Life Cycle Assessment (LCA) of the Use of Metallurgical Process Gas for Heat and Electricity, Combined with Salt Removal from Discarded Water

Abstract

:1. Introduction

- A pilot installation for the production of electricity and heat from metallurgical waste gas—which included a piston engine with a capacity of about 1.0 MWel;

- A pilot plant for removing salt from industrial wastewater consisting of a node for preliminary purification of the filtrate from heavy metals, and a node for concentrating the purified filtrate—the capacity of the salt removal node is about 60 kg/day.

2. Materials and Methods

- Electricity production using post-process gas and natural gas in a reciprocating engine will replace production from the current energy mix adopted for Poland (based on coal, and data from the Ecoinvent 3.0 database);

- The exhaust gases are based on those provided by the reciprocating engine;

- The post-process gas defined in the program is based on the data provided;

- The raw filtrate defined in the program is based on the data provided;

- Waste heat was assumed waste heat in a cogeneration engine, for Poland (the data is from Ecoinvent 3.0);

- Other substances and products used in the analysis, taken from the Ecoinvent database;

- Other substances, products or substrates not included in the analysis (not defined, not observed) have a negligible impact, like solid pollutants collected on the gas filter.

3. Results

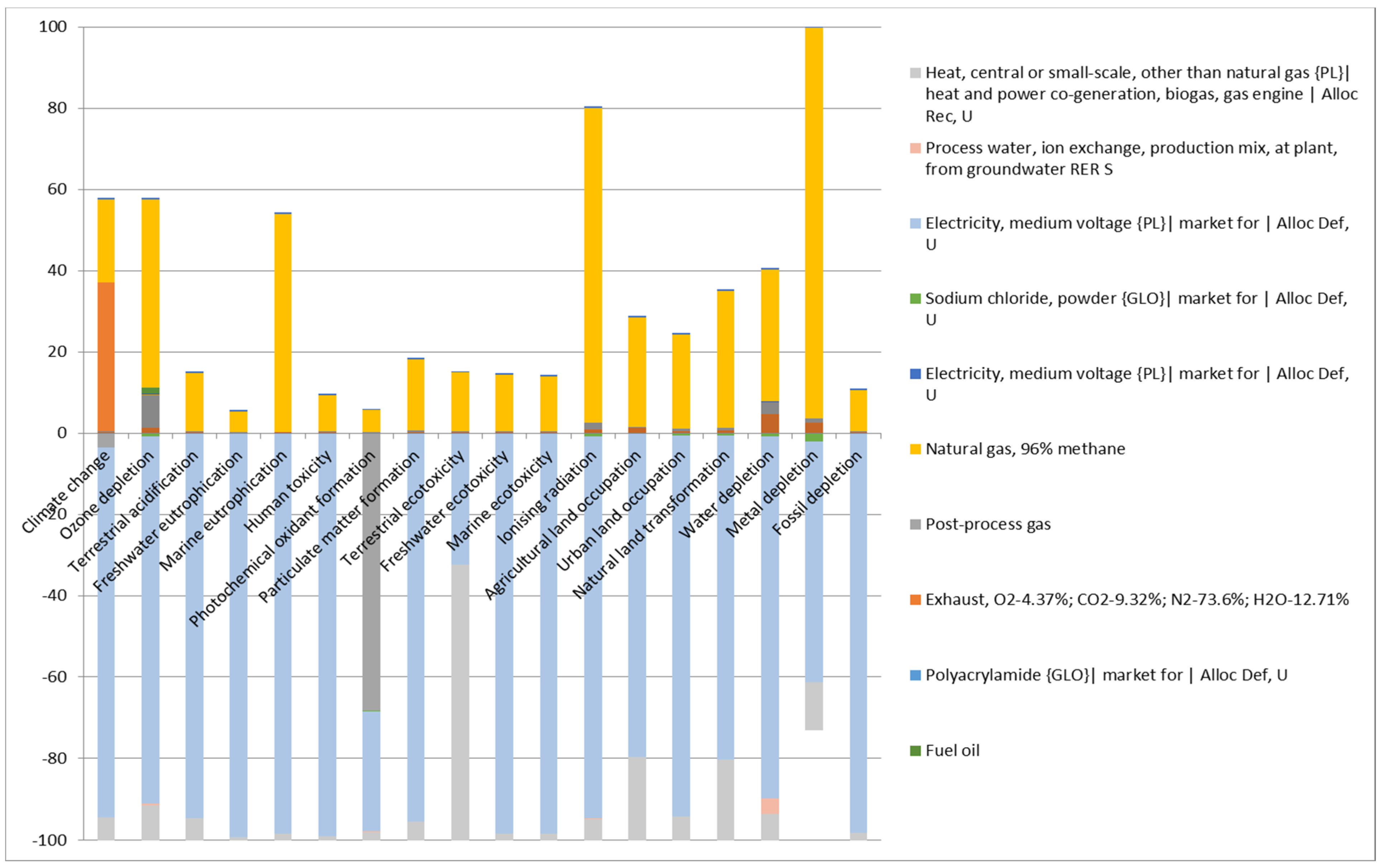

3.1. Mid-Point Analysis

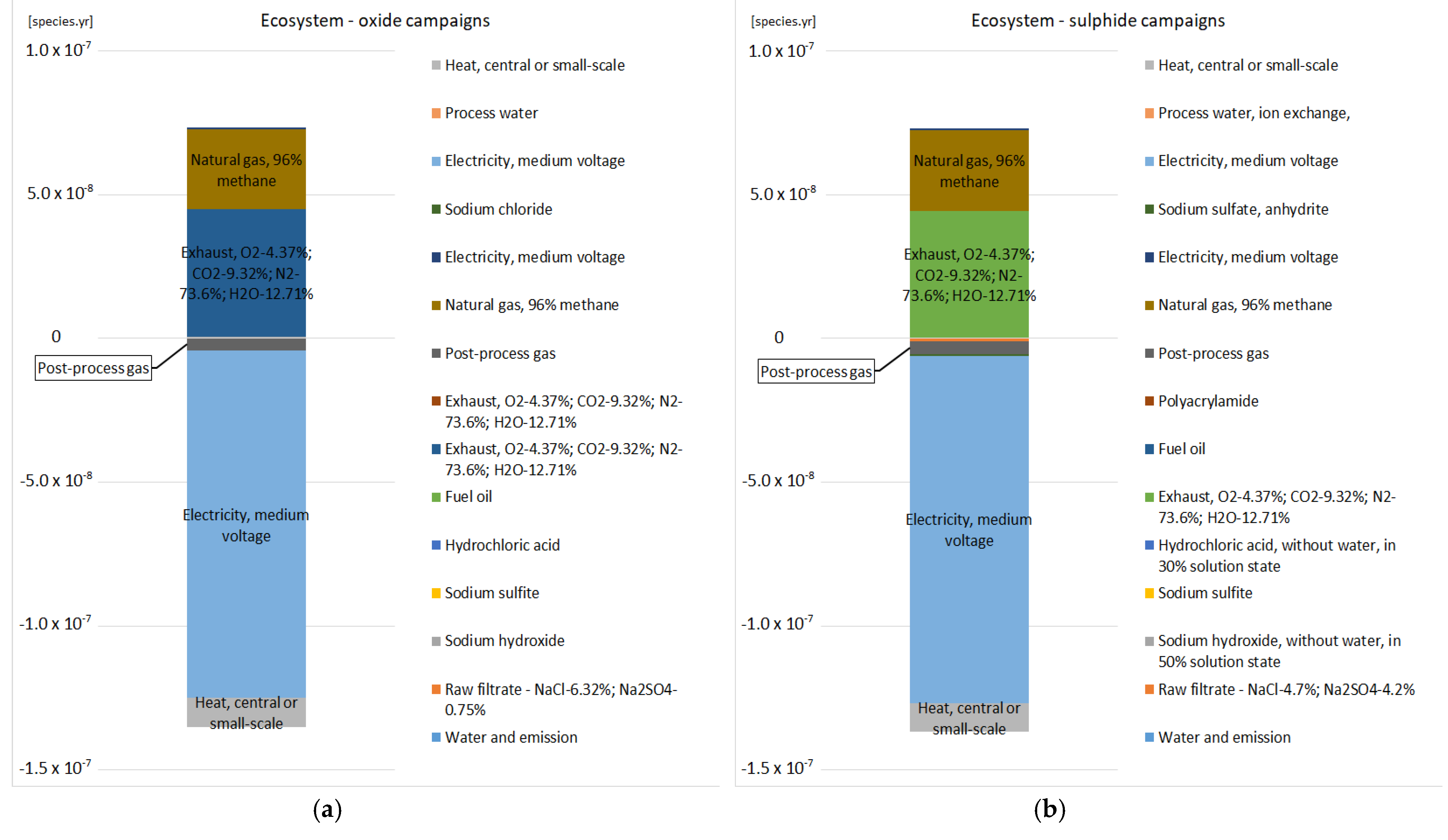

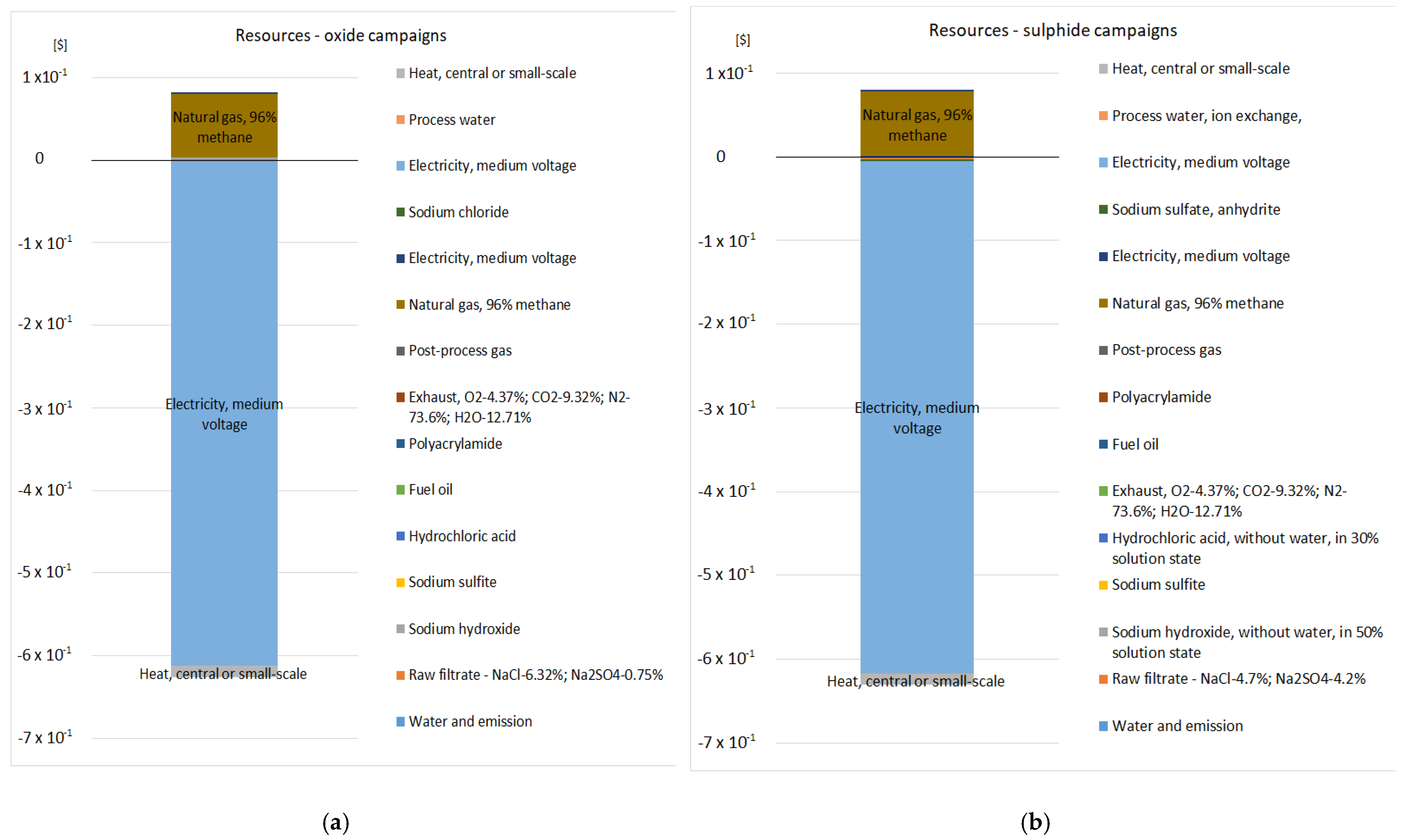

3.2. End-Point Analysis

4. Discussion

- Electricity generation using waste reduced gas, which replaces electricity production for the mix in Poland, mainly based on coal;

- The use of waste heat in the wastewater treatment process, as well as the production of this heat, which can be used for other processes;

- The production of salt, which can be used in further processes, is the result of the purification of the raw waste filtrate;

- The recycling of post-process water in the form of clean water to a zinc smelter, which has a beneficial effect on the impact categories related to the water environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: Paris, France, 2015; Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld/publication (accessed on 15 November 2020).

