SDG-Oriented Supply Chains: Business Practices for Procurement and Distribution

Abstract

:1. Introduction

2. Theoretical Background

2.1. Supply Chains and Sustainable Development Goals

2.2. Procurement and Sustainable Development Practices

2.3. Distribution and Sustainable Development Practices

3. Methodology, Data and Standardized Variables

3.1. Data Collection from Literature Review

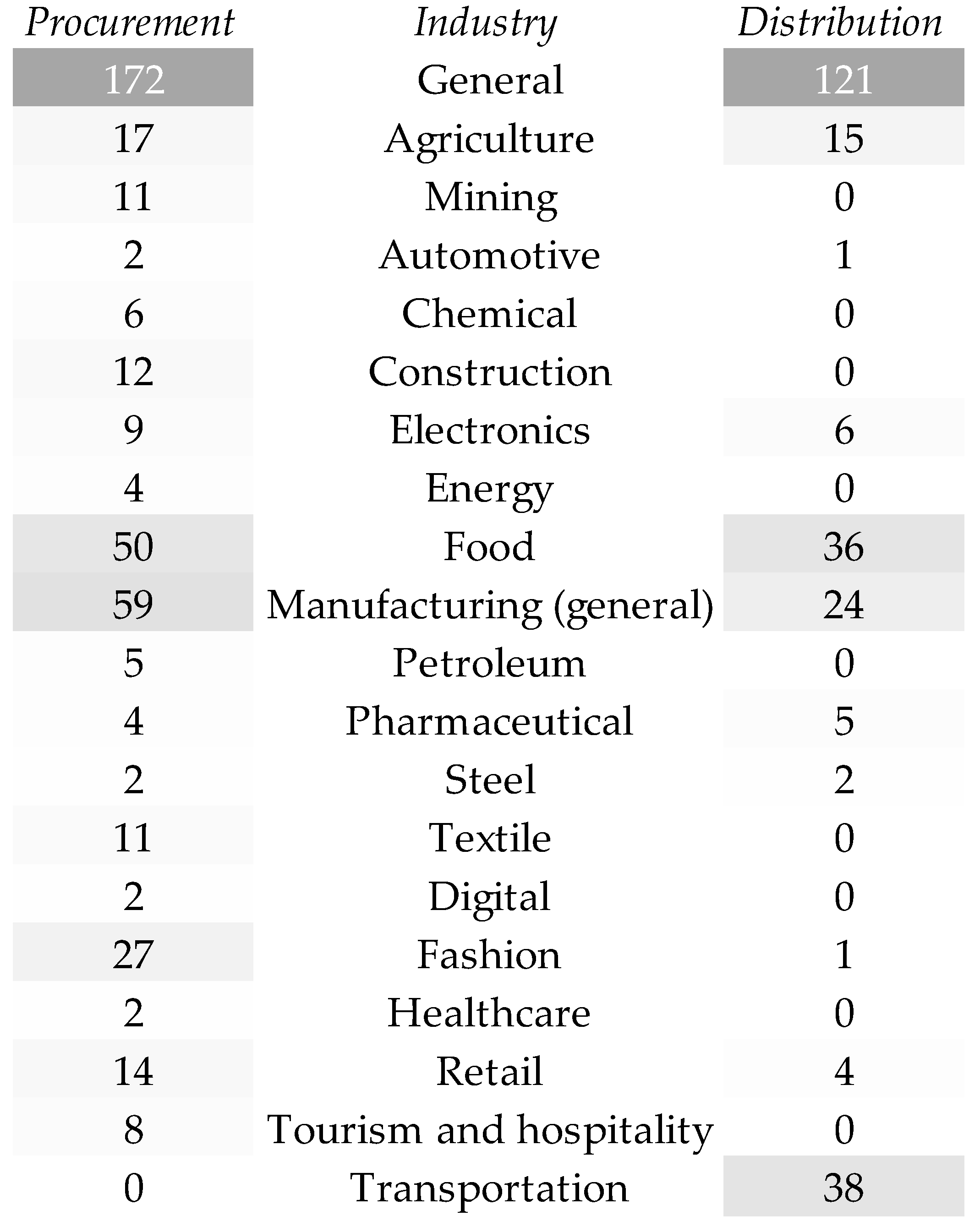

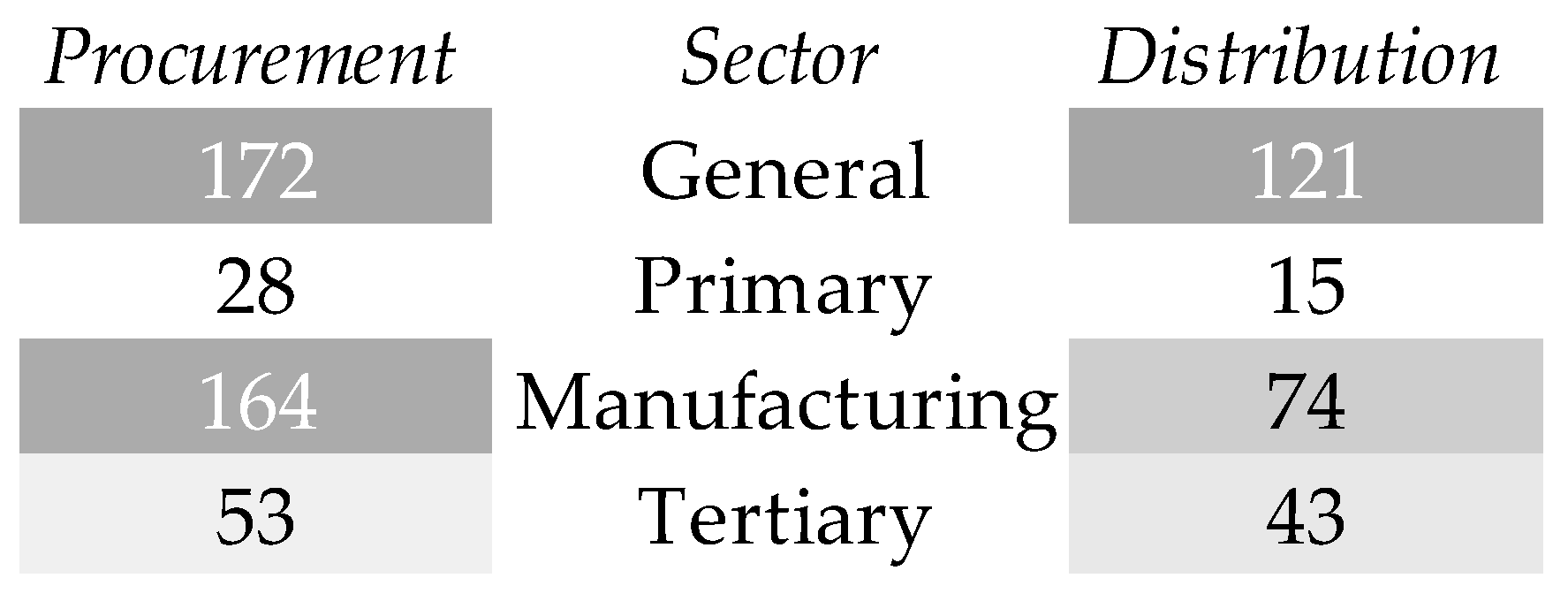

- The industry of belongingness of the actors within the SC, since from the analysis of the literature it is evident that there are different opportunities within different industries;

- The SC processes associated with such practices, distinguishing between “procurement” and “distribution”, with the first including all activities involving upstream partners, and the second including those engaging downstream actors;

- The positive business impact associated with the practice, which is independent of the concept of sustainability and refers to market and organizational performance that the focal company can achieve.

