [CrossRef]

- Bi, S.; Westerholm, M.; Hu, W.; Mahdy, A.; Dong, T.; Sun, Y.; Qiao, W.; Dong, R. The metabolic performance and microbial communities of anaerobic digestion of chicken manure under stressed ammonia condition: A case study of a 10-year successful biogas plant. Renew. Energy 2020, 167, 644–651. [Google Scholar] [CrossRef]

- Palma-Heredia, D.; Verdaguer, M.; Molinos-Senante, M.; Poch, M.; Cugueró-Escofet, M. Optimised blending for anaerobic co-digestion using ant colony approach: Besòs river basin case study. Renew. Energy 2020, 168, 141–150. [Google Scholar] [CrossRef]

- Ali, M.M.; Ndongo, M.; Bilal, B.; Yetilmezsoy, K.; Youm, I.; Bahramian, M. Mapping of biogas production potential from livestock manures and slaughterhouse waste: A case study for African countries. J. Clean. Prod. 2020, 256, 120499. [Google Scholar] [CrossRef]

- Chukwuma, E.C.; Okey-Onyesolu, F.C.; Ani, K.A.; Nwanna, E.C. GIS bio-waste assessment and suitability analysis for biogas power plant: A case study of Anambra state of Nigeria. Renew. Energy 2020, 163, 1182–1194. [Google Scholar] [CrossRef]

- Dehkordi, S.M.M.N.; Jahromi, A.R.T.; Ferdowsi, A.; Shumal, M.; Dehnavi, A. Investigation of biogas production potential from mechanical separated municipal solid waste as an approach for developing countries (case study: Isfahan-Iran). Renew. Sustain. Energy Rev. 2019, 119, 109586. [Google Scholar] [CrossRef]

- Stunzenas, E.; Kliopova, I. Optimizing municipal biodegradable waste management system to increase biogas output and nutrient recovery: A case study in Lithuania. Energy Procedia 2018, 147, 641–648. [Google Scholar] [CrossRef]

- Mustafa, M.Y.; Calay, R.K.; Román, E. Biogas from Organic Waste - A Case Study. Procedia Eng. 2016, 146, 310–317. [Google Scholar] [CrossRef]

- Bedoić, R.; Špehar, A.; Puljko, J.; Čuček, L.; Ćosić, B.; Pukšec, T.; Duić, N. Opportunities and challenges: Experimental and kinetic analysis of anaerobic co-digestion of food waste and rendering industry streams for biogas production. Renew. Sustain. Energy Rev. 2020, 130, 109951. [Google Scholar] [CrossRef]

- Malik, S.N.; Madhu, K.; Mhaisalkar, V.A.; Vaidya, A.N.; Mudliar, S.N. Pretreatment of yard waste using advanced oxidation processes for enhanced biogas production. Biomass Bioenergy 2020, 142, 105780. [Google Scholar] [CrossRef]

- Adami, L.; Schiavon, M.; Torretta, V.; Costa, L.; Rada, E.C. Evaluation of conventional and alternative anaerobic digestion technologies for applications to small and rural communities. Waste Manag. 2020, 118, 79–89. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhao, J.; Krooneman, J.; Euverink, G.J.W. Strategies to boost anaerobic digestion performance of cow manure: Laboratory achievements and their full-scale application potential. Sci. Total Environ. 2021, 755, 142940. [Google Scholar] [CrossRef] [PubMed]

- Tseng, C.-H.; Hsu, Y.-C.; Chen, Y.-C. System dynamics modeling of waste management, greenhouse gas emissions, and environmental costs from convenience stores. J. Clean. Prod. 2019, 239, 118006. [Google Scholar] [CrossRef]

- Sahoo, K.; Mani, S. Economic and environmental impacts of an integrated-state anaerobic digestion system to produce compressed natural gas from organic wastes and energy crops. Renew. Sustain. Energy Rev. 2019, 115, 109354. [Google Scholar] [CrossRef]

- Lu, F.; Zhu, Y.; Pan, M.; Li, C.; Yin, J.; Huang, F. Thermodynamic, economic, and environmental analysis of new combined power and space cooling system for waste heat recovery in waste-to-energy plant. Energy Convers. Manag. 2020, 226, 113511. [Google Scholar] [CrossRef]

- Yaman, C.; Anil, I.; Alagha, O. Potential for greenhouse gas reduction and energy recovery from MSW through different waste management technologies. J. Clean. Prod. 2020, 264, 121432. [Google Scholar] [CrossRef]

- Chen, Y.-C. Evaluating greenhouse gas emissions and energy recovery from municipal and industrial solid waste using waste-to-energy technology. J. Clean. Prod. 2018, 192, 262–269. [Google Scholar] [CrossRef]

- Yuan, X.; Fan, X.; Liang, J.; Liu, M.; Teng, Y.; Ma, Q.; Wang, Q.; Mu, R.; Zuo, J. Public Perception towards Waste-to-Energy as a Waste Management Strategy: A Case from Shandong, China. Int. J. Environ. Res. Public Health 2019, 16, 2997. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Che, Y.; Yang, K.; Tao, Y. Risk perception and public acceptance toward a highly protested Waste-to-Energy facility. Waste Manag. 2016, 48, 528–539. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Yu, L.; Ma, G.; Mi, H.; Jiao, Y. Residents’ acceptance towards waste-to-energy facilities: Formation, diffusion and policy implications. J. Clean. Prod. 2020, 287, 125560. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Hao, Y.; Zhang, Y. Does public opinion affect air quality? Evidence based on the monthly data of 109 pre-fecture- level cities in China. Energy Policy 2018, 116, 299–311. [Google Scholar] [CrossRef]

