1. Introduction

In the cyber-technological era, enterprises began their journey to the sustainable development of the business with the Industry 4.0 approach. The idea of sustainable development is challenging to formulate specifically. Based on a systemic approach, sustainable development can be achieved by considering the economic, environmental, and social aspects [

1]. Sustainable development means increasing productivity while reducing the need for resources and reducing environmental impacts. Business activities must also have positive social effects. For such a direction of the enterprise’s strategies, information is needed. The data can be properly obtained by involving information technologies (IT) in the processes of the enterprise [

2]. Sustainable development in production can be achieved by looking for opportunities in the company to increase its competitiveness in production [

3].

Small and medium-sized enterprises (SMEs) are the essence of many economies, and they have a huge impact on the environment and overall emissions. Owners of these enterprises are motivated to create sustainability [

4]. SMEs can reach a maximum of 250 employees. Otherwise, they are considered large enterprises [

5,

6]. Currently, the world’s events are directed towards so-called green activities and the protection of the environment. Sustainable development in today’s SMEs is mainly associated with emphasizing nature protection and environmental enhancement. Enterprises are planning and implementing eco-innovations, which means a rise of eco-friendly production and emissions reductions [

7]. Eco-innovation mostly affects the environmental side of sustainability. Its primary aims are new or improved processes, products, or services with decreased use of natural resources and release of dangerous substances through the life cycle. Eco-innovation becomes even more effective for SMEs if it is also characterized as open innovation [

8,

9]. SMEs encounter many challenges to implementing innovation towards sustainable development. The open innovation concept provides shared knowledge between enterprise and external subjects. Such a collaboration breaks down research and development challenges [

10].

SMEs’ key challenges were specified as financial instability, financial loan constraint, inexperience, and lack of innovation and creativity in the field of business, regulatory licenses and taxes, increased production and manufacturing cost, lack of technical means, poor managerial skills, and technology. In addition, major external challenges such as competition, unfriendly business environment, and government regulatory and law issues have an impact [

4,

11,

12]. However, studies [

5,

13,

14,

15] declare a positive relationship between sustainable development and SME’s innovation. Some previously mentioned studies even use more sophisticated and more expensive Industry 4.0 solutions towards sustainable development than ours. Many enterprises worldwide have already applied Industry 4.0 and try to adapt it to their specific processes and needs. Implementation of Industry 4.0 can provide enterprises competitiveness, flexibility, productivity, environmental improvement, ecological benefits, increasing employees’ expertise, and improving managerial skills. SMEs still prefer economic benefits from innovations instead of environmental and social ones [

6,

12].

However, the actual situation in Slovakia is different. In 2018, 73.2% of employees were employed in private sector SMEs. Of these SMEs, 61.6% did not perform any innovation activity, and 45.7% did not even consider it for the future. Most SMEs are still operating without sufficient support of cyber and IT or other sustainable development solutions [

16]. Lesáková et al. [

17] pointed out innovation barriers in Slovak SMEs: lack of financial sources, innovation costs, insufficient labor qualification, lack of external cooperation, an inappropriate system of state support, lack of knowledge about benefits of research and development, law ambiguity, bureaucracy and corruption, and lack of readiness to innovate. Enterprise readiness to innovate can be explained as a willingness to change, free implementation capacities, and the ability to achieve intention [

12].

