Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater

Abstract

:1. Introduction

2. Materials and Methods

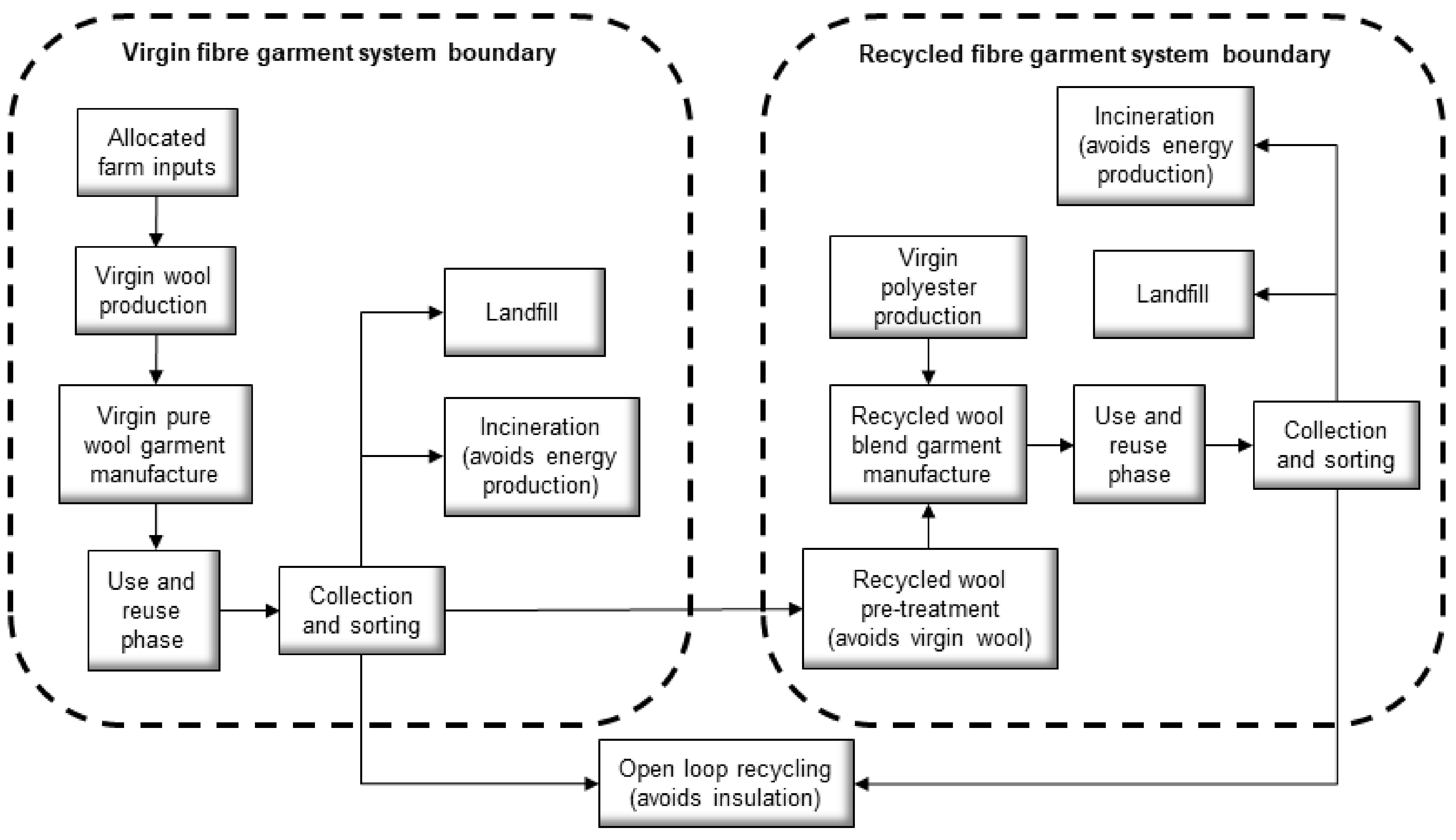

2.1. Goal and Scope

2.2. Inventory Data

2.3. Scenario Analyses

3. Results

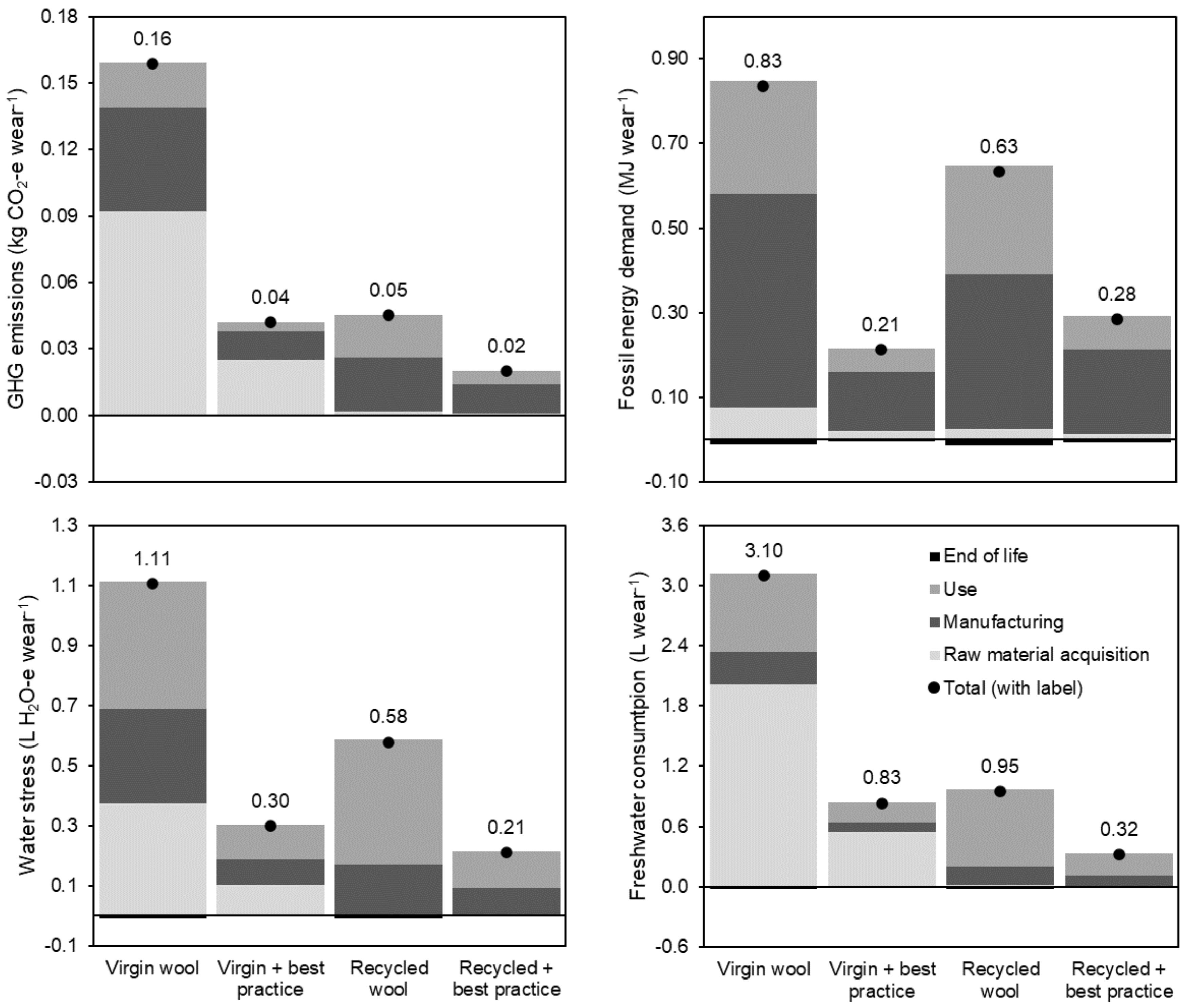

3.1. Recycled Wool Blend Sweater Impacts

3.2. Incorporating Best-Practice Garment Use and Care