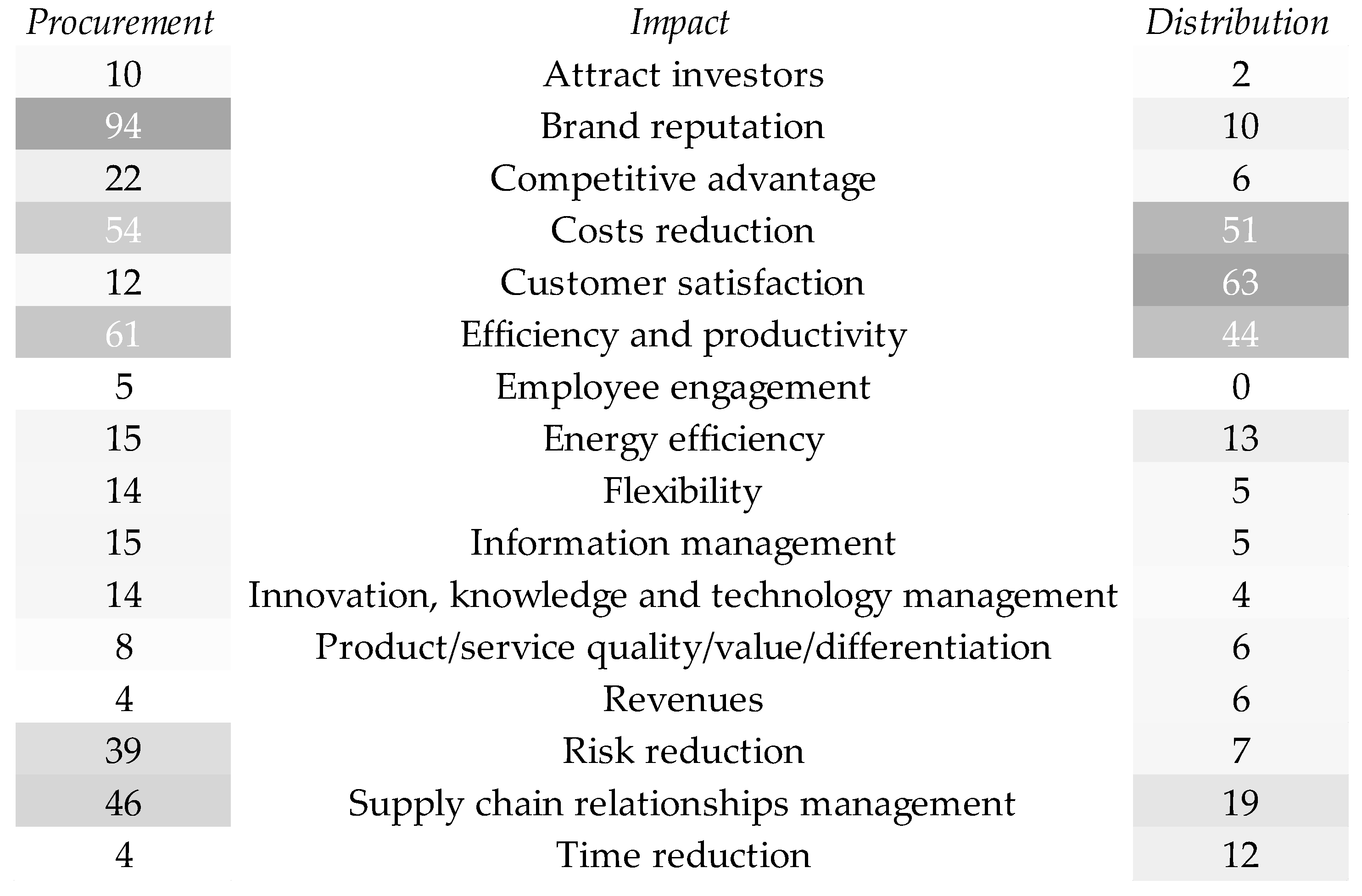

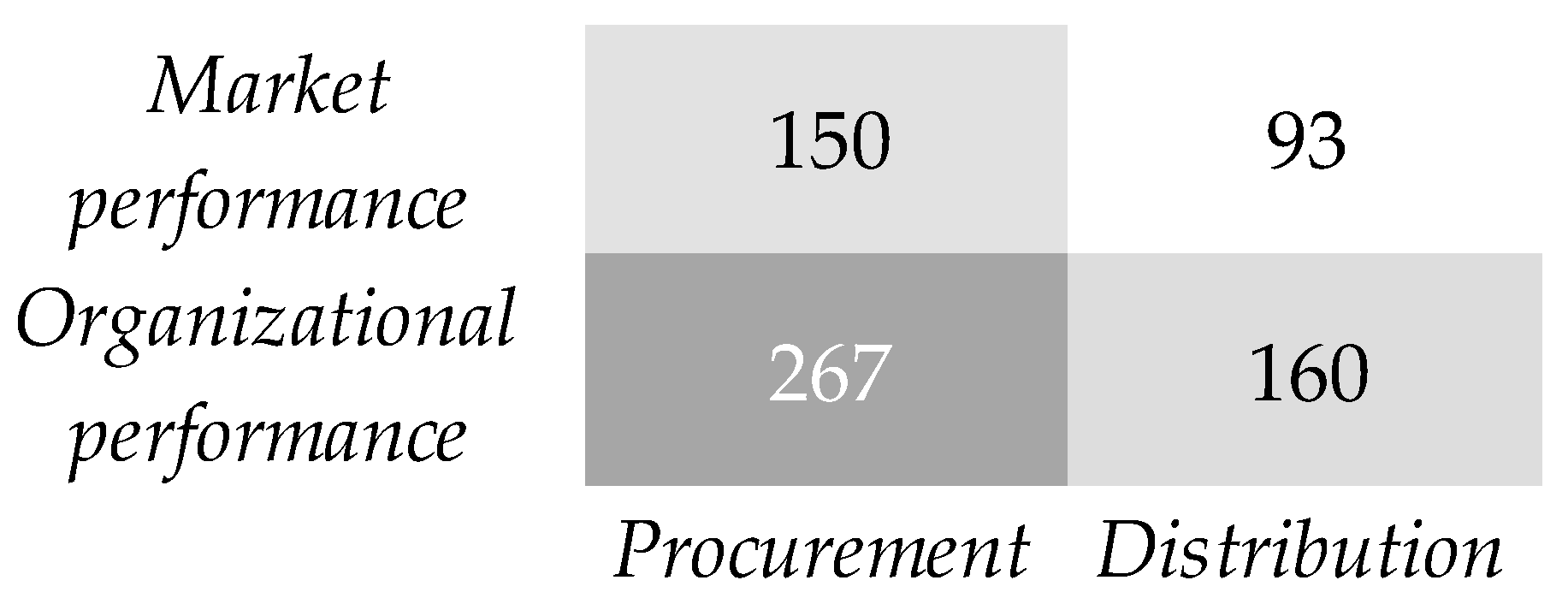

3.2. Business-Related Standardized Variables

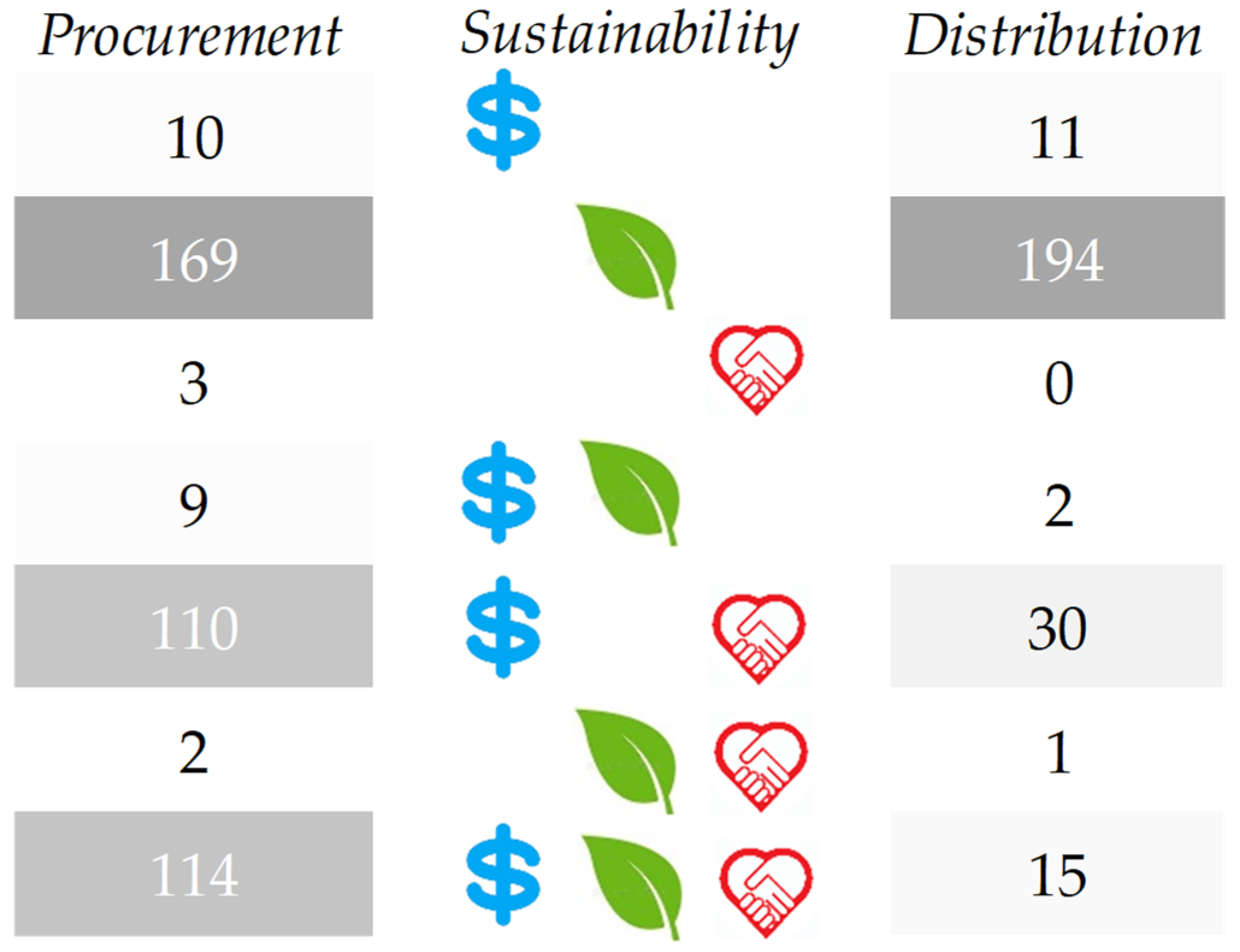

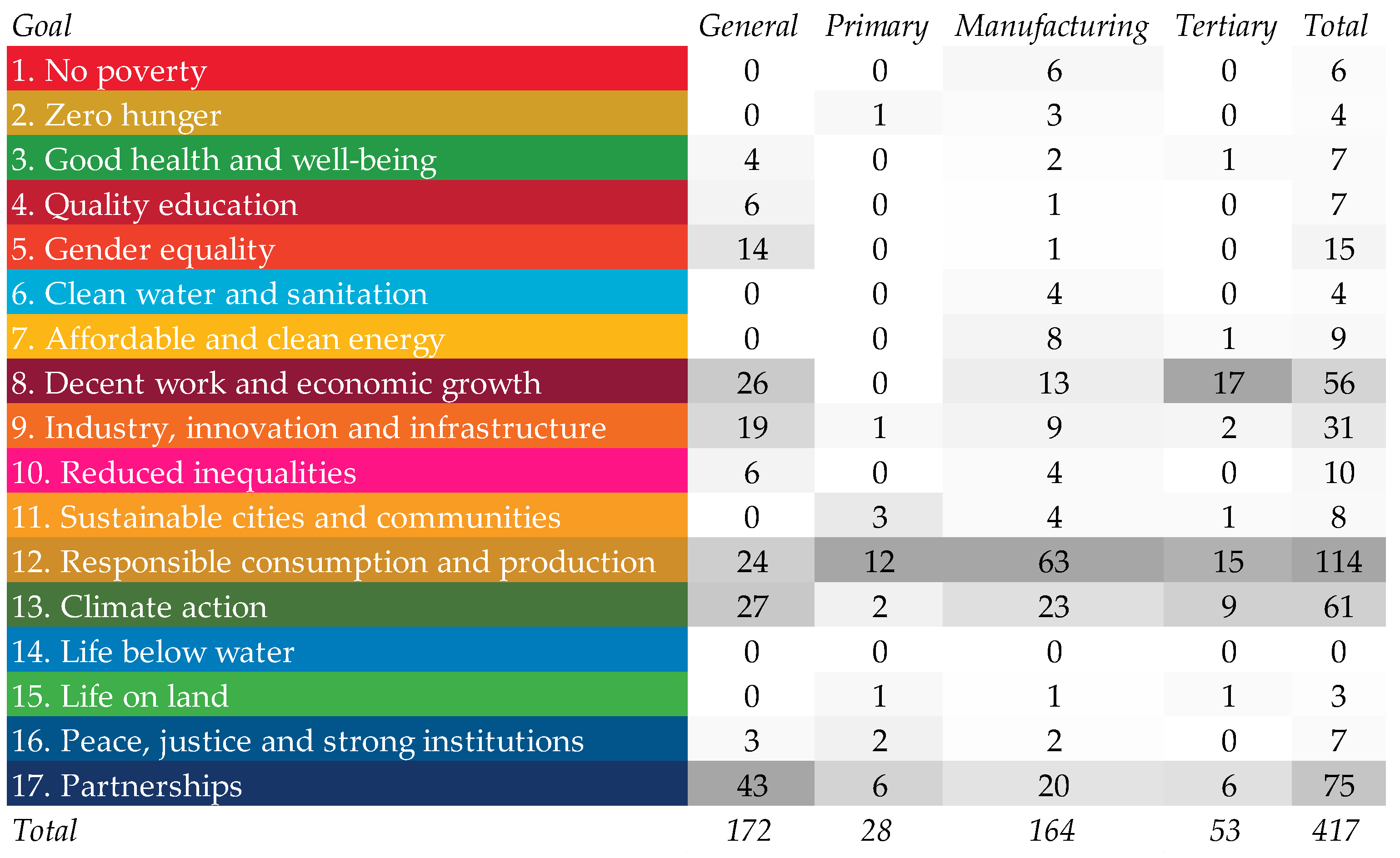

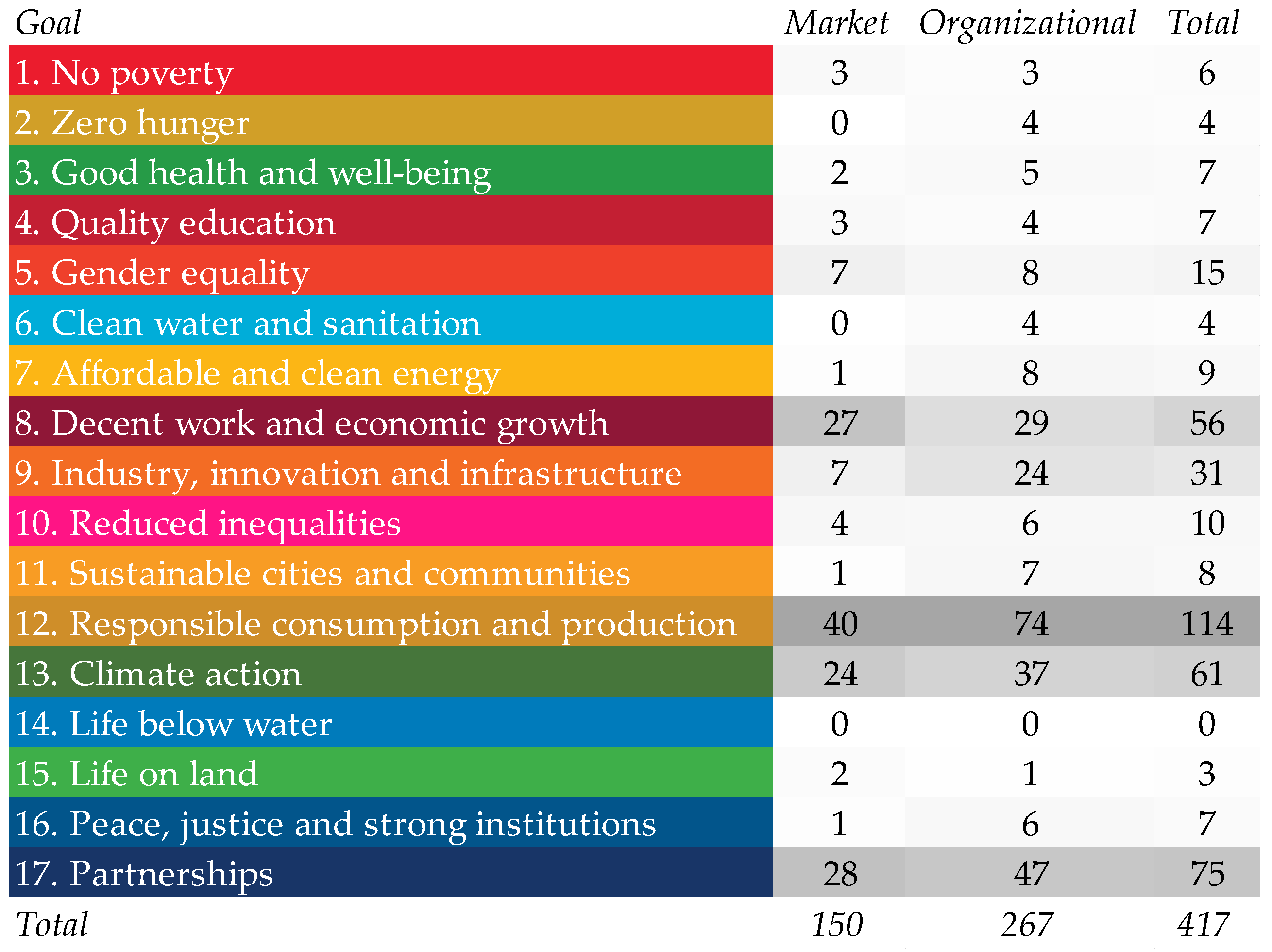

3.3. Sustainability-Related Standardized Variables

4. Analysis and Results

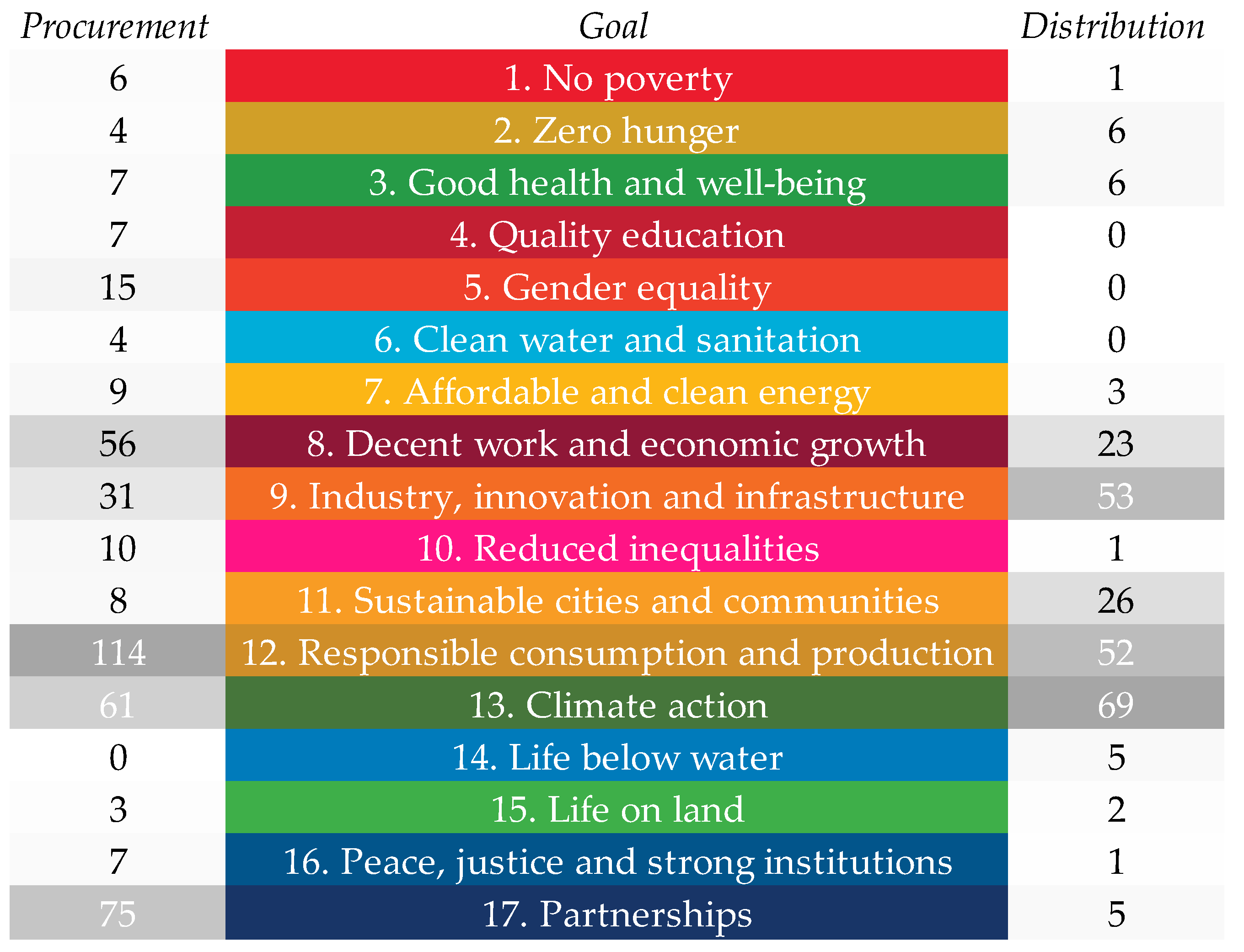

4.1. Sample Description

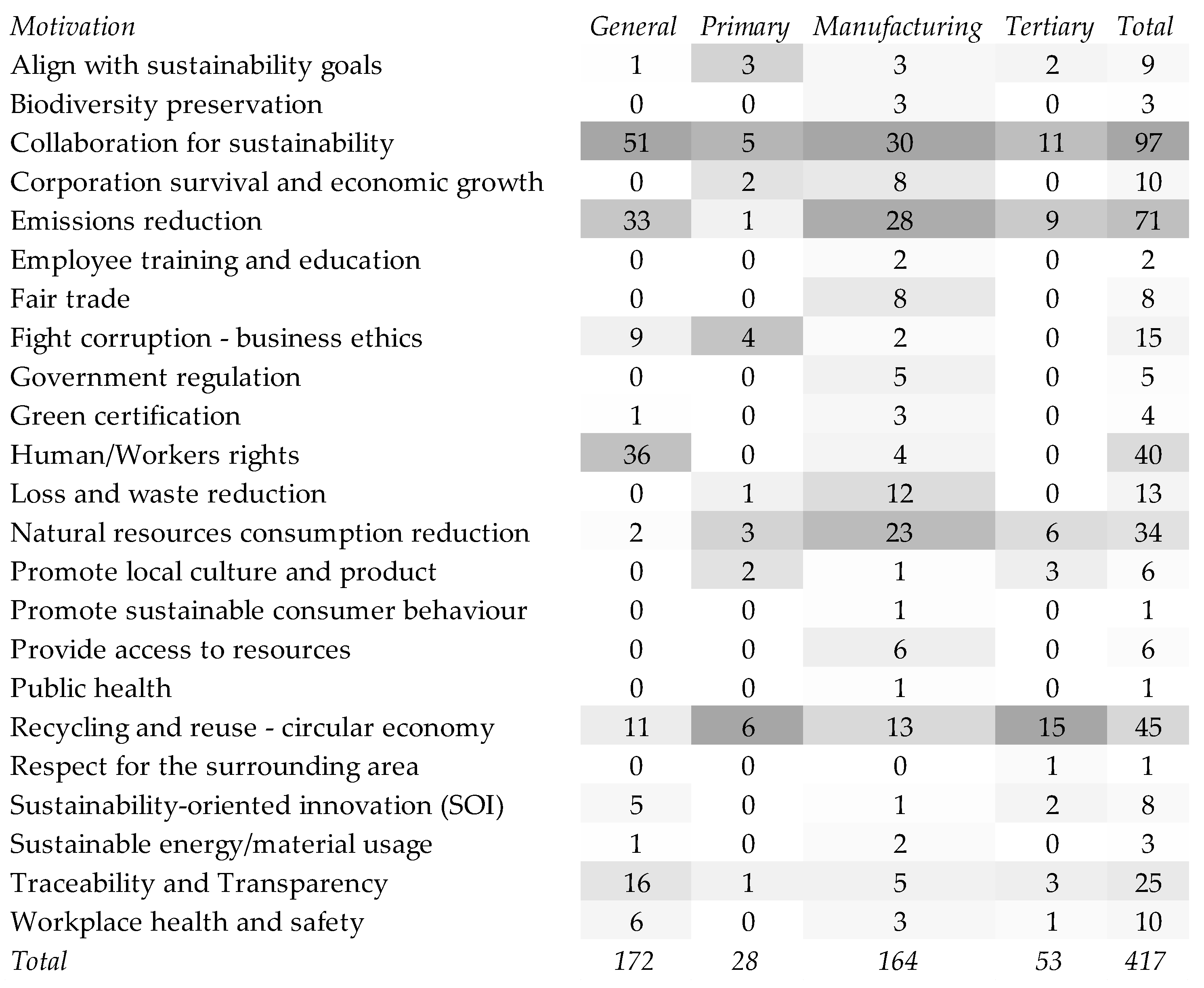

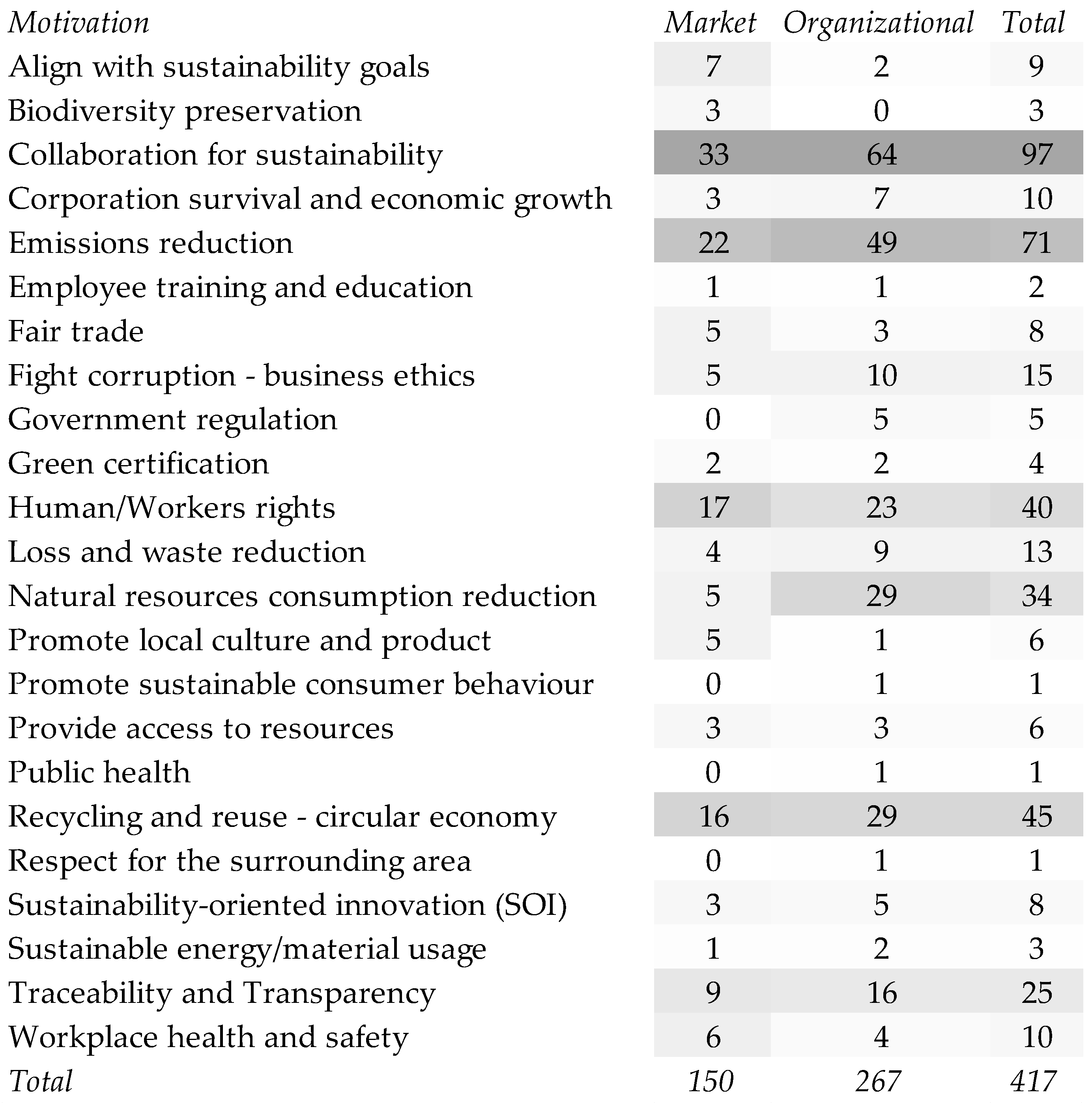

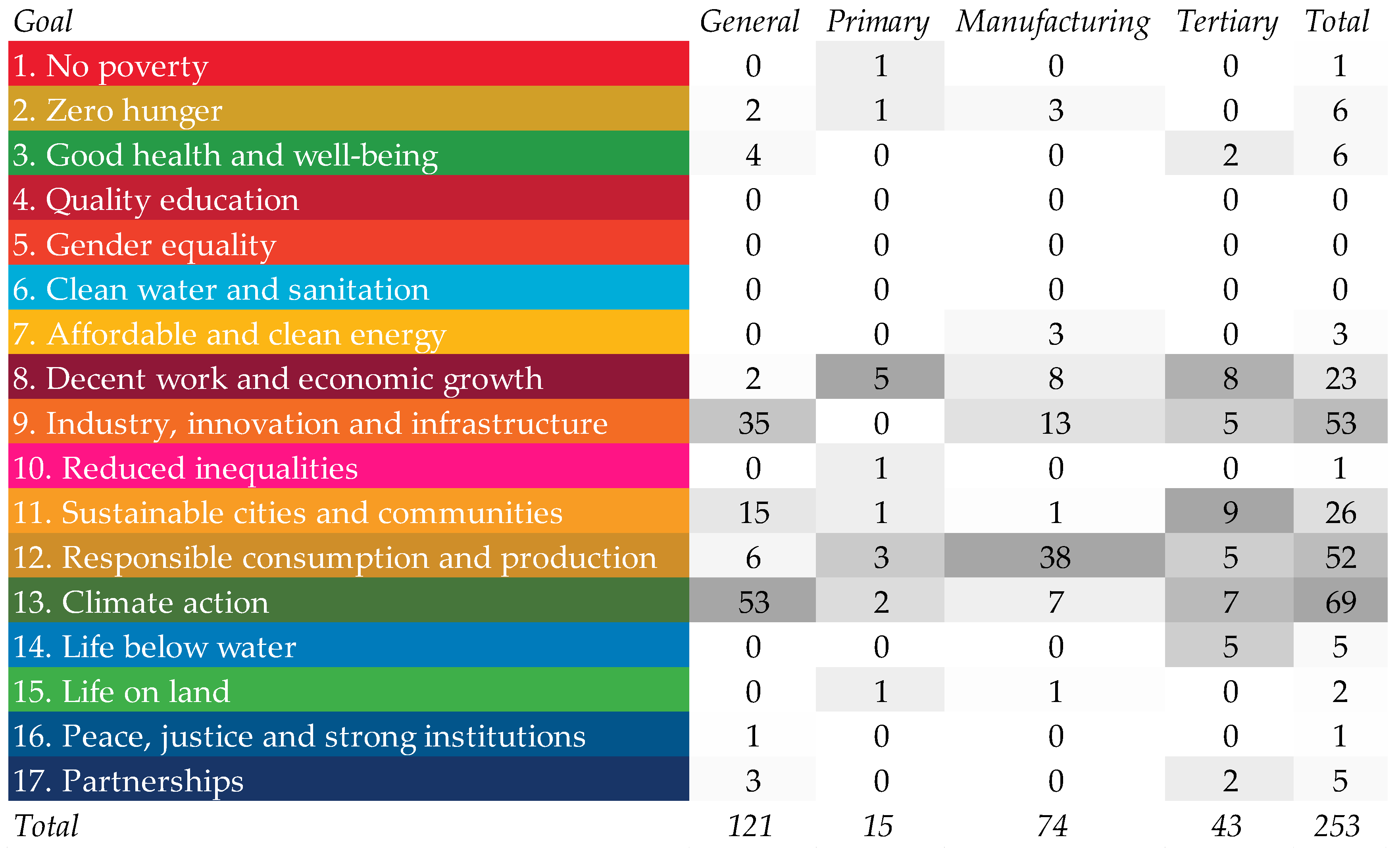

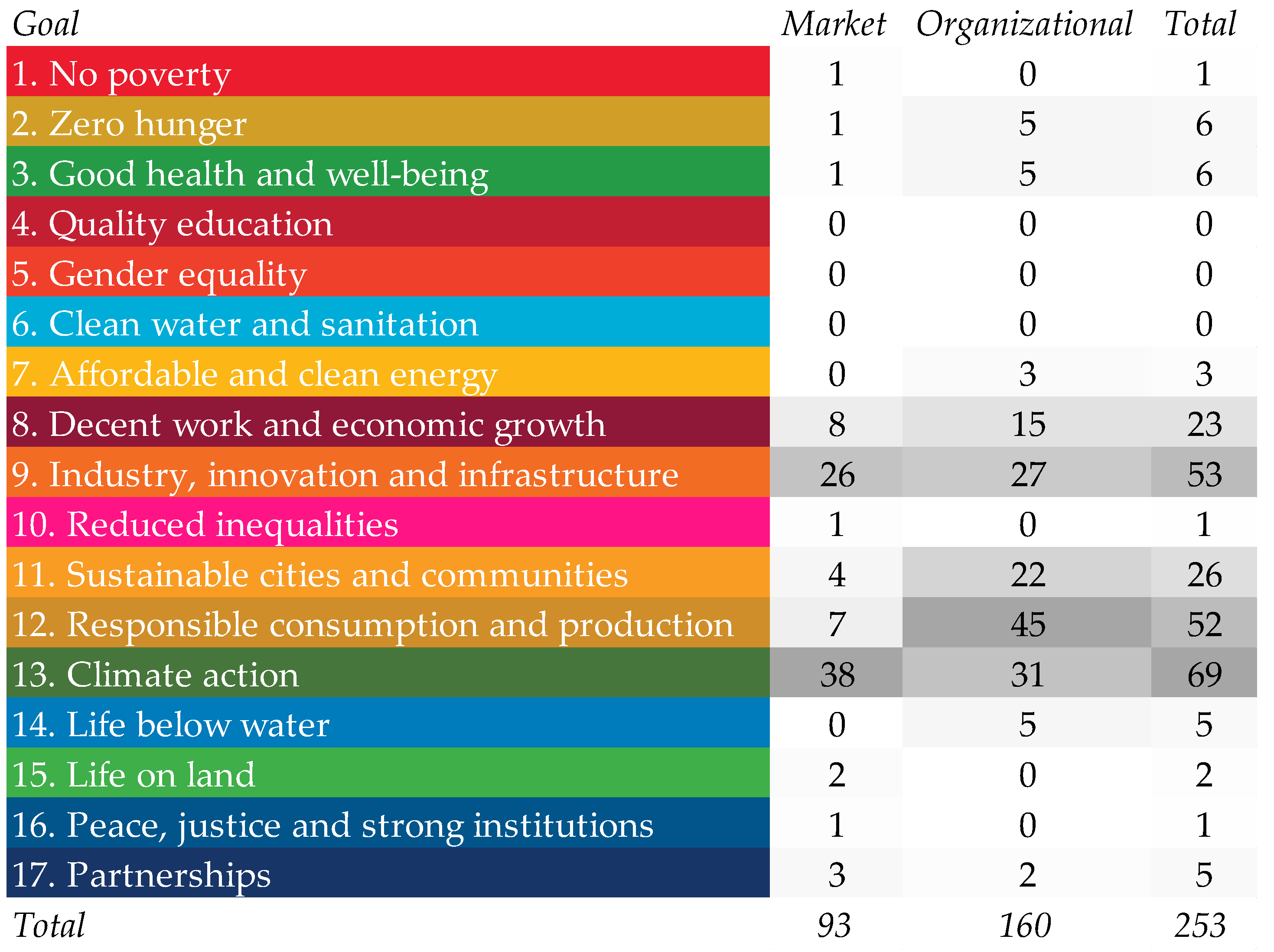

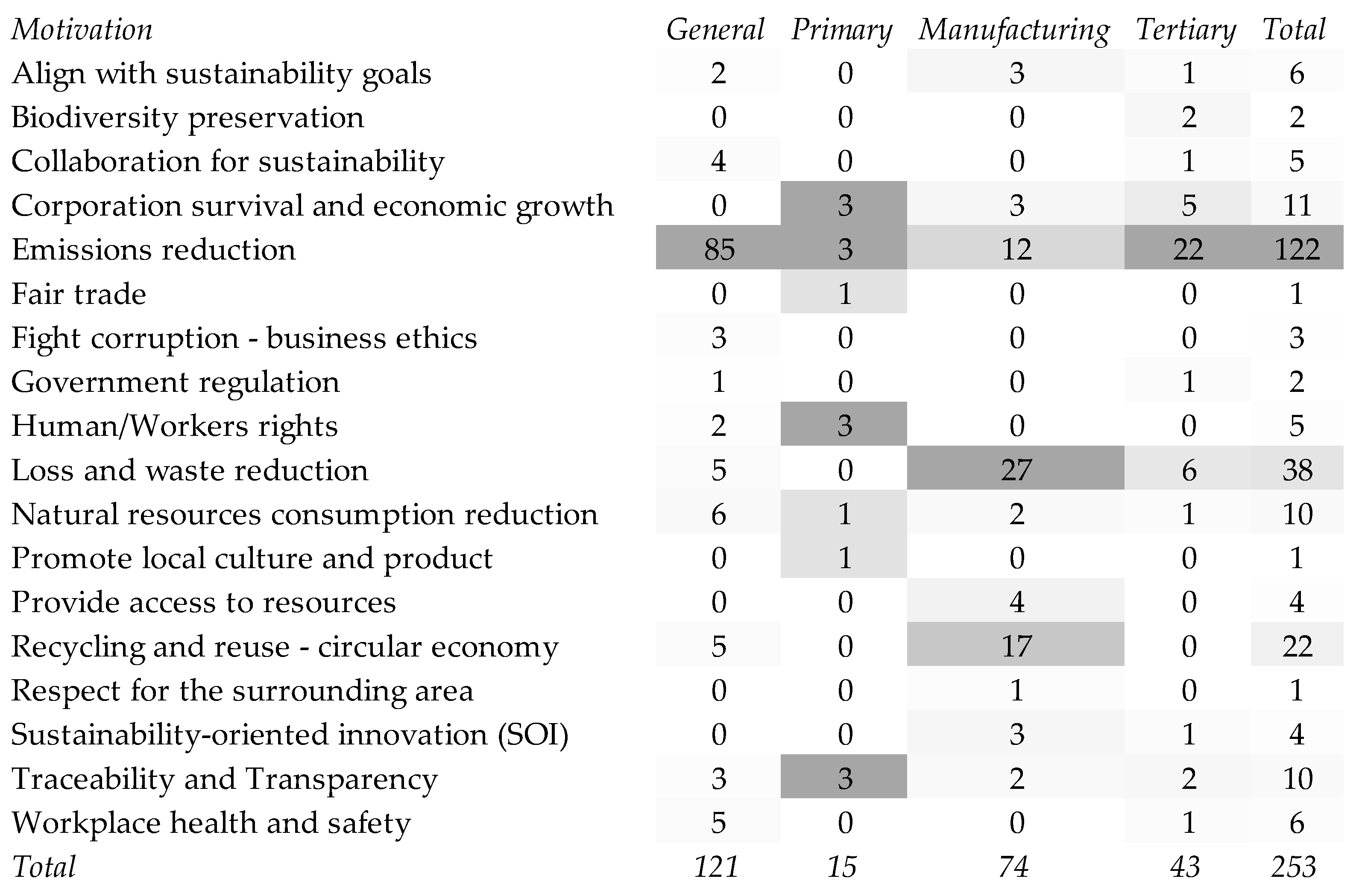

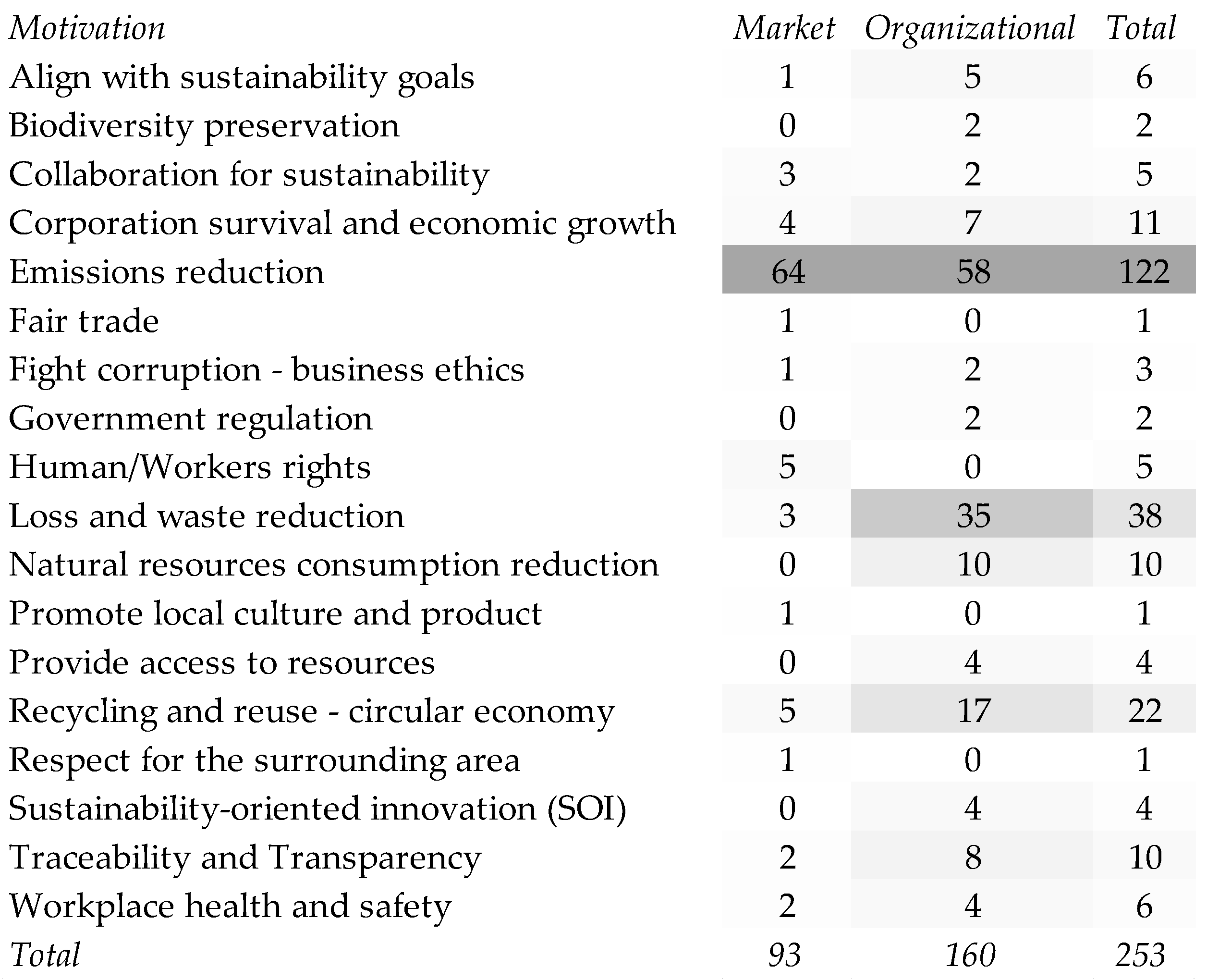

4.2. Descriptive Statistics

4.3. The Relationship between Business and Sustainability-Related Variables and Procurement

4.4. The Relationship between Business and Sustainability-Related Variables and Distribution

5. Discussions

5.1. Theoretical Contribution

5.2. Methodological Issues

5.3. Practical and Managerial Implications and Recommendations

6. Conclusions and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Botti, A.; Monda, A.; Pellicano, M.; Torre, C. The re-conceptualization of the port supply chain as a smart port service system: The case of the port of salerno. Systems 2017, 5, 35. [Google Scholar] [CrossRef] [Green Version]

- Brundtland, G.H. Our Common Future—The World Commission on Environment and Development; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Ahmadi, H.B.; Lo, H.W.; Gupta, H.; Kusi-Sarpong, S.; Liou, J.J.H. An integrated model for selecting suppliers on the basis of sustainability innovation. J. Clean. Prod. 2020, 277, 123261. [Google Scholar] [CrossRef]