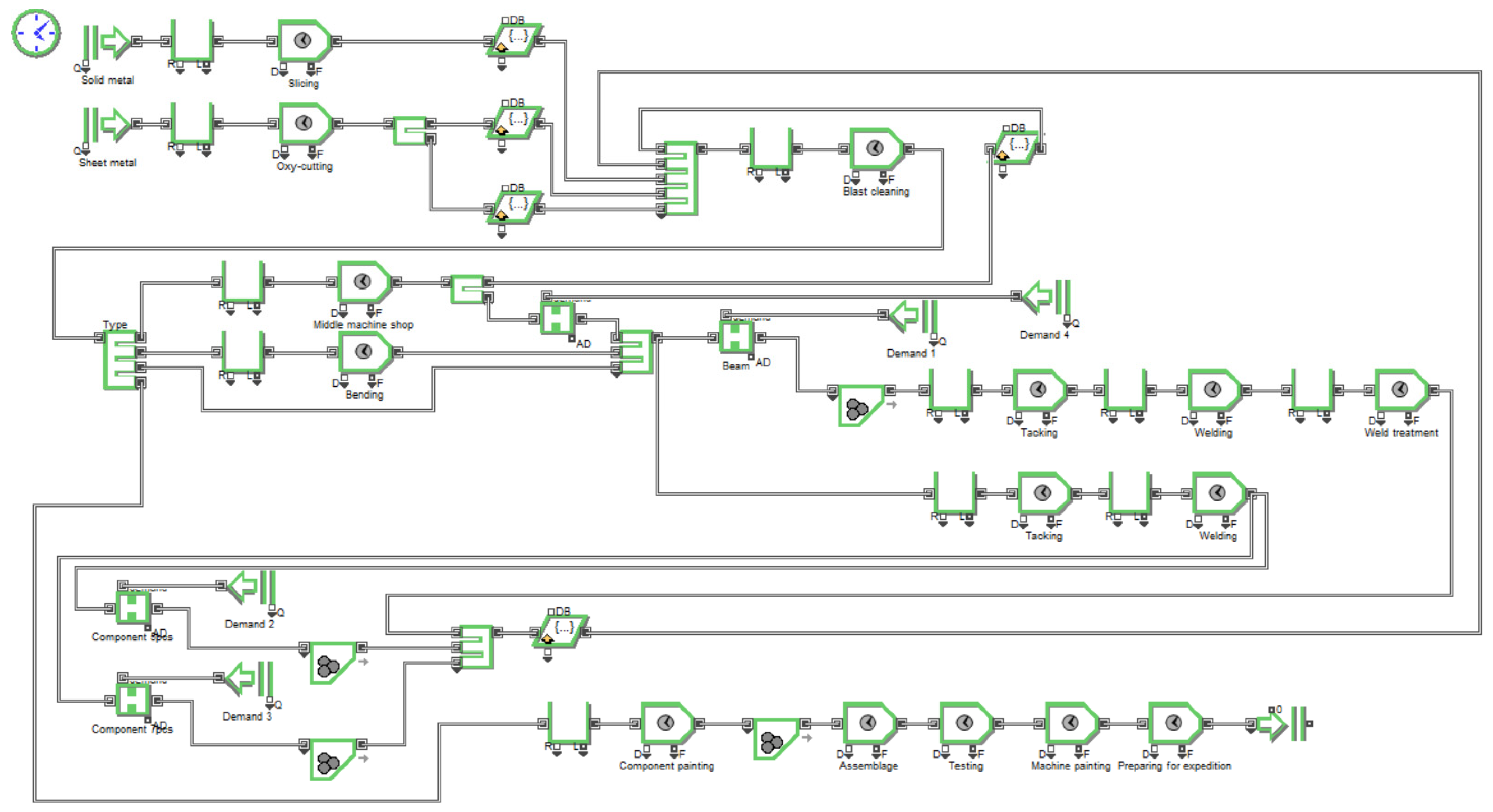

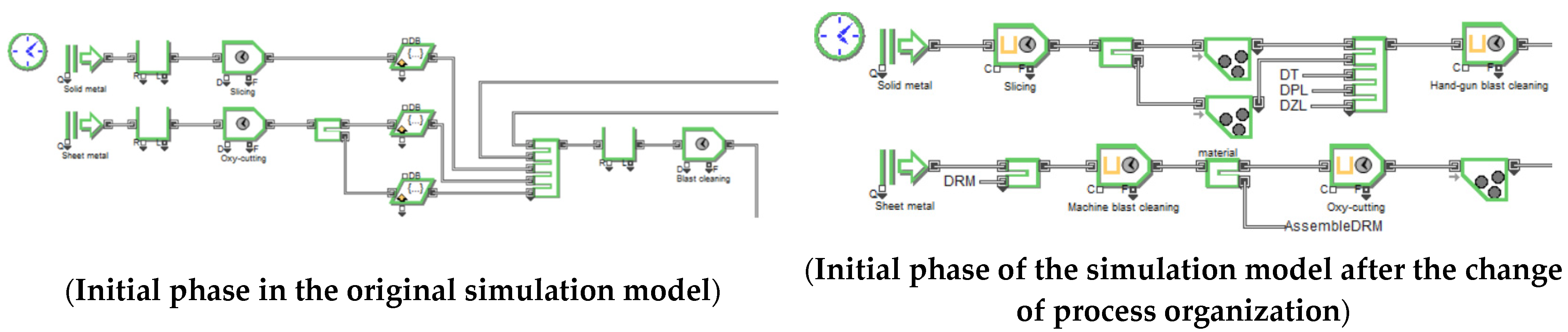

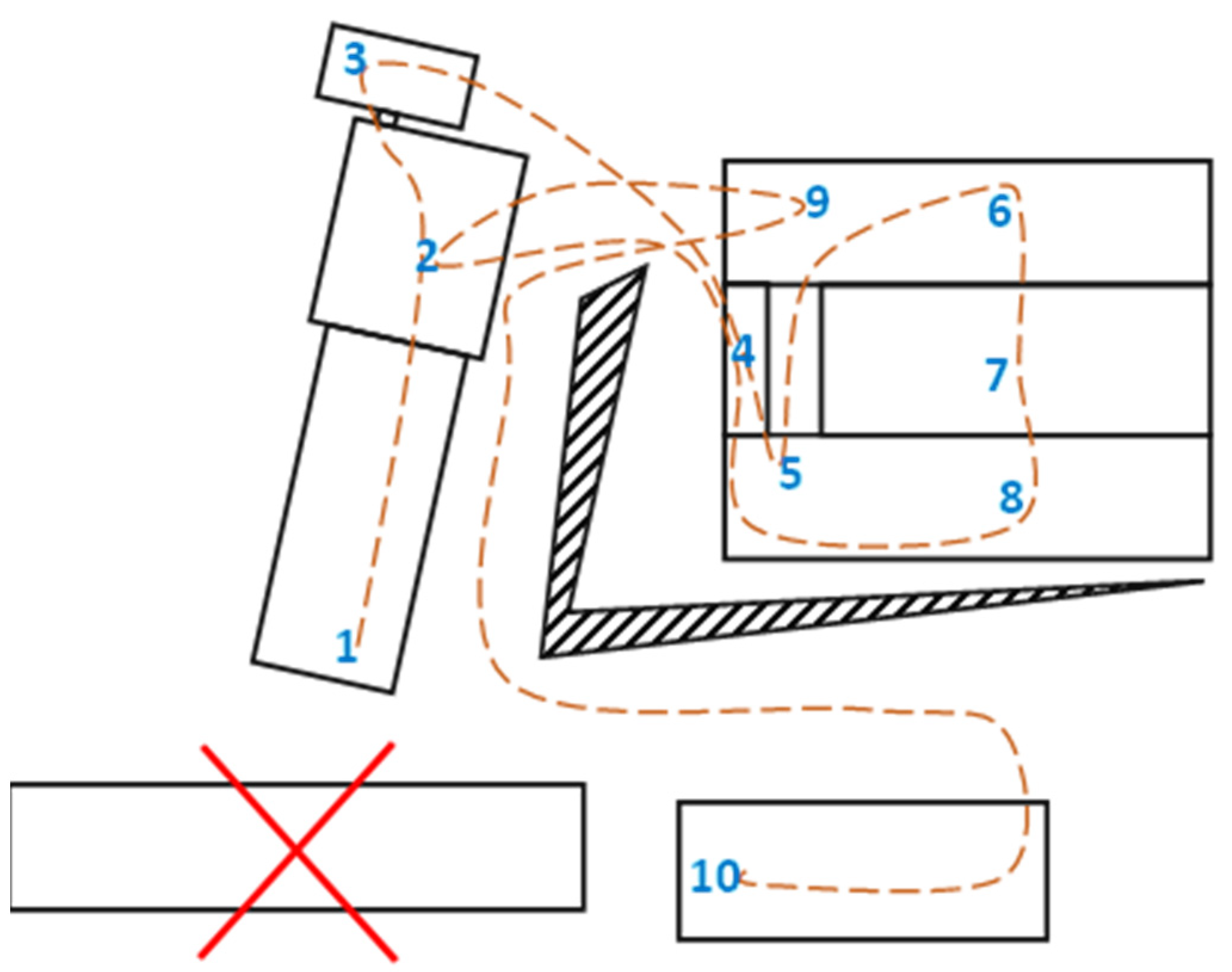

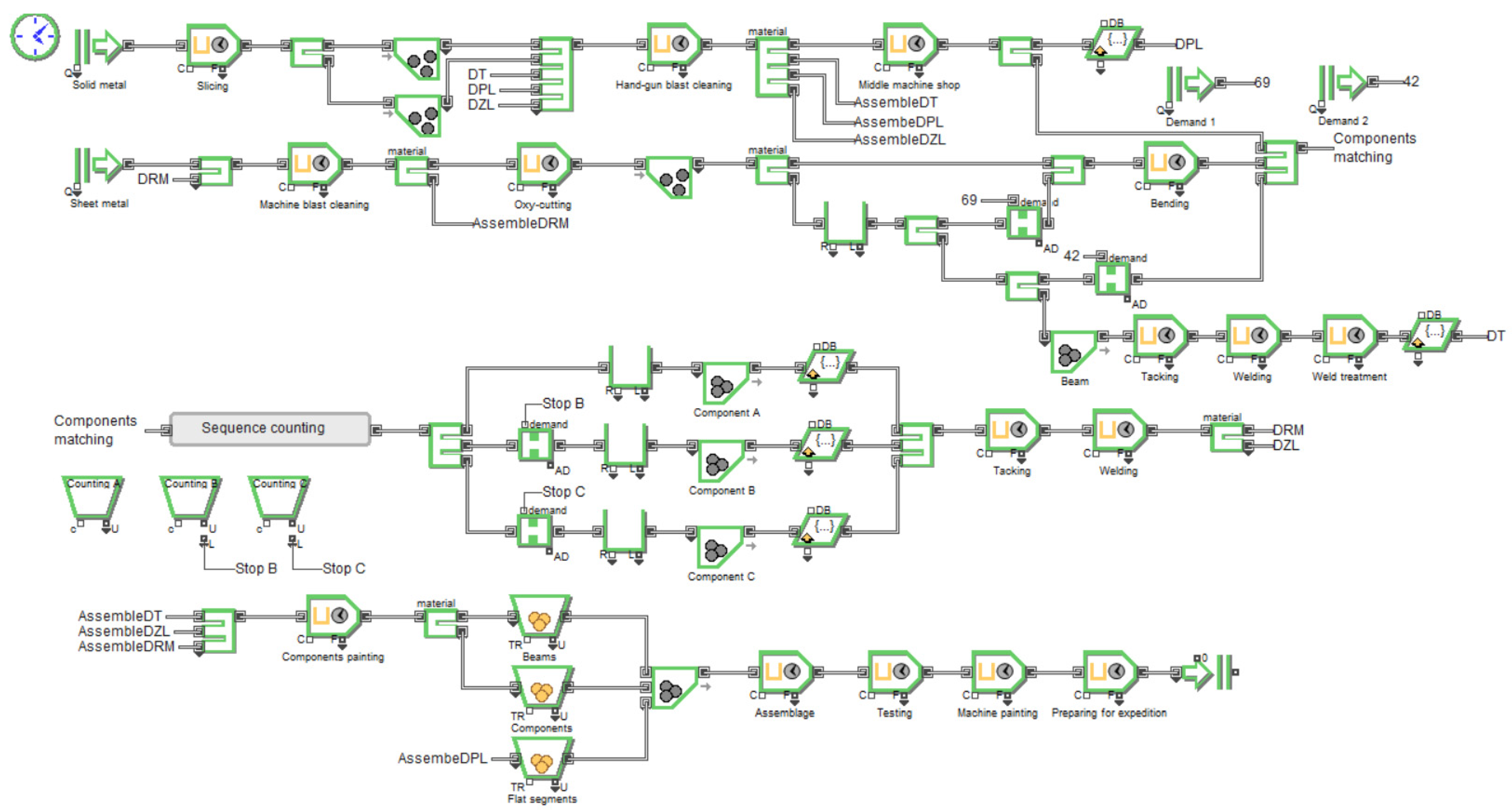

In the case study, an SME from Slovakia has established cooperation between the enterprise and an academic institution. This connection aims to lay down the basis of the sustainable development of the enterprise. Sustainable indicators such as energy consumption per unit and order acceptance rate are the most urgent. To satisfy these indicators, the Industry 4.0 approach is needed. Researchers must deal with barriers and find a suitable solution for the enterprise. The first step must be proper system analysis to identify the main problem. The most basic tool simulation model is created for the production process to achieve higher control of it. The simulation itself is not enough. A new blast cleaning machine is acquired according to system analysis results. Implementing new technology requires a change in the organization of the existing production process to exploit all the potential of the suggested innovation. The core of the innovation is the new machine positioning in the enterprise’s production process. Replaced machines are put out of service. Such a change in the production process requires sufficient investment means and sufficient time for verification. To avoid wasting resources, changes are firstly made to the virtual model in the ExtendSim simulation program. The creation of the model is preceded by a thorough analysis of the innovated system. The created model is verified and modified to match the real system.

This paper presents the case study that declares Slovak SME ability to start building sustainable development. The case study proves that even the simplest Industry 4.0 solution brings positive results and advantages for SMEs in Slovakia. The paper should encourage Slovak SMEs to implement innovations, even if there are many barriers in Slovakia. Despite obstacles in the implementation process, the advantages of sustainable development are worth it. The case study describes the implementation of a new machine and the creation of the production process model. To achieve sustainable development, Industry 4.0 tools are used. The new automated machine shortens production time, works on preprogrammed software, and decreases environmental pollution and energy consumption. The simulation model brings a basic digitalization in the production process and offers new possibilities for the enterprise, such as more precise forward control and quick capacity planning. The adapted model will be used for other solutions of sustainable development and Industry 4.0 in the enterprise.

2. Literature Review