- Pandyaswargo, A.H.; Gamaralalage, P.J.D.; Liu, C.; Knaus, M.; Onoda, H.; Mahichi, F.; Guo, Y. Challenges and An Implementation Framework for Sustainable Municipal Organic Waste Management Using Biogas Technology in Emerging Asian Countries. Sustainability 2019, 11, 6331. [Google Scholar] [CrossRef]

- Republic of Slovenia, Government of the Republic of Slovenia. Waste Management Program and Waste Prevention Program of the Republic of Slovenia; Official Journal RS nr. 35402-1/2016/6; Government of the Republic of Slovenia: Ljubljana, Slovenia, 2016.

- Tabasová, A.; Kropáč, J.; Kermes, V.; Nemet, A.; Stehlík, P. Waste-to-energy technologies: Impact on environment. Energy 2012, 44, 146–155. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Waste to energy—Key element for sustainable waste management. Waste Manag. 2015, 37, 3–12. [Google Scholar] [CrossRef]

- GOV UK; Department for Environment Food & Rural Affairs DEFRA. Advanced Biological Treatment of Municipal Solid Waste; DEFRA: London, UK, 2013.

- Suparmaniam, U.; Lam, M.K.; Uemura, Y.; Lim, J.W.; Lee, K.T.; Shuit, S.H. Insights into the microalgae cultivation technology and harvesting process for biofuel production: A review. Renew. Sustain. Energy Rev. 2019, 115, 109361. [Google Scholar] [CrossRef]

- Mat Aron, N.S.; Khoo, K.S.; Chew, K.W.; Show, P.L.; Chen, W.; Nguyen, T.H.P. Sustainability of the four generations of biofuels–A review. Int. J. Energy Res. 2020, 44, 9266–9282. [Google Scholar] [CrossRef]

- Alalwan, H.A.; Alminshid, A.; Aljaafari, H.A. Promising evolution of biofuel generations. Subject review. Renew. Energy Focus 2019, 28, 127–139. [Google Scholar] [CrossRef]

- Ganguly, P.; Sarkhel, R.; Das, P. The Second- and Third-Generation Biofuel Technologies: Comparative Perspectives. In Sustainable Fuel Technologies Handbook; Elsevier: Amsterdam, The Netherlands, 2020; pp. 29–50. [Google Scholar] [CrossRef]

- Thompson, P.B. The Agricultural Ethics of Biofuels: The Food vs. Fuel Debate. Agriculture 2012, 2, 339–358. [Google Scholar] [CrossRef]

- Žalec, D.; Hanak, D.P.; Može, M.; Golobič, I. Process development and performance assessment of flexible calcium looping biomass gasification for production of renewable gas with adjustable composition. Int. J. Energy Res. 2021. [Google Scholar] [CrossRef]

- Arriola, F.M.; Kumar, M.; Furumai, H.; Chaminda, T. Resilience, Response, and Risk in Water Systems, 1st ed.; Springer: Singapore, 2020. [Google Scholar]

- Rhyner, C.R.; Schwartz, L.J.; Wenger, R.B.; Kohrell, M.G. Waste Management and Resource Recovery; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Global Methane Initiative. Municipal Wastewater Methane: Reducing Emissions, Advancing Recovery and Use Oppor-Tunities. 2013. Available online: www.globalmethane.org (accessed on 2 February 2021).

- Kamperidou, V.; Terzopoulou, P. Anaerobic Digestion of Lignocellulosic Waste Materials. Sustainability 2021, 13, 12810. [Google Scholar] [CrossRef]

- Ahn, J.-Y.; Chang, S.W. Effects of Sludge Concentration and Disintegration/Solubilization Pretreatment Methods on Increasing Anaerobic Biodegradation Efficiency and Biogas Production. Sustainability 2021, 13, 12887. [Google Scholar] [CrossRef]

- Sara Tanigawa Environmental and Energy Study Institute. Fact Sheet-Biogas: Converting Waste to Energy. Available online: https://www.eesi.org/papers/view/fact-sheet-biogasconverting-waste-to-energy/ (accessed on 9 September 2020).

- Vögeli, Y.; Lohri, C.R.; Gallardo, A.; Diener, S.; Zurbrügg, C. Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies; Swiss Federal Institute of Aquatic Science and Technology: Dübendorf, Switzerland, 2014. [Google Scholar]

- Kiran, E.U.; Stamatelatou, K.; Antonopoulou, G.L. Handbook of Biofuels Production: Processes and Technologies. Production of Biogas via Anaerobic Digestion, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Hitachi Zosen Inova AG. References: Anaerobic Digestion. Available online: https://www.hz-inova.com/references/ (accessed on 10 January 2022).