- Quattrociocchi, B.; Mercuri, F.; Perano, M.; Calabrese, M. Tourism supply chain & strategic partnerships for managing the complexity in tourism industry. Enl. Tour. A Pathmaking J. 2017, 7, 62–93. [Google Scholar] [CrossRef]

- Yu, C.; Shao, Y.; Wang, K.; Zhang, L. A group decision making sustainable supplier selection approach using extended TOPSIS under interval-valued Pythagorean fuzzy environment. Expert Syst. Appl. 2019, 121, 1–17. [Google Scholar] [CrossRef]

- Song, Y.; Cai, J.; Feng, T. The influence of green supply chain integration on firm performance: A contingency and configuration perspective. Sustainability 2017, 9, 763. [Google Scholar] [CrossRef] [Green Version]

- Mazzucchelli, A.; Gurioli, M.; Graziano, D.; Quacquarelli, B.; Aouina-Mejri, C. How to fight against food waste in the digital era: Key factors for a successful food sharing platform. J. Bus. Res. 2020, 124, 47–58. [Google Scholar] [CrossRef]

- Caputo, F.; Scuotto, V.; Papa, A.; del Giudice, M. Dalla coercizione per la sostenibilità all’impegno sociale: Il ruolo della responsabilità sociale d’impresa. Corp. Gov. Res. Dev. Stud. 2021, 2, 15–31. [Google Scholar] [CrossRef]

- del Giudice, M.; Khan, Z.; de Silva, M.; Scuotto, V.; Caputo, F.; Carayannis, E. The microlevel actions undertaken by owner-managers in improving the sustainability practices of cultural and creative small and medium enterprises: A United Kingdom–Italy comparison. J. Organ. Behav. 2017, 38, 1396–1414. [Google Scholar] [CrossRef] [Green Version]