- European Union. Closing the Loop–An EU Action Plan for the Circular Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 17 November 2021).

- Poranek, N.; Łaźniewska-Piekarczyk, B.; Czajkowski, A.; Pikoń, K. Circular Economy for Municipal Solid Waste Incineration Bottom Ash (MSWIBA) Management in Mortars with CSA and CEM I, MSWIBA Glassy Phase, and DTG. Energies 2022, 15, 135. [Google Scholar] [CrossRef]

- Poranek, N.; Łaźniewska-Piekarczyk, B.; Czajkowski, A.; Pikoń, K. Possibilities of Management of Fly Ash from Municipal Solid Waste Incineration Plant in Building Industry in the Circular Economy. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203. [Google Scholar] [CrossRef]

- Miśkiewicz, R. Efficiency of Electricity Production Technology from Post-Process Gas Heat: Ecological, Economic and Social Benefits. Energies 2020, 13, 6106. [Google Scholar] [CrossRef]

- Bjørnbet, M.M.; Vildåsen, S.S. Life Cycle Assessment to Ensure Sustainability of Circular Business Models in Manufacturing. Sustainability 2021, 13, 11014. [Google Scholar] [CrossRef]

- Alexandrov, G.A.; Ames, D. Technical assessment and evaluation of environmental models and soft-ware: Letter to the Editor. Environ. Model. Soft. 2011, 26, 328–336. [Google Scholar] [CrossRef]