- La Fondation d’enterprise TotalEnergies, Planete Energies. How Does an Anaerobic Digester Work. Available online: https://www.planete-energies.com/en/medias/close/how-does-anaerobic-digester-work (accessed on 10 November 2020).

- Berg, J.J.D. Van Effects of sewage sludge disposal. Land Degrad. Dev. 1993, 4, 407–413. [Google Scholar] [CrossRef]

- Pham, M.; Pakrasi, A. Air Pollution Control Technologies, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Patil, J.H.; Raj, M.A.; Muralidhara, P.L.; Desai, S.M.; Raju, G.K.M. Kinetics of Anaerobic Digestion of Water Hyacinth Using Poultry as Inoculum. Int. J. Environ. Sci. Dev. 2012, 3, 94–98. [Google Scholar] [CrossRef]

- Hu, H.Y.Z. Anaerobic digestion of cattail by rumen cultures. Waste Manag. 2006, 26, 1222–1228. [Google Scholar] [CrossRef]

- Chusov, A.; Maslikov, V.; Badenko, V.; Zhazhkov, V.; Molodtsov, D.; Pavlushkina, Y. Biogas Potential Assessment of the Composite Mixture from Duckweed Biomass. Sustainability 2022, 14, 351. [Google Scholar] [CrossRef]

- Nachod, B.; Keller, E.; Hassanein, A.; Lansing, S. Assessment of Petroleum-Based Plastic and Bioplastics Degradation Using Anaerobic Digestion. Sustainability 2021, 13, 13295. [Google Scholar] [CrossRef]

- Oehmichen, K.; Majer, S.; Thran, D. Biomethane from Manure, Agricultural Residues and Biowaste—GHG Mitigation Potential from Residue-Based Biomethane in the European Transport Sector. Sustainability 2021, 13, 14007. [Google Scholar] [CrossRef]

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A Review of Biogas Utilisation, Purification and Upgrading Technologies. Waste Biomass Valorization 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Maile, O.I.; Muzenda, E.; Tesfagiorgis, H. Chemical Absorption of Carbon Dioxide in Biogas Purification. Procedia Manuf. 2017, 7, 639–646. [Google Scholar] [CrossRef]

- Ohioline The Ohio State University. Biogas Cleaning and Upgrading Technologies. Available online: https://ohioline.osu.edu/factsheet/AEX-653.1-14 (accessed on 10 November 2020).

- Ministry of Economic Affairs and Climate Policy. Integrated National Energy and Climate Plan, The Netherlands. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/nl_final_necp_main_en.pdf (accessed on 10 January 2022).

- Sardi, K.; De Vita, A.; Capros, P.; European Commission, Directorate-General for Energy. The Role of Gas Dsos and Distribution Networks in the Context of the Energy Transition; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- International Energy Agency. The Netherlands 2020, Energy Policy Review. Available online: https://www.connaissancedesenergies.org/sites/default/files/pdf-actualites/The_Netherlands_2020_Energy_Policy_Review.pdf (accessed on 10 January 2022).

- Republic of Slovenia, Government of the Republic Slovenia. Comprehensive National Energy and Climate Plan of The Republic of Slovenia. Available online: https://www.energetika-portal.si/fileadmin/dokumenti/publikacije/nepn/dokumenti/nepn_5.0_final_feb-2020.pdf (accessed on 22 March 2020).

- Ministry of Economic Development; Ministry of the Environment and Protection of Natural Resources and the Sea; Ministry of Infrastructure and Transport. Integrated National Energy and Climate Plan of Italy. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/it_final_necp_main_en.pdf (accessed on 16 March 2020).

- Federal Ministry Republic of Austria, Sustainability and Tourism. Integrated National Energy and Climate Plan for Austria. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/at_final_necp_main_en.pdf (accessed on 9 November 2020).

- Regeringen, The Ministry of Infrastructure. Sweden’s Integrated National Energy and Climate Plan. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/se_final_necp_main_en.pdf (accessed on 22 March 2020).

- Danish Ministry of Climate, Energy and Utilities. Denmark’s Integrated National Energy and Climate Plan. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/dk_final_necp_main_en.pdf (accessed on 22 March 2020).

- Slovenia, Ministry of Infrastructure of the Republic of Slovenia. Energy Portal. Available online: https://www.energetika-portal.si/statistika/ (accessed on 31 March 2020).

- Zheng, L. What Could China Give to and Take from Other Countries in Terms of the Development of the Biogas Industry? Sustainability 2020, 12, 1490. [Google Scholar] [CrossRef]

- Jain, S.; World Biogas Association. Global Potential of Biogas. Available online: https://www.worldbiogasassociation.org/wp-content/uploads/2019/09/WBA-globalreport-56ppa4_digital-Sept-2019.pdf (accessed on 11 February 2021).

- Republic of Slovenia, Ministry of the Environment and Spatial Planning, Slovenian Environment Agency. List of Landfills in the Republic of Slovenia and Their Status at 28 February 2020. 2020. Available online: https://www.gov.si/assets/organi-v-sestavi/ARSO/Odpadki/Podatki/Upravljalci-odlagalisc.pdf/ (accessed on 2 February 2021).

