Using Product Design Strategies to Implement Circular Economy: Differences between Students and Professional Designers

Abstract

1. Introduction

- The analysis is based on many case studies related to different application domains, in order to consider more heterogeneous design strategies and obtain results with a general validity.

- The comparison between the design strategies and the CE strategies was performed at a finer level of detail to make the reader aware about which design strategies was used and for what purpose.

- Different results were obtained both by professional designers and students and they were compared to understand their different perspectives, due to experience and to identify the main gaps of the students in comparison with the professional designers.

2. State of the Art

2.1. Overview about the Design Strategies

2.2. Applying the Design Strategies for the CE

3. Materials and Methods

3.1. Tested Design Strategies and CE Strategies

- “Substituting the product materials” consists of replacing the constituent materials of the product components with others having better characteristics for different aspects. Longer material life can reduce the waste and premature replacement of components. The lower mass of the material, conserving the mechanical resistance, is instead useful for reducing the energy consumption required to handle the product during the operating life and the transportation. The lower environmental impacts of the material during extraction, processing and disposal, allow instead to increase the environmental sustainability of the product.

- “Substituting the energy source/technology” consists of replacing the power sources of the product and/or the technologies on which they are based, by privileging the most efficient and least impacting ones.

- “Optimizing the product structure” consists of reducing the mass of the product by conserving its features (e.g., structural strength) and without replacing the constituent materials. In this way, by reducing the amount of material, environmental impacts are also reduced during extraction, use, and transport.

- “Designing the product considering the user experience” consists of a change in the designer’s perspective when designing a product to favour its usability. For this reason, the focus during the initial parts of the design activity is shifted from the structure of the product to the mode of user interaction, depending on the context of use, ergonomics, affective dimension and cognitive experience [9].

- “Dematerializing the product components” consists in eliminating and replacing them with another entity able to perform the same function. In the case of Trimming, as typically explained by TRIZ [26], the removed component is replaced by another component of the product that is used as such, if possible, or is modified accordingly. Another possibility, always suggested by TRIZ, is the Dematerialization, which can be declined in three different ways. According to TRIZ Evolutionary Law N. 7, the component to be eliminated is miniaturized, but not completely eliminated, by making it thinner or breaking it down into many small parts until it becomes dust, e.g., by passing from a saw to a diamond cutting disk. According to the same law, a phase transition of the component from solid to fluid state can also be considered, e.g., replacing a saw with the waterjet cutting. Finally, according to TRIZ Evolutionary Law N. 8, the component is eliminated completely, replacing it with a mechanical, chemical, fluid-dynamic, acoustic, electrical, magnetic, or electromagnetic field, e.g., substituting a saw with the laser cutting.

- “Segmenting/dynamizing the product parts and rhythms” consists of designing a product in such a way that it can better adapt to the characteristics of the operative context and the other entities. This strategy summarizes the essence of different approaches exploited by the TRIZ method to innovate a product. At a structural level, the different parts of the product can be disrupted and recombined in a more appropriate way, also allowing them a possible reciprocal mobility to increase their flexibility (TRIZ Inventive Principle N. 1) or by improving their quality locally, only where it is actually needed (TRIZ Inventive Principle N. 2). The product’s mode of operation can also be improved by dynamically adjusting work rhythms in relation to actual function and environmental needs (TRIZ Inventive Principle N. 15).

- “Exploiting modularity/using standard parts” consists of redesigning the product by exploiting components more standard and easily to be substituted and that are common or shared with other products. In this way, production costs can be reduced, avoiding the creation of ad hoc components and facilitating the maintenance and production of product components, also standardizing the manufacturing procedures to make them more environmentally sustainable [27].

- “Exploiting the resources/Recovering the energy” consists of identifying and using any means, both in the working environment and within the product, to reduce the consumption of raw materials, auxiliary materials and energy, related costs and environmental impacts. This is provided that systems are introduced for their exploitation that do not compromise the obtained benefits [18]. The definition of “resource” provided by the TRIZ method is one of the broadest, including also physical effects that are commonly considered as harmful, e.g., vibrations, but that can be useful if specifically exploited. A resource can be a physical entity to be used as is, or geometric, i.e., a morphological or a surface feature of the object (e.g., inclined plane, roughness) or even just an empty space to be exploited. The waste energy to be reused can be in any form, e.g., kinetic or thermal, including latent state energy, such as heat from the phase transition of a material (TRIZ Inventive Principle N. 36).