In the Introduction, we present the aim of our case study and state the situation of Slovak SMEs according to sustainable development. Many terms are used, but only a few have a deeper explanation. This section aims to provide a deeper look at terms like production process, innovation, redesign process, and simulation so the management of Slovak SMEs will better understand the intentions, steps, and processes we use in the case study. From a logistics point of view, only a deep understanding of the steps and processes we present in the case study could bring other Slovak SMEs toward building the basics of their sustainable development.

Today, many factors influence the performance of production processes. These factors can be divided into external and internal groups. The external group includes customers’ needs, ecological pressure (zero waste), delivery cycles, flexibility demands, and market changes. Internal factors follow the enterprise’s best interest, such as quality control, cost reduction, lead times, and reliability of machines [

18,

19,

20]. The customer has the largest share of the pressure to change production processes. Manufacturing enterprises are being forced to meet increasingly different and more demanding customer requirements. On the other side, enterprises are pushed into low production costs. The trend is the greatest possible flexibility of production processes at low costs [

21]. Many enterprises need to switch to so-called lean production, where production time and costs are reduced to a minimum, of course, while leaving as much flexibility as possible to meet customers’ needs. The increased need for information is directly linked to the shortening of production time. Information and data are becoming the most important source for achieving the objectives set [

18].

According to Tvrdoň and Fedorko [

22], the design of production systems is a long-standing process, but there are constant demands to accelerate this process. When designing production processes, we must ensure that each model consists of static objects such as machines. These dynamic objects change the position in the model and connections with the external environment [

23]. Linear programming and various mathematical methods can no longer keep up with the acceleration of designing production processes. With Industry 4.0 comes the trend of the digital twin and the promotion of simulation as a tool for designing production processes with great potential [

21]. A wide range of different simulation programs is available on the market. They can distinguish even the smallest details of virtual models of systems. By careful, precise, and well-located monitoring of simulations in these programs, we can distinguish individual bottlenecks and all discrepancies in the model. The redesign of production processes often offers high investment options and options with little need for resources. Simulation is the most appropriate tool for deciding whether low-cost changes will be sufficient for us [

