1. Introduction

Colombia has been recognized as a country with high potential for the agricultural sector. The department of Tolima, located in the middle of the country, is an area that has a tradition of growing horticultural crops and is also known as an agricultural breadbasket [

1]. Although it is a high-growing cultivation area, this region has a gap with other departments in food processing methods due to low incomes in the rural sector, the high costs of the required technology, and the lack of access to electricity [

2]. Local governments have identified the importance of the agricultural sector and focused on prioritizing strategies that could improve the income of farmers and their quality of life. However, it is sometimes difficult to define local government resource distributions and focus on increasing crop productivity [

3], excluding food processing alternatives that could lead to better incomes. Moreover, local fruit markets are often overcrowded during periods of full production and a large amount of food waste occurs. The recurring failure is because local farmers do not have a process for their fresh produce that can extend the shelf-life for future consumption, especially during the off-season.

Drying is one of the oldest and most popular alternatives of food preservation. It removes water from the food, which ensures stability of the product and minimizes chemical and physical changes [

4]. There are different drying methods: natural sun, solar tunnel, mechanical cabinet, freeze-drying, and oven-drying, among others. The selection of the drying technique is influenced by different factors. One of the most important factors for small farmers or home entrepreneurs are implementation costs. Oven-drying, microwave-vacuum drying, and freeze-drying methods involve dehydrating processes under controlled temperatures, along with controlled humidity and pressure conditions. These processes are expensive due to high-energy demands and are not widely implemented by small farmers in Colombia. Therefore, solar drying becomes the best alternative for these communities [

5].

Open sun drying is often differentiated from solar drying because it uses equipment to collect radiation from the sun to harness radioactive energy for drying applications. Open sun drying is one of the cheaper solar drying techniques; despite the advantages of open sun drying, it is well known that this method is susceptible to cross-contamination or excessive drying of food that compromise sensory quality attributes and nutritional composition of products. For these reasons, solar dryers are more cost-effective than other drying techniques and are sustainable due the use of renewable solar energy which is free. Moreover, Mohammed et al. (2020) found higher organoleptic quality of dry fruits in the conventional solar dryer, which consists of a greenhouse type of tunnel drying [

6].

Considering the cost-effective implementation and final product quality characteristics, solar drying is a good alternative for low-income communities. Among these communities are displaced people who reach a new destination searching for safety and stability to improve their quality of life. Colombia has one of the largest displaced populations in the world, where more than 10% of the population has been forced to migrate due to civil war. Forced displacement results in social and economic costs for migrants who are in worse conditions compared to the urban poor of the destination [

7]. The disadvantages associated with forced displacement have largely fallen on the vulnerable groups of the population, especially women and children who constitute 41% and 36% of this population, respectively. The Colombian government initiated a legal process of land restitution by which government institutions would assist internally displaced people with the aim of returning to the countryside and earn a living from agriculture. However, as the claim for restitution of lost land began, it became clear that the process would be more complex. Therefore, the current number of restitution claimants (17%) was considerably lower than the estimated families that have moved [

8]. Fear related to the current inhabitants and the possibility of reopening past experiences and bad memories that are often related to land is the reason for the low demand for potential claimants [

9].

Since forcibly displaced people are looking for new alternatives to improve their living standards based on family activities, such as agriculture, the implementation of the solar dehydrator represents an economic, social, and environmentally sustainable is an option to achieve this objective; moreover, although this kind of solar dehydration device is popular in other countries, in Colombia, most drying products are obtained from gas ovens and solar dryers are homemade. This study focuses on two main factors: the results of the mango dehydration process (Mangifera indica L.) with solar dehydration and the importance of project implementation in vulnerable communities, such as women.