- “Providing a timeless design to the product” has the objective of prolonging the operating life of the product, ensuring that the user does not discard it prematurely. A typical way to achieve this is to improve the design of the product, while considering how user’s needs might change over time, to make the product attractive to other users for reuse to perform the same or another function.

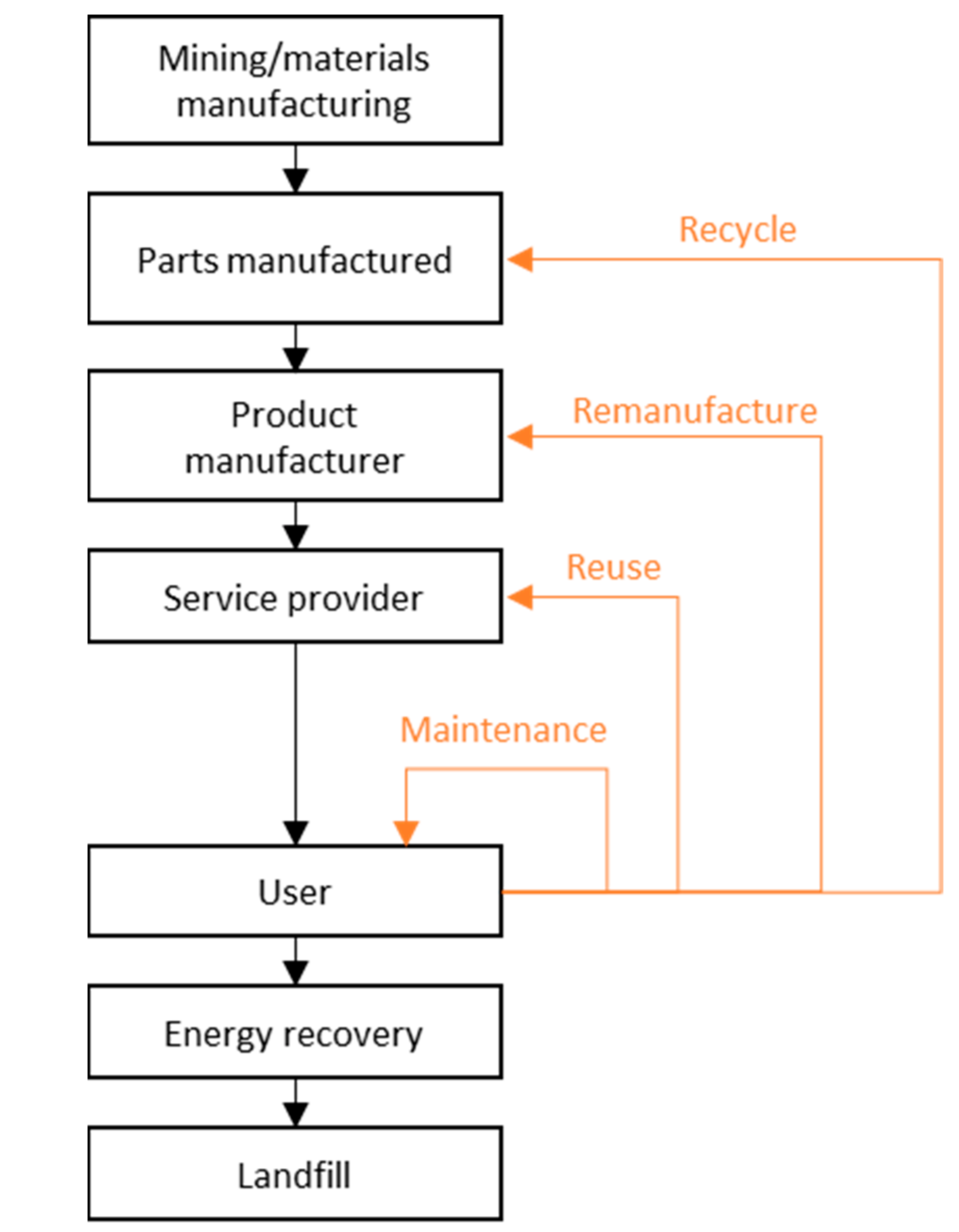

- “Reducing the waste” is intended to decrease the environmental impacts associated with waste and, at the same time, those resulting from the production of new products or replacement components. Increasing product service life, structural optimization aimed at reducing the mass of product components (e.g., [30]), fluid dynamic optimization aimed at rationalizing fluid auxiliary materials (e.g., [31]) and the dematerialization of the structures obtained by introducing fields (e.g., [10]) are just a few of the declinations that have been associated with this CE strategy in the literature.