24].

Innovation can be understood as introducing an unknown possibility into the system to improve the system. The upgrade can be done to all aspects of the business, from creating a new product through new planning to a change in the production process [

25]. According to Roper et al. [

26], innovation is the beginning of a process in which the performance of the enterprise may improve when certain characteristics occur and the specified conditions are met. Wojtaszek and Miciuła [

27] offer a more detailed view of innovation, innovation activities, different innovative concepts, and the relationship between innovation and competitiveness. We can find a strong relationship between innovation and development and improving the performance of small and medium-sized enterprises, which, however, cannot be fully exploited by these enterprises because of their limited financial resources. Industry 4.0 technologies lead enterprises to innovations aimed at digitization, strengthening customer relationships and activities resulting in increased productivity [

28].

Innovation uses many concepts and methods to achieve its goal. One of the most important methods used to improve processes is reengineering. If the word reengineering is used, the main meaning is a radical, often large and important change of the entire production process. However, it is necessary to realize that the term broader sense consists of three levels. The first level is a slight change at a particular place of the production process or only one process activity. At a higher level, we are talking about reengineering as a redesign of a process where change affects more than one part of the process, sometimes the whole process. The last third level is reengineering in the strict sense of the word, as a radical change of the whole production process [

29].

Reengineering may not relate to the production process but may also include information flow from a logistics perspective. Bottani [

30] describes reengineering in the information flow in the storage system for more efficient use of data stored in radio frequency identification (RFID) receivers. Reengineering can also improve the entire business process. Business process reengineering (BPR) is designed to analyze, manage, and modify the material flow and the entire business flow of the enterprise. BPR methods are highly unsuccessful, mainly due to the absence of a clear sequence of steps in these methods and the inability to identify fault factors [

31].