2. Project Contextualization

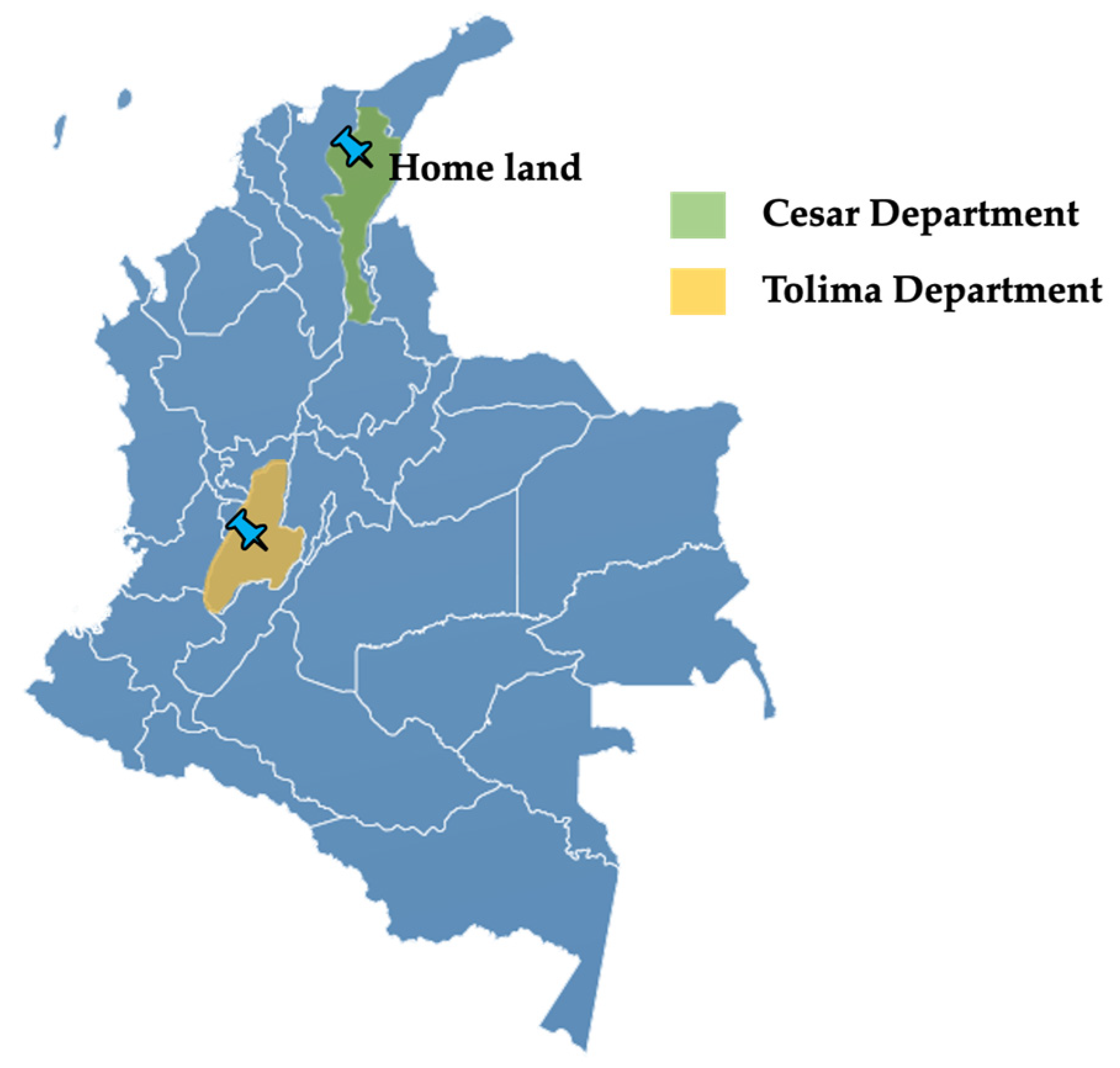

In 1994, due to the armed conflict in Colombia, large numbers of families in the Northern region were forced to leave their lands. Fifty-two of these families were placed on a big farm near Ibague in the department of Tolima in Central Colombia in Magdalena Valley (

Figure 1). This farm had been used for the extensive production of cane crops. Because of this, it has been named

La Miel (Honey) in reference to its sugar cane production. However, when those families arrived there, it was uncultivated land with no public services.

Since these families arrived, they have created a community group and dedicated most of their land to growing different crops to obtain income to live. Today, this community is a great example due to its progress and organization. Although the current conditions of this community are not optimal, they have experienced positive changes compared to when they arrived. This community is still pursuing opportunities to advance, nonetheless [

10]. In the search of opportunities, the community of

La Miel has been selected for the development of cooperation projects where international governments have implemented activities focused on improving the quality of life of people in developing countries. The project involves teaching the technique of solar dehydration to women with the aim to promote their autonomy and enhance their living conditions. Following a selection process with more than 30 women from the community of

La Miel, we selected 7 unemployed heads of family [

11,

12].

3. Materials and Methods

3.1. Dehydration Plant Description

The dehydration plant was designed and installed on flat land located in

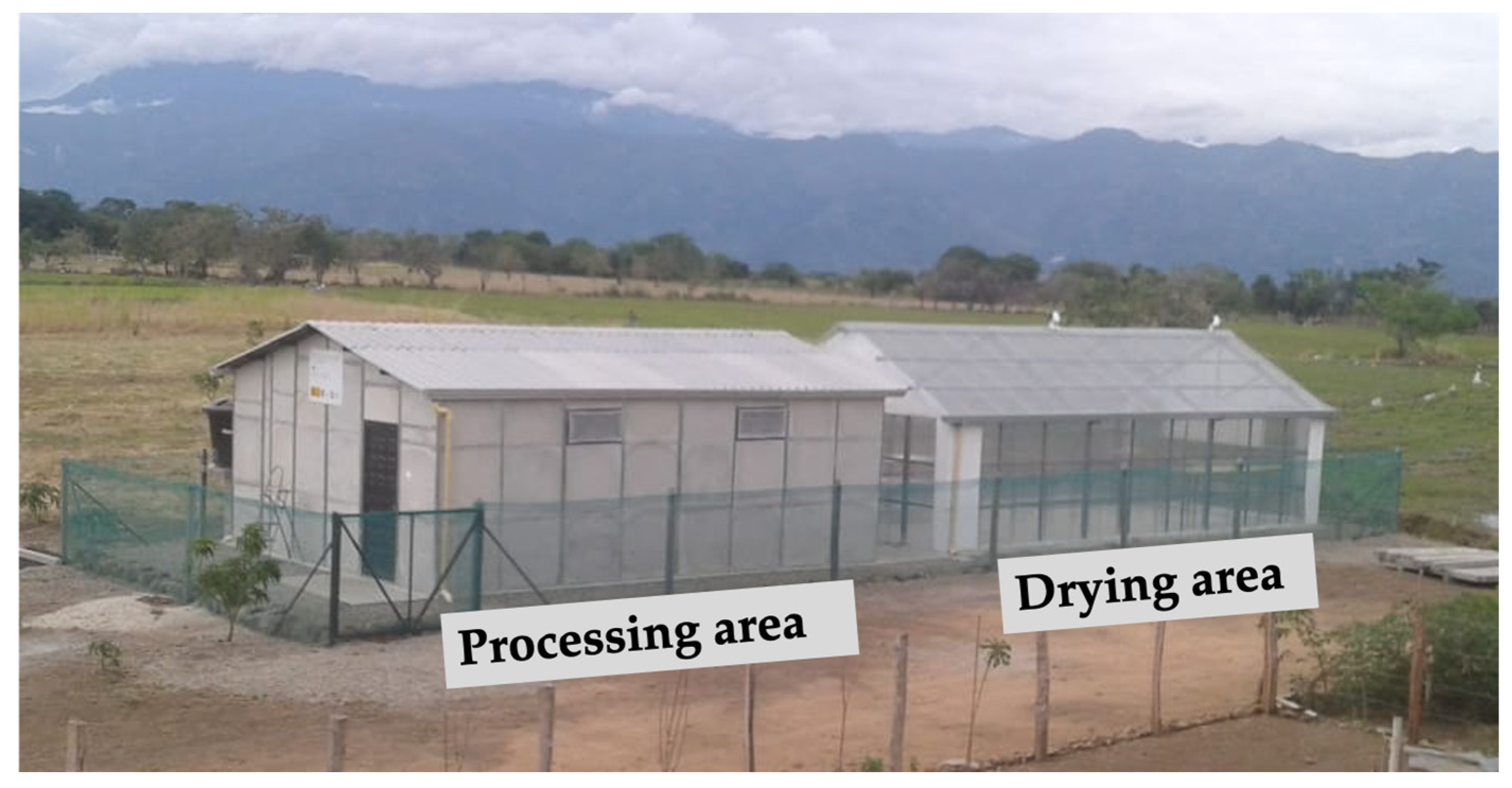

La Miel near the city of Ibagué, Colombia (425′59″ N, 75.13′1″ W). The construction consists of two sections, to secure both a food processing and a drying area, as is shown in

Figure 2.