- “Reusing the product” allows to extend the product operational life by identifying new uses for it beyond that for which it was designed, when this latter is compromised due to the product’s inability to perform the main useful function or meet secondary requirements. The main requirement behind this strategy is that the product must not undergo any processing prior to its reuse. The main declinations of this strategy, which can be learned from the literature, suggest to make the product structure more durable (e.g., [32]) or more easily modified to be readjusted for future needs (e.g., [33]).

- “Repairing/Refurbishing/Remanufacturing the product” allow the product, once compromised, to be reused for its original use or a new one, provided it is restored to its original state or one compatible with the new requirements, after restoring it to its original state, by ensuring the new requirements. From the environmental perspective, this strategy pays if the impacts from product restoration operations are offset by the reduction in impacts achieved by not disposing of the product [34]. The prerequisite for the application of this strategy depends on the ability to intervene in the product structure to restore its functionalities, which in turn depends on both the organization of these operations and the structure of the product itself [35].

- “Recycling the materials of the product” allows the materials of the product to be reintroduced into its life cycle or into that of other compatible products, thus avoiding the phase of extracting new virgin materials. This strategy can be declined in two different ways depending on the flow of recycled materials [36]. In the case of ecosystem restoration, the objective is to regenerate the biological cycles of various ecosystems including forests, fresh water, and inland wetlands, through different processes including extraction of biochemical feedstock, farming, and anaerobic digestion. While, in the case of technical recycling, the objective is instead to regenerate the technical cycles, or to reproduce the constituent materials of the product components, such as for recycled paper and plastic.

- “Making the product biodegradable” has the objective to improve the product so that its disposal has less impact, using biodegradable materials that decompose more quickly, emitting fewer pollutants and requiring fewer resources [18]. In the literature, this strategy typically refers to the use of natural materials, both the completely natural or the bio-based ones, used in place of, or in combination with, synthetic materials [37]. The main environmental benefit of this strategy is found in the reduction of the amount of waste that must be disposed of in landfills or in incinerators.

3.2. Testing Methodology

3.2.1. Testing Methodology for Students’ Solutions

- Firstly, the solutions were selected on the basis of their presentation criteria. Only those explaining in detail, with written descriptions and drawings, the following aspects, have been selected: structural and material arrangements, operating principle, design interventions carried out and advantages on environmental sustainability that the solutions aim to pursue, by specifying how CE can be implemented. Overall, the selected solutions are 183. All of them were evaluated by the authors.

- The descriptions of the selected solutions were compared by the authors by analogy with the tested design strategies. To do this, the authors compared the lexicon used by the students with the definitions of the ontological terms with which the Design strategies are expressed, which in turn derive from the TRIZ method.

- Then the authors also compared the descriptions of the solutions provided by the students with the CE strategies, always by analogy. In this case, the terms used by the students to describe their intentions in implementing CE were compared with the definitions of the terms used to define the CE strategies in Section 3.1, which derive from the reference literature.

- To dispel the doubts of interpretation about the meaning attributed by the students to some terms within the descriptions, the same students were interviewed by the authors.

3.2.2. Testing Methodology for Professional Designers’ Solutions

- Firstly, the solutions were selected, keeping only those that have a detailed description according to the criteria specified in step 1 of the procedure adopted in the selection of the solutions proposed by the students (see Section 3.2.1). As a result, 93 solutions were collected from professional designers.

- The descriptions of the selected solutions, provided in the selected articles, were compared by analogy by the authors with the tested Design strategies, in the same way as previously done to analyse students’ solutions (see step 2 of Section 3.2.1).

- Moreover, this step was carried out in the analogous manner of step 3 of Section 3.2.1 to comprehend what CE strategies were implemented.