3.3. Effect of End of Life Allocation Method

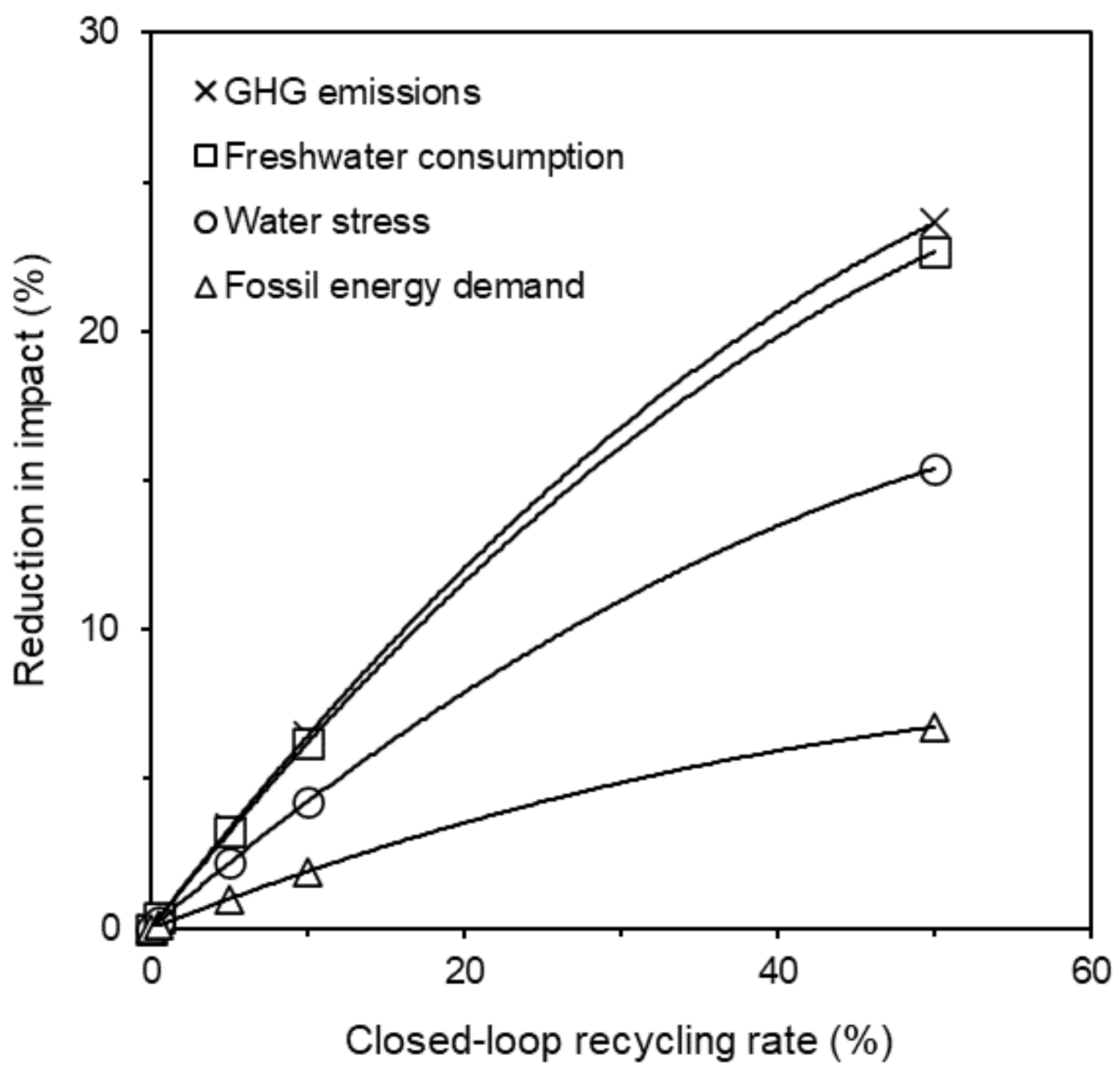

3.4. Effect of Varying the Closed-Loop Recycling Rate

3.5. Impacts of an Average Market Product

4. Discussion

4.1. Increasing the Circularity of Garment Life Cycles Reduces Environmental Impacts

4.2. Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNIDO. Development of Recycling Industries within the UNIDO Circular Economy Approach; United Nations Industrial Development Organization (UNIDO): Vienna, Austria, 2019. [Google Scholar]

- Zamani, B.; Sandin, G.; Peters, G. Life cycle assessment of clothing libraries: Can collaborative consumption reduce the environmental impact of fast fashion? J. Clean. Prod. 2017, 162, 1368–1375. [Google Scholar] [CrossRef]