- Republic of Slovenia, Ministry of Public Administration. Records of Processors of Biodegradable Waste into Compost. 2019. Available online: https://www.gov.si/podrocja/okolje-in-prostor/okolje/ravnanje-z-odpadki/ (accessed on 2 February 2021).

- Republic of Slovenia, Ministry of Public Administration. Records of Operators of Waste Incineration Plants and Waste Co-Incineration Plants. 2019. Available online: https://podatki.gov.si/dataset/evidenca-upravljavcev-naprav-za-sosezig-ali-sezigalnic/resource/85a90137-e9a2-4d54-917b-b5af6c6f2a40 (accessed on 2 February 2021).

- Hitachi Zosen INOVA AG. Reference Projects. 2021. Available online: https://www.hz-inova.com/media-downloads/ (accessed on 16 September 2020).

- Global Methane Initiative. Successful Applications of Anaerobic Digestion from Across the World. 2013. Available online: https://www.globalmethane.org/documents/gmibenefitsreport.pdf (accessed on 2 February 2021).

- Weltec Biopower GMBH. Biogas Plants. 2016. Available online: https://www.weltec-biopower.com/en/references/reference-sheets.html (accessed on 2 February 2021).

- HOST Holding, B.V. Bio- Energy Installations. Biogas Plants, Renewable Energy from Anaerobic Digestion of Organic Waste. 2021. Available online: https://www.host.nl/en/biogas-plants/ (accessed on 2 February 2021).

- Ultrawaves. Installation List- Biogas Plants, Installations on Food Waste Biogas Plants and Farmland Biogas Plants. 2018. Available online: https://ultrawaves.de/biogas-plants (accessed on 2 February 2021).

- Veolia. Insights from Veolia Water Technologies, Innovative Water Solutions. 2022. Available online: https://www.veoliawatertechnologies.com/sites/g/files/dvc2476/files/document/2021/05/VeoliaWaterTech_WaveMagazine_2021_Hubgrade.pdf (accessed on 2 February 2021).

- European Biogas Association. European Biomethane Map. 2018. Available online: https://www.gie.eu/download/maps/2018/GIE_BIO_2018_A0_1189x841.pdf (accessed on 2 February 2021).

- Global Methane Initiative. Watewater Treatment Plants. 2013. Available online: https://www.globalmethane.org/documents/ww_fs_eng.pdf (accessed on 2 February 2021).

- Strabag Umwelttechnik GmbH. References Biogas Plants. 2016. Available online: https://www.strabag.com/databases/internet/_public/files.nsf/aee78406ed324031c1257f720047de11/35f50bf5a234e070c125802c00429b5a/$FILE/Refliste_Biogas_e.pdf (accessed on 2 February 2021).

- Waterleau. Anaerobic Digestion: Energy Recovery from Bioeffluent, Sludge and Mixed Organic Waste. 2020. Available online: https://www.waterleau.com/files/Anaerobic_digestion.pdf (accessed on 16 September 2020).

- EPA 456-R-20-001, An Overview of Renewable Natural Gas from Biogas. 2020. Available online: https://www.epa.gov/sites/production/files/2020-07/documents/lmop_rng_document.pdf (accessed on 11 February 2021).

- Government of India, Ministry of New and Renewable Energy. Bio Energy, Bio Mass Overview. 2020. Available online: https://mnre.gov.in/bio-energy/current-status (accessed on 11 February 2021).

- Enea Consulting, Bioenergy Australia. Biogas Opportunities of Australia. 2019. Available online: https://www.enea-consulting.com/en/publication/biogas-opportunities-for-australia/ (accessed on 11 February 2021).

- ABiogas, Associacao Brasileira do Biogas. Changing the World through Biogas. 2020. Available online: https://www.worldbiogasassociation.org/wp-content/uploads/2020/06/ABIOGÁS_Webinar-WBA.pdf (accessed on 11 February 2021).

- Ministry of Foreign Affairs, Netherlands Enterprise Agency. Marchket Research: Biogas and Biomethane Current Stage and Opportunities for Dutch Companies in Brazil. 2019. Available online: https://www.rvo.nl/sites/default/files/2019/12/Marchket_Study_Report_NBSO_EN_20191202.pdf (accessed on 11 February 2021).

- Tonrangklang, P.; Therdyothin, A.; Preechawuttipong, I. Overview of Biogas Production Potential from Industry Sector to Produce Compressed Bio-Methane Gas in Thailand. Energy Procedia 2017, 138, 919–924. [Google Scholar] [CrossRef]

- Federal Ministry for Economic Affairs and Energy. Thailand: Biogas Policy Update 12/2015. 2015. Available online: https://www.thai-german-cooperation.info/admin/uploads/publication/61c41993cd0d31b62f9e712b1bb96151en.pdf (accessed on 11 February 2021).

- EnviTec Biogas AG. Biogas, Agricultural Biogas Plants. 2022. Available online: https://www.envitec-biogas.com/biogas (accessed on 10 November 2020).

- World Biogas Association; Jain, S. Marchket Report: Japan. 2021. Available online: http://epower.pw/wp-content/themes/epower/img/WBA-japan-4ppa4.pdf (accessed on 11 February 2021).

- Canadian Biogas Association. Current Status and Future Potential of Biogas Production from Canada’s Agriculture and Agri-Food Sector. 2018. Available online: https://biogasassociation.ca/index.php/resources/canadian_agricultural_biogas_study (accessed on 11 February 2021).