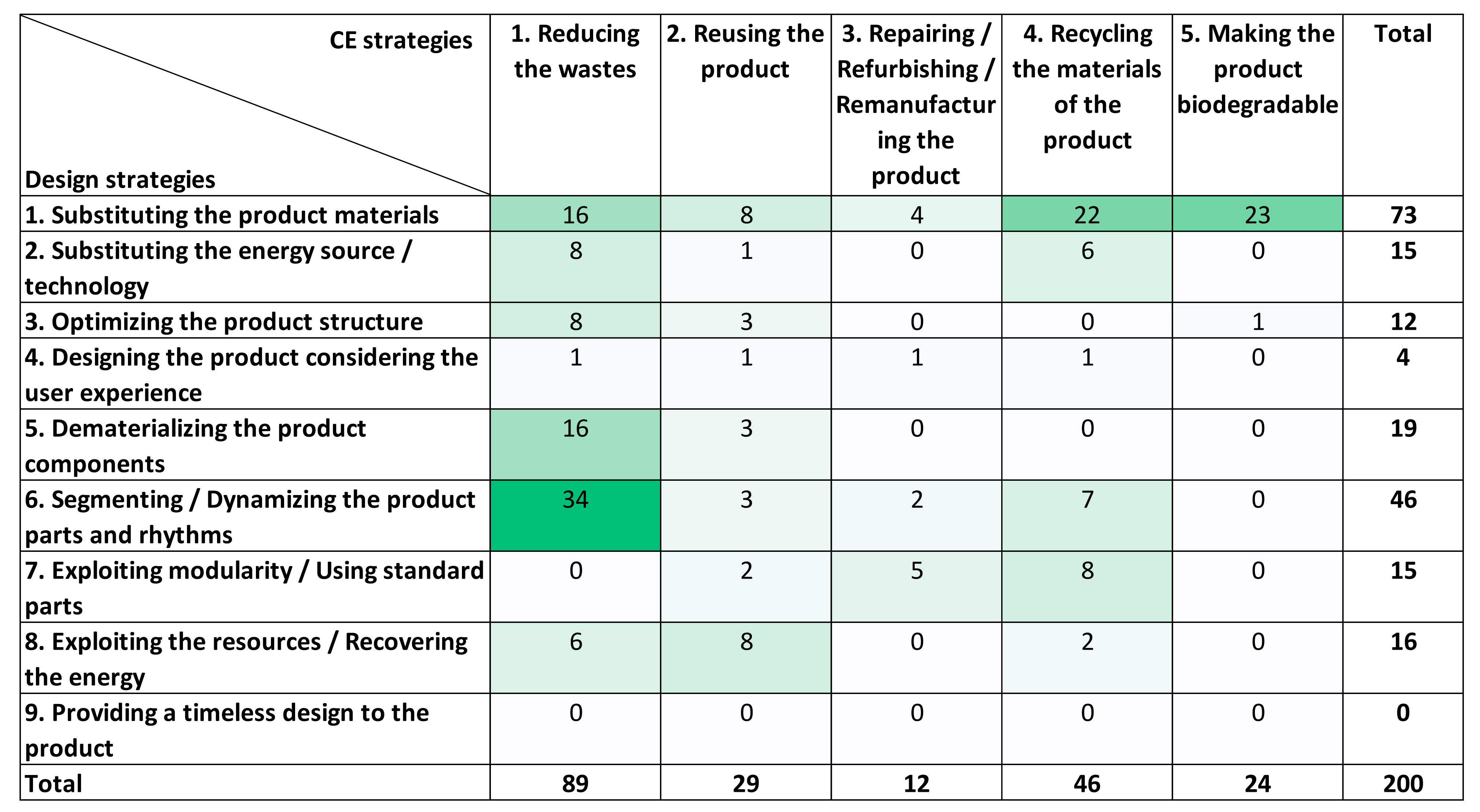

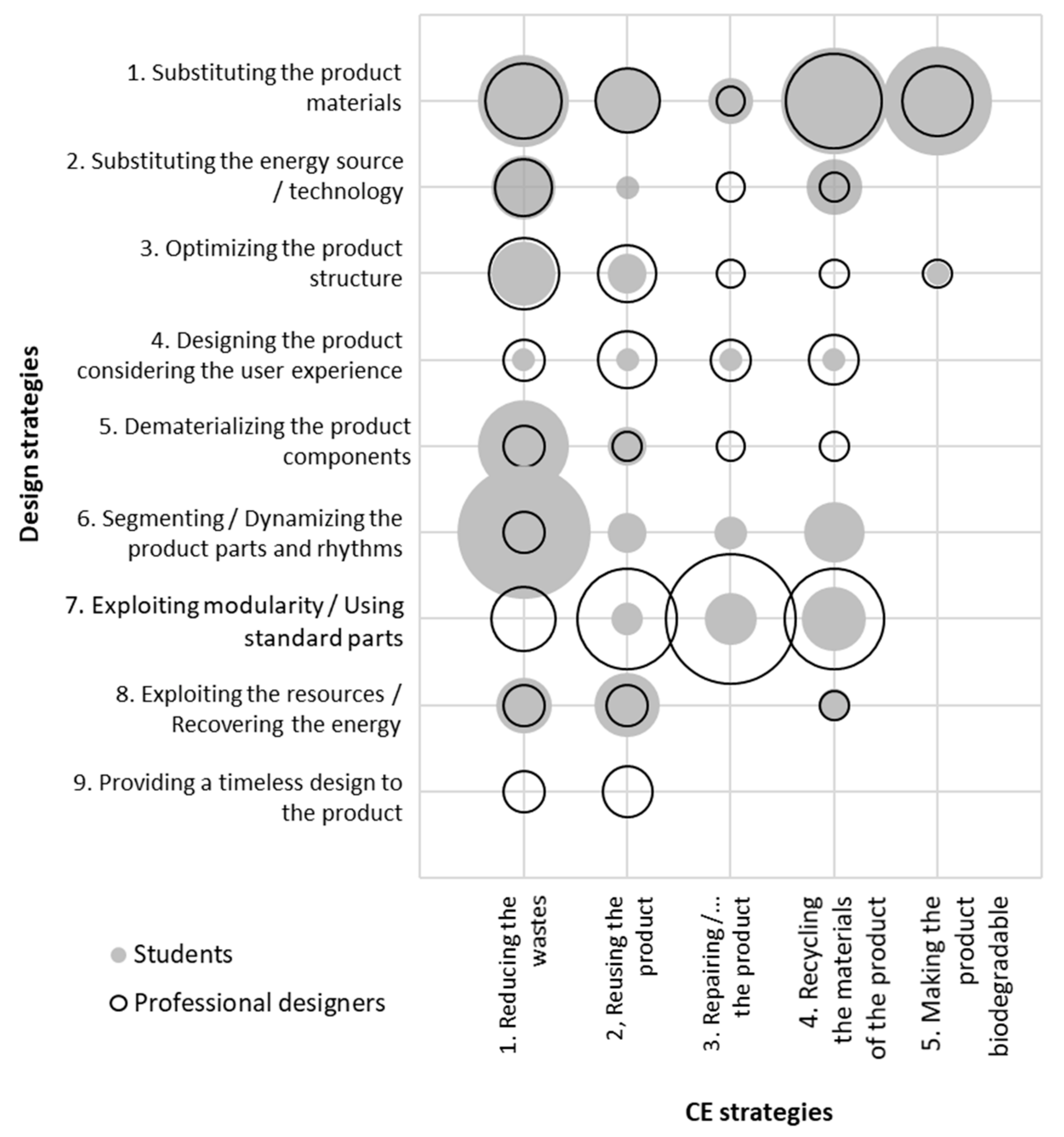

4. Results

5. Discussion

6. Conclusions

- The design strategies deriving from systematic innovation, and from the TRIZ method, were preferred by students quite clearly.

- The design strategies most typically referable to industrial design, i.e., exploiting components modularity, user-centered-design and timeless design have been preferred by professional designers.

- The design strategies related to the most routine design, i.e., materials substitution, reducing resources and energy consumption and structural optimization, have been used more or less equally by both students and professional designers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fogarassy, C.; Finger, D. Theoretical and practical approaches of circular economy for business models and technological solutions. Resources 2020, 9, 76. [Google Scholar] [CrossRef]

- Howard, T.J.; Culley, S.J.; Dekoninck, E. Describing the creative design process by the integration of engineering design and cognitive psychology literature. Des. Stud. 2008, 29, 160–180. [Google Scholar] [CrossRef]

- Gero, J.S. Design prototypes: A knowledge representation schema for design. AI Mag. 1990, 11, 26. [Google Scholar]

- Mossali, E.; Gentilini, L.; Merati, G.; Colledani, M. Methodology and application of electric vehicles battery packs redesign for circular economy. Procedia CIRP 2020, 91, 747–751. [Google Scholar] [CrossRef]