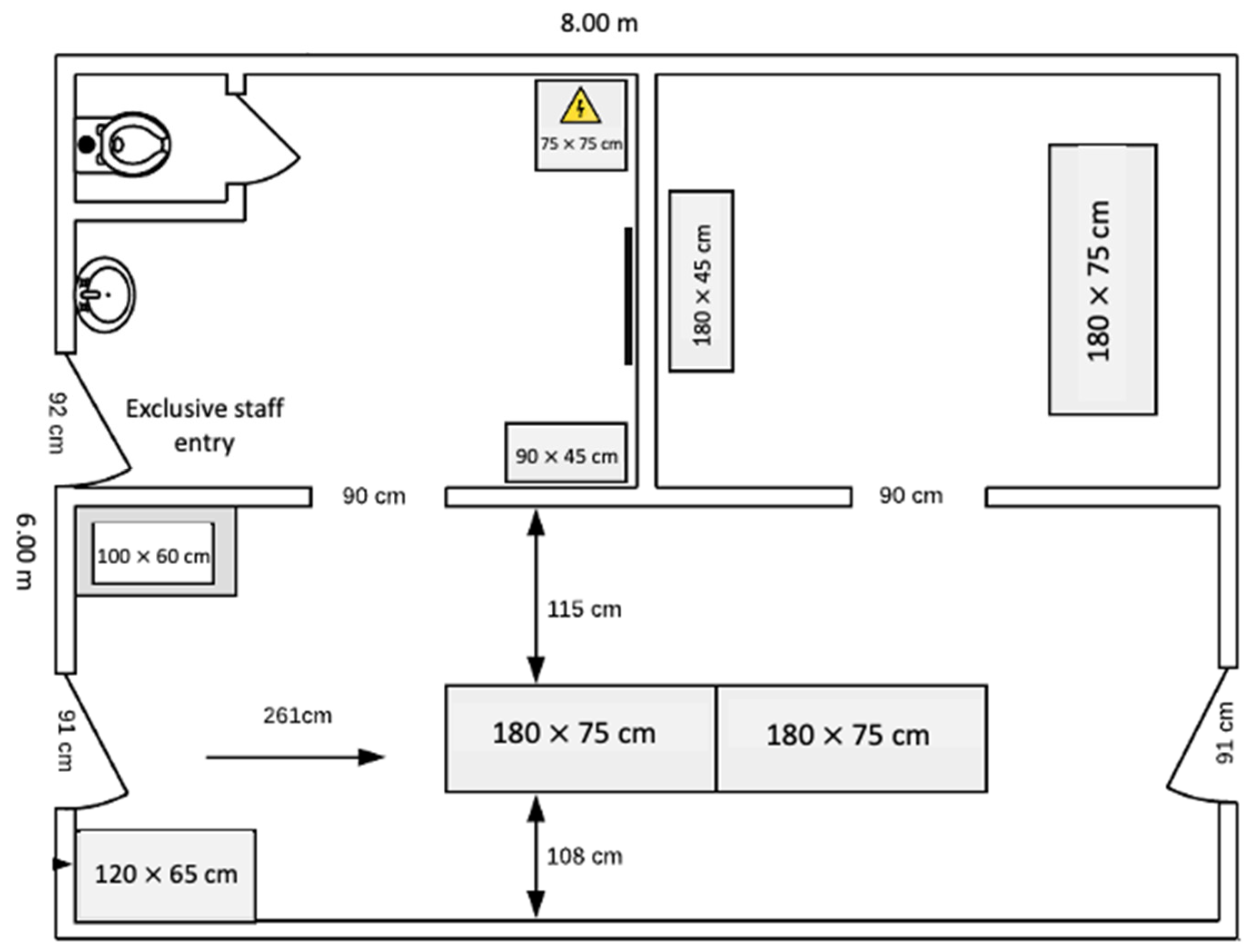

The food processing area is a prefabricated house of 48 m

2 of surface and is 3.50 m tall. It is divided into three spaces that help the manufacturing process. Each space is assigned to a specific function as follows: a dressing room area with a bathroom for women workers, a cutting and processing area, and a packaging and storage area (

Figure 3). All electrical needs are supplied by two solar cells and the battery storage, located in the dressing room area, as is shown in

Figure 3.