- Pontieri, P.; Mennini, F.S.; Magni, D.; Fiano, F.; Scuotto, V.; Papa, A.; Aletta, M.; Del Giudice, L. Sustainable open innovation for the agri-food system: Sorghum as healthy food to deal with environmental challenges. Br. Food J. 2021. ahead of print. [Google Scholar] [CrossRef]

- van der Waal, J.W.H.; Thijssens, T.; Maas, K. The innovative contribution of multinational enterprises to the Sustainable Development Goals. J. Clean. Prod. 2020, 285, 125319. [Google Scholar] [CrossRef]

- van der Waal, J.W.H.; Thijssens, T. Corporate involvement in Sustainable Development Goals: Exploring the territory. J. Clean. Prod. 2019, 252, 119625. [Google Scholar] [CrossRef]

- Zavyalova, E.; Studenikin, N.; Starikova, E. Business participation in implementation of socially oriented sustainable development goals in countries of central Asia and the Caucasus region. Cent. Asia Cauc. 2018, 19, 56–63. [Google Scholar]

- Fathollahi-Fard, A.M.; Ahmadi, A.; Al-e-Hashem, S.M.J.M. Sustainable closed-loop supply chain network for an integrated water supply and wastewater collection system under uncertainty. J. Environ. Manag. 2020, 275, 111277. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Meinke, H.; Wilson, M.; Marcelis, L.F.M.; Heuvelink, E. Towards delivering on the sustainable development goals in greenhouse production systems. Resour. Conserv. Recycl. 2021, 169, 105379. [Google Scholar] [CrossRef]