In this case study, a redesign of the process is used as a tool for the sustainable development of production in the enterprise. The design of the process can take a dual approach. The first is a multicriterial design, where the model works with the same structure and units of variables while meeting multiple requirements and respecting limitations. The second way is two-phase stochastic optimization when it is designed in uncertain conditions. The second phase variables correspond to the selected option from a set of possible scenarios, so they adapt the first phase to the selected scenario [

32]. The level of failure of reengineering projects is up to 50% due to the low success rate of predicting the impacts and results of changes made by reengineering and the dynamic nature of the processes. Another reason is the lack of options to evaluate changes before they are implemented. In recent years, simulation has become an integral part of reengineering projects as a tool for evaluating a given project before implementation. Simulation with the correct parameters corresponding to the real system is an essential factor preventing the waste of financial resources for projects with an inappropriate solution [

29].

A simulation is an analytical tool which displays the object as a digital model. First, the displayed model must be verified on a functional and logical side to match the modelled system. If the model was not a copy of a real object, the statistics obtained would not correspond to reality and lead to incorrect conclusions. Subsequently, it is possible to experiment with the model, which brings a lot of data and information. It is possible to formulate solutions and apply them to the real object [

33]. A simulation is a tool that has become widely used since the 1950s. Simulation is not a tool for optimizing real systems but for obtaining the statistics needed to optimize and test different solutions [

34,

35].

Simulation on real process models aims to obtain information, one of the most valuable sources today. Simulation eliminates the need for surplus financial resources from interventions in the real system. The information thus obtained is used to evaluate and improve the modelled system [

35,

36]. In the case of a new system or product, the simulation provides an overview of the selected design and functionality before implementing the new program or product [

37]. According to Siderska [

37], it is advisable to follow these steps:

To formulate the problem;

To test the possibilities of performing a simulation;

To formulate the objectives;

To gather and analyze data;

To perform the simulation;

To analyze and interpret the results;

To draw up documentation.

The advantages of the simulation are great flexibility, lower financial resource intensity compared to real object testing, relatively long-term usability, and it does not affect ongoing business processes. On the other hand, the minus is sometimes the need to comply with the limits of the simulation program, the need for quantification of parameters [

38].

The creation of a simulation model is based on the nature of dynamic elements of the production process. Therefore, a discrete simulation is distinguished when dynamic elements are often subjects of a material nature, often declared in pieces. For such a type of simulation, the time is controlled by jumping, i.e., only the time of each event occurred is recorded. On the other hand, there is the possibility of a continuous, non-discrete simulation, used mainly for value flows. The continuous simulation time is controlled by a fixed time interval in which simulation statistics are recorded [

33,

38].

Many simulation programs are currently being used. The programs use a wide range of simulation languages. For discrete simulation, it is good to mention GPSS, TECNOMATIX, SIMUL8, and WITNESS, for purely continuous simulation, STEELA, and, for complex simulation programs, ExtendSim and ARENA [

38,

39].

The simulation is used to solve various problems. Ištokovic et al. [

40] used simulation to determine the order and batch size in the production plant. To rationalize the downtime of traffic and services during the production process, the simulation was used by Ambriško et al. [

41]. The collective Šaderová et al. [

39] were among the first who presented the use of simulation using ExtendSim8 in the mining process. Several articles using simulation to demonstrate stock operations or their redesign have also been published [

34,

42,

43]. Pekarcikova et al. [

44,

45] used the TECNOMATIX program to solve bottlenecks in production by applying KANBAN or e-KANBAN (in meaning to the Industry 4.0) of the system. In manufacturing enterprises, the priority is to avoid investment-intensive interventions in the production process. Simulation is an appropriate tool to evaluate the efficiency of the production process even in the case of non-invasive changes, such as adjusting production scheduling and rationalizing logistics operations [

46,

47].

5. Discussion

A simulation is a tool that offers more statistical results.

Section 4.5 simulation results are mainly devoted to the decisive factors influencing the decision to implement the proposed innovation into the enterprise’s production process. However, the simulation also provided other results showing the direction of the production process (

Table 7).

Most production operations in

Table 7 are low utilized. In the case of custom production, it represents free production capacities for other orders. However, these questions also need to be asked:

Does the production process need so many workers at tacking operation?

Does the quantity of welders exceed the optimal need for the production process?

Does the production process need to reallocate the workforce more effectively?

Does the assemblage operation require reinforcement by the worker? Will such a reinforcement speed up assembly time?

Redesign plays a significant role in shortening production time and removing the identified bottleneck. However, the innovation of the production process of an enterprise should not end only with the redesign presented. A new bottleneck is created elsewhere in the production process by removing a bottleneck. According to the table above, we can identify the newly created bottleneck.