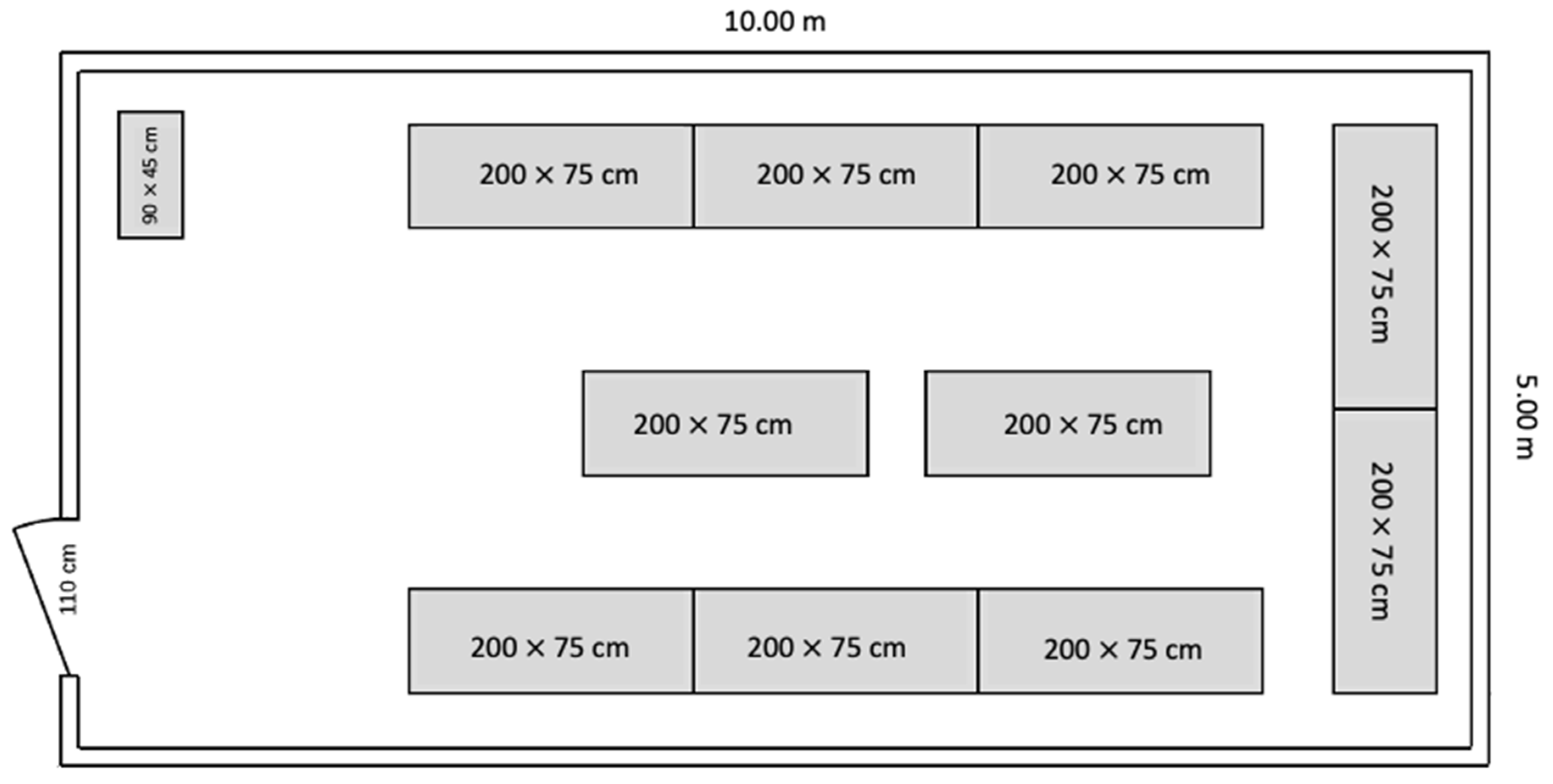

The total dehydration area corresponds to 50 m

2 of surface area and 3.65 m in height (

Figure 4). This area consists of a solar dehydrator that was designed using the principles of a greenhouse. The greenhouse solar dryer was proposed to be installed for drying fruits and vegetables. In this area, there are 10 tables (200 cm × 75 cm) where fruit is placed in the dehydration process.

The solar dehydrator consists of a greenhouse-type tunnel drying unit without a forced ventilation system, which was designed with a Gothic arch shape and steel profiles. Both the ceilings and walls were covered with polycarbonate shingles due to their cost-effectiveness and long-term ultraviolet stability and durability. In addition, they prevent UV solar thermal radiation that could destroy some of the light-sensitive nutrients when exposed to fresh food during drying. Three air extractors were installed in the upper part of the ceiling, providing air flow over the product to enhance moisture removal.

3.2. Drying Parameters

Mango

(Mangifera indica L.) variety Tommy Atkins was selected because of its frequent consumption in the local diet and the strong production of these crops in the region where the plant is located. Additionally, this type of mango has shown results in transformation studies [

13,

14]. Slice maturation and thickness are the main factors that affect the drying results.