- Fraser, J. Creating shared value as a business strategy for mining to advance the United Nations Sustainable Development Goals. Extr. Ind. Soc. 2019, 6, 788–791. [Google Scholar] [CrossRef]

- Fallahpour, A.; Wong, K.Y.; Rajoo, S.; Fathollahi-Fard, A.M.; Antucheviciene, J.; Nayeri, S. An integrated approach for a sustainable supplier selection based on Industry 4.0 concept. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Scheyvens, R.; Banks, G.; Hughes, E. The Private Sector and the SDGs: The Need to Move Beyond ‘Business as Usual’. Sustain. Dev. 2016, 24, 371–382. [Google Scholar] [CrossRef]

- Calabrese, A.; Costa, R.; Ghiron, N.L.; Tiburzi, L.; Pedersen, E.R.G. How sustainable-orientated service innovation strategies are contributing to the sustainable development goals. Technol. Forecast. Soc. Chang. 2021, 169, 120816. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Denyer, D.; Overy, P. Sustainability-oriented Innovation: A Systematic Review. Int. J. Manag. Rev. 2016, 18, 180–205. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. The role of supplier innovation performance and strategies on the smartphone supply market. Eur. Manag. J. 2021, in press. [CrossRef]

- Cammarano, A.; Michelino, F.; Vitale, M.P.; la Rocca, M.; Caputo, M. Technological Strategies and Quality of Invention: The Role of Knowledge Base and Technical Applications. IEEE Trans. Eng. Manag. 2020, 1–17. [Google Scholar] [CrossRef]

- Cammarano, A.; Michelino, F.; Lamberti, E.; Caputo, M. Investigating technological strategy and relevance of knowledge domains in R&D collaborations. Int. J. Technol. Manag. 2019, 79, 60–83. [Google Scholar] [CrossRef]