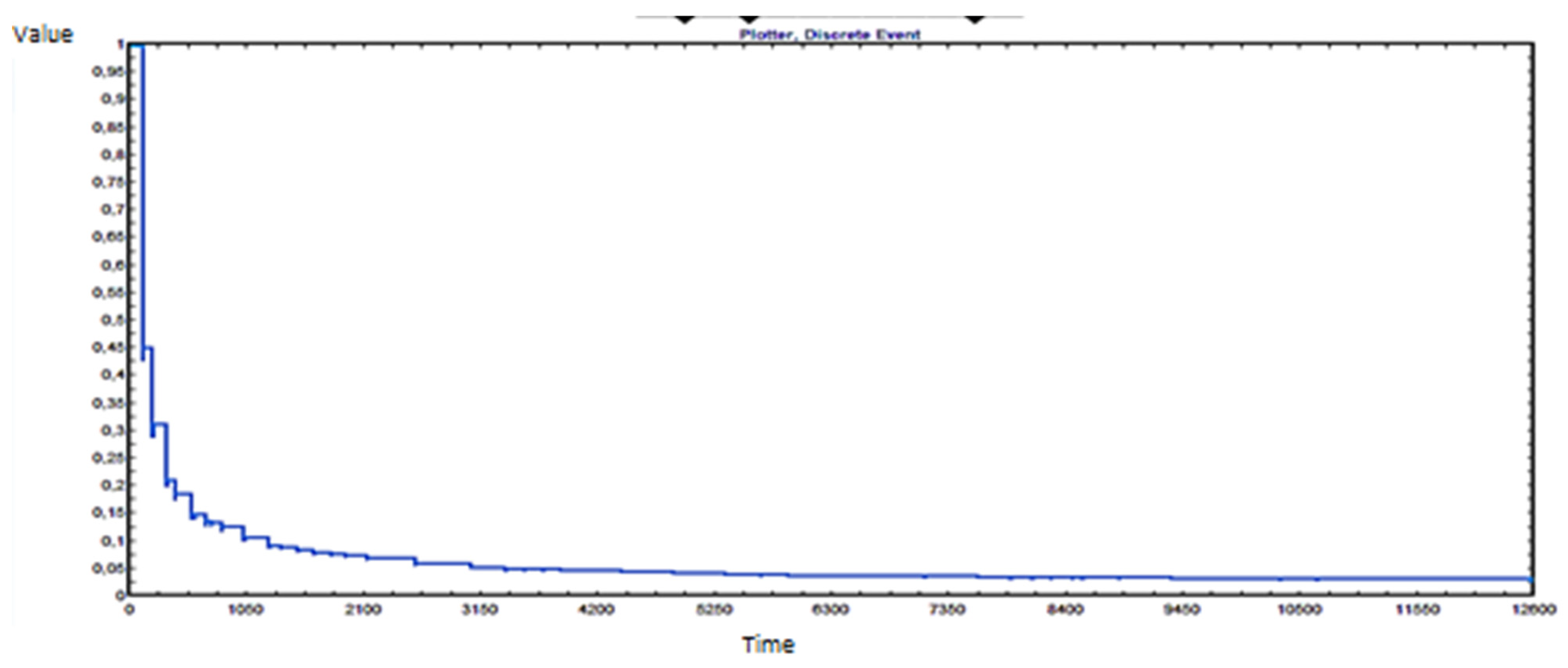

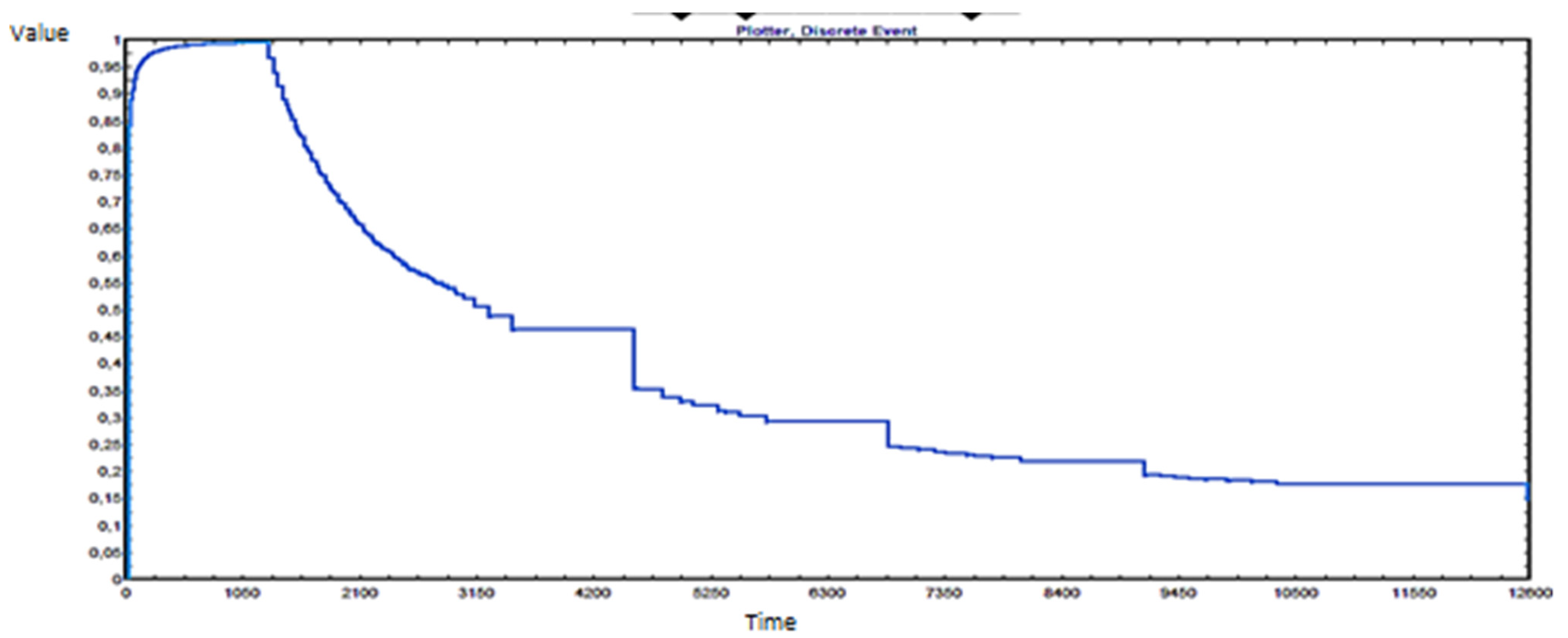

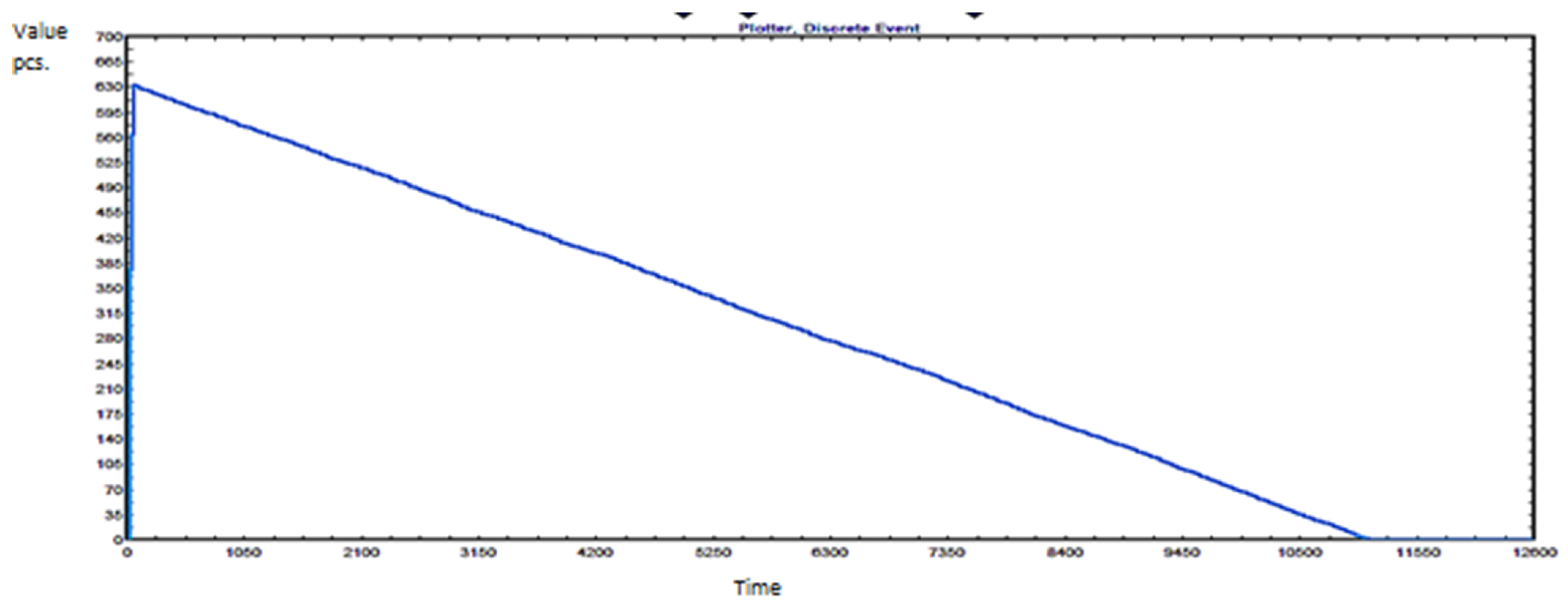

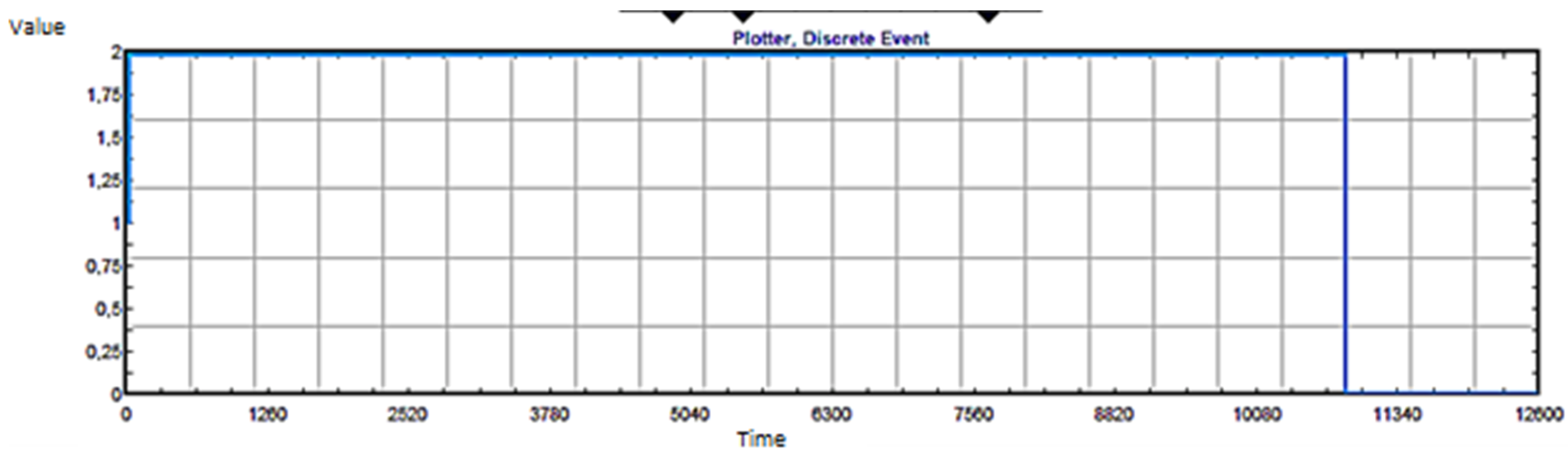

After streamlining the blast cleaning operation, bending does not meet production process requirements. During the production of the sample order, it processes a total of 636 demands, and the maximum length of the queue reaches, at some point, 632 demands waiting for the processing (