- EPA, United States Environmental Protection Agency. Projects & Opportunities. AgSTAR Data and Trends. 2021. Available online: https://www.epa.gov/agstar/agstar-data-and-trends (accessed on 11 February 2021).

- WBA, World Biogas Association. Anaerobic Digestion Marchket Report: The Netherlands. 2019. Available online: http://www.worldbiogasassociation.org/wp-content/uploads/2018/07/The-Netherlands-International-Marchket-Report.pdf (accessed on 11 February 2021).

- IEA Bioenergy, IEA Energy Technology Network. Task 37-Energy from Biogas, Biogas Country Overview (Country Reports). 2014. Available online: http://task37.ieabioenergy.com/files/member-upload/Countryreportsummary2013.pdf (accessed on 11 February 2021).

- IEA Bioenergy, Technology Collaboration Programme, University College Cork. Country Reports Summary 2017. 2018. Available online: https://www.ieabioenergy.com/blog/publications/iea-bioenergy-task-37-country-report-summaries-2017/ (accessed on 11 February 2021).

- IEA Bioenergy; Theobald, O.; French Agency for Environment and Energy Management. Task 37-France Country Report. 2015. Available online: http://task37.ieabioenergy.com/files/daten-redaktion/download/publications/country-reports/2015/France_Country_Report_Berlin_10-2015.pdf (accessed on 11 February 2021).

- Nordic Council of Ministers. BAT in Smaller Biogas Plants in the Nordic Countries. 2020. Available online: https://norden.diva-portal.org/smash/get/diva2:1477056/FULLTEXT01.pdf (accessed on 11 February 2021).

- Lybaek, R.; University of Roskilde, Institute of Human and Technology. The Danish Biogas Sector-Biogas Technology & Policies & Way Forward. 2020. Available online: https://www.maff.go.jp/primaff/koho/seminar/2016/attach/pdf/170111_01.pdf (accessed on 11 February 2021).

- Kirchmeyr, F.; Austrian Compost; Biogas Association; Biosurf, Fueling Biomethane. Biogas Report from Austria: Possible Phase out of FIT and Perspectives How to Proceed. 2017. Available online: http://www.biosurf.eu/wordpress/wp-content/uploads/2015/06/Trebon-VPBPS_2017_13_ARGE_Kirchmeyr.pdf (accessed on 11 February 2021).

- BIOVOIMA. Biogas Plant- from Organic Waste and Side Streams to Income. 2019. Available online: https://biovoima.com/en/solutions/biogas-plant (accessed on 10 November 2021).

| Advantages | Disadvantages |

|---|---|

| Less heat released, resulting in lower and less efficient destruction of pathogens as in aerobic composting |

| Unsuitable for waste containing less organic matter |

| Requirement for waste separation to improve decommissioning efficiency |

| Pretreatment is essential |

| Temperature sensitivity |

| Post-processing is required |

| 2–4 months of start-up time |

| |

| |

| |

| |

| |

| |

| |

|

| Country | Biogas Producer’s Tasks | TSO’s Tasks |

|---|---|---|

| Austria | Biogas producers are responsible for maintaining gas quality in accordance with the requirements. | - |

| Czech Republic | Biogas producers are responsible for maintaining gas quality in accordance with the requirements. | - |

| Denmark | The biogas producers operate the upgrading plants that make biomethane from biogas. | TSO operates the injection plants, including gas compression. |

| France | The upgrading of biogas to biomethane is handled by the biogas producers. | The TSO is responsible for the operation and the maintenance of the connection facilities and monitors the quality of the biomethane before injection. |

| Germany | A biomethane plant owner who wants to inject into the network is responsible for gas quality. | - |

| Italy | The owner of the biomethane plant is responsible for complying with quality standards. | TSO can interrupt injection if the quality does not meet the requirements. |

| Spain | The biomethane producer is responsible for meeting gas quality standards for injection. | - |

| Sweden | The biomethane producer operates the gas quality upgrading facility. | TSO operates the injection facility. |

| Netherlands | Producer’s tasks are odourisation, compliance with quality specifications, pressure and ability for odourisation according to standards. Investment and operational costs are producer’s tasks. | Gas must be injected according to the requirements of the DSO. System operator’s tasks are safety and technical efficiency of the network. TSO and DSOs are responsible for operating and maintaining the gas network. |

| Country | Biogas Producer | DSO or TSO |

|---|---|---|

| Denmark | - | The obligation to provide a connection is for both the DSO and the TSO, with the cost distribution and the determination of connection point being regulated by the natural gas act. |

| France | - | Network operators are obliged to provide a biomethane connection point (at DSO or TSO levels) in cases where the cost of this connection is below a given threshold. |

| Germany | The natural gas network operator is obliged to check whether it is possible to inject biomethane. | |

| Hungary | The biomethane producer must finance the necessary investment for the connection. | The technical conditions for that are defined by the TSO. |

| Italy | - | A connection point must be provided by the TSO, as long as the connection request meets the relevant technical and economic requirements. |

| Poland | - | A biomethane plant which is connected to the network must follow the rules defined by the TSO. |