- Cammarano, A.; Michelino, F.; Caputo, M. Open innovation practices for knowledge acquisition and their effects on innovation output. Technol. Anal. Strat. Manag. 2019, 31, 1297–1313. [Google Scholar] [CrossRef]

- Cammarano, A.; Caputo, M.; Lamberti, E.; Michelino, F. R&D Collaboration Strategies for Innovation: An Empirical Study Through Social Network Analysis. Int. J. Innov. Technol. Manag. 2017, 14, 1740001. [Google Scholar] [CrossRef]

- Muff, K.; Kapalka, A.; Dyllick, T. The Gap Frame—Translating the SDGs into relevant national grand challenges for strategic business opportunities. Int. J. Manag. Educ. 2017, 15, 363–383. [Google Scholar] [CrossRef]

- Raith, M.G.; Siebold, N. Building Business Models around Sustainable Development Goals. J. Bus. Models 2018, 6, 71–77. [Google Scholar] [CrossRef]

- Williams, A.; Whiteman, G.; Parker, J.N. Backstage Interorganizational Collaboration: Corporate Endorsement of the Sustainable Development Goals. Acad. Manag. Discov. 2019, 5, 367–395. [Google Scholar] [CrossRef]

- Zimon, D.; Tyan, J.; Sroufe, R. Drivers of sustainable supply chain management: Practices to alignment with un sustainable development goals. Int. J. Qual. Res. 2020, 14, 219–236. [Google Scholar] [CrossRef]

- Blair, M.J.; Gagnon, B.; Klain, A.; Kulišić, B. Contribution of biomass supply chains for bioenergy to sustainable development goals. Land 2021, 10, 181. [Google Scholar] [CrossRef]