- Seroka-Stolka, O.; Ociepa-Kubicka, A. Green logistics and circular economy. Transp. Res. Procedia 2019, 39, 471–479. [Google Scholar] [CrossRef]

- Andrews, D. The circular economy, design thinking and education for sustainability. Local Econ. 2015, 30, 305–315. [Google Scholar] [CrossRef]

- Dym, C.L.; Agogino, A.M.; Eris, O.; Frey, D.D.; Leifer, L.J. Engineering design thinking, teaching, and learning. J. Eng. Educ. 2005, 94, 103–120. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L. Towards an education for the circular economy (ECE): Five teaching principles and a case study. Resour. Conserv. Recycl. 2019, 150, 104406. [Google Scholar] [CrossRef]

- Berni, A.; Borgianni, Y. Making Order in User Experience Research to Support Its Application in Design and Beyond. Appl. Sci. 2021, 11, 6981. [Google Scholar] [CrossRef]

- Altshuller, G.S. Creativity as an Exact Science: The Theory of the Solution of Inventive Problems; Gordon and Breach: Luxembourg, 1984. [Google Scholar]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. In Architectural Engineering and Design Management; Taylor and Francis Ltd.: Oxfordshire, UK, 2020; pp. 1–21. [Google Scholar] [CrossRef]

- Moorhouse, D.; Moorhouse, D. Sustainable design: Circular economy in fashion and textiles. Des. J. 2017, 20 (Suppl. S1), S1948–S1959. [Google Scholar] [CrossRef]

- Mestre, A.; Cooper, T. Circular Product Design. A Multiple Loops Life Cycle Design Approach for the Circular Economy. Des. J. 2017, 20, S1620–S1635. [Google Scholar] [CrossRef]

- Wastling, T.; Charnley, F.; Moreno, M. Design for Circular Behaviour: Considering Users in a Circular Economy. Sustainability 2018, 10, 1743. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Sumter, D.; De Koning, J.; Bakker, C.; Balkenende, R. Circular Economy Competencies for Design. Sustainability 2020, 12, 1561. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- De los Rios, I.C.; Charnley, F.J. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Cross, N. Engineering Design Methods: Strategies for Product Design; John Wiley & Sons: New York, NY, USA, 2021. [Google Scholar]

- Russo, D.; Spreafico, C. TRIZ-Based Guidelines for Eco-Improvement. Sustainability 2020, 12, 3412. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Ou, J.J.R.; Lin, G.Y.P.; Chen, M.-Y. An eco- and inno-product design system applying integrated and intelligent qfde and triz methodology. J. Syst. Sci. Syst. Eng. 2011, 20, 443–459. [Google Scholar] [CrossRef]

- Vidal, R.; Salmeron, J.L.; Mena, A.; Chulvi, V. Fuzzy Cognitive Map-based selection of TRIZ (Theory of Inventive Problem Solving) trends for eco-innovation of ceramic industry products. J. Clean. Prod. 2015, 107, 202–214. [Google Scholar] [CrossRef]

- Lim, I.S.S. The effectiveness of TRIZ tools for eco-efficient product design. In Research and Practice on the Theory of Inventive Problem Solving (TRIZ); Springer: Cham, Switzerland, 2016; pp. 35–53. [Google Scholar]

- Spreafico, C. Quantifying the advantages of TRIZ in sustainability through life cycle assessment. J. Clean. Prod. 2021, 303, 126955. [Google Scholar] [CrossRef]

- Sheu, D.D.; Hou, C.T. TRIZ-based Systematic Device Trimming: Theory and Application. Procedia Eng. 2015, 131, 237–258. [Google Scholar] [CrossRef]

- Ma, J.; Kremer, G.E.O. A systematic literature review of modular product design (MPD) from the perspective of sustainability. Int. J. Adv. Manuf. Technol. 2016, 86, 1509–1539. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Russo, D.; Rizzi, C. Structural optimization strategies to design green products. Comput. Ind. 2014, 65, 470–479. [Google Scholar] [CrossRef]

- Cheshmehzangi, A.; Zhu, Y.; Li, B. Application of environmental performance analysis for urban design with Computational Fluid Dynamics (CFD) and EcoTect tools: The case of Cao Fei Dian eco-city, China. Int. J. Sustain. Built Environ. 2017, 6, 102–112. [Google Scholar] [CrossRef]