| Portugal | - | Operators shall provide information about capacity available for the injection of biomethane into the network at different points, as well as provide a connection point upon request by a producer. |

| Netherlands | Since DSO is not obligated to connect, biogas producer must carry the costs. | DSO is not obligated to connect. |

| Country | Planned GHG Emission Reduction by 2030 |

|---|---|

| Austria | 36% |

| Denmark | 39% |

| Italy | 33% |

| Slovenia | 20% |

| Sweden | 20% |

| Netherlands | >40% |

| Country | Planned Share of RES in End Use by 2030 |

|---|---|

| Austria | 45–50% |

| Denmark | 55% |

| Italy | 30% |

| Slovenia | 27% |

| Sweden | 50% |

| Netherlands | 27–35% |

| Country | RES in Transport |

|---|---|

| Austria | Increasing the share of RES in transport to at least 14% with biofuels and increasing the share of e-mobility by 2030 |

| Denmark | A 55% share of RES by 2030 End of sales of new diesel and petrol cars by 2030 |

| Italy | A 21.6% share of RES in transport by 2030 A 6% reduction in GHG emissions by 2030 Incentives for biomethane and other advanced fuels |

| Slovenia | A 21% share of RES in transport (share of biofuels in transport of at least 11%) by 2030 Sustainable orientation towards the introduction of RES gases in CNG and LNG filling stations Sustainable focus on advanced biofuels and hydrogen, including change in the liquid fuel price regulation model |

| Sweden | A 27.2% share of RES in transport by 2030; the additional target share is 52% by 2040 A total 85% of public transport already used biofuels in 2018 Gas stations selling more than 1500 m3 of petrol or diesel annually are required to offer at least one type of renewable source, by law |

| Netherlands | Share of RES in transport has increased to 9.5 % from 2005 to 2018 No energy taxes for the consumption of Promotion of electro-mobility, including hydrogen and fuel cell options By 2030 all new cars will be emission free Greater use of biofuels |

| Country | Projects |

|---|---|

| Austria | Avoiding methane and carbon dioxide emissions from waste management, reducing biodegradable waste, reducing single-use plastic products and increasing the proportion of recycled municipal waste and reducing methane emissions from landfills. |

| Denmark | Improving the targets for organic food and strengthening initiatives against food waste, doubling the area under organic farming, exporting organic food, consuming organic food and implementing initiatives to reduce food waste. |

| Italy | Between 2000 and 2017, 3.5 Mt of organic waste was treated, but the number of organic waste processing plants is still increasing. An ambitious goal is to achieve 60% separate waste collection by 2030. |

| Slovenia | Promoting change in consumer patterns (pilot projects and tools to raise awareness of reuse, sharing, food waste reduction). |

| Sweden | Prohibited disposal of organic waste, landfill taxes, financial support for biogas production and anaerobic digestion processes. |

| Netherlands | Reducing the incineration and dumping of waste. Increase in biofuels, obtained from renewable residual waste. |

| Slovenia | Italy | Austria | Sweden | Denmark | Netherlands | |

|---|---|---|---|---|---|---|

| Share of biogas compared to natural gas in 2020 | 1.8% | 0% | 1.5% | 0% | 15% | - |

| The target of the share of biogas compared to natural gas in 2030 | 10% | 1% | 6.6% | No information. | 30% | - |

| Aims to upgrade biogas to biomethane, hydrogen? | No | Yes, hydrogen non-existent. | Yes, both non-existent. | No | Yes, both already existing. | Yes |

| Aims to introduce smart networks, power-to-gas? | No | Yes | Yes | Yes | Yes | Yes |

| Location | Company | Year | Type of Waste | Amount of Waste Conversion | Biogas Production | Ref. |

|---|---|---|---|---|---|---|

| Denmark, Hamburg | Hitachi Zosen INOVA | 2019 | SE | - | 930 Nm3/h | [120] |

| Italy, Bresso | - | 2019 | SE | - | 120 Nm3/h | [121] |

| Spain, Madrid | - | 2019 | SE | - | 50 Nm3/h | [121] |

| Netherlands, Den Hoorn | - | 2019 | SE | - | 720 Nm3/h | [121] |

| France, Marseille | - | 2019 | SE | - | 296 Nm3/h | [121] |

| France, Frejus | - | 2019 | SE | - | 107 Nm3/h | [122] |

| Ireland, Youghal | HoSt | 2018 | SE | 16,000 PE | - | [123] |

| Hungary, Zalaegerszeg | - | 2018 | SE | - | 50 Nm3/h | [121] |

| Estonia, Kunda | - | 2018 | SE | - | 550 Nm3/h | [121] |

| Germany, Bad Lippspringe | Ultrawaves | 2018 | SE | 30,000 PE | - | [124] |

| Germany, Delbruck | Ultrawaves | 2018 | SE | 54,000 PE | - | [124] |

| Germany, Hanau | Ultrawaves | 2018 | SE | 180,000 PE | - | [124] |

| Germany, Loddenbach | Ultrawaves | 2018 | SE | 45,000 PE | - | [124] |

| Germany, Nordhausen | Ultrawaves | 2018 | SE | 100,000 PE | - | [124] |

| Israel, Netanya | Ultrawaves | 2018 | SE | 260,000 PE | - | [124] |

| Germany, Magdeburg- Gerwisch | Ultrawaves | 2017 | SE | 430,000 PE | - | [124] |