- Russell, E.; Lee, J.; Clift, R. Can the SDGs provide a basis for supply chain decisions in the construction sector? Sustainability 2018, 10, 629. [Google Scholar] [CrossRef] [Green Version]

- Genc, T.S. Implementing the United Nations sustainable development Goals to supply chains with behavioral consumers. Ann. Oper. Res. 2021, 1–32. [Google Scholar] [CrossRef]

- Althaf, S.; Babbitt, C.W. Disruption risks to material supply chains in the electronics sector. Resour. Conserv. Recycl. 2020, 167, 105248. [Google Scholar] [CrossRef]

- Mina, H.; Kannan, D.; Gholami-Zanjani, S.M.; Biuki, M. Transition towards circular supplier selection in petrochemical industry: A hybrid approach to achieve sustainable development goals. J. Clean. Prod. 2020, 286, 125273. [Google Scholar] [CrossRef]

- Haeri, S.A.S.; Rezaei, J. A grey-based green supplier selection model for uncertain environments. J. Clean. Prod. 2019, 221, 768–784. [Google Scholar] [CrossRef]

- Gao, H.; Ju, Y.; Gonzalez, E.D.R.S.; Zhang, W. Green supplier selection in electronics manufacturing: An approach based on consensus decision making. J. Clean. Prod. 2020, 245, 118781. [Google Scholar] [CrossRef]

- Fallahpour, A.; Yazdani, M.; Mohammed, A.; Wong, K.Y. Green sourcing in the era of industry 4.0: Towards green and digitalized competitive advantages. Ind. Manag. Data Syst. 2021, 121, 1997–2025. [Google Scholar] [CrossRef]

- Lahri, V.; Shaw, K.; Ishizaka, A. Sustainable supply chain network design problem: Using the integrated BWM, TOPSIS, possibilistic programming, and ε-constrained methods. Expert Syst. Appl. 2020, 168, 114373. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Ahmadi, H.B.; Sarkis, J. Social sustainable supplier evaluation and selection: A group decision-support approach. Int. J. Prod. Res. 2019, 57, 7046–7067. [Google Scholar] [CrossRef]

- Schiessl, A.; Müller, R.; Volk, R.; Schultmann, F. Site-specific environmental impact assessment as a basis for supplier selections–exemplary application to aluminum. J. Clean. Prod. 2021, 290, 125703. [Google Scholar] [CrossRef]

- Wu, C.; Lin, C.; Barnes, D.; Zhang, Y. Partner selection in sustainable supply chains: A fuzzy ensemble learning model. J. Clean. Prod. 2020, 275, 123165. [Google Scholar] [CrossRef]

- Sultan, F.A.; Routroy, S.; Thakur, M. A simulation-based performance investigation of downstream operations in the Indian Surimi Supply Chain using environmental value stream mapping. J. Clean. Prod. 2020, 286, 125389. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Govindan, K.; Murniningsih, R.; Setiawan, A. Industry 4.0 based sustainable circular economy approach for smart waste management system to achieve sustainable development goals: A case study of Indonesia. J. Clean. Prod. 2020, 269, 122263. [Google Scholar] [CrossRef]

- Nasr, A.K.; Tavana, M.; Alavi, B.; Mina, H. A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. J. Clean. Prod. 2020, 287, 124994. [Google Scholar] [CrossRef]

- Wan, X.; Liu, X.; Du, Z.; Du, Y. A novel model used for assessing supply chain sustainability integrating the ANP and ER approaches and its application in marine ranching. J. Clean. Prod. 2020, 279, 123500. [Google Scholar] [CrossRef]

- Mirzaee, H.; Naderi, B.; Pasandideh, S.H.R. A preemptive fuzzy goal programming model for generalized supplier selection and order allocation with incremental discount. Comput. Ind. Eng. 2018, 122, 292–302. [Google Scholar] [CrossRef]

- Sodhi, M.M.S.; Tang, C.S. Extending AAA Capabilities to Meet PPP Goals in Supply Chains. Prod. Oper. Manag. 2020, 30, 625–632. [Google Scholar] [CrossRef]

- Silvestre, B.S.; Ţîrcă, D.M. Innovations for sustainable development: Moving toward a sustainable future. J. Clean. Prod. 2018, 208, 325–332. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, K.M.; Kannan, D. Achieving sustainable development goals through identifying and analyzing barriers to industrial sharing economy: A framework development. Int. J. Prod. Econ. 2020, 227, 107575. [Google Scholar] [CrossRef]

- Malik, A.; Lafortune, G.; Carter, S.; Li, M.; Lenzen, M.; Kroll, C. International spillover effects in the EU’s textile supply chains: A global SDG assessment. J. Environ. Manag. 2021, 295, 113037. [Google Scholar] [CrossRef]

- Spreafico, C.; Russo, D. A sustainable cheese packaging survey involving scientific papers and patents. J. Clean. Prod. 2021, 293, 126196. [Google Scholar] [CrossRef]

- Chen, Z.S.; Zhang, X.; Govindan, K.; Wang, X.J.; Chin, K.S. Third-party reverse logistics provider selection: A computational semantic analysis-based multi-perspective multi-attribute decision-making approach. Expert Syst. Appl. 2020, 166, 114051. [Google Scholar] [CrossRef]

- Govindan, K.; Kadziński, M.; Ehling, R.; Miebs, G. Selection of a sustainable third-party reverse logistics provider based on the robustness analysis of an outranking graph kernel conducted with ELECTRE I and SMAA. Omega 2019, 85, 1–15. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Asadi-Gangraj, E. Scenario-based design of a steel sustainable closed-loop supply chain network considering production technology. J. Clean. Prod. 2020, 277, 123298. [Google Scholar] [CrossRef]

- Mojtahedi, M.; Fathollahi-Fard, A.M.; Tavakkoli-Moghaddam, R.; Newton, S. Sustainable vehicle routing problem for coordinated solid waste management. J. Ind. Inf. Integr. 2021, 23, 100220. [Google Scholar] [CrossRef]

- Baral, N.R.; Asher, Z.D.; Trinko, D.; Sproul, E.; Quiroz-Arita, C.; Quinn, J.C.; Bradley, T.H. Biomass feedstock transport using fuel cell and battery electric trucks improves lifecycle metrics of biofuel sustainability and economy. J. Clean. Prod. 2020, 279, 123593. [Google Scholar] [CrossRef]

- Liu, X.; Elgowainy, A.; Vijayagopal, R.; Wang, M. Well-to-Wheels Analysis of Zero-Emission Plug-In Battery Electric Vehicle Technology for Medium- and Heavy-Duty Trucks. Environ. Sci. Technol. 2020, 55, 538–546. [Google Scholar] [CrossRef]

- Karakas, S.; Acar, A.Z.; Kirmizi, M. Development of a multidimensional performance evaluation model for container terminals at Marmara Sea. Res. Transp. Bus. Manag. 2020, 37, 100498. [Google Scholar] [CrossRef]

- Dutta, P.; Talaulikar, S.; Xavier, V.; Kapoor, S. Fostering reverse logistics in India by prominent barrier identification and strategy implementation to promote circular economy. J. Clean. Prod. 2021, 294, 126241. [Google Scholar] [CrossRef]

- Kumar, A.; Wasan, P.; Luthra, S.; Dixit, G. Development of a framework for selecting a sustainable location of waste electrical and electronic equipment recycling plant in emerging economies. J. Clean. Prod. 2020, 277, 122645. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.Z.; Sarkar, B. Optimum sustainable inventory management with backorder and deterioration under controllable carbon emissions. J. Clean. Prod. 2020, 279, 123699. [Google Scholar] [CrossRef]

- Mehmann, J.; Teuteberg, F. The fourth-party logistics service provider approach to support sustainable development goals in transportation—A case study of the German agricultural bulk logistics sector. J. Clean. Prod. 2016, 126, 382–393. [Google Scholar] [CrossRef]

- Goodarzian, F.; Taleizadeh, A.A.; Ghasemi, P.; Abraham, A. An integrated sustainable medical supply chain network during COVID-19. Eng. Appl. Artif. Intell. 2021, 100, 104188. [Google Scholar] [CrossRef] [PubMed]

- Goodarzian, F.; Hosseini-Nasab, H.; Fakhrzad, M.B. A multi-objective sustainable medicine supply chain network design using a novel hybrid multi-objective metaheuristic algorithm. Int. J. Eng. 2020, 33, 1986–1995. [Google Scholar] [CrossRef]

- Cao, S.; Liao, W.; Huang, Y. Heterogeneous fleet recyclables collection routing optimization in a two-echelon collaborative reverse logistics network from circular economic and environmental perspective. Sci. Total Environ. 2020, 758, 144062. [Google Scholar] [CrossRef]

- Ben-Daya, M.; As’ad, R.; Nabi, K.A. A single-vendor multi-buyer production remanufacturing inventory system under a centralized consignment arrangement. Comput. Ind. Eng. 2019, 135, 10–27. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Lawson, B.; Pil, F.K.; Wagner, S.M. The digitalization of operations and supply chain management: Theoretical and methodological implications. J. Oper. Manag. 2019, 65, 728–734. [Google Scholar] [CrossRef]

- Jagtap, S.; Garcia-Garcia, G.; Rahimifard, S. Optimisation of the resource efficiency of food manufacturing via the Internet of Things. Comput. Ind. 2021, 127, 103397. [Google Scholar] [CrossRef]

- Shayganmehr, M.; Kumar, A.; Garza-Reyes, J.A.; Moktadir, M.A. Industry 4.0 enablers for a cleaner production and circular economy within the context of business ethics: A study in a developing country. J. Clean. Prod. 2021, 281, 125280. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. New organizational changes with blockchain: A focus on the supply chain. J. Organ. Chang. Manag. 2021, 34, 420–438. [Google Scholar] [CrossRef]

- Mastos, T.D.; Nizamis, A.; Terzi, S.; Gkortzis, D.; Papadopoulos, A.; Tsagkalidis, N.; Ioannidis, D.; Votis, K.; Tzovaras, D. Introducing an application of an industry 4.0 solution for circular supply chain management. J. Clean. Prod. 2021, 300, 126886. [Google Scholar] [CrossRef]