- Górzyński, J. Podstawy Analizy Środowiskowej Wyrobów i Obiektów (Basics of Environmental Analysis of Products and Objects); Wydawnictwa Naukowo-Techniczne: Warsaw, Poland, 2007. [Google Scholar]

- Bogacka, M.; Pikon, K. Best Practice in Environmental Impact Evaluation Based on LCA-Methodologies Review, Geo Conference on Ecology, Economics, Education and Legislation, vol II Book Serie. In Proceedings of the International Multidisciplinary Scientific Geo Conference-SGEM, Albena, Bulgaria, 17–26 June 2014; pp. 101–108. [Google Scholar]

- Bernal, D.C.; Muñoz, E.; Manente, G.; Sciacovelli, A.; Ameli, H.; Gallego-Schmid, A. Environmental Assessment of Latent Heat Thermal Energy Storage Technology System with Phase Change Material for Domestic Heating Applications. Sustainability 2021, 13, 11265. [Google Scholar] [CrossRef]

- Noël, J.A.; Allred, P.M.; White, M.A. Life cycle assessment of two biologically produced phase change materials and their related products. Int. J. Life Cycle Assess. 2015, 20, 367–376. [Google Scholar] [CrossRef]

- Smita, R.; Vikrant, B.; Chelikani, S.; Sangwan, K.S. Waste Water Treatment Plant Life Cycle Assessment: Treatment Process to Reuse of Water. Procedia CIRP 2017, 61, 761–766. [Google Scholar]