- Marques, A.D.; Marques, A.; Ferreira, F. Homo Sustentabilis: Circular economy and new business models in fashion industry. SN Appl. Sci. 2020, 2, 306. [Google Scholar] [CrossRef] [Green Version]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Goldsworthy, K.; Earley, R.; Politowicz, K. Circular Speeds: A Review of Fast & Slow Sustainable Design Approaches for Fashion & Textile Applications. J. Text. Des. Res. Pr. 2018, 6, 42–65. [Google Scholar] [CrossRef]

- EMF. A New Textiles Economy: Redesigning Fashion’s Future; Ellen MacArthur Foundation (EMF): Cowes, UK; Available online: https://www.ellenmacarthurfoundation.org/publications/a-new-textiles-economy-redesigning-fashions-future (accessed on 1 July 2017).

- Russell, S.; Swan, P.; Trebowicz, M.; Ireland, A. Review of wool recycling and reuse. In Natural Fibres: Advances in Science and Technology Towards Industrial Applications: From Science to Market; Fangueiro, R., Rana, S., Eds.; Springer: Dordrecht, The Netherlands, 2016; pp. 415–428. [Google Scholar] [CrossRef]

- Thompson, P.; Willis, P.; Morley, N. A Review of Commercial Textile Fibre Recycling Technologies; WRAP: Banbury, UK, 2012. [Google Scholar]

- Hall, C. Mixing it up in Prato: Identifying innovation hotspots within mechanical textile recycling. In What’s Going On? A Discourse on Fashion, Design and Sustainability; Global Fashion Conference: London, UK, 2019; pp. 1–19. [Google Scholar]

- Norris, L. Waste, dirt and desire: Fashioning narratives of material regeneration. Sociol. Rev. 2019, 67, 886–907. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things; North Point: New York, NY, USA, 2002. [Google Scholar]

- Geyer, R.; Kuczenski, B.; Zink, T.; Henderson, A. Common Misconceptions about Recycling. J. Ind. Ecol. 2016, 20, 1010–1017. [Google Scholar] [CrossRef]

- Accelerating Circularity. Research and Mapping Report, Fall Accelerating Circularity. Available online: https://www.acceleratingcircularity.org/s/CircularSupplyChainPotential-US-EastCoast-OCT2020.pdf (accessed on 1 July 2020).

- EC. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission (EC): Brussels, Belgium, 2015. [Google Scholar]

- Wiedemann, S.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.; Swan, P.; Watson, K. Environmental impacts associated with the production, use, and end-of-life of a woollen garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Nguyen, Q.V.; Clarke, S.J.; Laitala, K.; Klepp, I.G. Reducing environmental impacts from garments through best practice garment use and care, using the example of a Merino wool sweater. Int. J. Life Cycle Assess. 2021, 26, 1188–1197. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006.

- ISO 14046:2014; Environmental Management-Water Footprint-Principles, Requirements and Guidelines. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2014.

- IWTO. Guidelines for Conducting a Life Cycle Assessment of the Environmental Performance of Wool Textiles; Henry, B., Ledgard, S., Nebel, B., Wiedemann, S., Eds.; International Wool Textile Organisation (IWTO): Brussels, Belgium, 2016. [Google Scholar]

- IPCC. Working Group I Contribution to the IPCC Fifth Assessment Report, Climate Change 2013: The Physical Science Basis; Cambridge University Press: New York, NY, USA, 2013. [Google Scholar]

- Pfister, S.; Koehler, A.; Hellweg, S. Assessing the Environmental Impacts of Freshwater Consumption in LCA. Environ. Sci. Technol. 2009, 43, 4098–4104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pré-Consultants. SimaPro 9.3 Software; Pré-Consultants: Amersfoort, The Netherlands, 2021. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method, EUR 29682 EN; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Cardato. The Green District; Cardato: Prato, Italy. Available online: http://www.cardato.it/en/green-district/ (accessed on 1 July 2020).