- Hooton, R.D.; Bickley, J.A. Design for durability: The key to improving concrete sustainability. Constr. Build. Mater. 2014, 67, 422–430. [Google Scholar] [CrossRef]

- Torroja, Y.; Riesgo, T.; de la Torre, E.; Uceda, J. Design for reusability: Generic and configurable designs. Proc. Syst. Modeling Code Reusability 1997, 1, 11–21. [Google Scholar]

- Nasr, N.; Thurston, M. Remanufacturing: A Key Enabler to Sustainable Product Systems; Rochester Institute of Technology: Rochester, NY, USA, 2006; Volume 23. [Google Scholar]

- Haziri, L.L.; Sundin, E. Supporting design for remanufacturing—A framework for implementing information feedback from remanufacturing to product design. J. Remanuf. 2019, 10, 57–76. [Google Scholar] [CrossRef]

- de Groot, W.J.; Flannigan, M.; Cantin, A.S. Climate change impacts on future boreal fire regimes. For. Ecol. Manag. 2013, 294, 35–44. [Google Scholar] [CrossRef]

- Godavitarne, C.; Robertson, A.; Peters, J.; Rogers, B. Biodegradable materials. Orthop. Trauma 2017, 31, 316–320. [Google Scholar] [CrossRef]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Davila Delgado, J.M.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for deconstruc-tion using a circular economy approach: Barriers and strategies for improvement. Prod. Plan. Control. 2020, 31, 829–840. [Google Scholar] [CrossRef]

- Bauer, T.; Zwolinski, P.; Nasr, N.; Mandil, G. Characterization of circular strategies to better design circular industrial systems. J. Remanuf. 2020, 10, 161–176. [Google Scholar] [CrossRef]

- Fontana, A.; Barni, A.; Leone, D.; Spirito, M.; Tringale, A.; Ferraris, M.; Reis, J.; Goncalves, G. Circular Economy Strategies for Equipment Lifetime Extension: A Systematic Review. Sustainability 2021, 13, 1117. [Google Scholar] [CrossRef]

- Franco, M.A. A system dynamics approach to product design and business model strategies for the circular economy. J. Clean. Prod. 2019, 241, 118327. [Google Scholar] [CrossRef]

- Goldsworthy, K.; Ellams, D. Collaborative circular design. Incorporating life cycle thinking into an interdisciplinary design process. Des. J. 2019, 22 (Suppl. 1), 1041–1055. [Google Scholar] [CrossRef]

- Hapuwatte, B.M.; Jawahir, I.S. Closed-loop sustainable product design for circular economy. J. Ind. Ecol. 2021, 25, 1430–1446. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry. Sustainability 2021, 13, 7223. [Google Scholar] [CrossRef]

- Lin, K.-Y. User experience-based product design for smart production to empower industry 4.0 in the glass recycling circular economy. Comput. Ind. Eng. 2018, 125, 729–738. [Google Scholar] [CrossRef]

- Moreno, M.; de los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Reuter, M.A.; van Schaik, A.; Gutzmer, J.; Bartie, N.; Abadías-Llamas, A. Challenges of the Circular Economy: A Material, Metallurgical, and Product Design Perspective. Annu. Rev. Mater. Sci. 2019, 49, 253–274. [Google Scholar] [CrossRef]

- Shahbazi, S.; Jönbrink, A.K. Design Guidelines to Develop Circular Products: Action Research on Nordic Industry. Sustainability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Sumter, D.; Koning, J.; Bakker, C.; Balkenende, R. Key Competencies for Design in a Circular Economy: Exploring Gaps in Design Knowledge and Skills for a Circular Economy. Sustainability 2021, 13, 776. [Google Scholar] [CrossRef]

- Cambier, C.; Galle, W.; Vandervaeren, C.; Tavernier, I.; De Temmerman, N. An Analysis of Design Support Tools for Circular Building Practice. In Sustainability in Energy and Buildings; Springer: Singapore, 2020; pp. 43–53. [Google Scholar]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Kanters, J. Circular Building Design: An Analysis of Barriers and Drivers for a Circular Building Sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Settembre-Blundo, D. Identifying the equilibrium point between sustainability goals and circular economy practices in an Industry 4.0 manufacturing context using eco-design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef]

- Romani, A.; Rognoli, V.; Levi, M. Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability 2021, 13, 7269. [Google Scholar] [CrossRef]