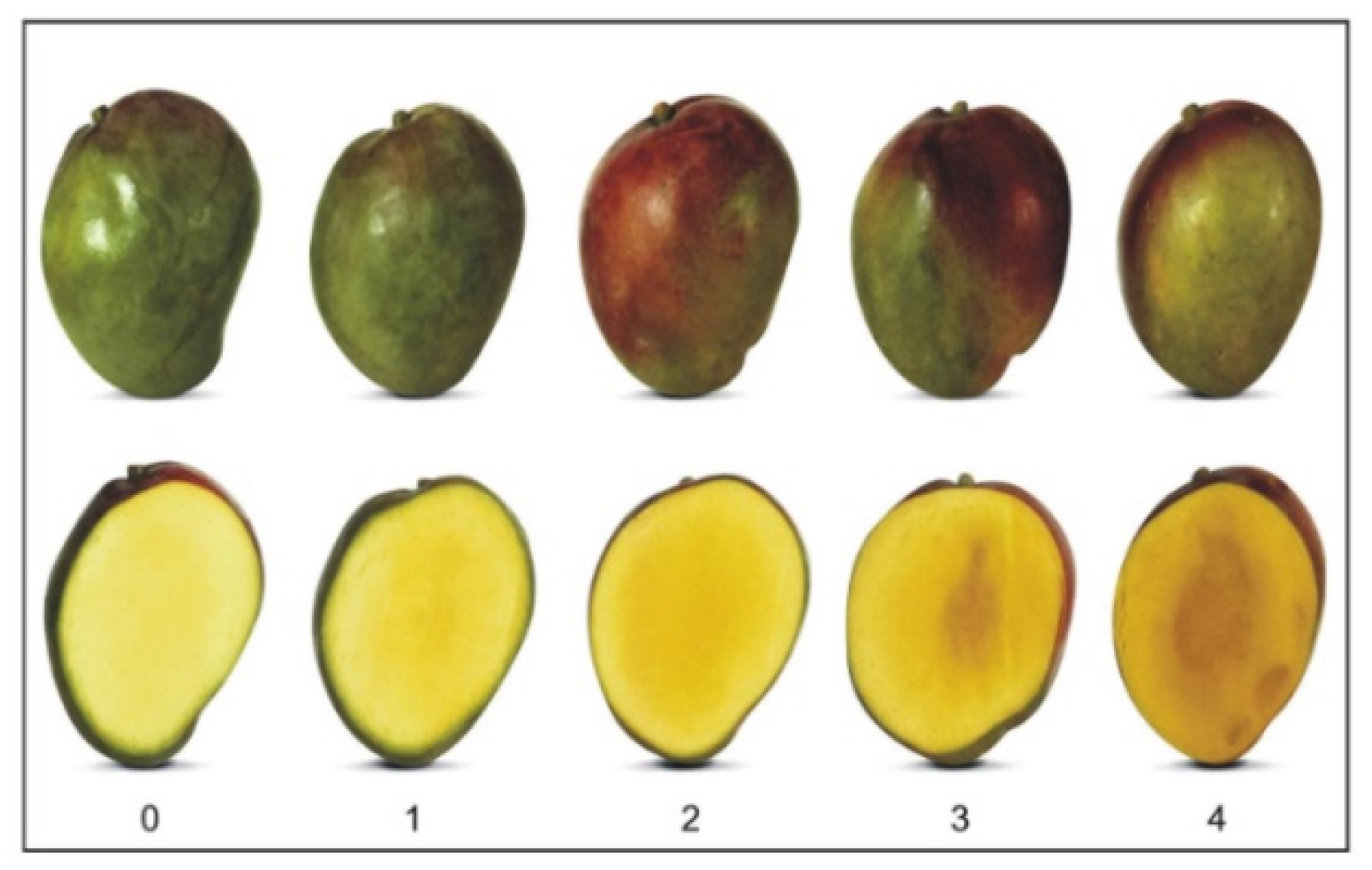

The mango slices were cut as follows: 20.0 ± 3.2 mm of width, 82.0 ± 12.4 mm of length, and 15.6 ± 12.9 mm of thickness and the maturation stage was selected with a maturation stage 3 (

Figure 5) according to Colombian standard NTC 5210-2003.

The initial mass of each plate (containing around 60 slices of mango) was measured using an electronic weighing scale (Bernalo Hs; range: 0.01–5000 g; Bernalo, Colombia). Before starting the dehydration process, all slices were visually inspected to ensure uniformity and then carefully placed over the plates to avoid overlapping. Mango slices were drying until they attained a satisfactory water activity of 0.45 or lower, ensuring safe storage.

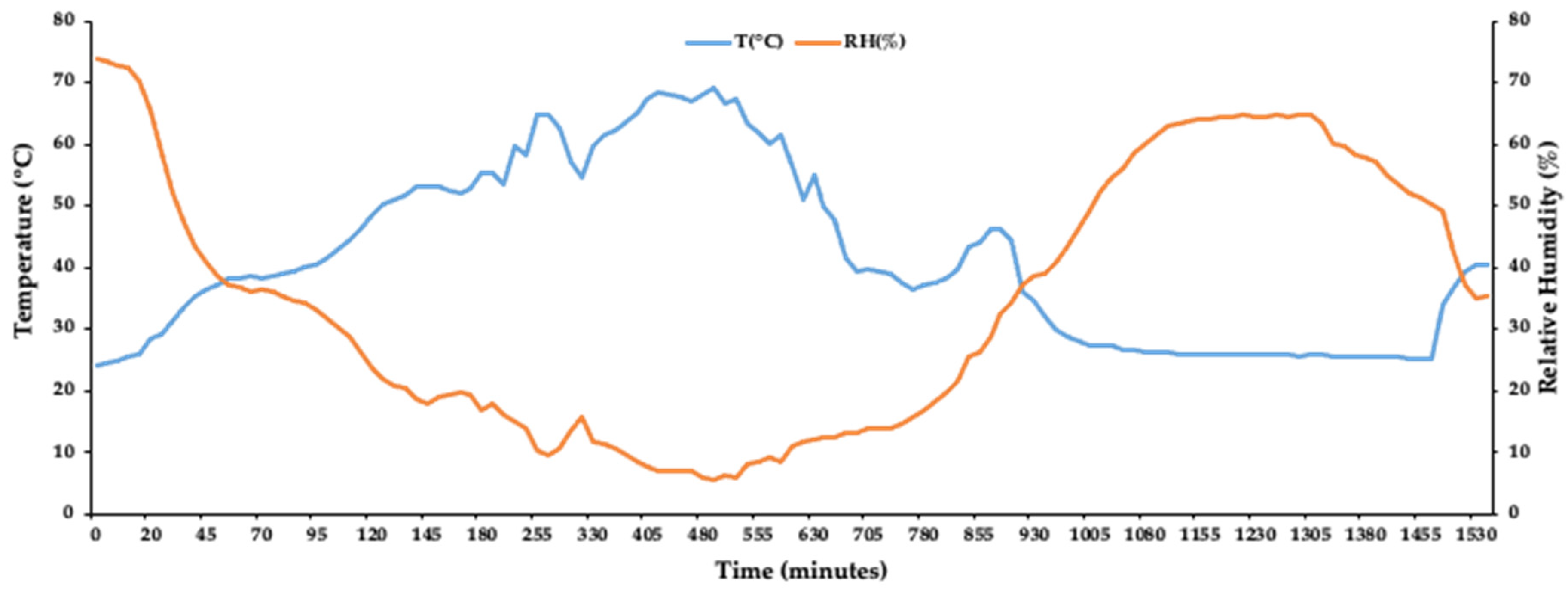

Temperature and relative humidity are important parameters that define the final quality of products. The humidity and temperature inside the dehydrator were recorded with Data logger Elitech RC-51 USB (Elitech) placed inside of the dehydration area. Data was recorded every 5 min during the dehydration process.

3.3. Drying Efficiency

The internal area of the dehydrator was used to calculate the available energy to conduct the dehydration process. This value provides the capacity of the dryer to increase the air temperature assessed and also the capacity to remove water from the products [

15]. The efficiency

is calculated as follows (Equation (1)):

where

is the drying efficiency,

the mass of water lost,

the latent vaporization heat,

is the incident solar radiation,

A the total exposed area, and

t the time taken to accomplish the drying process.

3.4. Quality of Dried Products

Before and after drying, mango color and water activity of the slices were measured to compare these characteristics.

3.4.1. Color

Color measurements of both fresh and dried mango samples were performed to obtain color changes during the drying process. The CIE color scale was used due to uniform distribution of colors. Before and after the mangoes were placed into the dehydrator, the color measurements were obtained by a portable colorimeter (ARTBULL–WR10). The values were obtained as an average of 10 mango slices and with the aim to compare the color changes after and before drying, a hypothesis test was carried out.