| Switzerland, Uetendorf | - | 2017 | SE | - | 1000 Nm3/h | |

| Switzerland, Niedergösgen | Hitachi Zosen INOVA | 2017 | SE | - | 280 Nm3/h | [120] |

| Switzerland, Thun | Hitachi Zosen INOVA | 2017 | SE | - | 130 Nm3/h | [120] |

| Germany, Bad Kreuznach | Ultrawaves | 2017 | SE | 110,000 PE | - | [124] |

| Germany, Rheda- Wiedenbruck | Ultrawaves | 2017 | SE | 100,000 PE | - | [124] |

| Germany, Gera | Veolia | 2017 | SE | 200,000 PE | - | [125] |

| Germany, Burgebrach | Weltec BP | 2016 | SE | 13,000 PE | - | [122] |

| Germany, Heide | Ultrawaves | 2016 | SE | 40,000 PE | - | [124] |

| United Kingdom, Southport | Ultrawaves | 2016 | SE | 90,000 PE | - | [124] |

| Germany, Trier | Ultrawaves | 2015 | SE | 170,000 PE | - | [124] |

| Romania, Danutoni | Ultrawaves | 2015 | SE | 130,000 PE | - | [124] |

| Romania, Targu Secuiesc | Ultrawaves | 2015 | SE | 25,000 PE | - | [124] |

| Germany, Leinetal | Ultrawaves | 2015 | SE | 55,000 PE | - | [124] |

| Germany, Ratheim | Ultrawaves | 2014 | SE | 45,000 PE | - | [124] |

| UAE, Dubai | Ultrawaves | 2015 | SE | 1,100,000 PE | - | [124] |

| USA, Marengo | Ultrawaves | 2014 | SE | 10,000 PE | - | [124] |

| Germany, Ratzeburg | Ultrawaves | 2014 | SE | 34,000 PE | - | [124] |

| Switzerland, Zuchwil | Hitachi Zosen INOVA | 2014 | SE | - | 130 Nm3/h | [120] |