- Wilcox, C.; Armstrong, L.; Williams, S.; Pattinson, R. Wool 2030—A Strategic Plan for Australian Wool Growers. Discussion Paper 1: Wool Supply and Demand; Australian Wool Innovation Limited: Sydney, NSW, Australia, 2020. [Google Scholar]

- Eco TLC. Annual Report; #Eco TLC: Paris, France, 2019. [Google Scholar]

- Quantis. Draft Product Environmental Footprint Category Rules (PEFCR)—Apparel and Footwear. Version 1.2, 7 July; Quantis: Zürick, Switzerland, 2021. [Google Scholar]

- Braun, G.; Som, C.; Schmutz, M.; Hischier, R. Environmental Consequences of Closing the Textile Loop—Life Cycle Assessment of a Circular Polyester Jacket. Appl. Sci. 2021, 11, 2964. [Google Scholar] [CrossRef]

- Zamani, B.; Svanström, M.; Peters, G.; Rydberg, T. A Carbon Footprint of Textile Recycling: A Case Study in Sweden. J. Ind. Ecol. 2014, 19, 676–687. [Google Scholar] [CrossRef]

- Schmidt, A.; Watson, D.; Roos, S.; Askham, C.; Poulsen, P. Gaining Benefits from Discarded Textiles: LCA of Different Treatment Pathways; TemaNord: Copenhagen, Denmark, 2016. [Google Scholar] [CrossRef] [Green Version]

- Levänen, J.; Uusitalo, V.; Härri, A.; Kareinen, E.; Linnanen, L. Innovative recycling or extended use? Comparing the global warming potential of different ownership and end-of-life scenarios for textiles. Environ. Res. Lett. 2021, 16, 054069. [Google Scholar] [CrossRef]

- Esteve-Turrillas, F.; de la Guardia, M. Environmental impact of Recover cotton in textile industry. Resour. Conserv. Recycl. 2017, 116, 107–115. [Google Scholar] [CrossRef]

- Koligkioni, A.; Parajuly, K.; Sørensen, B.L.; Cimpan, C. Environmental Assessment of End-of-Life Textiles in Denmark. Proc. CIRP 2018, 69, 962–967. [Google Scholar] [CrossRef]

- Woolridge, A.C.; Ward, G.D.; Phillips, P.S.; Collins, M.; Gandy, S. Life cycle assessment for reuse/recycling of donated waste textiles compared to use of virgin material: An UK energy saving perspective. Resour. Conserv. Recycl. 2006, 46, 94–103. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Textile Exchange. Material Change Insights Report 2019: The State of Fiber and Materials Sourcing; Textile Exchange: Lamesa, TX, USA, 2020. [Google Scholar]

- Sandvik, I.M.; Stubbs, W. Circular fashion supply chain through textile-to-textile recycling. J. Fash. Mark. Manag. Int. J. 2019, 23, 366–381. [Google Scholar] [CrossRef]

- Franco, M.A. Circular economy at the micro level: A dynamic view of incumbents’ struggles and challenges in the textile industry. J. Clean. Prod. 2017, 168, 833–845. [Google Scholar] [CrossRef]

- Koszewska, M. Circular Economy—Challenges for the Textile and Clothing Industry. Autex Res. J. 2018, 18, 337–347. [Google Scholar] [CrossRef] [Green Version]