The color values consisted of three different parameters: (1)

L scale which measures degree of lightness (100 = light to 0 = black), (2)

scale which measures red to green with true red equal to +100 and true green equal to −100, and (3)

scale which measures yellow to blue with true yellow equal to +100 and true blue equal to −100 [

16]. The cylindrical coordinate

(hue angle) was determined from these parameters using (Equation (2)).

The total color change was determined by using Equation (3) [

17].

3.4.2. Water Activity ()

The

is a thermodynamic property which defines the equilibrium relative humidity of the air surrounding the system at the same temperature in foods.

is an important parameter for food stability and safety, even some authors report that water activity could be much more important to the total amount of water present in food [

18,

19].

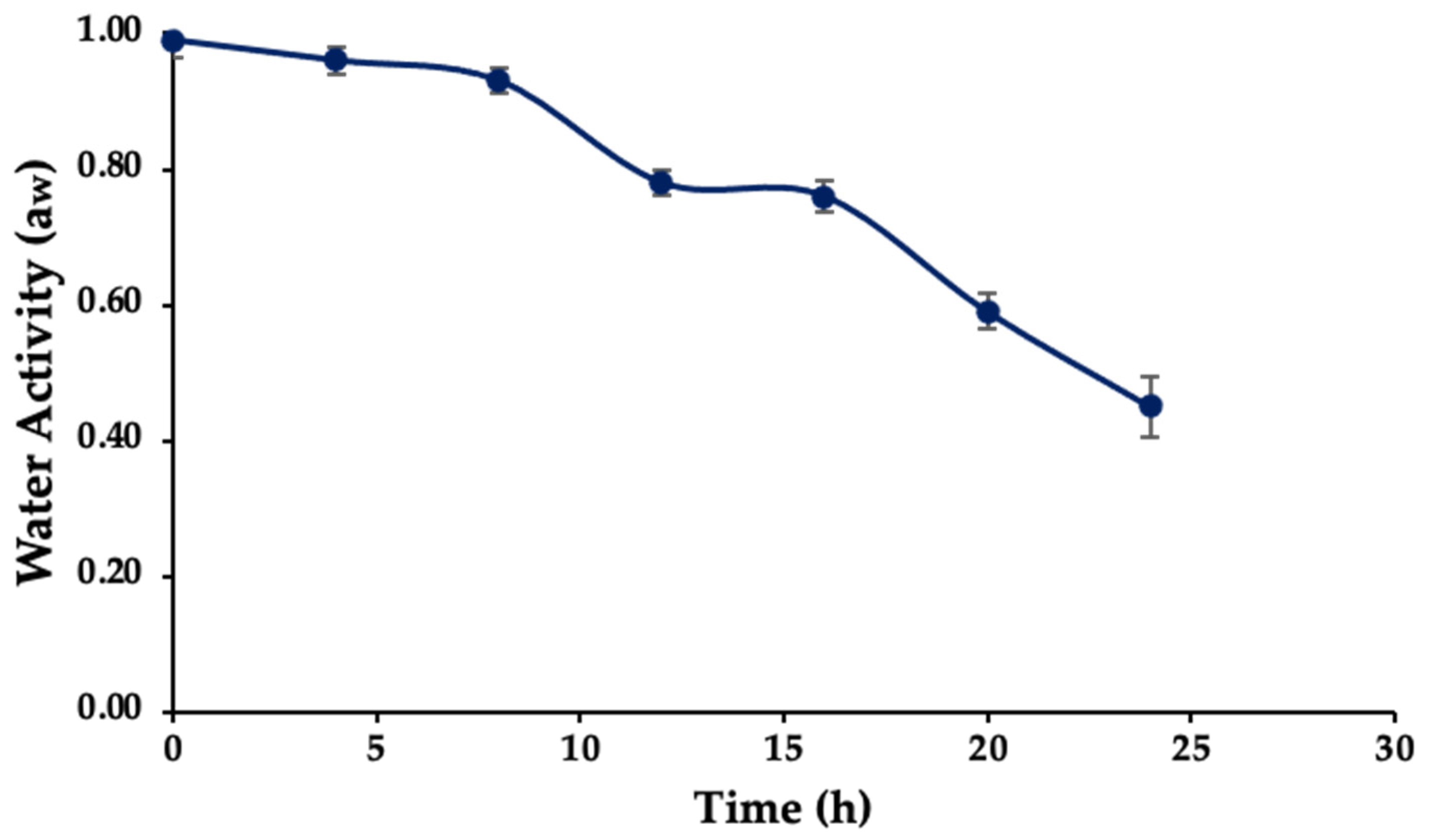

The portable water activity meter Pawkit (Aqualab, Washington, DC, USA) was employed to determine the changes in water activity during the solar drying process. Three measurements per sample were done to report the average of .

3.5. Project’s Experiences

To evaluate the life experiences gained with the implementation of the solar dehydrator in the La Miel community, the women employees, as well as their core families, were interviewed in a group meeting. The discussions with them sought to define their perception about this kind of project and how it contributes to improving their life standards.

The meeting was focused on determining how the project improved the economic situation, what the differences of this project have been in comparison with others that have been developed previously, what the main impacts of this project have been for the La Miel community, and finally, what the main advantages of this project are.

4. Results and Discussion

4.1. Drying Parameters

In preliminary studies, the maturation stage was tested to obtain the best characteristics in the final product; mango was dried at three different stages of maturation. Below the maturation stage 3 means 0–2, the final product is sour, colorless, and difficult to chew. On the other hand, at the later stage (4), the final product enhances the sugar, and the final color tends to darken; moreover, processing times increase due to varying pulp consistencies (