- Szulc, P.; Kasprzak, J.; Dymaczewski, Z.; Kurczewski, P. Life Cycle Assessment of Municipal Wastewater Treatment Processes Regarding Energy Production from the Sludge Line. Energies 2021, 14, 356. [Google Scholar] [CrossRef]

- Skoczko, I.; Szatyłowicz, E.; Horysz, M.; Malinowski, Ł.; Tunc, A. Life cycle assessment of industrial and urban wastewater treatment plant. Econ. Environ. Stud. 2016, 1, 37. [Google Scholar]

- Corominas, L.; Byrne, D.M.; Guest, J.S.; Hospido, A.; Roux, P.; Shaw, A.; Short, M.D. The application of life cycle assessment (LCA) to wastewater treatment: A best practice guide and critical review. Water Res. 2020, 184, 116058. [Google Scholar] [CrossRef] [PubMed]

- Renou, S.; Thomas, J.S.; Aoustin, E.; Pons, M.N. Influence of impact assessment methods in wastewater treatment LCA. J. Clean. Prod. 2008, 16, 1098–1105. [Google Scholar] [CrossRef]

- Parra-Saldivar, R.; Bilal, M.; Iqbal, H.M.N. Life cycle assessment in wastewater treatment technology. Curr. Opin. Environ. Sci. Health 2020, 13, 80–84. [Google Scholar] [CrossRef]

- Rebello, T.A.; Roque, R.P.; Gonçalves, R.F.; Calmon, J.L.; Queiroz, L.M. Life cycle assessment of urban wastewater treatment plants: A critical analysis and guideline proposal. Water Sci. Technol. 2020, 83, 501–514. [Google Scholar] [CrossRef] [PubMed]

- Hertwich, E.G.; Thomas, B.; Evert, A.; Suh, A.; Heath, S.; Bergesen, G.; Ramírez, J.; Vega-Coloma, A.; Shi, M. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2014, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rödger, J.-M.; Beier, J.; Schönemann, M.; Schulze, C.; Thiede, S.; Bey, N.; Herrmann, C.; Hauschild, M.Z. Combining Life Cycle Assessment and Manufacturing System Simulation: Evaluating Dynamic Impacts from Renewable Energy Supply on Product-Specific Environmental Footprints. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 1007–1026. [Google Scholar] [CrossRef]

- Bengtsson, J.; Howard, N. A Life Cycle Impact Assessment, Part 1: Classification and Characterization; BPIC/ICIP Life Cycle Inventory Project, Building Products Innovation Council (BPIC) and AusIndustry: Sydney, Australia, 2010. [Google Scholar]

- For More Information, Appendix A–Reference materials, Sustainability & Sustainable Business. In Berkshire Encyclopedia of Sustainability; Berkshire Publishing Group: Great Barrington, MA, USA, 2009–2011; Chapter 10; Volumes 1–10.

- Bilitewski, B.; Hardtle, G.; Marek, K. Podręcznik Gospodarki Odpadami. Teoria i Praktyka (Waste Management Manual. Theory and Practice); Wyd. Seidel Przywecki: Warsaw, Poland, 2006. [Google Scholar]

- EMEP/EEA Air Pollutant Emission Inventory Guidebook 2013, Technical Report No 12/2013. Available online: http://www.eea.europa.eu//publications/emep-eea-guidebook-2013 (accessed on 10 December 2021).

- EMEP/EEA Air Pollutant Emission Inventory Guidebook 2016, Small Combustion 2016. Available online: http://www.eea.europa.eu//publications/Small-combustion-2016 (accessed on 12 December 2021).

- Emissions Factors & AP 42, Compilation of Air Pollutant Emission Factors, AP 42, Fifth Edition, Volume 1: Stationary Point and Area Sources, US EPA. Available online: http://www.epa.gov/ttnchie1/ap42/ (accessed on 14 December 2021).

- EPA. Emissions from Waste Incineration. In Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories; Report Accepted by the IPCC Plenary at Its 16th Session Held in Montreal, Canada, 1–8 May 2000; Available online: https://www.ipcc-nggip.iges.or.jp/public/gp/english/ (accessed on 31 December 2021).