| Category | Material/Process | Unit | Value |

|---|---|---|---|

| Input | Wool rags | kg | 1068.4 |

| Electricity, high voltage | kWh | 1372.6 | |

| Water | L | 44.3 | |

| HDPE, laminated | kg | 2.3 | |

| Steel wire | kg | 0.9 | |

| PET strap | kg | 0.5 | |

| Alkyl benzoate | kg | 0.5 | |

| Freight transport, lorry | tkm | 987 | |

| Freight transport, ship | tkm | 6310 | |

| Output | Wool fibre | kg | 1000.0 |

| Water, to wastewater treatment | L | 44.3 | |

| Short wool fibres, to municipal waste | kg | 68.4 |

| Category | Material/Process | Unit | Value |

|---|---|---|---|

| Input | Wool fibre | kg | 1005.1 |

| Electricity, high voltage | kWh | 420.7 | |

| Coal | kg | 252.5 | |

| Water | L | 4970.6 | |

| Water, steam | L | 141.4 | |

| Dyes | kg | 13.6 | |

| Acetic acid | kg | 8.1 | |

| Sodium chloride | kg | 3.6 | |

| Sodium sulphate | kg | 7.4 | |

| Formic acid (75%) | kg | 3.7 | |

| Ethoxylate amine | kg | 3.7 | |

| Packaging, undefined | kg | 0.4 | |

| Freight transport | tkm | 31 | |

| Output | Over-dyed wool fibre | kg | 1000.0 |

| Water, to wastewater treatment | L | 4526.1 | |

| Water, emissions to air | L | 444.5 | |

| Short wool fibres, to municipal waste | kg | 5.1 |

| Category | Material/Process | Unit | Value |

|---|---|---|---|

| Input | Over-dyed wool fibre | kg | 186.2 |

| Pre-dyed wool fibre | kg | 875.6 | |

| Over-dyed polyester | kg | 124.4 | |

| Electricity, high voltage | kWh | 2447.0 | |

| Electricity, self-generated solar | kWh | 6.6 | |

| Lubricating/antistatic oil | kg | 166.1 | |

| Water | L | 512.6 | |

| Water, steam | kg | 430.5 | |

| Cardboard cone | kg | 40.2 | |

| HDPE, film | kg | 10.9 | |

| Freight transport | tkm | 27.1 | |

| Output | Spun yarn | kg | 1000.0 |

| Water, emissions to air | L | 512.6 | |

| Wool fibre, to recovery | kg | 111.3 | |

| Short wool fibres, to municipal waste | kg | 74.9 |

| Category | Material/Process | Unit | Value |

|---|---|---|---|

| Input | Spun yarn | kg | 1011.6 |

| Electricity, high voltage | kWh | 3495.0 | |

| Diesel | kg | 6.6 | |

| Petrol, unleaded | kg | 6.9 | |

| Output | Woven fabric | kg | 1000.0 |

| Wool fibre, to recovery | kg | 6.5 | |

| Short wool fibres, to municipal waste | kg | 5.1 |

| Category | Material/Process | Unit | Value |

|---|---|---|---|

| Input | Woven fabric | kg | 1035.7 |

| Electricity, high voltage | kWh | 990.3 | |

| Coal | kg | 171.7 | |

| Water | L | 3092.6 | |

| Water, steam | kg | 56.0 | |

| Washing detergent | kg | 10.8 | |

| Milling agent | kg | 8.0 | |

| Softener | kg | 5.4 | |

| Acetic acid | kg | 1.9 | |

| Ethoxylated alcohol | kg | 8.3 | |

| Silicone | kg | 11.1 | |

| Output | Wool fabric | kg | 1000.0 |

| Water, to wastewater treatment plant | L | 3036.6 | |

| Water, emissions to air | kg | 56.0 | |

| Short wool fibres, to municipal waste | kg | 35.7 |

| Impact Category | Relative Impact by Treatment (%) | |||

|---|---|---|---|---|

| Virgin Pure Wool | Virgin Pure Wool + Best Practice Garment Care | Recycled Wool Blend | Recycled Wool Blend + Best Practice Garment Care | |

| Climate change | 99 | 99 | 94 | 93 |

| Fossil energy demand | 97 | 97 | 93 | 92 |

| Water stress | 99 | 99 | 98 | 96 |

| Freshwater consumption | 99 | 99 | 97 | 95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiedemann, S.G.; Biggs, L.; Clarke, S.J.; Russell, S.J. Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater. Sustainability 2022, 14, 1081. https://doi.org/10.3390/su14031081

Wiedemann SG, Biggs L, Clarke SJ, Russell SJ. Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater. Sustainability. 2022; 14(3):1081. https://doi.org/10.3390/su14031081

Chicago/Turabian StyleWiedemann, Stephen G., Leo Biggs, Simon J. Clarke, and Stephen J. Russell. 2022. "Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater" Sustainability 14, no. 3: 1081. https://doi.org/10.3390/su14031081

APA StyleWiedemann, S. G., Biggs, L., Clarke, S. J., & Russell, S. J. (2022). Reducing the Environmental Impacts of Garments through Industrially Scalable Closed-Loop Recycling: Life Cycle Assessment of a Recycled Wool Blend Sweater. Sustainability, 14(3), 1081. https://doi.org/10.3390/su14031081