- Bovea, M.D.; Pérez-Belis, V. Identifying design guidelines to meet the circular economy principles: A case study on electric and electronic equipment. J. Environ. Manag. 2018, 228, 483–494. [Google Scholar] [CrossRef]

- Cong, L.; Zhao, F.; Sutherland, J.W. A design method to improve end-of-use product value recovery for circular economy. J. Mech. Des. 2019, 141, 044502. [Google Scholar] [CrossRef]

- Van den Berg, M.R.; Bakker, C.A. A. A product design framework for a circular economy. In Product Lifetimes and the Environment; Nottingham Trent University: Nottingham, UK, 2015; ISBN 978-0-9576009-9-7. [Google Scholar]

- Karell, E.; Niinimäki, K. Addressing the Dialogue between Design, Sorting and Recycling in a Circular Economy. Des. J. 2019, 22, 997–1013. [Google Scholar] [CrossRef]

- McHattie, L.-S.; Ballie, J. Material Futures: Design-led Approaches to Crafting Conversations in the Circular Economy. J. Text. Des. Res. Pract. 2018, 6, 184–200. [Google Scholar] [CrossRef]

- Kane, G.; Bakker, C.; Balkenende, A. Towards design strategies for circular medical products. Resour. Conserv. Recycl. 2018, 135, 38–47. [Google Scholar] [CrossRef]

- Buck, L.; Lee, S. Sustainable design approaches using waste furniture materials for design students. In Proceedings of the DS 104: 22nd International Conference on Engineering and Product Design Education (E&PDE 2020), VIA Design, Herning, Denmark, 10–11 September 2020. [Google Scholar]

- Saidani, M.; Kravchenko, M.; Cluzel, F.; Pigosso, D.; Leroy, Y.; Kim, H. Comparing life cycle impact assessment, circularity and sustainability indicators for sustainable design: Results from a hands-on project with 87 engineering students. Proc. Des. Soc. 2021, 1, 681–690. [Google Scholar] [CrossRef]

- Kahraman, Z.E.H. Using user-centered design approach in course design. Procedia Soc. Behav. Sci. 2010, 2, 2071–2076. [Google Scholar] [CrossRef][Green Version]

- Gershenson, J.K.; Prasad, G.J.; Zhang, Y. Product modularity: Measures and design methods. J. Eng. Des. 2004, 15, 33–51. [Google Scholar] [CrossRef]

- Pucillo, F.; Cascini, G. A framework for user experience, needs and affordances. Des. Stud. 2014, 35, 160–179. [Google Scholar] [CrossRef]

- Cascini, G.; Montagna, F. Modelling (pre-) Design Activities with a Multi-Stakeholder Perspective. In Principia Designae-Pre-Design, Design, and Post-Design; Springer: Tokyo, Japan, 2015; pp. 175–197. [Google Scholar]

- Faludi, J.; Hoffenson, S.; Kwok, S.Y.; Saidani, M.; Hallstedt, S.I.; Telenko, C.; Martinez, V. A Research Roadmap for Sustainable Design Methods and Tools. Sustainability 2020, 12, 8174. [Google Scholar] [CrossRef]

| Application Fields | Sources |

|---|---|

| Product industrial design | [6,16,19,38,39,40,41,42,43,44,45,46,47,48,49] |

| Buildings | [11,50,51,52,53] |

| Manufacturing, Additive manufacturing | [54,55,56] |

| Electronic and appliances | [57,58] |

| User behavior and user experience design | [14,59] |

| Fashion design | [60,61] |

| Medical | [62] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spreafico, C.; Landi, D. Using Product Design Strategies to Implement Circular Economy: Differences between Students and Professional Designers. Sustainability 2022, 14, 1122. https://doi.org/10.3390/su14031122

Spreafico C, Landi D. Using Product Design Strategies to Implement Circular Economy: Differences between Students and Professional Designers. Sustainability. 2022; 14(3):1122. https://doi.org/10.3390/su14031122

Chicago/Turabian StyleSpreafico, Christian, and Daniele Landi. 2022. "Using Product Design Strategies to Implement Circular Economy: Differences between Students and Professional Designers" Sustainability 14, no. 3: 1122. https://doi.org/10.3390/su14031122

APA StyleSpreafico, C., & Landi, D. (2022). Using Product Design Strategies to Implement Circular Economy: Differences between Students and Professional Designers. Sustainability, 14(3), 1122. https://doi.org/10.3390/su14031122