- Goedkoop, M. ReCiPe 2008 a Life Cycle Impact Assessment Method which Comprises Harmonised Category Indicators at The Midpoint and The Endpoint Level, Report, Ruimte en Milieu, Ministerie van Volkshuisvesting, Ruimtelijke Ordening en Milieubeheer. Holandia. 2009. Report Published in the Framework of the ReCiPe Project. Available online: http://www.lcia-recipe.net (accessed on 12 December 2021).

- de Bruijn, H.; van Duin, R.; Huijbregts, M.A.J.; Guinee, J.B.; Gorree, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards; Eco-Efficiency in Industry and Science; Kluwer Academic Publishers: Amsterdam, The Netherlands, 2004; Volume 7. [Google Scholar]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. ILCD Handbook. Analysing of Existing Environmental Impact Assessment Methodologies for Use in Life Cycle Assessment; Institute for Environment and Sustainability, Joint Research Centre, European Commission: Ispra, Italy, 2010. [Google Scholar]

- International Energy Agency Optimising Russian Gas. Reform and Climate Policy. OECD/IEA, 2006, Dostępny w Internecie: Stan na Dzień 25.05.2013 r. Available online: www.iea.org/textbase/npsum/opt_russ_gas.pdf (accessed on 12 December 2021).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- PN-EN ISO 14042; Zarządzanie Środowiskowe–Ocena Cyklu Życia–Ocena Wpływu Cyklu Życia (Environmental Management-Life Cycle Assessment-Life Cycle Impact Assessment). PKN (Polski Komitet Normalizacyjny): Warsaw, Poland, 2000.

- PN-EN ISO 14043; Zarządzanie Środowiskowe–Ocena Cyklu Życia–Interpretacja Cyklu Życia (Environmental Management-Life Cycle Assessment-Life Cycle Interpretation). PKN (Polski Komitet Normalizacyjny): Warsaw, Poland, 2000.

- Poland’s informative inventory report 2016. In Submission under the UN ECE Convention on Long-Range Transboundary Air Pollution; IOŚ-PIB KOBIZE: Warsaw, Poland, 2016.

- Konieczyński, J. (Ed.) Właściwości Pyłu Respirabilnego Emitowanego z Wybranych Instalacji (Properties Of Respirable Dust Emitted From Selected Installations); Instytut Podstaw Inżynierii Środowiska Polskiej Akademii Nauk. Pod redakcją: Zabrze, Poland, 2010. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess 2017, 22, 138–147. [Google Scholar] [CrossRef]