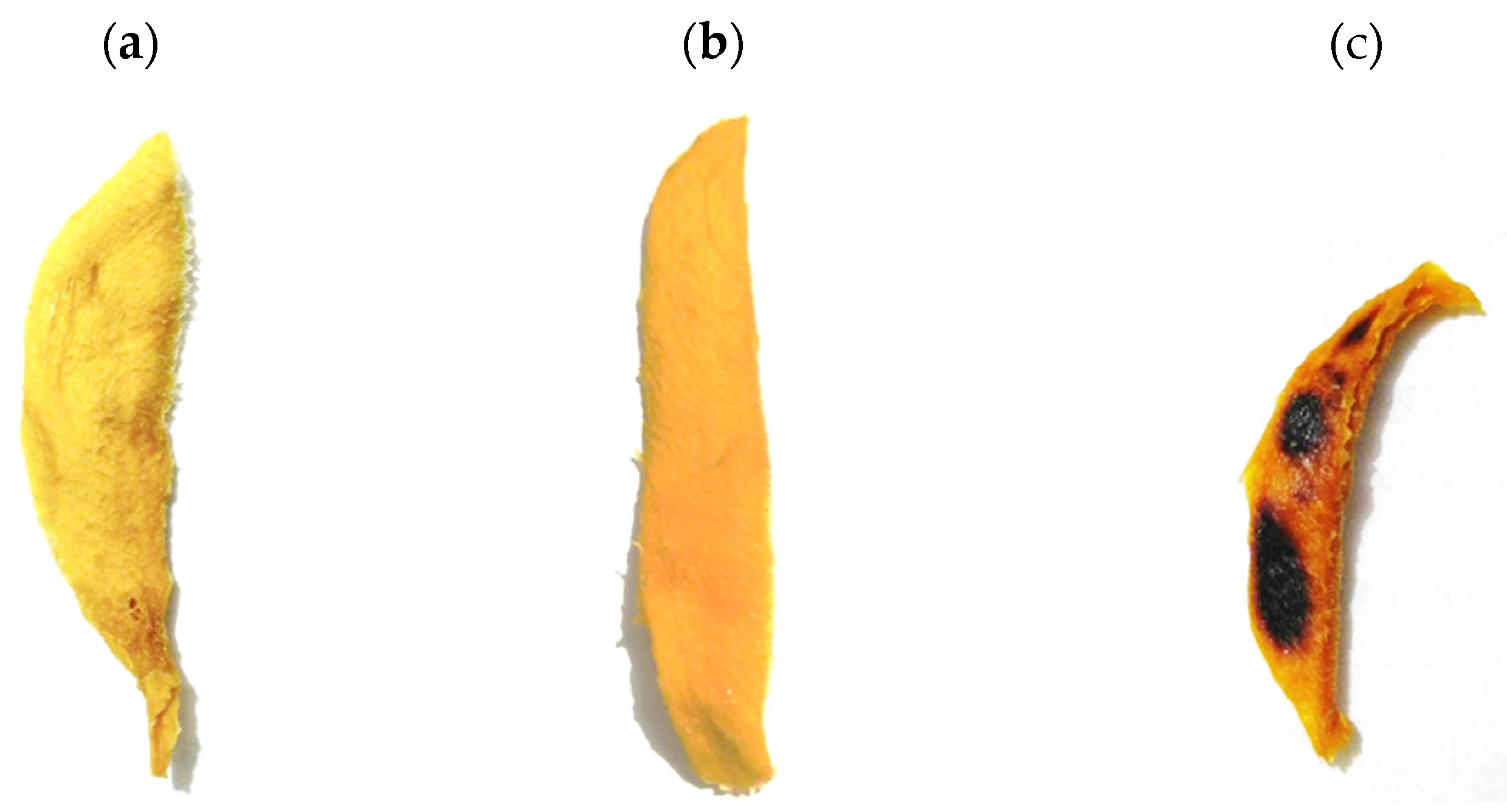

Figure 6).

The mango slices were placed above perforated trays of stainless steel above the tables, then into the solar dehydrator (

Figure 7); the selection of stainless steel is based of requirements about INVIMA (Colombia National Food and Drug Surveillance Institute), which is the regulatory Colombian entity in charge of inspecting and supervising the marketing and manufacturing of food and health products. After the dehydration process, the maximum dimension change variation was in the thickness, which results in 6.5 ± 2.1 mm. This means there is a decrease of 42%.

Mango slices were removed from the dehydrator when the moisture content of mango slices was below 12% with an average value of 9.78 ± 0.8%. Drying parameters used for mangos are shown in

Table 1; subsequent measurements of the weight of these samples showed that their adequate moisture content (below 12%) was obtained within 24–27 h of drying. The drying time for this method is longer compared to other dehydration methods because the temperature does not exceed 70 °C. The maximum temperature inside the dehydrator was 67.4 °C, while the minimum was 26.0 °C, and there is a large fluctuation because this dehydrator does not have heat collectors that can regulate the temperature at night.

The climate of Colombia is characterized as being tropical and isothermal due to its geographical location; however, it is possible to identify two seasons: rainy and sunny. The experiment was carried out in the sunny season. Which represents around 75% of the year. Solar drying was performed with a mean daily temperature and relative humidity of 23.6 °C and 26.5%, respectively.

Figure 8 shows the temperature and relative humidity inside the dehydrator during process execution. Time 0 indicates 6:30 a.m. of day 1 and the final time was 1545 min, which indicates 8:15 a.m. of day 2.

The relative humidity in the dehydrator has a direct influence on the drying process as well as on the water activity of the product. It is possible to observe that, at time 0, both relative humidity and temperature are similar to ambient conditions; however, there is a slight high relative humidity at the beginning of the process compared with ambient conditions due the water steam liberation. As the mango is drying, the relative humidity decreases because the water steam liberation also decreases and the fans extract the excess water steam inside the dehydrator. At night, around minute 705 (7:00 p.m) the relative humidity starts to increase due to the decrease in temperature. Chua et al. (2003) studied different solar drying methods for mangos and pineapples. They showed the that the most effective solar dehydrators are those that have metallic collectors, reaching an average temperature of 40.3 °C; compared with other methods, it increases the drying air temperatures by approximately 10 °C [

6]. The solar drying greenhouse design with polycarbonate walls reaches an average temperature of 41.5 °C. This design maintains a minimum and maximum temperature of around 26 °C and 70 °C, respectively, demonstrating the efficiency of the design.

4.2. Drying Efficiency

Solar radiation intensity, relative humidity, ambient temperature, initial moisture content, and product types are the factors that are necessary to consider while designing the solar dryer [

21]. The dehydrator was positioned to maximize the capture of available solar radiation with a north-south orientation to maximize all-year sunlight radiation into the greenhouse [

22]. Polycarbonate walls reduce heat losses, allowing about 80% of the incident sunlight to enter the dehydrator.