- Mehrjerdi, Y.Z.; Shafiee, M. A resilient and sustainable closed-loop supply chain using multiple sourcing and information sharing strategies. J. Clean. Prod. 2020, 289, 125141. [Google Scholar] [CrossRef]

- Jouzdani, J.; Govindan, K. On the sustainable perishable food supply chain network design: A dairy products case to achieve sustainable development goals. J. Clean. Prod. 2020, 278, 123060. [Google Scholar] [CrossRef]

- Karki, S.T.; Bennett, A.C.T.; Mishra, J.L. Reducing food waste and food insecurity in the UK: The architecture of surplus food distribution supply chain in addressing the sustainable development goals (Goal 2 and Goal 12.3) at a city level. Ind. Mark. Manag. 2021, 93, 563–577. [Google Scholar] [CrossRef]

- Mavi, R.K.; Mavi, N.K. National eco-innovation analysis with big data: A common-weights model for dynamic DEA. Technol. Forecast. Soc. Chang. 2020, 162, 120369. [Google Scholar] [CrossRef]

- Karaosman, H.; Perry, P.; Brun, A.; Morales-Alonso, G. Behind the runway: Extending sustainability in luxury fashion supply chains. J. Bus. Res. 2018, 117, 652–663. [Google Scholar] [CrossRef]

- Cai, Y.J.; Choi, T.M. A United Nations’ Sustainable Development Goals perspective for sustainable textile and apparel supply chain management. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 102010. [Google Scholar] [CrossRef]

- Cozzio, C.; Volgger, M.; Taplin, R.; Woodside, A.G. Nurturing tourists’ ethical food consumption: Testing the persuasive strengths of alternative messages in a natural hotel setting. J. Bus. Res. 2020, 117, 268–279. [Google Scholar] [CrossRef]

- Dauvergne, P. Is artificial intelligence greening global supply chains? Exposing the political economy of environmental costs. Rev. Int. Political Econ. 2020, 1–23. [Google Scholar] [CrossRef]

- Chicco, A.; Diana, M. Air emissions impacts of modal diversion patterns induced by one-way car sharing: A case study from the city of Turin. Transp. Res. Part D Transp. Environ. 2021, 91, 102685. [Google Scholar] [CrossRef]

- de Villiers, C.; Kuruppu, S.; Dissanayake, D. A (new) role for business—Promoting the United Nations’ Sustainable Development Goals through the internet-of-things and blockchain technology. J. Bus. Res. 2020, 131, 598–609. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Sustainable supply chains with blockchain, IoT and RFID: A simulation on order management. Sustainability 2021, 13, 6372. [Google Scholar] [CrossRef]

- Meqdadi, O.; Johnsen, T.E.; Johnsen, R.E.; Salmi, A. Monitoring and mentoring strategies for diffusing sustainability in supply networks. Supply Chain Manag. Int. J. 2020, 25, 729–746. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S.; Good, J. Us before me: A group level approach to the circular economy. Ecol. Econ. 2020, 179, 106838. [Google Scholar] [CrossRef]

- Shashi, S.; Centobelli, P.; Cerchione, R.; Ertz, M. Food cold chain management: What we know and what we deserve. Supply Chain. Manag. 2021, 26, 102–135. [Google Scholar] [CrossRef]

- Mani, V.; Jabbour, C.J.C.; Mani, K.T.N. Supply chain social sustainability in small and medium manufacturing enterprises and firms’ performance: Empirical evidence from an emerging Asian economy. Int. J. Prod. Econ. 2020, 227, 107656. [Google Scholar] [CrossRef]

- Guo, S.; Sun, X.; Lam, H.K.S. Applications of Blockchain Technology in Sustainable Fashion Supply Chains: Operational Transparency and Environmental Efforts. IEEE Trans. Eng. Manag. 2020, 1–17. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. The unknown potential of blockchain for sustainable supply chains. Sustainability 2020, 12, 9400. [Google Scholar] [CrossRef]

- Mohammed, A. Towards a sustainable assessment of suppliers: An integrated fuzzy TOPSIS-possibilistic multi-objective approach. Ann. Oper. Res. 2019, 293, 639–668. [Google Scholar] [CrossRef]

- Sabatini, A.; O’Toole, T.; Gregori, G. Integrating sustainability in business network initiation: The case of an Italian pasta maker. J. Bus. Ind. Mark. 2021, 36, 1894–1908. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Bazilian, M.; Griffiths, S.; Kim, J.; Foley, A.; Rooney, D. Decarbonizing the food and beverages industry: A critical and systematic review of developments, sociotechnical systems and policy options. Renew. Sustain. Energy Rev. 2021, 143, 110856. [Google Scholar] [CrossRef]

- Venkatesh, V.G.; Zhang, A.; Deakins, E.; Mani, V. Drivers of sub-supplier social sustainability compliance: An emerging economy perspective. Supply Chain Manag. Int. J. 2020, 25, 655–677. [Google Scholar] [CrossRef]

- Mohammadi, E.; Singh, S.J.; Habib, K. Electronic waste in the Caribbean: An impending environmental disaster or an opportunity for a circular economy? Resour. Conserv. Recycl. 2020, 164, 105106. [Google Scholar] [CrossRef]

- Osti, L.; Goffi, G. Lifestyle of health & sustainability: The hospitality sector’s response to a new market segment. J. Hosp. Tour. Manag. 2021, 46, 360–363. [Google Scholar] [CrossRef]

- Lin, Y.T.; Sun, H.; Wang, S. Designing sustainable products under coproduction technology. Manuf. Serv. Oper. Manag. 2020, 22, 1181–1198. [Google Scholar] [CrossRef]

- Saha, K.; Dey, P.K.; Papagiannaki, E. Implementing circular economy in the textile and clothing industry. Bus. Strat. Environ. 2021, 30, 1497–1530. [Google Scholar] [CrossRef]

- Calabrese, A.; Costa, R.; Ghiron, N.L.; Menichini, T.; Miscoli, V.; Tiburzi, L. Operating modes and cost burdens for the European deposit-refund systems: A systematic approach for their analysis and design. J. Clean. Prod. 2020, 288, 125600. [Google Scholar] [CrossRef]

- Shoukohyar, S.; Seddigh, M.R. Uncovering the dark and bright sides of implementing collaborative forecasting throughout sustainable supply chains: An exploratory approach. Technol. Forecast. Soc. Chang. 2020, 158, 120059. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.; Cabarcas-Reyes, J.; Ishizaka, A.; Barbati, M.; Jaramillo-Rueda, N.; Carrascal-Zambrano, G.d. A hybrid fuzzy multi-criteria decision making model for selecting a sustainable supplier of forklift filters: A case study from the mining industry. Ann. Oper. Res. 2020, 307, 443–481. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Pursuing supply chain sustainable development goals through the adoption of green practices and enabling technologies: A cross-country analysis of LSPs. Technol. Forecast. Soc. Chang. 2020, 153, 119920. [Google Scholar] [CrossRef]

- Sheppard, P.; Rahimifard, S. Embodied energy in preventable food manufacturing waste in the United Kingdom. Resour. Conserv. Recycl. 2019, 146, 549–559. [Google Scholar] [CrossRef]

- Han, J.W.; Zuo, M.; Zhu, W.Y.; Zuo, J.H.; Lü, E.L.; Yang, X.T. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Qi, H.; Zeng, S.; Shi, L.; Dong, X. What the reclaimed water use can change: From a perspective of inter-provincial virtual water network. J. Environ. Manag. 2021, 287, 112350. [Google Scholar] [CrossRef] [PubMed]

| Primary | Manufacturing | Tertiary |

|---|---|---|

| Agriculture Mining | Manufacturing (general) Automotive Chemical Construction Electronics Energy Food Petroleum Pharmaceutical Steel Textile | Digital Fashion Healthcare Retail Tourism and Hospitality Transport |

| Market | Organizational |

|---|---|

| Attract investors Brand reputation Competitive advantage Customer satisfaction Product/service quality/value/differentiation Revenues | Costs reduction Efficiency and productivity Employee engagement Energy efficiency Flexibility Information management Innovation, knowledge, and technology management Supply chain relationships management Time reduction |

| Align with sustainability goals |  |  |  |

| Biodiversity preservation |  | ||

| Collaboration for sustainability |  |  |  |

| Corporation survival and economic growth |  | ||

| Emissions reduction |  | ||

| Employee training and education |  | ||

| Fair trade |  |  | |

| Fight corruption—Business ethics |  |  | |

| Government regulation |  |  | |

| Green certification |  |  | |

| Human/workers’ rights |  |  | |

| Loss and waste reduction |  | ||

| Natural resources consumption reduction |  | ||

| Promote local culture and product |  |  | |

| Promote sustainable consumer behavior |  |  | |

| Provide access to resources |  |  | |

| Public health |  | ||

| Recycling and reuse—Circular economy |  | ||

| Respect for the surrounding area |  |  | |

| Sustainability-Oriented Innovation (SOI) |  |  |  |

| Sustainable energy/material usage |  | ||

| Traceability and transparency |  |  | |

| Workplace health and safety |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cammarano, A.; Perano, M.; Michelino, F.; Del Regno, C.; Caputo, M. SDG-Oriented Supply Chains: Business Practices for Procurement and Distribution. Sustainability 2022, 14, 1325. https://doi.org/10.3390/su14031325

Cammarano A, Perano M, Michelino F, Del Regno C, Caputo M. SDG-Oriented Supply Chains: Business Practices for Procurement and Distribution. Sustainability. 2022; 14(3):1325. https://doi.org/10.3390/su14031325

Chicago/Turabian StyleCammarano, Antonello, Mirko Perano, Francesca Michelino, Claudio Del Regno, and Mauro Caputo. 2022. "SDG-Oriented Supply Chains: Business Practices for Procurement and Distribution" Sustainability 14, no. 3: 1325. https://doi.org/10.3390/su14031325

APA StyleCammarano, A., Perano, M., Michelino, F., Del Regno, C., & Caputo, M. (2022). SDG-Oriented Supply Chains: Business Practices for Procurement and Distribution. Sustainability, 14(3), 1325. https://doi.org/10.3390/su14031325