| Unit | Stream No. | Oxide Campaign | Sulphide Campaign | |

|---|---|---|---|---|

| Oxide campaign | hour/year | 7700 | 0 | |

| Sulphide campaign | hour/year | 0 | 7700 | |

| Total installation operating time | hour/year | 7700 | 7700 | |

| Raw material | ||||

| Raw filtrate | Mg/year | 1 | 41,854.2 | 42,456.9 |

| of which NaCl | Mg/year | 1 | 2643.4 | 1987.0 |

| of which Na2SO4 | Mg/year | 1 | 313.8 | 1784.9 |

| 50% NaOH solution | Mg/year | 2 | 741.0 | 235.7 |

| 10% Na2S solution | Mg/year | 3 | 19.6 | 24.2 |

| 30% HCl solution for neutralisation | Mg/year | 4 | 6.1 | 5.6 |

| Products from wastewater treatment | ||||

| Distillate—process water | Mg/year | 5 | 36,760.0 | 33,084.0 |

| NaCl | Mg/year | 6 | 2103.2 | 0.0 |

| Na2SO4 | Mg/year | 6 | 0.0 | 1251.5 |

| Waste | ||||

| Brine from the centrifuge | Mg/year | 7 | 2003.4 | 7783.7 |

| of which NaCl | Mg/year | 7 | 540.2 | 1987.0 |

| of which Na2SO4 | Mg/year | 7 | 313.8 | 533.3 |

| Raw materials and materials | ||||

| Heat for evaporators (hot water) | MWh/year | 8 | 22,176.0 | 22,176.0 |

| Water for flocculant | Mg/year | 9 | 154.0 | 154.0 |

| Praestol 2540 (Polyacrylamide) | Mg/year | 9 | 0.4 | 0.4 |

| Electricity | MWh/year | 10 | 1657.0 | 1657.0 |

| Reduced gas | Mg/year | 11 | 147,070 | 147,070 |

| Natural gas | Mg/year | 12 | 68,299 | 68,299 |

| Engine oil | Mg/year | 13 | 22.5 | 22.5 |

| Products from the processing of reduced gas | ||||

| Electricity generated in the engine | MWh/year | 14 | 392,700 | 392,700 |

| Useful heat | MWh/year | 15 | 355,894 | 355,894 |

| Exhaust gases | Mg/year | 16 | 1,889,580 | 1,889,580 |

| Ingredient | Quantity | Unit |

|---|---|---|

| O2 | 0.00 | % |

| CO2 | 6.30 | % |

| Central heating | 31.80 | % |

| N2 | 60.10 | % |

| CH4 | 0.20 | % |

| H2 | 1.60 | % |

| H2O | 0.00 | % |

| Mz | 28.85 | kg/kmol |

| Wd | 4.27 | MJ/Nm3 |

| Ingredient | Quantity | Unit |

|---|---|---|

| O2 | 4.37 | % |

| CO2 | 9.32 | % |

| Central heating | 0.00 | % |

| N2 | 73.60 | % |

| CH4 | 0.00 | % |

| H2 | 0.00 | % |

| H2O | 12.71 | % |

| C2H6 | 0.00 | % |

| Mz | 28.40 | kg/kmol |

| Ingredient | Quantity | Unit |

|---|---|---|

| CO2 | 0.18 | % |

| N2 | 0.60 | % |

| CH4 | 96.95 | % |

| C2H6 | 2.26 | % |

| Mz | 16.40 | kg/kmol |

| Wd | 36.13 | MJ/Nm3 |

| No. | Damage Category | Unit | Sulphide Campaign | Oxide Campaign | PL Energy Mix |

|---|---|---|---|---|---|

| 1. | Human Health | DALY | −5.20 × 10−11 | −5.12 × 10−11 | 7.10 × 10−7 |

| 2. | Ecosystem | species.yr | −1.63 × 10−13 | −1.57 × 10−13 | 2.69 × 10−9 |

| 3. | Natural Resources | $ | −1.40 × 10−6 | −1.38 × 10−6 | 1.36 × 10−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogacka, M.; Iluk, T.; Pikoń, K.; Ściążko, M.; Stec, M.; Czaplicki, A.; Wajda, A. Life Cycle Assessment (LCA) of the Use of Metallurgical Process Gas for Heat and Electricity, Combined with Salt Removal from Discarded Water. Sustainability 2022, 14, 1205. https://doi.org/10.3390/su14031205

Bogacka M, Iluk T, Pikoń K, Ściążko M, Stec M, Czaplicki A, Wajda A. Life Cycle Assessment (LCA) of the Use of Metallurgical Process Gas for Heat and Electricity, Combined with Salt Removal from Discarded Water. Sustainability. 2022; 14(3):1205. https://doi.org/10.3390/su14031205

Chicago/Turabian StyleBogacka, Magdalena, Tomasz Iluk, Krzysztof Pikoń, Marek Ściążko, Marcin Stec, Andrzej Czaplicki, and Agata Wajda. 2022. "Life Cycle Assessment (LCA) of the Use of Metallurgical Process Gas for Heat and Electricity, Combined with Salt Removal from Discarded Water" Sustainability 14, no. 3: 1205. https://doi.org/10.3390/su14031205

APA StyleBogacka, M., Iluk, T., Pikoń, K., Ściążko, M., Stec, M., Czaplicki, A., & Wajda, A. (2022). Life Cycle Assessment (LCA) of the Use of Metallurgical Process Gas for Heat and Electricity, Combined with Salt Removal from Discarded Water. Sustainability, 14(3), 1205. https://doi.org/10.3390/su14031205