Figure 10). Such a quantity also requires a large space in the location of the operation. The utilization of the operation is diametrically higher than other operations utilization (

Figure 11). The enterprise should pay attention to this operation in the future. The question arises as to whether such a medium-sized enterprise can afford another investment after purchasing the LAUCO 200 NS machine. In this case, will it not be more advantageous for the enterprise to look for other options? For example, will outsourcing the bending activity be a sufficient and more economically acceptable solution to the new problem?

6. Conclusions

The case study carried out in the medium-sized enterprise aimed to take the first step towards the sustainable development of production, eliminate the bottleneck in production, and shorten the production process. The conditions of Slovak SMEs are tough, but, as our case study presents, there is always a way to start building the basics of sustainable development. The other Slovak SMEs may follow the presented example. We proved that even the simplest Industry 4.0 solution brings desirable improvement.

The means to verify and evaluate the suggested solution was a simulation in the program ExtendSim. Using simulation, the enterprise avoided the waste of resources and saved time needed to verify in classic and established ways. The model developed to evaluate the implemented innovation is a tool that enterprise can use even in the future. The model can be used to validate and evaluate future solutions to problems in the enterprise. The model can be used in the enterprise for capacity planning of agreed orders. This planning is based on one month period in the enterprise. In addition, simulation can quickly answer if spare time capacities are enough to sign special orders during the planning period. The custom production of the enterprise shows the flexibility of its production process. However, the core of the production process is essentially uniform, and the model created for the sample order, with the right modifications, can simulate the production of any order or solution to another problem. Slovak SMEs should start with proper system analysis. A deep understanding of their production process is the key. There are only small steps to the creation simulation model from system analysis. Simulation and simulation models could be used in many ways in the productions process, as declared above.

The results of the simulation are analyzed according to each production operation. The analysis demonstrates the correctness of the solution to the problem and confirms the main objectives requested. In addition to the main indicators, other outputs are evaluated after implementing the solution.

In the case of machine blast cleaning, the possibility of pre-production is open for the enterprise. The free production capacity of this operation can also be offered by the enterprise to external subjects and, thus, the enterprise can obtain additional profits. On the other hand, it also pointed to the shortcoming of this operation, which did not equal the demands from handgun blast cleaning. Although handgun blast cleaning is much less busy than in the original process, it still must process more demands than the machine blast cleaning. There is a challenge for technologists to reduce machine blast cleaning limitations and achieve greater balance.

Negative outputs include identifying a new bottleneck. After streamlining the blast cleaning operation, bending cannot quickly process the demands and holds back production. The acquisition of a wheel blast machine represents a high investment solution for the enterprise. Therefore, the enterprise must seek low-investment solutions to eliminate the new bottleneck. At first, bending metal sheets to stock or outsourcing the operation seems rational.

A question remains upon the allocation of workers of tacking and welding. To produce the beam, one tack worker and two welding workers are needed in the production process. In the case of the manufacture of other components of the product, seven workers are tacking, and seven workers are welding. Tacking and welding beams achieve higher utilization. On the contrary, the utilization of these operations for other components is relatively low. The enterprise should start to think about the analysis of the workforce. After analysis, the enterprise can answer questions about the optimal need for workers and their correct allocation between production operations.

Slovak SMEs must understand that sustainable development is a complex and complicated goal. In the beginning, the resolved problem shows other problems. There is no way to achieve sustainable development just by one simple solution. Therefore, when the basis is given, SMEs must realize that further work is needed and keep fighting with their problems towards sustainable development.

Based on simulation statistics, the suggested solution has been accepted by the enterprise and implemented and used in the company since 2021. After the redesign, the outputs of the real production process correspond to the expected outputs obtained by simulation before the solution was implemented.

After the implementation of the innovation, chosen sustainability indicators were improved. Indicators of energy use per production unit and environment and workplace pollution were decreased due to the elimination of obsolete machines. Indicators of order acceptance rate and worker satisfaction rate were increased. The enterprise has yet to start applying technologies to improve more indicators and create sustainable production development.

The implemented solution has brought the following improvements for the enterprise:

The basis for sustainable production development and deployment of Industry 4.0 technologies;

Shortening of the production time of the order by almost 50%;

Automation of the blast cleaning operation and increased speed of the processing of demands by this operation;

Shortening the handling movement trajectory during production;

Removing obsolete technology and thus reducing adverse impacts on the environment;

New possibilities for pre-production and transfer of production capacities to other orders in case of some production operations.

Simulation as a statistical tool is the right choice in a thorough analysis of the production process when it is possible to know all the elements of the process and the relationships between them so they can be sufficiently understood. In the case of innovation, simulation is an invaluable way to verify the suggested solution while not wasting financial and material resources. Simulation verification also offers, in addition to monitored outputs, outputs from each production process operation. This way, the enterprise can analyze statistics in advance and identify new problems that will show up when the original problem is resolved.