To calculate the efficiency of the dryer, a specific area was selected of the total collecting area (50 m

2). The latent heat was calculated as 2264 kJ/kg. The insolation was calculated as 30% of the solar radiation in this location, and time of drying was adjusted at 24 h. To calculate the water loss mass, the initial water content of the mango was evaluated to be an average of 85.0 ± 6.5%; the quantity of moisture in the mango after dehydration was measured between 10% and 12.30% wt. These values are considered “Dehydrated” by the CAC/RCP 75-2015 [

23] and the CODEX STAN 39-1981 [

24].

The drying efficiency was calculated as 6.7%. The efficiency value is a low result compared to what was reported by Camas-Nafate et al. (2019) where efficiencies were reported between 23% and 37%. However, the results reported above were conducted at the experimental level. The low efficiency on this dehydrator is related to the amount of product that is used, because it does not use the total storage capacity of the dehydrator. That is, with the total occupation of the dehydration area, efficiencies could be obtained around 30%, which is a good indicator for this type of technology.

4.3. Quality of Dried Products

4.3.1. Water Activity

Different studies have shown that water activity in food significantly influences the growth rate of health-hazardous microorganisms [

25] and results in a smaller lifespan. The behavior of

changes when food is heated and is influenced by food components [

18]; water activity below 0.83 has been shown to be considered as the lowest

for pathogenic bacteria growth [

26]. However, some pathogenic bacteria can still exist and survive for years in low-

foods. Safefood 360°, an enterprise dedicated to providing food safety, indicates that most enzymes are inactivated at

< 0.85. Less than 0.75 bacterial growth is inhibited, but some yeasts and molds may grow, and at less than 0.6, all growth is inhibited [

19].

Moreno et al. (2014), assessed water activity in dry commercial tomatoes, obtaining values between 0.52–0.77 [

27], and water activity has been reported in commercial dry fruits between 0.80–0.72 [

19,

28]. Variation in water activity (

) during the mango dehydration process is shown in

Figure 9; the time 00 indicates 9:00 a.m. of day 1 and the final time was 24 h, which indicates 9:00 a.m. of day 2.

Figure 8 shows a reduction in water activity as exposure time increases; this behavior is typical of fruits and vegetables in any dryer and is related to an initial decrease in accelerated humidity related to the content of “FreeWater” [

29].

According to

Figure 9, the dehydration process finishes when mango slices reach a water activity around 0.45, indicating that the product could be safely stored, avoiding the growth of microorganisms. These results extend the life cycle of the dried mango, which provides the community of

La Miel more levels of coverage for commercialization and distribution of products.

4.3.2. Color

Drying may change the superficial appearance and color of products due to reaction, pigment degradation, enzymatic browning, and ascorbic acid oxidation [

30]. The appearance is one of the main parameters evaluated by consumers and it is a critical factor for acceptance. Color is a sensory parameter that is important to evaluate since it also determines the characteristics and acceptability of products for food [

31].

Table 2 shows the average, standard deviation, and p-values of the hypothesis test of mean differences of colos parameters of mango slices before and after the drying process.

According to the results, the solar dehydration process does not significantly affect (

p < 0.05) the luminosity and yellow/blue values of mango slices. However, red/green values increase after dehydration, which coincides with previously reported studies where it is has been demonstrated that this value increases for yellow materials; the increase of a value denotes a more red chroma, which is indicative of the browning reaction [

32,

33]. The absence of variation in brightness after the dehydration process is an indication of a natural product without addition of products that increase total solids [

34]. This value assures a color similar to the fruit pulp, which is highly valued by consumers. Low-processed products are popular in new consumption trends. Therefore, this productive process would be focused on a specific market niche, primarily healthy consumers.

The hue angle varied from 79.96 to 74.59, which is associated with the yellow color characteristic of fresh mangoes. These values indicate that the color parameters of mangos are located in the first quadrant of the CIELAB color diagram (+ and +), corresponding to the region of red and yellow color, where 0° is pure red and 90° is yellow.

The total color change

of dehydrated mango was 6.21, which is a relatively low value compared to that reported by [

30], where different dehydration methods and different fruits were studied. The low value obtained in this study is directly related with the dehydration method; solar dehydration does not significantly change the color characteristics of fruits [

6].

4.4. Project’s Experiences

At first, women in the community of La Miel did not trust this project because they have had other bad experiences with projects that promoted changes in their livelihood. In addition, it has been proven that there is not sufficient participation on behalf of women in the decision-making process of similar projects. In order to address this problem, regain the trust of these women, and promote their participation, project managers were required to be attentive and committed to the project. It was necessary to involve the community from the beginning in all decisions around the project, from plant constructions to the process of selecting and distributing logos.

Women associated with the dehydrating plant have indicated that such projects contribute to their economic independence. Furthermore, they stated that there is personal and professional growth due to the business, market, and empowerment training they received. Another important point women highlighted is that work allows them to spend more time with their families while they are working due to the plant’s proximity to their homes. According to Kassie et al. (2020), it is expected that, empowered women will have a better understanding of nutrition, health, decision-making power, income control, and the time to apply that knowledge in their personal care practices. Therefore, women’s empowerment can lead to better nutritional outcomes, such as dietary diversity, not only for the women, but for their families [

35] as well.

Finally, they feel they are impacting the community because more and more people are interested in what they are doing, and there is more interest for active participation around the project.

5. Conclusions

According to the results, better final water dried products are obtained when fresh mangoes have reached maturation stage 3. In this stage, there are no significant color changes in dry mango slices. Therefore, as the product has a similar color to fresh fruit, it will be more acceptable to the consumers.

It was found that with the solar dryer proposed, the temperature of the drying air at the outlet of the solar greenhouse dryer varied between 26 and 76 °C during the drying process. This is a sufficient temperature range to dry approximately 207 kg of mangoes with a drying time of 1 day, depending on weather conditions. This dehydrator helps reduce post-harvest losses of agricultural products.

At the beginning of the drying process, relative humidity is slightly higher than ambient conditions because the drying process allows water steam liberation as the mango is drying from the relative humidity decrease because the water steam liberation also decreases.

According to conversations among the women involved in the project, they suggest that the implementation of this low-cost technology to transform fruit plantations can contribute to self-empowerment and job creation. Home plant proximity is highly appreciated by employees because it provides more time for the women to be with their families by avoiding a commute.