| Poland, Skarzysko | Ultrawaves | 2014 | SE | 65,000 PE | - | [124] |

| Netherlands, Assen | HoSt | 2013 | SE | - | 40 Nm3/h | [123] |

| USA, Akron | - | 2013 | SE | 330,000 PE | - | [126] |

| Brazil, Sabara | - | 2012 | SE | 1,944,000 PE | - | [127] |

| Hungary, Erd | Weltec BP | 2012 | SE | 33,000 PE | - | [122] |

| Finland, Espoo | - | 2012 | SE | - | 450 Nm3/h | [121] |

| Germany, Bargteheide | Ultrawaves | 2012 | SE | 34,500 PE | - | [124] |

| Denmark, Sondeborg | Ultrawaves | 2012 | SE | 80,000 PE | - | [124] |

| Spain, Tomelloso | Ultrawaves | 2012 | SE | 200,000 PE | - | [124] |

| France, Chebourg | Ultrawaves | 2011 | SE | 230,000 PE | - | [124] |

| France, St. Nazaire | Ultrawaves | 2011 | SE | 200,000 PE | - | [124] |

| Germany, Schleswig | Ultrawaves | 2011 | SE | 60,000 PE | - | [124] |

| Hungary, Zalaegerszeg | - | 2011 | SE | - | 42 Nm3/h | [121] |

| Germany, Hochst | - | 2011 | SE | - | 825 Nm3/h | [121] |

| Germany, Hamburg | - | 2011 | SE | - | 275 Nm3/h | [121] |

| Germany, Jockgrim | Ultrawaves | 2011 | SE | 21,000 PE | - | [124] |

| Ireland, Shanganagh | Ultrawaves | 2011 | SE | 186,000 PE | - | [124] |

| Poland, Bytom | Ultrawaves | 2011 | SE | 175,000 PE | - | [124] |

| Poland, Kielce | Ultrawaves | 2011 | SE | 350,000 PE | - | [124] |

| Chile, Santiago | - | 2011 | WW | 3,200,000 PE | - | [121] |

| Taiwan, Dan- Shui | Ultrawaves | 2011 | SE | 5,000,000 PE | - | [124] |

| China, Wuxi | Weltec Biopower | 2010 | AF, CR, SE | - | - | [122] |

| Brazil, Arrudas | Ultrawaves | 2010 | SE | 2,000,000 PE | - | [124] |

| Romania, Iasi | Strabag | 2010 | SE | 6,264,000 PE | - | [128] |

| France, Lille Marquette | Strabag | 2010 | SE | - | - | [128] |

| Germany, Kleinsteinbach | Ultrawaves | 2010 | SE | 40,000 PE | - | [85] |

| Austria, Asten/Linz | - | 2010 | SE | - | 450 m3/h | [126] |

| Hungary, Szombathely | Ultrawaves | 2010 | SE | 80,000 PE | - | [124] |

| Poland, Glogow | Ultrawaves | 2010 | SE | 150,000 PE | - | [124] |

| Spain, Montornes | Ultrawaves | 2010 | SE | 100,000 PE | - | [124] |

| Germany, Ahrensburg | Ultrawaves | 2009 | SE | 50,000 PE | - | [124] |

| Netherlands, Veendam | HoSt | 2009 | SE | - | - | [123] |

| United Kingdom, Mauri Hull | Waterleau | 2009 | IFW | - | 598 Nm3/h | [123] |

| Norway, Oslo | - | 2009 | SE | - | 375 Nm3/h | [126] |

| Spain, Tablada | Ultrawaves | 2009 | SE | 200,000 PE | - | [124] |

| Spain, San Jeronimo | Ultrawaves | 2008 | SE | 275,000 PE | - | [124] |

| Spain, La Gavia | Ultrawaves | 2008 | SE | 268,000 PE | - | [124] |

| Poland, Slupsk | Ultrawaves | 2008 | SE | 250,000 PE | - | [124] |

| Poland, Babrowa- Gornicza | Ultrawaves | 2008 | SE | 200,000 PE | - | [124] |

| Hungary, Zalaergerszeg | Ultrawaves | 2008 | SE | 60,000 PE | - | [124] |

| Spain, Lorqui | Ultrawaves | 2007 | SE | 50,000 PE | - | [124] |

| Germany, Braunschweig | Veolia | 2007 | SE | 275,000 PE | 1104 Nm3/h | [125] |

| Sweden, Goteborg | - | 2007 | SE | - | 1000 Nm3/h | [126] |

| Greece, Psyttalia | Ultrawaves | 2007 | SE | 5,000,000 PE | - | [124] |

| Germany, Bunde | Ultrawaves | 2007 | SE | 54,000 PE | - | [124] |

| Denmark, Marselisborg- Arhus | Ultrawaves | 2006 | SE | 220,000 PE | - | [124] |

| Denmark, Frederikshavn | Ultrawaves | 2006 | SE | 130,000 PE | - | [124] |

| Netherlands, Nieuwgraaf | Ultrawaves | 2006 | SE | 440,000 PE | - | [124] |

| Netherlands, Willem- Annapolder | Ultrawaves | 2006 | SE | 55,000 PE | - | [124] |

| Korea, Gang- Byeun | Ultrawaves | 2006 | SE | 1,500,000 PE | - | [124] |

| Germany, Meldorf | Ultrawaves | 2005 | SE | 72,000 PE | - | [124] |

| Germany, Bamberg | Ultrawaves | 2004 | SE | 230,000 PE | - | [124] |

| Germany, Stavenhagen | Strabag | 2003 | SE | - | - | [128] |

| China, Haikou | Strabag | 2002 | SE | - | - | [128] |

| Netherlands, Zeist | Ultrawaves | 2000 | SE | 75,000 PE | - | [124] |

| China, Yantai | Strabag | 2000 | SE | - | - | [128] |

| Vietnam | - | 1999 | WW | - | - | [126] |

| Hungary, North Pest | Veolia | - | SE | 200,000 PE | - | [125] |

| Germany, Bitterfeld | Waterleau | - | CIW | - | 433 Nm3/h | [129] |

| Spain (Heineken) | Waterleau | - | BP | - | 400 Nm3/h | [129] |

| France, Tereos | Waterleau | - | IFW | - | 1083 Nm3/h | [129] |

| Netherlands (Heineken) | Waterleau | - | BP | - | 163 Nm3/h | [129] |

| Belgium, (Claerebout Waesten) | Waterleau | - | IFW, AR, CR | - | 475 Nm3/h | [129] |

| Ghana (Diageo Kumasi) | Waterleau | - | BP | - | 133 Nm3/h | [129] |

| Togo (Castel) | Waterleau | - | BP | - | 108 Nm3/h | [129] |

| Morocco, Marrakech | Waterleau | - | SE | - | 750 Nm3/h | [129] |

| Morocco, Fez | Waterleau | - | SE | - | 1200 Nm3/h | [129] |

| India | - | - | WW | 8300 PE | 0.5 Nm3/h | [126] |

| Ghana (Diageo Kumasi) | Waterleau | - | BP | - | 133 Nm3/h | [129] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zupančič, M.; Možic, V.; Može, M.; Cimerman, F.; Golobič, I. Current Status and Review of Waste-to-Biogas Conversion for Selected European Countries and Worldwide. Sustainability 2022, 14, 1823. https://doi.org/10.3390/su14031823

Zupančič M, Možic V, Može M, Cimerman F, Golobič I. Current Status and Review of Waste-to-Biogas Conversion for Selected European Countries and Worldwide. Sustainability. 2022; 14(3):1823. https://doi.org/10.3390/su14031823

Chicago/Turabian StyleZupančič, Matevž, Valerija Možic, Matic Može, Franc Cimerman, and Iztok Golobič. 2022. "Current Status and Review of Waste-to-Biogas Conversion for Selected European Countries and Worldwide" Sustainability 14, no. 3: 1823. https://doi.org/10.3390/su14031823

APA StyleZupančič, M., Možic, V., Može, M., Cimerman, F., & Golobič, I. (2022). Current Status and Review of Waste-to-Biogas Conversion for Selected European Countries and Worldwide. Sustainability, 14(3), 1823. https://doi.org/10.3390/su14031823